Pipeline section type automatic erasing moisture analyzer

An automatic erasing, pipe-segment technology, applied in the direction of analyzing materials, instruments, material inspection products, etc., can solve the problems of high manufacturing cost, micro-motor damage, inconvenient installation, etc., and achieves low manufacturing cost, reliable operation, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

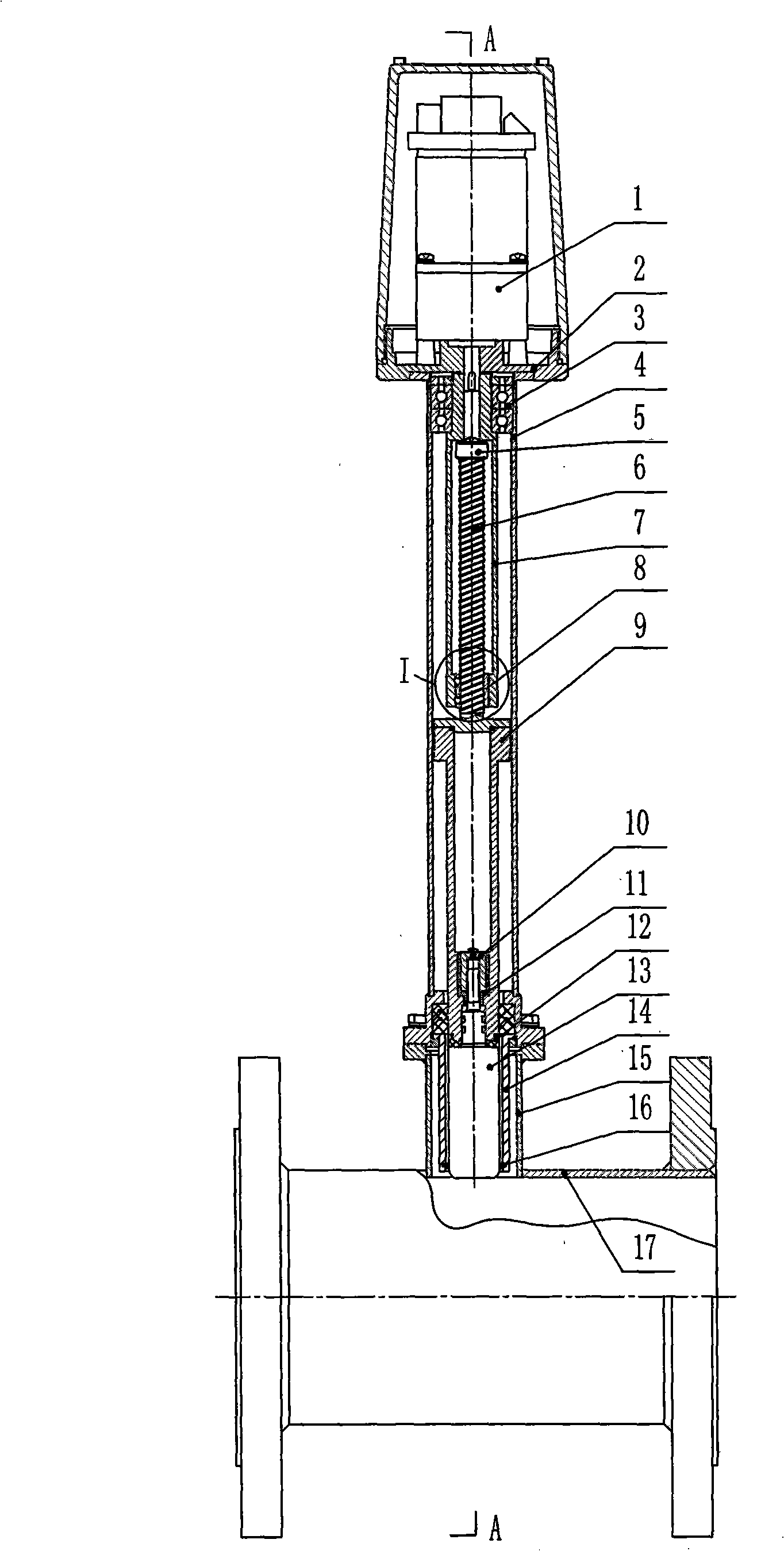

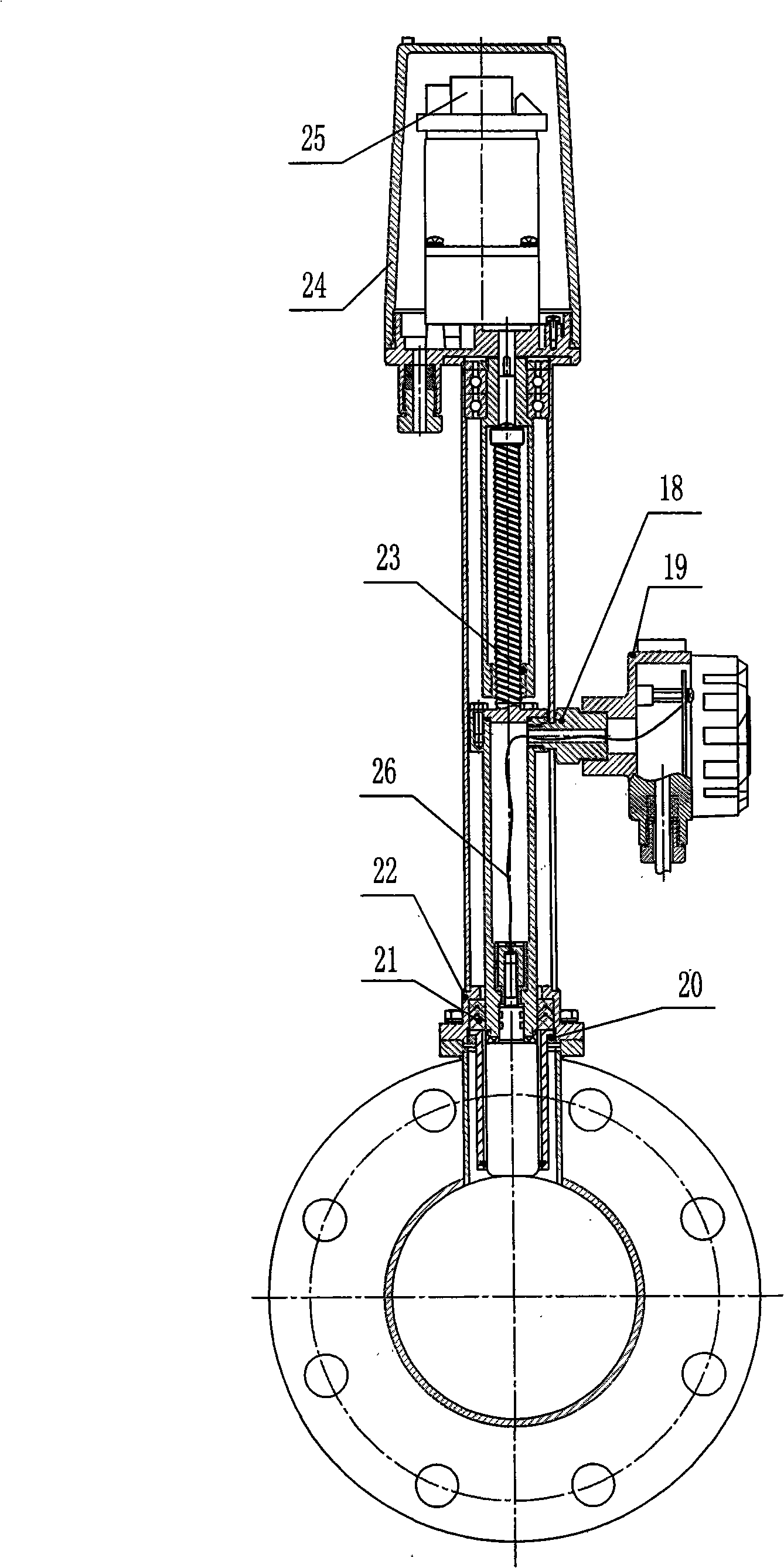

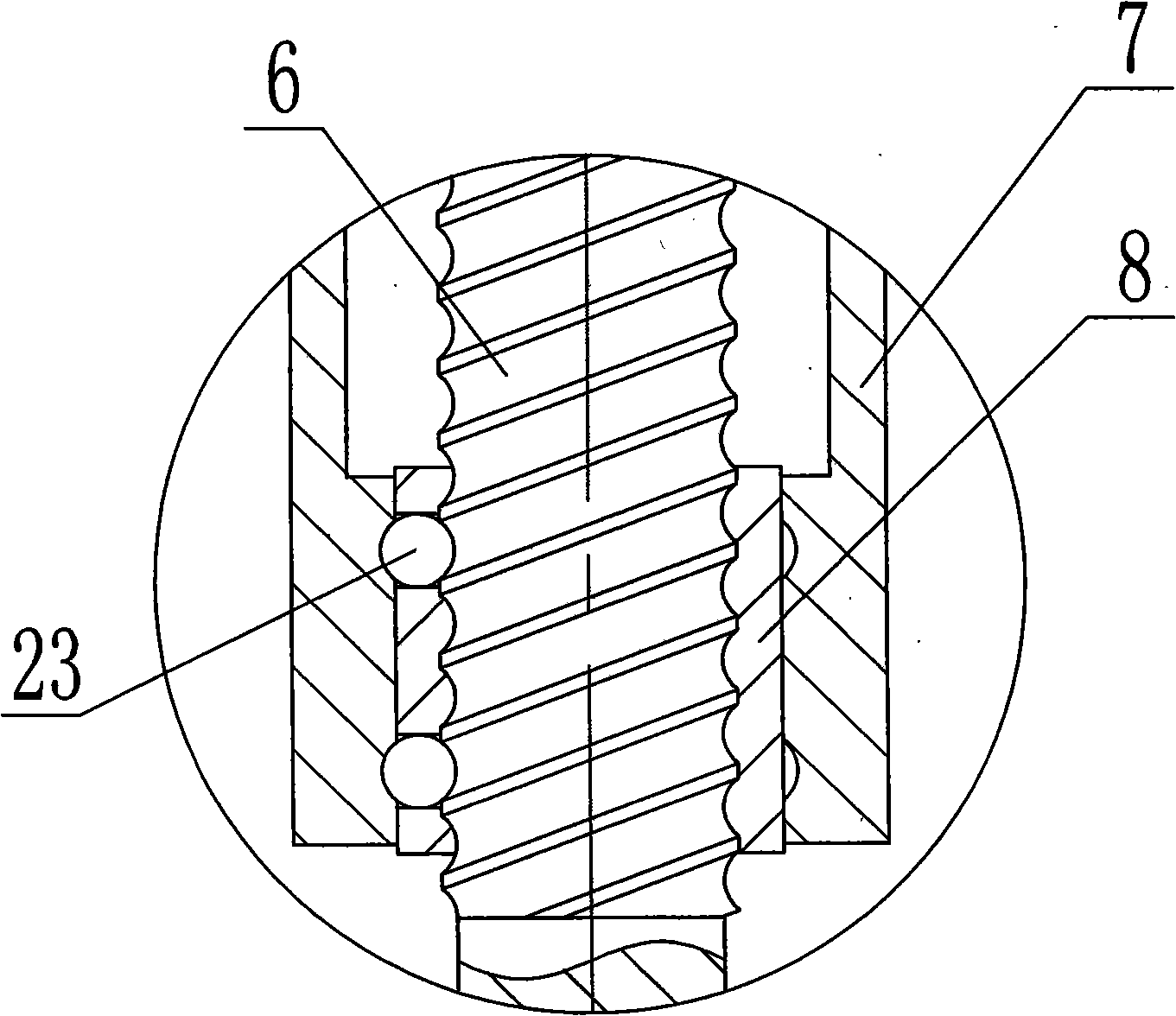

[0012] As shown in the figure, the present invention has a support sleeve 4, a support disc 2 is fixedly connected to the upper end of the support sleeve 4, a micro motor 1 and a control unit 25 are installed on the support disc 2, and a micro motor 1 and the control unit 25 A motor shield 24 is provided on the outside, and the motor shield 24 is screwed onto the support plate 2, and the micro-motor shaft is inserted vertically downward into the support sleeve 4. A reciprocating mechanism is arranged in the supporting sleeve 4, and the reciprocating mechanism is fixed in the supporting sleeve 4 by two sets of bearings 3 and is connected with the micro-motor shaft by a key. The inner nut 8, screw 6 and ball 23 are formed by the limit adjustment sleeve 5 fixed on the upper end of the screw 6 by screws and the hollow joint body 9 connected to the lower end of the screw 6 by bolts. The screw nut 8 is set In the lower port of the nut jacket 7 and with the nut jacket 7 clearance fit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com