Patents

Literature

77results about How to "Solve the problem of dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

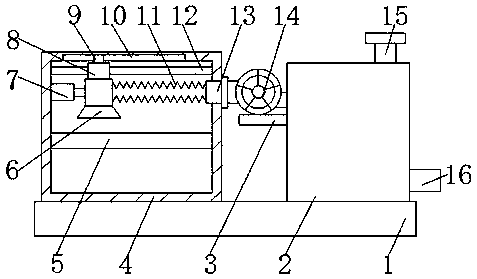

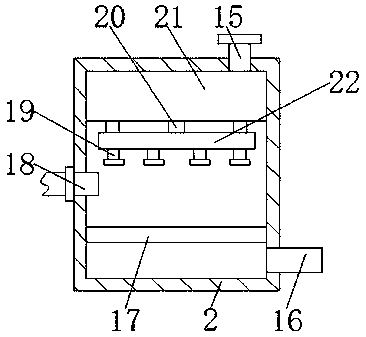

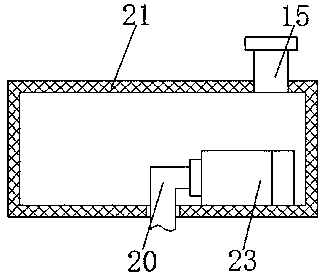

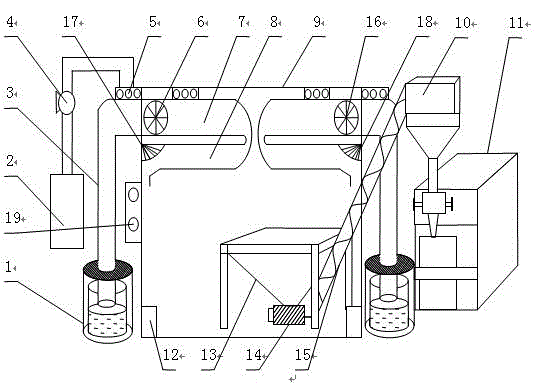

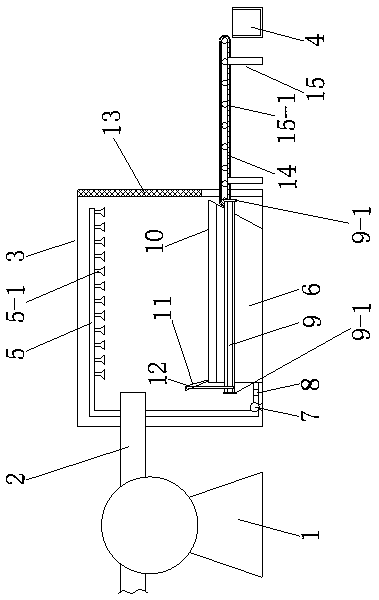

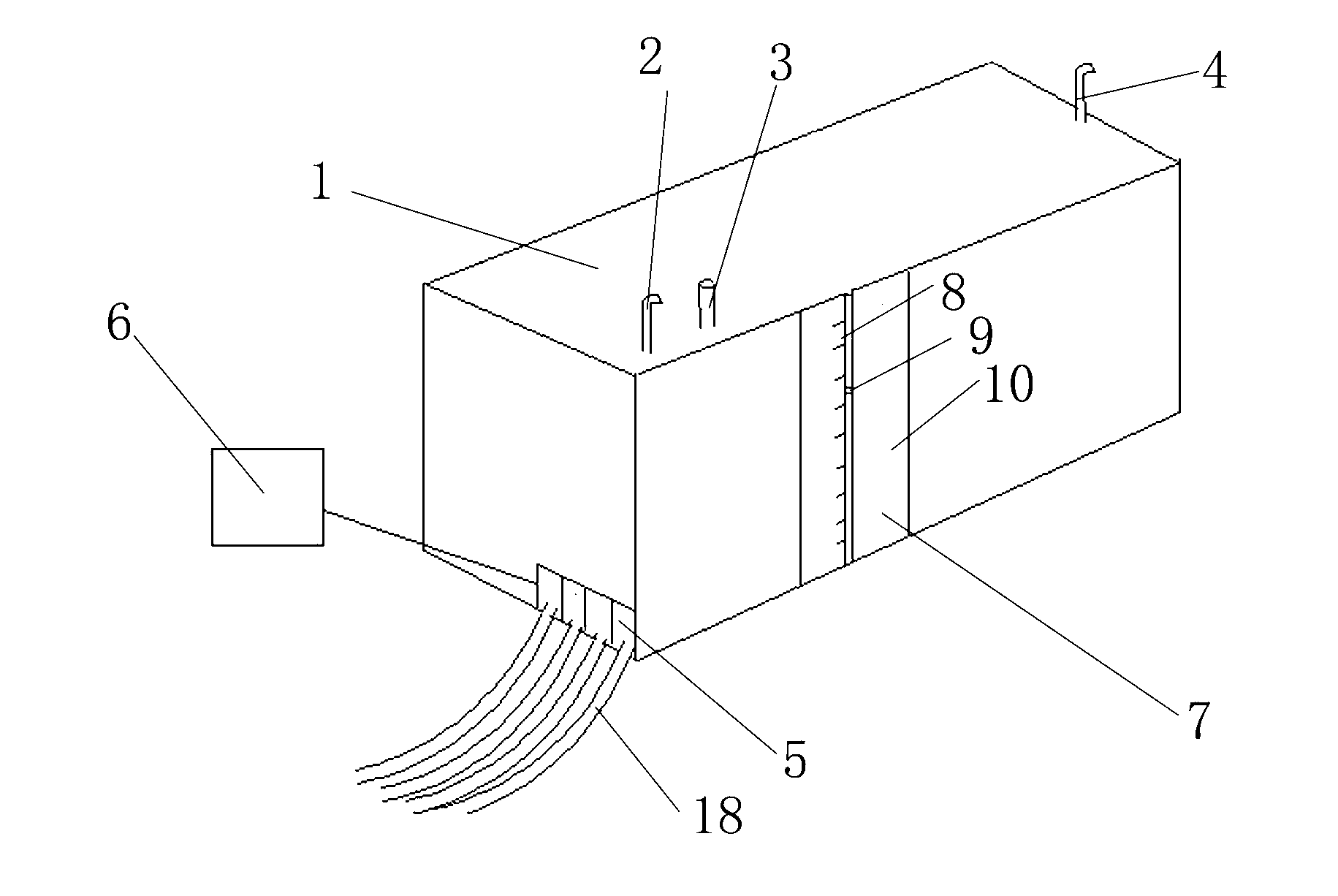

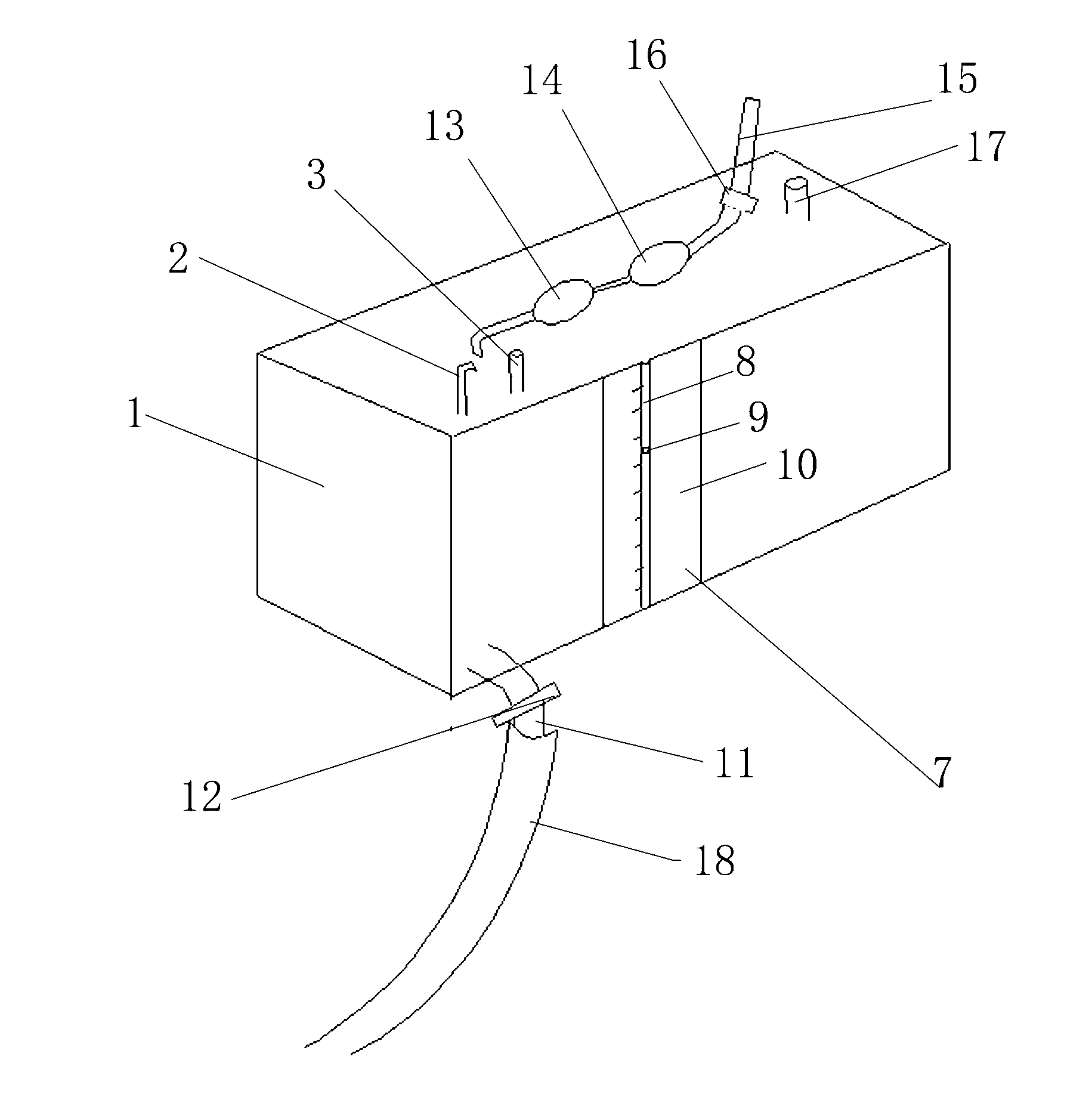

Embedded network intelligent information processing server

ActiveCN109308102ASolve the cooling problemSolve the problem of dust removalCombination devicesDirt cleaningInformation processingFiltration

