Automatic KKs code generating method for power plant equipment elements

A technology of automatic generation and equipment components, applied in instruments, data processing applications, computing and other directions, can solve problems such as affecting design work, tedious design work, slow work efficiency, etc., to improve work efficiency and work quality, realize resource sharing, The effect of maintaining consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The thermal engine major needs to establish the system diagram of J1201 water supply system flow chart volume in Unit 1 of a certain project, so the volume number is: J1201 water supply system flow chart; the picture name of the system diagram is J1201p&ID2481A1, so the drawing number is J1201p&ID2481A1. The system has a LAB water supply system and a LAF medium pressure reduction warm water system.

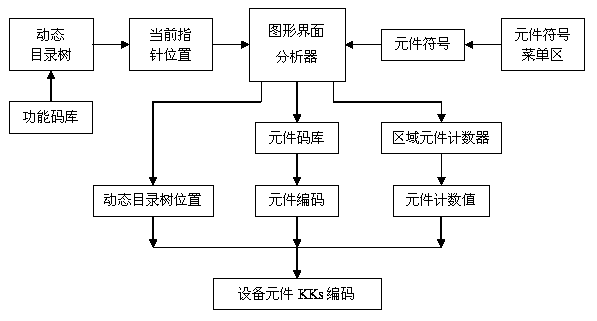

[0023] The KKs coding automatic generation method specifically includes the following steps:

[0024] A. Enter the automatic generation system, according to the above engineering design, establish the following dynamic directory tree,

[0025] -10

[0026] - J1201 water supply system flow chart

[0027] + J1201p&ID2481A1

[0028] - LAB water supply system

[0029] + 10

[0030] + 20 ← current dynamic pointer position

[0031] + 30

[0032] - LAF medium pressure desuperheating water system

[0033] +90

[0034] +91

[0035] +92;

[0036] B. Locate the pointer posi...

Embodiment 2

[0042] Put another pressure gauge on the pipeline of embodiment 1. Since it is on the pipeline, its dynamic directory position is also 10LAB20. The component code of the electric pump read by the graphical interface analyzer from the component code library is CP, because it is The first meter is placed in this area, so the component count value is 001, that is, the KKs value of the pressure gauge is 10LAB20CP001.

Embodiment 3

[0044] According to the dynamic directory tree that step A in the embodiment 1 establishes, the dynamic pointer changes to the 91 area of the LAF of the dynamic directory tree, and the current dynamic directory tree position is: 10LAF91, selects the electric pump graphic symbol from the component symbol menu area and drags it into the graphic design Area, the graphic interface analyzer reads the component code of the electric pump from the component code library as AP, and the area component counter records that three electric pump equipment components have been placed in the same area, so the component count value is automatically displayed as 004, and the obtained The KKs value of the pipeline is: 10LAF91AP004.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com