High-temperature-resistant MIM capacitor for microwave internal matching transistor and manufacturing method thereof

A manufacturing method and internal matching technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve the long-term stability of internal matching transistors, the disadvantage of reliable operation, the threat of long-term stable operation of MIM capacitors, and the impact on the yield of MOM capacitors, etc. problems, to achieve the effect of improving reliability and overall yield, excellent microwave characteristics, improving overall electrical performance and reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

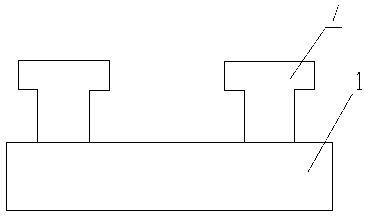

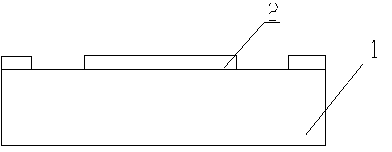

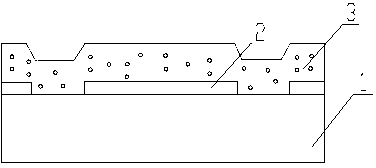

[0049] Such as Figure 14 As shown, a high-temperature-resistant MIM capacitor for microwave internally matched transistors includes a substrate 1 , a metal lower electrode 2 , an insulating dielectric layer 3 and a metal upper electrode 5 . The metal lower electrode 2 is fixed on the upper surface of the substrate 1, and the outer side of the metal lower electrode 2 is wrapped with an insulating medium layer 3. The insulating medium layer 3 has been subjected to high-temperature annealing treatment and has a penetrating insulating medium layer on it. The metal lower electrode lead-out hole 9 of the layer, the lower electrode lead-out electrode 4 fixedly connected with the metal lower electrode 2 is arranged in the metal lower electrode lead-out hole 9, and the metal upper electrode 5 is fixed on the insulating medium layer 3 on the upper surface.

[0050] Such as Figure 15 As shown, a high-temperature-resistant microwave internal matching transistor MIM capacitor, and Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com