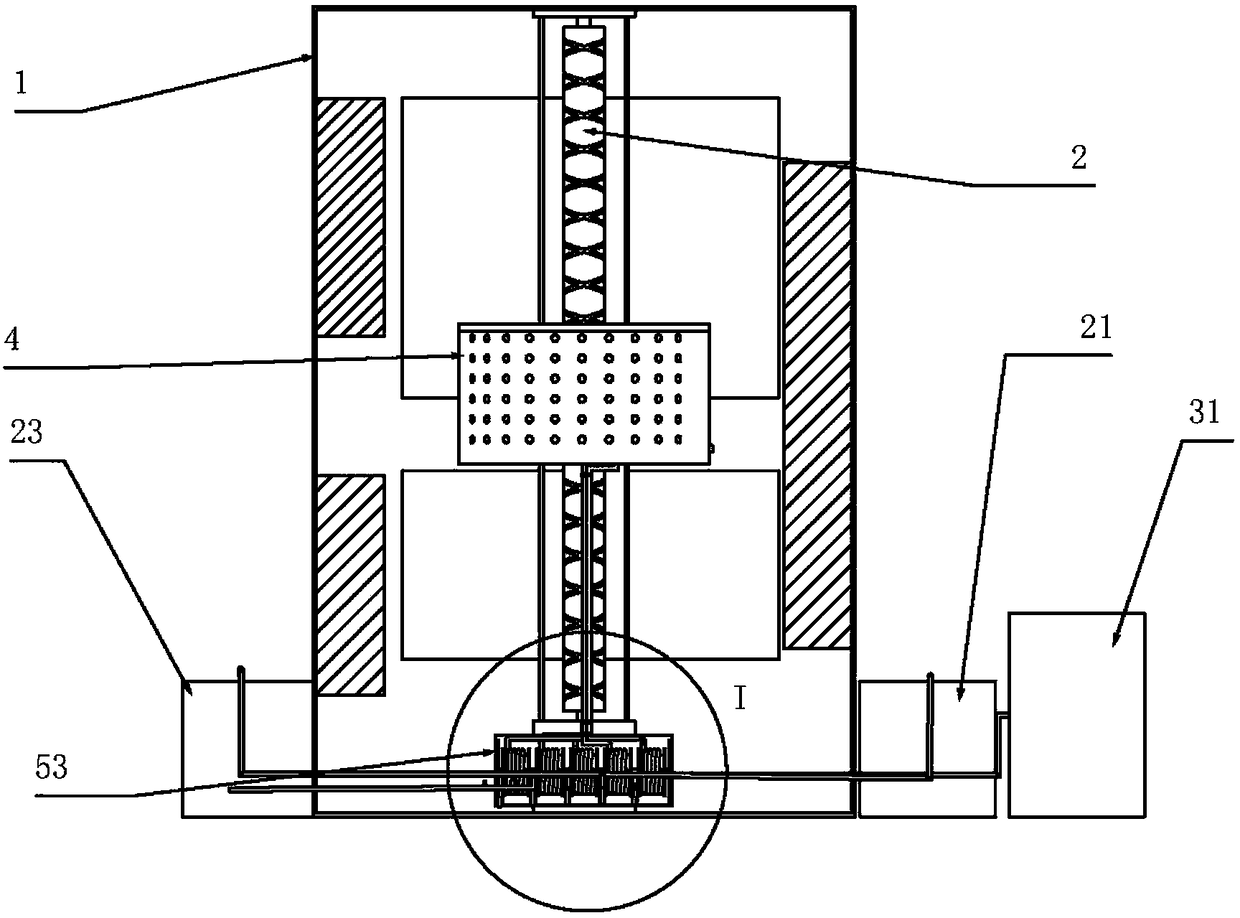

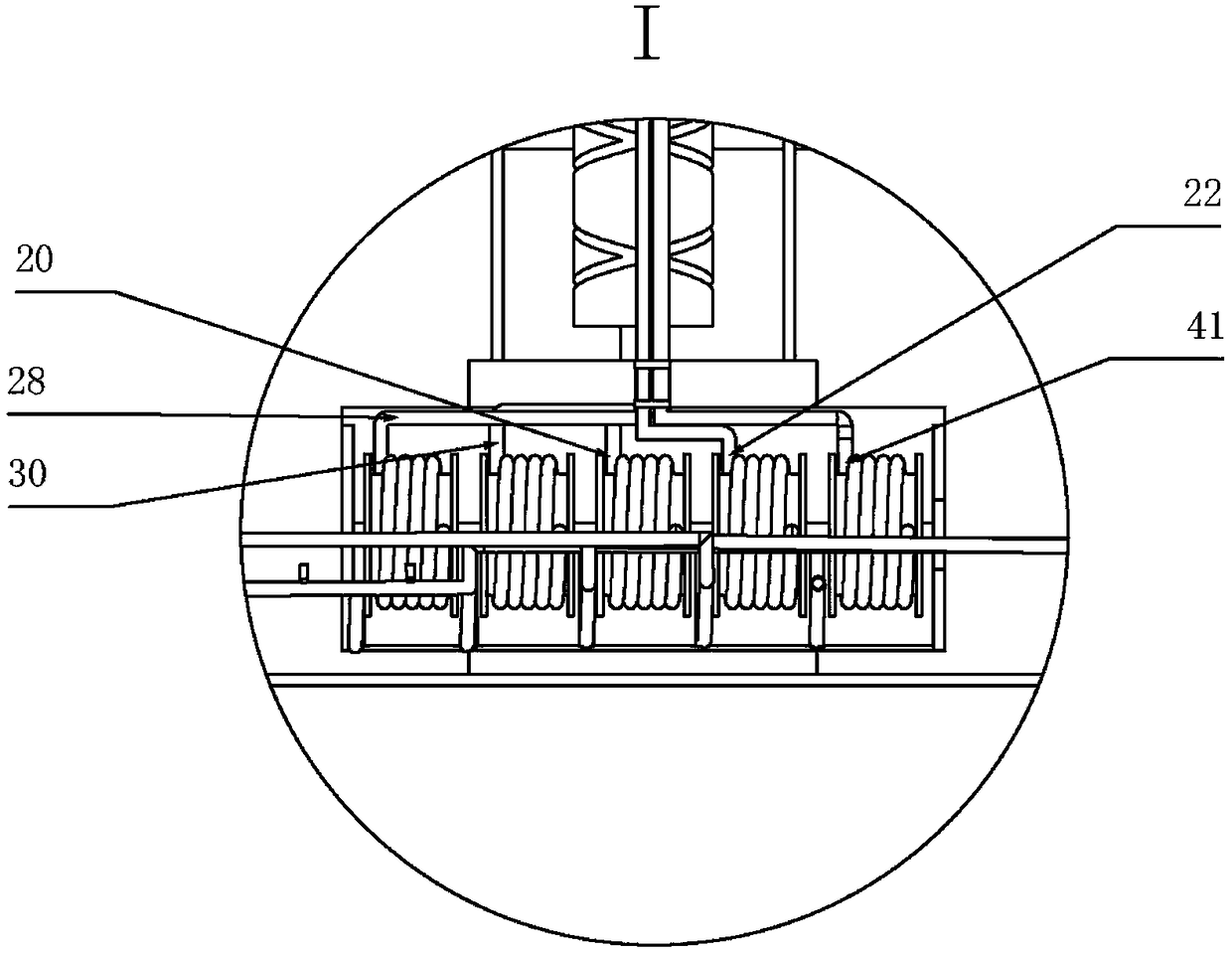

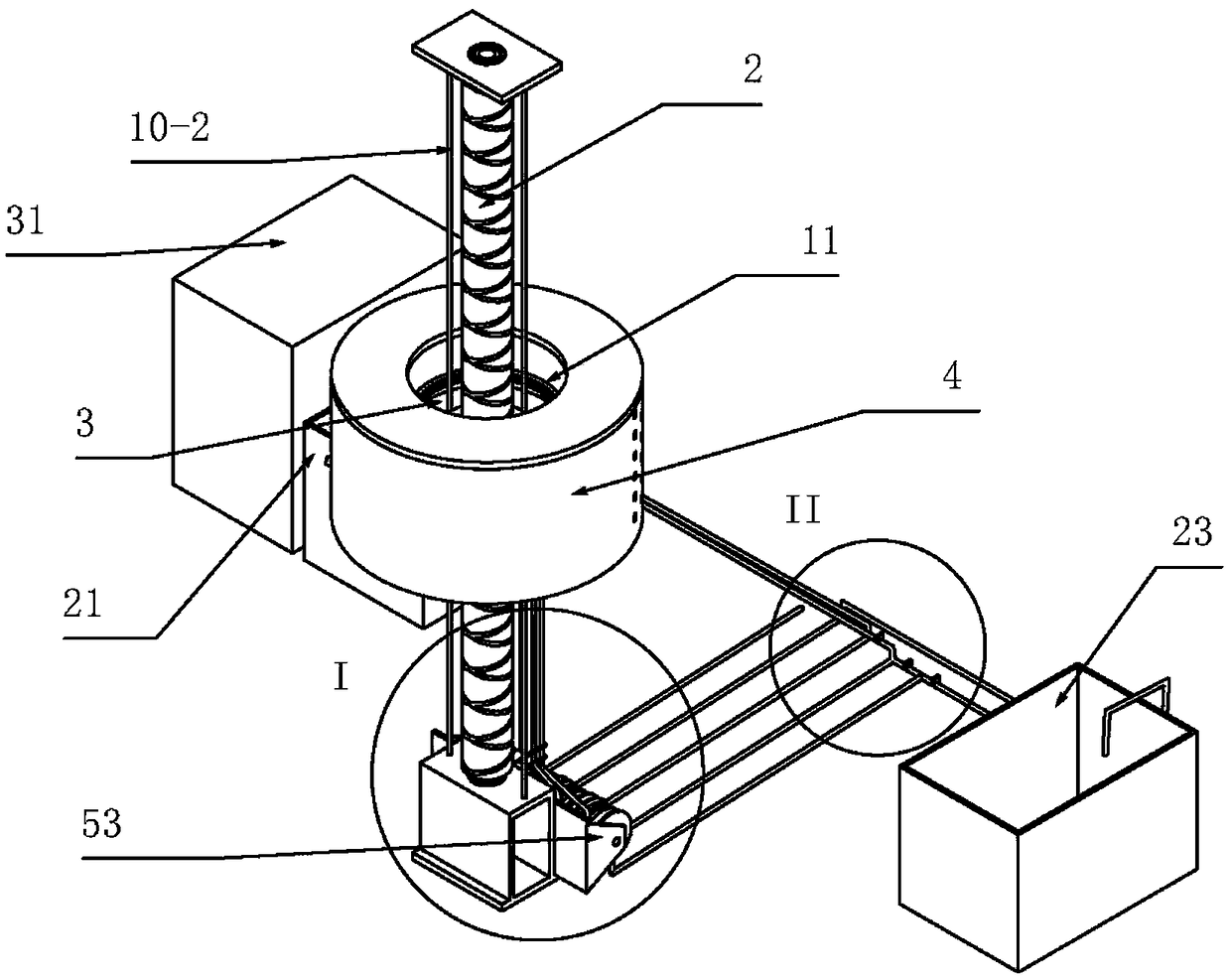

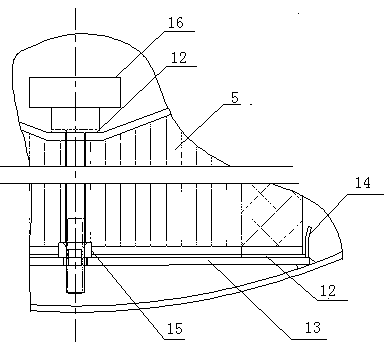

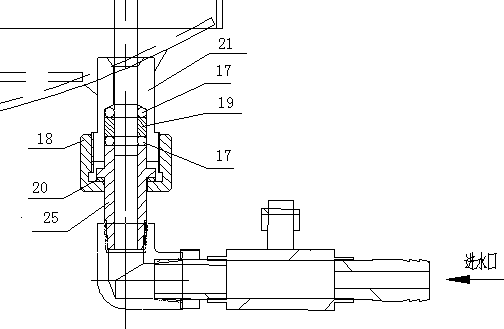

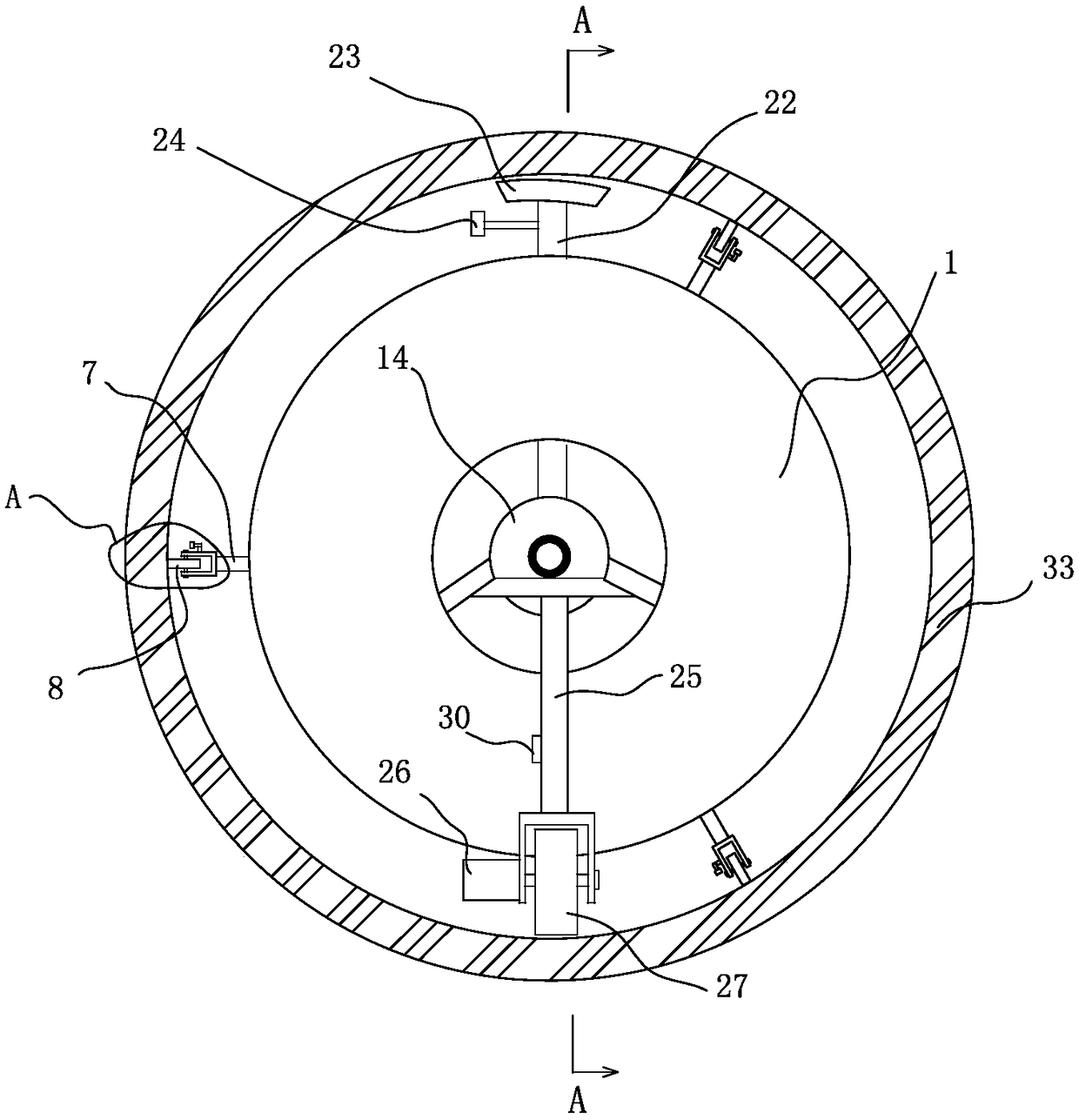

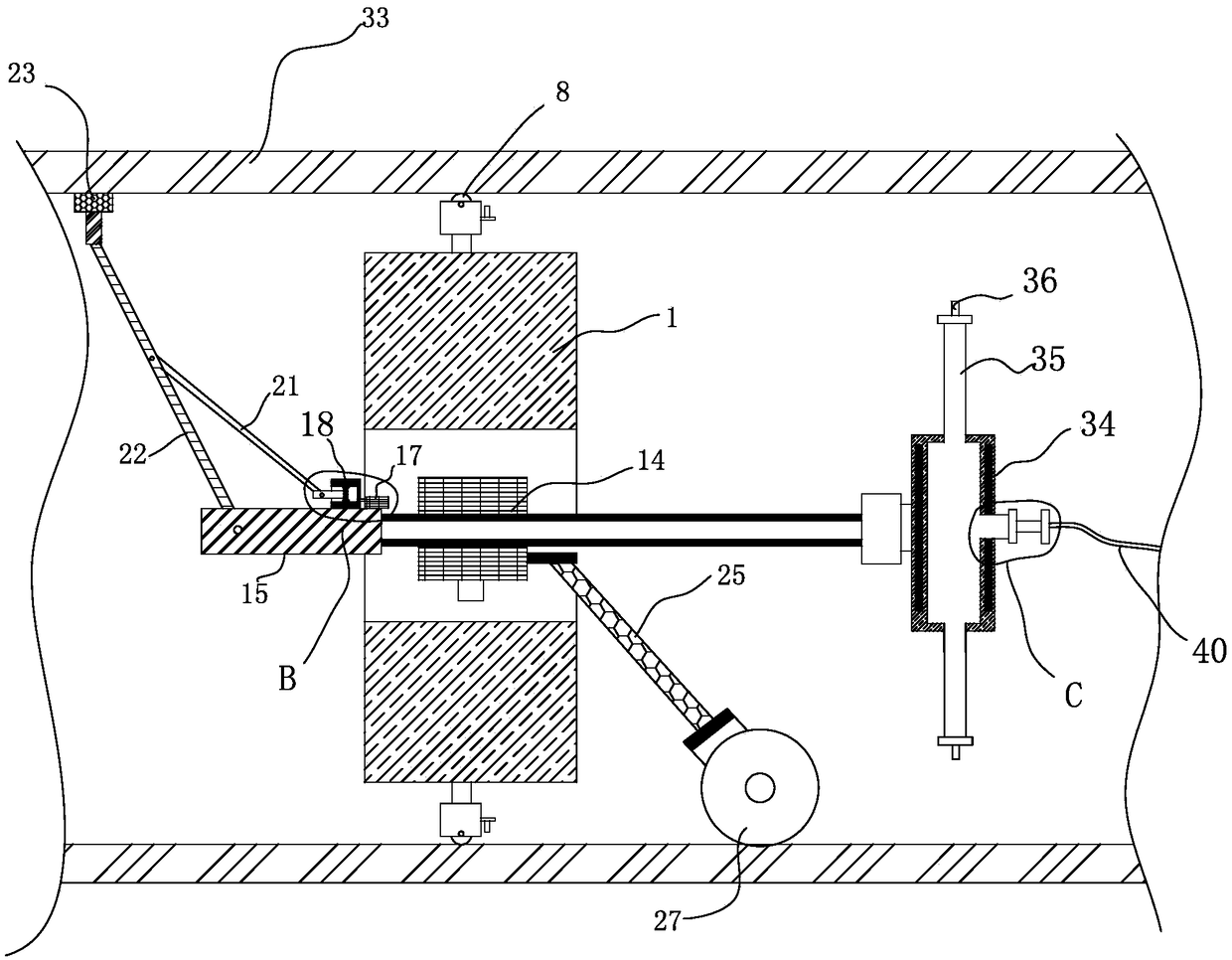

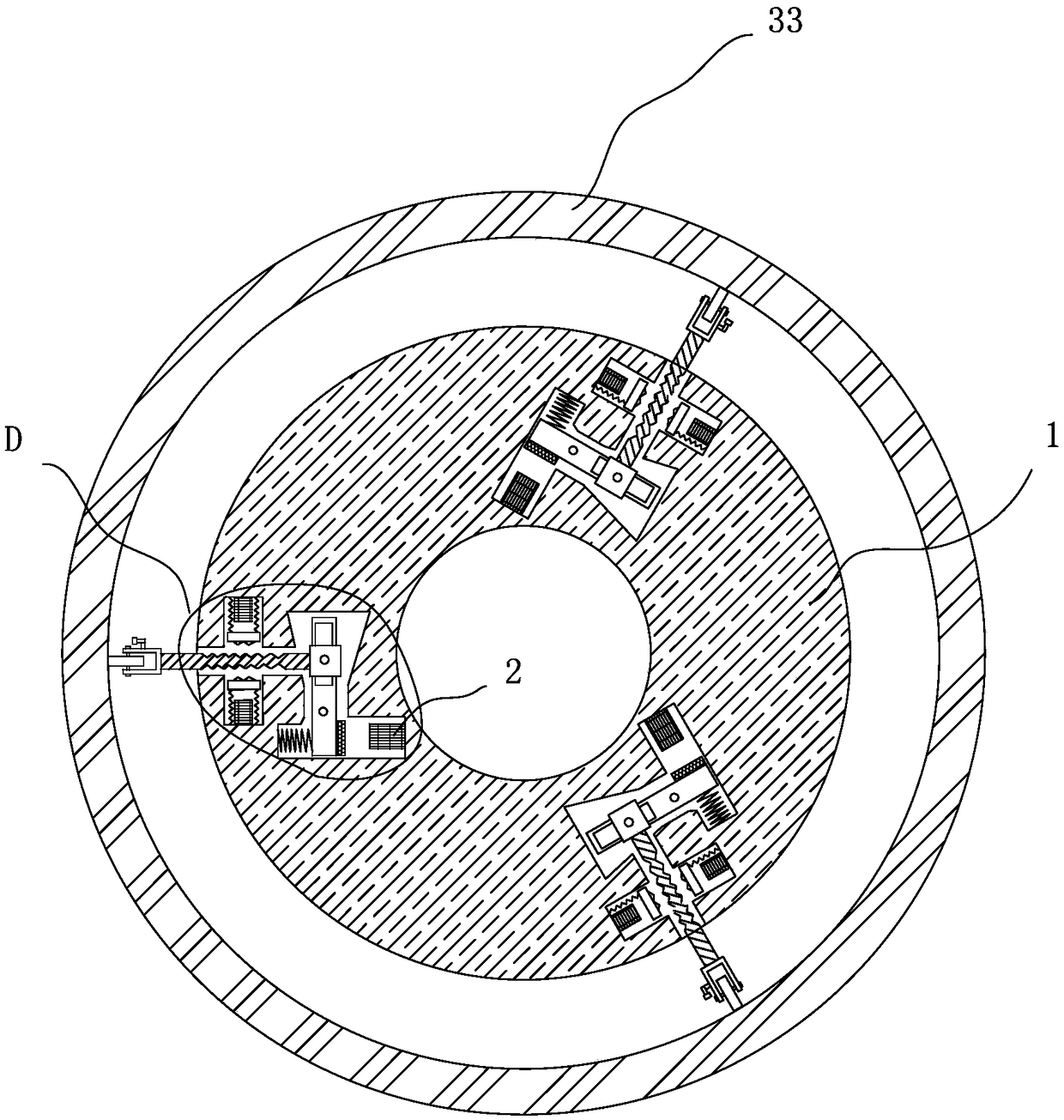

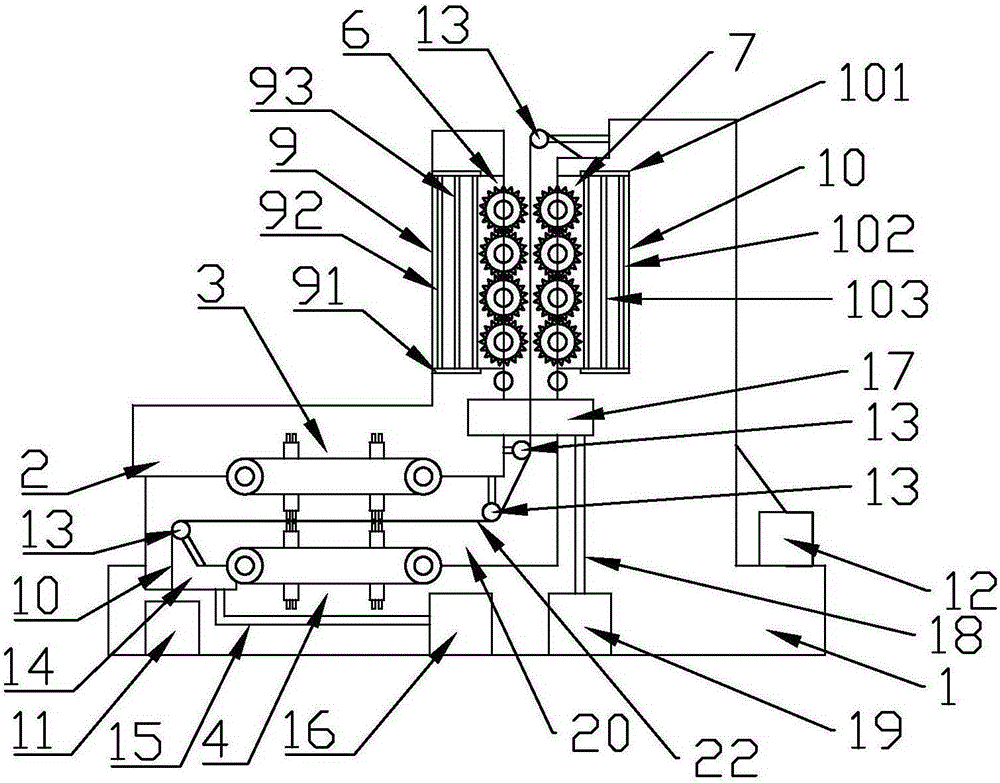

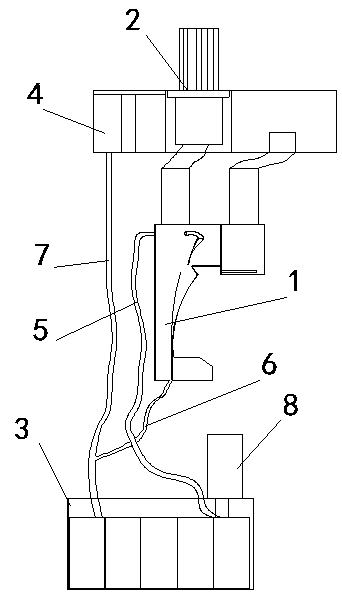

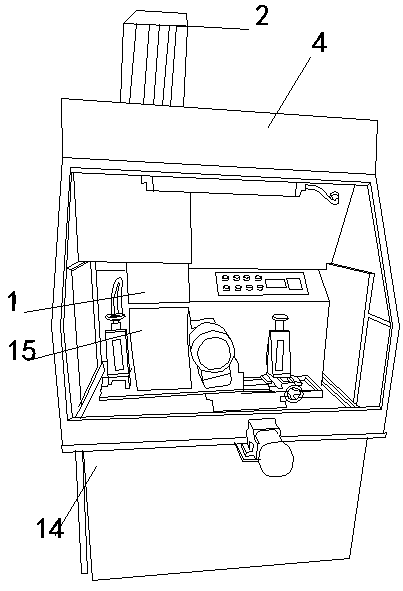

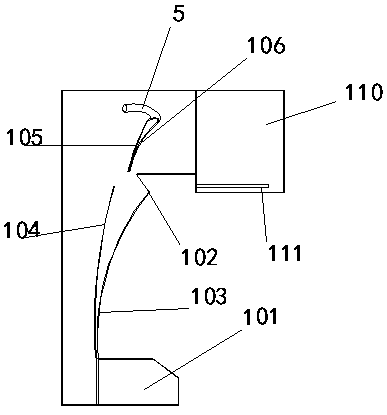

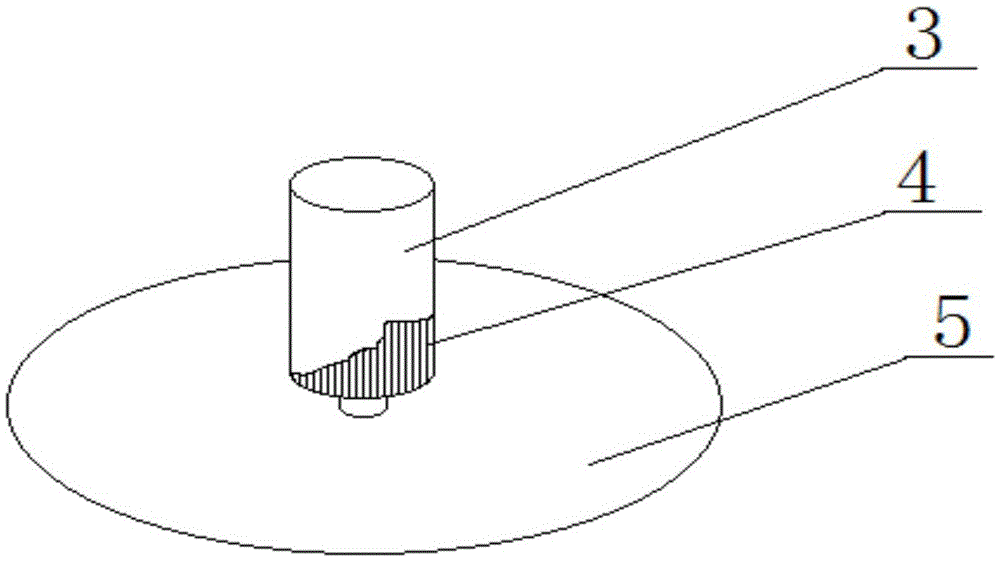

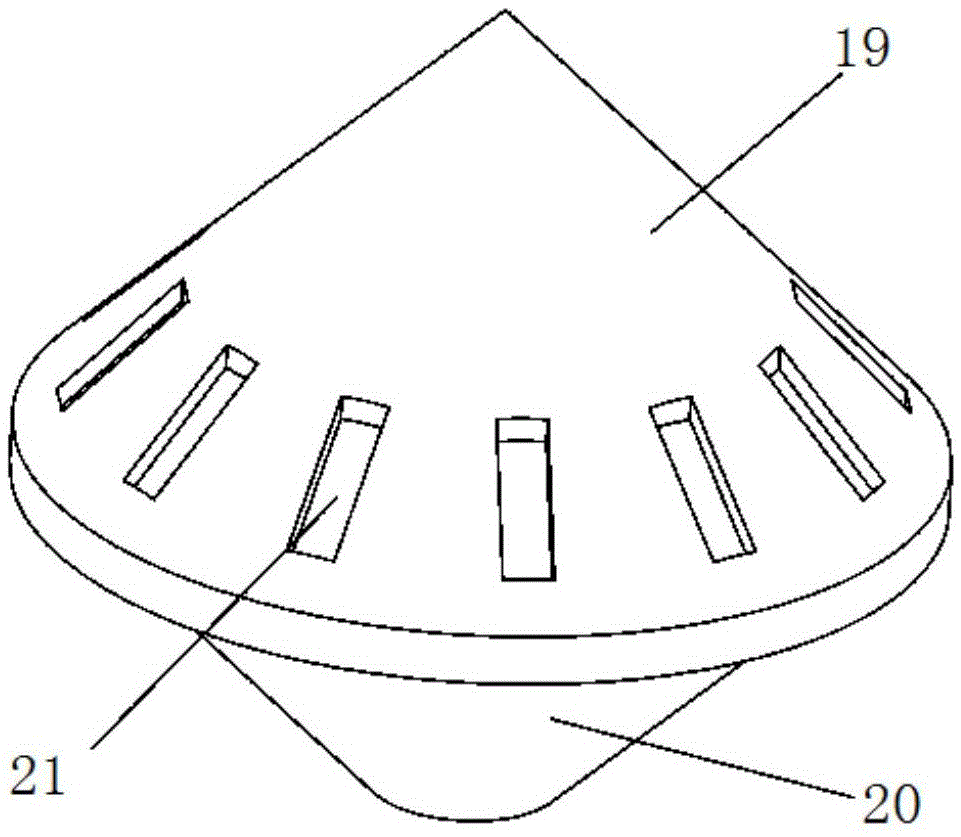

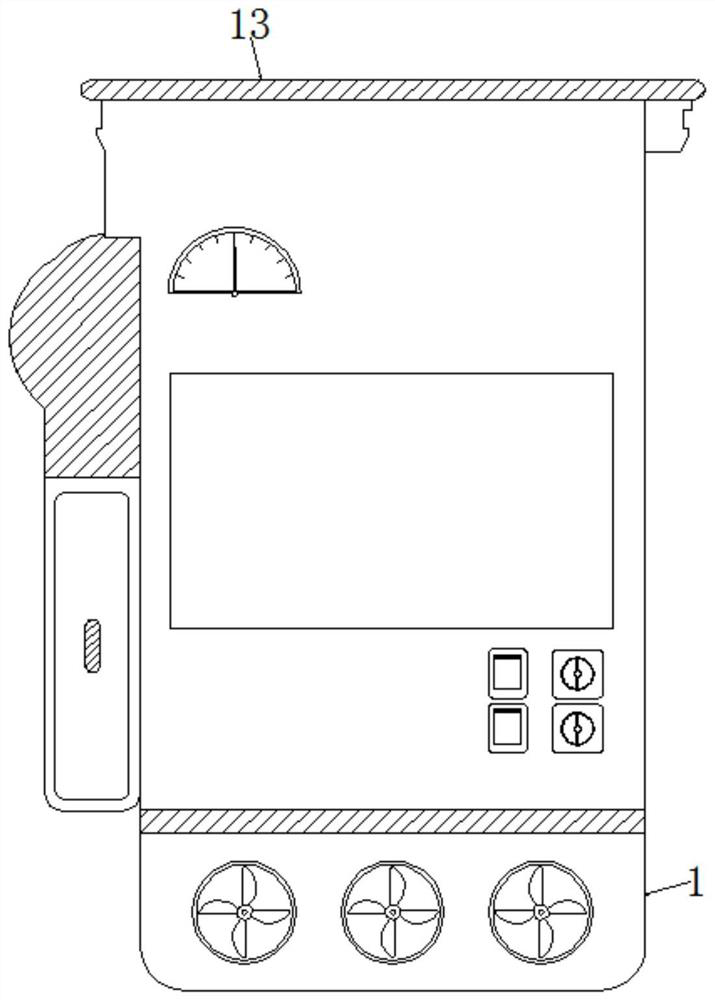

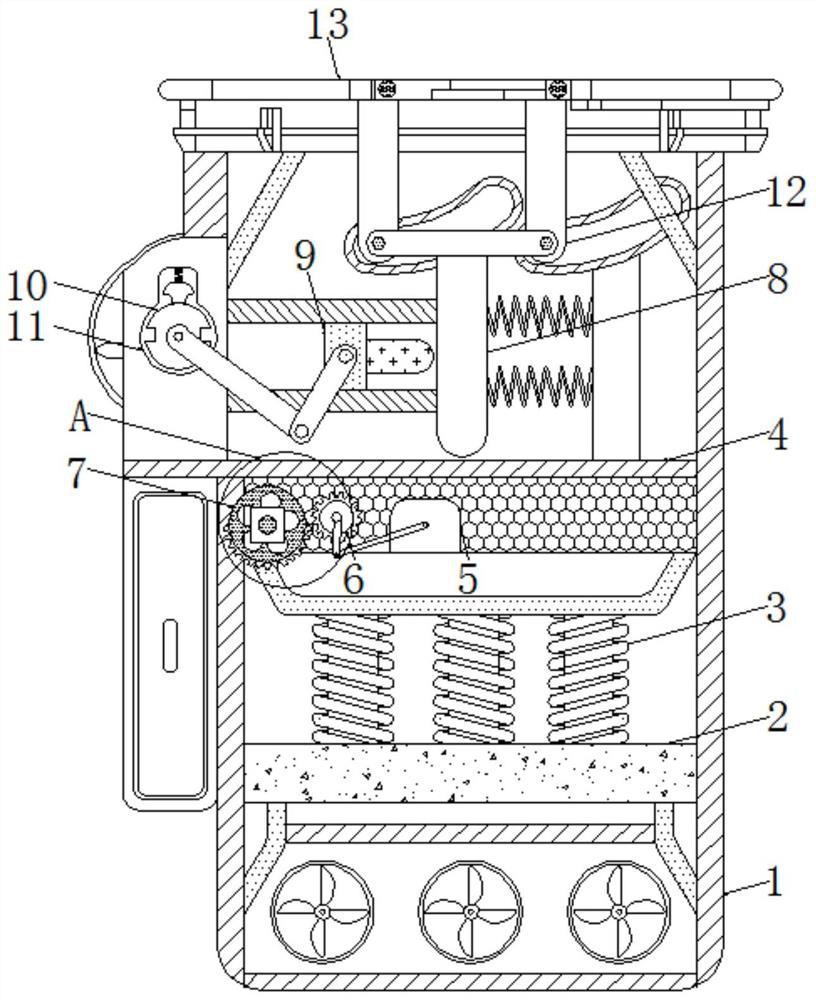

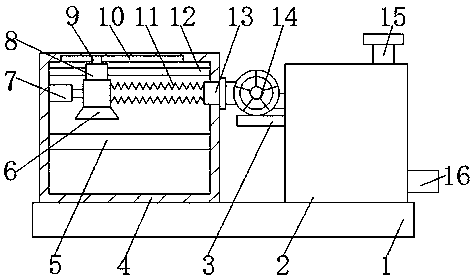

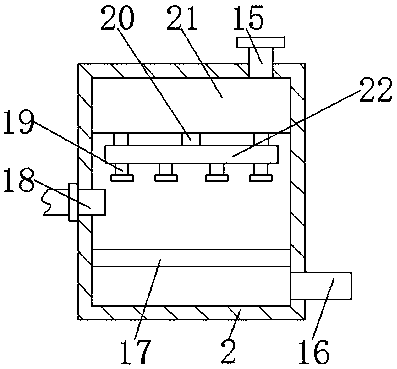

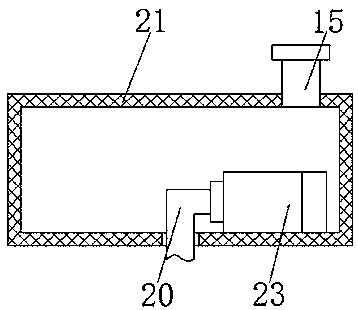

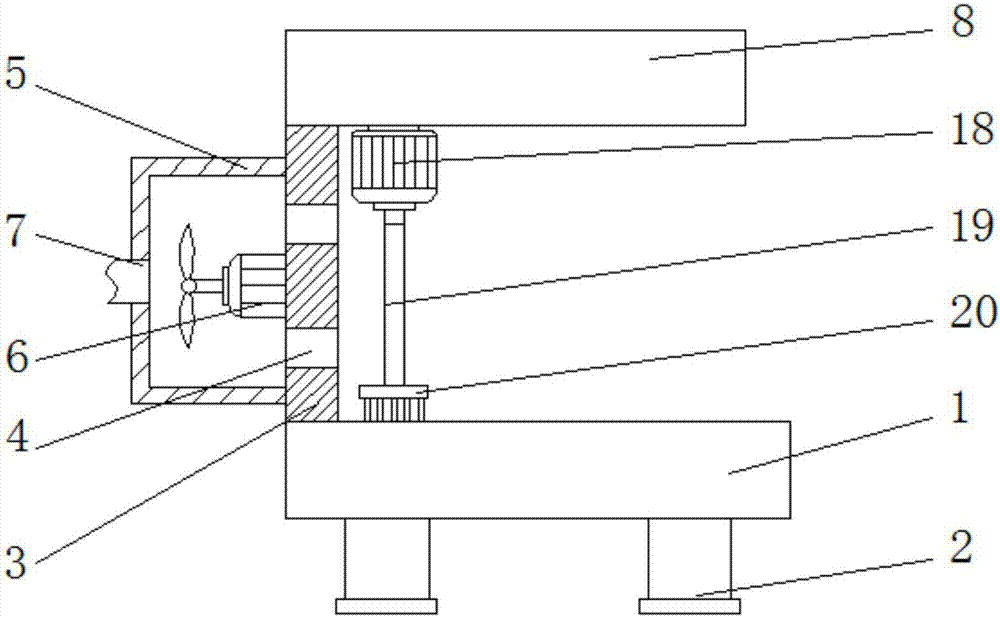

The present invention relates to the field of computers, especially the embedded network intelligent information processing server, including server shells, Reciprocating screws, screw nut, rotary purifier installed in the server shell, with the cooperation of the reciprocating screw and the screw nut, As that rotary purify device reciprocates upward and downward in the inn seat of the server housing and also rotates, A blow nozzle is arranged on the rotary purification device to blow up the dust inside the server, A suction chamber is also provided for that rotate purification device, atomizing chamber and drying chamber, the air with dust and heat inside the server is sucked away and cooled by atomizing dust removal, filtration and centrifugal drying, The treated air is discharged out ofthe server through the pipeline, and plays the role of dust removal and temperature reduction for the server. At the same time, the air treated by the rotary purification device contains certain moisture, which can be circulated to the inside of the server to increase the humidity, and plays the role of eliminating static electricity, thus greatly prolonging the service life of the server and reducing the maintenance difficulty of the server.

Owner:河北文曦科技有限公司

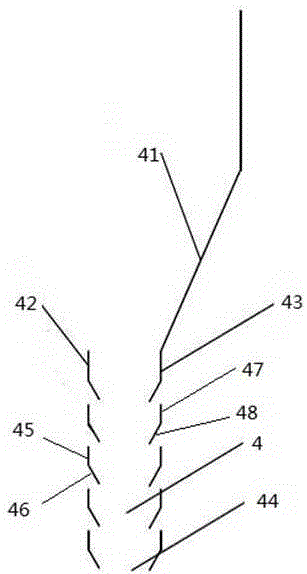

Vacuum filter

InactiveCN105498380AOptimize the installation structureQuick and easy installationHuman health protectionDispersed particle filtrationFiltrationUpstream downstream

