Cooling liquid circulating integrated device for fracturing pump valve box cutting machine tool

A technology for cutting machine tools and coolant, which is applied to the accessories of sawing machines, metal sawing equipment, metal processing machinery parts, etc. It can solve the problems of waste of coolant, high friction, and high hardness of the valve box of fracturing pumps, etc., to prevent Anti-scratch and anti-abrasion effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

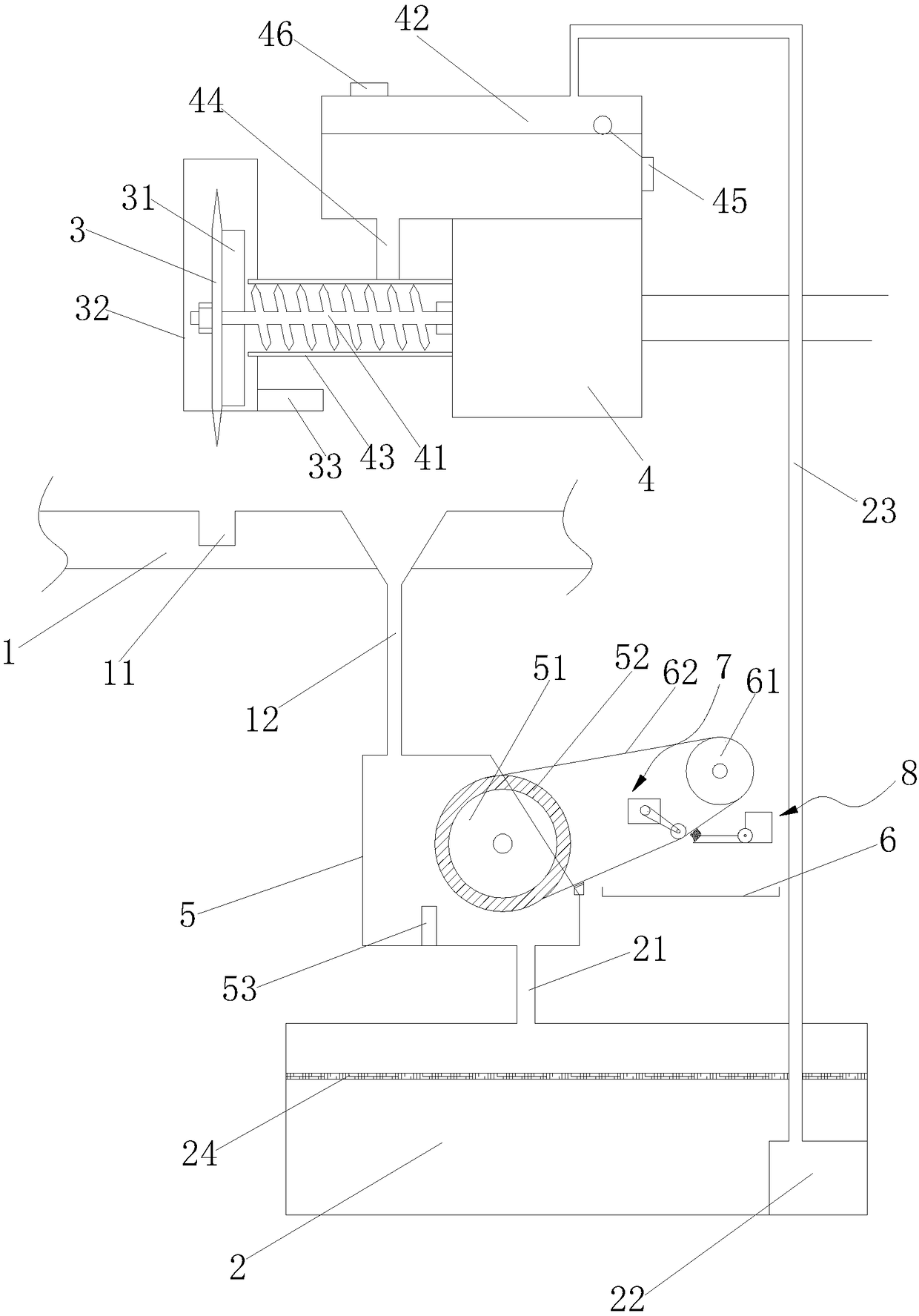

