Patents

Literature

118results about How to "Simple loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

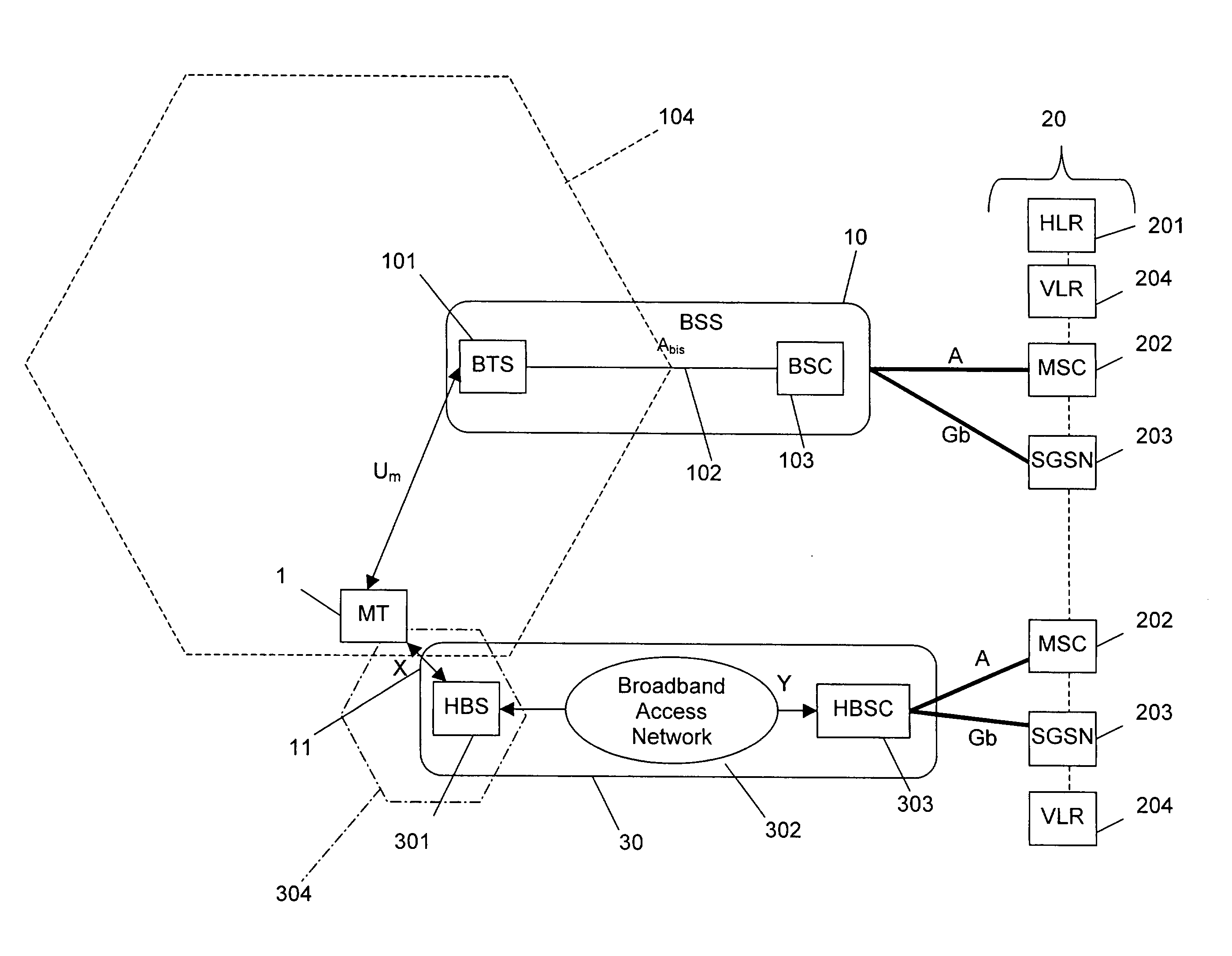

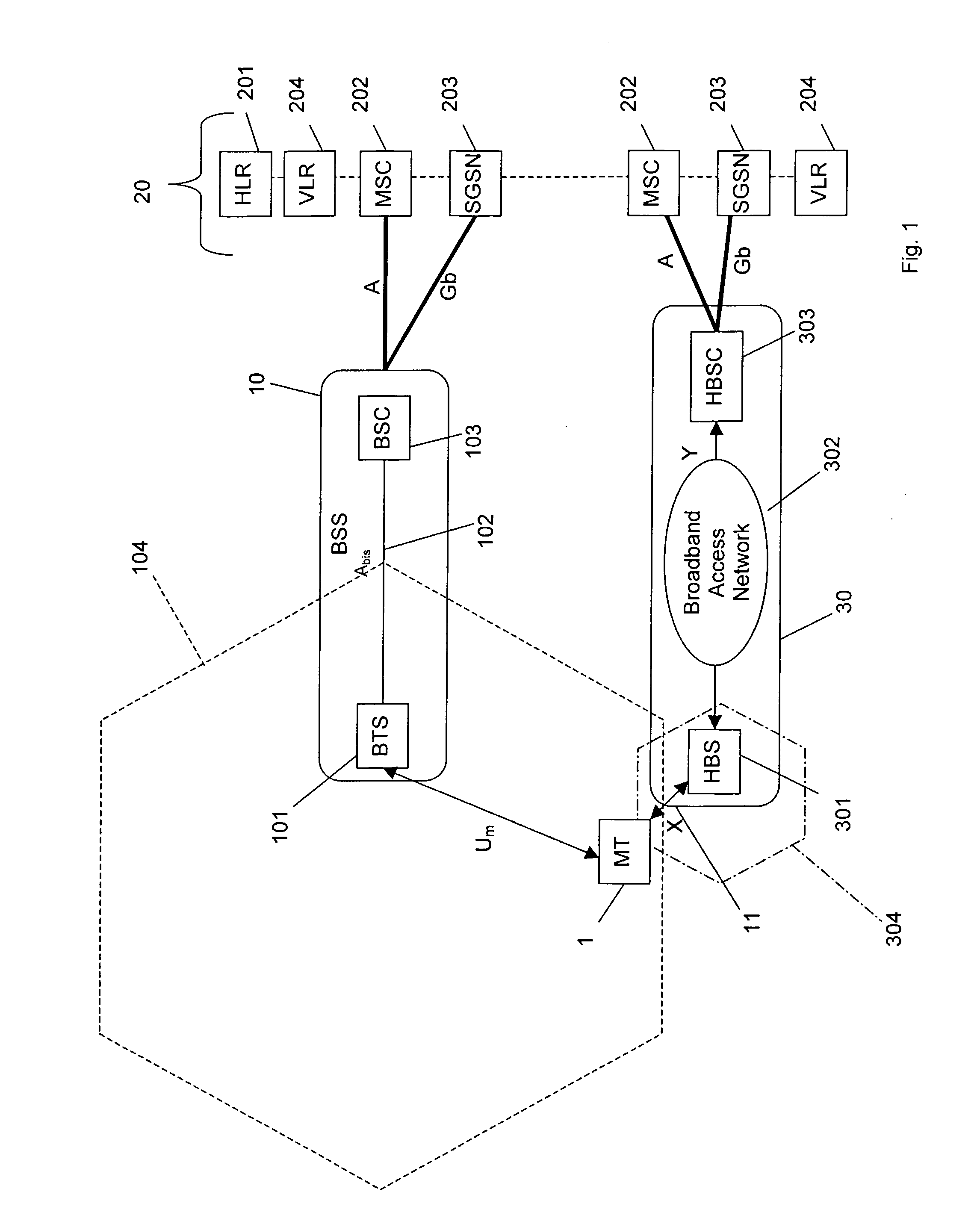

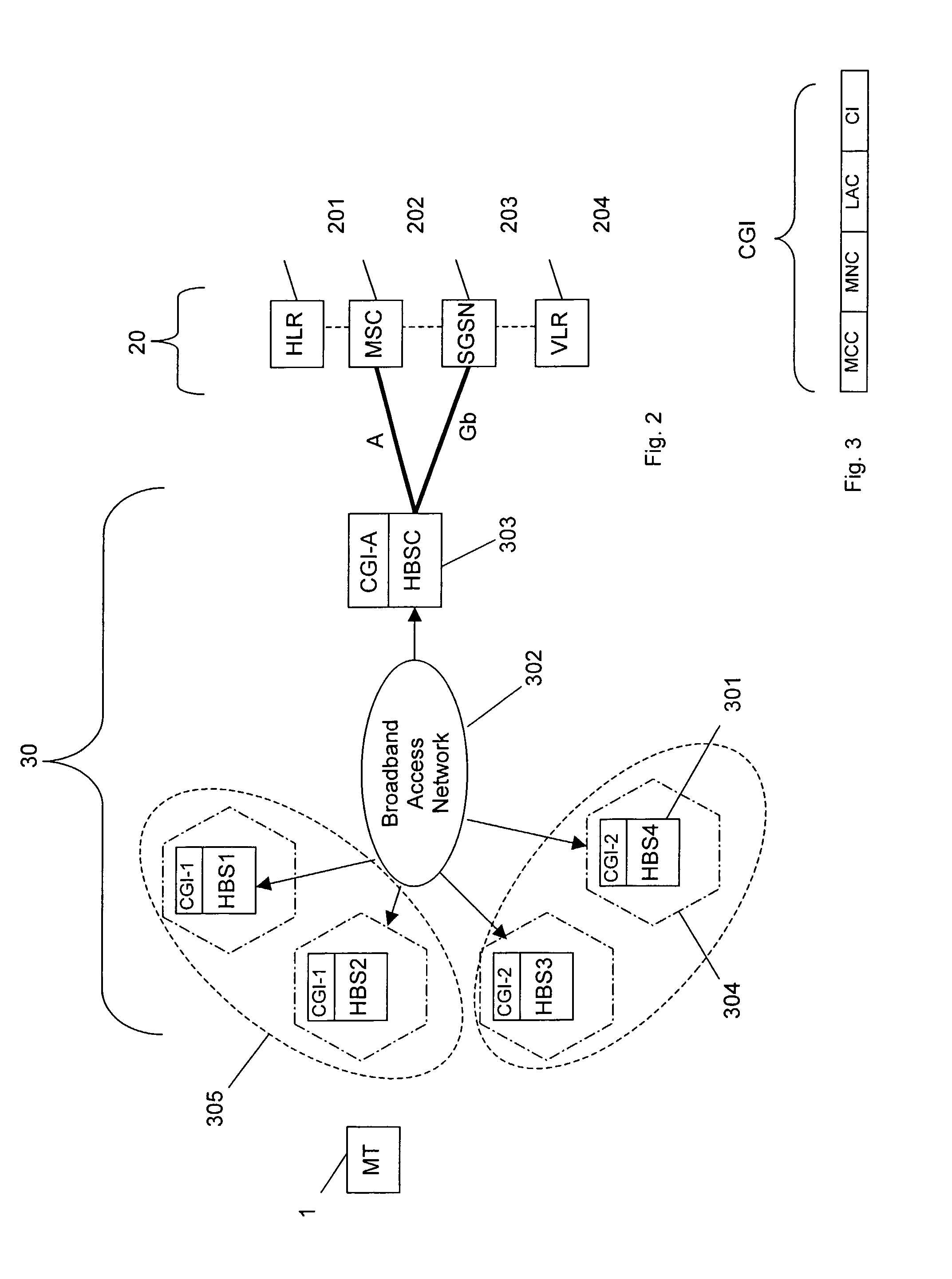

Mobile Communications With Unlicensed-Radio Access Networks

InactiveUS20070293222A1Simplifies installation loadSimple loadingData switching by path configurationRadio/inductive link selection arrangementsRadio accessRadio interface

Owner:TELEFON AB LM ERICSSON (PUBL)

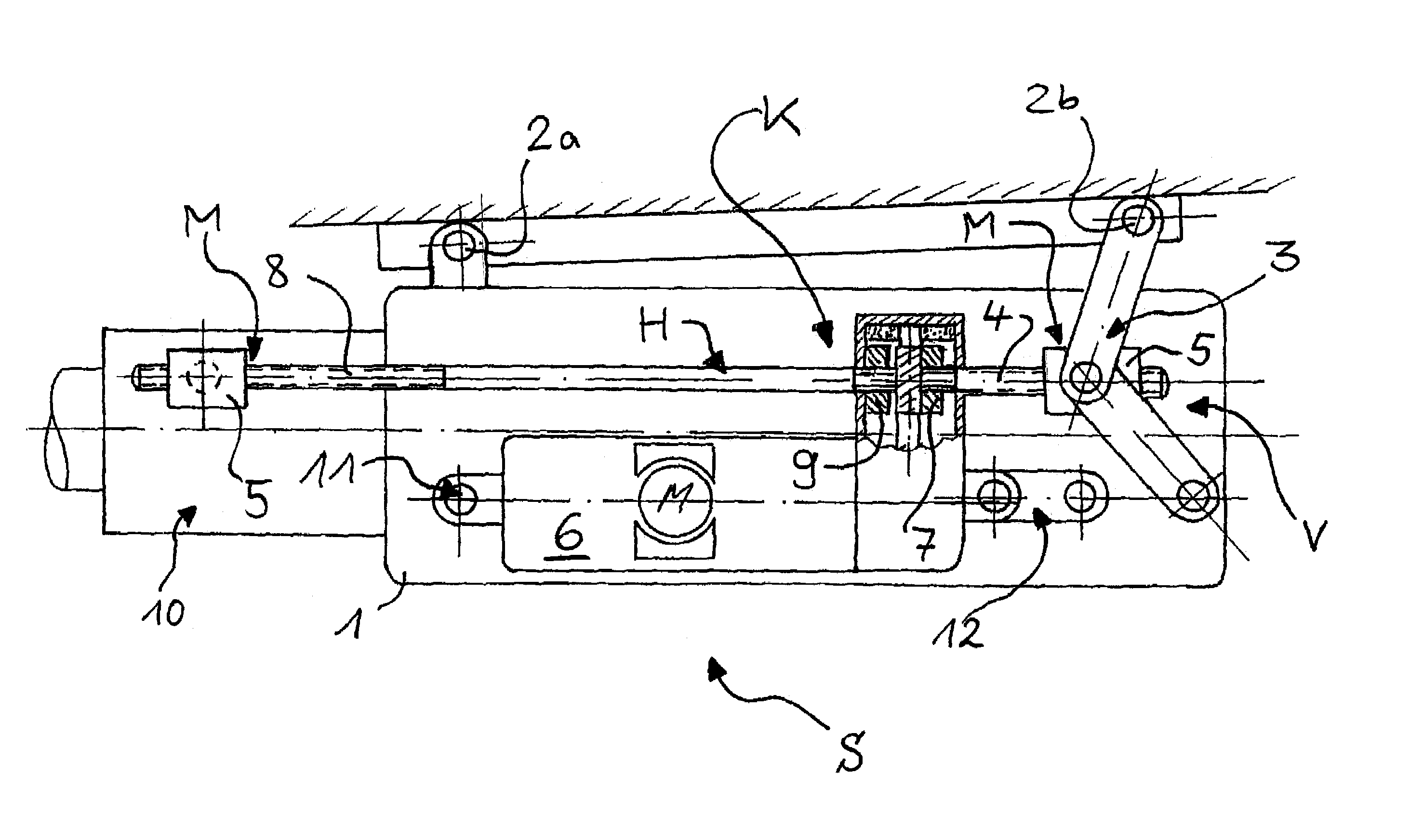

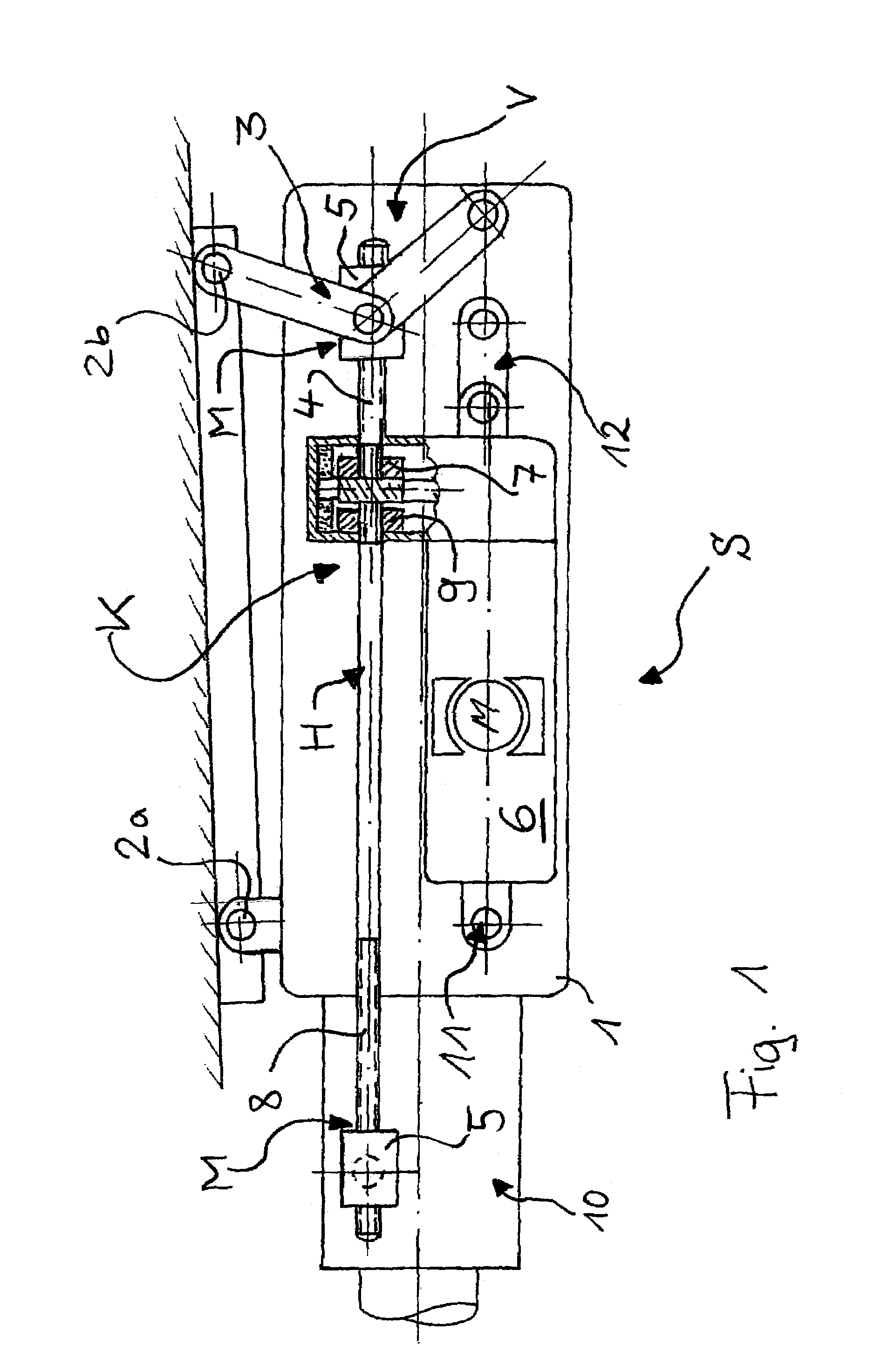

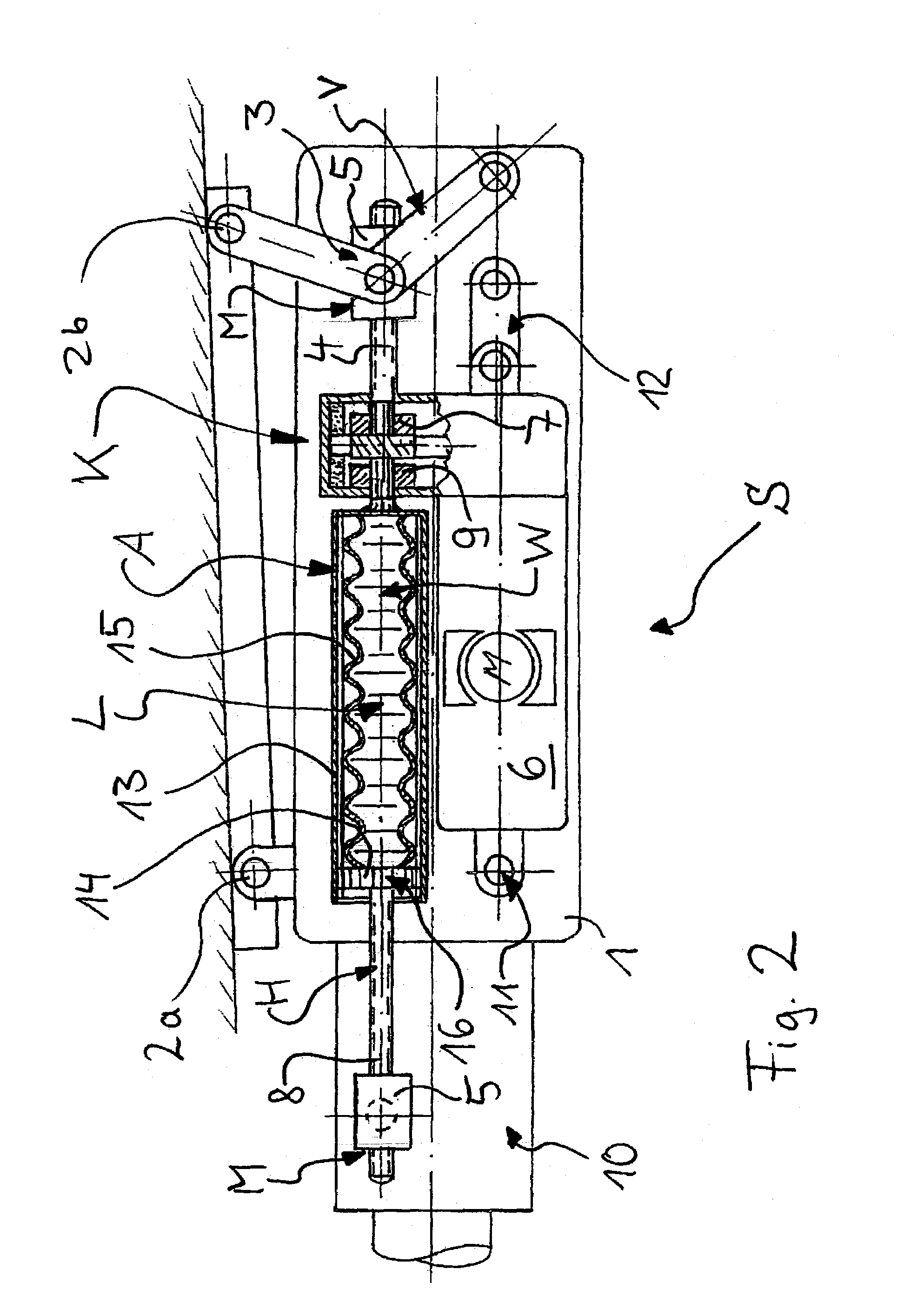

Safety steering and mechanism and a method of operating

A safety steering mechanism for a steering column, with a steering-column comfort adjustment having linear positioning devices, and provided with safety devices designed such that, in an accident situation, at least an end area of the steering column can be moved away from a driver's position. The linear positioning devices include load absorption devices and / or withdrawal devices regarding the movement of at least the end area of the steering column away from a driver's position. An operating method for a safety steering mechanism for a steering column that can be adjusted by a comfort adjustment in accordance with the requirements and / or wishes of a driver by means of linear positioning devices and of which at least an end area of the steering column can be moved away from a driver's position in an accident situation. The movement of at least the end or the steering column away from a driver's position is braked in an accident situation in a load-receiving manner by load absorption devices contained in the linear positioning devices.

Owner:THYSSENKRUPP PRESTA AG

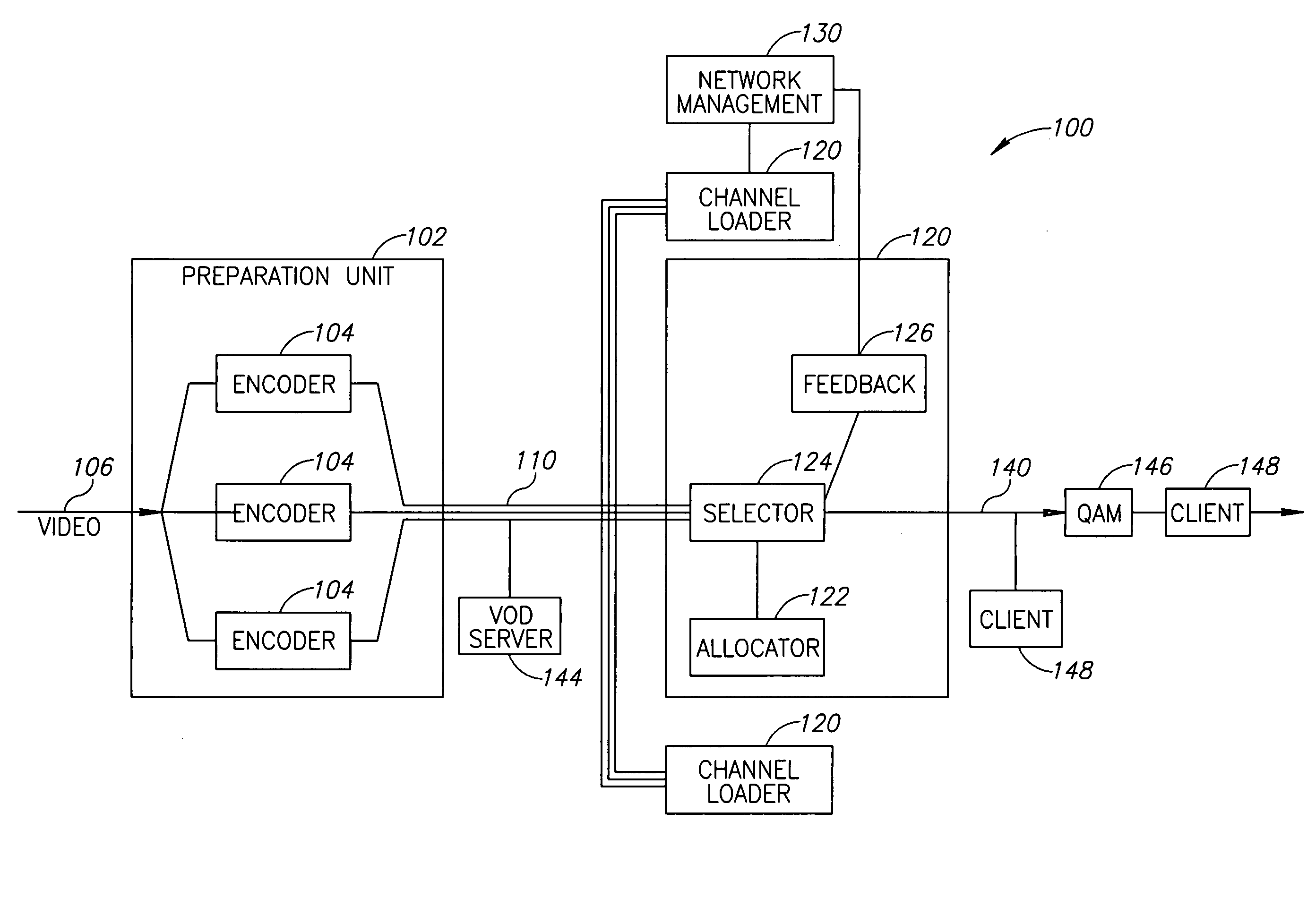

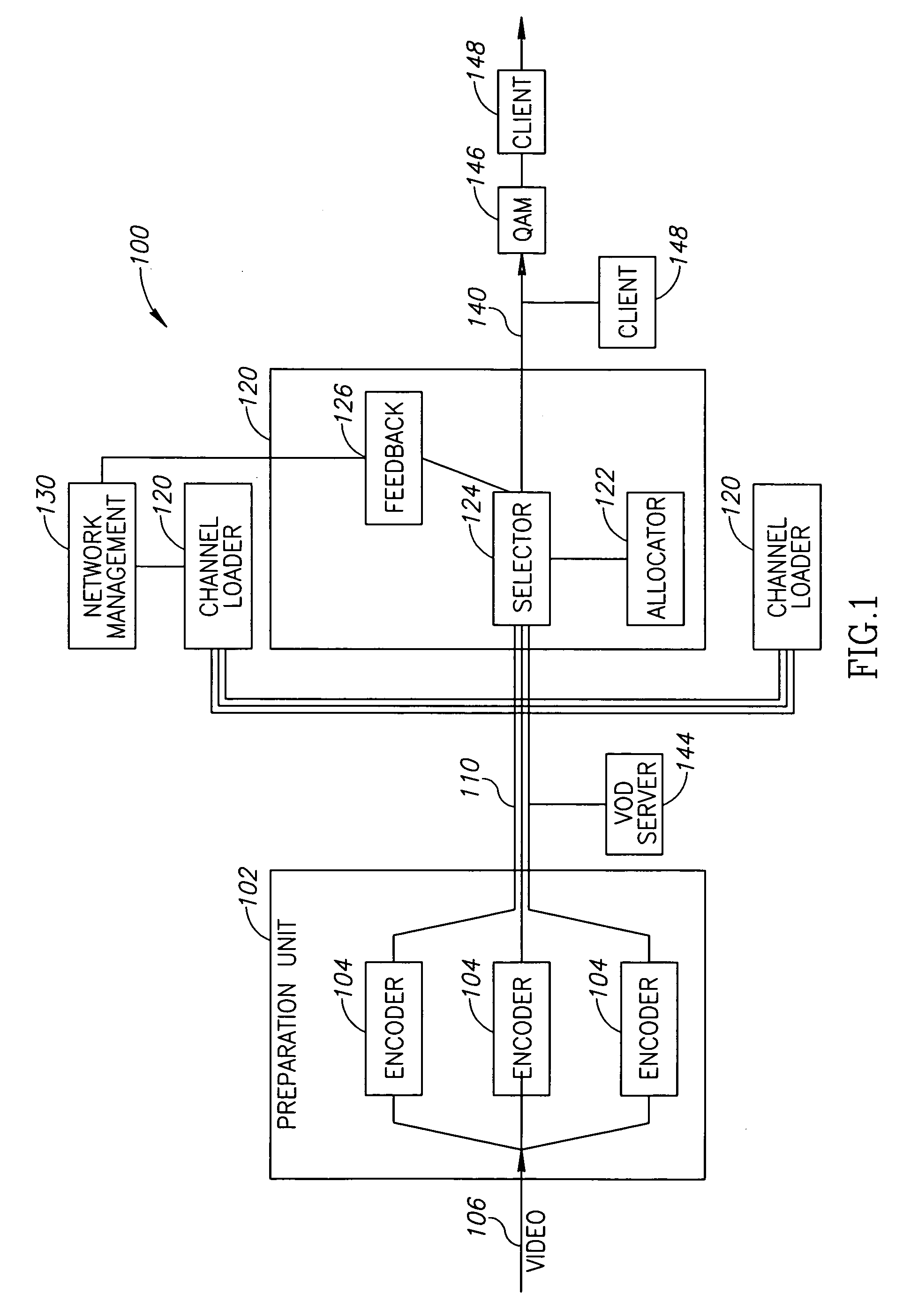

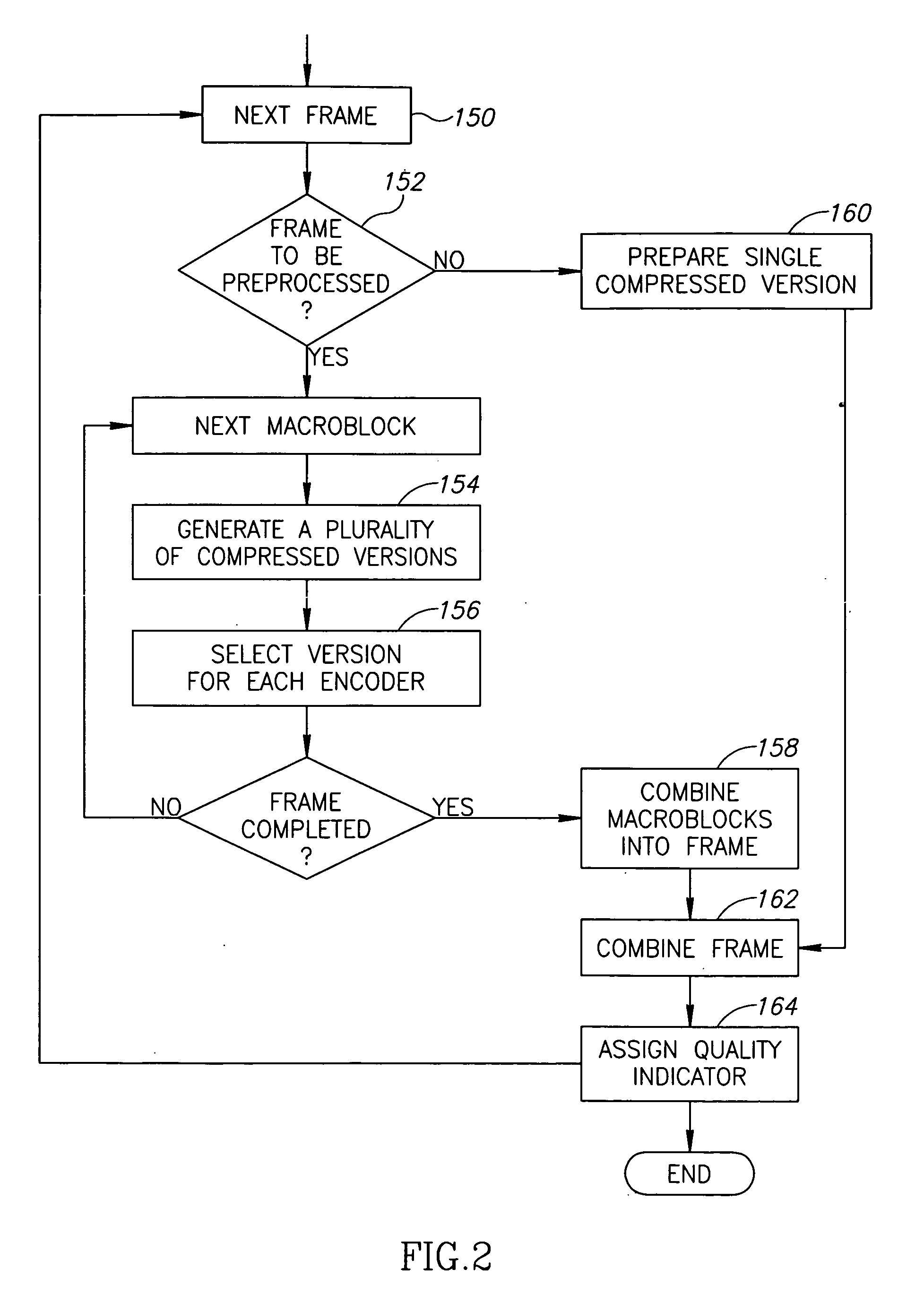

Quality based video encoding

InactiveUS20090052540A1Few processing resourceChannel loading can be simplerPicture reproducers using cathode ray tubesPicture reproducers with optical-mechanical scanningQuality levelComputer graphics (images)

A method of preprocessing a video stream including receiving a video stream formed of a sequence of blocks and setting one or more quality level constraints for the video stream. The method further includes selecting for each of at least a plurality of the blocks of the video stream, one or more sets of compression parameters for compressing the block, such that the block compressed according to the set of parameters meets a respective quality level constraint set for the video stream and generating for each of the sets of compression parameters a corresponding data unit representing the block compressed by the set of compression parameters.