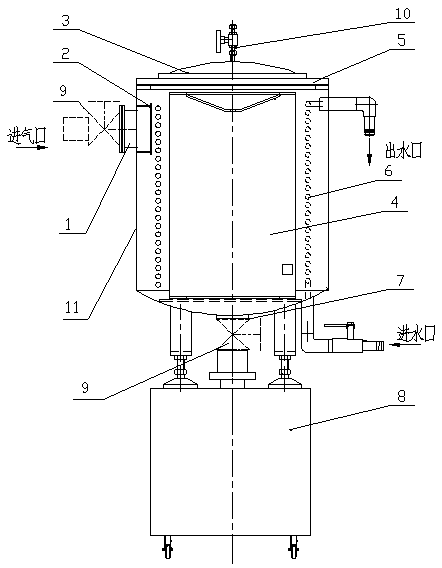

The invention discloses a vacuum filter, and belongs to the field of filtration, which is used for solving the problems of cooling and dedusting of high-temperature and dust-contained gas in a vacuum working system. The vacuum filter comprises a cavity body, a diffuser and a filter element, wherein the cavity body is provided with a gas inlet connected with a specific gas pipeline and a gas outlet connected with a vacuum pump; the top end of the cavity body is provided with a top cover connected with the cavity body in a sealed mode; the cavity body is internally provided with the diffuser at the gas inlet; the filter element is installed at the center in the cavity body; the side wall of the filter element is provided with filter holes; the bottom surface of the filter element is provided with an opening leading to the gas outlet of the cavity body, thereby preventing the vacuum pump and an upstream-downstream system from being damaged by high-temperature, corrosive and dangerous dust particles, and solving the problem of too complex and frequent maintaining frequency of the vacuum pump of the vacuum filtration system. From the aspect of environment protection, gas in pipelines can be further cooled down and purified, and air pollution can be reduced.

Owner:青岛赛瑞达电子科技有限公司

Air dust-removing equipment

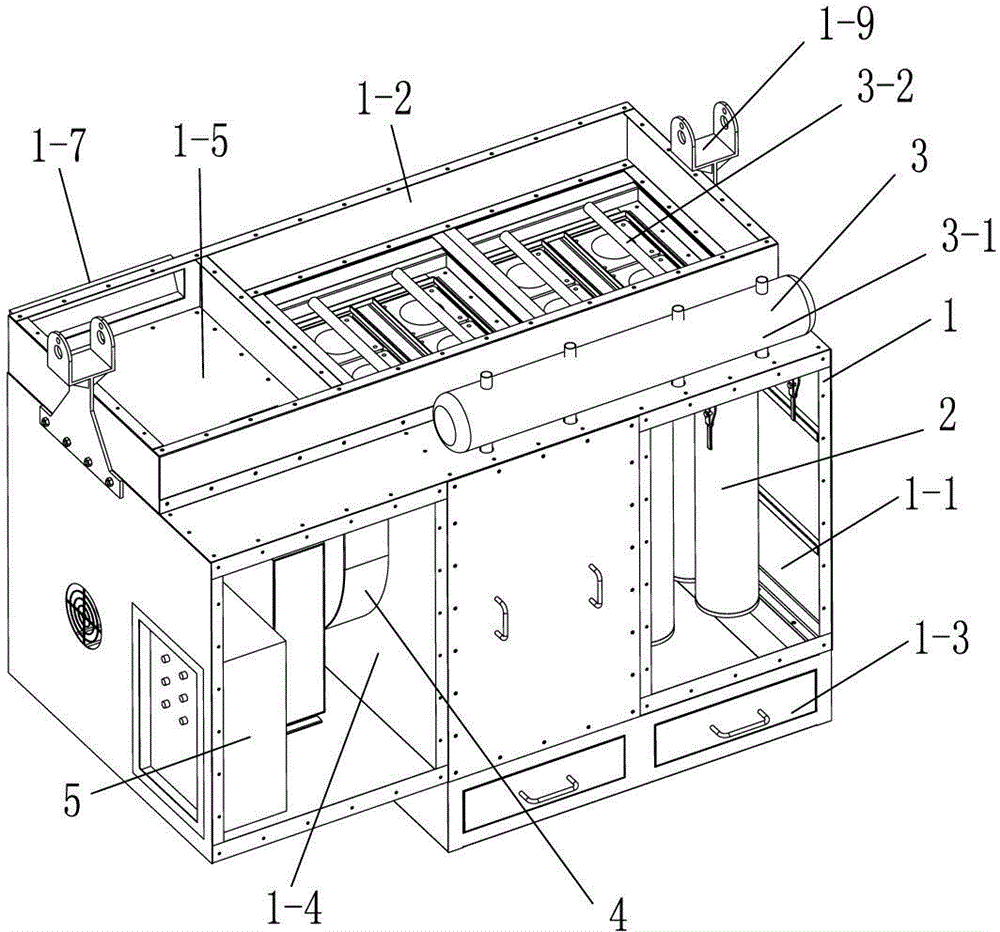

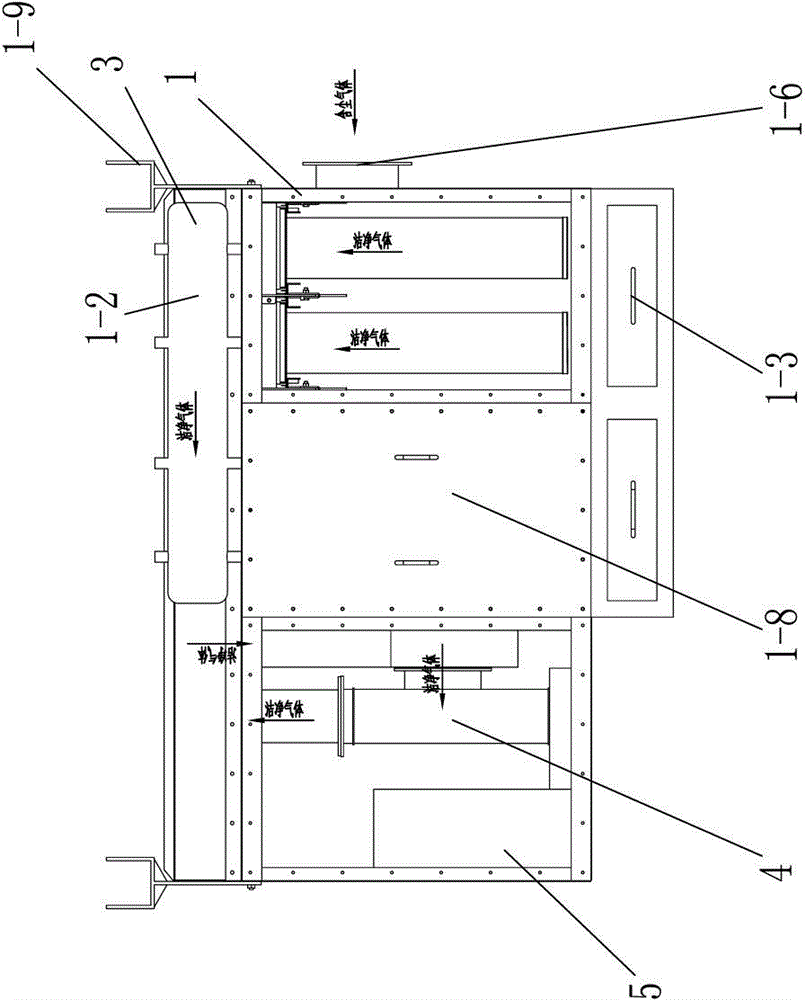

ActiveCN104801123ASolve the problem of dust removalEasy to install and useDispersed particle filtrationFlue gasModular design

The invention provides air dust-removing equipment. The air dust-removing equipment comprises a machine body, an injecting device, a fan and an electric cabinet, wherein the machine body comprises a plurality of filter chambers, a dust collecting chamber, air purifying chambers, a fan chamber, an air inlet, an air outlet, one or more side-mounted multi-filter core structures, filter core bearing frames, a compressing handle and a lifting lug; the air purifying chambers are arranged above each filter chamber, the dust collecting chamber is connected to the lower part of each filter chamber correspondingly, and one or more side-mounted multi-filter core structures which are mounted on the filter core bearing frame in an inserting manner