Non-friction clutch

A clutch and non-friction technology, applied in the field of clutches, can solve the problems of severe friction plate wear, short service life, and reduce operating costs, and achieve the effects of strong torque transmission, avoiding frequent maintenance, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

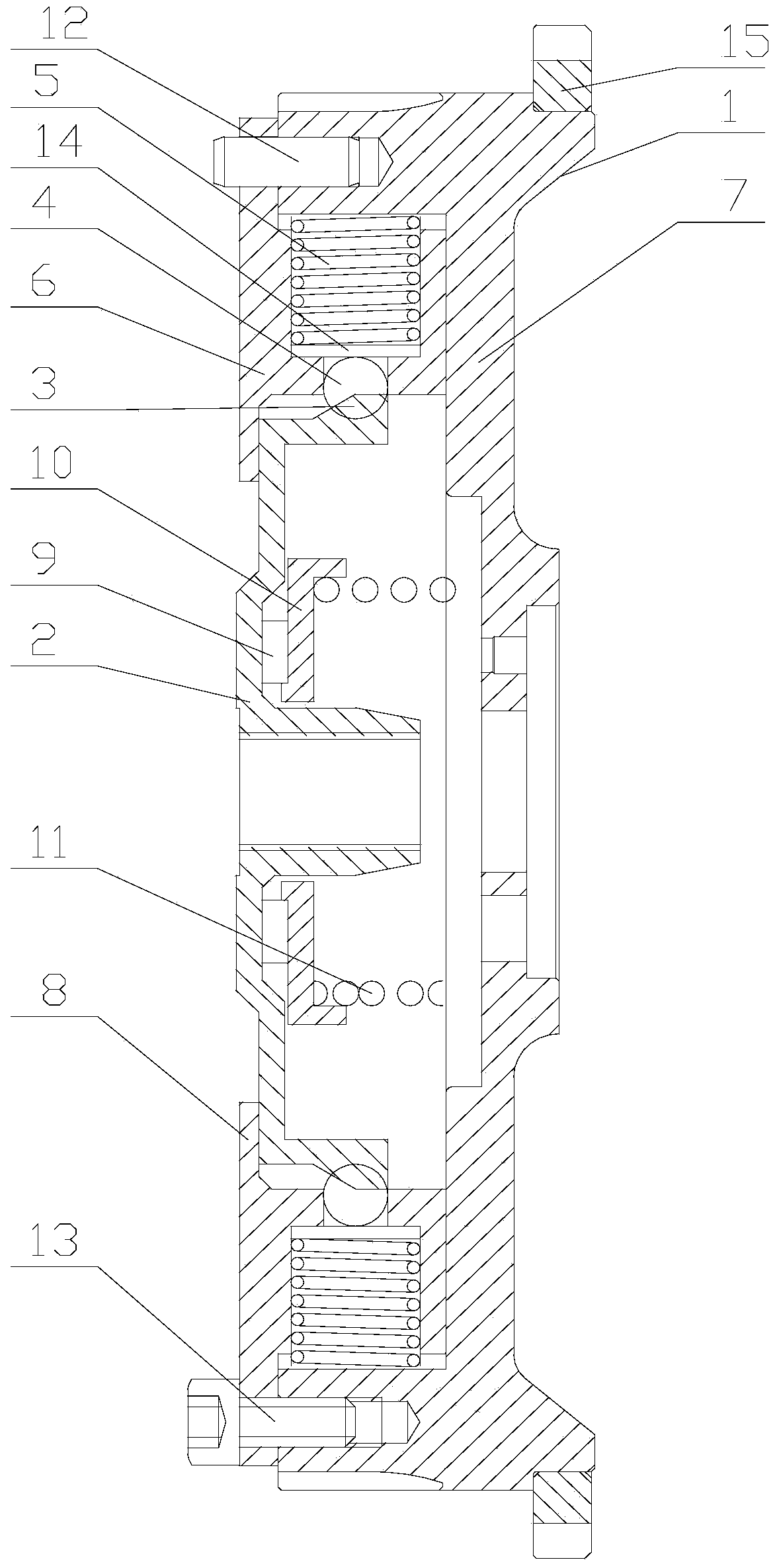

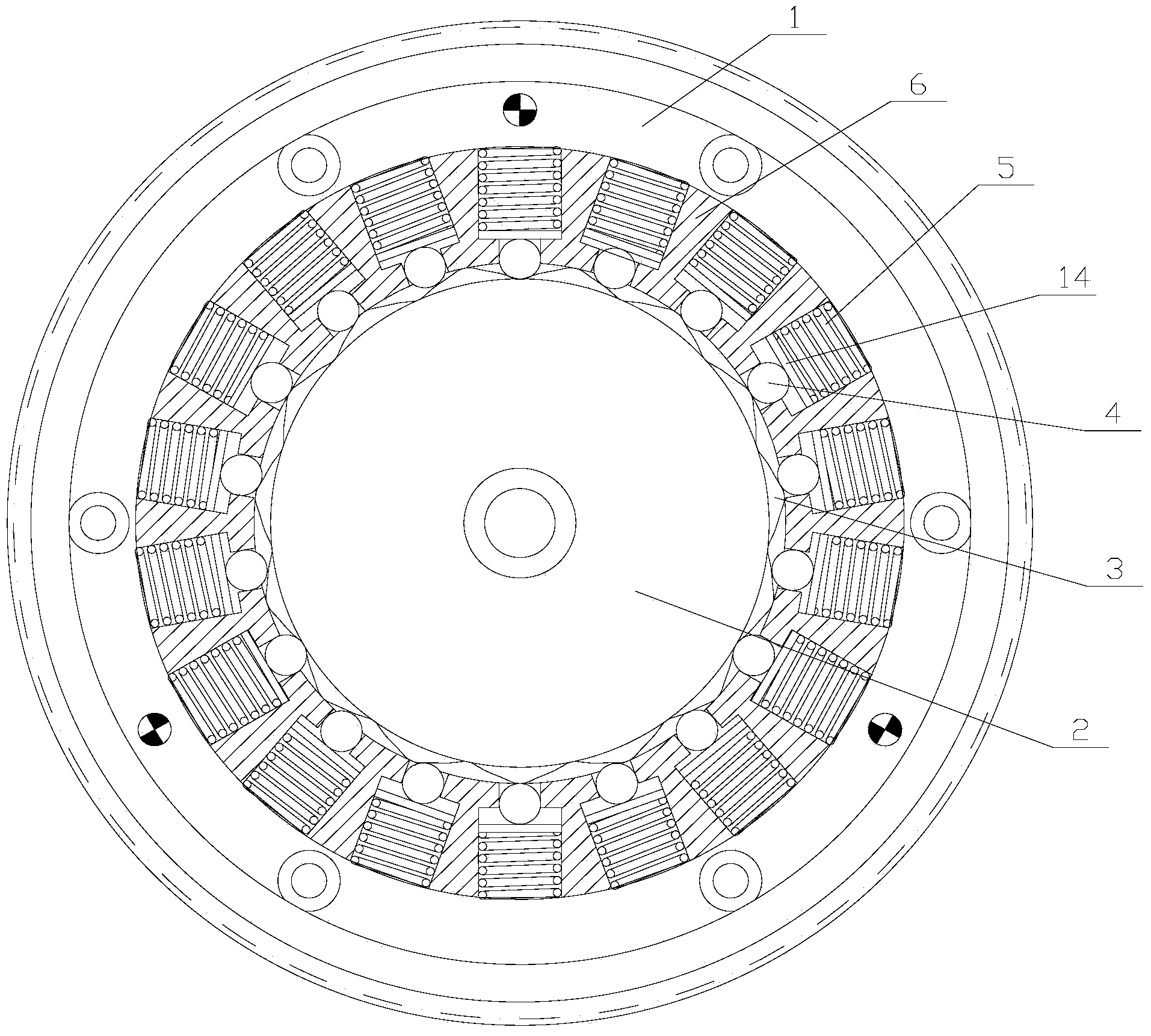

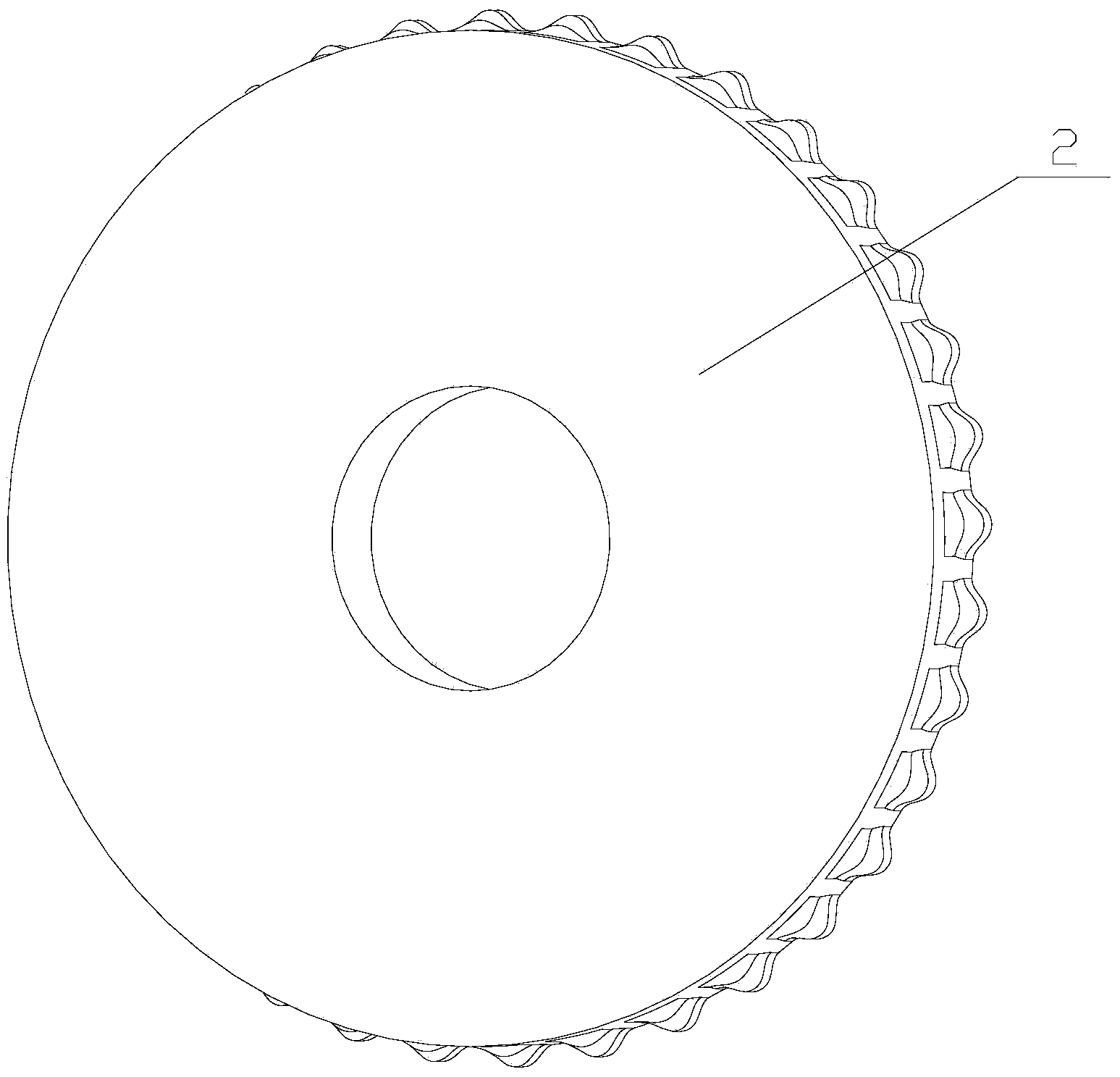

[0019] figure 1 It is a structural schematic diagram of the present invention; figure 2 for figure 1 left view of image 3 It is a three-dimensional view of the driven part, as shown in the figure: the non-friction clutch of this embodiment includes the driving part 1, the driven part 2 and the transmission part; the driving part 1 and the driven part 2 are coaxially fitted together And rotation fit, gear teeth 3 are provided on the rotation mating surface of the driven part 2; the transmission part includes a floating block radially floating on the rotation mating surface of the active part 1 and meshing with the gear teeth for transmission The tangential direction angle between the floating block and the point of action of the gear teeth 3 is continuously variable; the rotating mating surface of the driven part 2 refers to the mating surface on the driven part 2 that is rotationally matched with the active part 1; the rotation of the active part 1 The mating surface refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com