Jet stirrer

An agitator and jet technology, which is used in fluid mixers, mixers with rotary stirring devices, chemical instruments and methods, etc., to avoid frequent maintenance and facilitate installation and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

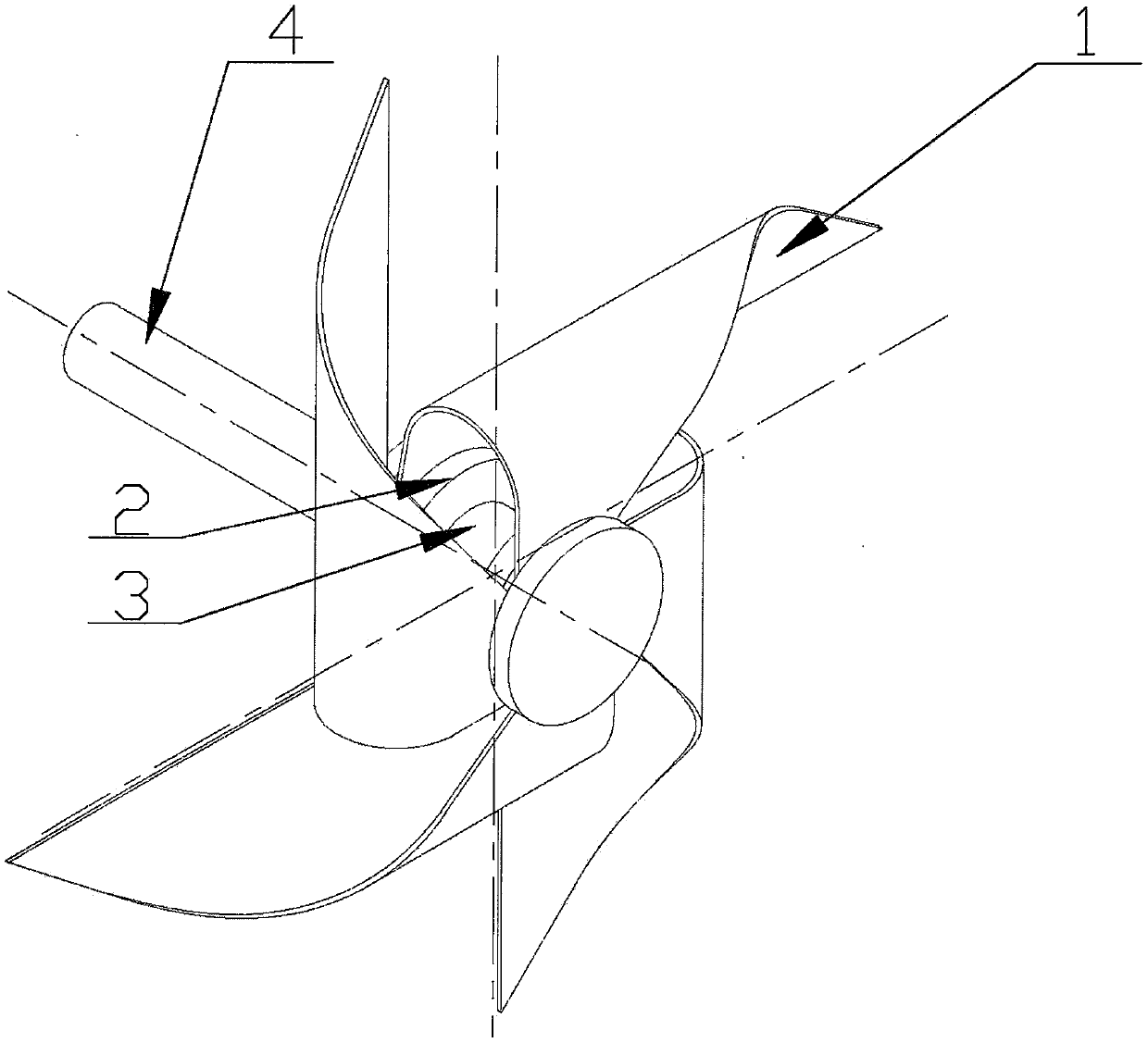

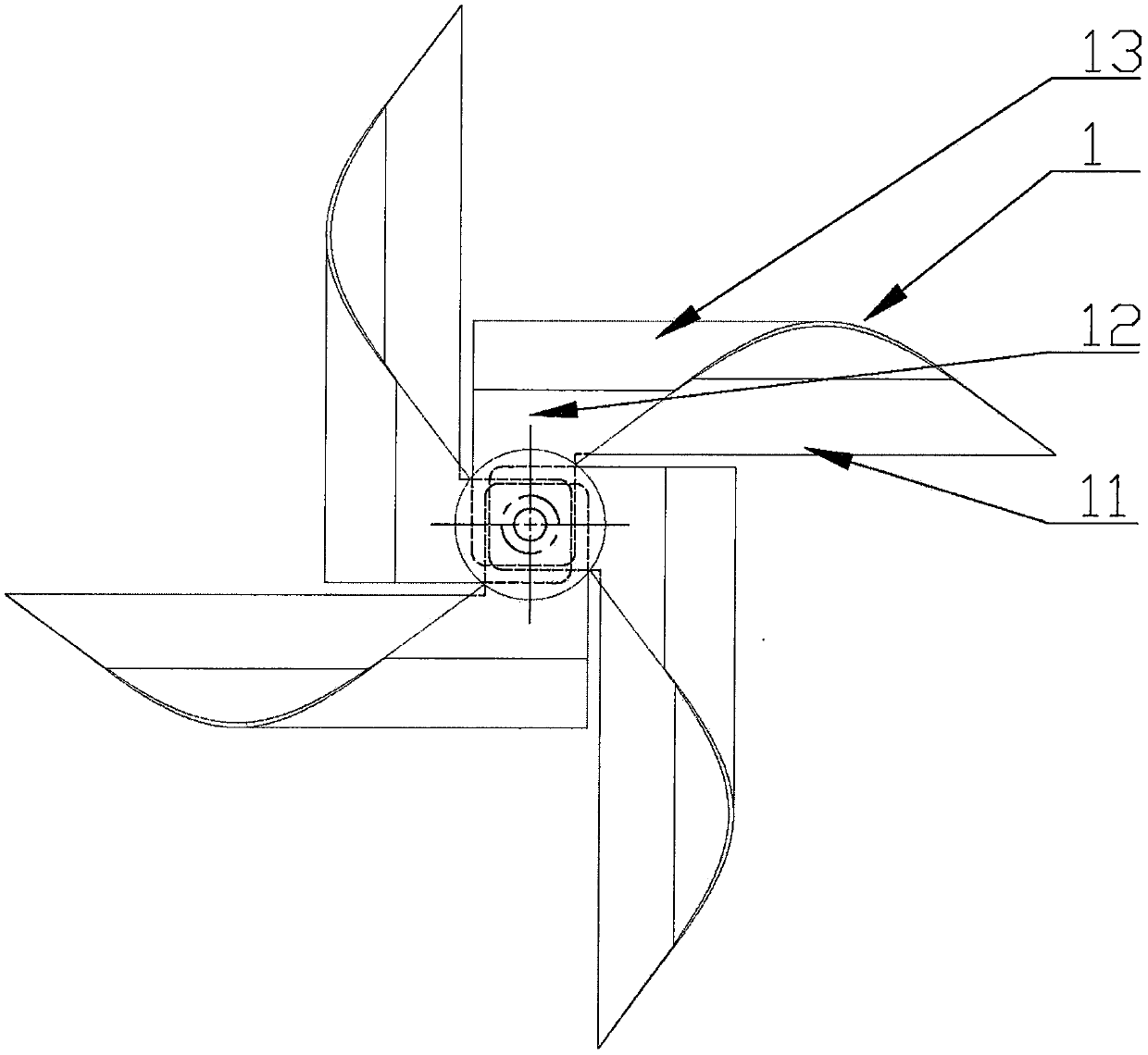

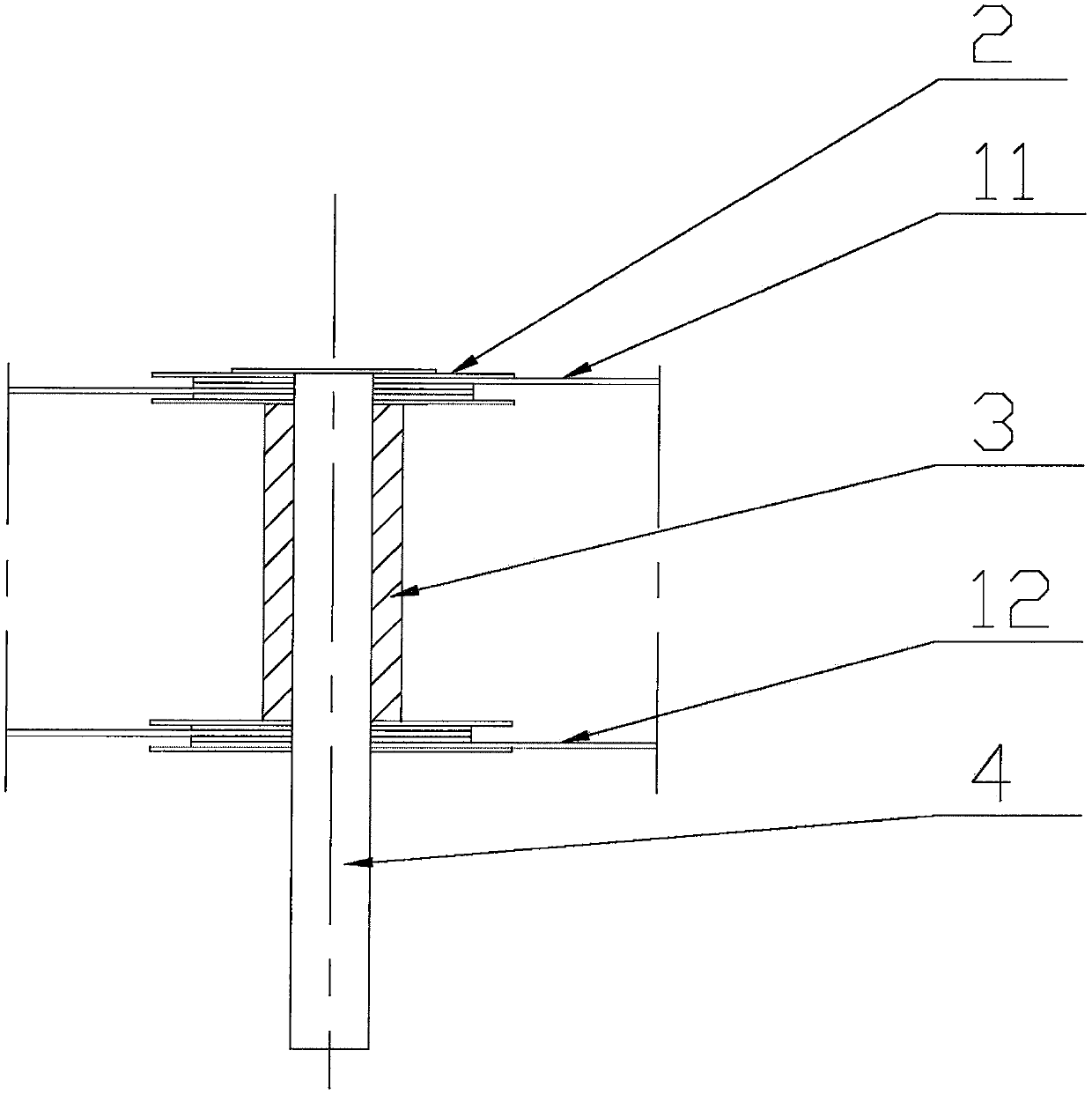

[0012] As an embodiment of the jet agitator, the jet agitator is located above the jet flow direction of the jet pipe 5 in the kettle, and is installed on the kettle wall 6 through the pin shaft 4 . The agitator includes an impeller 1, a splint 2 and a spacer 3. The impeller 1 includes a flat plate 11, a flat plate 12 and a curved plate 13 connecting them through one side. When the impeller 1 is installed on the pin shaft 4, the flat plate 11 at one end consists of two upper and lower The splint 2 is clamped and fixed, and the flat plate 12 at the other end is also clamped and fixed by the upper and lower two splints 2. The distance between the two ends is opened by the spacer 3. Four impellers 1 are used, and the outer edge is 45 degrees oblique, that is, The outer edge of the flat plate 11 and the flat plate 12 is 45 degrees to the radial direction, the surface where the outer edge of the curved panel 13 is located is 45 degrees to the pin axis, and the three sections of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com