Preparation method of rock mass sample

A technology for rock mass and test piece, applied in the field of rock mass sample preparation, can solve the problems of complicated operation, difficult preparation, low efficiency, etc., and achieve the effects of simple equipment, wide application and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

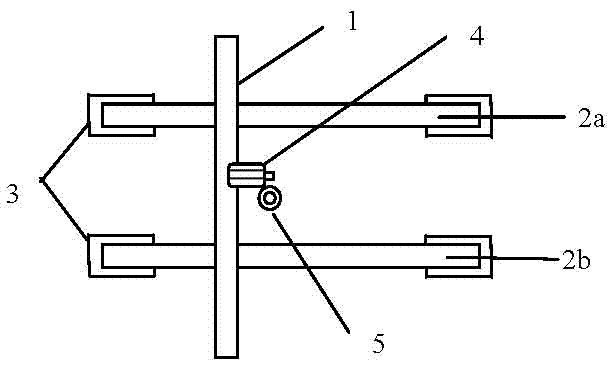

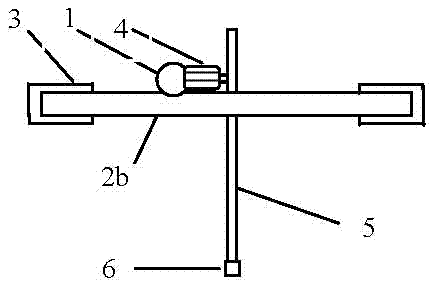

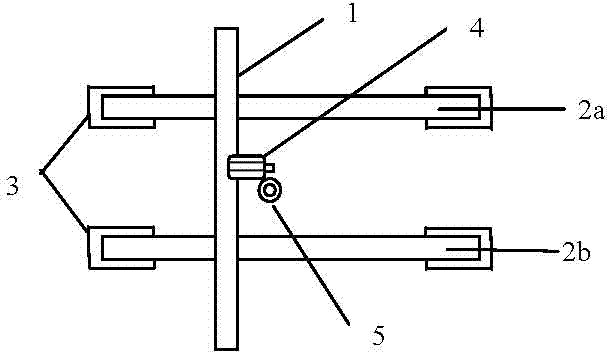

[0008] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0009] In concrete implementation, the present invention is realized by the following steps:

[0010] Step 1: Use a hammer and a steel drill to remove the rocks loosened by the cannon at the test point;

[0011] Step 2: Find a relatively flat place on the left and right walls of the cave or the top and bottom of the cave next to the test point, or manually chisel it, erect the first support beam 2a, and install wires on both ends of the first support beam. The rod or hydraulic device 3 is pushed against the wall of the cave, and the lead screw or hydraulic device is adjusted to make it tight to ensure firmness;

[0012] Step 3: Based on the length of the first support beam, select the second support beam 2b so that it is at the same height as the first support beam, install screw or hydraulic device on both ends of the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com