Owner:IMAGINE COMM

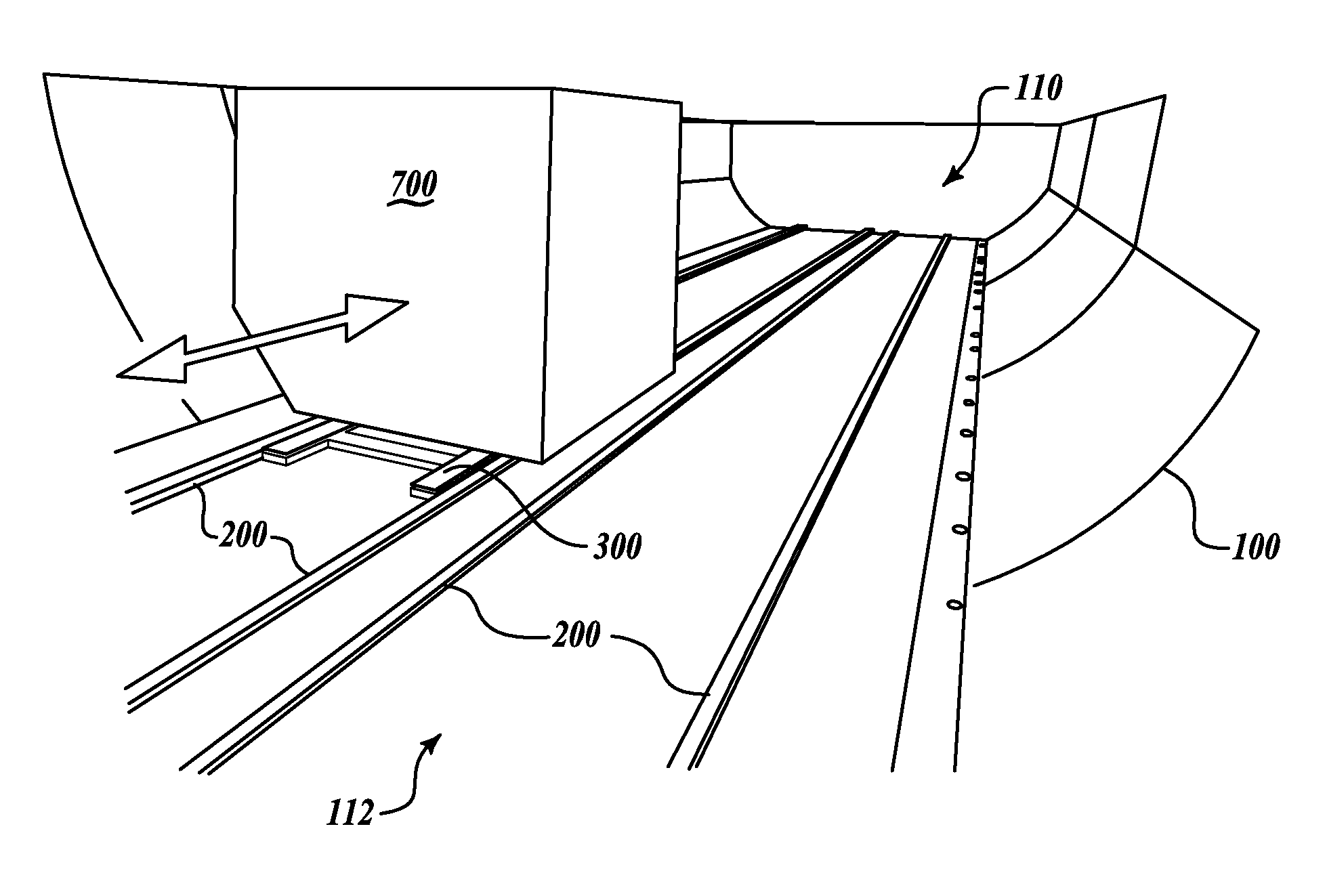

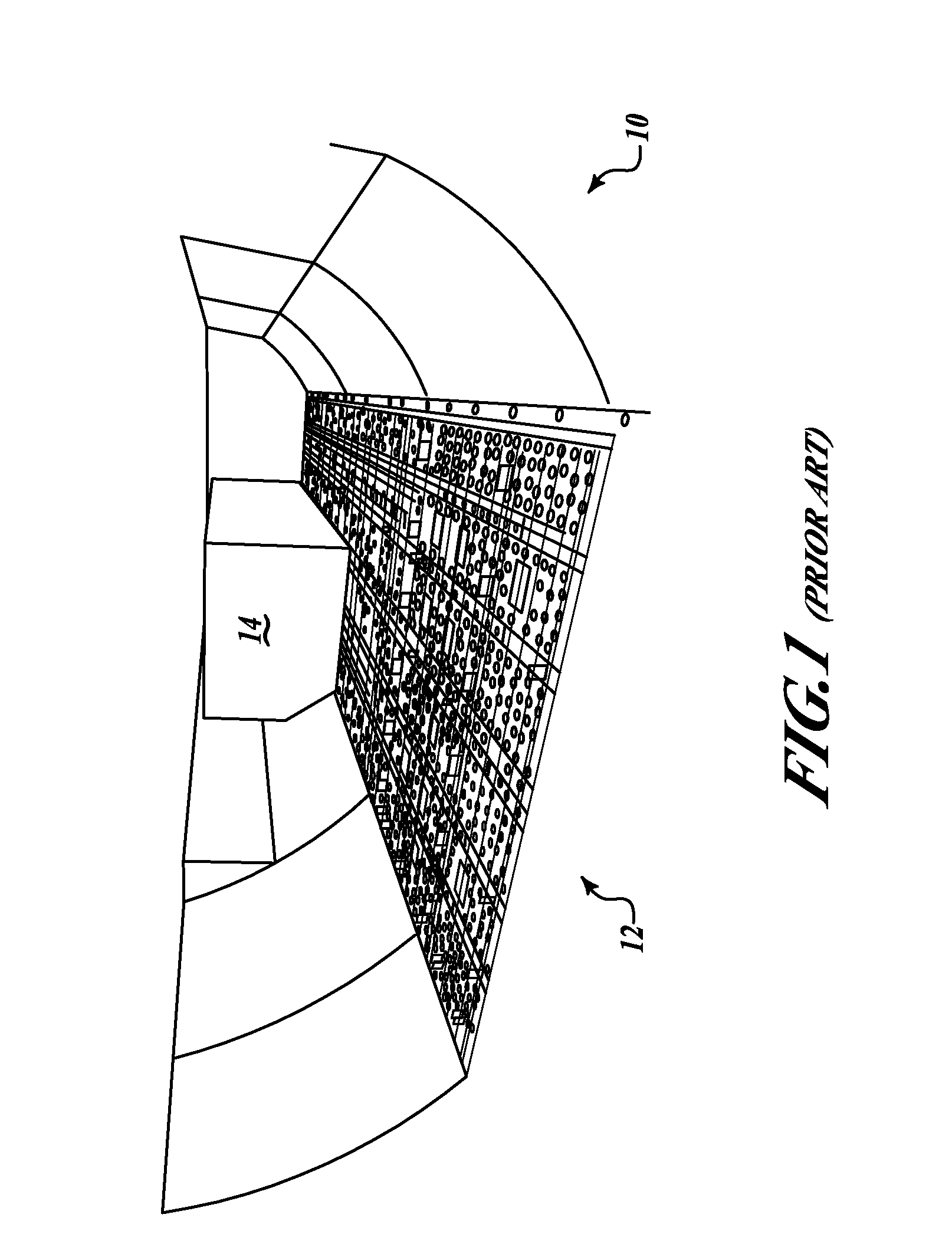

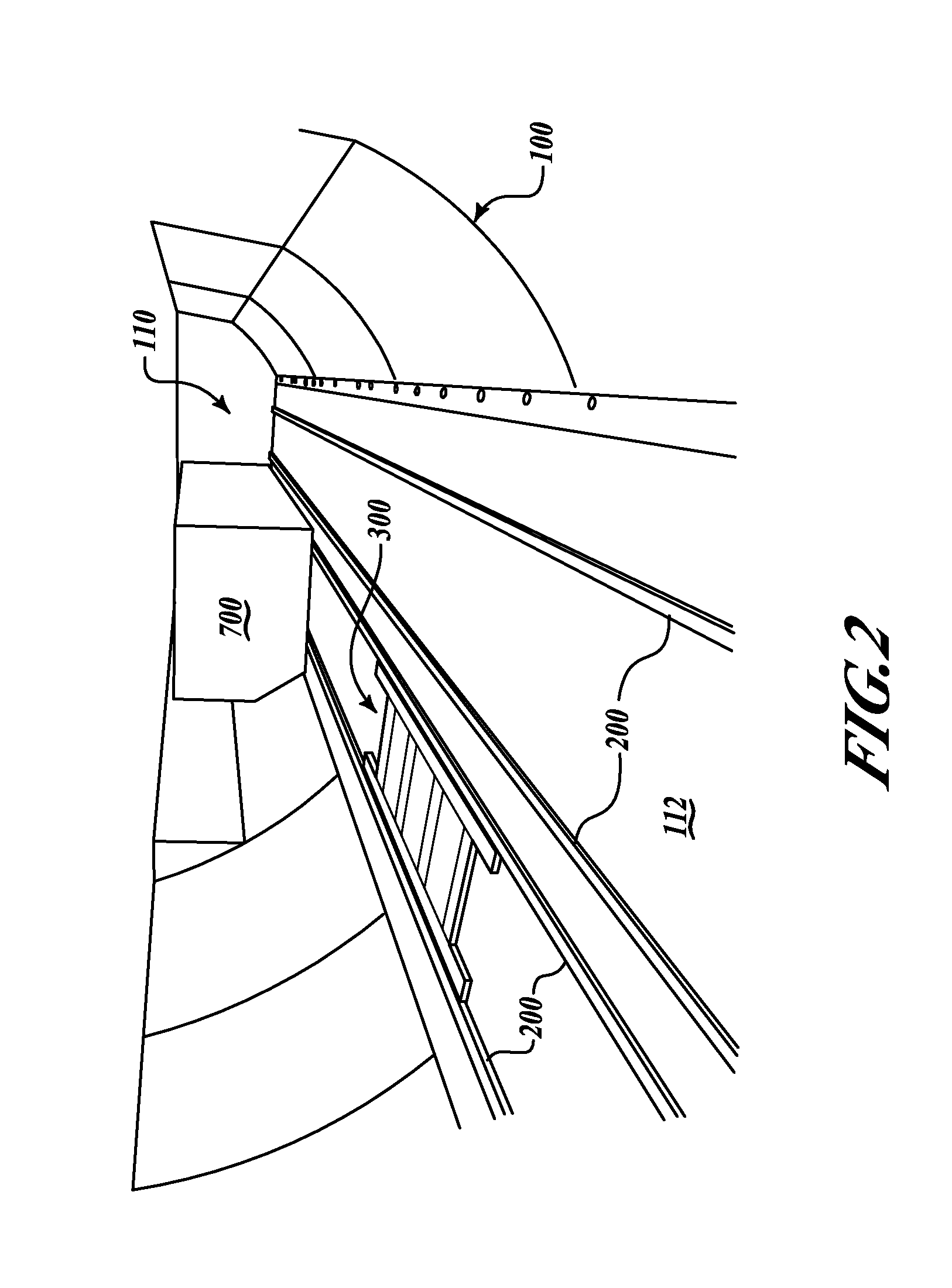

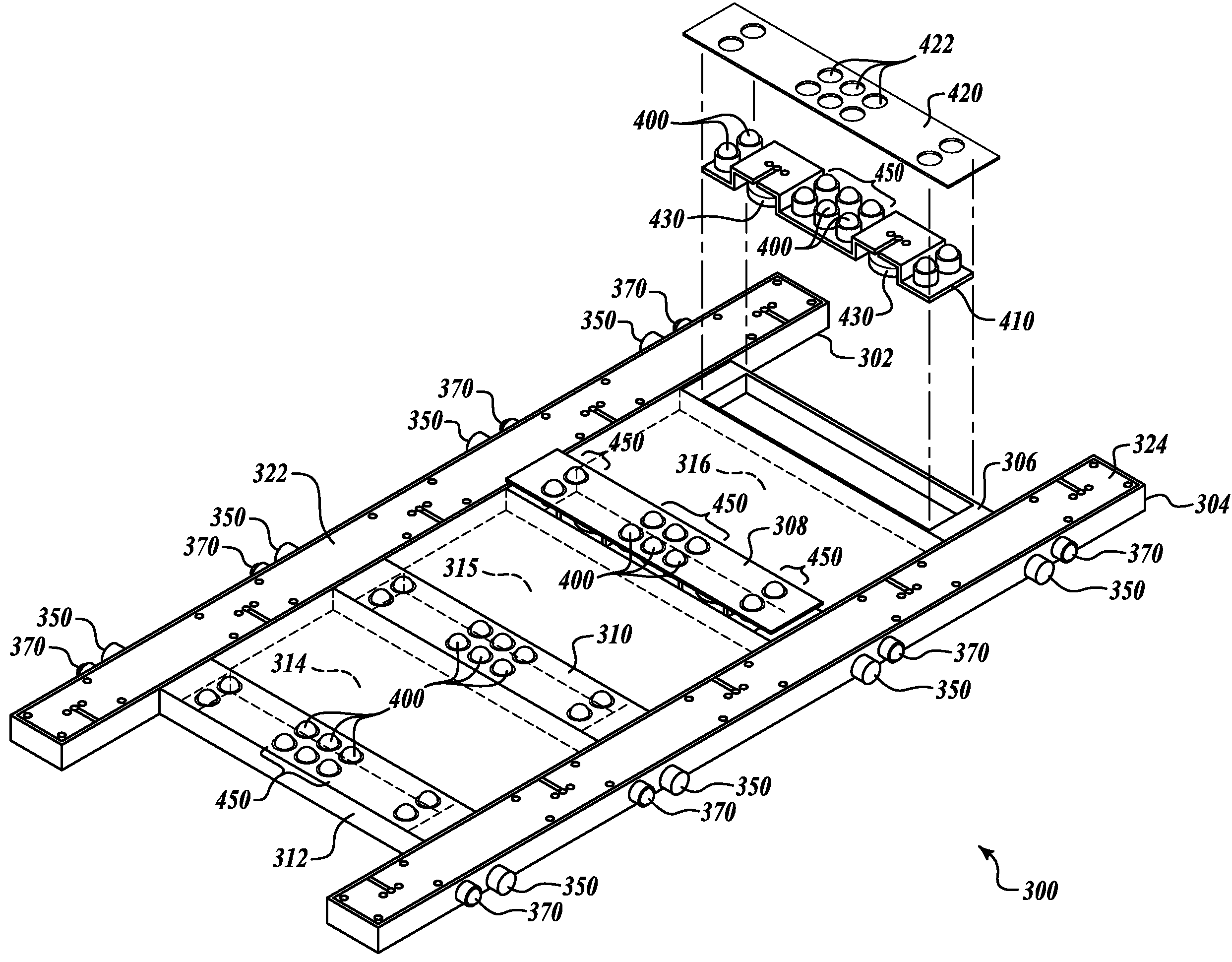

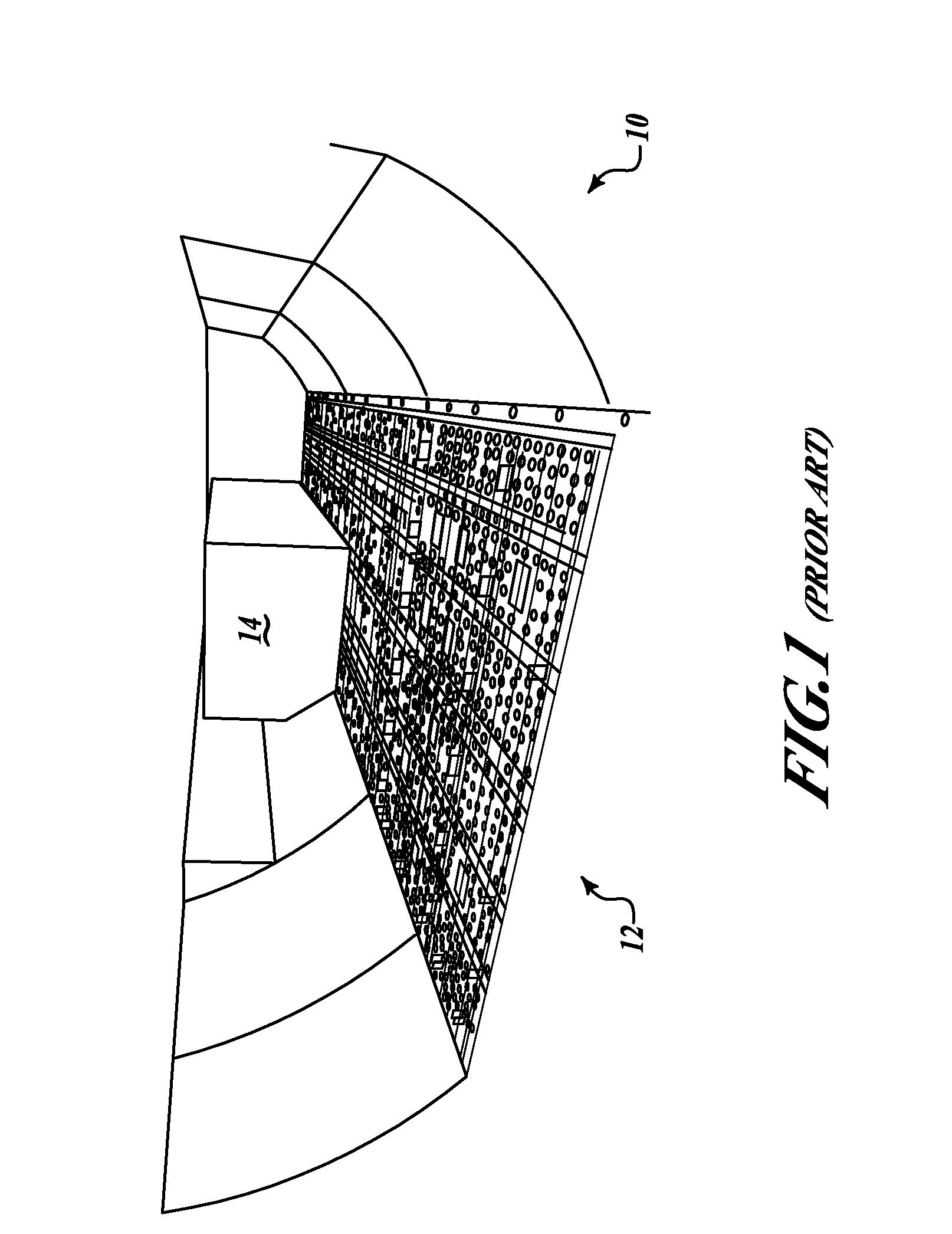

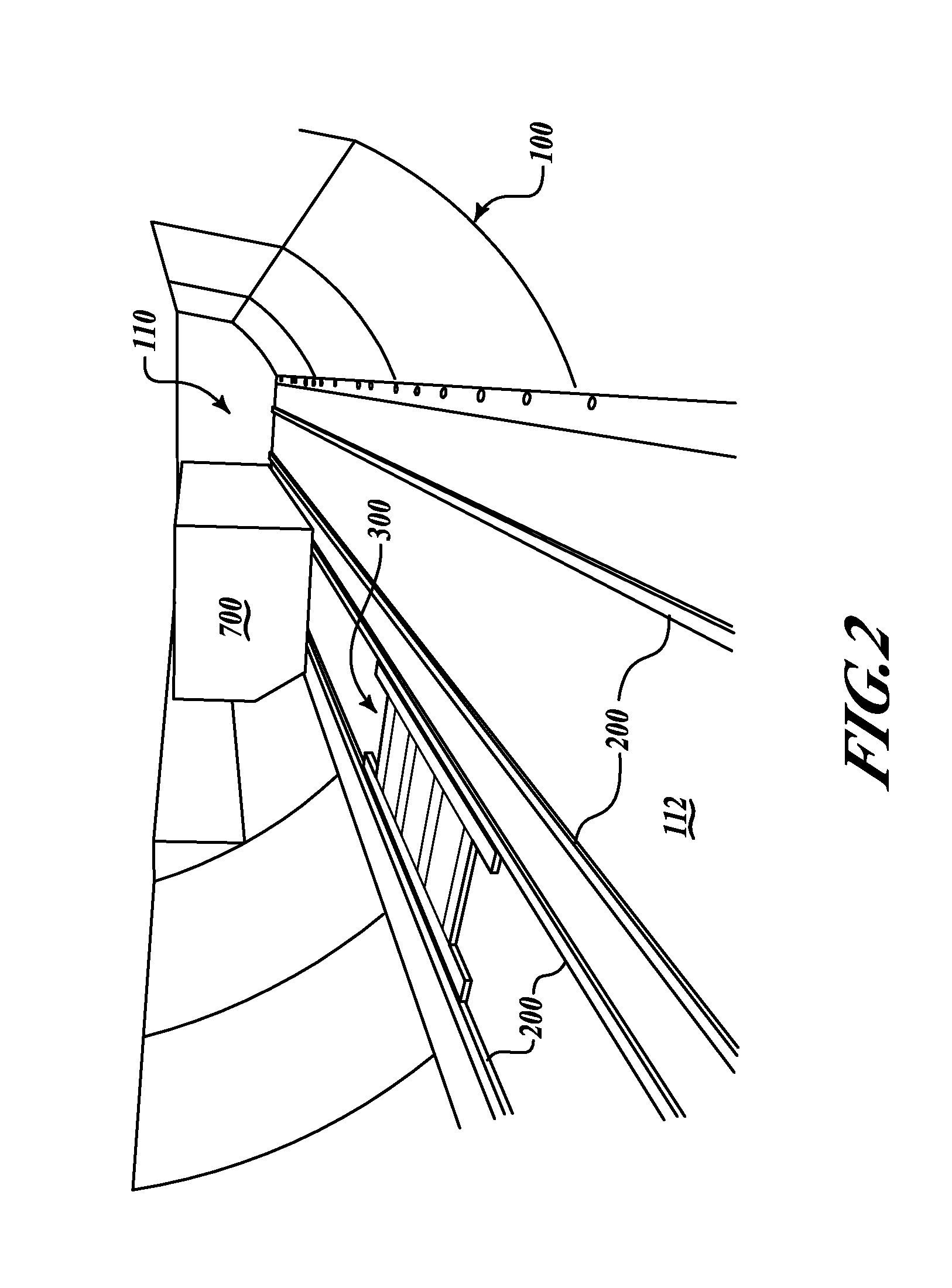

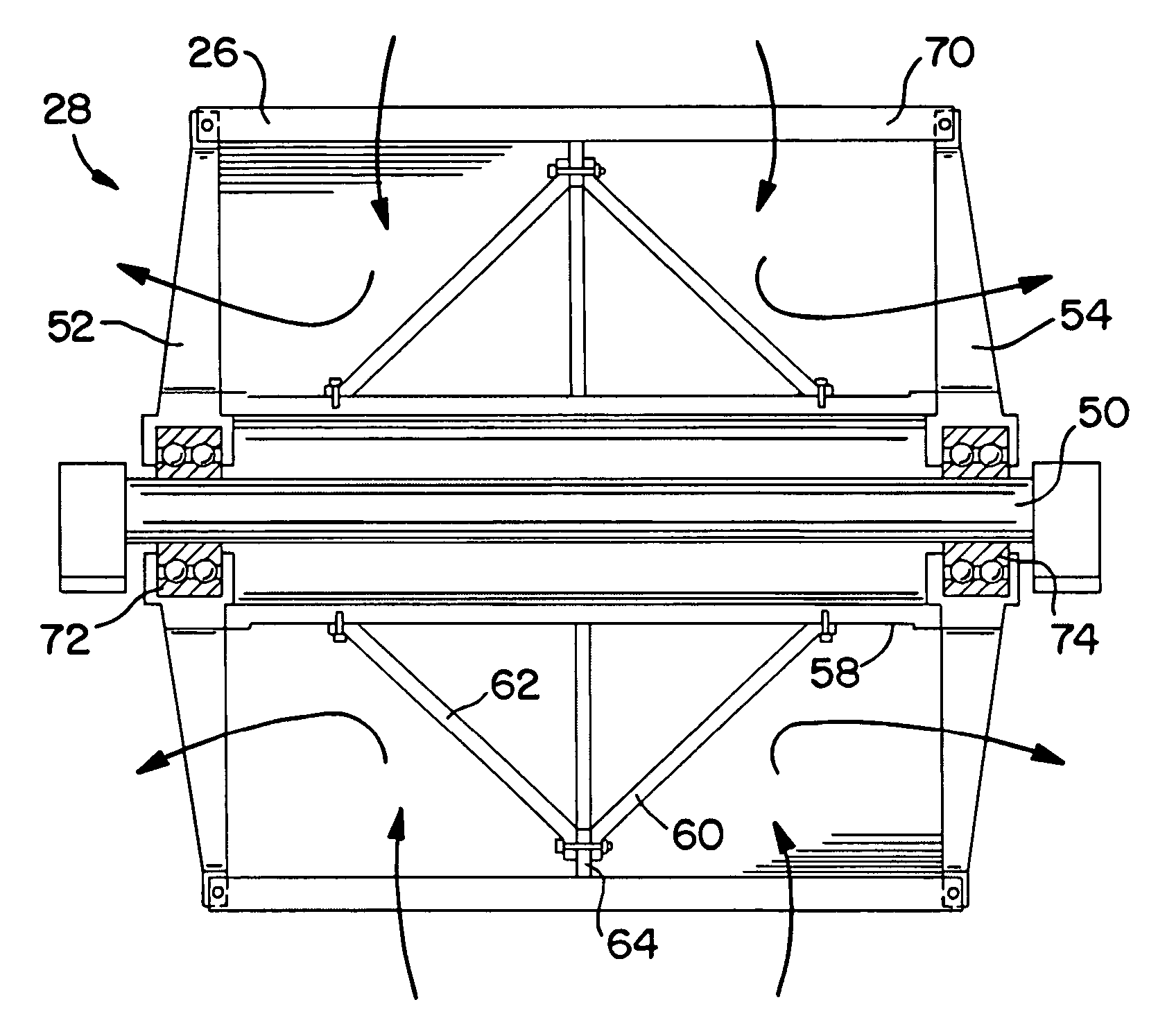

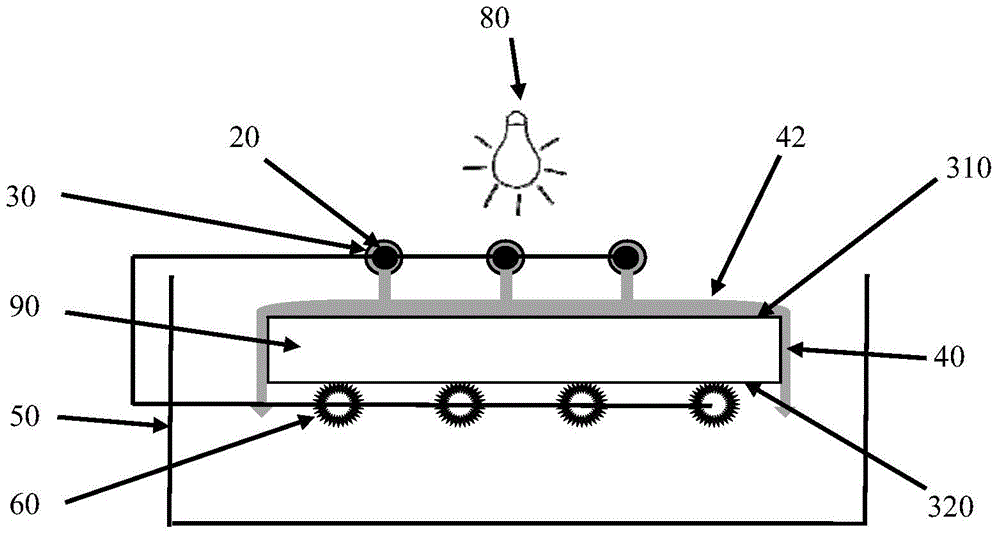

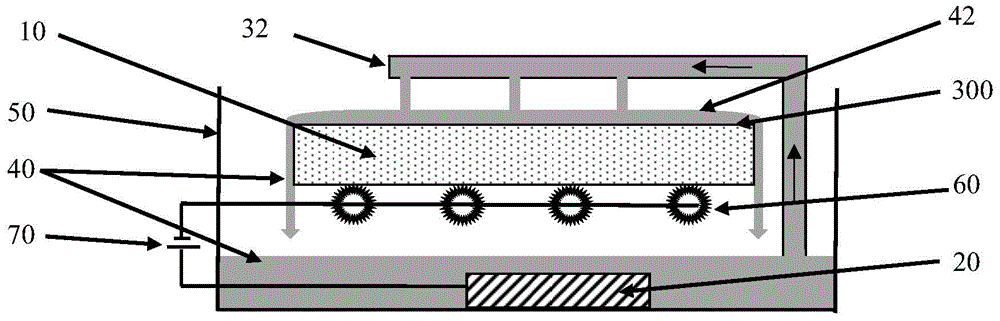

Cargo transport system and method

ActiveUS20090304482A1Reduce weightSimplification of loading operationRefuse receptaclesWeight reductionTransport systemTransit system

A system for loading cargo containers into a storage hold, and offloading cargo containers from the storage hold, especially of a vehicle, such as an aircraft. The system includes at least one guide rail and a motorized platform, onto which cargo containers are loaded, cooperating mechanically with the guide rail. The guide rail guides the cargo laden motorized platform into the storage hold, and the motorized platform deposits the cargo upon remote command. The motorized platform has a chassis; a power source; a control module controlling drive motors of the wheels of the platform; and means for reciprocating at least a portion of an upper surface of the platform sufficient to elevate a load placed thereon above the guide rail height.

Owner:THE BOEING CO

Cargo transport system and method

ActiveUS7785056B2Reduce weightReduce harmRefuse receptaclesWeight reductionTransport systemTransit system

A system for loading cargo containers into a storage hold, and offloading cargo containers from the storage hold, especially of a vehicle, such as an aircraft. The system includes at least one guide rail and a motorized platform, onto which cargo containers are loaded, cooperating mechanically with the guide rail. The guide rail guides the cargo laden motorized platform into the storage hold, and the motorized platform deposits the cargo upon remote command. The motorized platform has a chassis; a power source; a control module controlling drive motors of the wheels of the platform; and a device for reciprocating at least a portion of an upper surface of the platform sufficient to elevate a load placed thereon above the guide rail height.

Owner:THE BOEING CO

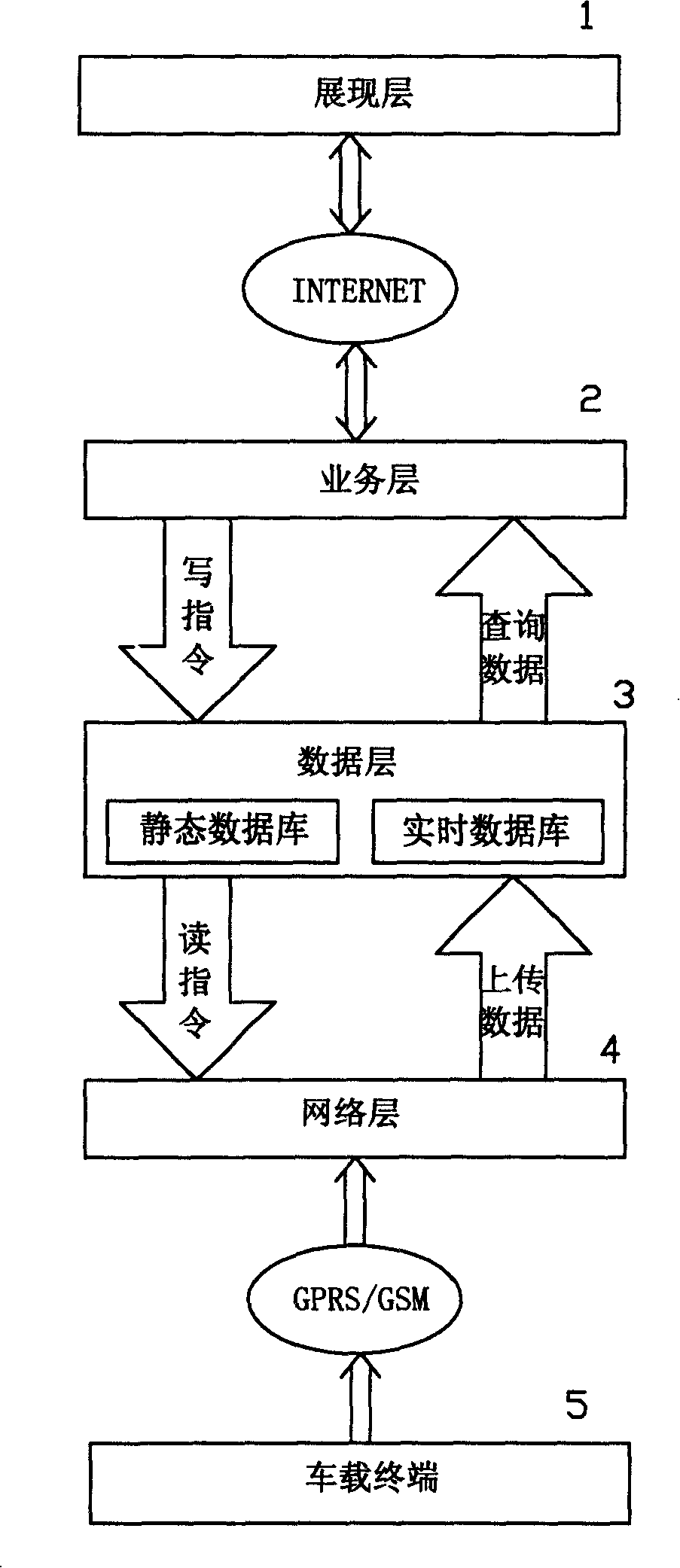

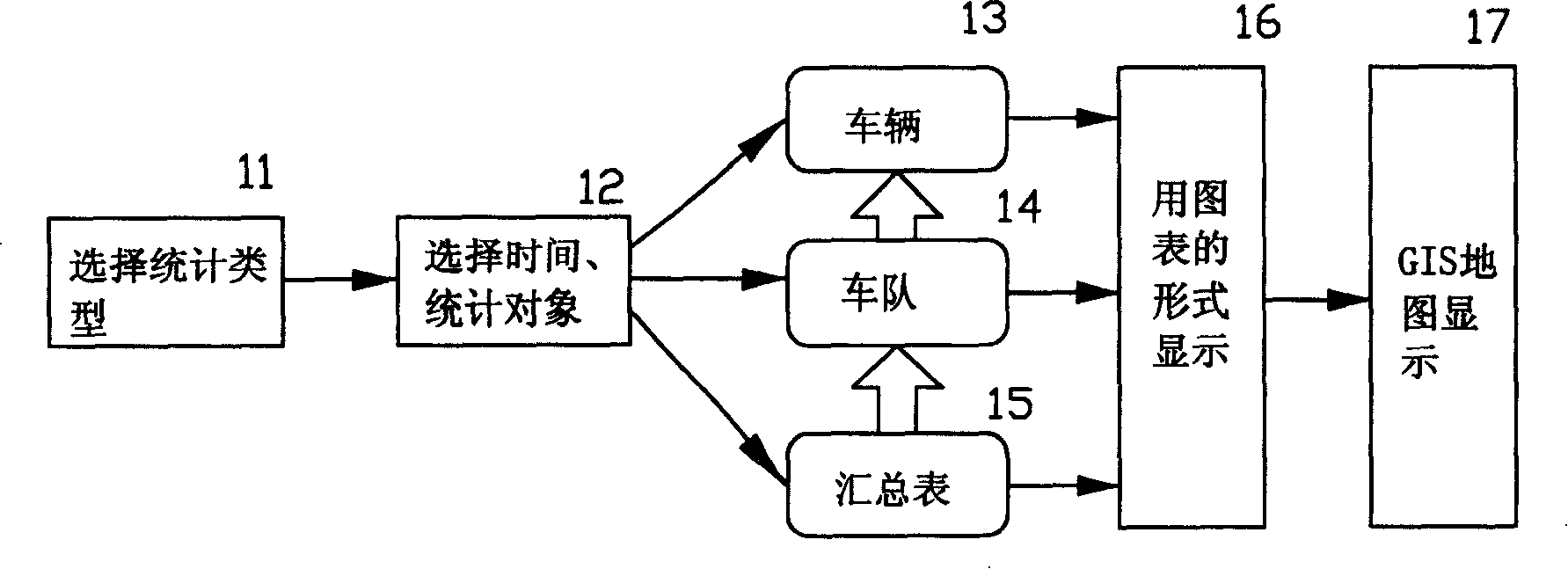

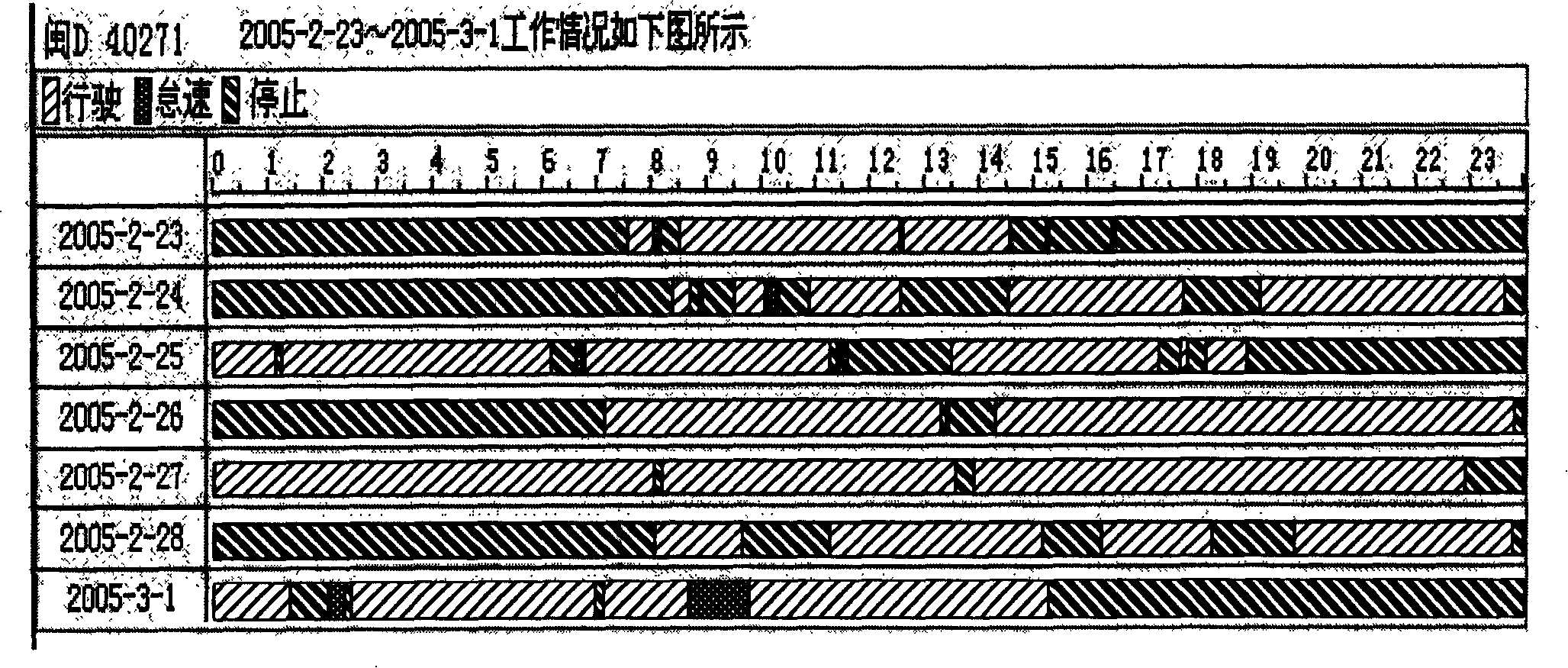

Vehicle usage statistical method

InactiveCN101211429ALow costSimple loadingData processing applicationsSpecial data processing applicationsData displayData science

The invention discloses a vehicle utilization statistics method for establishing a service center including an exhibition layer, a business layer, a data layer and a network layer, wherein, the data layer is composed of a database; vehicle-mounted terminals can upload running data to the service center regularly; the network layer in the service center can resolve the uploaded data from the vehicle-mounted terminals before saving the data into a database; when receiving vehicle utilization statistics inquiry from the vehicle manager, the service center can acquire data from a specified table in the database through the data statistics module; then, the service center can perform calculation for such data as times, mileage, amount and time according to statistics demands, conclude statistics results and transmit into the data display module; the data display module can use report forms making tools to exhibit all the statistics results to users with the report forms and charts; meanwhile, the invention also uses a GIS map display module to provide a function of GIS map display, so that the user can browse the data according to the map, so as to help the user learn about inquired information in a direct-viewing manner.