and are fixed by the compressing handle are mounted in each filter chamber so as to form an independent side-mounted multi-filter core structure unit module, so that the design of an air dust remover can adopt an integrated and modular design idea; according to the service condition, a plurality of groups of side-mounted multi-filter core structure unit modules are selected, so that the operating requirements are met; during manufacturing and mounting, the operation is simpler and more convenient; the production in a batched manner is realized, so that the cost is reduced. While the air dust-removing equipment is in use, the hoisting is convenient, so that the problem that during moving a casting ladle, the dust in flue gas cannot be removed is solved.

Owner:苏州思逸环保科技有限公司

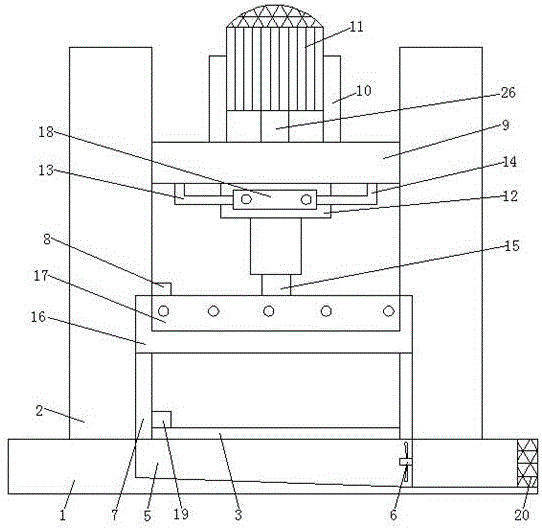

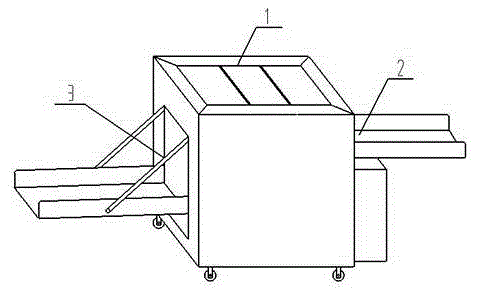

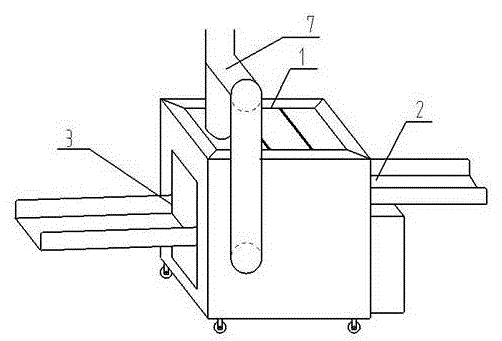

Efficient dustproof paper cutting machine

InactiveCN106476060AAchieve the effect of stoppingAvoid bendingMetal working apparatusPaper dustHydraulic pump

The invention discloses an efficient dustproof paper cutting machine. The efficient dustproof paper cutting machine comprises a base; the upper surface of the base is fixedly connected with a support column and a worktable; a blade groove is formed in the middle part of the worktable; a dust removing box is arranged in the base; a dust removing fan is arranged on one side of the dust removing box; a cutter guide groove is formed in the surface of the support column; the top of the cutter guide groove is fixedly connected with an upper limiting switch; the top of the support column is fixedly connected with a support frame; and the top of the support frame is fixedly connected with a support leg. The efficient dustproof paper cutting machine can realize a stop effect of a hydraulic pump when touching a paper cutter, achieves an effect of recovering paper chip dust, generated by cutting papers through the paper cutter, into the dust removing box, can reverse an electromagnetic reversing valve when touching a reinforcing plate, can upwards move the paper cutter through changing an oil supply direction of hydraulic oil, improves the working efficiency, and effectively solves hydraulic system protection measures and the dust removing problem.

