Horizontal electrochemical metal deposition method

A metal deposition, electrochemical technology, applied in the direction of circuits, electrical components, electrolysis process, etc., can solve the problems of unfavorable large-scale production, and achieve the effect of improving effectiveness and improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] With reference to the drawings, the present invention can be further described in detail. Obviously, these descriptions are not intended to limit the present invention. Without departing from the spirit and essence of the present invention, those skilled in the art can make various other corresponding combinations, changes or modifications according to the present invention. These corresponding combinations, changes and modifications all fall within the protection scope of the appended claims of the present invention.

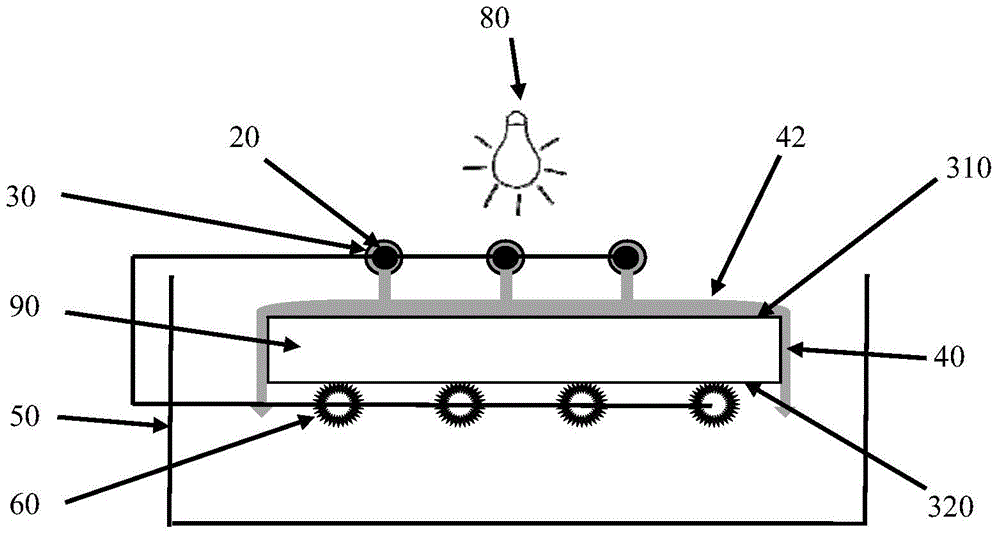

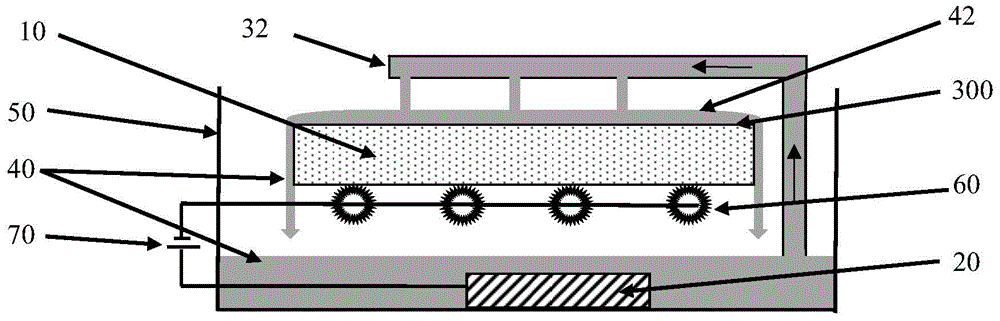

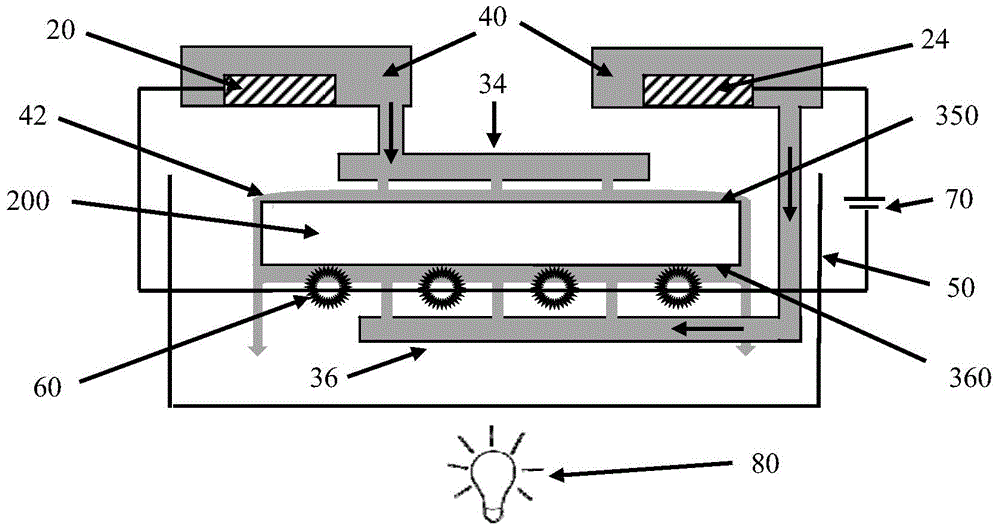

[0032] figure 1 An example of the electrochemical metal deposition method of the present invention using the light-induced electrochemical metal deposition method is shown. In this embodiment, the sheet substrate 90 is a p-type crystalline silicon screen printed solar cell. The so-called p-type crystalline silicon screen-printed solar cell means that the metal electrode 320 of the positive electrode of the cell is produced by screen-printing aluminum past...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com