Owner:XIAMEN YAXON NETWORKS CO LTD

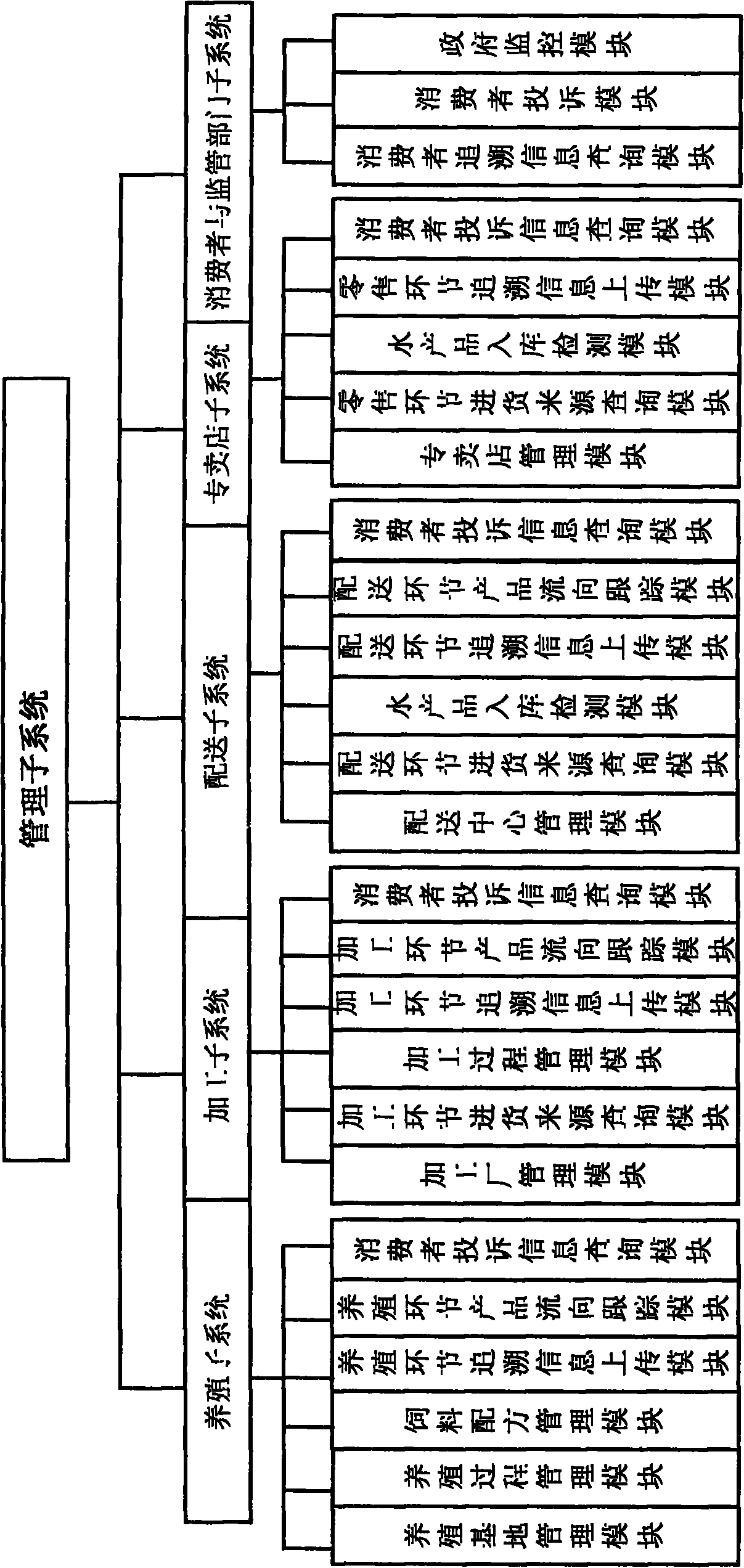

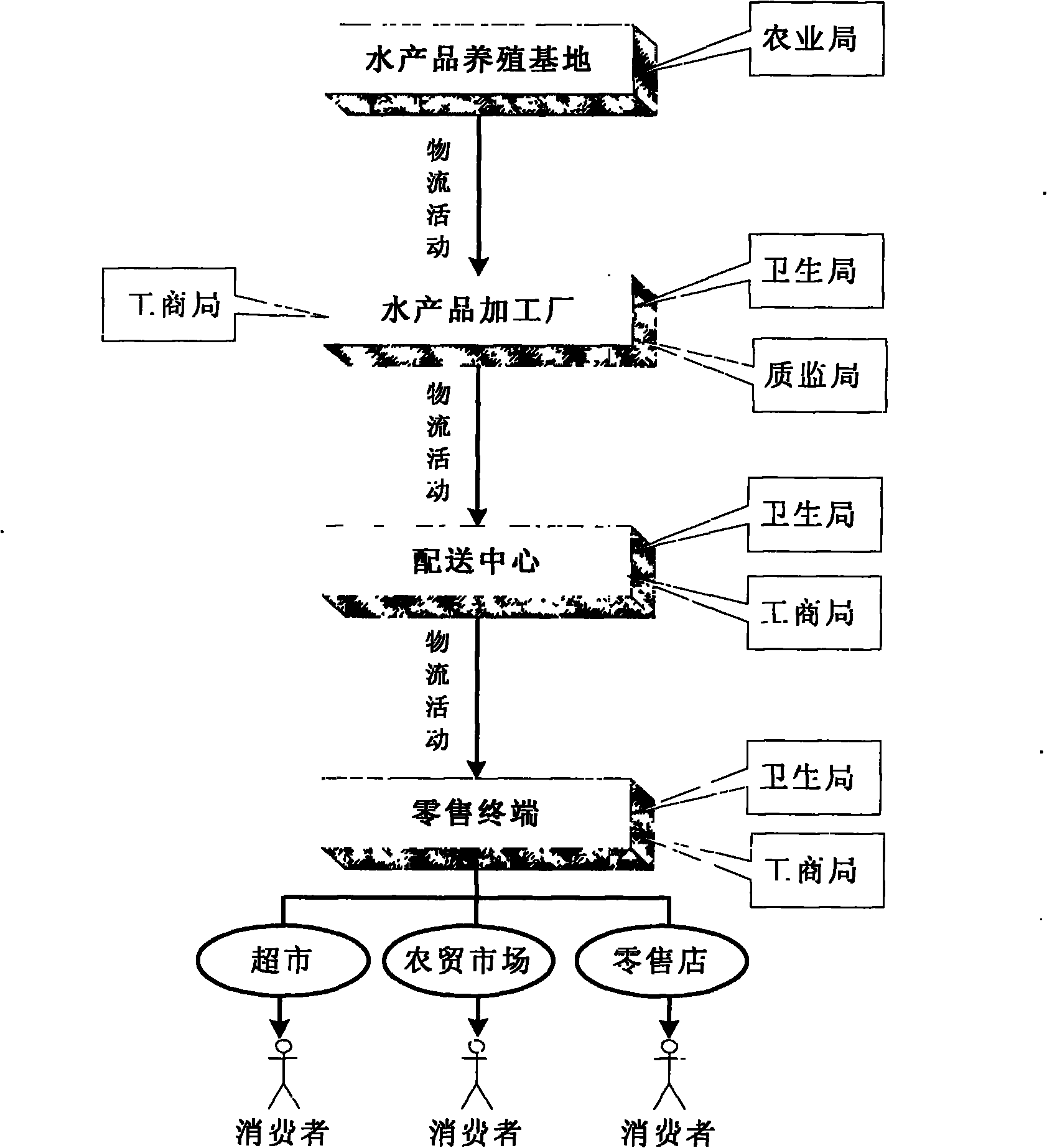

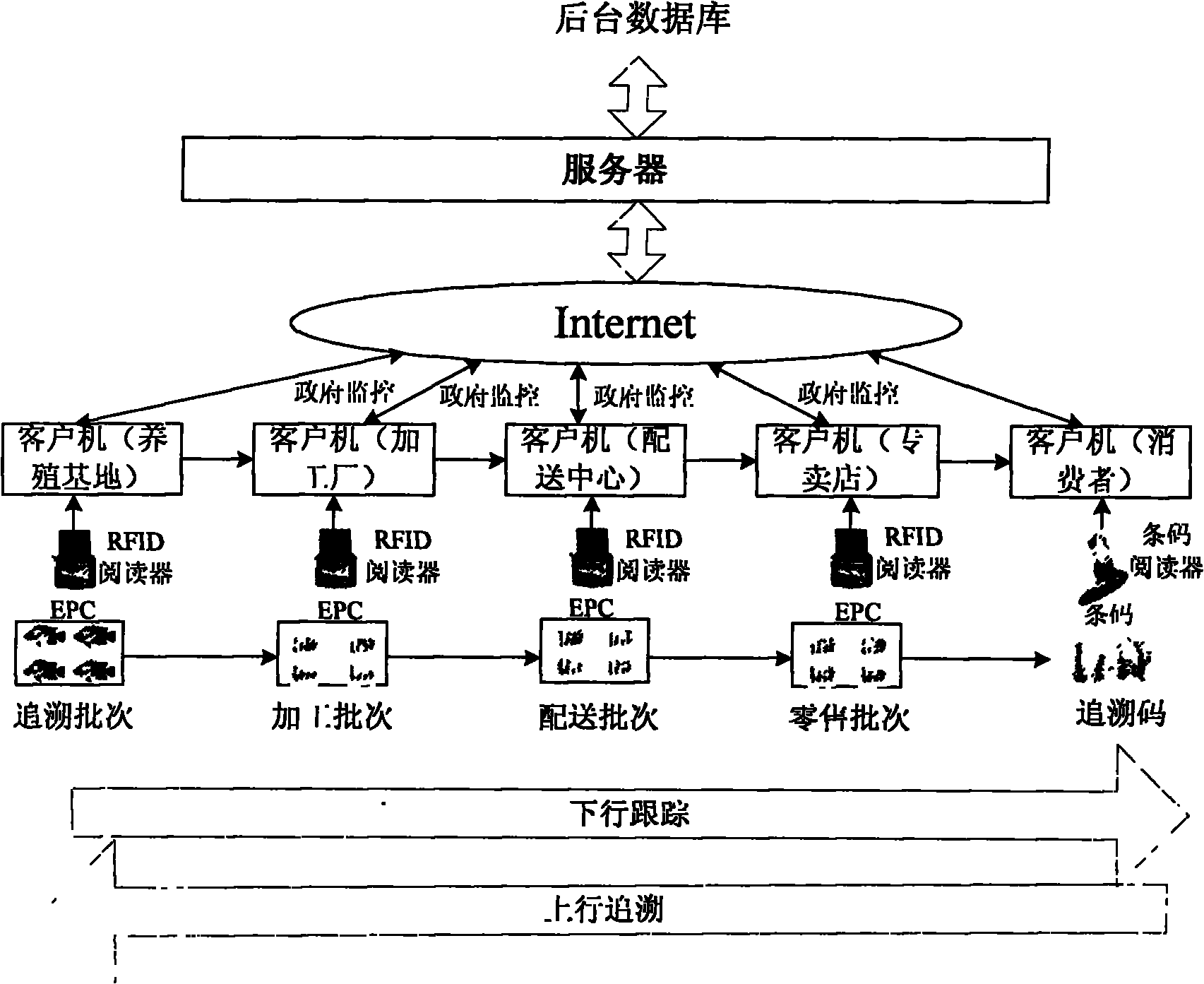

RFID (Radio Frequency Identification Device) based seafood supply chain traceability system under exclusive shop direct sales model

InactiveCN101819656AAvoid defectsImprove work efficiencyCo-operative working arrangementsCommerceRelevant informationNetwork connection

The invention discloses an RFID (Radio Frequency Identification Device) based seafood supply chain traceability system under an exclusive shop direct sales model, comprising a client, a server and a backend database which are all in network connection; the client comprises RFID reader-writers, an RFID electronic label and a client computer, wherein the RFID reader-writer is in network connection with a plurality of RFID electronic label networks, and a plurality of RFID read-writers are in network connection with the client computer; the server comprises a culture subsystem, a processing subsystem, a delivery subsystem, an exclusive shop subsystem, a consumer and controlling authority subsystem and a management subsystem, wherein the management subsystem is respectively connected with the culture subsystem, the processing subsystem, the delivery subsystem, the exclusive shop subsystem and the consumer and controlling authority subsystem, and the culture subsystem, the processing subsystem, the delivery subsystem, the exclusive shop subsystem and the consumer and controlling authority subsystem are in network connection. The invention has the advantages of high speed, high efficiency, convenient management, capability of tracking relevant information of each link of a supply chain, and the like.

