Fish pond bait throwing-in device

A feeding device and bait technology, which is applied in fish farming, application, animal husbandry, etc., can solve problems such as easy blockage of pipelines, uneven material distribution, and danger, and achieve turbulent flow, stable fluid flow, and wind energy. low loss effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

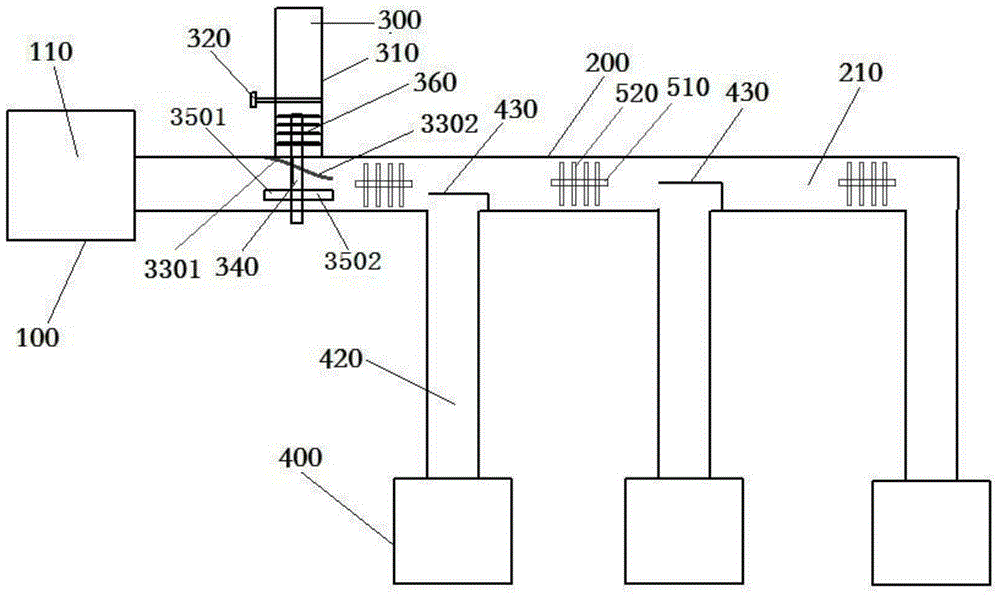

[0056] Such as figure 1 As shown, the fishpond bait feeding device of the present invention includes a blast system 100 , a feeding system 200 , a feeding system 300 and a material spraying system 400 .

[0057] In one embodiment, the blowing system 100 includes a blower 110 with a power of 750W, and the feeding system 200 includes a feeding pipe 210, one end of the feeding pipe 210 is connected with the blower 110, and the blower 110 introduces external air into the feeding pipe 210 .

[0058] In another embodiment, the blower system may include multiple blowers.