Owner:无锡龙翔印业有限公司

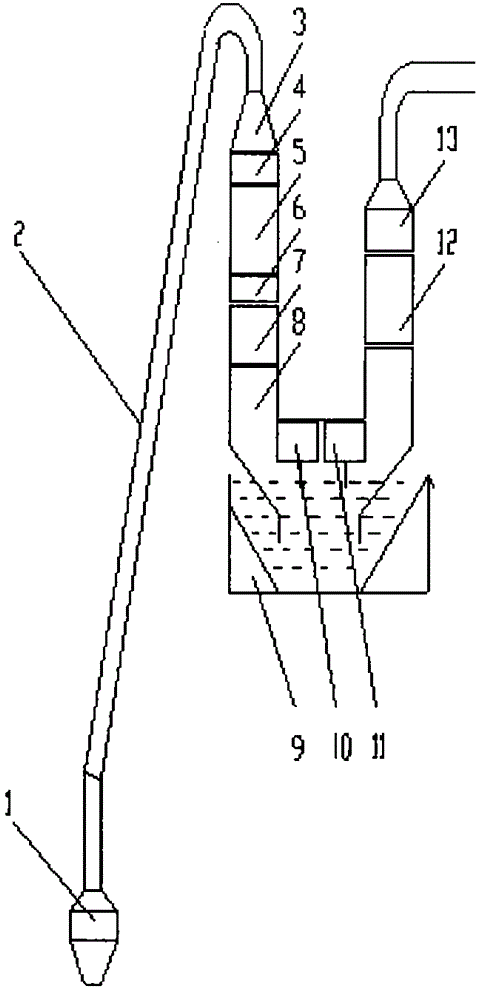

Dry type dust collector for mining drilling orifice

A dry type dust collector for a mining drilling orifice relates to coal mine drilling dust collecting equipment. A slag discharging case is a sealed case body; the middle part of the slag discharging case is provided with a water layer; the lower end of a cyclone dust collector passes through the water layer and reaches the lower part of the slag discharging case; the lower part of the slag discharging case is provided with a packing auger and a pneumatic motor; the back part of a dust collecting device is connected with an inlet of the cyclone dust collector via a hose; the inlet of the cyclone dust collector is arranged on the upper part of the slag discharging case; a gas outlet is further formed in the upper part of the slag discharging case; one end of an air duct is connected to the center of the cyclone dust collector from the upper part and the other end enters into the water; an outlet of the lower part of the cyclone dust collector reaches the slag discharging pipe; and the packing auger is driven by the pneumatic motor. The beneficial effects of the dry type dust collector for the mining drilling orifice are that particles and dust can be separated via the dust collecting device; the dust and gas can be absorbed into the cyclone dust collector of the slag discharging case via a negative pressure pipeline; after separation of the dust and gas, the dust falls into the packing auger and is exhausted; the gas enters the water layer for secondary purification and then enters a gas pumping and discharging pipeline; and dual purposes of orifice dust collection and gas pumping can be achieved.

Owner:河南中煤矿业科技发展有限公司

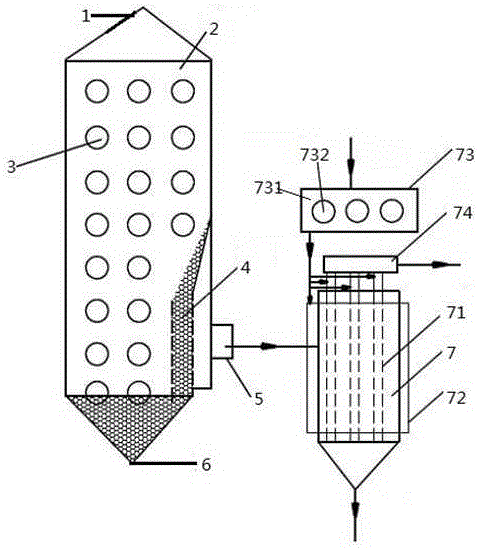

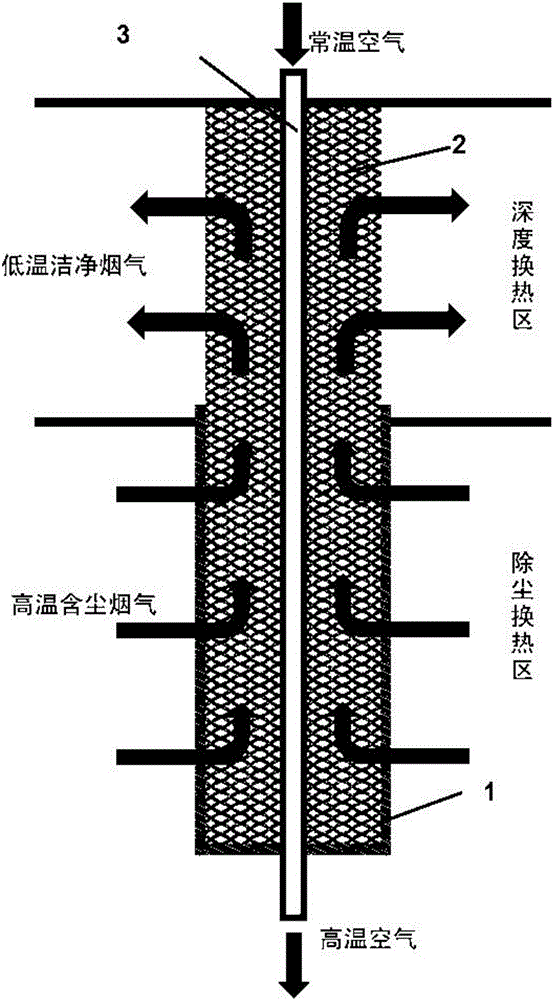

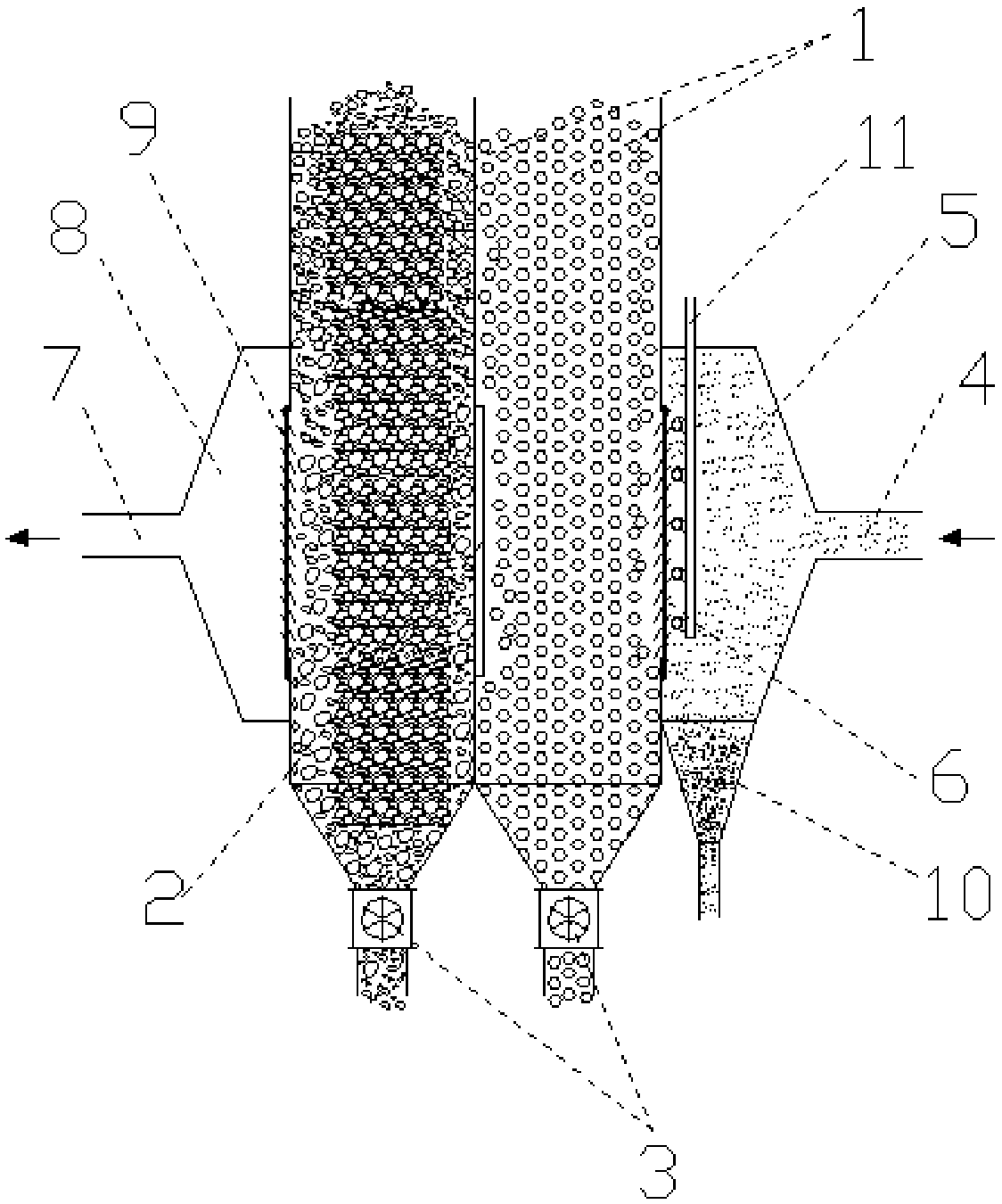

Pulverized coal pyrolysis dedusting system with granular bed and tubular filter inside

PendingCN105885896AHigh temperature resistantImprove insulation effectDispersed particle filtrationChemical industryProcess engineeringFilter material

The invention belongs to the field of quality-based gradient utilization of coal and mainly relates to a dedusting system used in the process of pyrolysis of pulverized coal. Aiming at the defects of the prior art, a pulverized coal pyrolysis dedusting system with a granular bed and a tubular filter inside is designed and developed. Characteristics of a reactor itself are combined, the granular bed is adopted for primary dedusting of pyrolysis gas, the pyrolysis gas after being primarily dedusted by the granular bed enters the tubular filter for secondary dedusting, pyrolysis char is utilized as a filtering material, and the filtering material is easy to reproduce, so that the dedusting problem of pulverized coal pyrolysis gas can be solved with low cost and high efficiency.

Owner:SHENWU TECH GRP CO LTD

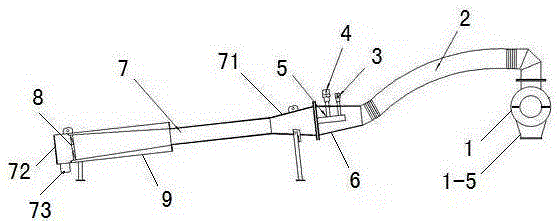

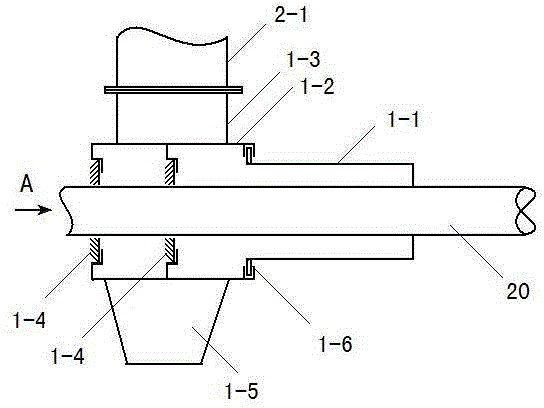

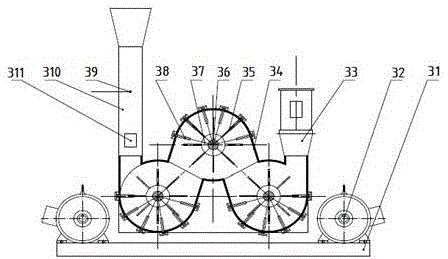

Dust removal type intelligent steel pipe oiling device

The invention aims at providing a dust removal type intelligent steel pipe oiling device. The dust removal type intelligent steel pipe oiling device is used for achieving the technical aim of dust removal on the inner cavity wall of a steel pipe. The dust removal type intelligent steel pipe oiling device comprises a control system, a dust removal system, a supporting system, an oiling system and adrive system, wherein the dust removal system, the supporting system, the oiling system and the drive system are electrically connected with the control system. The system has the beneficial effectsof oil removal and oiling of inner cavity faces of steel pipes with multiple pipe diameters.