Owner:SOUTH CHINA UNIV OF TECH

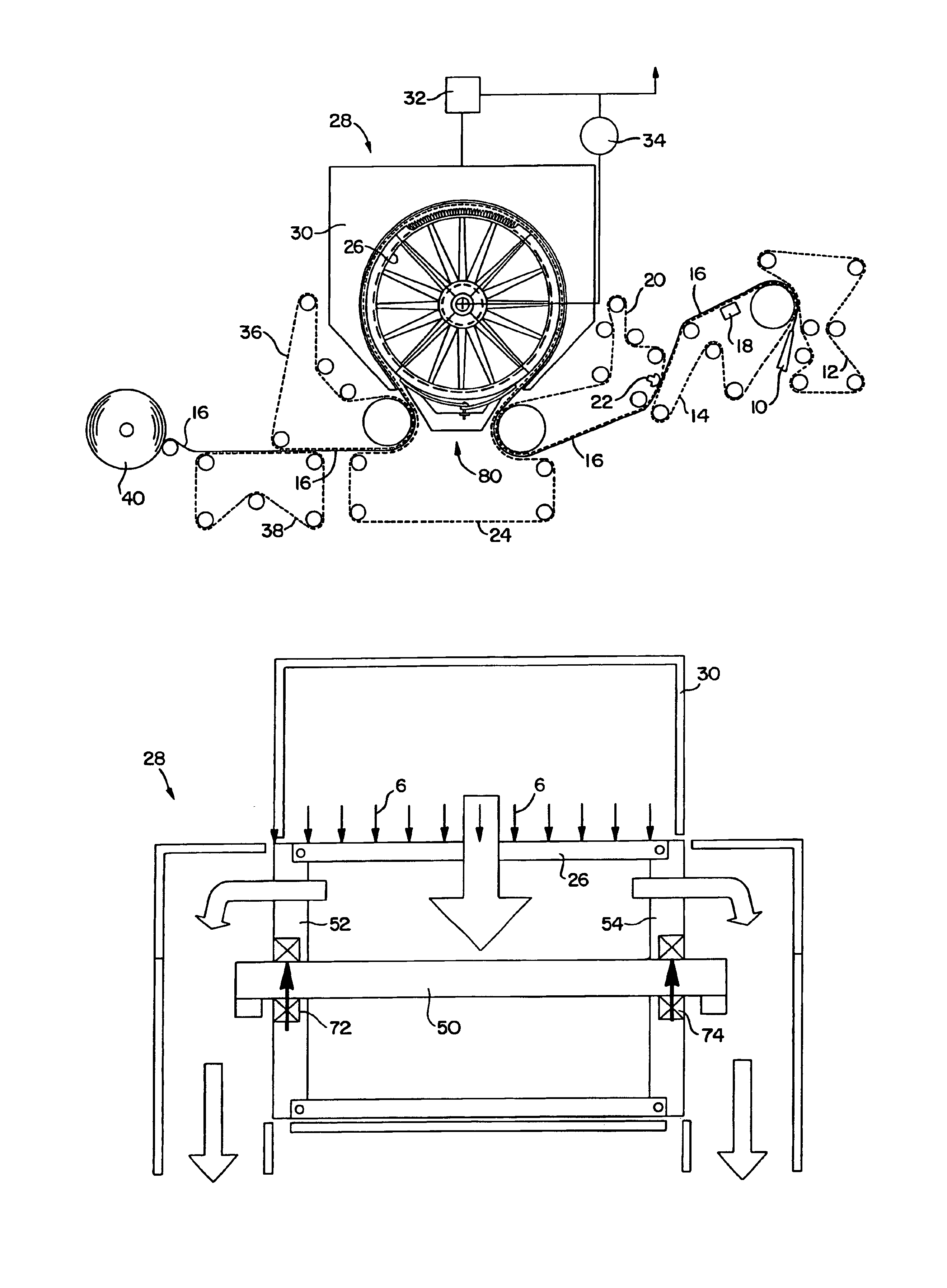

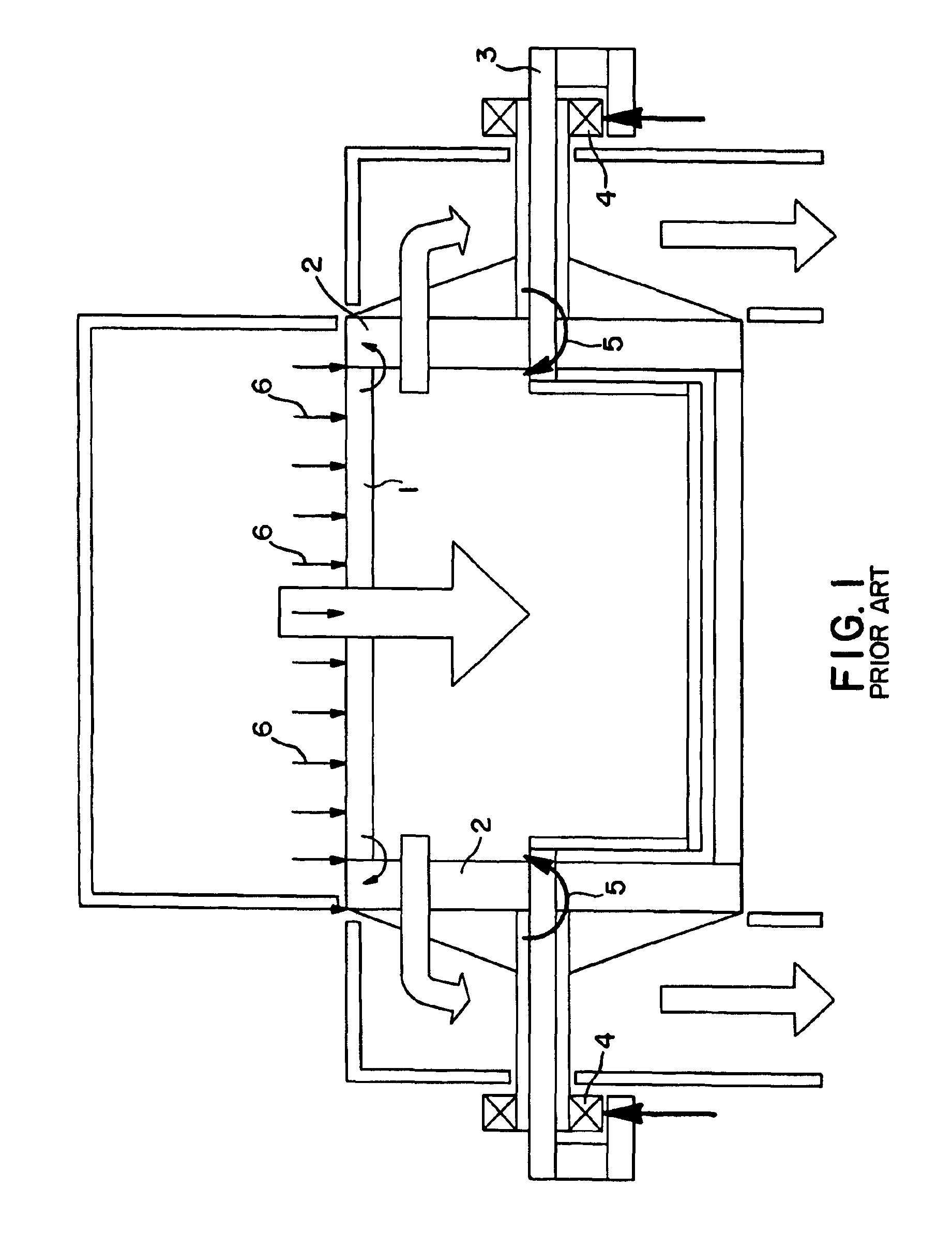

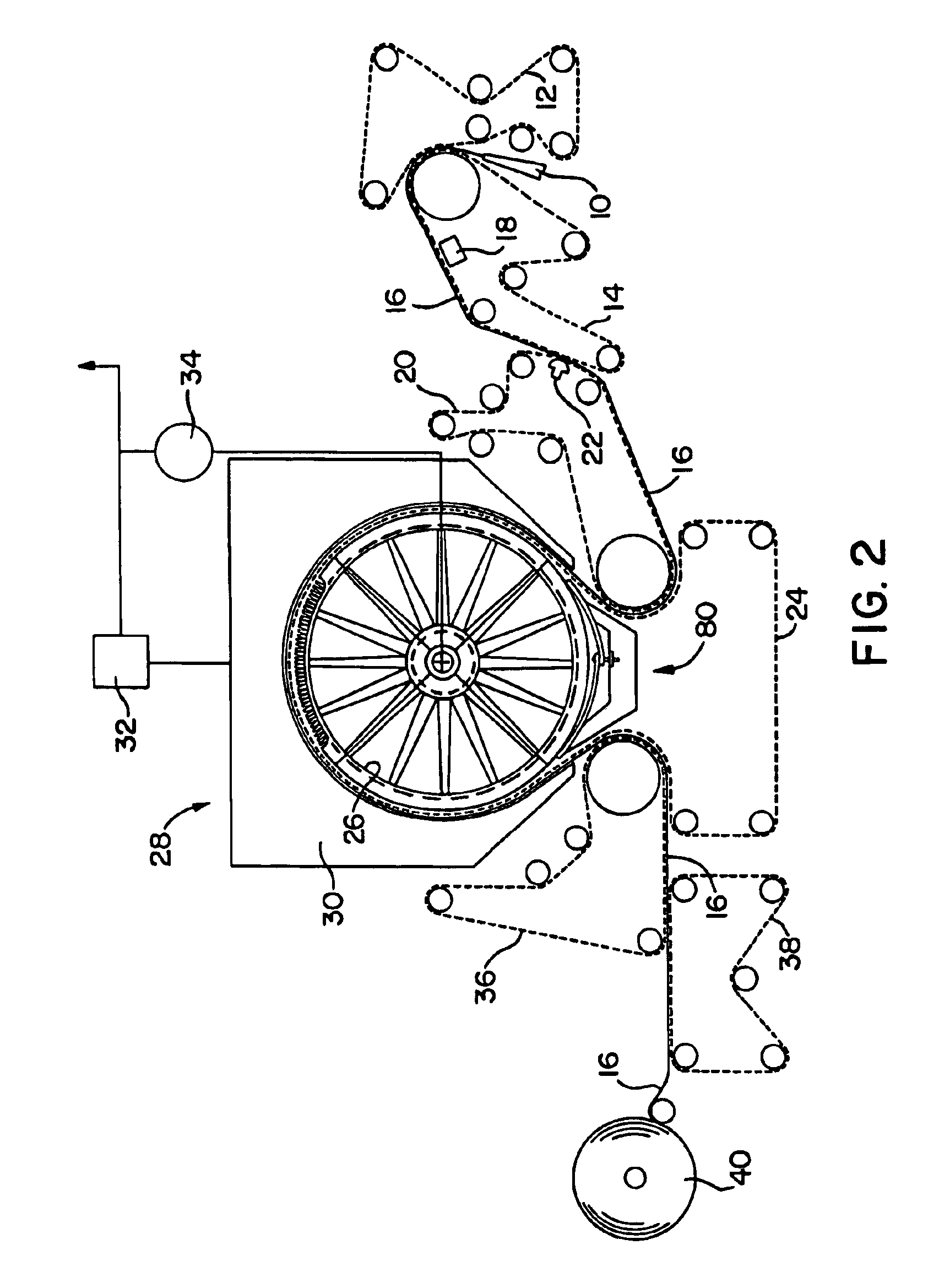

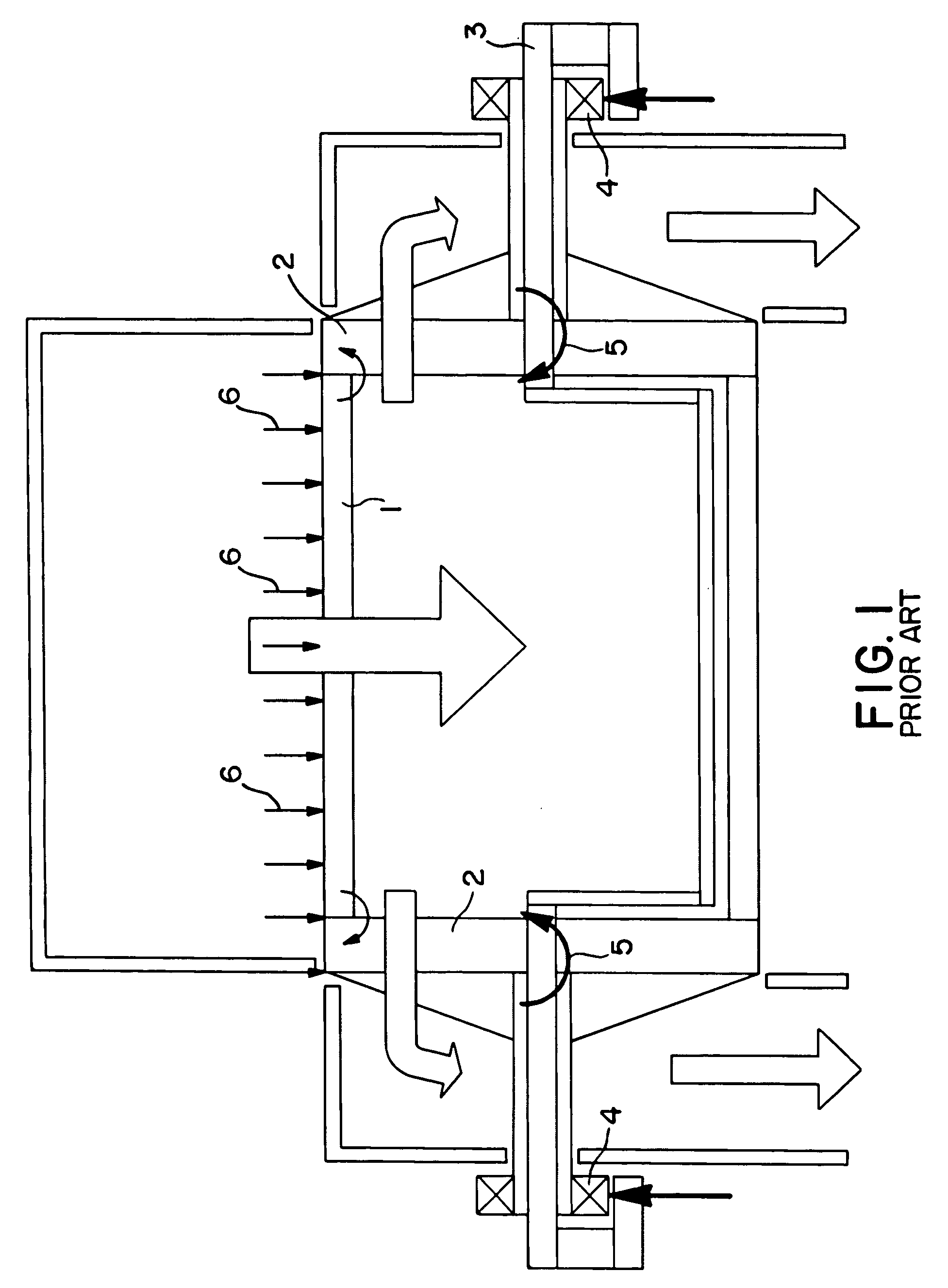

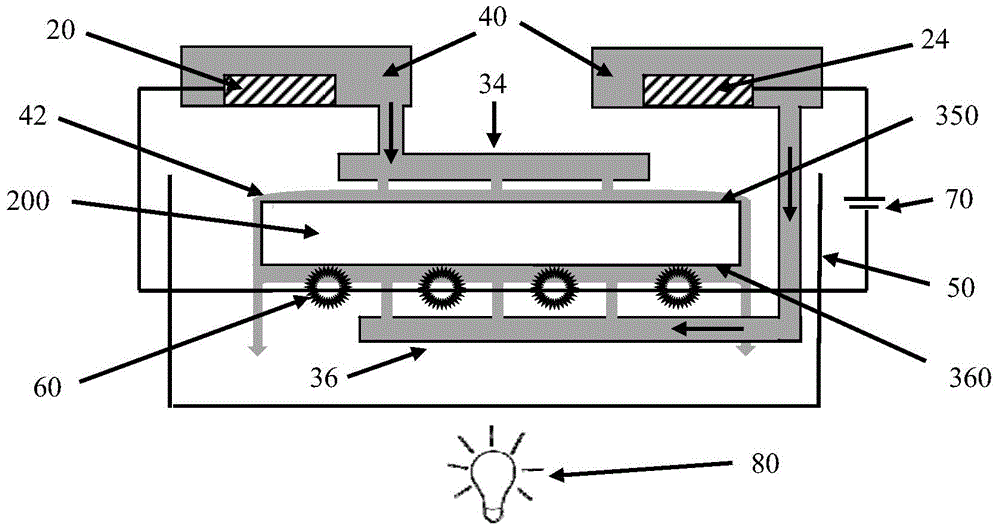

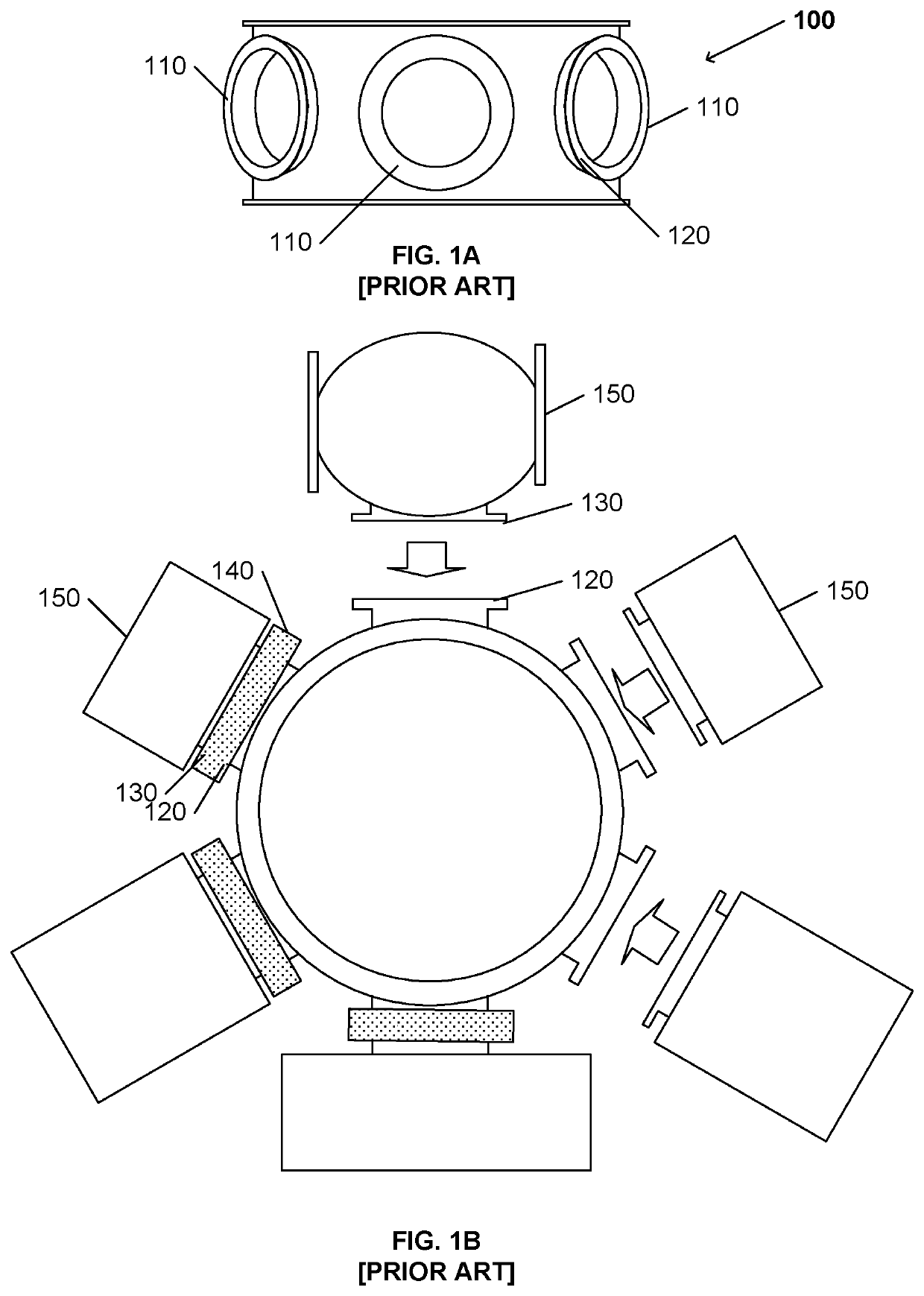

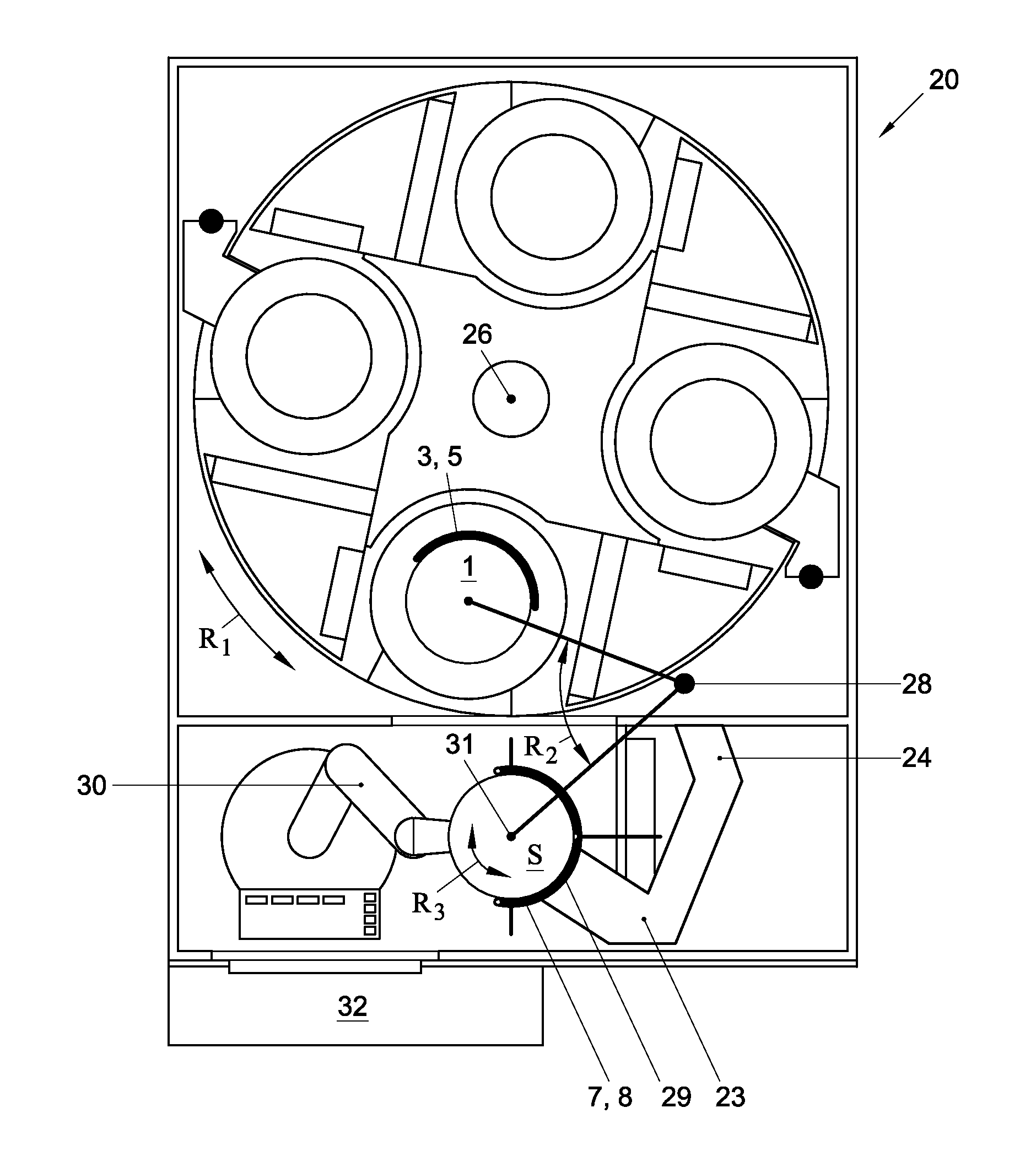

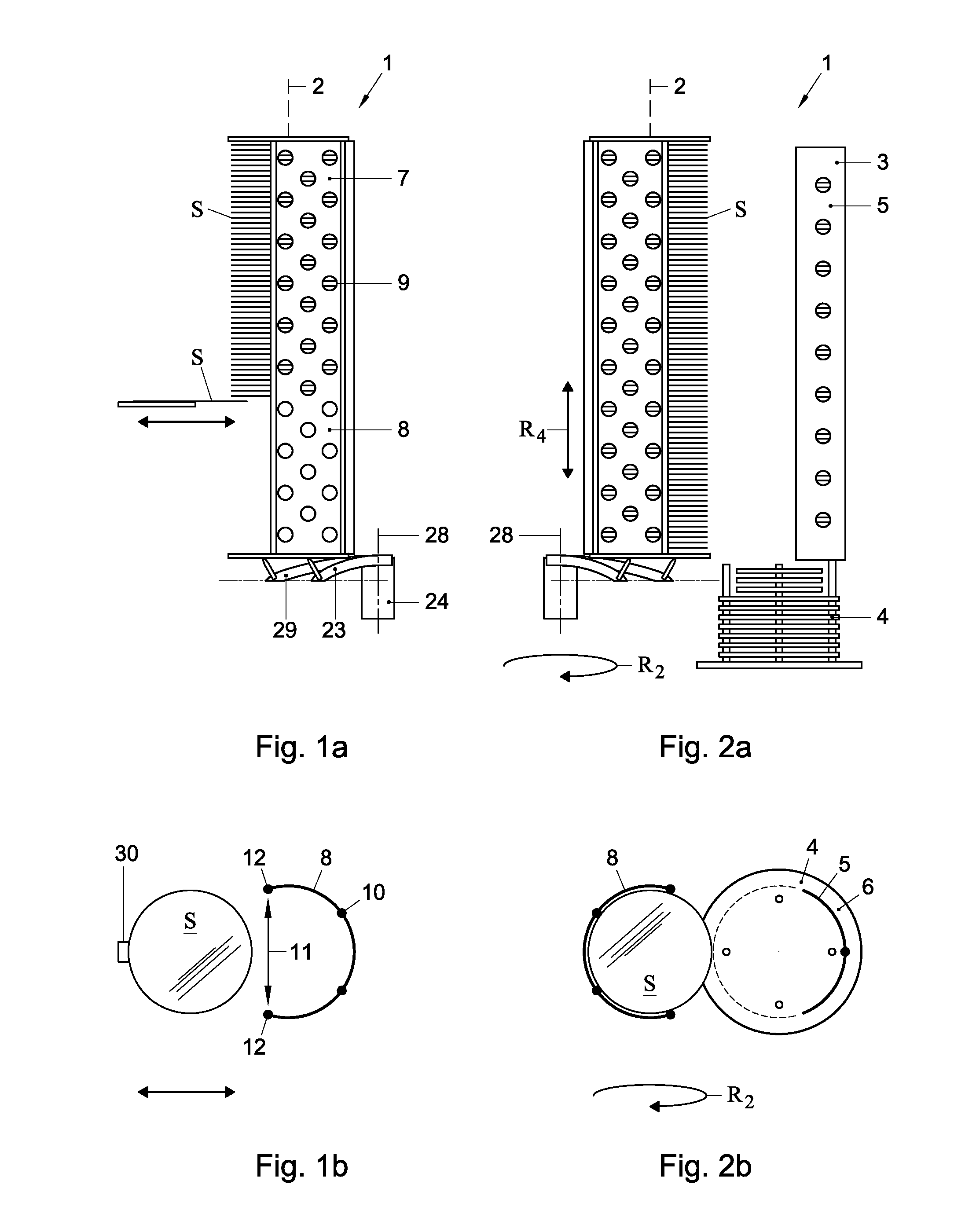

Through-air dryer assembly

ActiveUS6877246B1Easy to transportLessening structural demandDryer sectionDrying machines with progressive movementsAir dryerMechanical engineering

A through-air dryer is disclosed. The through-air dryer includes a cylindrical deck made from a plurality of deck plates that support a throughdrying fabric. The deck plates are supported by opposing hubs. Each of the hubs is in communication with the bearing that is mounted to a stationary shaft for allowing the cylindrical deck and the hubs to rotate. The bearings are positioned so as to create a through-air dryer structure that remains stable during operation and allows for easy calculation of loads on the dryer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

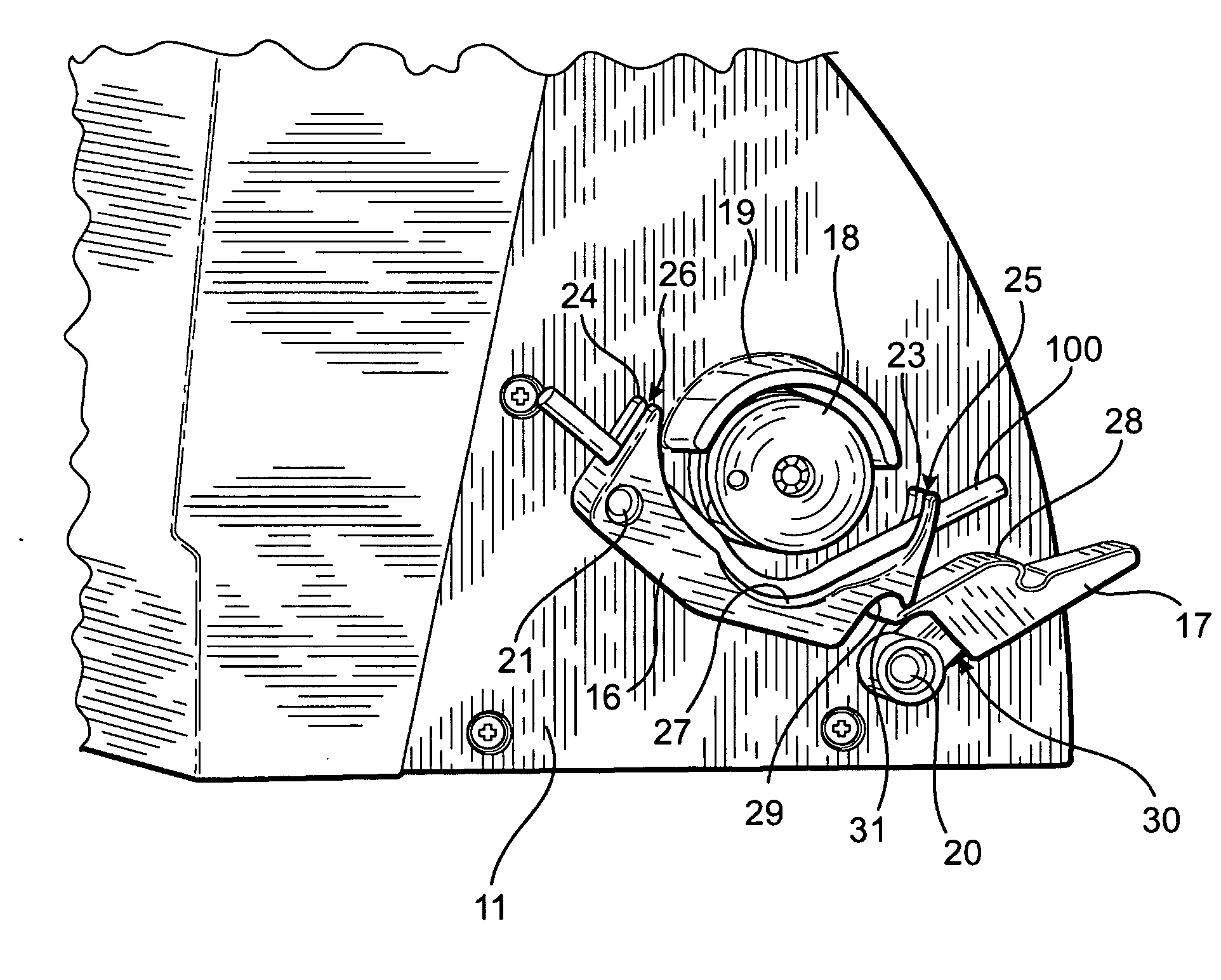

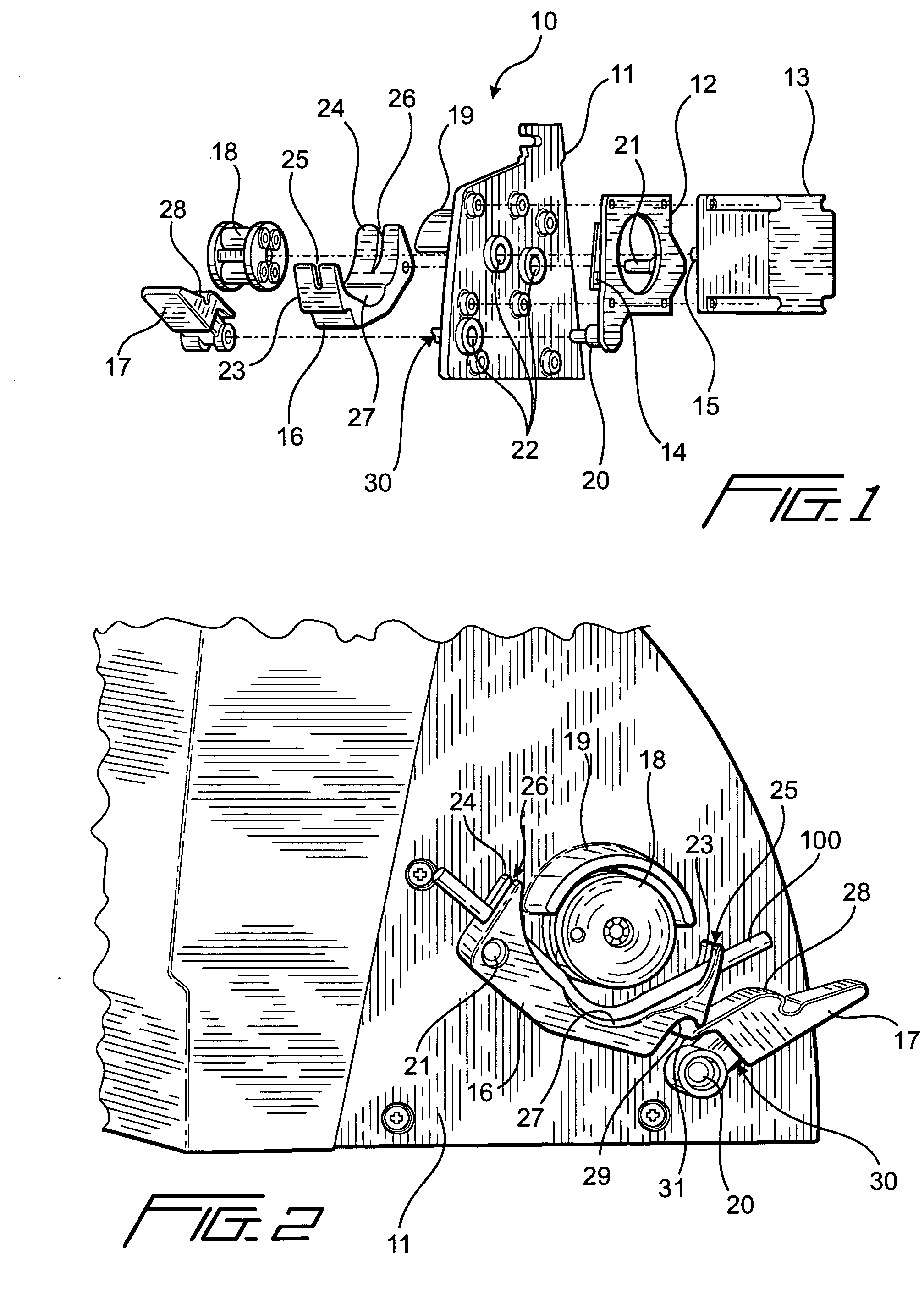

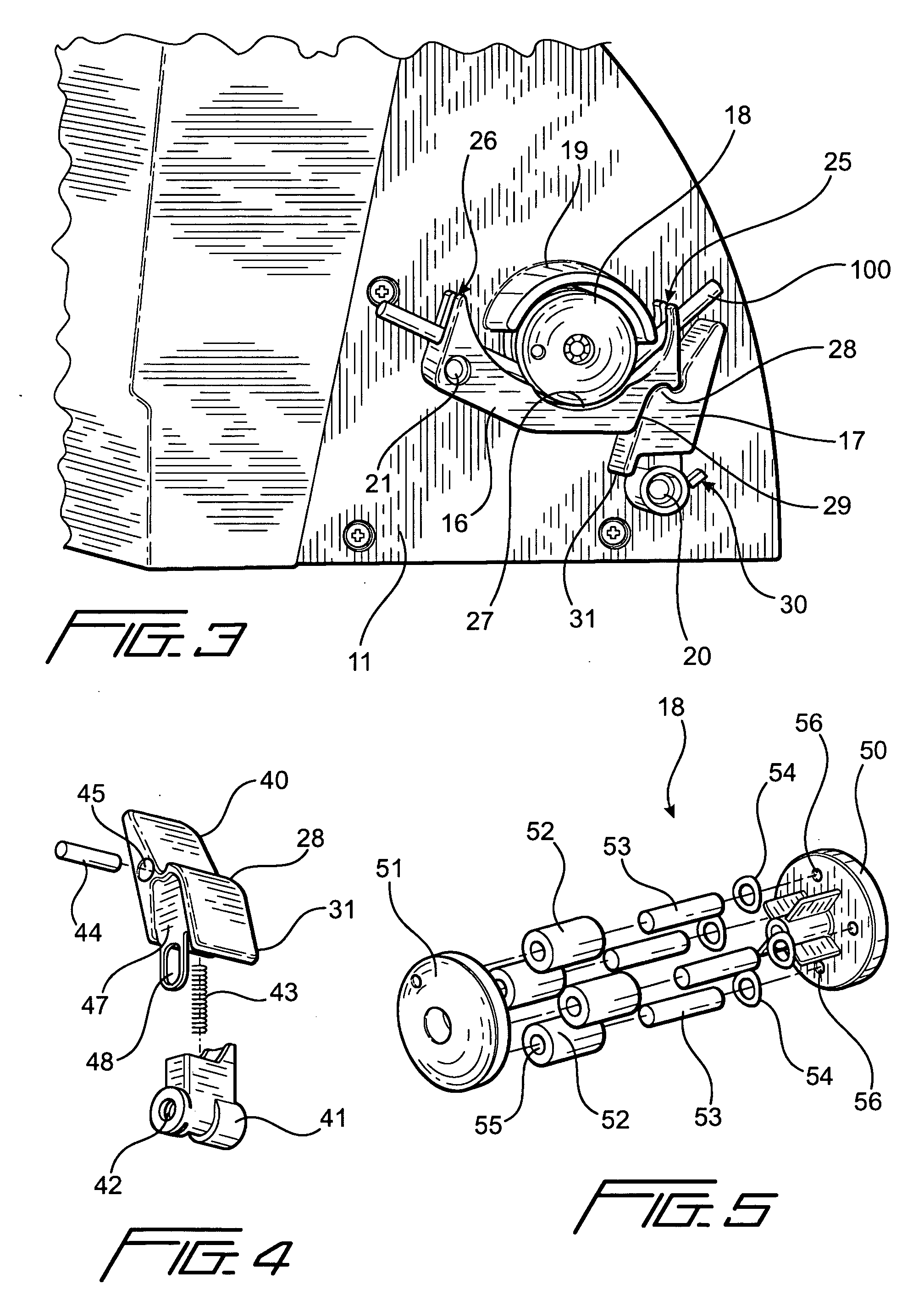

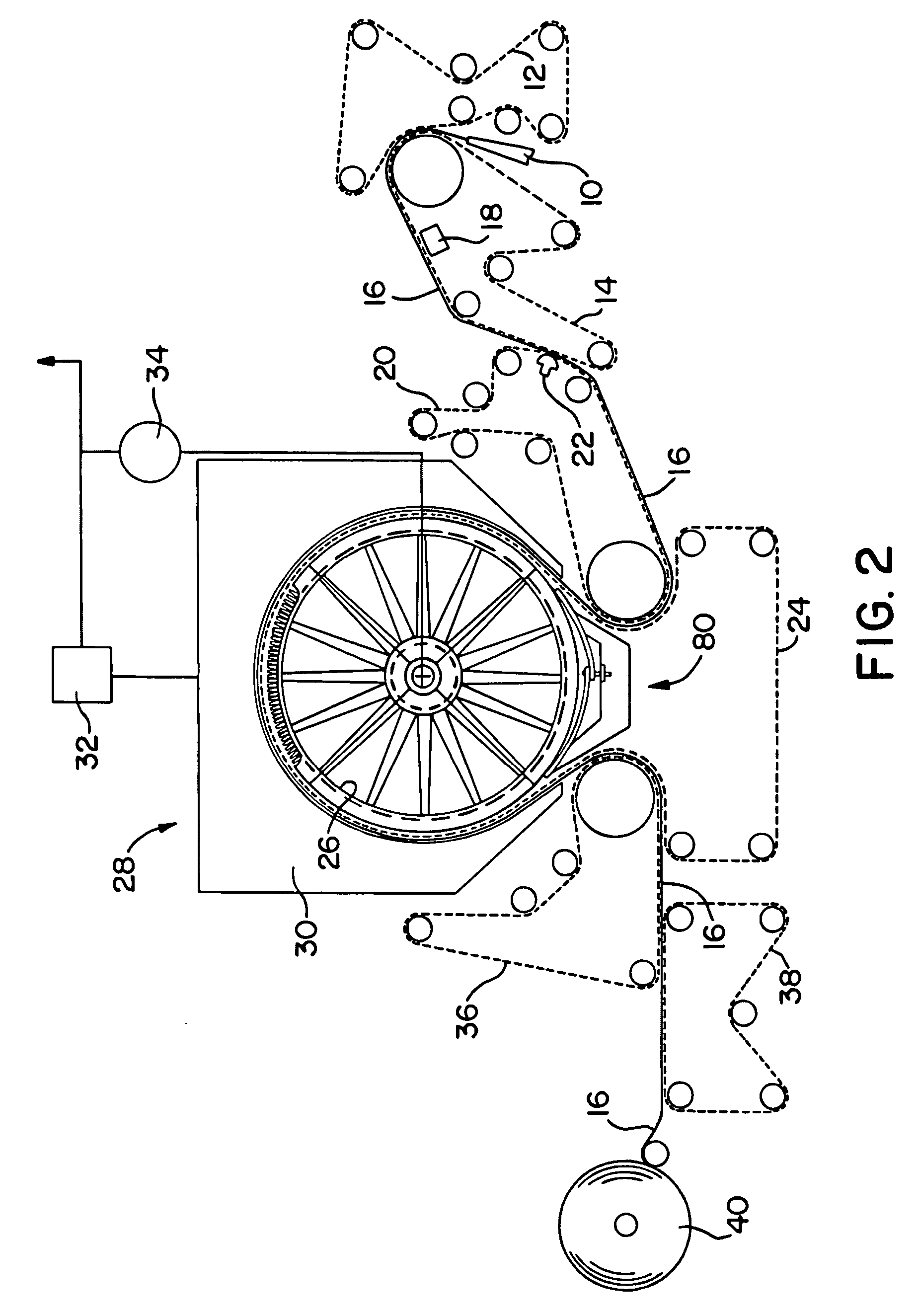

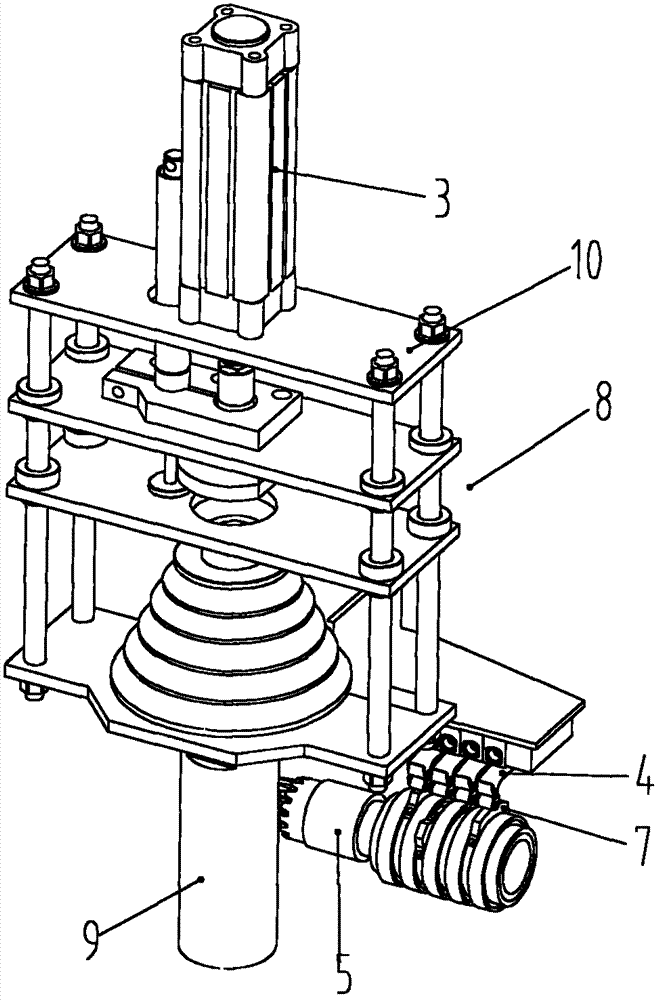

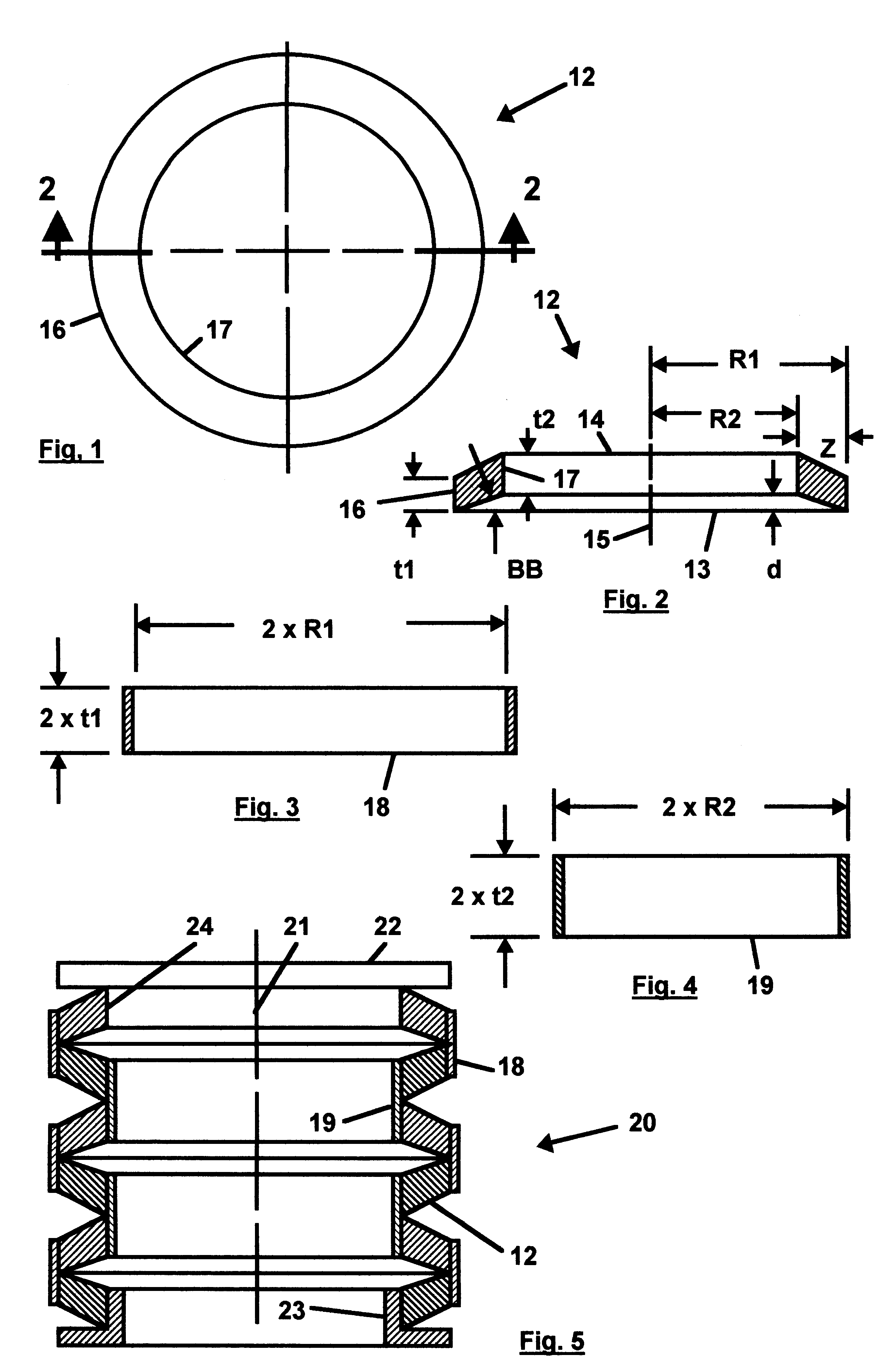

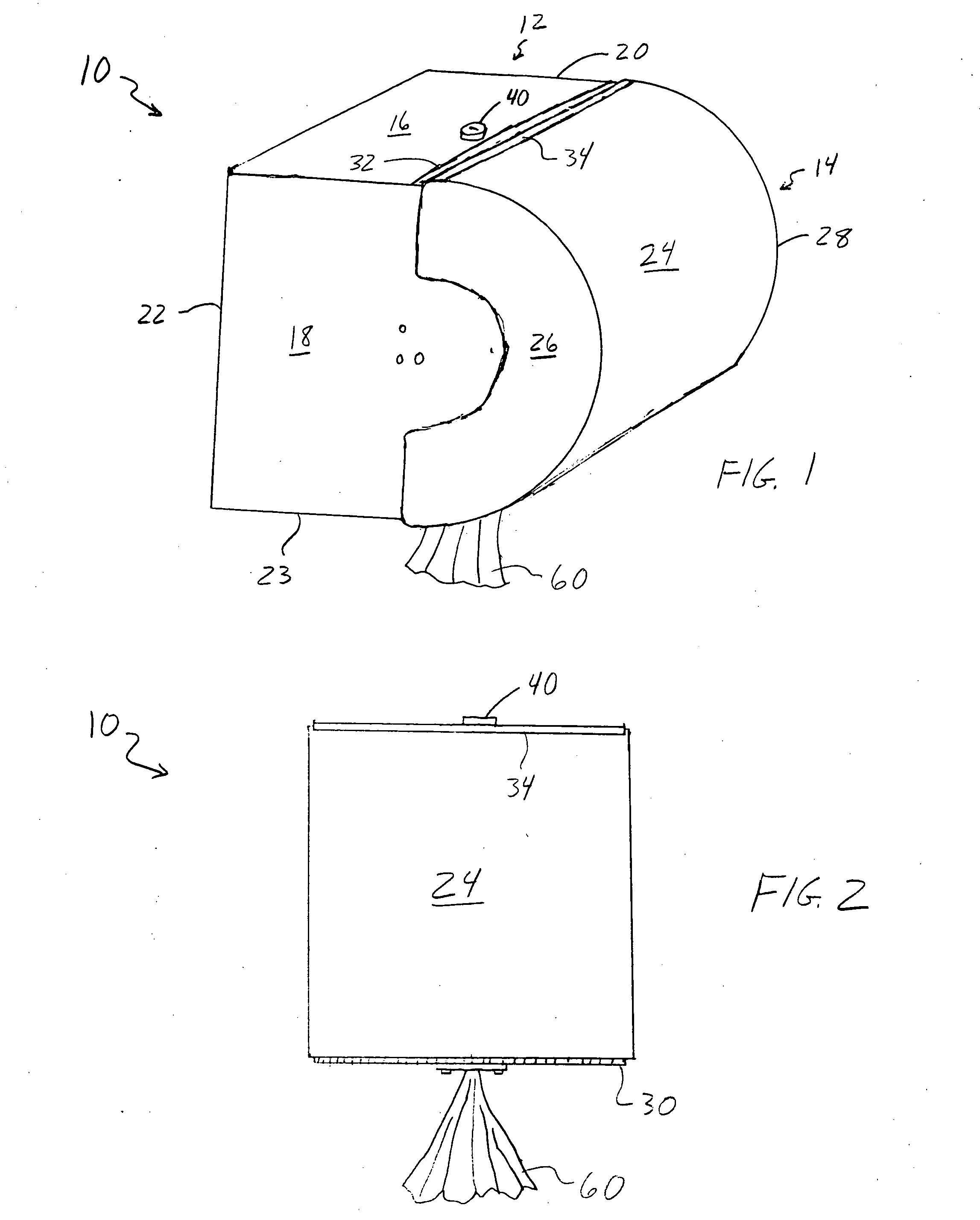

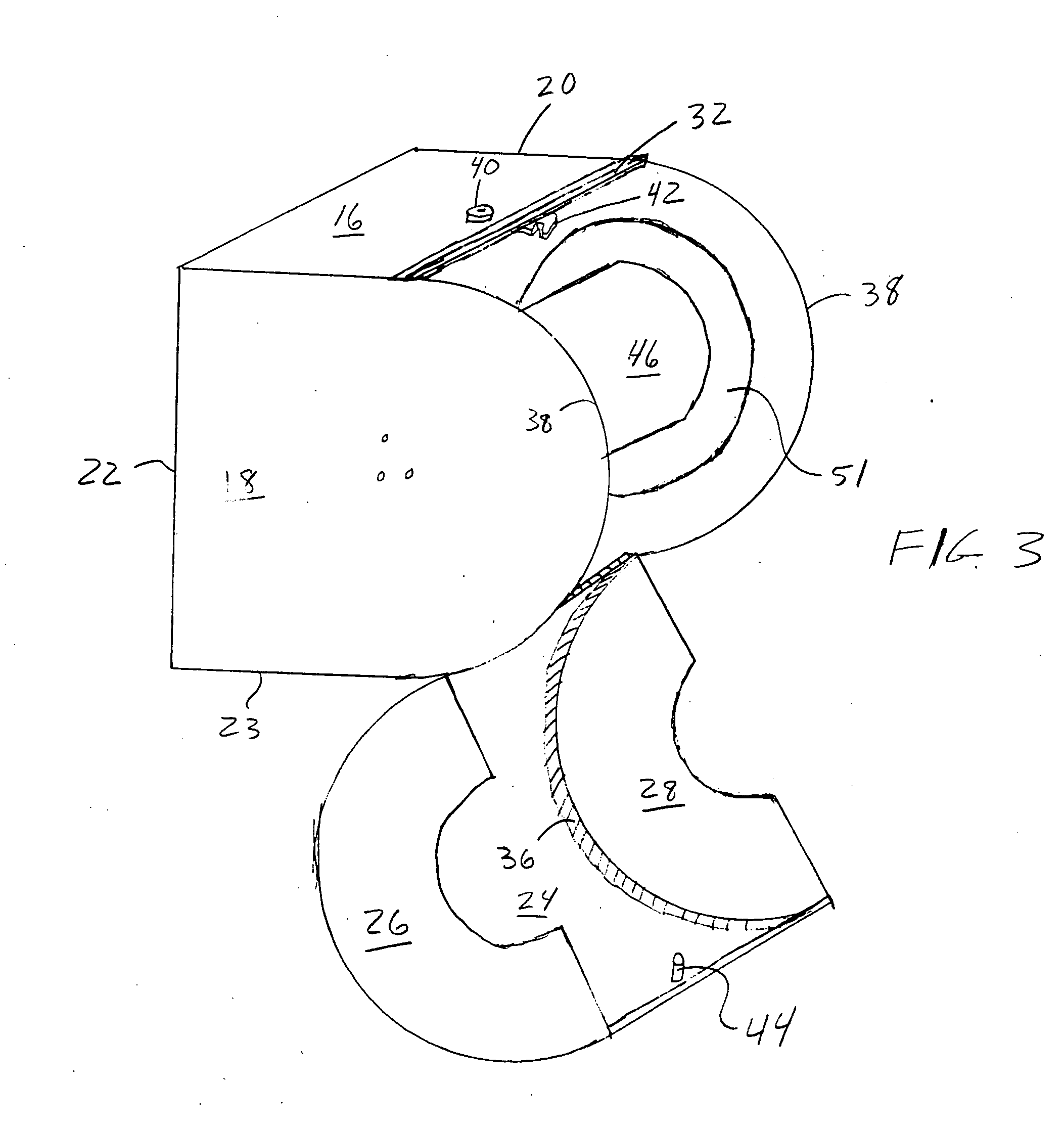

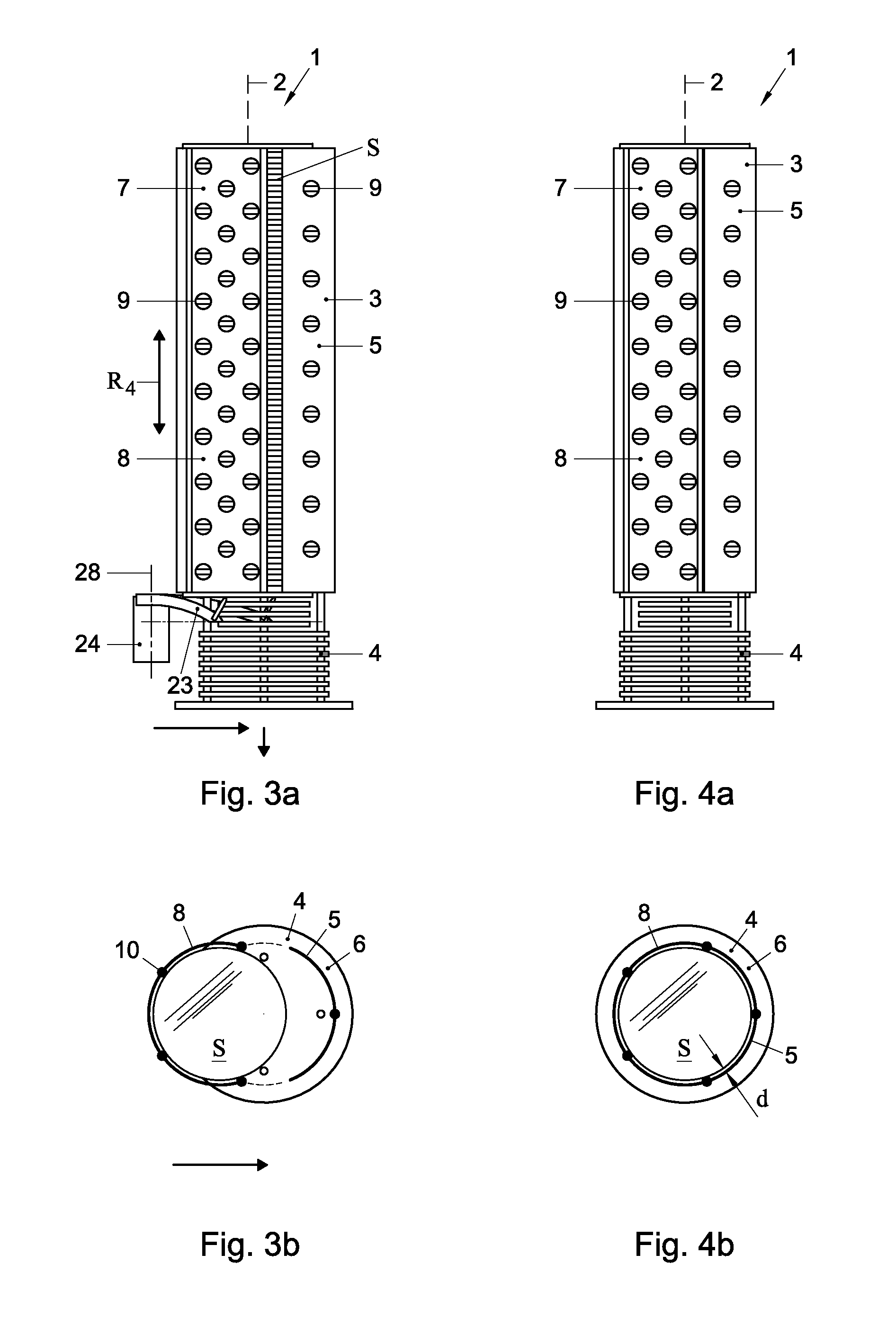

Peristaltic pump providing simplified loading and improved tubing kink resistance

