Special drilling balancer for hydrology and water resources

A technology of water resources and balancer, applied in spring/shock absorber, spring/shock absorber design features, vibration suppression adjustment, etc., can solve the problem of inconvenient transportation of large drilling equipment for repeated use, short service life of balancer and poor balance effect Poor and other problems, to achieve the effect of alleviating tension, prolonging service life, avoiding maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

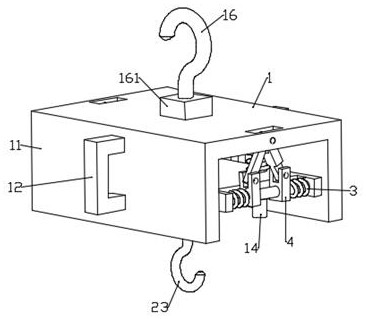

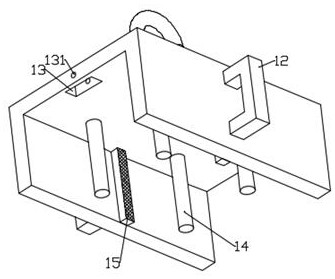

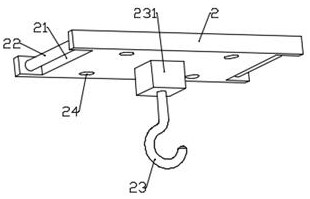

[0025] see Figure 1~5 , a special drilling balancer for hydrology and water resources, including a mounting frame 1 and a movable plate 2, a first hook 16 is installed on the top of the mounting frame 1, and a pair of side rails are symmetrically arranged on the front and rear sides of the bottom of the mounting frame 1 plate 11, the front and rear ends of the movable plate 2 are slidably connected with a pair of side plates 11, and a pair of through installation grooves 21 are symmetrically opened at the left and right ends of the movable plate 2, and a connection is fixedly installed in the installation groove 21. Shaft 22, a pair of symmetrically arranged sliders 4 are slidably installed at both ends of the connecting shaft 22, and the sliders 4 and the installation groove 21 are movably connected through the first extension spring 3, and the first extension spring 3 is movably installed on the The outer surface of the connecting shaft 22, the top of the slider 4 is provid...

Embodiment 2

[0029] see Figure 1~5 , a special drilling balancer for hydrology and water resources. On the basis of Embodiment 1, a pair of connection grooves 13 are symmetrically arranged at both ends of the installation frame 1, and a rotation installation hole 131 is arranged in the connection groove 13. An installation shaft 51 is installed in the rotation installation hole 131, and one end of the hinge bar 5 away from the hinge seat 41 is rotatably installed in the installation shaft 51, and the inner side of the side plate 11 is fixedly installed with a vertically arranged linear slide rail 15, so The front and rear ends of the movable plate 2 are slidably installed in a pair of linear slide rails 15, which improves the stability of the vertical sliding of the movable plate 2. The outer side of the side plate 11 is fixedly equipped with a handle 12, and the mounting frame 1 The top of the movable plate 2 is provided with a first mount 161, the first hook 16 is fixedly mounted on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com