Owner:唐山京华制管有限公司

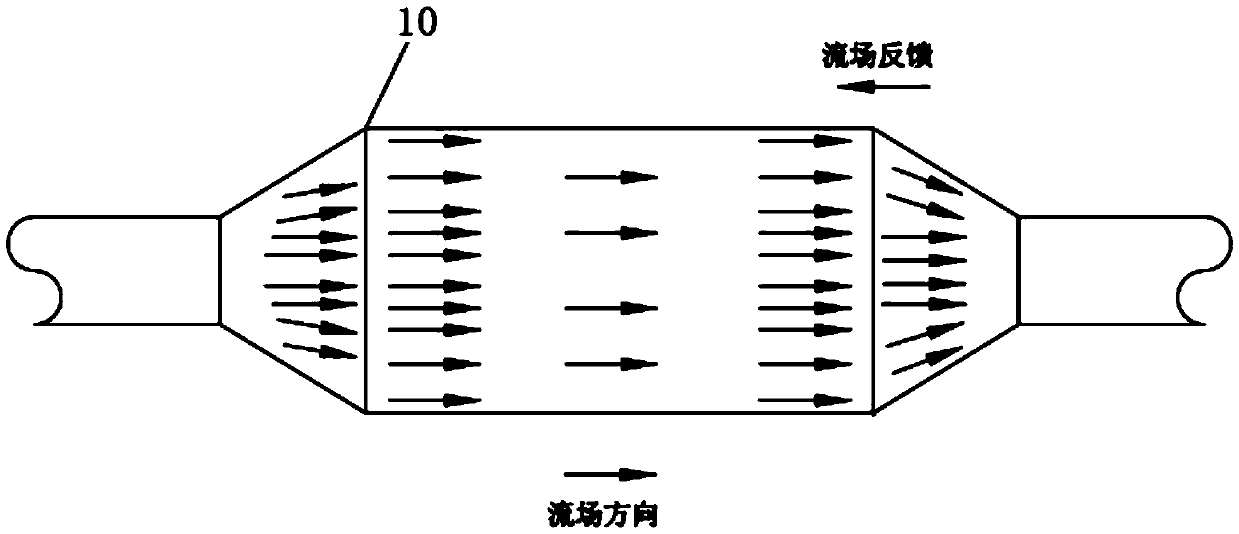

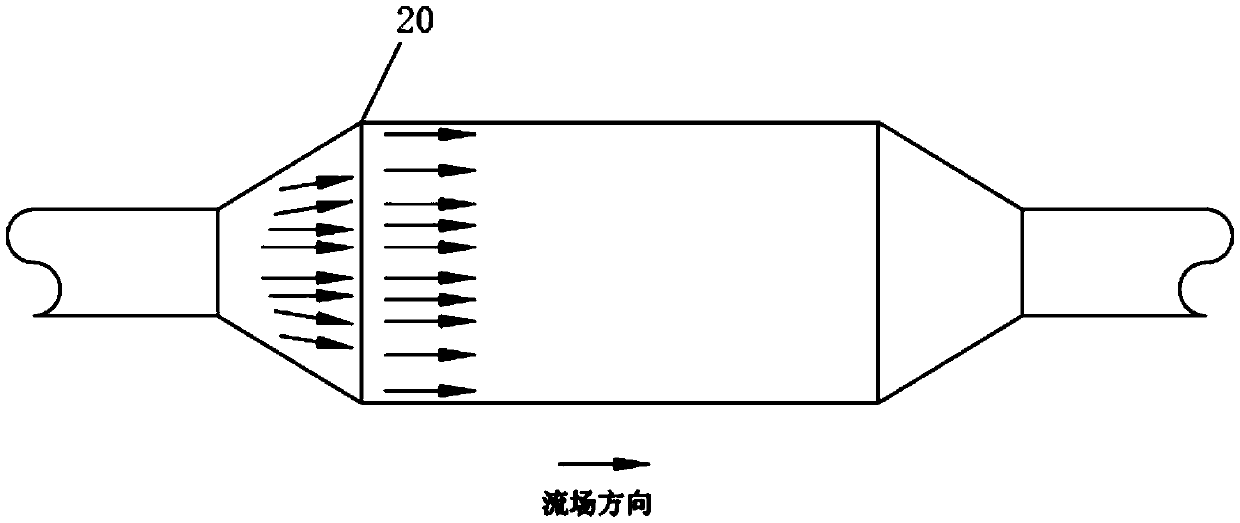

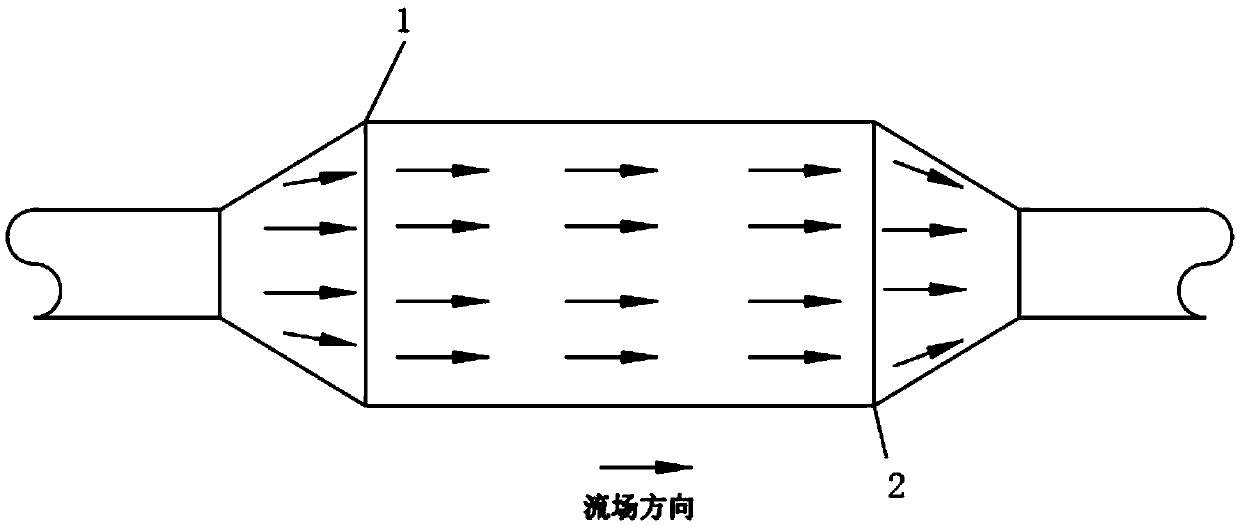

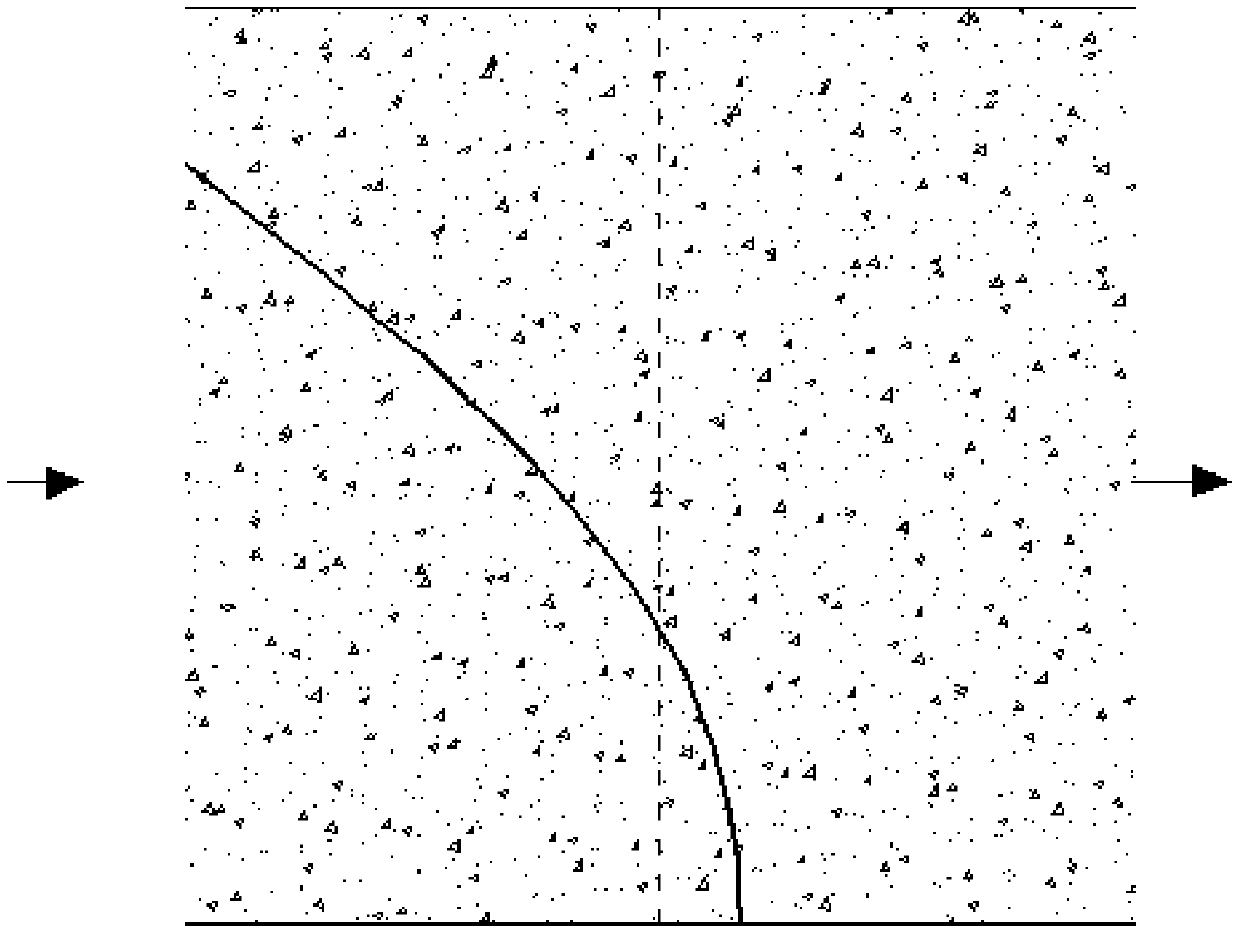

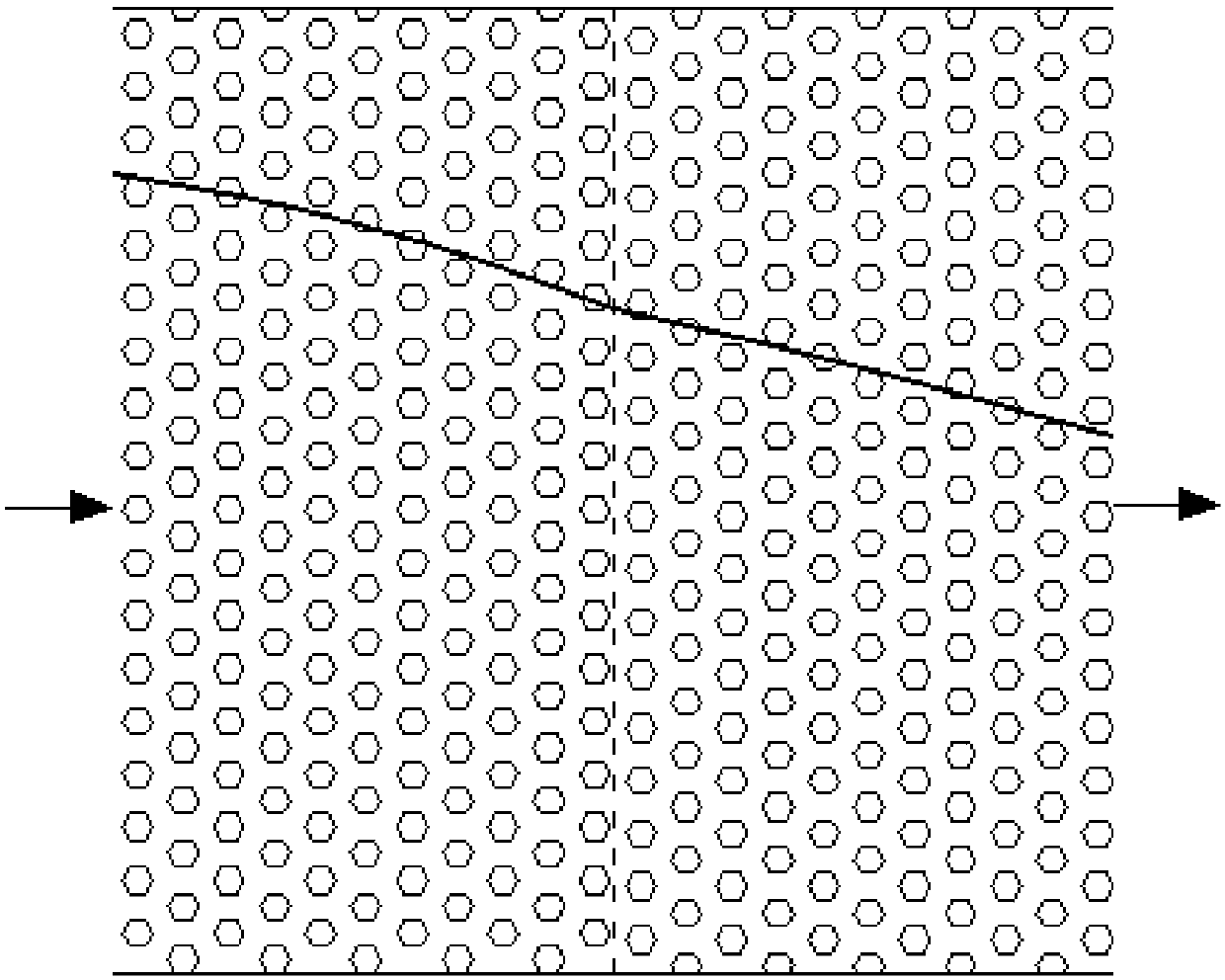

Airflow distribution system applied to wet electrostatic dust collector

ActiveCN105498971ASolve the problem of dust removalReduce resistanceVapor flow controlDistribution systemPressure difference

The invention discloses an airflow distribution system applied to a wet electrostatic dust collector. The system comprises two flow equalization boards which are an inlet airflow equalization board arranged at an airflow inlet and an outlet airflow equalization board arranged at an outlet. The inlet airflow equalization board is a non-equal-pressure-difference flow equalizing board, and the outlet airflow equalization board is an equal-pressure-difference flow equalizing board. The system solves the problem that airflow in a dust collector is not distributed evenly. Compared with a conventional airflow uniform distribution plate, the energy-saving effect is better.

Owner:SHANGHAI CHAOQING ENVIRONMENTAL PROTECTION TECH CO LTD

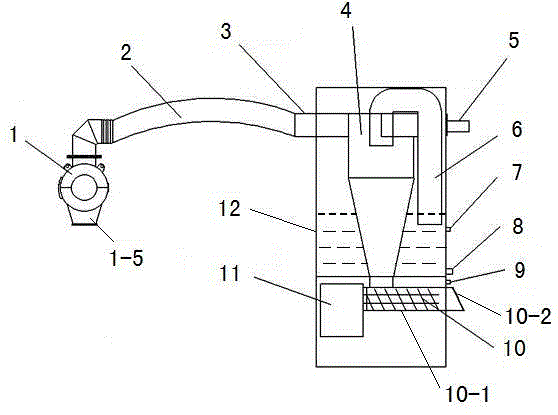

Wet type dust collector for mining drilling orifice

InactiveCN105019933AAvoid dischargeTo achieve the purpose of dust removalDust removalFire preventionWater dischargeJet flow

A wet type dust collector for a mining drilling orifice relates to coal mine drilling dust collecting equipment. The wet type dust collector comprises a dust collecting device and a jet flow dust removing device, wherein the back part of the dust collecting device is connected with the jet flow dust removing device via a hose; the jet flow dust removing device is structured by a jet flow disc, an atomizing chamber and a jet flow pipe orderly form front to back; the front part of the jet flow disc is connected with a hose; a steam nozzle is placed in the middle of the jet flow disc; the steam nozzle is provided with a water joint and a steam joint both connected to the jet flow disc; water and steam can be injected to the steam nozzle via the water joint and the steam joint; the back part of the jet flow disc is connected with the atomizing chamber; the atomizing chamber is connected with a jet flow pipe; the tail part of the jet flow pipe is provided with a diversion gate; and behind the diversion gate is provided with a backward water discharging port and a downward sewage discharging port. The beneficial effects of the wet type dust collector for mining drilling orifice are that particles and dust can be separated by the dust collecting device; dust can be absorbed into the jet flow dust removing device via a negative pressure pipeline formed by the steam nozzle; the dust in the jet flow dust removing pipe is fully mixed with mist and then settles in the jet flow dust removing pipe; and orifice dust removal can be achieved.

Owner:河南中煤矿业科技发展有限公司

Spinner dust removal device with good dust removal effect

InactiveCN108442023AImprove dust removal effectSolve the problem of dust removalAuxillary apparatusKnittingEngineeringWater tanks

The invention discloses a spinner dust removal device with the good dust removal effect. The device comprises a workbench, a protecting box and a dust removal box are sequentially fixedly connected tothe top of the workbench from left to right, a base plate is fixedly connected to the bottom of an inner cavity of the protecting box, and an air cylinder is fixedly connected to the top of the leftside of the inner wall of the protecting box. By cooperative use of the workbench, the dust removal box, a bearing platform, the protecting box, the base plate, a dust suction pipe, the air cylinder,a sleeve plate, a sliding rod, a sliding groove, a corrugated pipe, a sliding column, a conveying pipe, a fan, a water inlet, a water outlet, a filter et, an output pipe, a nozzle, a connecting pipe,a water tank, a spraying plate and a water pump, the problems that when an existing spinner is in use, due to the fact that a cloth body carries dust, if no treatment is performed, dust can enter thespinner, the existing spinner is not good in dust removal effect when in use are solved, a user can conveniently use the spinner, and practicability of the spinner is improved.

Owner:WUJIANG MAIDAO TEXTILE

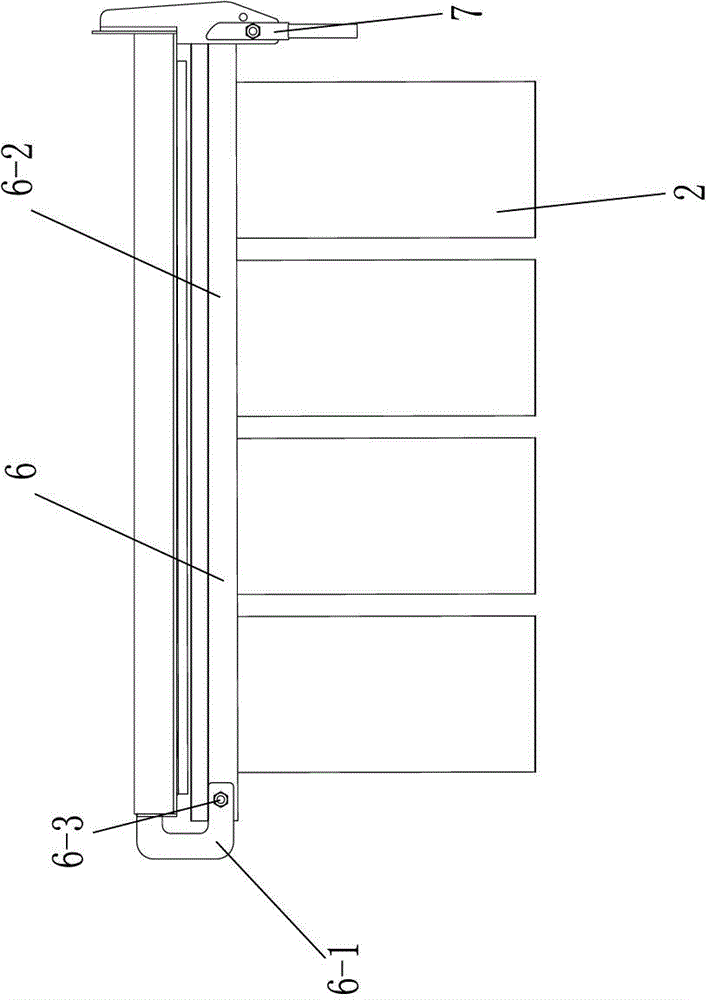

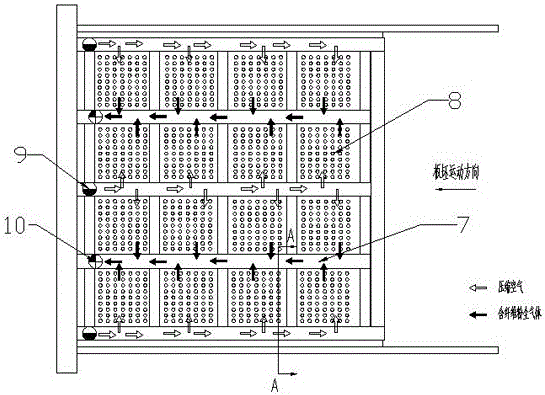

Cloth inspecting dust removing system applied to clothing production

ActiveCN105170499ASimple structureTargetedCleaning using toolsElectrostatic chargesEngineeringTextile

The invention discloses a cloth inspecting dust removing system applied to clothing production. The cloth inspecting dust removing system applied to clothing production comprises a cloth inspecting rack and a dust removing rack. A dust removing channel is formed between the cloth inspecting rack and the dust removing rack and is internally provided with dust removing cloth and dust removing devices. The dust removing devices comprise the horizontal dust removing device and the vertical dust removing device. The horizontal dust removing device comprises an upper dust removing mechanism, a lower dust removing mechanism and a horizontal driving mechanism. The upper dust removing mechanism and the lower dust removing mechanism are both connected with the horizontal driving mechanism. The vertical dust removing device comprises a left dust removing mechanism, a right dust removing mechanism and a vertical driving mechanism. The left dust removing mechanism and the right dust removing mechanism are both connected with the vertical driving mechanism. The horizontal dust removing device and the vertical dust removing device are used for performing dust removal on the upper surface and the lower surface of the dust removing cloth two times respectively, the dirt, dust and electrostatic effect of the cloth is eliminated, the eliminating rate can reach up to 98%, and therefore the purposes that a cloth cover is clean and tidy, product quality is improved, the product yield rate is increased, the reject ratio is reduced, and product cost is reduced can be achieved.

