High-torque wear-free transmission clutch for vehicle

A clutch, wear-free technology, applied in the field of clutches, can solve problems such as high operating costs, friction plate wear, increased clutch operating frequency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

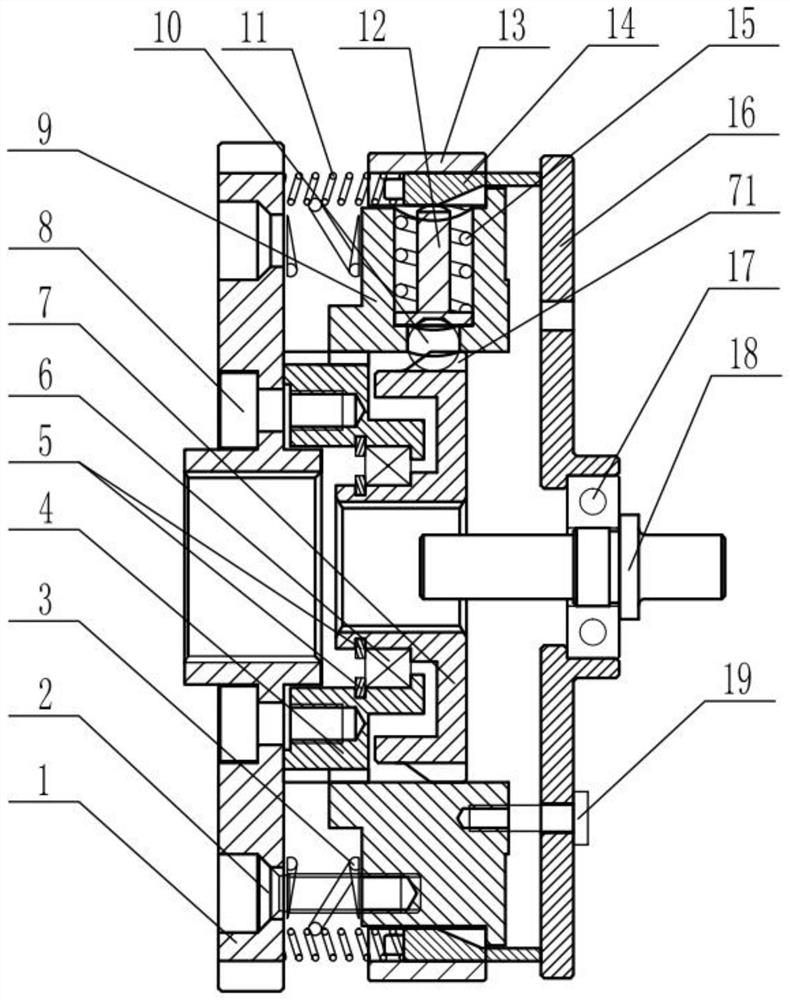

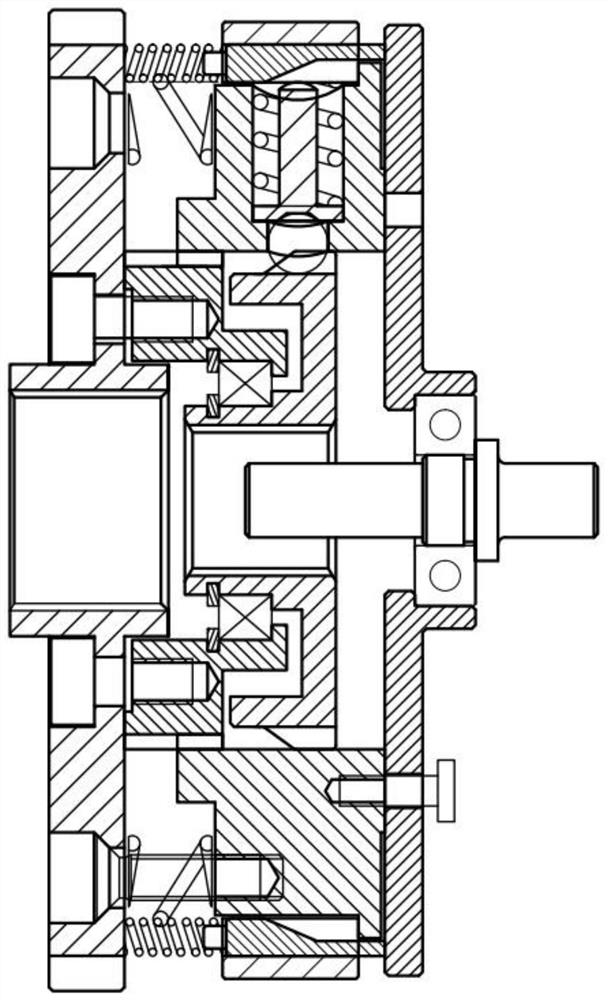

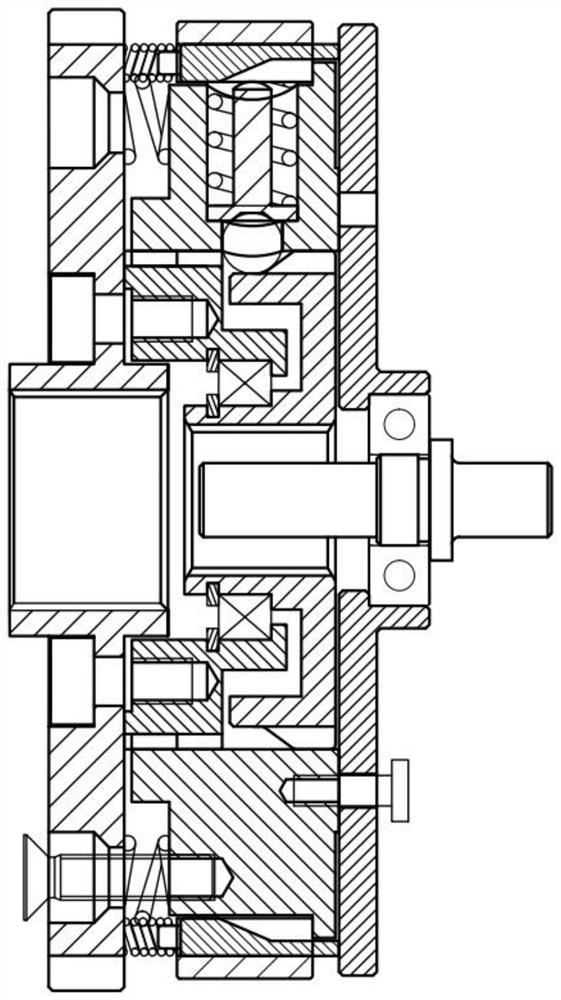

[0027] A high-torque, wear-free vehicle transmission clutch, comprising: a driving disc 1, a clutch mechanism, and an actuating disc 16, which are coaxially rotatable and sequentially arranged;

[0028] Wherein, the clutch mechanism includes the driven sleeve 9 of the outer ring and the driven disc 7 of the inner ring, and the driven sleeve 9 is provided with a plurality of spring bead mechanism radially, and the spring bead mechanism is provided with a cavity, and the cavity is located in the driven sleeve. 9 The inner diameter surface is provided with an outlet, and a steel ball 10 is arranged in the cavity, and the steel ball 10 is pressed against the outlet by a spring 15;

[0029] The outer diameter surface of the driven disk 7 is provided with gear teeth 71, and the gear teeth 71 are press-fitted with the part of the steel ball 10 exposed to the outlet for torque transmission.

[0030] The driving disc 1 is synchronously connected with the driven sleeve 9 to move axially...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com