InactiveUS20060177328A1Simple loading processReduce kinksFlexible member pumpsPositive-displacement liquid enginesPeristaltic pumpEngineering

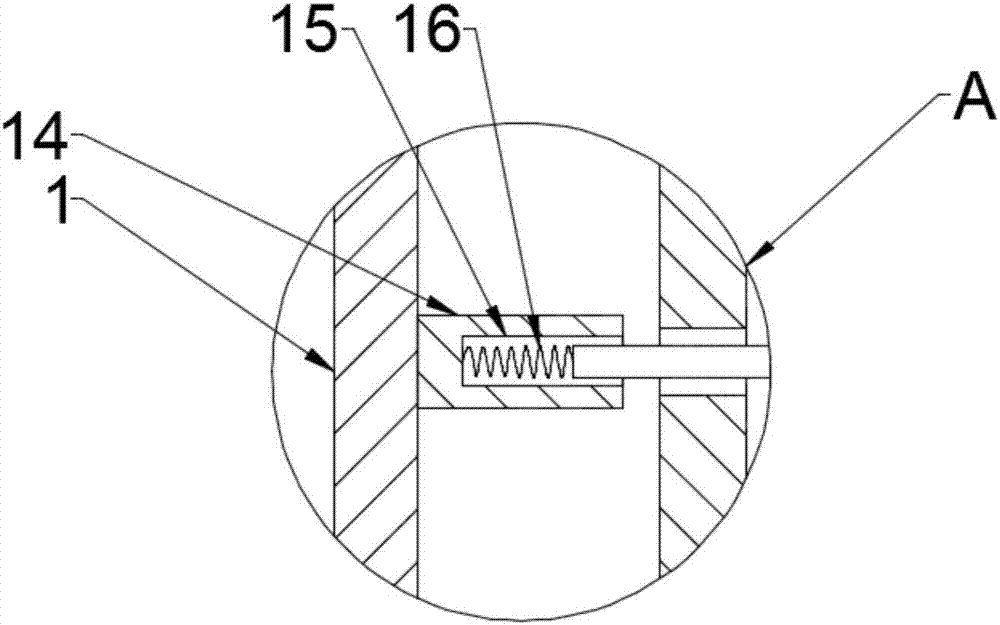

A peristaltic pump is provided that simplifies the loading of tubing and automatically self-centers the tubing relative to the pump wheel, wherein the pump includes an elongated arm having slotted pinch forks for engaging the tubing. The pinch forks are arranged substantially tangential to the pump wheel to reduce tubing kinking. The pump further includes a spring-loaded clamp that moves the elongated arm between engaged and disengaged positions, the clamp optionally including a sensor element used to detect when the pump is ready for operation.

Owner:VERATHON

Through-air dryer assembly

InactiveUS20050138832A1Easy to transportLessening structural demandDrying solid materials with heatDryer sectionEngineeringAir dryer

A through-air dryer is disclosed. The through-air dryer includes a cylindrical deck made from a plurality of deck plates that support a throughdrying fabric. The deck plates are supported by opposing hubs. Each of the hubs is in communication with a bearing that is mounted to a stationary shaft for allowing the cylindrical deck and the hubs to rotate. The bearings are positioned so as to create a through-air dryer structure that remains stable during operation and allows for easy calculation of loads on the dryer.

Owner:KIMBERLY-CLARK WORLDWIDE INC

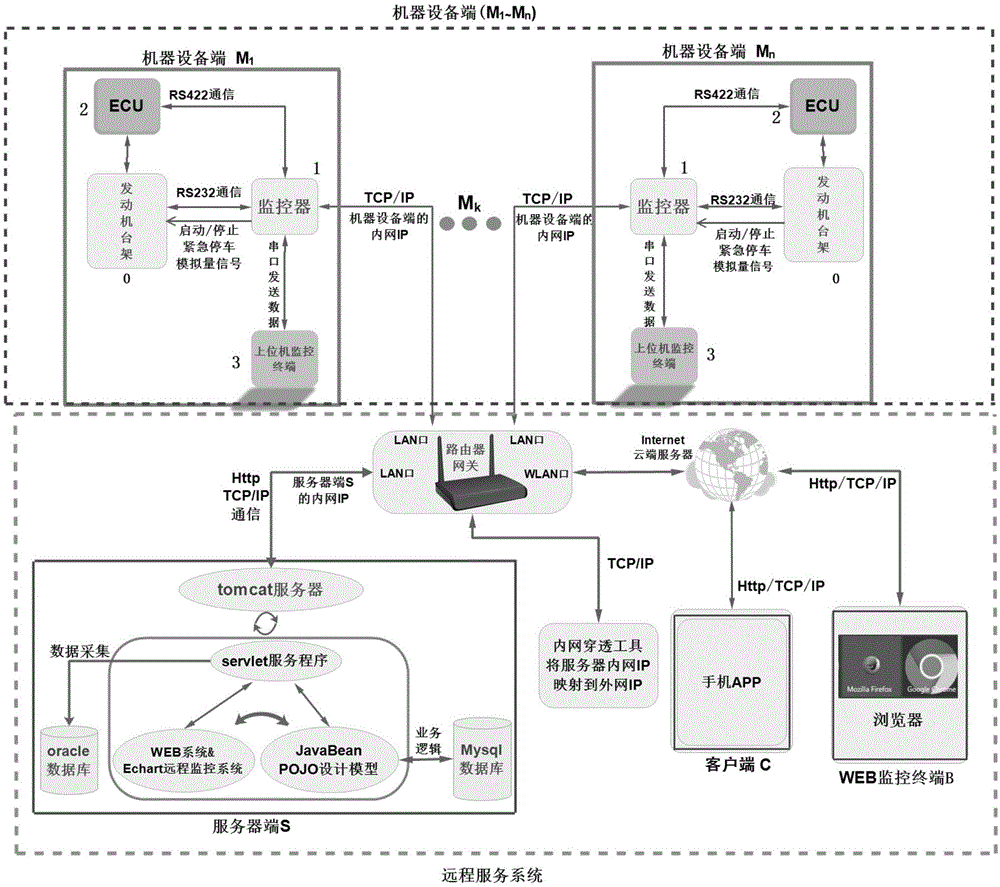

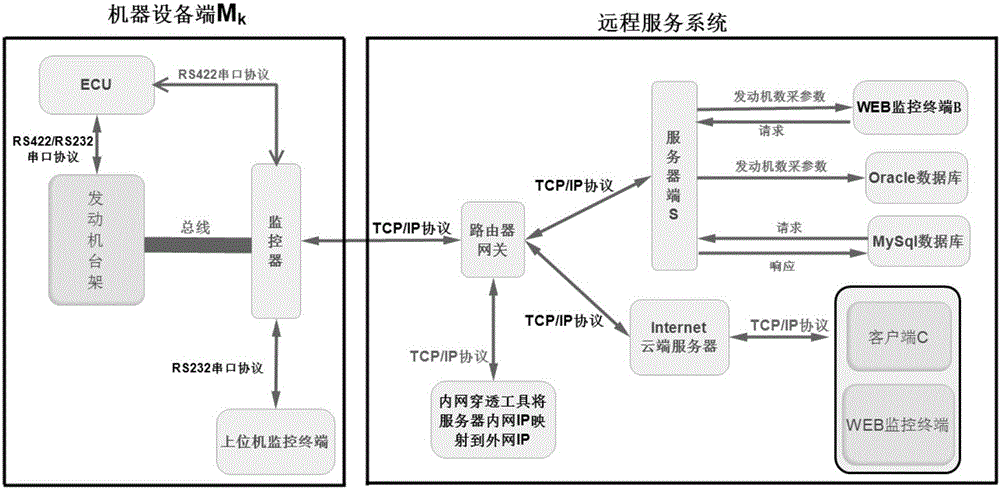

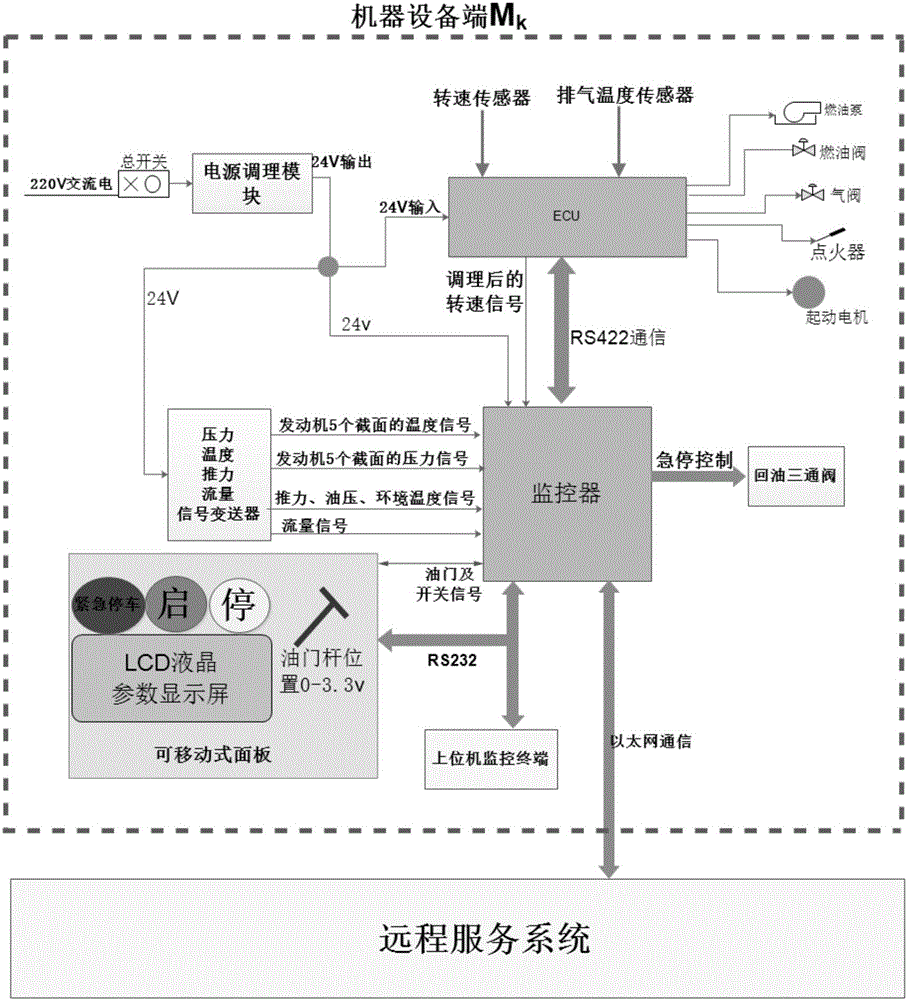

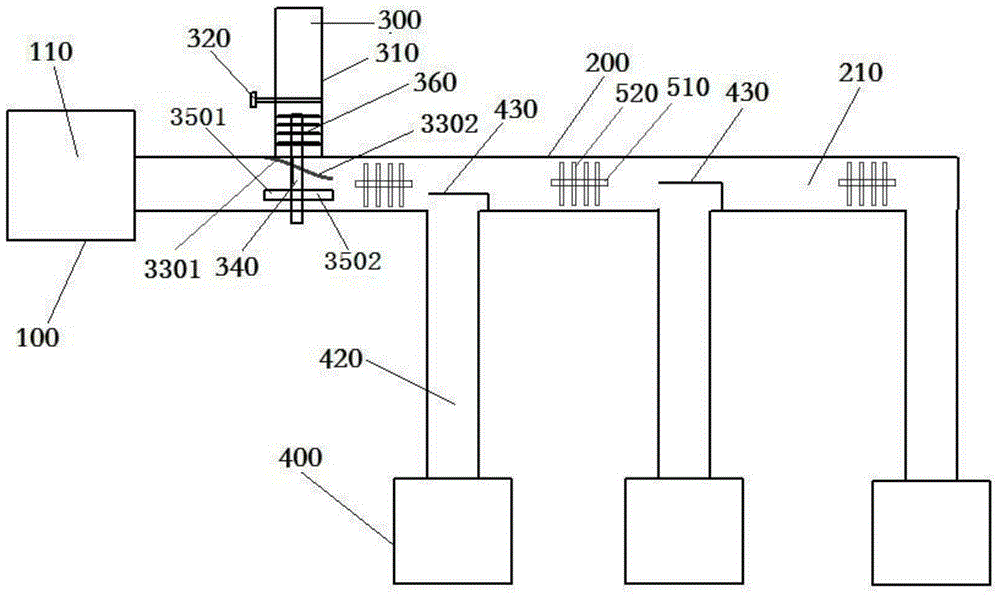

Stable universal type data state acquisition and remote monitoring multifunctional system

PendingCN106100908ASimplify PC loadReduce workload and costData switching networksTotal factory controlUpgradeMultiple function

The invention discloses a stable universal type data state acquisition and remote monitoring multifunctional system. The stable universal type data state acquisition and remote monitoring multifunctional system comprises an equipment state data acquisition system and a remote service system. The equipment state data acquisition system comprises a plurality of machinery equipment ends; each machine equipment end comprises a monitor, a data acquisition module and an equipment controller; each data acquisition module and each equipment controller are connected with each monitor; each monitor processes the received state parameter data and transmits the processed data to a monitoring terminal of an upper computer or the remote service system in time; and when an operating instruction sent by the remote service system is received, each monitor is responsible for converting the operating instruction into a control signal and sending the control signal to each equipment controller so as to realize remote monitoring for equipment. The stable universal type data state acquisition and remote monitoring multifunctional system greatly simplifies the load of a PC of a client, lightens cost and workload of system maintenance and upgrade, reduces total cost of a user, is steady in performance, is good in remote data transmission capability and can adapt to occasions with high requirements on real-time performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

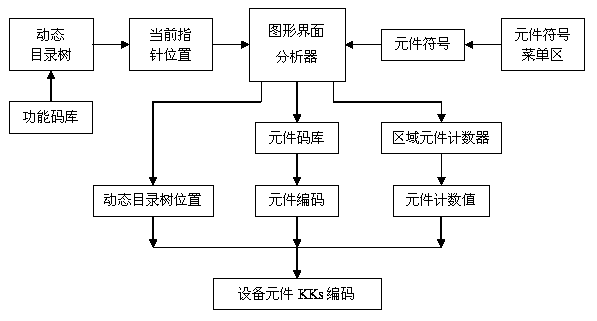

Automatic KKs code generating method for power plant equipment elements

ActiveCN103955869AGenerate job standardizationGenerate job normalizationData processing applicationsGraphicsSoftware engineering

The invention relates to an automatic KKs code generating method for power plant equipment elements. The method is completed in an automatic generating system on the basis of the computer technology. An automatic generating system comprises a graphical interface analyzer, a dynamic catalog tree, an element symbol menu area and a graphic design area, wherein the graphical interface analyzer, the dynamic catalog tree, the element symbol menu area and the graphic design area are connected with an ORACLE database and a graphic environment interface. The automatic generating method comprises the steps of establishing the dynamic catalog tree and reading pointer positions, element codes and element count values and the like. The system automatically generates the KKs codes, formed by the position of the dynamic catalog tree, the element codes and the element count values, of power plant equipment elements. According to the automatic KKs code generating method for the power plant equipment elements, through a visual operation interface and simple condition input and modification, the KKs codes of the power plant equipment elements can be generated automatically, the generating work of the KKs codes is made to be more standardized and normalized, the time of code generating is shortened greatly, and working efficiency and working quality are improved.

Owner:POWERCHINA HEBEI ELECTRIC POWER SURVEY & DESIGN INST CO LTD

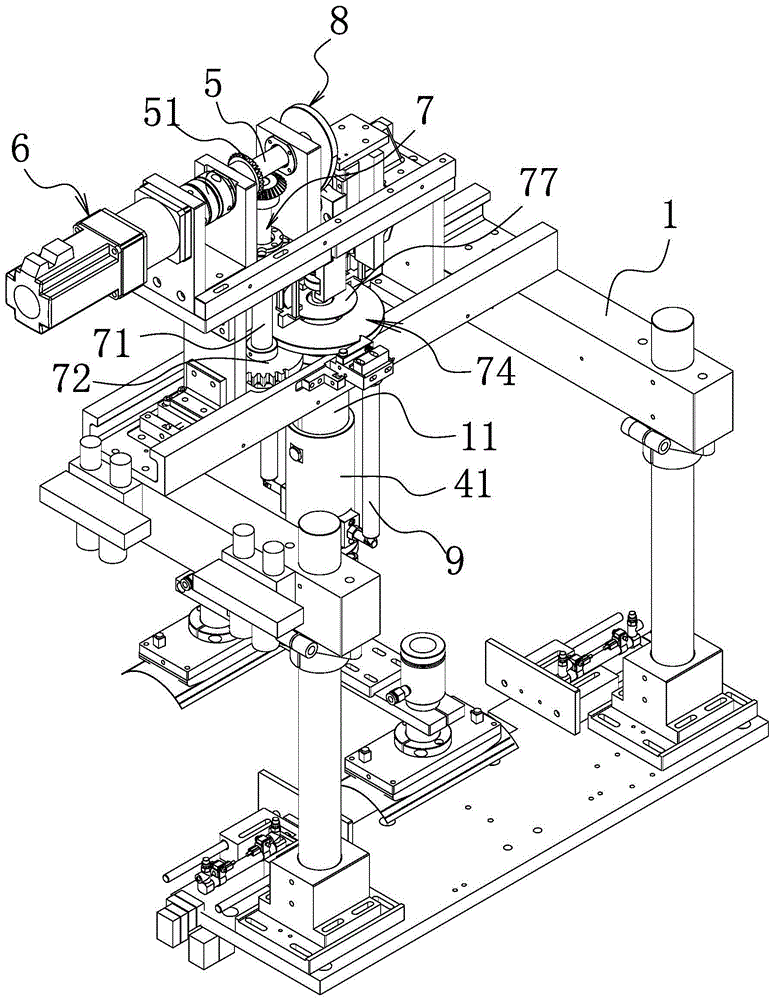

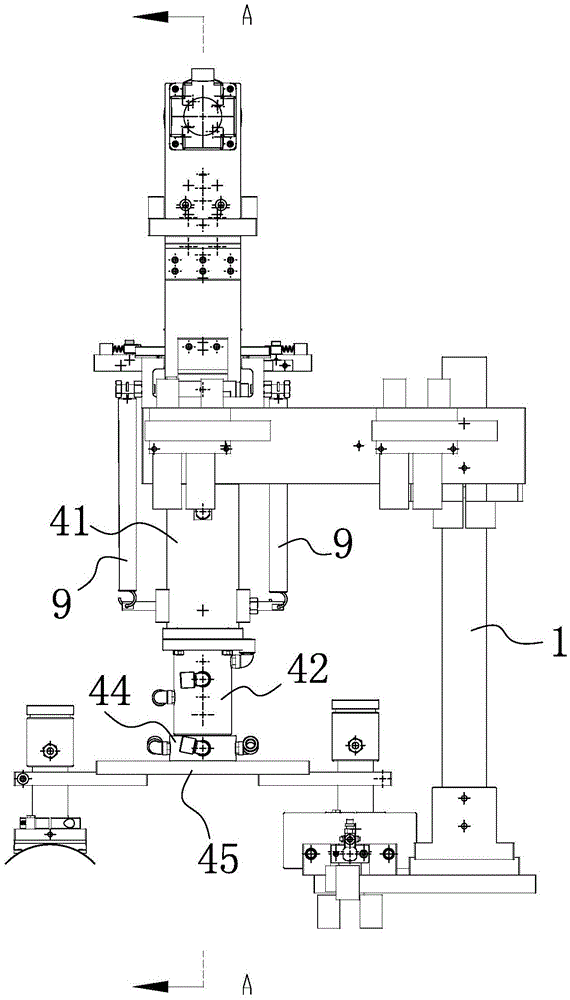

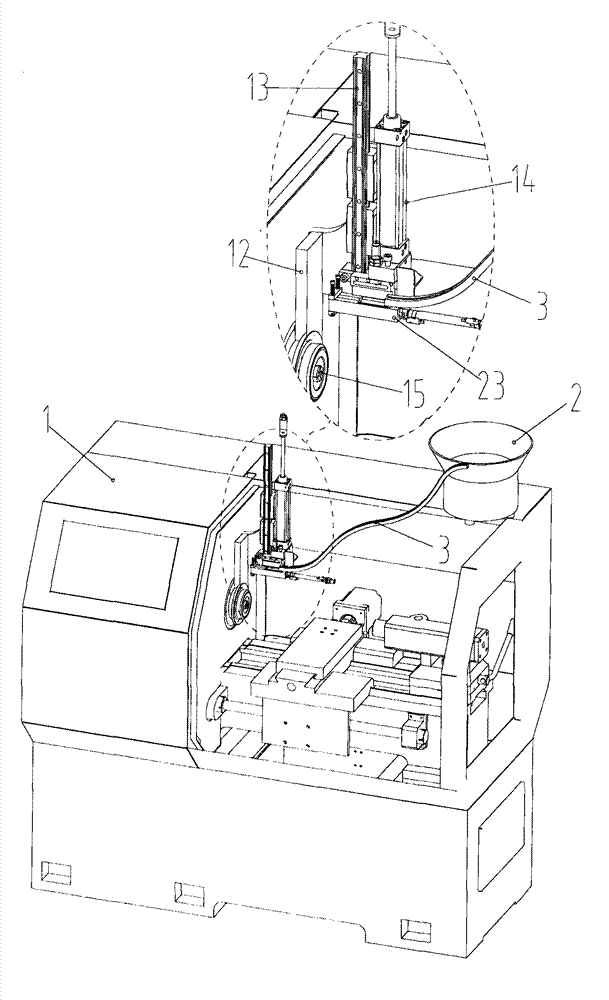

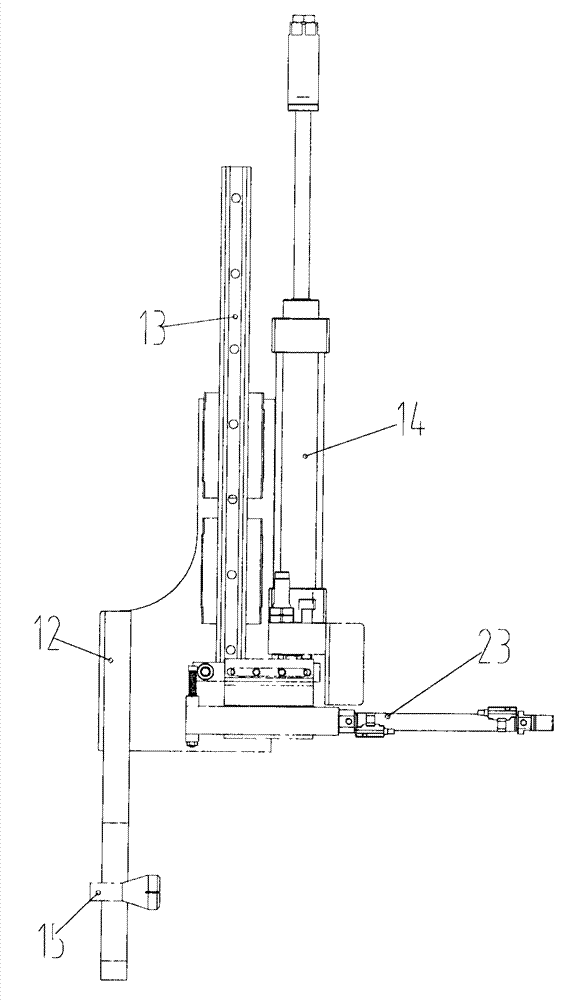

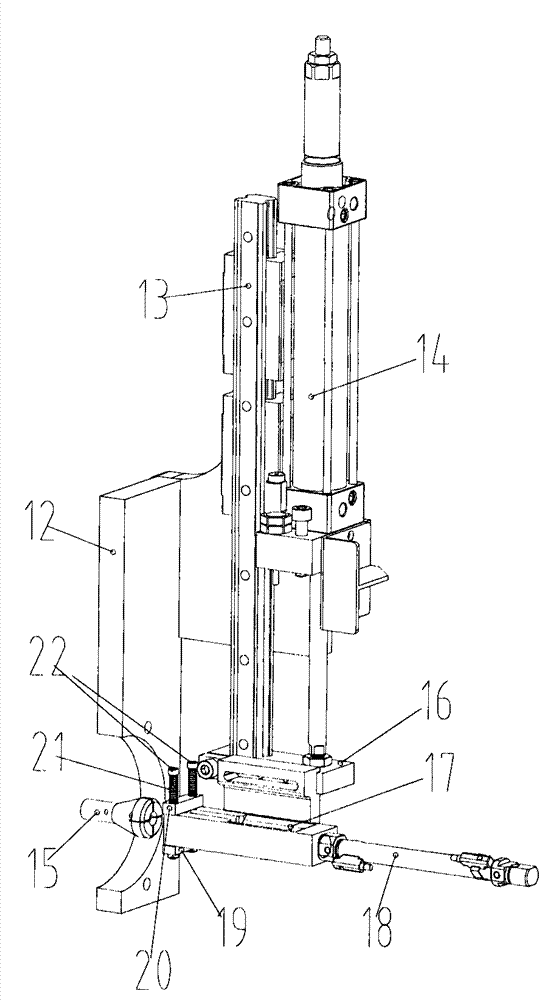

Rotary feeding device for cam

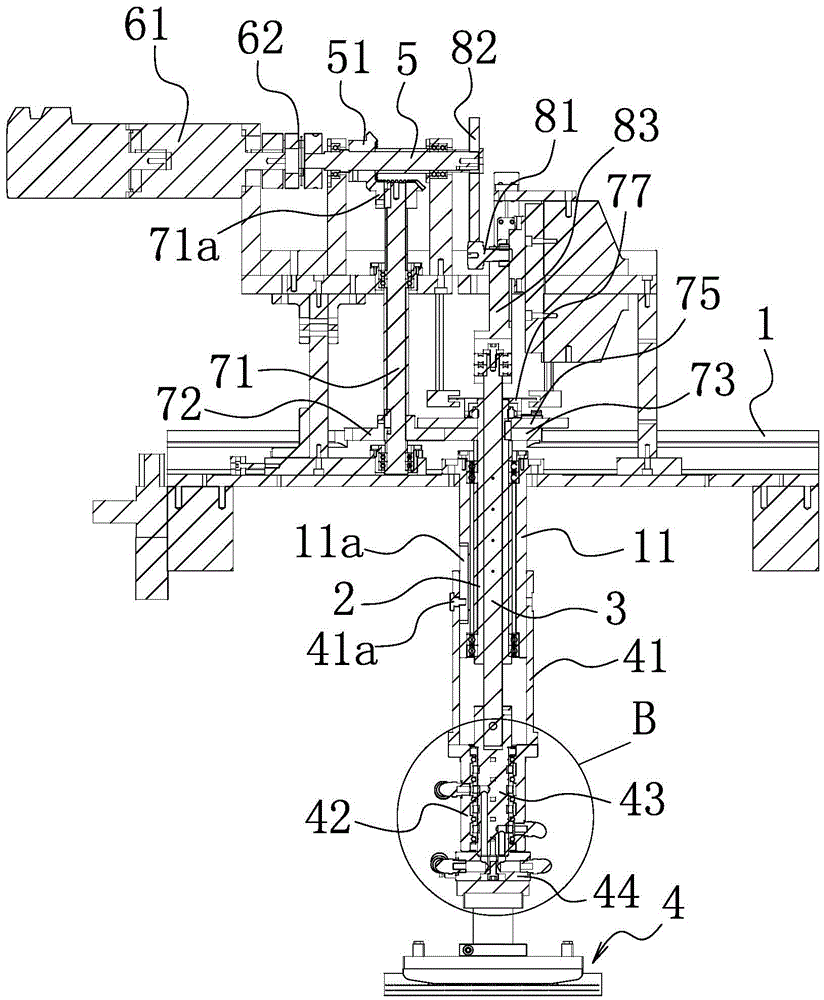

The invention relates to a rotary feeding device for a cam, and solves the problem of unreasonable design in the prior art. The rotary feeding device comprises a mounting bracket. A tubular rotating shaft, which is arranged vertically and can rotate relative to the mounting bracket, is arranged on the mounting bracket. A lifting shaft, which rotates with the tubular rotating shaft synchronously and can ascend and descend axially along the tubular rotating shaft, is arranged in the tubular rotating shaft. The two ends of the lifting shaft are lengthened outside the two ends of the tubular rotating shaft respectively. An executing manipulator, which rotates with the lifting shaft synchronously, is connected with the lower end of the lifting shaft. A driving shaft which is arranged horizontally and a driving mechanism which can drive the driving shaft to rotate are arranged on the mounting bracket. A rotary transmission mechanism, which can drive the tubular rotating shaft to rotate after the driving shaft rotates, is arranged between the tubular rotating shaft and the driving shaft. A cam transmission mechanism, which can drive the lifting shaft to ascend and descend after the driving shaft rotates, is arranged between the lifting shaft and the driving shaft. The rotary feeding device has the advantages of being more compact, low in cost and high in practicability.

Owner:TANAC AUTOMATION

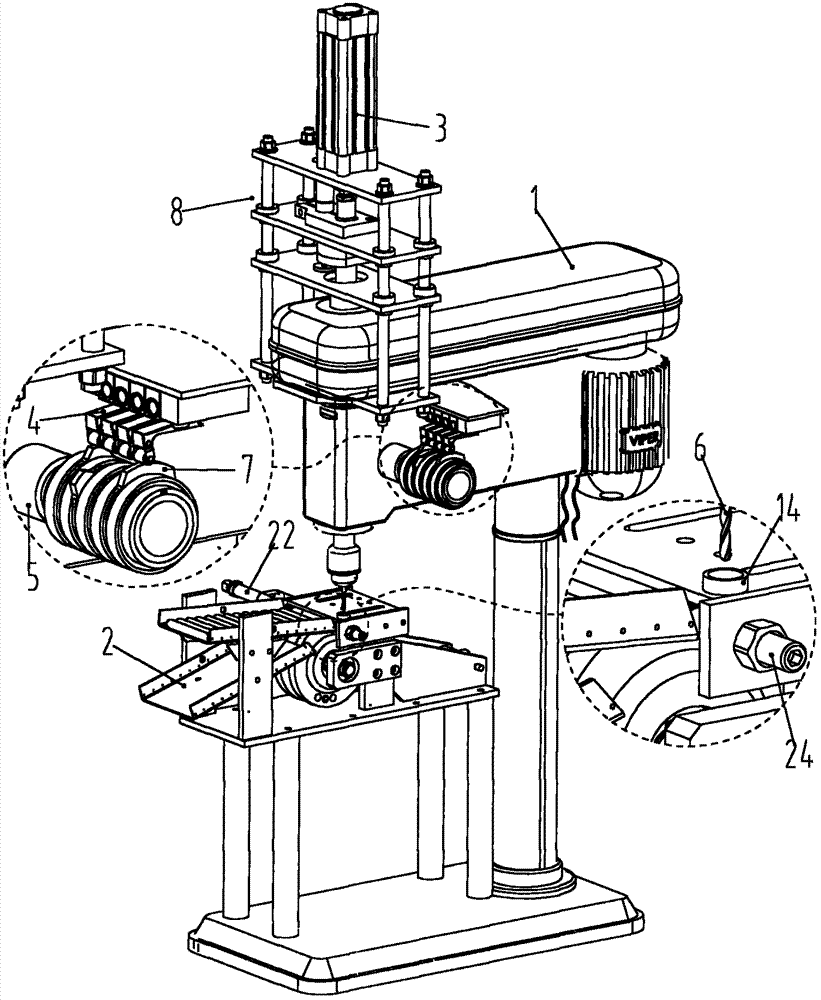

Full-automatic drilling automatic machine

InactiveCN104722793AKeep performance stableLow failure rateWork clamping meansFeeding apparatusManufacturing technologyEngineering

The invention relates to the technical field of the machining and manufacturing technology, in particular to a device for drilling holes in a workpiece. A full-automatic drilling automatic machine comprises a bench mill, an automatic tool and a feed mechanism, wherein the automatic tool is fixedly connected to the bench mill, the feed mechanism is fixedly connected to the bench mill, a mandrel is arranged at the center of a cam, and a groove capable of containing the workpiece is formed in the radial surface of the cam and is of a triangular structure; a baffle is arranged above the cam in the extending direction of a feed hopper. By means of the full-automatic drilling automatic machine, holes are drilled in the workpiece, the bench mill is automatically refitted, the workpiece is machined in a full-automatic and unmanned mode, the automatic feeding, clamping, drilling and discharging are achieved, and the full-automatic drilling automatic machine is compact in structure, small in occupied area, economical and practical.

