Rotary feeding device for cam

A technology of rotary feeding and cam, applied in the field of mechanical equipment, can solve the problems of incomplete technical problems, cumbersome debugging process, and increase the cost of use, and achieves the effects of strong versatility, compact structure and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

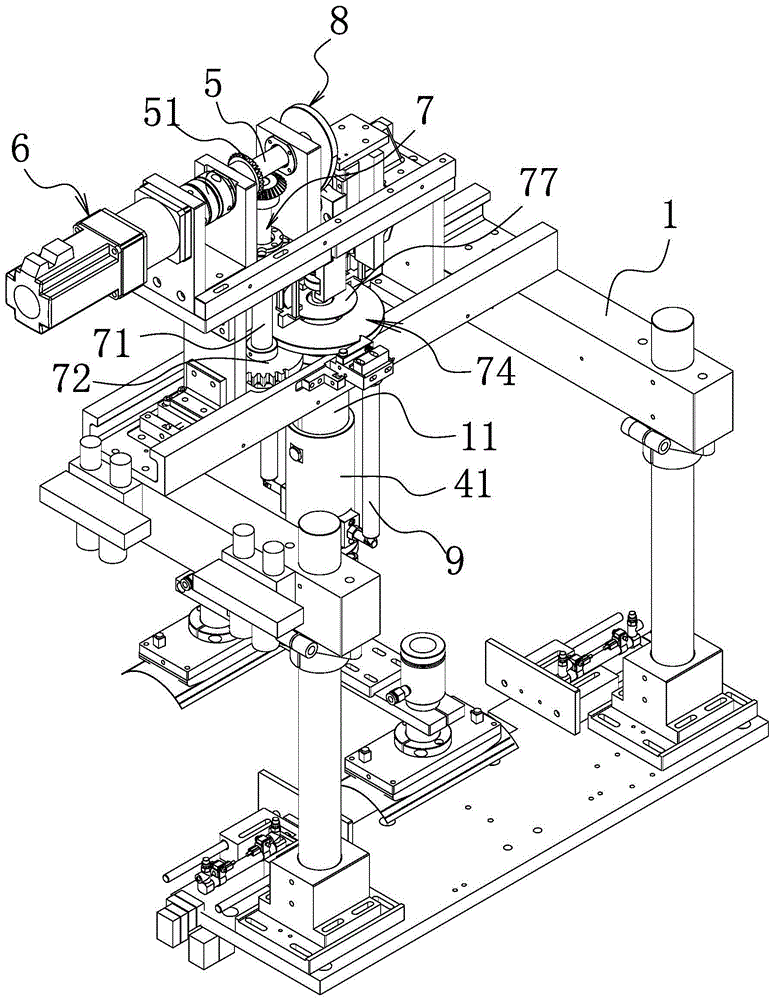

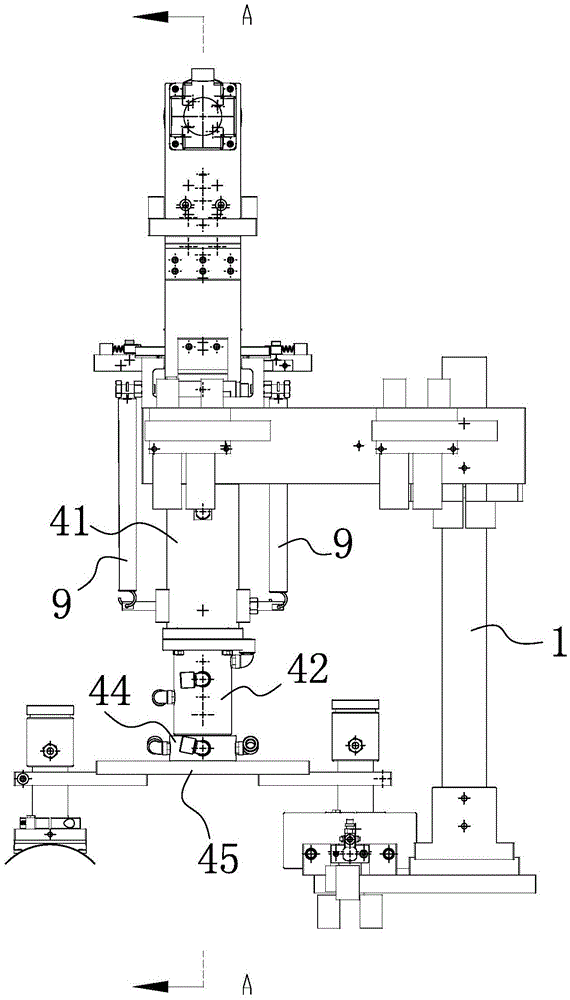

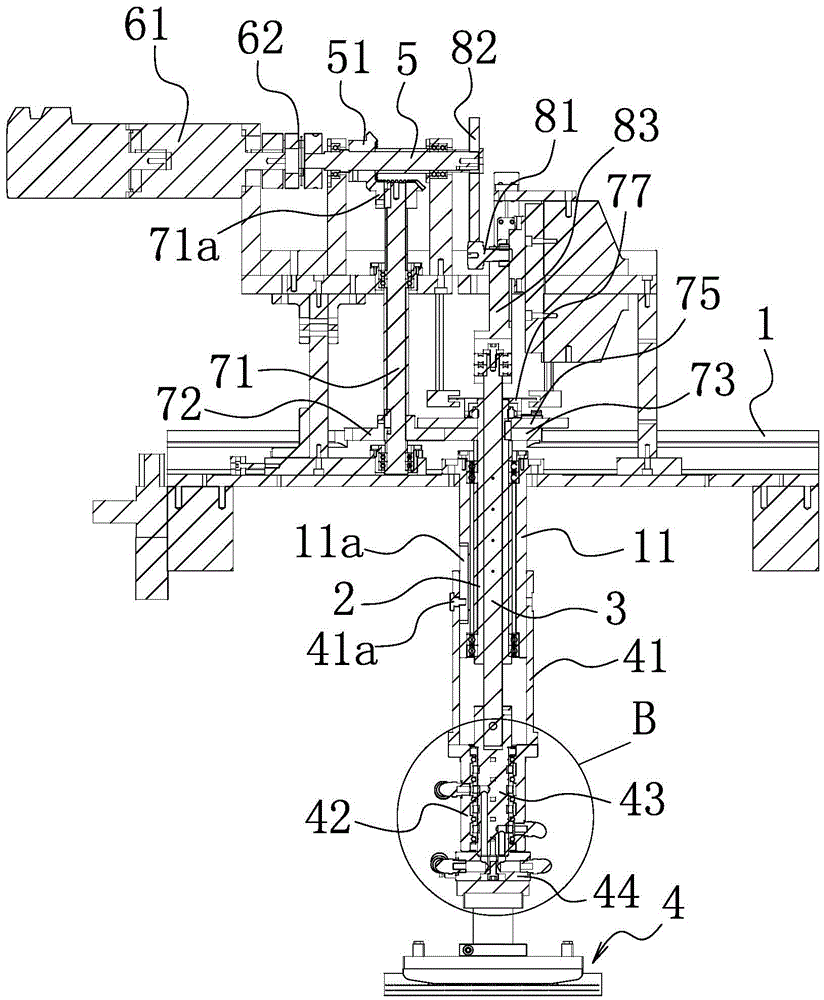

[0026] Such as Figure 1-3 As shown, the cam rotary feeding device includes a mounting bracket 1, and the mounting bracket 1 includes a mounting portion and a cantilever portion connected to the mounting portion. On the mounting bracket 1, there is a cylindrical rotating shaft 2 which is vertically arranged and can rotate relative to the mounting bracket 1. In the cylindrical rotating shaft 2, there is a cylindrical rotating shaft 2 which rotates synchronously with the cylindrical rotating shaft 2 and can rotate along the cylindrical rotating shaft 2. The lifting shaft 3 that lifts axially, the two ends of the lifting shaft 3 are respectively extended to the two ends of the cylindrical rotating shaft 2, and at least one is arranged along the axial direction of the cylindrical rotating shaft 2 on the inner wall of the cylindrical rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com