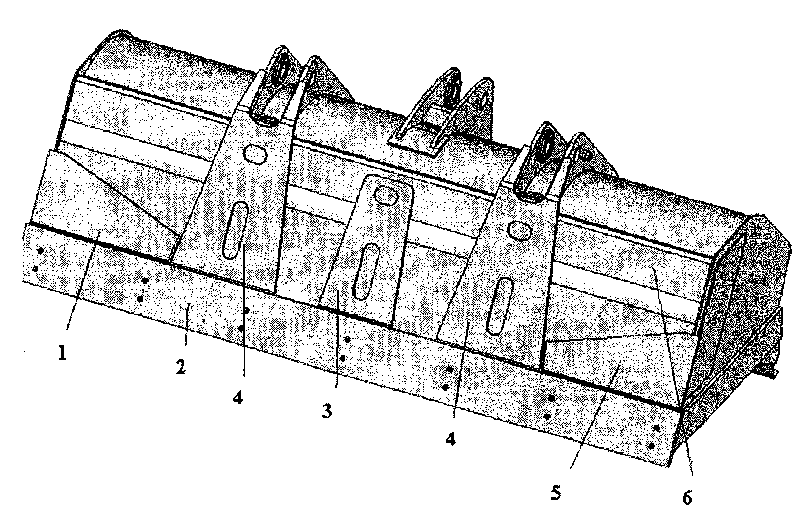

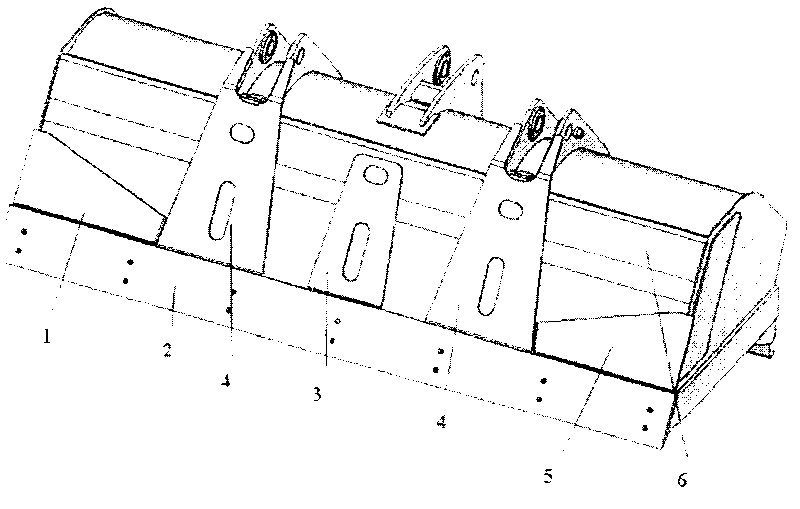

Method for realizing abrasion proof treatment to loader hopper and special welding wire thereof

A loader and hopper technology is applied in the field of anti-wear treatment and special welding wire for loader hopper, which can solve the problems of low service life and poor wear resistance, and achieve the effect of improving service life, avoiding frequent maintenance and saving steel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Including two processes of manufacturing special surfacing flux cored wire and surfacing hopper wear-resistant plate.

[0049] The manufacturing steps of special surfacing flux-cored wire for loader river sand hopper are as follows:

[0050] (1) Determine the alloy system of the flux-cored wire deposited metal according to the working conditions of the river sand hopper, and weigh the following powder (in parts by weight, unit: kg): 30 parts of high-carbon ferrochromium, 18 parts of metallic chromium, 10 parts of boron iron, 6 parts of vanadium iron, 2 parts of high carbon ferromanganese, 0.8 parts of rare earth ferrosilicon, 4 parts of ferromolybdenum, 5 parts of graphite, 2 parts of titanium iron, 2 parts of aluminum-magnesium alloy, 1 part of NaF.

[0051] The particle diameter of the above powder is 60-270 μm.

[0052] (2) Mix the weighed powders, and mix the powders with a conventional powder mixer for 20 minutes to prepare powder for flux-cored welding wire.

[0053] (3) C...

Embodiment 2

[0071] Including two processes of manufacturing special surfacing flux cored wire and surfacing hopper wear-resistant plate.

[0072] The manufacturing steps of special surfacing flux-cored wire for loader river sand hopper are as follows:

[0073] (1) Determine the alloy system of the flux-cored wire deposited metal according to the working conditions of the river sand hopper, and weigh the following powder (in parts by weight, unit: kg): 22 parts high-carbon ferrochrome, 15 parts metallic chromium, 10 parts of ferroboron, 6 parts of vanadium iron, 2 parts of high carbon ferromanganese, 0.8 parts of rare earth ferrosilicon, 3.5 parts of ferromolybdenum, 4 parts of tungsten iron, 3.5 parts of graphite, 2.5 parts of vanadium-nitrogen alloy, 0.5 parts of nitrogen-manganese alloy, 1.5 parts of ferro-titanium, 2.5 parts of aluminum-magnesium alloy, 0.5 parts of fluorite, 0.5 parts of potassium titanate.

[0074] The particle diameter of the above powder is 60-270 μm.

[0075] (2) Mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com