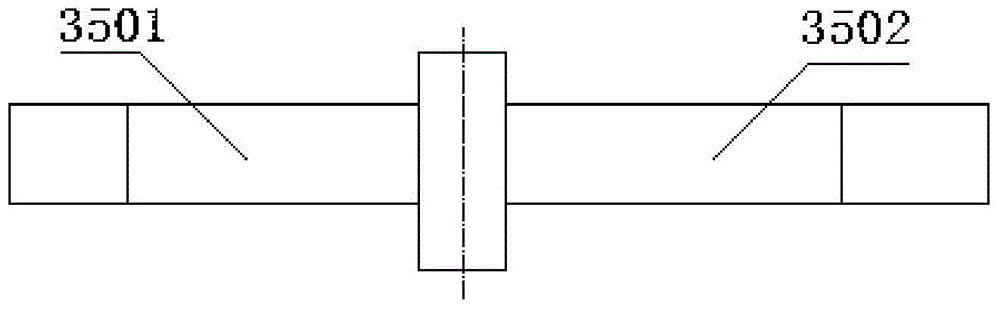

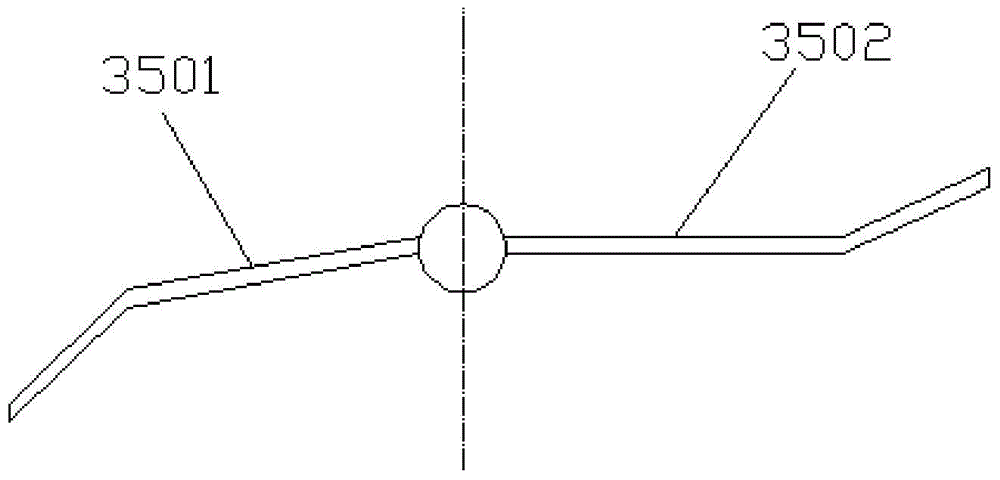

[0059] exist figure 1 Among them, the feeding system 300 includes a feeding pipe 310, a flow controller 320, a windshield 330, a stirring shaft 340, a first stirring blade 3501, a second stirring blade 3502 and a stirring tooth 360; wherein the feeding pipe 310 is arranged on On the end of the feeding pipe 210 close to the blower 100, the feeding pipe 310 is placed vertically, allowing the bait to fall into the ...

Embodiment 2

[0083] Such as figure 1 As shown, the fishpond bait feeding device of the present invention includes a blast system 100 , a feeding system 200 , a feeding system 300 and a material spraying system 400 .

[0084] In one embodiment, the blowing system 100 includes a blower 110 with a power of 750W, and the feeding system 200 includes a feeding pipe 210, one end of the feeding pipe 210 is connected with the blower 110, and the blower 110 introduces external air into the feeding pipe 210 .

[0085] In another embodiment, the blower system may include multiple blowers.

[0086] exist figure 1 Among them, the feeding system 300 includes a feeding pipe 310, a flow controller 320, a windshield 330, a stirring shaft 340, a first stirring blade 3501, a second stirring blade 3502 and a stirring tooth 360; wherein the feeding pipe 310 is arranged on On the end of the feeding pipe 210 close to the blower 100, the feeding pipe 310 is placed vertically, allowing the bait to fall into the ...

Embodiment 3

[0110] Such as figure 1 As shown, the fishpond bait feeding device of the present invention includes a blast system 100 , a feeding system 200 , a feeding system 300 and a material spraying system 400 .

[0111] In one embodiment, the blower system 100 includes a blower 110 with a power of 750W, and the feeding system 200 includes a feeding pipe 210, one end of the feeding pipe 210 is connected with the blower 110, and the blower 110 introduces external air into the feeding pipe 210 .

[0112] In another embodiment, the blower system may include multiple blowers.

[0113] exist figure 1 Among them, the feeding system 300 includes a feeding pipe 310, a flow controller 320, a windshield 330, a stirring shaft 340, a first stirring blade 3501, a second stirring blade 3502 and a stirring tooth 360; wherein the feeding pipe 310 is arranged on On the end of the feeding pipe 210 close to the blower 100, the feeding pipe 310 is placed vertically, allowing the bait to fall into the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com