Owner:HAIAN RUNDE CLOTHING CO LTD

Waste-heat-recovery converter dry-method dust removal process

InactiveCN104962681ALess investmentTake up a lot of spaceManufacturing convertersIncreasing energy efficiencyThermal energyWater tanks

The invention relates to the technical field of converter smoke dust removal and waste heat recovery. The waste-heat-recovery converter dry-method dust removal process comprises the following steps: step 1, extinguishing converter smoke by utilizing steam; step 2, recovering the heat of the extinguished converter smoke by utilizing a waste heat boiler heat exchanger and an oxygen extractor water heat exchanger; step 3, removing the dust by utilizing a gravity dust collector, and collecting smoke and dust by utilizing a water sealing water tank below the gravity dust collector; step 4, introducing the converter smoke passing through the gravity dust collector into an industrial water heat exchanger, cooling the converter smoke to 40 to 50 DEG C, then sending the cooled converter smoke to a heating heat exchanger, and heating to 3 to 5 EG C; step 5, sending the heated smoke to an air filter to remove the dust, and discharging the converter smoke after the dust removal by virtue of an exhaust pipe. The waste-heat-recovery converter dry-method dust removal process is less in investment, when the dust removal problem is solved, a great amount of waste heat can be recovered, the environment-friendly index requirement can be completely met, and the economic benefit and environmental protection effect are good.

Owner:汤海军

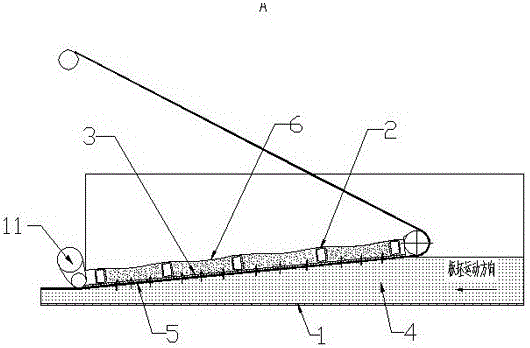

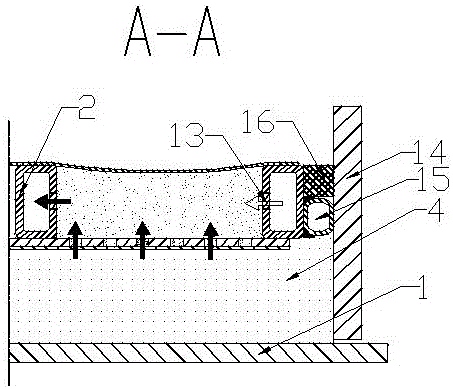

Exhaust frame of density plate pre-pressing machine

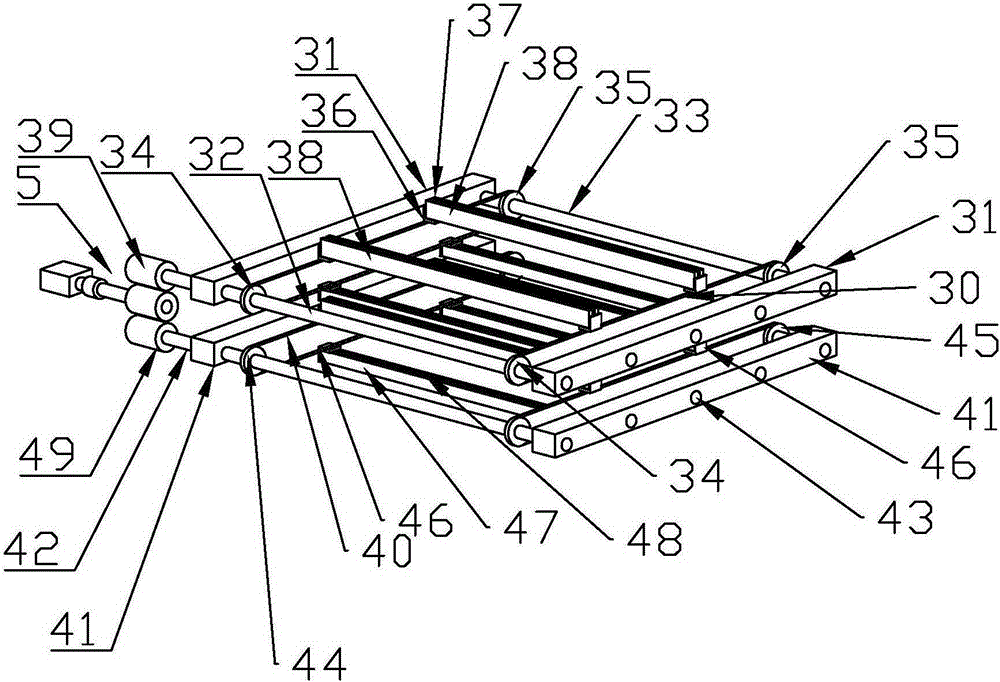

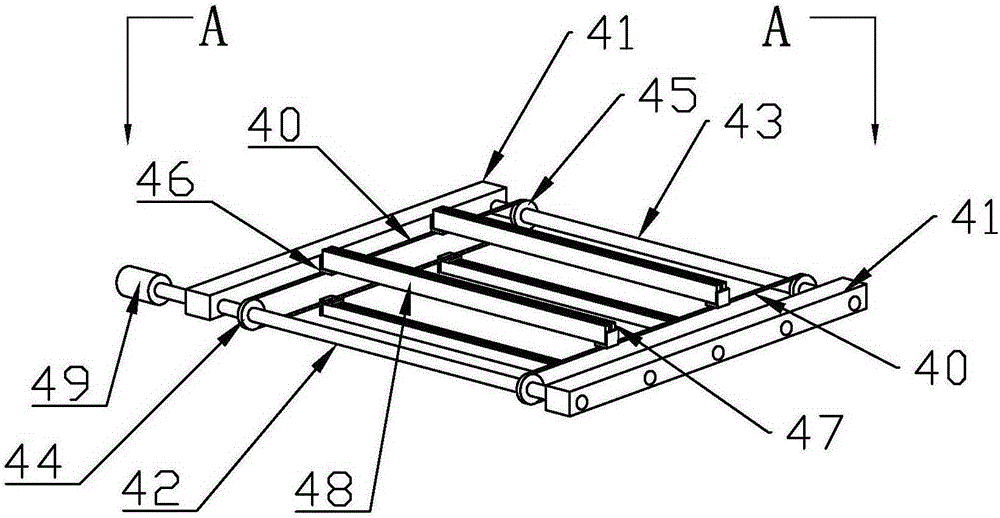

ActiveCN106426499APrevent leakageAvoid accumulationWood working apparatusDomestic articlesFiberEngineering

The invention discloses an exhaust frame of a density plate pre-pressing machine. The exhaust frame comprises a horizontally-arranged conveying belt and a guiding-in frame, wherein the guiding-in frame is arranged above the conveying belt, the inclination angle is formed between the guiding-in frame and the conveying belt, a layer of mesh plate is arranged at the lower portion of the guiding-in frame, a slab is placed above the conveying belt, a ventilation net belt capable of running synchronously with the conveying belt is arranged below the mesh plate, and a sealing cover is arranged at the upper portion of the guiding-in frame. The guiding-in frame is provided with frame grids longitudinally and transversely arranged. A negative pressure cavity is formed between each frame grid and the sealing cover at the upper portion of the guiding-in frame, a negative pressure cavity is formed between each frame grid and the mesh plate at the lower portion of the guiding-in frame, and each negative pressure cavity is provided with an air inlet and an air outlet. After the above structure is adopted, the problems about dust removing and sealing between the guiding-in frame and baffles on the two sides and the upper surface of the guiding-in frame are solved, and fiber is not prone to leaking from the two sides of a guiding-in section; meanwhile, gas exhausted from the mesh plate of the guiding-in frame and the fiber escaping from the mesh plate of the guiding-in frame are removed, the fiber is prevented from being accumulated above the guiding-in section, and the fiber is effectively removed.

Owner:SUZHOU SUFOMA MACHINERY

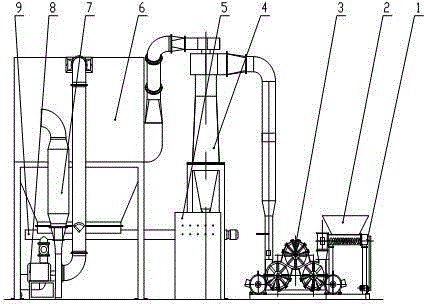

Continuous powder surface modification system

InactiveCN104555448AAdvanced conceptReasonable matchCharge manipulationBulk conveyorsGranularityMetallurgy

The invention relates to a continuous powder surface modification system. The continuous powder surface modification system comprises a double-spiral feeder, a raw material bucket, a continuous powder modifier, a whirlwind powder collector, an electric cabinet, a pulse dust remover, a muffler, a centrifugal fan and a finished product spiral conveyor; the double-spiral feeder is arranged at a material outlet of the raw material bucket; the output end of the double-spiral feeder is arranged above a material inlet of the continuous powder modifier; the material outlet of the continuous powder modifier is connected to the whirlwind powder collector through a pipeline; a finished product outlet of the whirlwind powder collector is formed in the finished product spiral conveyor; the negative pressure of the whirlwind powder collector is connected with the pulse dust collector and the centrifugal fan; a raise dust collecting output of the pulse dust collector is formed in the finished product spiral conveyor; the muffler is also provided. The continuous powder surface modification system is high in adaptability for the type, granularity, shape and density of raw powder, high in dispersing capacity for powder and modifying agents, and convenient to adjust the modification temperature and dwell time, and can perform compound modification for the modifying agent and the powder through one machine; the continuous powder surface modification system has the advantages of being continuous to produce, stable in product quality, low in energy consumption, and free of pollution.

Owner:上海建冶路桥机器设备有限公司

Method for absorbing SO2 in smoke and removing dust from coal boiler

InactiveCN1862092ASatisfy the absorption reaction processSolve pollutionLighting and heating apparatusDispersed particle separationRed mudPollutant emissions

The invention includes the following steps of first removing the dust from the smoke exhaust when firing the coal in the boiler via a dust preremover; loading the dust-removed smoke into a desulfurizing tower with the Bayer red mud inside; desulfurizing after making contact of the smoke led into the desulfurizing tower with the Bayer red mud; then removing the dust from the desulfurizing smoke led into the second-stage dust-remover and at last discharging the smoke treated by desulfurizing and dust-removing from the chimney.

Owner:GUIYANG AL-MG DESIGN & RES INST

Air exhausting and dust separating device for packaging machine

InactiveCN105329467ASolve the problem of dust removalImprove work efficiencySolid materialSprayerDust control

The invention discloses an air exhausting and dust separating device for a packaging machine. The air exhausting and dust separating device comprises the packaging machine and a dust separating box. The dust separating box is arranged above a discharge hopper. An upper pipeline and a lower pipeline communicated with the upper pipeline are arranged on a top plate above the dust separating box. A draught fan I is arranged at the left end of the upper pipeline, and a draught fan II is arranged at the right end of the upper pipeline. The two ends of the draught fan I and the two ends of the draught fan II stretch to the position above the water surface in a receiving tank through the pipelines. An axial flow fan I and an axial flow fan II are arranged at an inlet of the lower pipeline. Two end openings of the lower pipeline are in a horn shape, wastewater receiving tanks are placed below the two end openings of the lower pipeline, a slidable water sprayer is arranged on the upper wall of the upper pipeline, one end of the water sprayer is connected with a water collecting basin through a water pump, and the other end of the water sprayer is connected with a controller through a wire. The dust removal device is simple in structure, high in dust removal efficiency, stable in work, not prone to blockage, convenient to maintain and long in service life, a good working environment is created for workers, and the working efficiency of the workers is improved.

Owner:QINGDAO LANNONGGU AGRI PROD RES & DEV

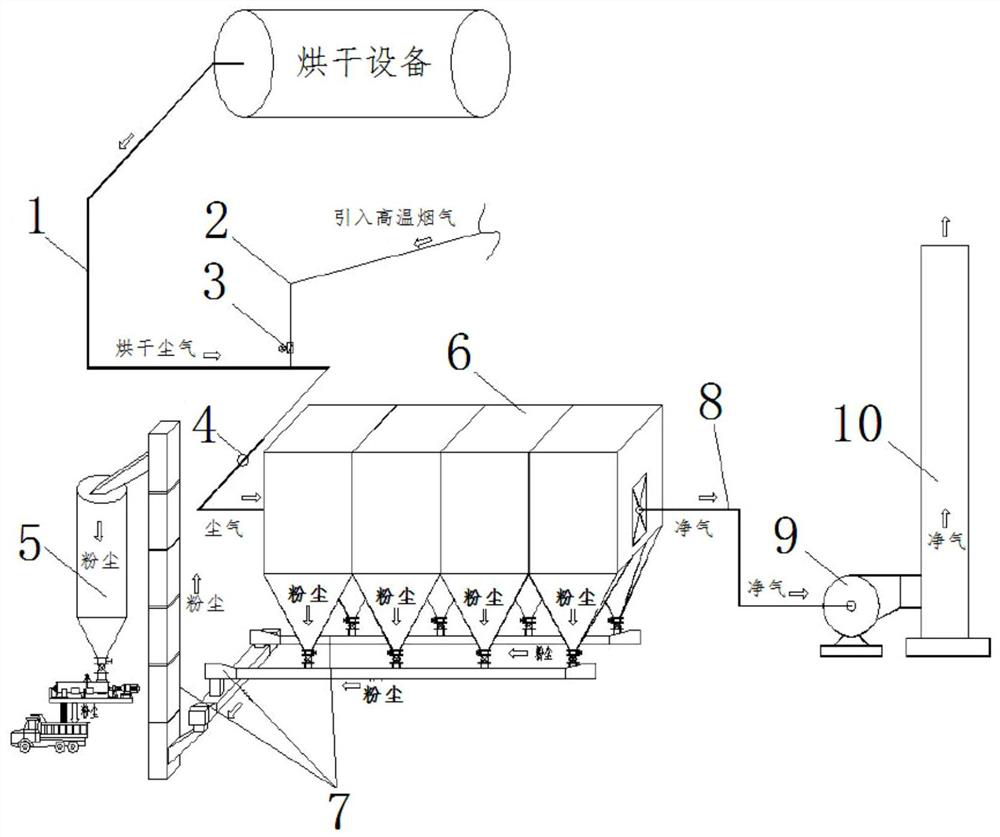

Flue gas dedusting device and dedusting process

ActiveCN108480042BSolve the problem of dust removalMeet emission standardsExternal electric electrostatic seperatorFlue gasDust control

The invention discloses a flue gas dedusting device, which includes an air inlet flue, an electric precipitator, a fan and a chimney, and also includes drying equipment and a hot air pipe for introducing high-temperature flue gas. The drying equipment is arranged at the inlet On the air flue, the air inlet flue and the hot air pipe are connected with the inlet of the electrostatic precipitator, and the outlet of the electrostatic precipitator is connected with the chimney through the fan. The flue gas dust removal process includes the following steps: 1) The dust gas dried by the drying equipment is mixed with the high-temperature flue gas introduced through the hot air pipe into the electrostatic precipitator; 2) The electric field wind speed in the electrostatic precipitator is controlled at 0.6-1.5 Between m / s; 3) The dust is collected by the electrostatic precipitator and transported to the powder bin through the ash conveying equipment, and the purified flue gas is discharged through the fan and the chimney. Ensure stable and up-to-standard emission of dust and safe operation.