Owner:WENZHOU POLYTECHNIC

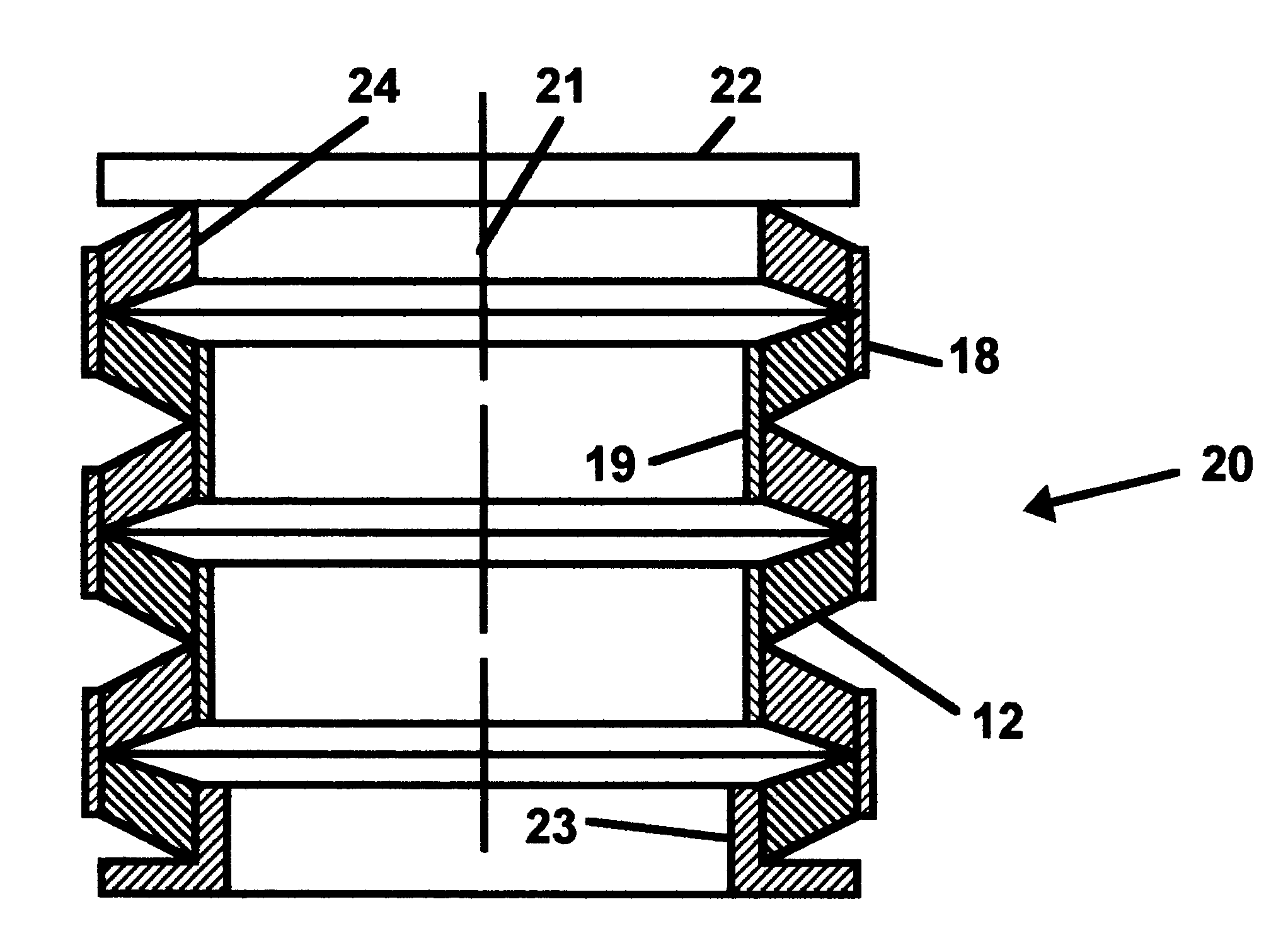

Mechanical duty rubber bellows

InactiveUS6237922B1Long service life resultSimple shear loadingEngine sealsElongated constructional elementsStress levelEngineering

A mechanical duty bellows seal is constructed from a number of annular rubber diaphragms of comparatively thick cross-section alternately bonded to a series of outer and inner metal hoops so that the hoops hold the rubber diaphragms in simple shear during flexure of the bellows. The stresses in the rubber in shear are predictable thus allowing the calculation of diaphragm proportions to control stress levels.

Owner:ARMSTRONG RICHARD JAMES

Horizontal electrochemical metal deposition method

ActiveCN105590987AUniform concentrationImprove effectivenessContacting devicesSemiconductor devicesElectrochemistryElectron

The invention discloses a method of applying electrochemical metal deposition on a sheet substrate. According to the method disclosed by the invention, a metal anode in the electrochemical metal deposition process is placed above an electrolyte solution level in the electrochemical metal deposition process; after the electrolyte solution in the electrochemical metal deposition process is contacted with the metal anode, the electrolyte solution flows on the upper surface of the sheet substrate from top to bottom; under the effect of the positive electric potential, an oxidation reaction happens to the upper metal anode, electrons are lost, metal ions are generated, the metal anode flows on the upper surface of the sheet substrate along with the electrolyte solution; and the metal ions in the electrolyte solution acquire electrons on a cathode on the sheet substrate, metal is generated and deposed on the surface of the cathode of the sheet substrate.

Owner:SHARESUN CO LTD

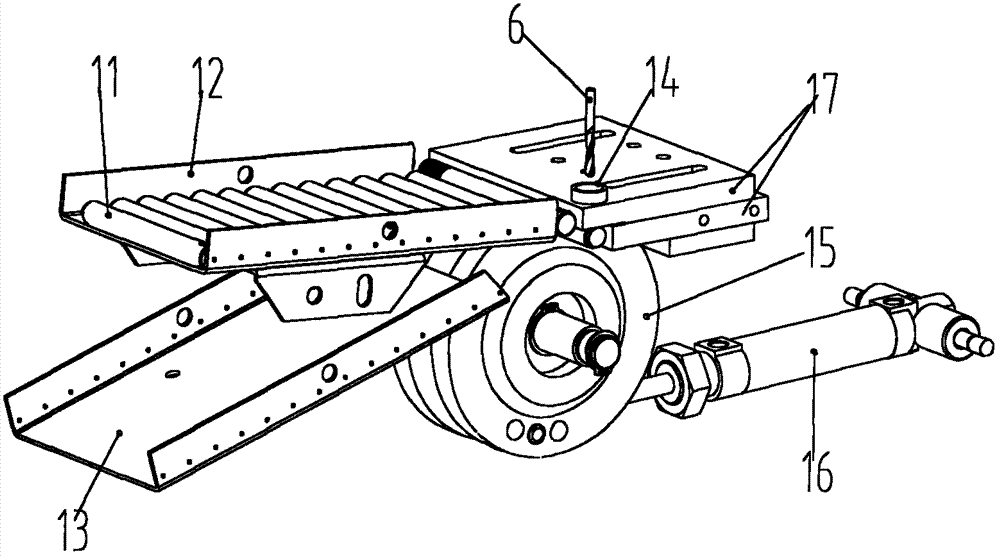

Direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system

ActiveCN104741631APrecision mechanical structureSimple loadingAutomatic workpiece supply/removalMetal working apparatusPiston rodIndustrial engineering

The invention relates to a machining device, in particular to an automatic feeding-discharging system of a numerically-controlled lathe. The direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system comprises a vibrating disc, a feeding mechanism, a discharging mechanism, a linear guide rail, a lifting air cylinder and a support. The support is fixedly connected to the numerically-controlled lathe. The linear guide rail is movably connected to the support, a lifting plate is fixedly connected with the tail end of the linear guide rail, the lifting air cylinder is fixedly connected to the support, and a piston rod of the lifting air cylinder is fixedly connected with the lifting plate. The feeding mechanism is fixedly connected to the lifting plate. A technology for achieving automatic feeding and automatic discharging of the numerically-controlled lathe is disclosed. By means of the direct-pushing-type numerically-controlled-lathe feeding-discharging assisting system, clamping jaws widely used in the industry are omitted, a simpler and more durable direct-pushing type mechanism is developed, and the feeding process and the discharging process of workpieces on a chuck of the numerically-controlled lathe are achieved. Motions are accurate in the feeding process, and the speed is high in the discharging process.

Owner:湖北信友汽车零部件有限公司

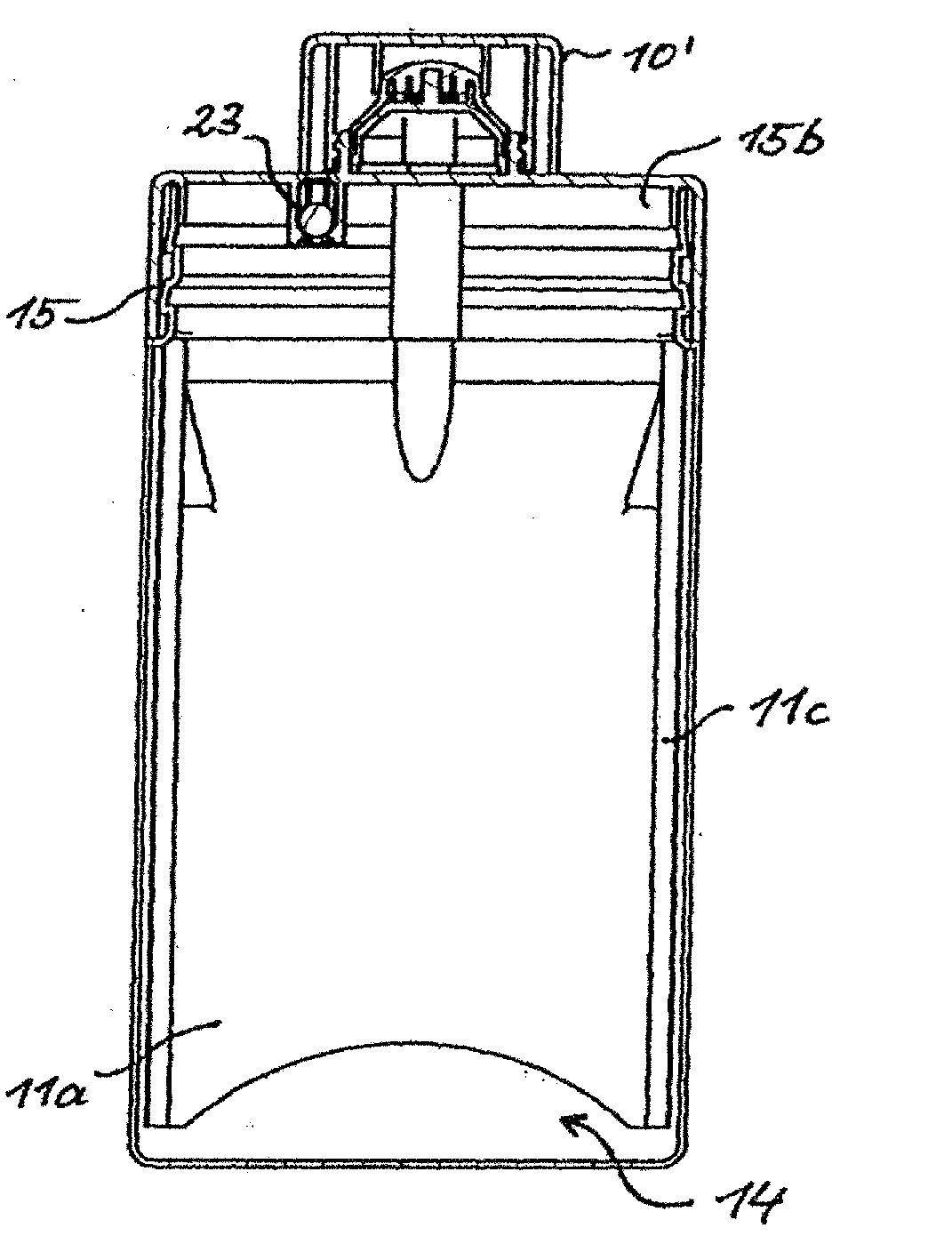

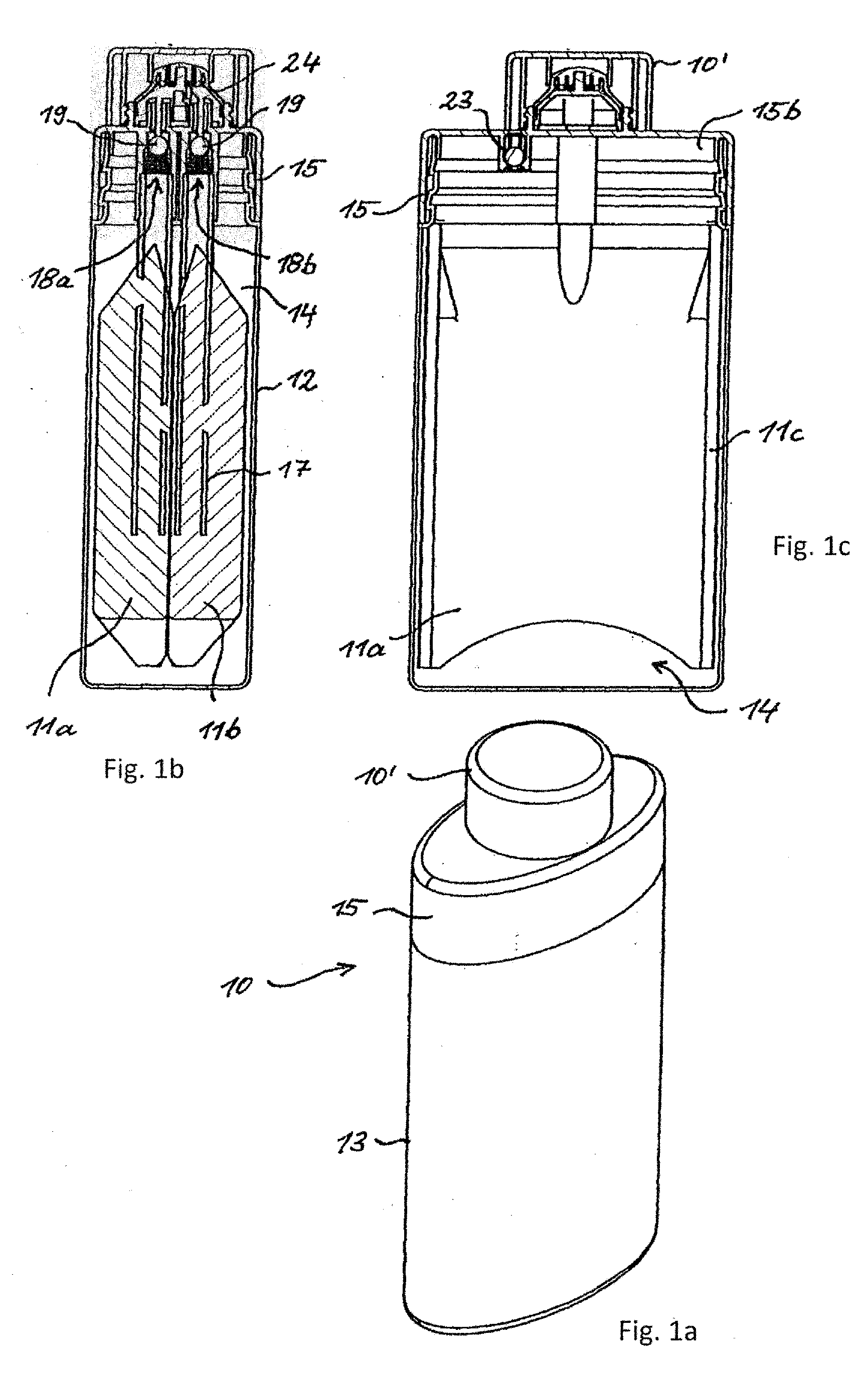

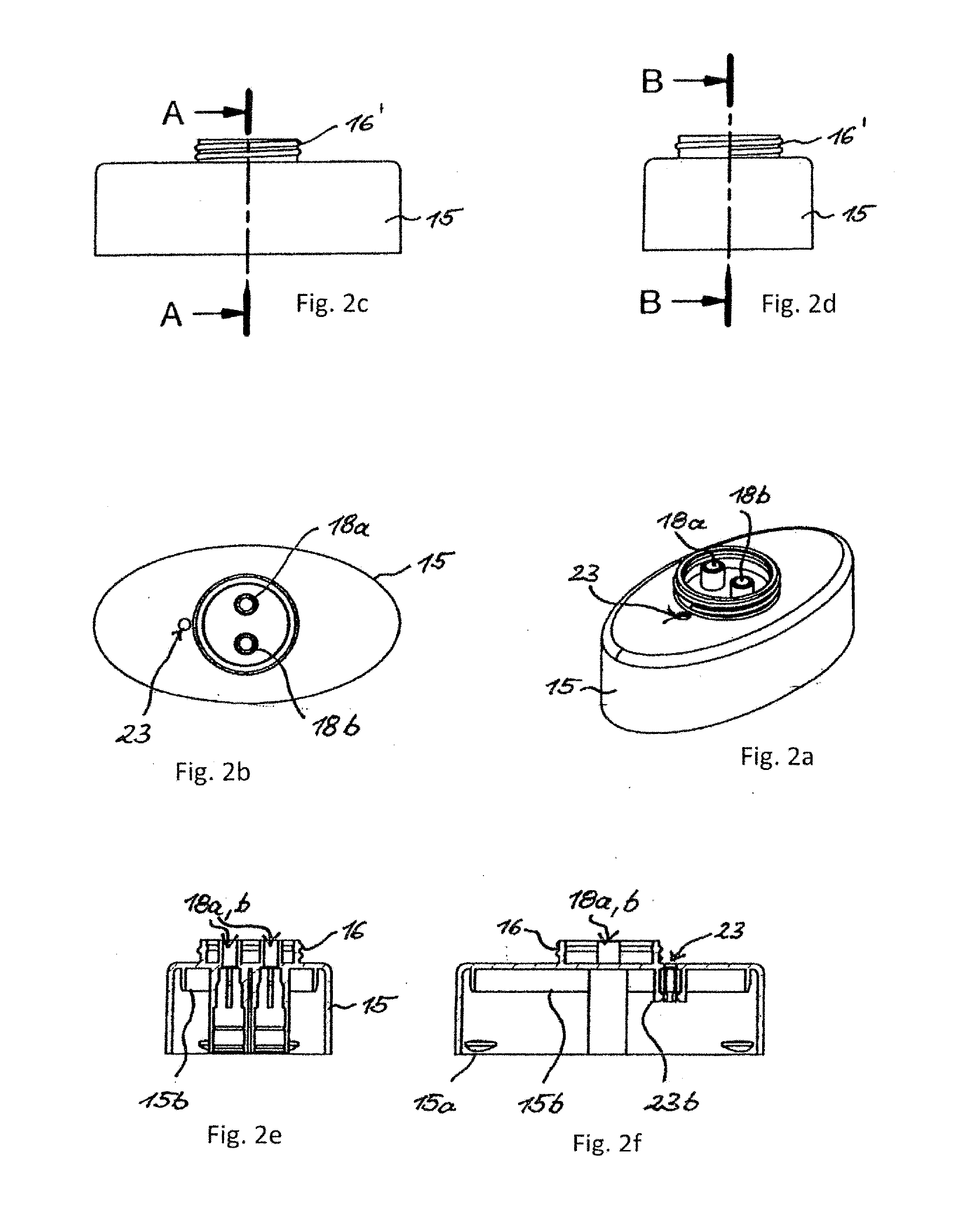

Dispenser

ActiveUS20170056904A1Facilitate quick refillFacilitates safe sealingClosuresDispensing apparatusPaste substanceEngineering

A dispenser for substances includes an outer shell with a deformable outer wall which encloses the deformable container arrangement and also comprising at least one balancing valve for balancing air, wherein an air filled interspace is provided between the outer wall and the container arrangement and substances are dispensed once the outer shell has been subjected to pressure, and wherein the container arrangement has at least two containers for the separate storage of liquid for pasty substances. For long term storage of the substances in particular an outlet portion of the container arrangement has a diffusion seal made from metal which is pierced and opened by the dispensing head using points just before the dispenser is being used.

Owner:DUAL DISPENSERS GMBH

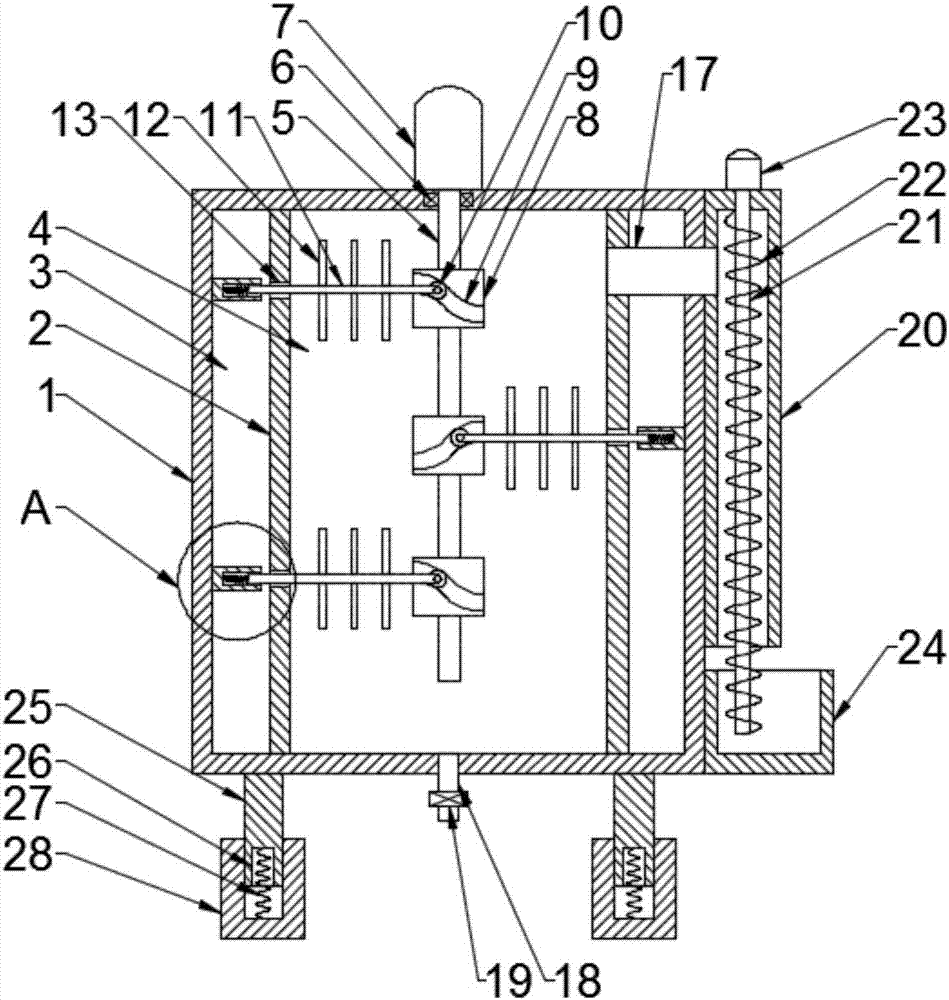

Concrete stirring device for construction site

InactiveCN107310032AImprove stirring efficiencyGuaranteed stirringMixing operation control apparatusCement mixing apparatusArchitectural engineeringMotor shaft

The invention discloses a concrete stirring device for a construction site, which comprises a case. The inner cavity of the case is symmetrically provided with baffles left and right, a plurality of through holes are arranged in the baffles, the baffles divide the inner cavity of the case into a stirring cavity and two clamping cavities, the inner wall on one side of each clamping cavity is provided with a plurality of pushing covers corresponding to the through holes, pushing holes are arranged in the pushing covers, a main stirring rod is arranged in the stirring cavity, the top end of the main stirring rod penetrates through the case and is fixedly connected to the motor shaft of a main motor, the main stirring rod is uniformly provided with a plurality of rollers, track grooves are arranged in the rollers, idler wheels are arranged in the track grooves, the idler wheels are fixedly connected to secondary stirring rods, the secondary stirring rods are uniformly provided with a plurality of stirring blades, and the bottom end of the case is uniformly provided with a plurality of support legs. The main motor of the concrete stirring device drives the main stirring rod to rotate and further drives the rollers to rotate, the rollers drive the secondary stirring rods to move and stir, such that the stirring blades stir materials irregularly, the stirring efficiency of the materials is improved, and sand, stones, and the like are enabled to be totally stirred.

Owner:童贤波

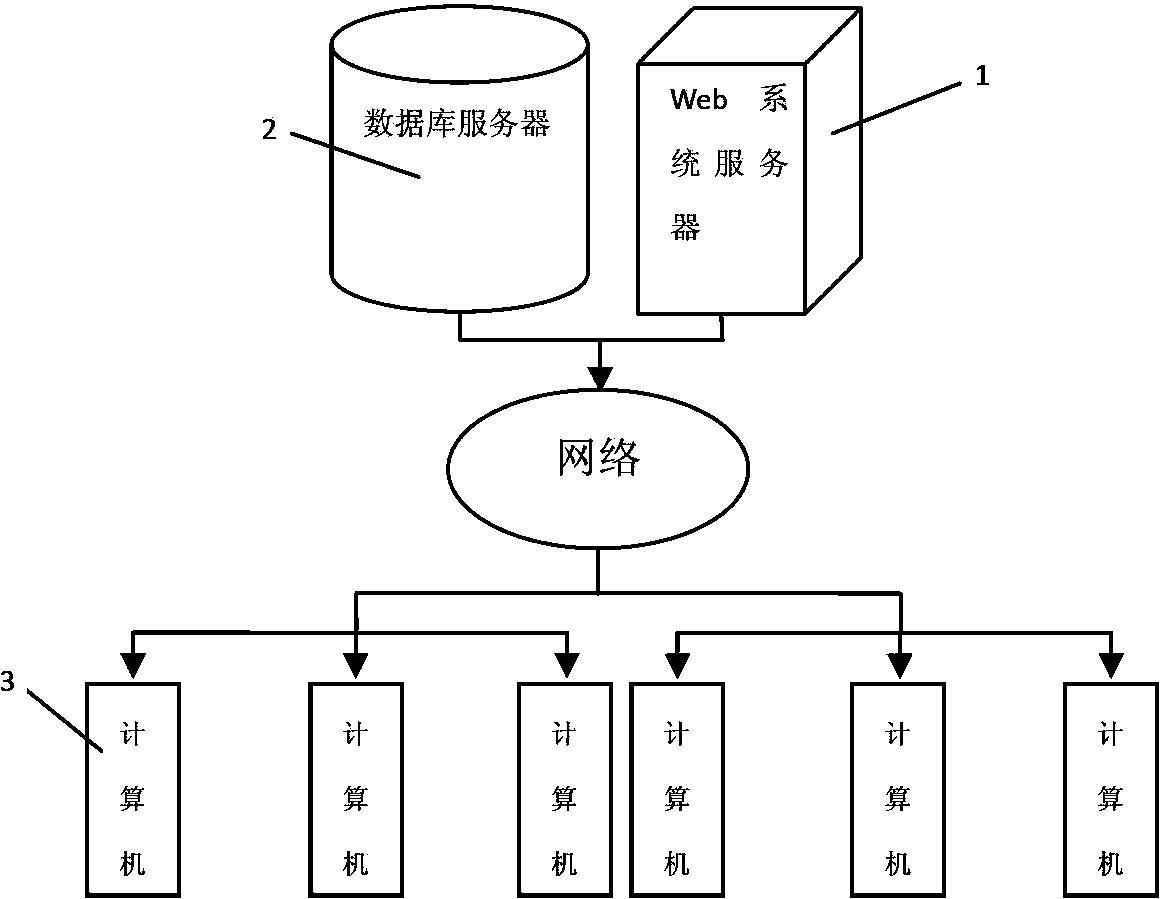

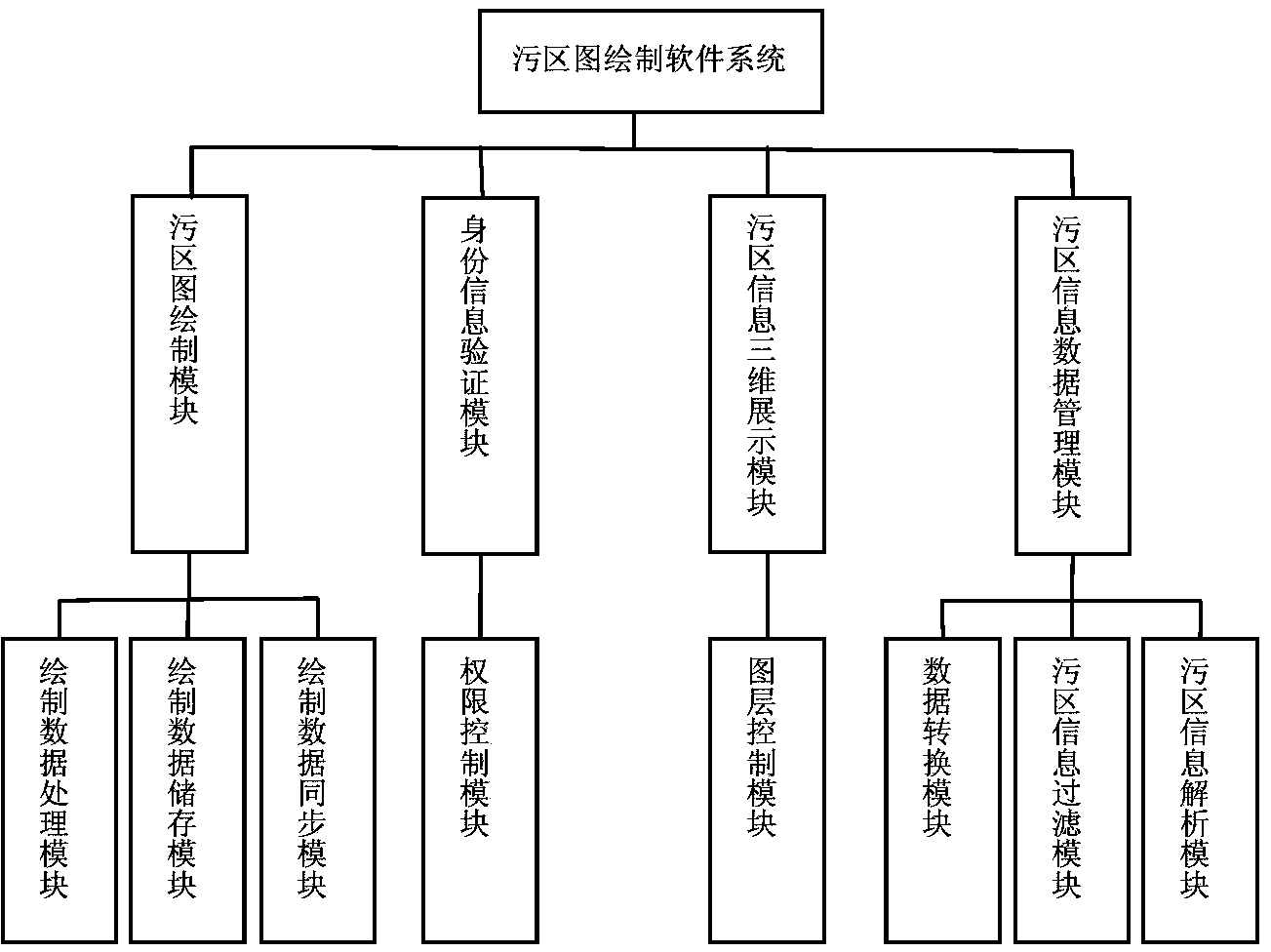

Distributed rendering system and distributed rendering method for dirty area graphs of power grids

ActiveCN103455662ARich and preciseHigh automatic drawing efficiencyData processing applicationsSpecial data processing applicationsData conversionAuthority control

The invention discloses a distributed rendering system for dirty area graphs of power grids. The distributed rendering system comprises a database server and a Web system server. A dirty area graph rendering software system is installed in the Web system server and comprises a dirty area graph rendering module, an identity information verification module, a three-dimensional dirty area information display module and a dirty area information data management module, the dirty area graph rendering module comprises a rendering data processing module, a rendering data storage module and a rendering data synchronizing module, the identity information verification module comprises an authority control module, the three-dimensional dirty area information display module comprises a graph layer control module, the dirty area information data management module comprises a data conversion module, a dirty area information filter module and a dirty area information analysis module, and the two servers are connected with a plurality of distributed client computers by a network. The invention further relates to a distributed rendering method for the dirty area graphs of the power grids. The method is implemented by the aid of the distributed rendering system.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

