Online repair construction method for steel-making converter by means of laser strengthening

A technology of laser strengthening and steelmaking converters, which is applied in the manufacture of converters, metal material coating processes, coatings, etc., can solve the problems of converters not working properly, poor wear resistance of repaired surfaces, gaps between support rings and furnace shells, etc. Achieve the effects of shortening the time to put into use again, prolonging the service life and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

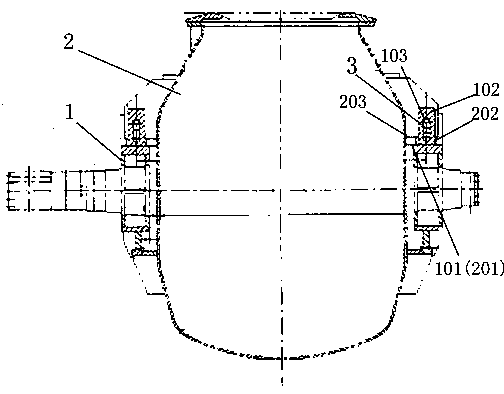

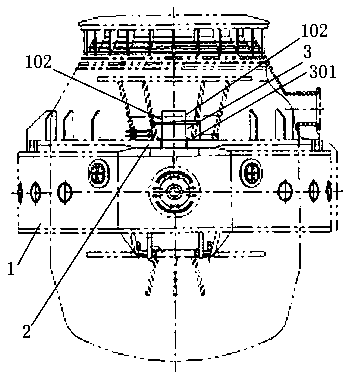

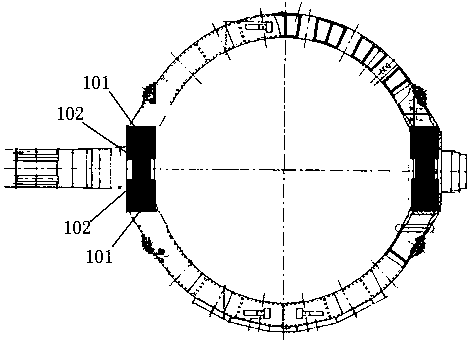

[0032] The laser intensified on-line repair construction method of a steelmaking converter includes the following steps:

[0033] Step 1. Build working platforms 7 above the driving side and driven side trunnion 6 of the converter support ring 1 close to the junction with the furnace shell 2, open the junction of the converter support ring 1 and the furnace shell 2 and jack up the furnace The shell sets the height.

[0034] Step 2. Manually polish and derust each surface to be repaired corresponding to the junction of the separated converter support ring 1 and the furnace shell 2, and carry out surface coloring flaw detection, take pictures for recording, and calculate the repair amount.

[0035] Step 3. According to the flaw detection results, select the working face that needs to be surfacing and use the gas shielded welding machine for surfacing welding, including the lower surface 201 around the square hole of the furnace skirt plate on the driving and driven sides, the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com