High-plasticity aluminum alloy for heat exchange fin plate and processing technology of high-plasticity aluminum alloy

A processing technology and high plasticity technology, which is applied in the processing technology field of aluminum alloy materials and aluminum alloy sheets, can solve the problems such as the failure of aluminum alloy sheets to meet the requirements, achieve high dimensional accuracy of finished products, high corrosion resistance, and is conducive to promotion applied effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Casting billet specification 7.0mm×1060mm; finished product specification 0.4mm×1000mm O state

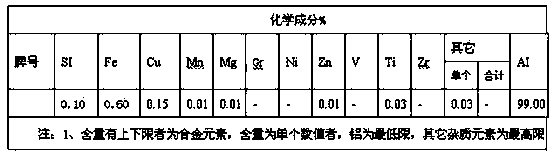

[0054] A high-plastic aluminum alloy for heat exchange fins, the aluminum alloy contains 0.06wt% silicon, 0.59wt% iron, 0.11wt% copper, manganese, zinc, and magnesium less than or equal to 0.01, and less than or equal to 0.03wt % titanium and unavoidable impurities, and the rest is aluminum (the purity of aluminum is ≥99.50%).

[0055] A process for processing high-plasticity aluminum alloys for heat exchange fins, the process comprising the following process steps:

[0056] The first step: ingredients, the raw materials are prepared according to the above chemical composition and ratio;

[0057] The second step: smelting, adding the qualified aluminum ingots and scraps into the flame reverberatory furnace, the melting temperature is 800-850 ℃, fully stirred after heating and melting, and the composition analysis is carried out when the temperature reaches 730-740 ℃, accord...

Embodiment 2

[0070] Casting billet specifications 7.0mm×1060mm; finished product specifications 0.35mm×1000mm O state

[0071]A high plastic aluminum alloy for heat exchange fins, the aluminum alloy contains 0.08wt% silicon, 0.57wt% iron, 0.10wt% copper, less than or equal to 0.01 manganese, zinc, magnesium, less than or equal to 0.03wt% % titanium and unavoidable impurities, and the remaining content is ≥99.50% aluminum.

[0072] A process for processing high-plasticity aluminum alloys for heat exchange fins, the process comprising the following process steps:

[0073] The first step: ingredients, the raw materials are prepared according to the above chemical composition and ratio;

[0074] The second step: smelting, adding the qualified aluminum ingots and scraps into the flame reverberatory furnace, the melting temperature is 800-850 ℃, fully stirred after heating and melting, and the composition analysis is carried out when the temperature reaches 730-740 ℃, according to the analysis ...

Embodiment 3

[0087] Casting billet specifications 7.0mm×1060mm; finished product specifications 0.35mm×1000mm O state

[0088] A high-plastic aluminum alloy for heat exchange fins, wherein the preferred technical solution is that the aluminum alloy contains 0.07wt% of silicon, 0.58wt% of iron, 0.09wt% of copper, and less than or equal to 0.01% of manganese and zinc , magnesium, titanium less than or equal to 0.03wt% and unavoidable impurities, and the remaining content is ≥99.50% aluminum.

[0089] A process for processing high-plasticity aluminum alloys for heat exchange fins, the process comprising the following process steps:

[0090] The first step: ingredients, the raw materials are prepared according to the above chemical composition and ratio;

[0091] The second step: smelting, adding the qualified aluminum ingots and scraps into the flame reverberatory furnace, the melting temperature is 800-850 ℃, fully stirred after heating and melting, and the composition analysis is carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com