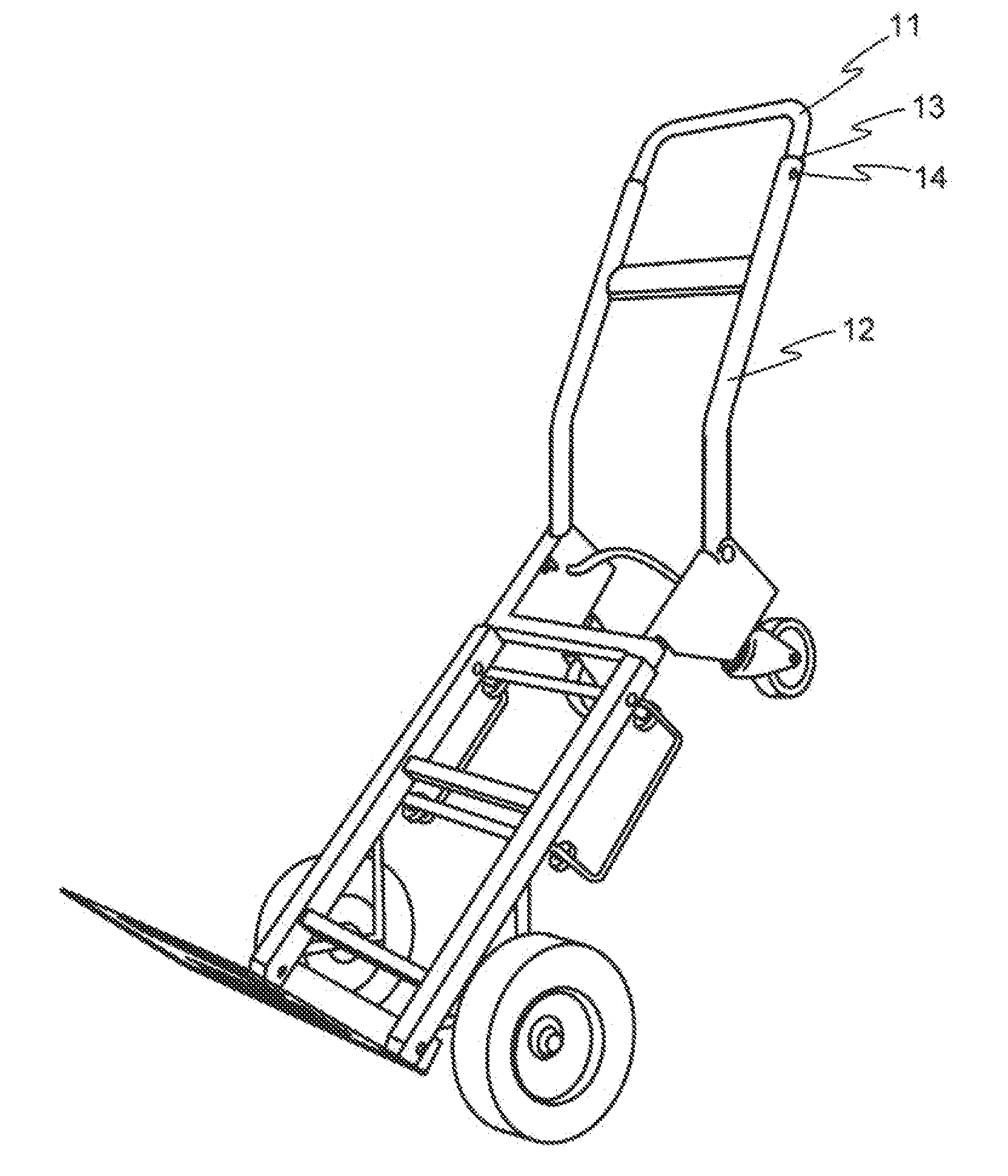

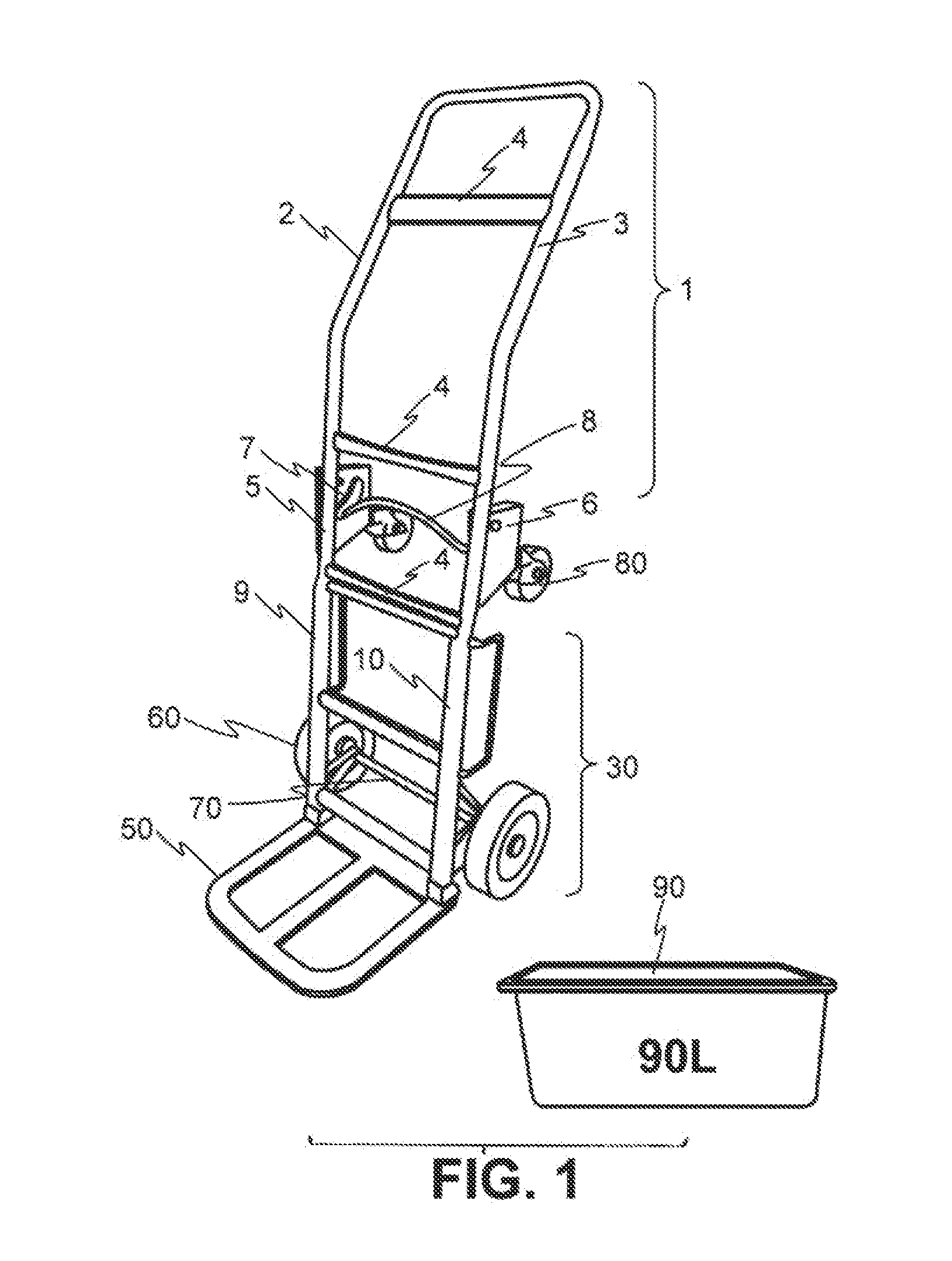

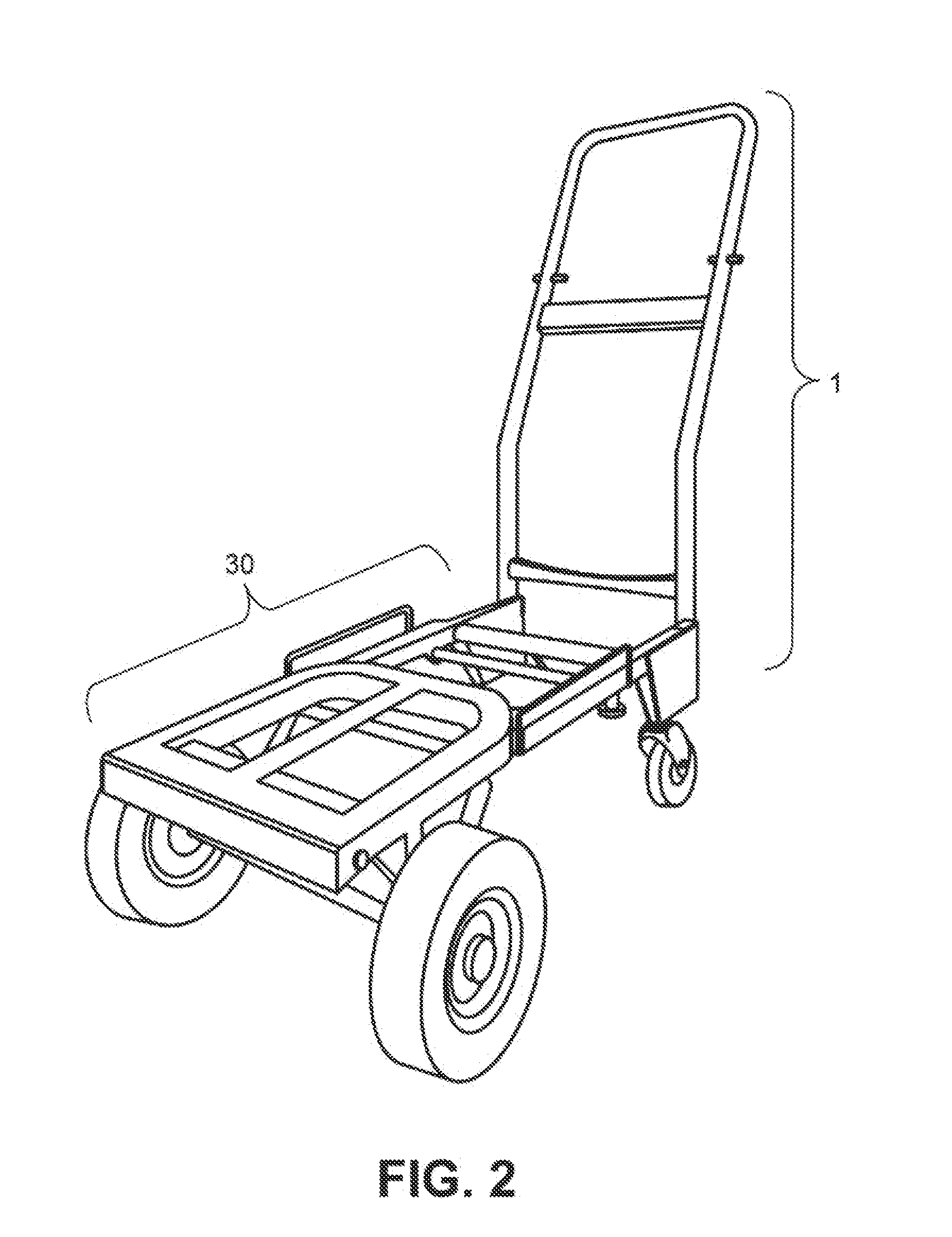

Three-in-One Convertible Cart

InactiveUS20130328279A1Easy to convertImprovement in structural constructionCarriage/perambulator with single axisSupporting partsEngineeringKneeling position

An improved convertible cart can be converted from a hand truck to a platform by a simple pull of a spring loaded adjustment arm. The convertible cart has reversible wire retainers. When the edge of the wire retainer is facing upward, it prevents an object being carried from shifting sideways off of the rails. The wire retainers can also be flipped downwards to allow an oversized object to be carried flat and extend outside the retaining rails. The toe plate of the cart can be used as a seat with a pad that can be attached as a weeding pad either from the seated or kneeling position. The cart's handle frame can be sleeves into its base frame so that entire cart can be packed tightly within the tub to allow the tub to be the principal storage and delivery means for display, sale and shipment.

Owner:FEICK WILLIAM KURT

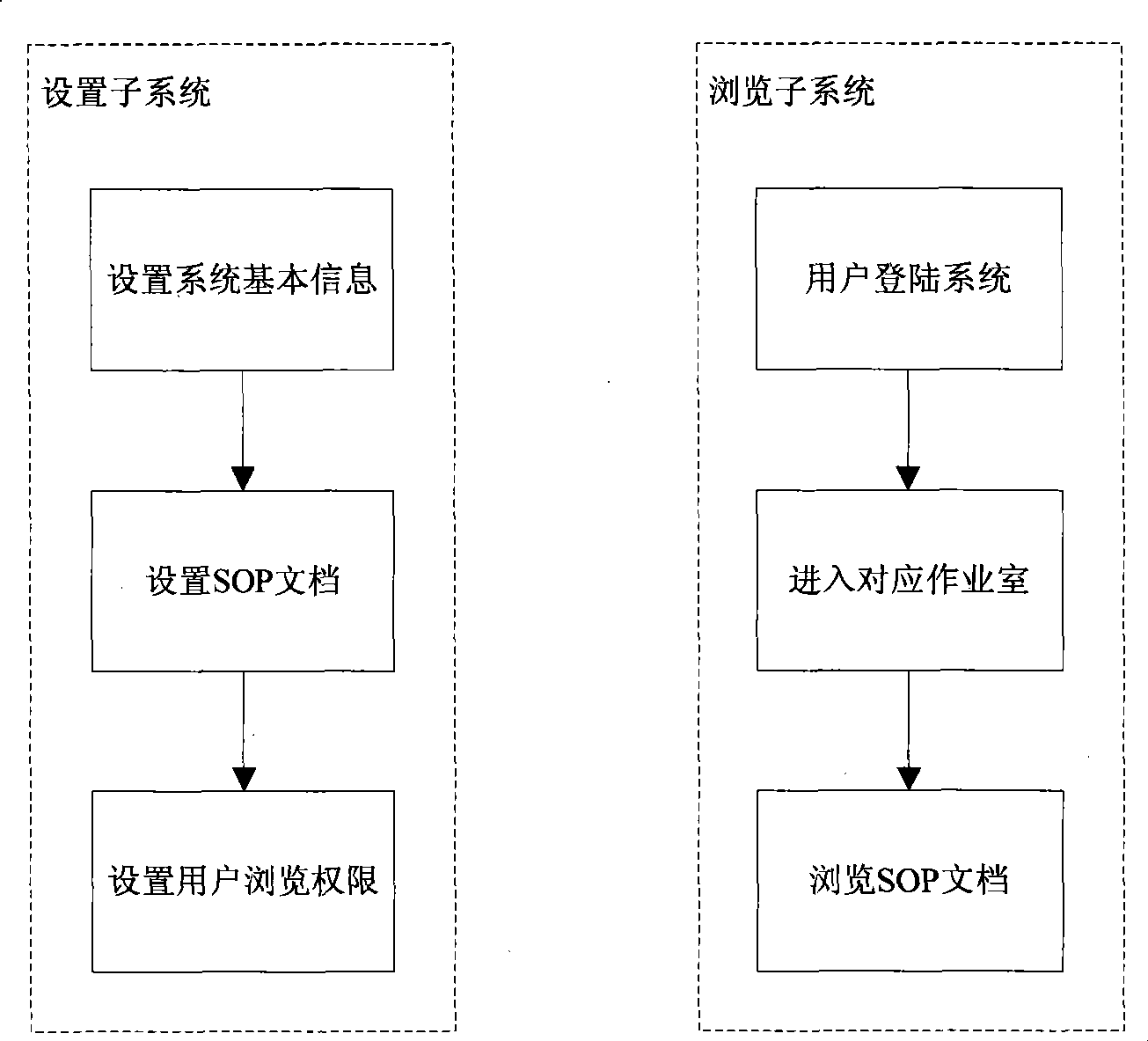

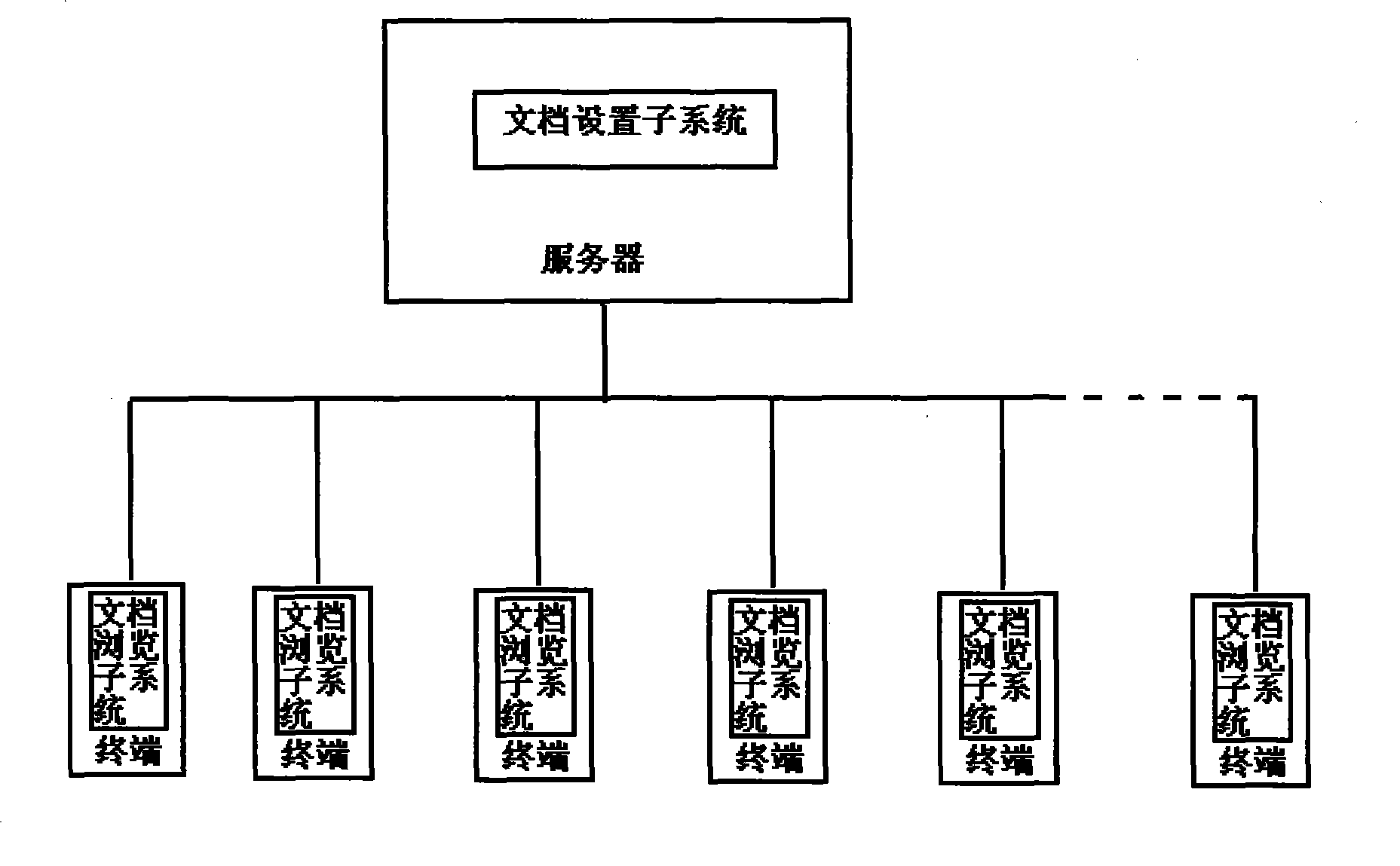

Method and system for real-time browsing production technique document in production field

InactiveCN101488203ASafe and efficient production operationsConvenient and flexible managementResourcesTechnical documentationComputer science

The invention relates to a method for browsing production technique documents in real time on a production field, comprising a document setting step and a document browsing step. The document setting step comprises the following steps of: collecting basic information which is needed; classifiably storing the information in a database of an LAN server in a document way; and setting different browse and access authorities. Furthermore, the document browsing step comprises the following steps of matching operators and production stations; displaying a corresponding operating procedure on a terminal when the operators log on an LAN with an identity number at the locating terminal; closing the browse terminal after the operation is completed and opening the browse terminal by logging on again when the production is started next time; and examining a new operating procedure again and following and executing the new operating procedure by the operators informed by the terminal when the operating procedure is changed. The invention causes persons at a production operation spot to actually the obtain production operation directions in real time, thereby greatly enhancing the work efficiency and simultaneously uniformly managing all files and documents. In addition, the invention is convenient and easy to operate, thereby greatly reducing the maintenance cost.

Owner:SHANGHAI HUIHUAN INFORMATION TECH +1

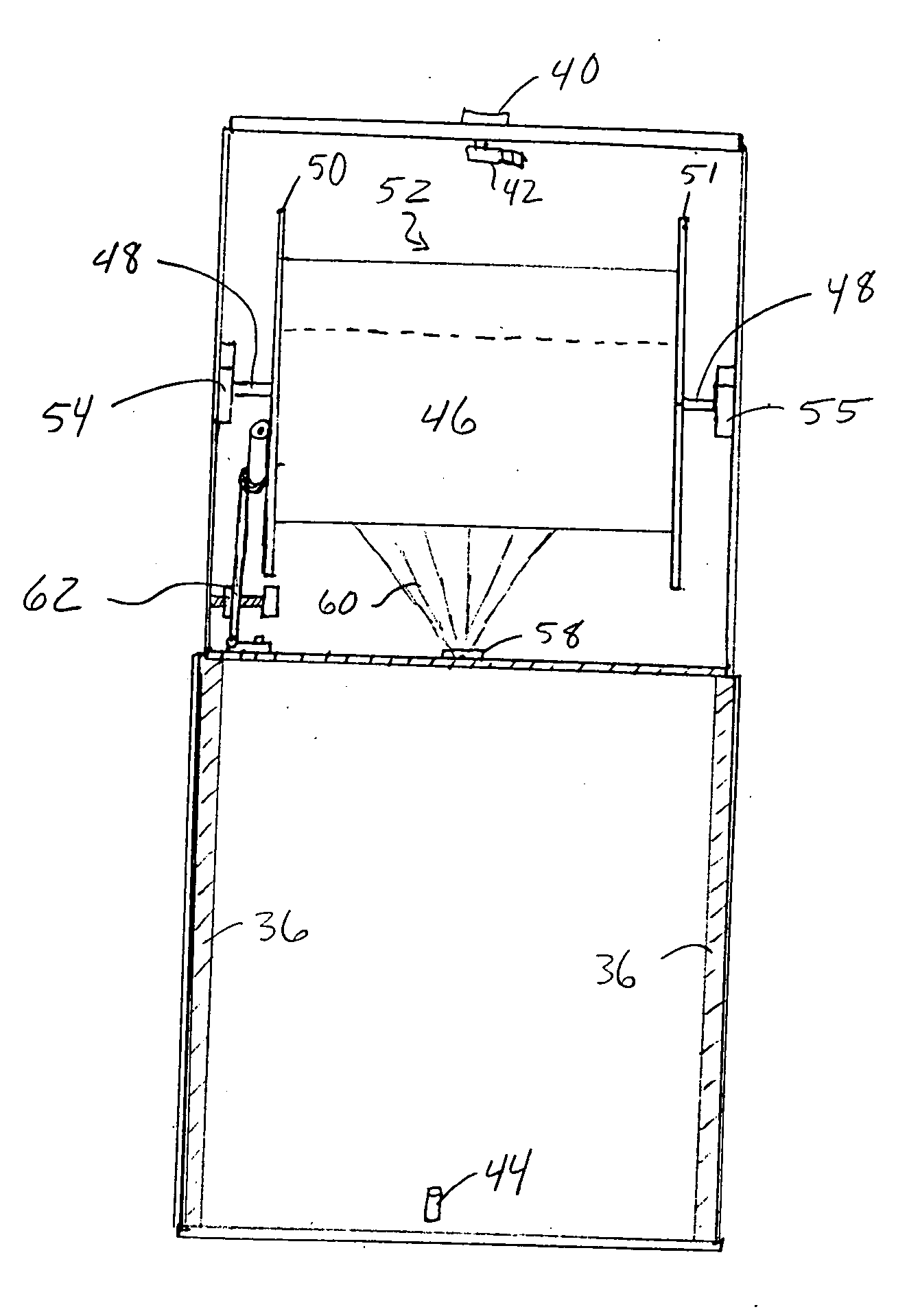

Pre-moistened towelette dispenser

InactiveUS20060208130A1Simple loadingSimple to useFilament handlingDomestic applicationsTowelettesEngineering

The pre-moistened towelette dispenser of the present invention includes a substantially sealed housing to retain moisture within the housing. A roll of pre-moistened, perforated towelettes wound about a cylindrical core is supported within the housing on an axle to allow rotation of the roll of towelettes about the axle to dispense towelettes from the roll. A nipple located in the housing provides a restricted point opening that allows towelettes to exit the housing. The nipple is preferably located in the bottom of the housing to dispense towelettes from the bottom of the housing. An adjustable roll tension system is also provided within the housing. The roll tension system preferably includes a roller that is in contact with and biased against an end cap attached to the cylindrical core at one end of the roll of towelettes. The roll tension system provides resistance to the rotation of the roll of towelettes. The roll tension system is also preferably adjustable so that the dispenser may be adjusted and adapted to accommodate perforated towelettes with different perforation characteristics and tear resistances.

Owner:CASTOR SCOTT +1

System and method to attach and remove space vehicles

ActiveUS20200017243A1Reduce the amount requiredLow costCosmonautic power supply systemsArtificial satellitesSpacecraft designScrew thread

A system and method for installing, deploying, and recovering a plurality of spacecraft that provides an ease of use and structural stability, and facilitates a standardization of spacecraft design. In embodiments of this invention, threaded rods are arranged orthogonal to a surface of a baseplate, and each spacecraft includes a coupling mechanism that selectively engages or disengages each threaded rod. Each spacecraft is added to the stack by engaging its coupling mechanism and rotating the threaded rods while the preceding spacecraft on the stack disengage their coupling mechanisms, thereby enabling the spacecraft to travel along the threaded rods toward the baseplate. When all of the spacecraft are added to the stack, the stack is preloaded by rotating the treaded rods into a terminator component at the top of the stack while the coupling mechanisms in all of the spacecraft are disengaged. Spacecraft are deployed by reversing the process.

Owner:PLANETARY SYST CORP

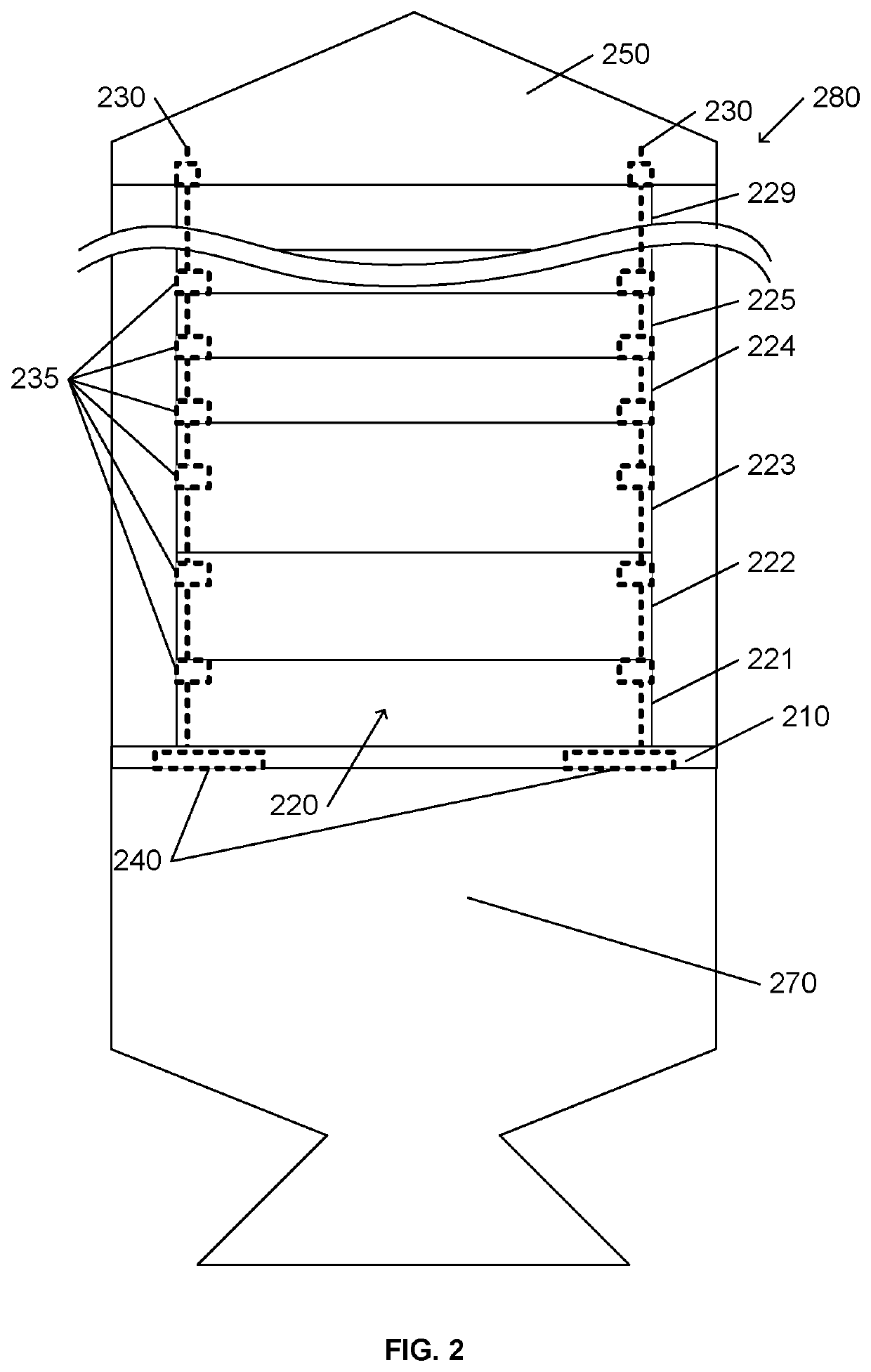

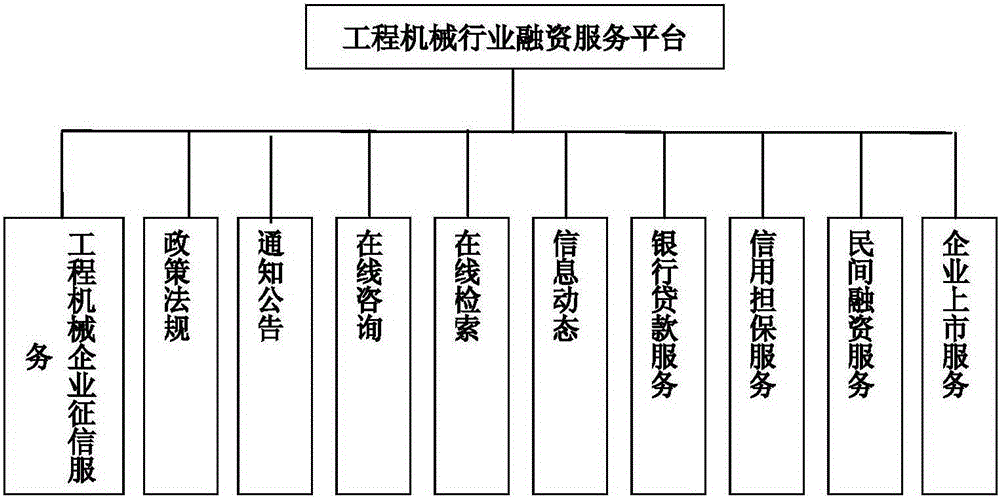

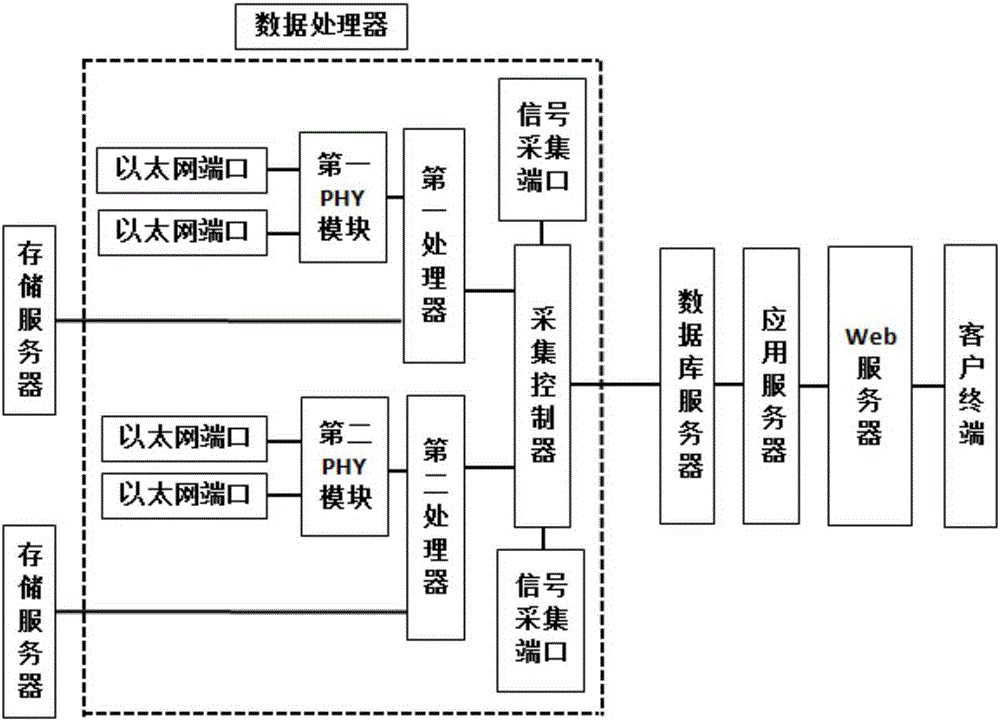

Financing service system structure for engineering machinery industry

InactiveCN105184650ASimple loadingLow costFinanceTransmissionWeb serviceStructure of Management Information

Provided is a financing service system structure for engineering machinery industry. The financing service system structure comprises a database service layer, an intermediate layer, and a client layer. The database service layer provides data storage and management service. The intermediate layer achieves control of the service logic and the service rule of an application program. The client layer achieves the interaction between a final user and the application program and provides input-output support. The financing service system structure for engineering machinery industry comprises a storage server, a database server, an application server, a Web server, a client terminal, and a data processor arranged between the storage server and the database server. The service logic of the financing service system structure is mainly implemented at a server end so that the load of the client end is greatly simplified, the cost and the workload of system maintenance and upgrade are reduced, and user cost is decreased. The financing service system structure may filter demand information in a non-service type or not belonging to a service range, and improves the operating efficiency and security of a system.

