An induction wafer baking system

A baking and pancake technology, applied in the field of automatic pancake baking equipment, can solve maintenance and safety issues, achieve the effects of preventing wear or disconnection, low cost, and avoiding maintenance and production accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The invention relates to an automatic pancake baking plant 1 for baking pancakes from liquid or pasty dough.

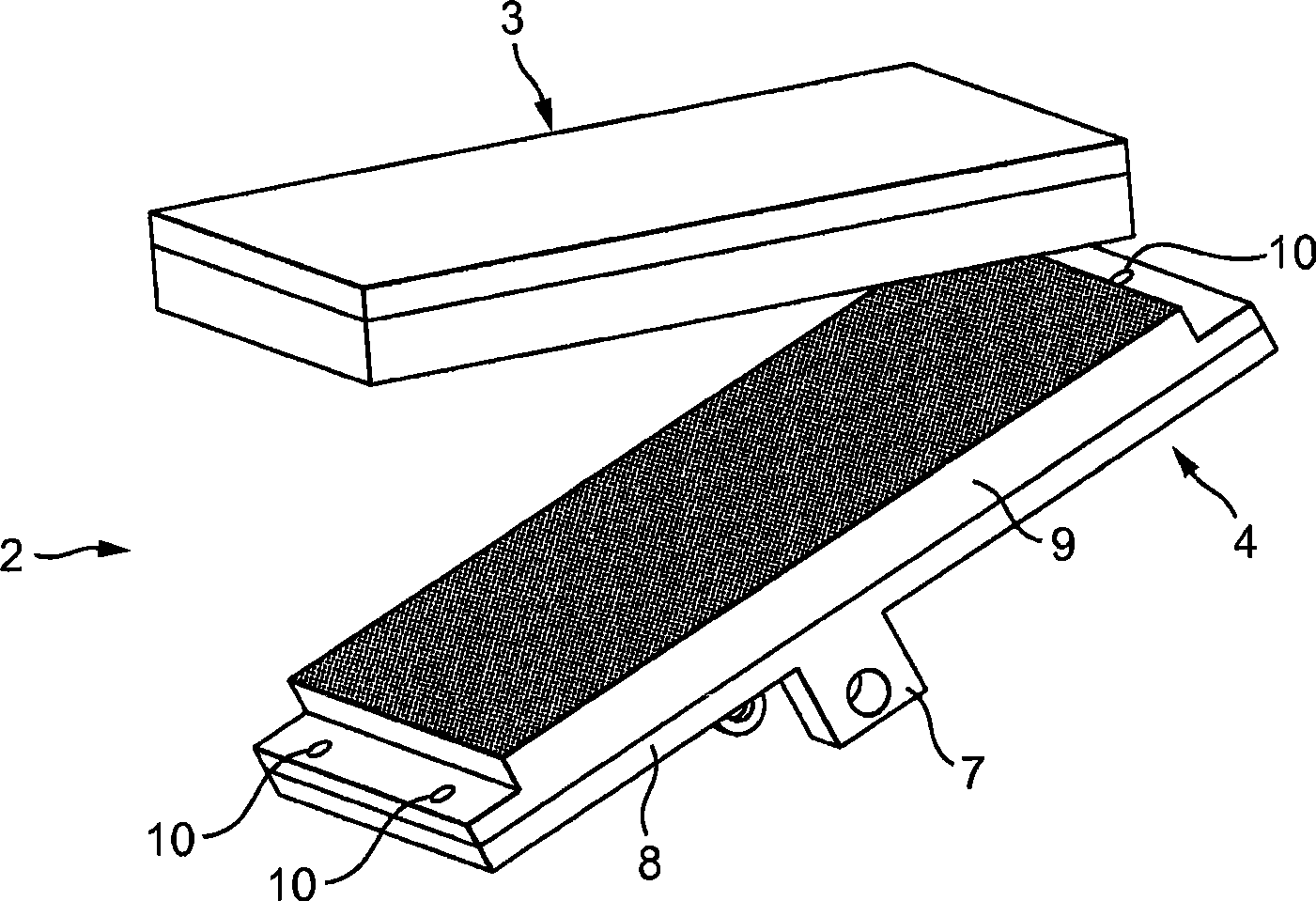

