LED (Light Emitting Diode) mine explosion-proof locomotive lamp

A flameproof, mining technology, applied in the field of LED mining flameproof locomotive lights, can solve the problems of unsafe use, short service life, large heat generation, etc., and achieve high airtightness, safety and performance of mobile equipment. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the object, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

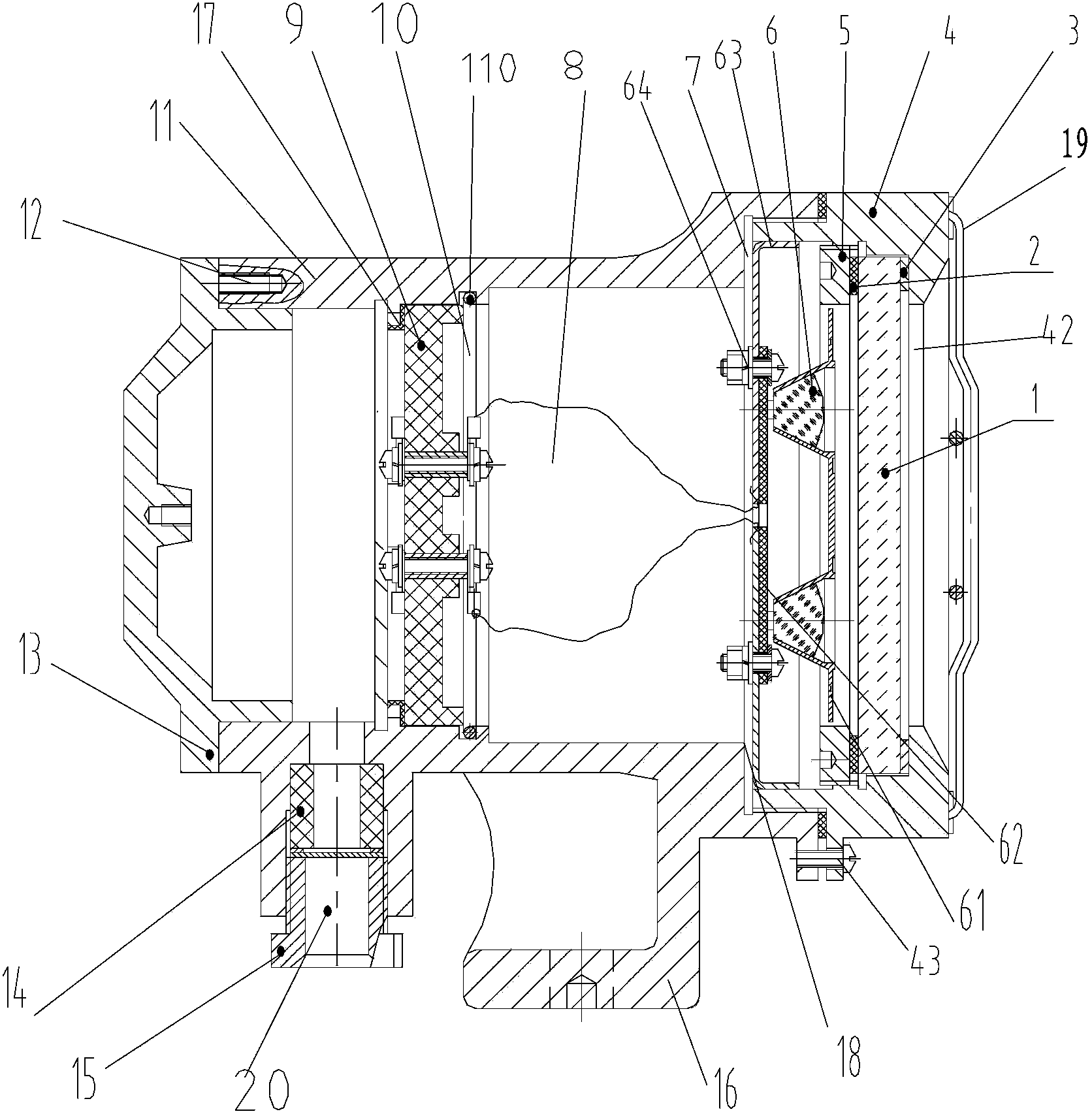

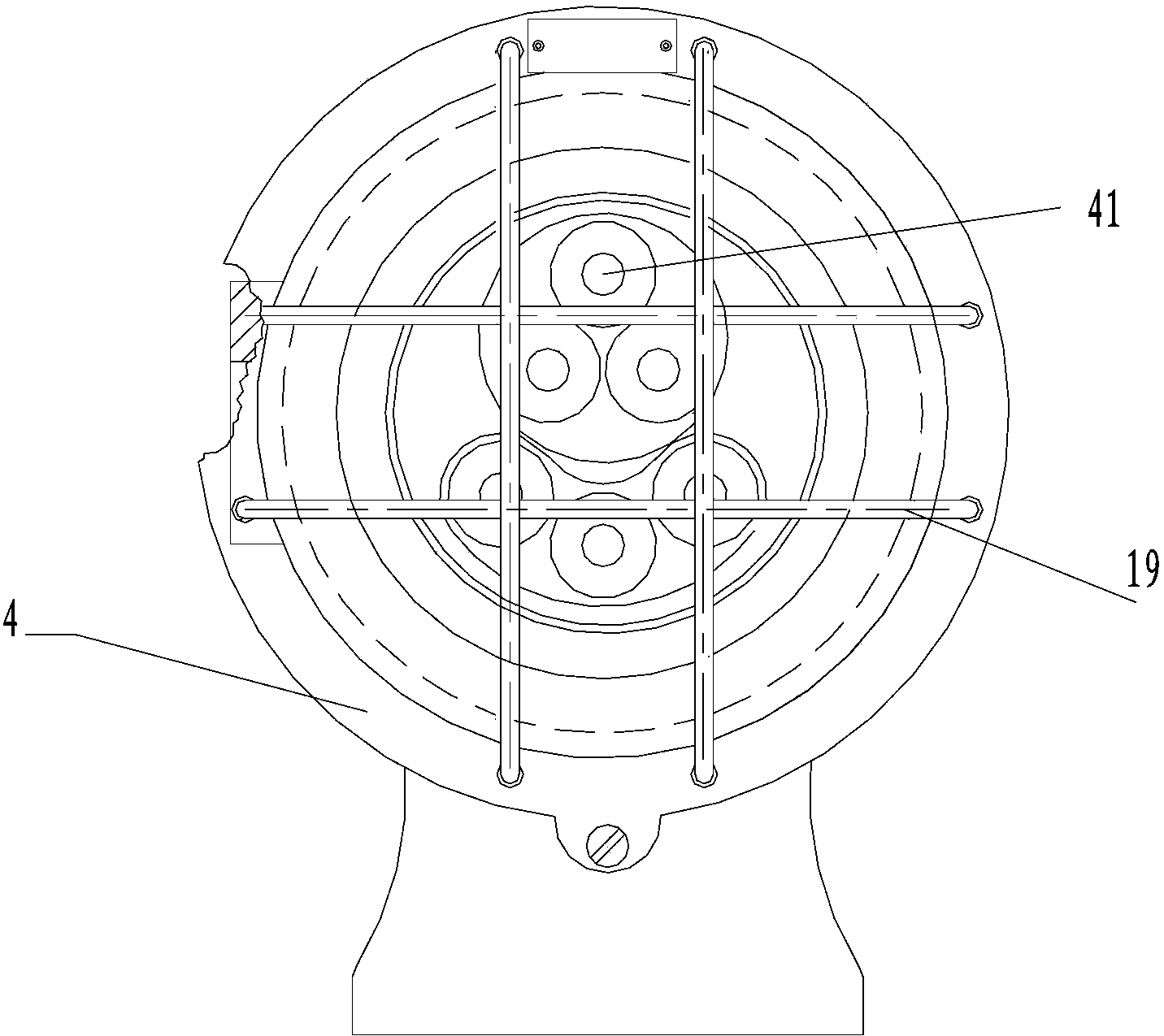

[0015] Such as figure 1 , 2 As shown, the LED mining explosion-proof locomotive light includes a front cover 4, a front cover protective net cover assembly, and a lamp tube 11. Threaded connection, the front cover 4 is a hollow ring shape, the front cover 4 center is provided with a front cover transparent net cover assembly 42, the front cover transparent net cover assembly 42, the lamp tube 11, and the rear cover 13 form an airtight cavity, the lamp tube 11 is provided with a first stepped surface 18 and a second stepped surface 17, and between the first stepped surface 18 and the second stepped surface 17 is a light so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com