Owner:CHANGSHA HIGH NEW TECH IND DEVZONE ENTREPRENEUR SERVICES CENT

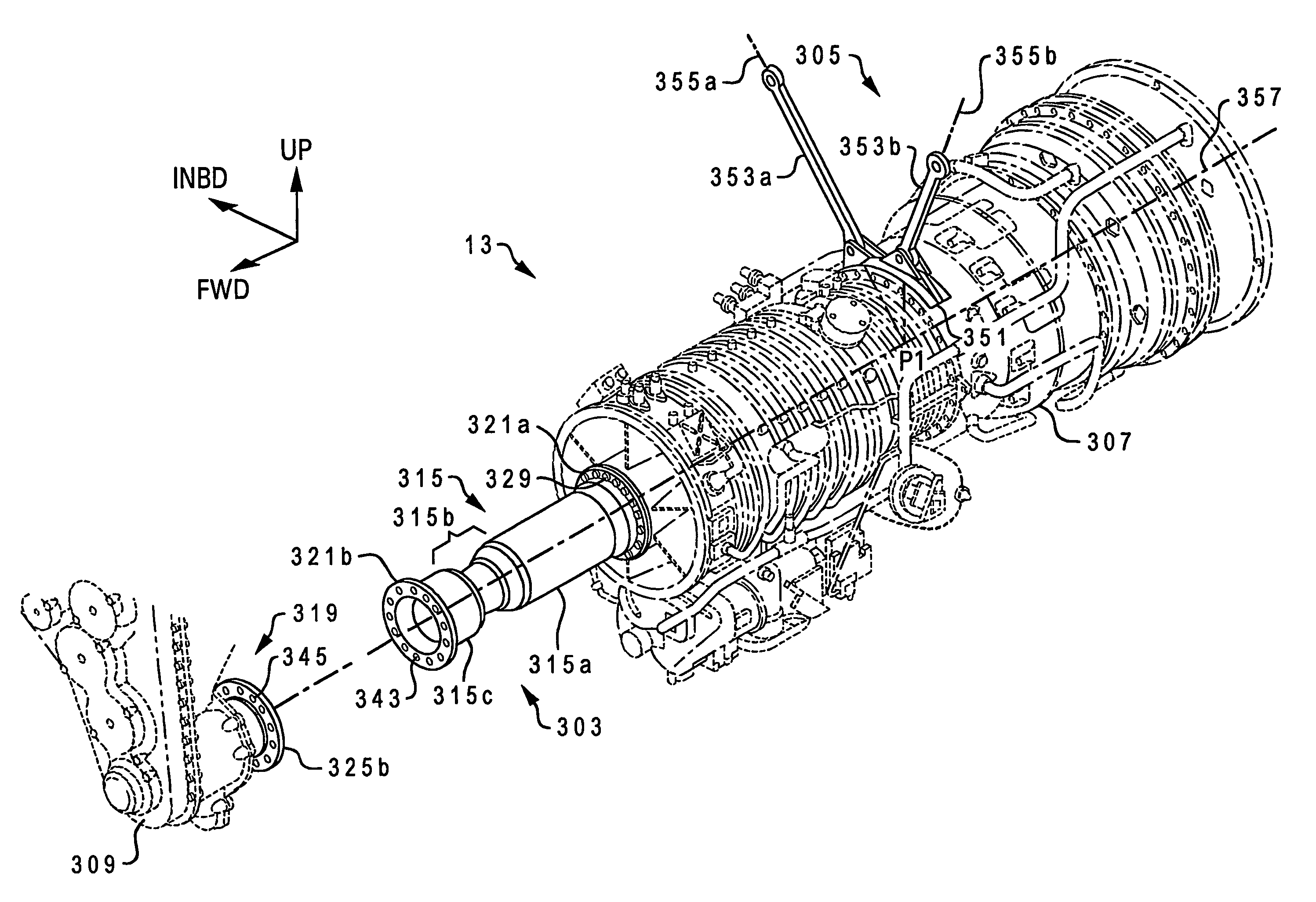

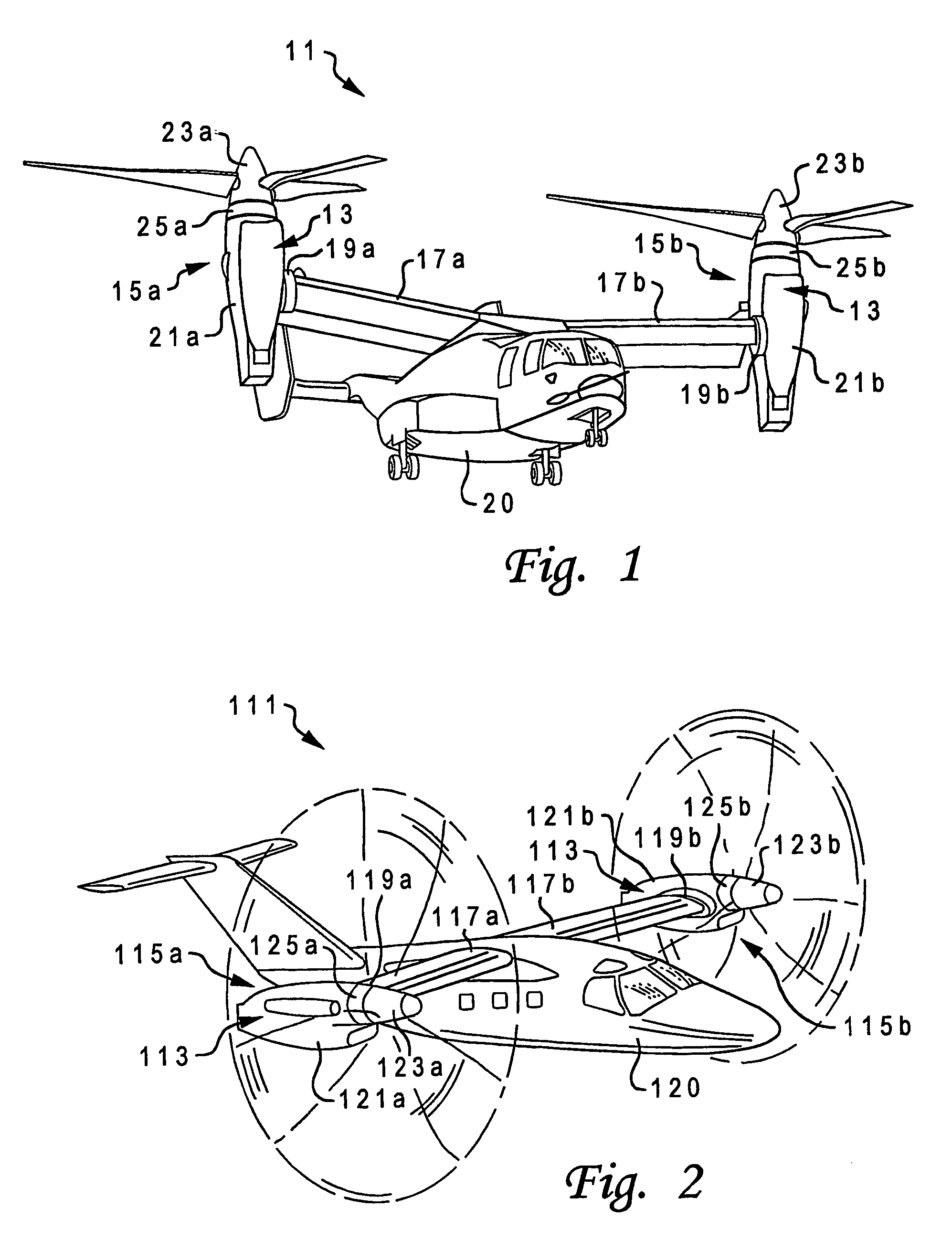

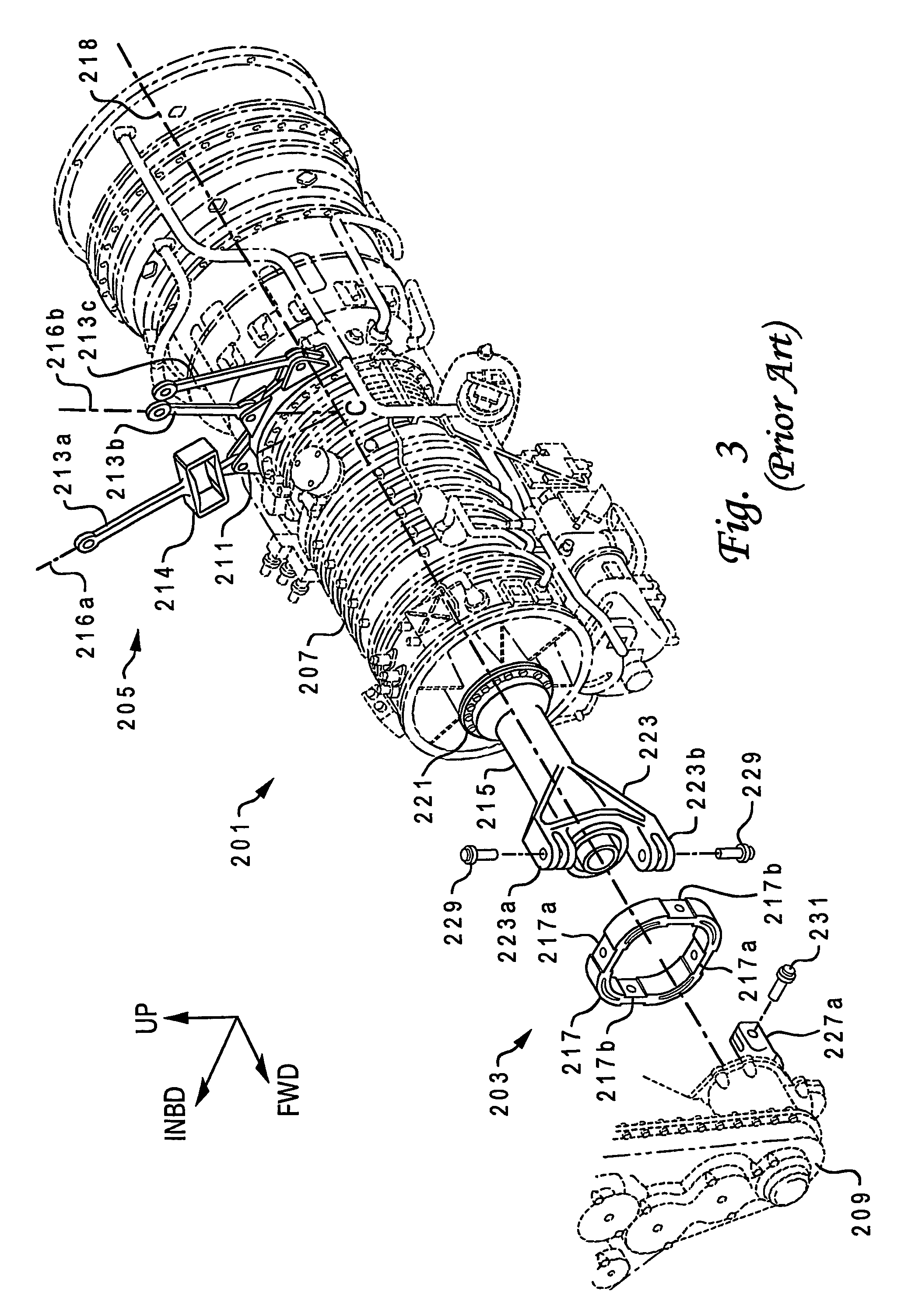

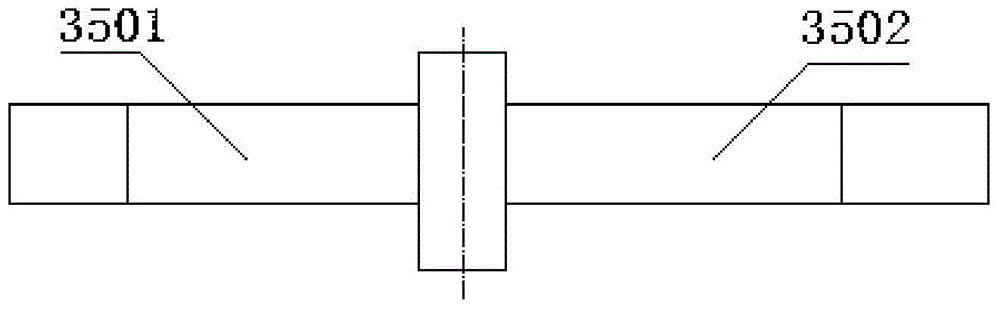

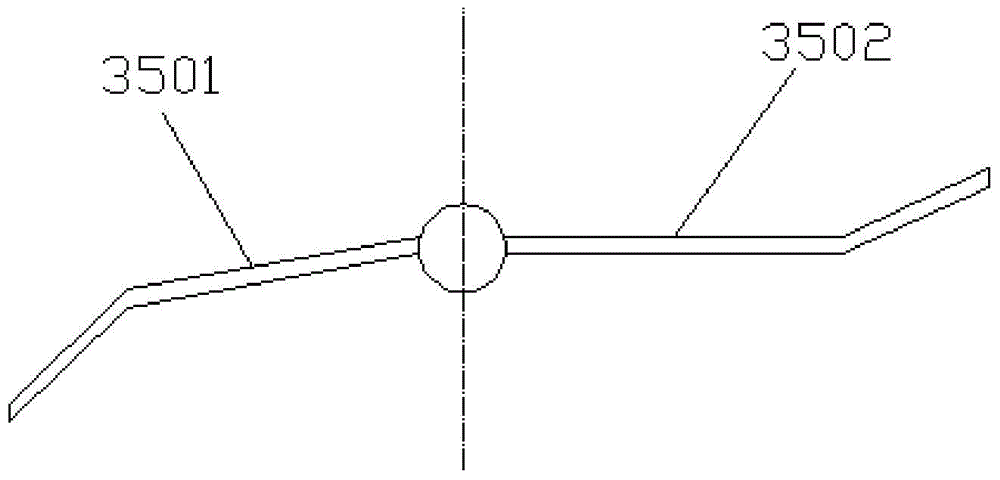

Torsionally de-coupled engine mount system

ActiveUS7594623B2Loads in the engine mounts are significantly reducedLess complicatedGas turbine type power plantsPower plant constructionVertical loadEngine mount

A torsionally de-coupled engine mount system (13) for use in tilt rotor aircraft (11) applications is disclosed, in which an engine is mounted at its forward end to a prop rotor gear box by means of a forward mount (303) that is a simple adapter fitting, and at its aft end to a pylon assembly by an aft mount (305) that is a simple bi-pod fitting. The forward mount (303) counteracts forces and moments in six degrees of freedom, but the aft mount (305) only counteracts lateral and vertical loads. The contribution from the engine to the overall dynamic response of the aircraft is tuned by selectively tailoring the size, shape, weight, and material of the forward mount (303). The engine mount system torsionally de-couples the engines from the prop rotors, thereby preventing rotor torque from being induced into the engines. In addition, the contribution from the engines to the overall dynamic response of the aircraft can be tuned by selectively tailoring the size, shape, weight, and material of the forward mounts between the engines and the transmissions.

Owner:TEXTRON INNOVATIONS

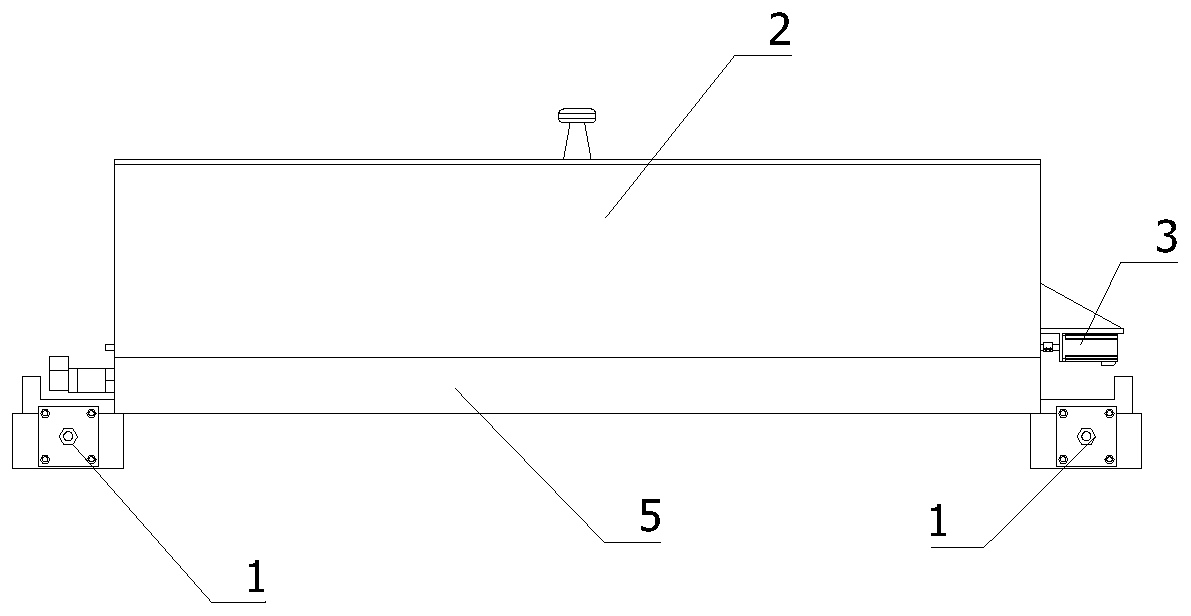

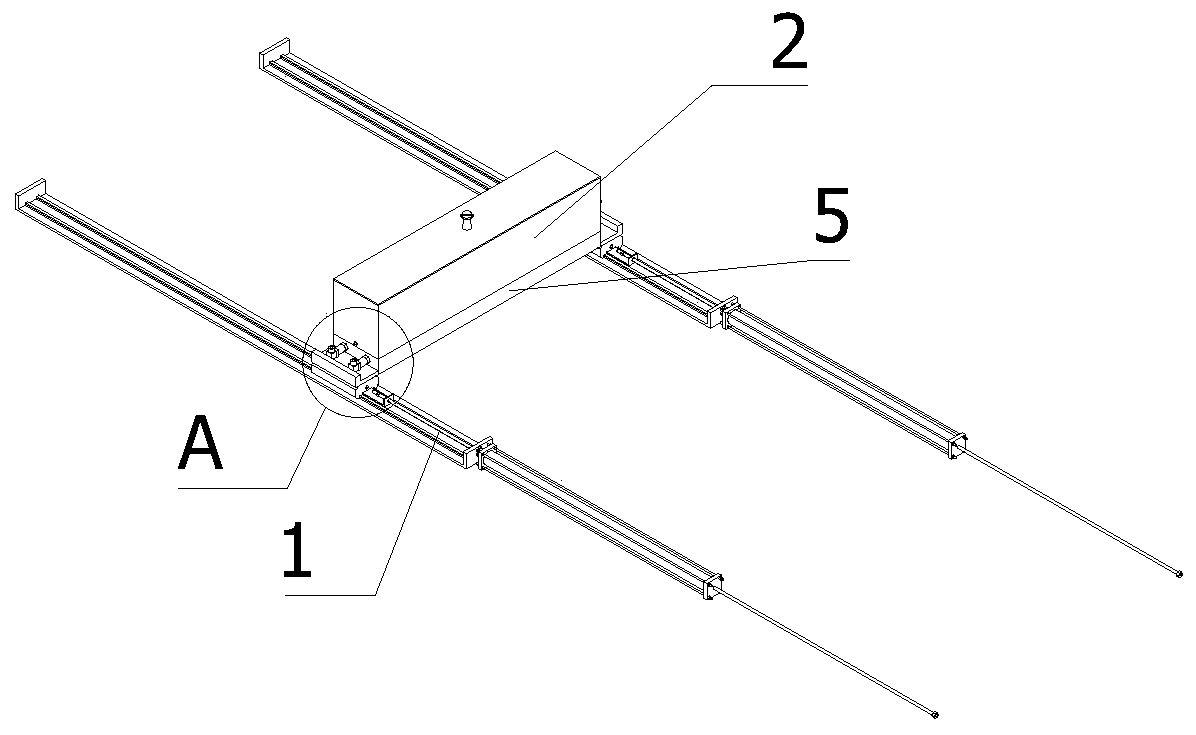

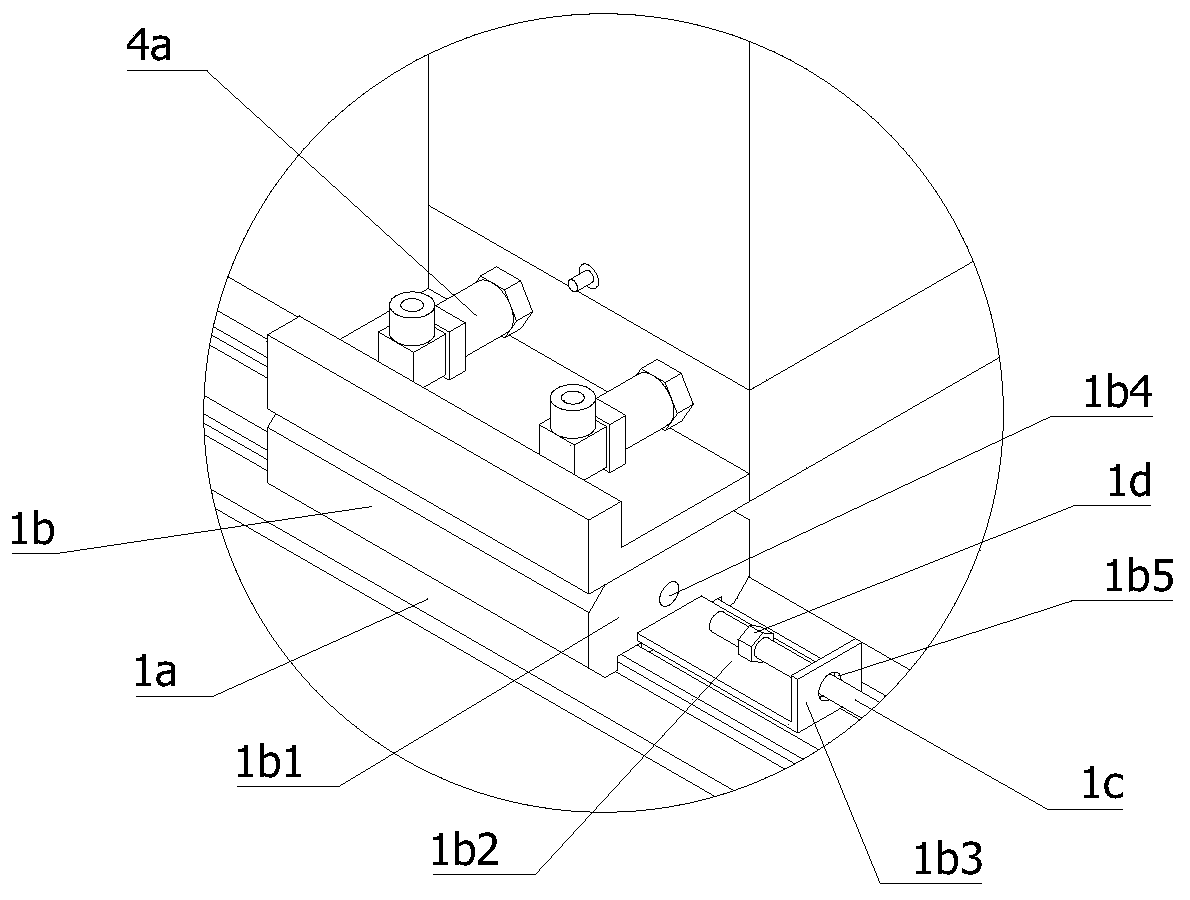

Automatic blanking device for powder material for powder metallurgical equipment

InactiveCN111375768ASpread evenlySimple loadingAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringMechanical engineering

The invention relates to the technical field of powder metallurgy, in particular to an automatic blanking device for a powder material for powder metallurgical equipment. The device comprises a translation mechanism, a powder box, an air injection mechanism and a discharge valve, wherein the translation mechanism is fixedly arranged on a powder sintering workbench, and the powder box straddles twosides of the powder sintering workbench through the translation mechanism; a plurality of air inlets vertically penetrating through a bottom plate of the powder box are uniformly arranged on the powder box, a discharge port vertically penetrating through the bottom plate of the powder box is further arranged on the powder box, and the discharge port is in an elongated strip shape parallel to thelength direction of the powder box; the discharge valve is fixedly arranged on the powder box, the output end of the air injection mechanism is fixedly arranged in each air inlet, and the output end of the air injection mechanism is closed and the discharge port is closed by a working part of the discharge valve in a non-working state; and the device is simple in feeding, vibration discharging isnot needed, the size of the equipment is reduced, the discharging speed is not affected by the volume of the excess material, the spreading speed is fast, the spreading can be carried out through moving back and forth, and the spreading thickness is uniform and can be controlled.

Owner:罗哲

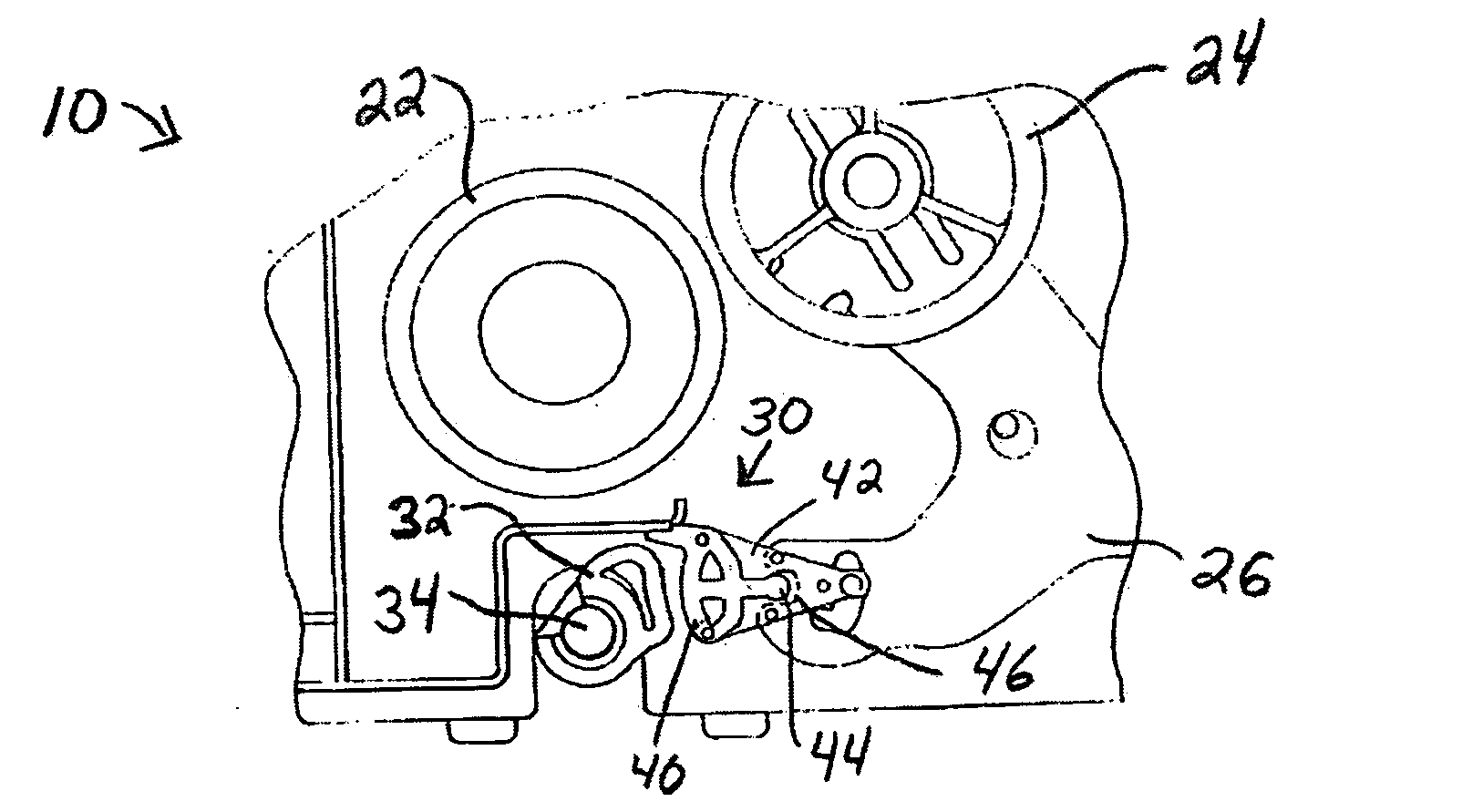

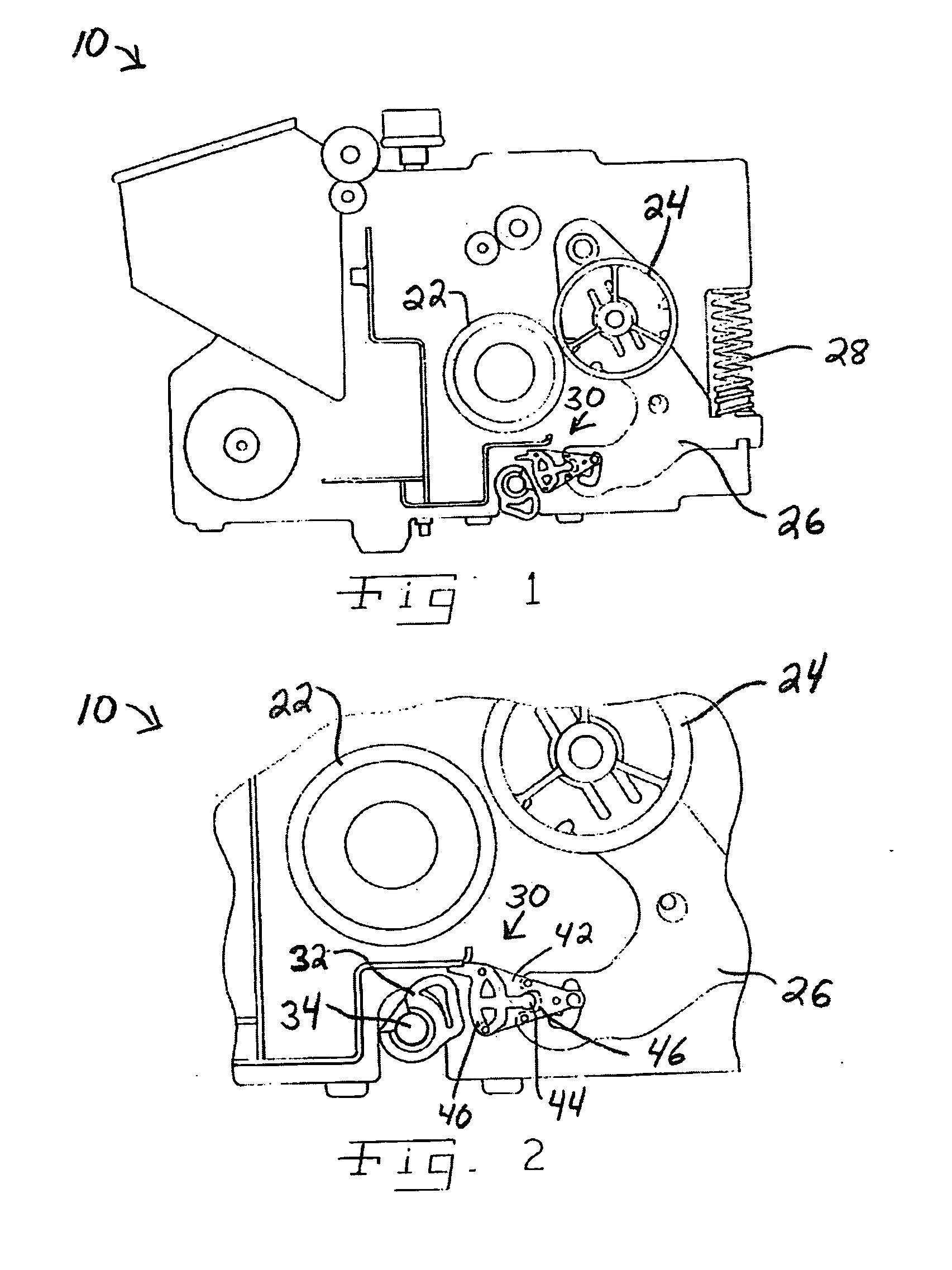

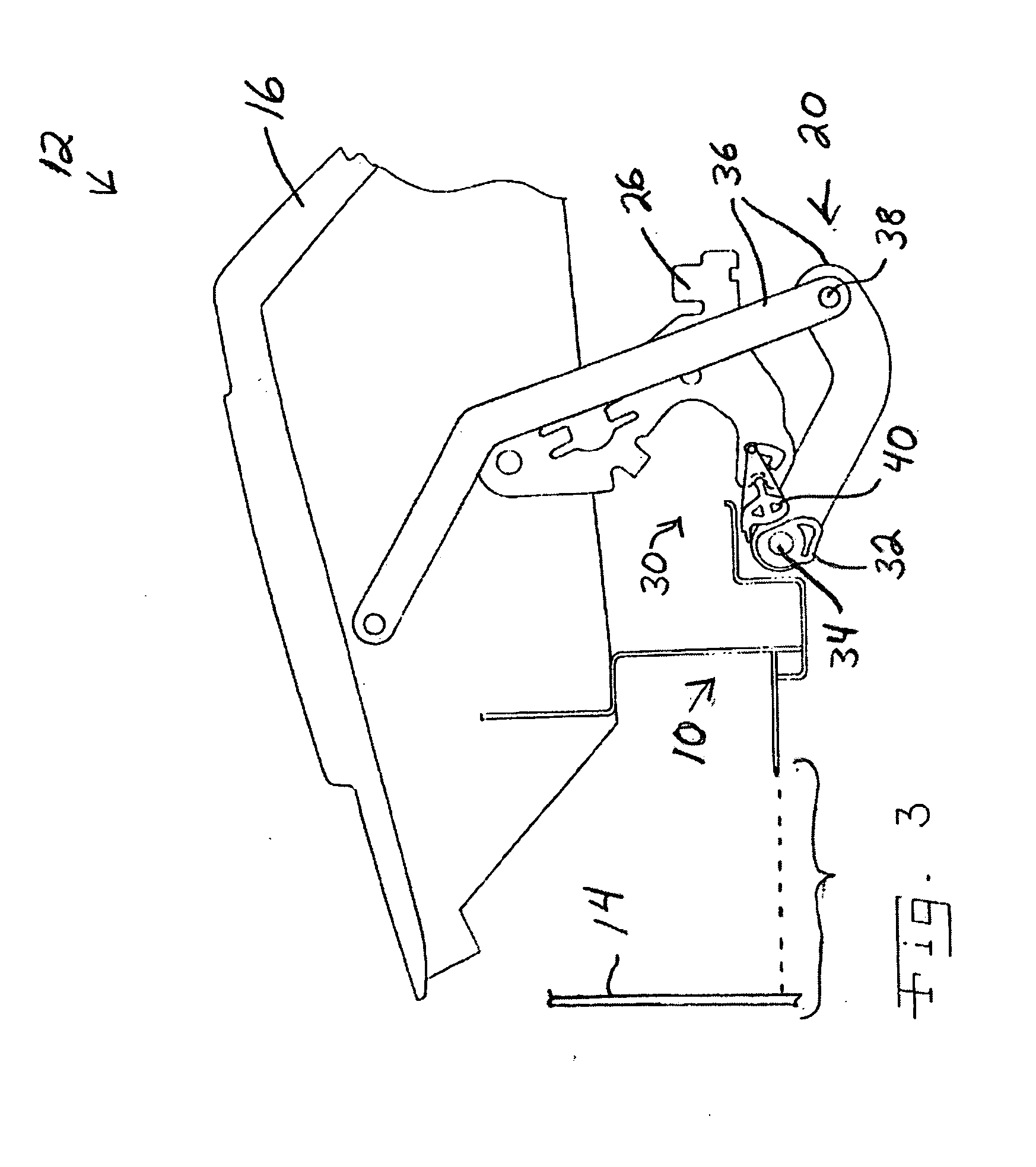

Fuser nip release mechanism

ActiveUS20050214042A1Easy maintenanceSimple loadingElectrographic process apparatusMechanical engineeringComputer printing

Owner:LEXMARK INT INC

Fish pond bait throwing-in device

InactiveCN105265369AAvoid cloggingSave energyPisciculture and aquariaMechanical engineeringAir blast

The invention provides a fish pond bait throwing-in device, which comprises an air blasting system, a conveying system, a feeding system and a spraying system, wherein the feeding system further comprises a wind board, a stirring shaft and stirring blades, the wind board forms a covering space at a connecting port of a feeding pipe and a conveying pipe, the stirring shaft is located at the bottom part of the feeding pipe, extends downward and penetrates through the wind board and the conveying pipe, and the stirring blades are fixedly connected on the stirring shaft and can drive the stirring shaft to rotate. The fish pond bait throwing-in device has the advantages of abilities of preventing blockage of the feeding pipe, preventing inability of bait for falling into the conveying pipe, preventing uneven distribution of spraying platforms, increasing oxygen in water, being applicable to a large-area fish pond or multiple fish ponds, and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

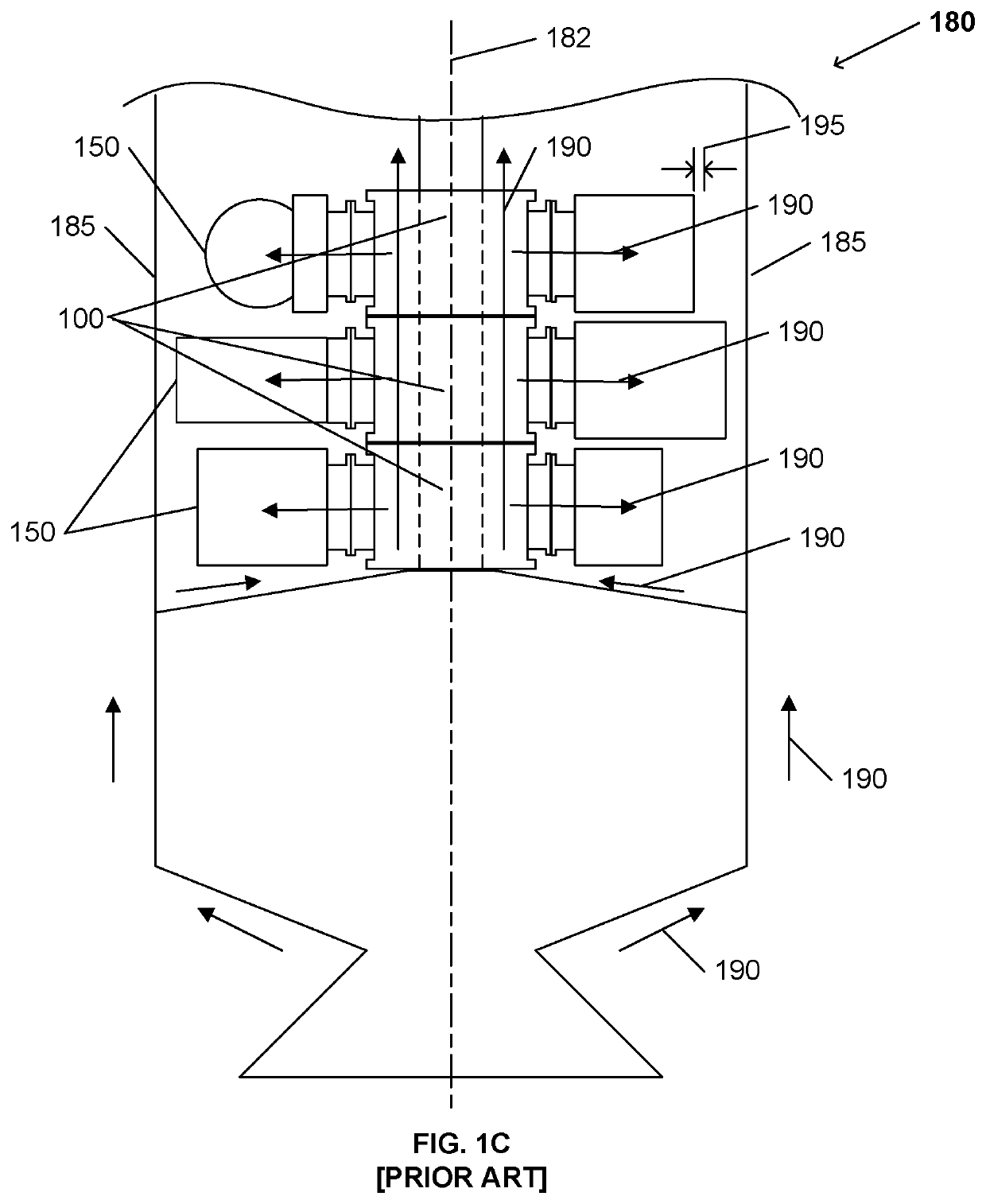

Wafer boat assembly, loading apparatus comprising such a wafer boat assembly and method for loading a vertical furnace

ActiveUS20120213613A1Improve throughputEasy to handleConveyorsCharge supportsBatch processingEngineering

Wafer boat assembly for use in a loading apparatus for loading semiconductor substrates in a vertical furnace configured for batch processing, wherein the wafer boat assembly comprises a wafer boat for holding semiconductor substrates and a cover configured to substantially surround the substrates, wherein the wafer boat assembly is provided witha first wafer boat part comprising a base and a first cover part mounted thereto, said first cover part extending at least partially along a base upper perimeter; anda second wafer boat part comprising a second cover part removably provided on the first wafer boat part and configured to cooperate with the first cover part, said second cover part comprising receiving slots for receiving at least a semiconductor substrate to be processed.

Owner:ASM INTERNATIONAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com