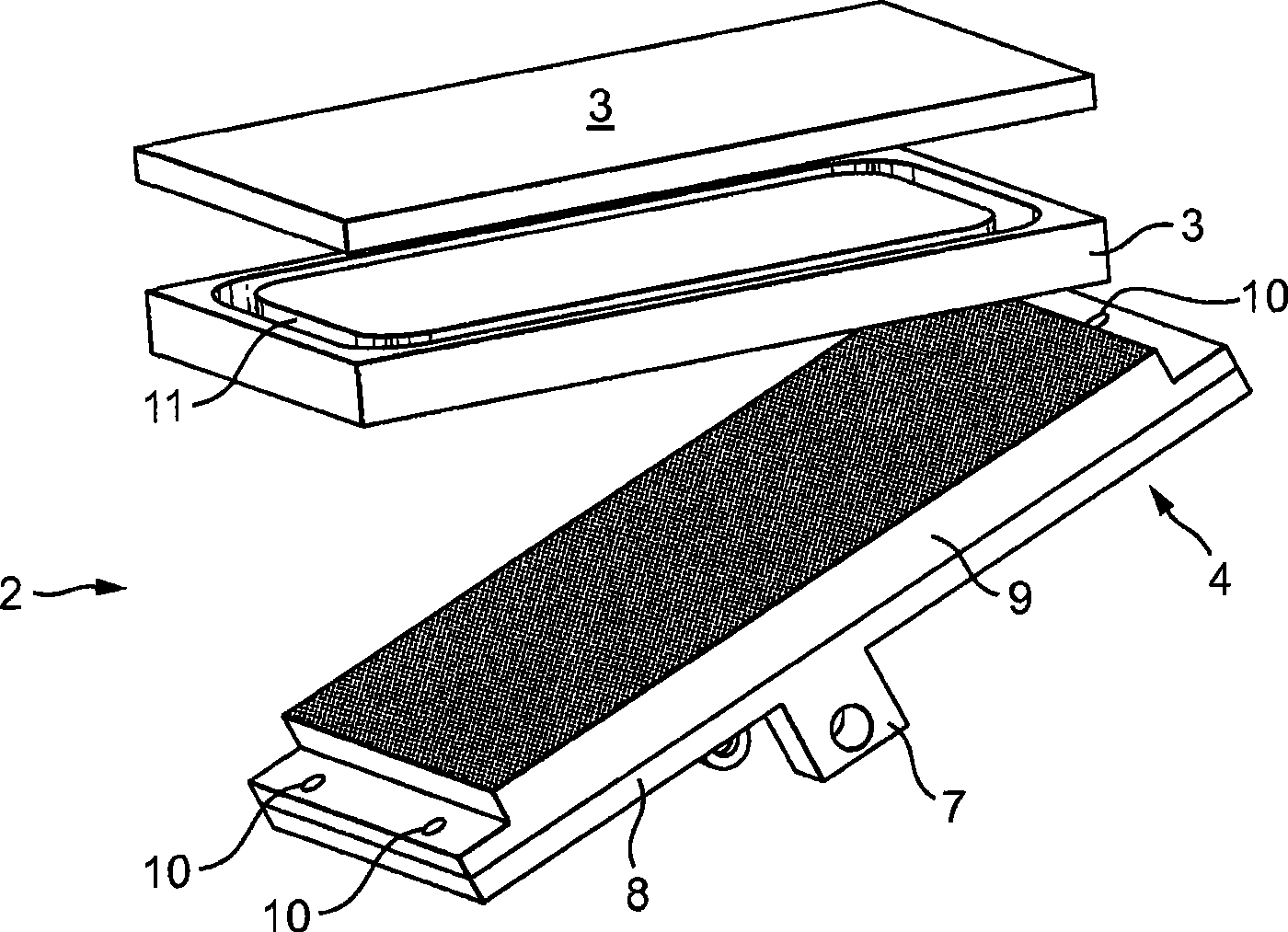

[0037] The apparatus comprises a plurality of baking molds 2, each baking mold has a pair of upper baking plates 3 and lower baking plates 4 all made of cast iron, the outer surfaces of the baking plates (i.e. not contacting the pancake batter during cooking) contact surfaces) are covered with insulating material such as Glastherm 68, an asbestos-free, powder-free hardboard enclosed and sealed within an outer steel shell.