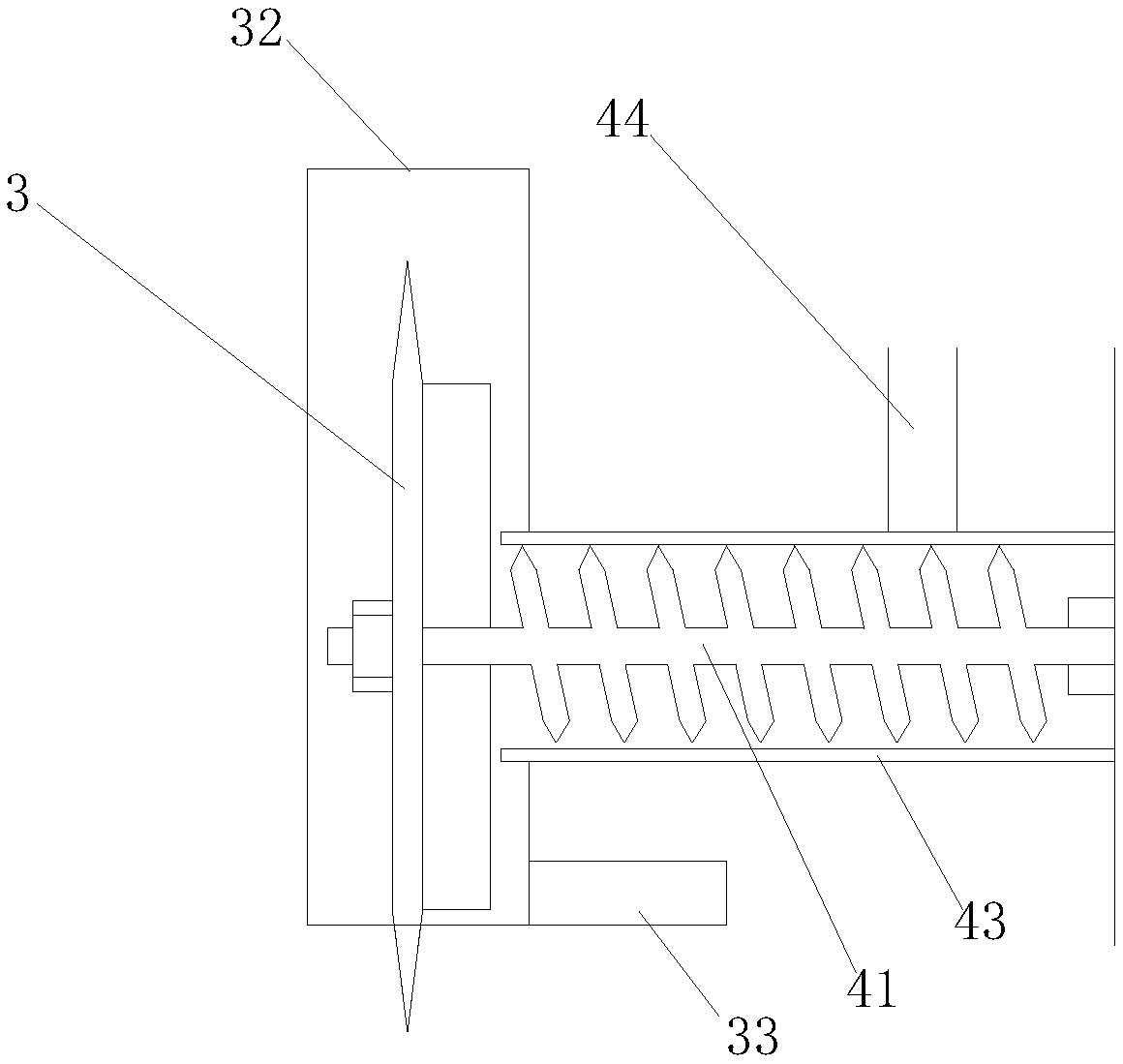

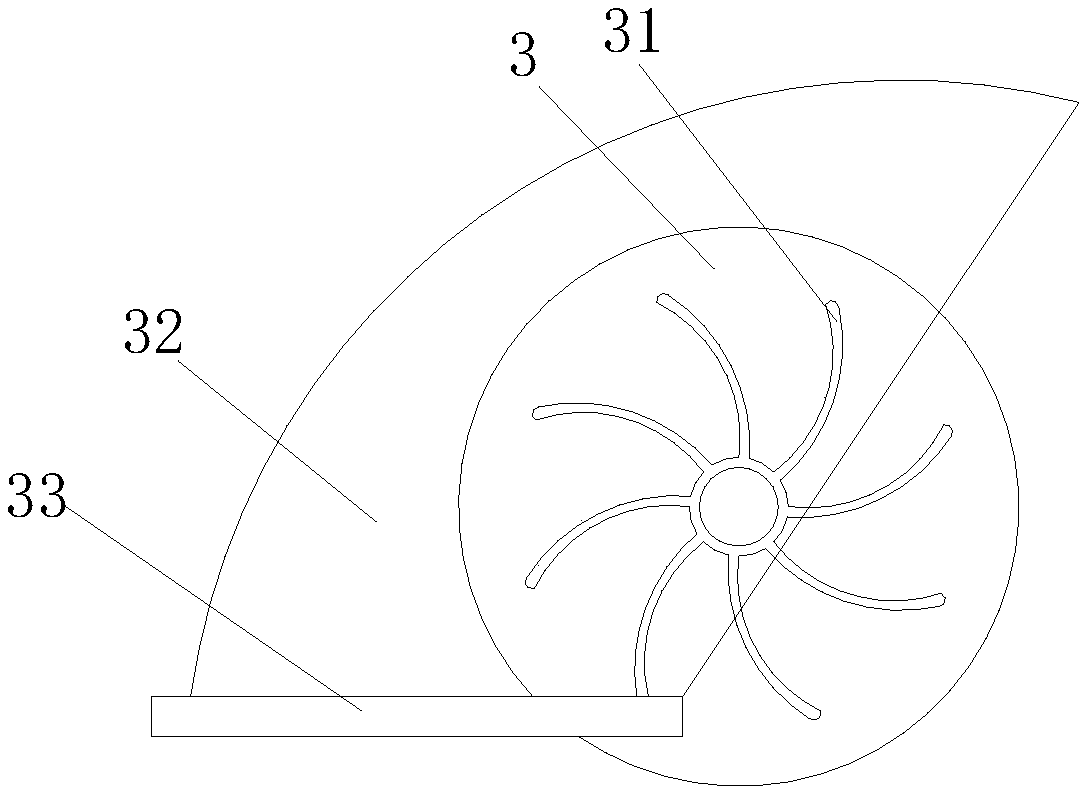

[0026] Such as figure 1 Shown: a fracturing pump valve box cutting machine coolant circulation integrated device, from top to bottom sequentially includes a cutting device, a workbench 1, iron filings removal device and a liquid storage tank I 2; the cutting device includes a saw blade 3 and the motor 4, a helical shaft 41 is arranged between the saw blade 3 and the motor 4, the left end of the helical shaft 41 is welded to the center of the saw blade 3, and the right end of the saw blade 3 is matched with the motor 4; A saw groove 11 is provided directly below the corresponding saw blade 3 on the workbench 1; the iron chip removal device includes a cube-shaped housing 5 and a receiving plate 6, and the housing 5 and the receiving plate 6 are horizontally arranged side by side. A driven roller 51 is arranged in the body 5, and a driving roller 61 is arranged above the receiving plate 6. The driving roller 51 and the driven roller 61 are driven and matched by a belt 62, and a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com