Full-automatic drilling automatic machine

An automatic and fully automatic technology, applied in the direction of boring/drilling, drilling/drilling equipment, and components of boring machines/drilling machines, etc., can solve the problems of large volume, large equipment investment, occupying space, etc., and achieve comprehensive performance Reliability, reduced equipment footprint, and reduced failure rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As described above, the present invention provides a fully automatic drilling machine with simple structure and easier operation.

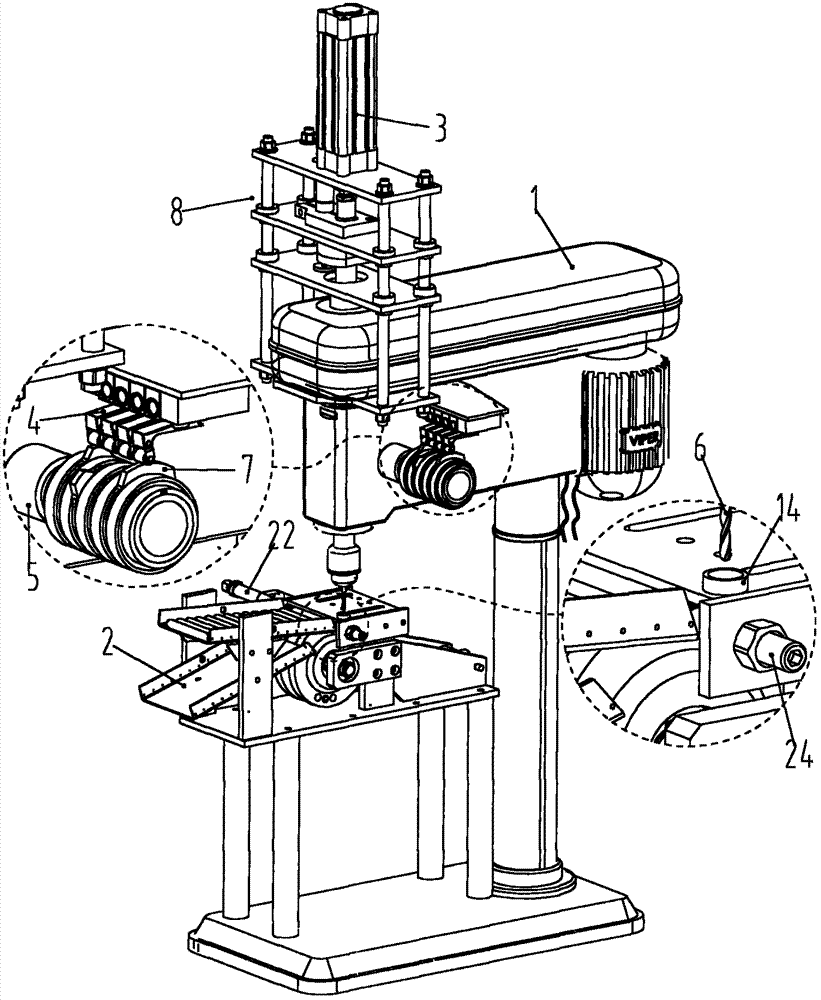

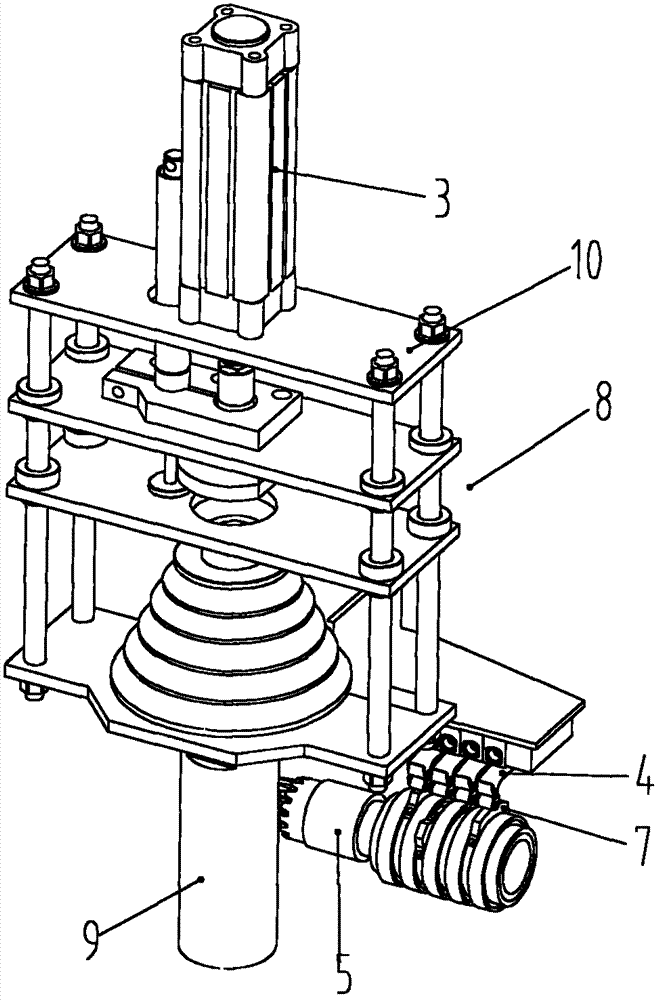

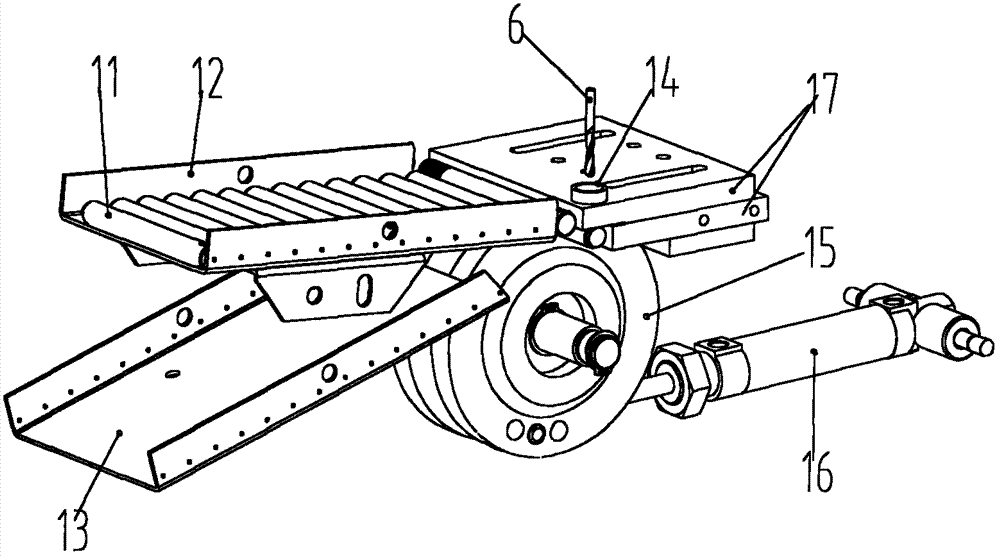

[0028] figure 1 It is a schematic structural view of the automatic drilling machine of the present invention, figure 2 It is a schematic structural view of the feeding mechanism of the automatic drilling machine of the present invention, image 3 , 4 , 5, 6 are structural representations of the automatic tooling of the automatic drilling machine of the present invention.

[0029] A fully automatic drilling automatic machine, comprising: a bench drill 1, an automatic tooling 2, and a feeding mechanism 8; the automatic tooling 2 is fixedly connected to the bench drill 1, and the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com