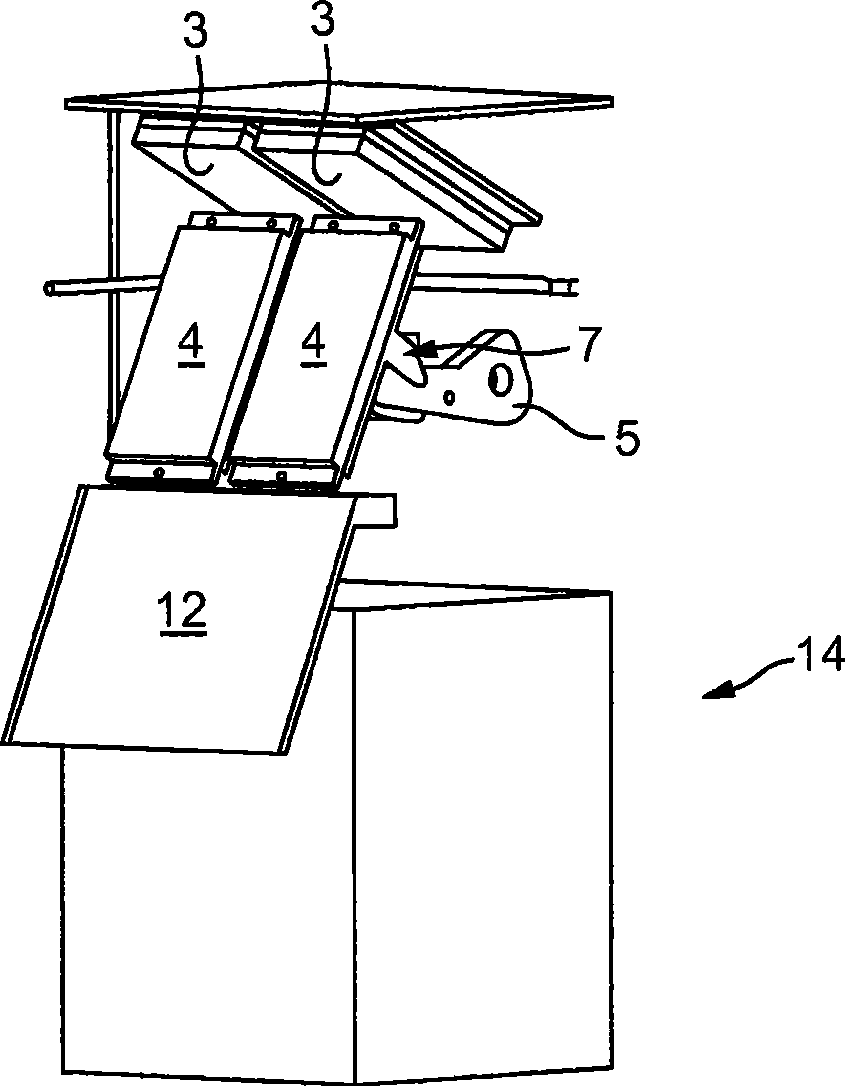

[0038] figure 1 with 2 A baking mold 2 according to the invention is shown. The upper baking plate 3 of the baking mold 2 is fixed on the equipment frame, while the lower baking plate 4 is movable relative to the upper baking plate 3 . In order to realize the movement of the lower baking plate 4 relative to the upper baking plate 3, a image 3 with 4 The moving device shown in , so that the baking mold 2 can be moved from the closed con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com