Owner:MAANSHAN IRON & STEEL CO LTD

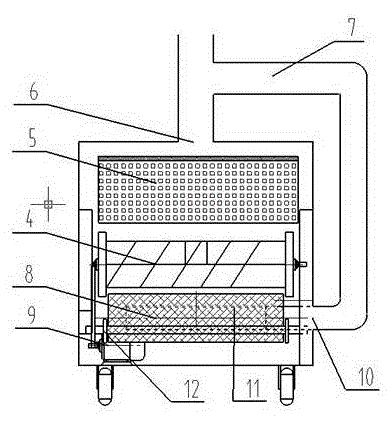

Biomass composite combustion heat-exchange integrated furnace

InactiveCN101012933ASolve the problem of efficient, stable and clean combustionReduce pollutionIncinerator apparatusCombustion chamberSlag

The invention relates to a burning gasifying boiler which uses biological fuel, for resolving the problems as instable burning, over air and pollution or the like. The invention has novel structure, less steel consumption, small volume, and high thermal efficiency. The invention comprises a material storage room, a gasifying burning room, a multilayer burning room, a slag room, and a heat exchanger. The invention is characterized in that: the burning room comprises integrated gasifying burning room (3) and multilayer burning room (6) while they are separated by the water cooling furnace bed (4); the grid (7) is arranged at the bottom of multilayer burning room (6); the side of the multilayer burning room (6) via the smoke window (10) is communicated with the slag room (12) in the chamber of boiler; and the smoke tube heat exchange face (13) in the chamber is mounted between the smoke box (15) at the top of boiler and the slag room (12).

Owner:JILIN UNIV

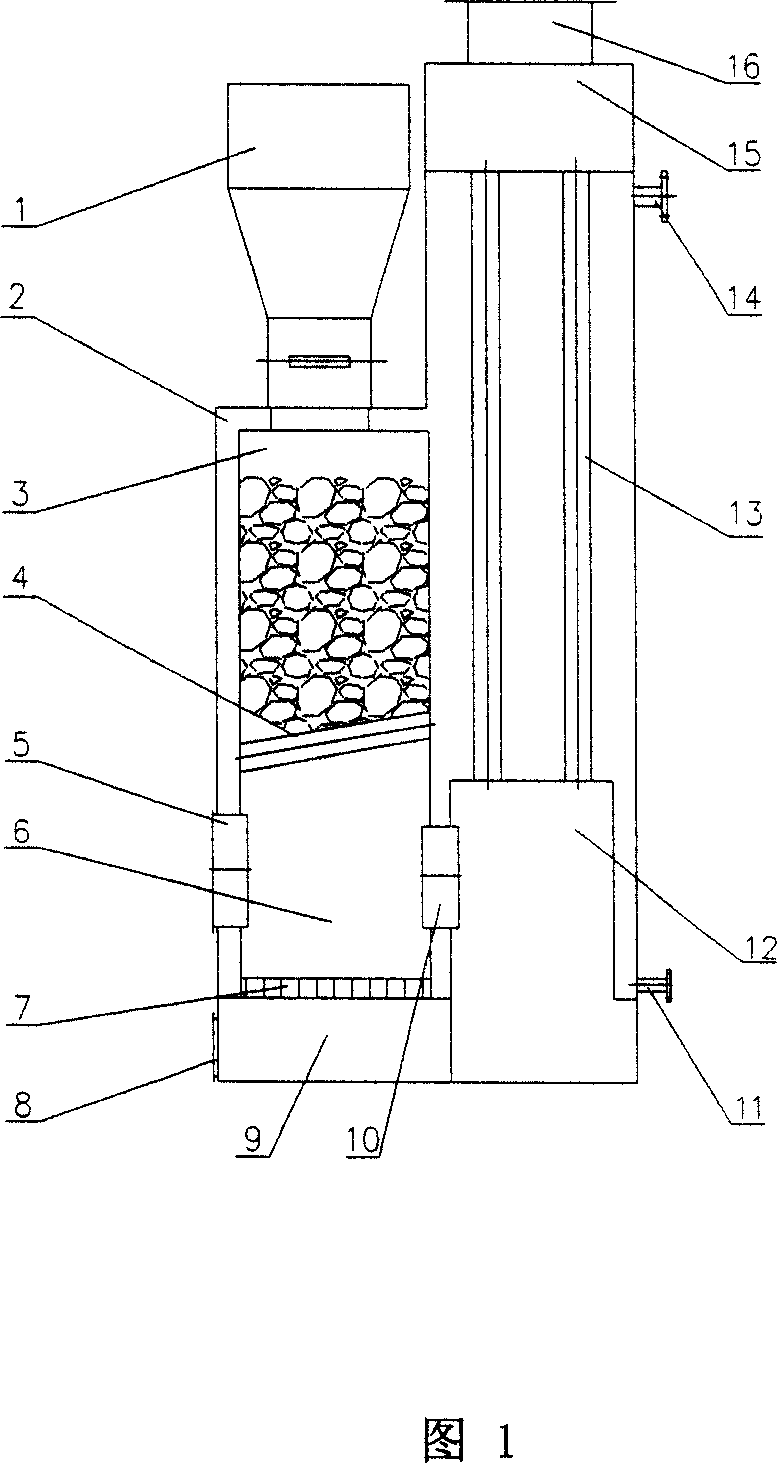

Dust removal and heat exchange all-in-one treatment device and method for high temperature dusty flue gas

ActiveCN106731330ASufficient heat exchangeOvercoming low purification efficiencyDispersed particle filtrationTransportation and packagingHoneycombFlue gas

The invention provides a dust removal and heat exchange all-in-one treatment device and method for high temperature dusty flue gas, and belongs to the technical field of industrial energy conservation and environmental protection. The device consists of a dust removal and heat exchange pipe, wherein the dust removal and heat exchange pipe comprises a metal filter membrane, a metal honeycomb framework and a heat exchange pipe; an upper box body of a box body where the dust removal and heat exchange pipe is located is a deep heat exchange region, and a lower box body of the box body is a dust removal and heat exchange region; in the lower box body, the heat exchange pipe penetrates through the metal honeycomb framework and is covered with the dense metal filter membrane; and in the upper box body, the heat exchange pipe penetrate through the metal honeycomb framework and is not covered with the dense metal filter membrane. The high temperature dusty flue gas passes through the dust removal and heat exchange region and the deep heat exchange region from bottom to top, and air passes through the heat exchange pipe from top to bottom. The method realizes a breakthrough in continuous dust removal and heat exchange integration for the high temperature dusty flue gas with the temperature of 800 DEG C or above; the heat recycling efficiency can be up to 90 percent, and the dust removal efficiency can be up to 99 percent; and the dust removal and heat exchange all-in-one treatment device has the advantages of efficient purification, full heat exchange, continuous work, difficulty in ash deposition and the like.

Owner:UNIV OF SCI & TECH BEIJING

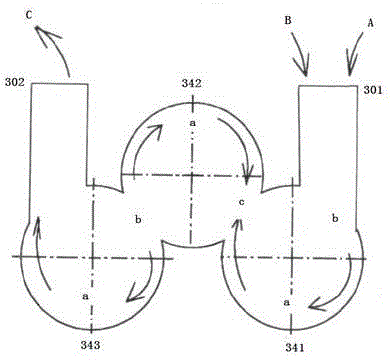

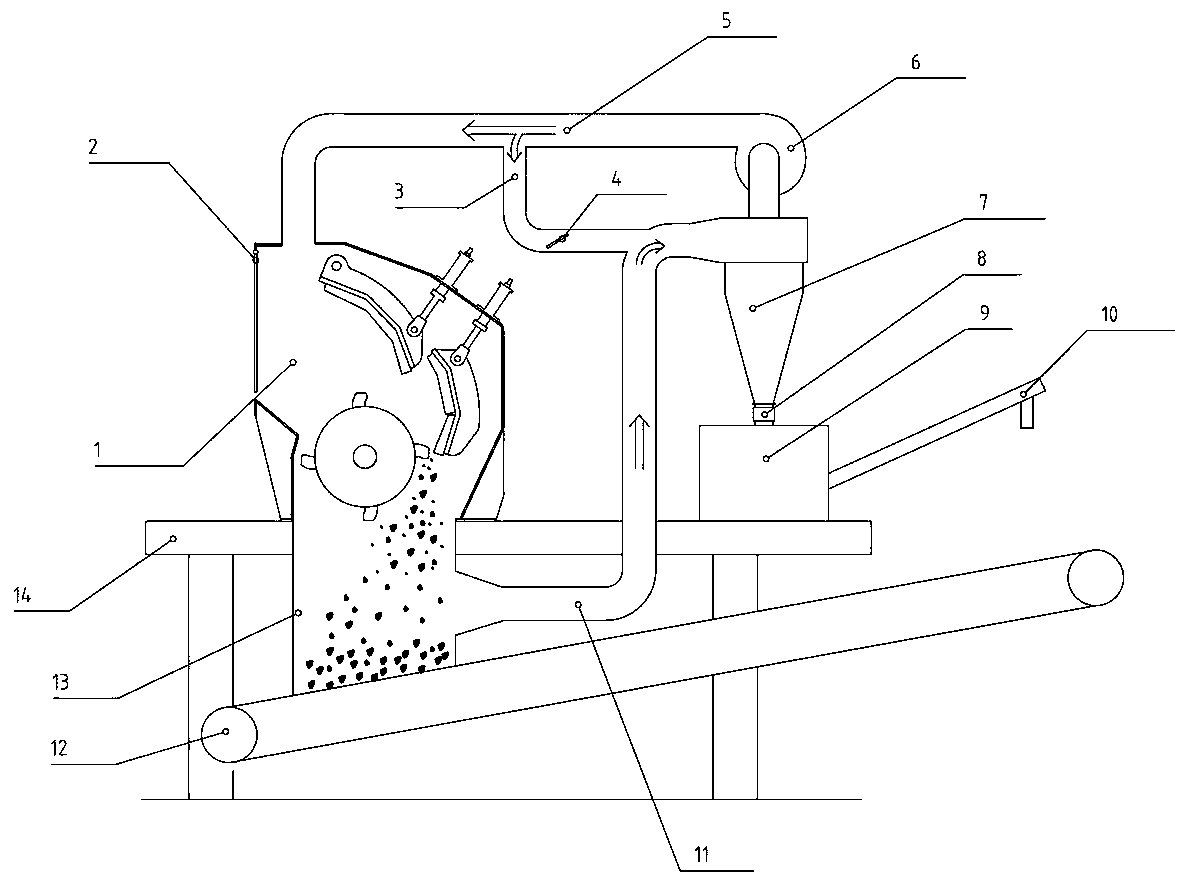

Closed circulation dust removal device of impact crusher

ActiveCN110756279ASolve the problem of dust removalReduce wasteHuman health protectionDispersed particle separationDust controlEnvironmental engineering

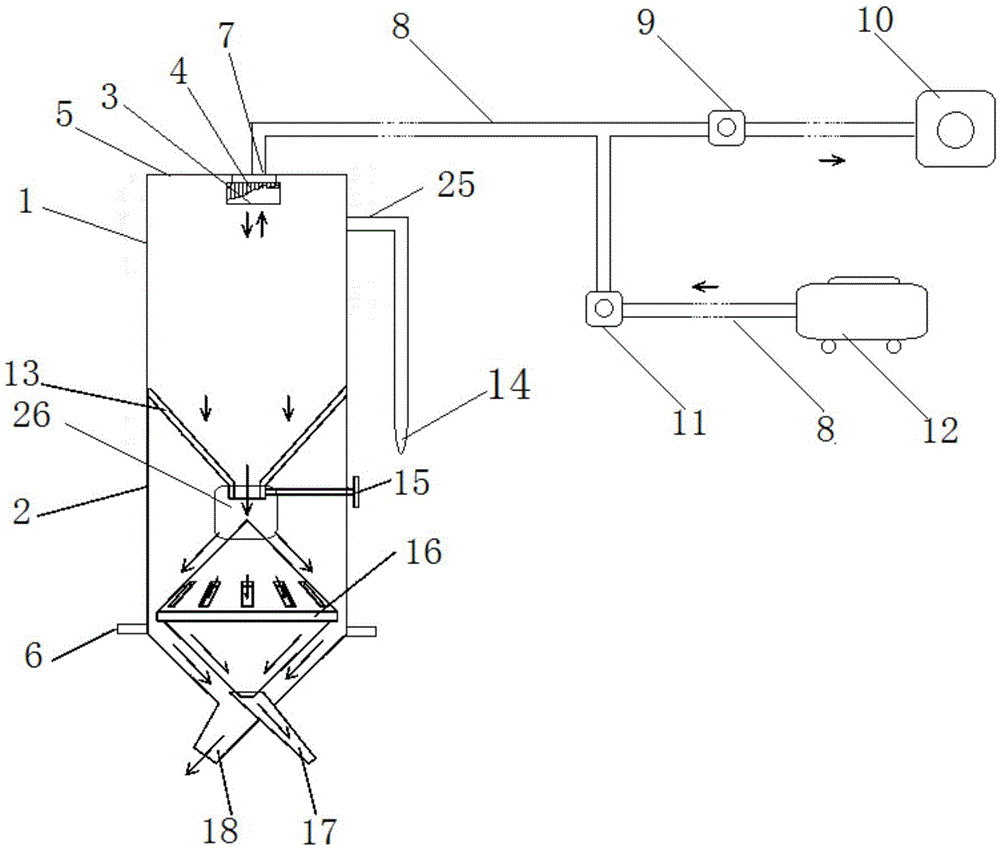

The invention relates to dust removal equipment of a crusher, in particular to a closed circulation dust removal device of an impact crusher. The closed circulation dust removal device of the impact crusher comprises the impact crusher arranged on a base; a material inlet blocking curtain is arranged at a material inlet of the impact crusher; a material outlet of the impact crusher is provided with a material outlet hopper; a conveying belt is arranged below the material outlet hopper; an air inlet is arranged above the material inlet of the impact crusher; an air outlet is arranged at one side of the material outlet hopper; the air outlet is connected with an air suction pipeline; an outlet of the air suction pipeline is connected with a cyclone powder collector; an air inlet of the cyclone powder collector is hermetically connected with the outlet of the air suction pipeline; an air outlet of the cyclone powder collector is connected with a centrifugal fan; an air outlet of the centrifugal fan is connected with an exhaust pipeline; the other end of the exhaust pipeline communicates with the air inlet of the impact crusher; the exhaust pipeline is also connected with an air supplementing pipeline; the other end of the air supplementing pipeline communicates with the air inlet of the cyclone powder collector; and an adjusting air valve is arranged in the air supplement pipeline.

Owner:HENAN LIMING HEAVY IND SCI & TECH

Water curtain dust fall device for machining dust

PendingCN109647094ASolve the problem of dust removalAvoid emissionsUsing liquid separation agentSeparation devicesWater flowMachining

The invention discloses a water curtain dust fall device for machining dust. The water curtain dust fall device comprises a water curtain air bellow, a fan and a filtering water tank. An air sucking channel is formed in the water curtain air bellow and communicated with a water curtain channel, the fan is driven to conduct air sucking, an air inlet is formed in the outer end of the water curtain air bellow and communicated with the air sucking channel, a water inlet pipe is connected to the water curtain channel and connected with the filtering water tank, the filtering water tank is providedwith a water pump, the water pump presses water flows which form a flowing water curtain through the water inlet pipe and the water curtain channel, the flowing water curtain is arranged at a sectionend between the air inlet and the air sucking channel, and a drainage pipe is arranged at the lower end of an air draft channel and connected with the filtering water tank. According to the product design, the water curtain dust fall device used for dust fall is installed on existing machining equipment, the fan is driven to conduct air sucking to suck the dust generated by machining and conduct mixed removal on the dust through the water curtain, then a circulating air bin conducts secondary dust removal on wet waste gas through mixed collection, and discharged waste gas enters dust fall circulation to be prevented from being discharged.

Owner:台州新融智能设备有限公司

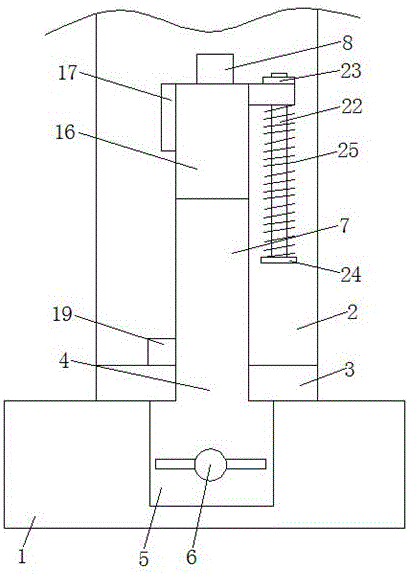

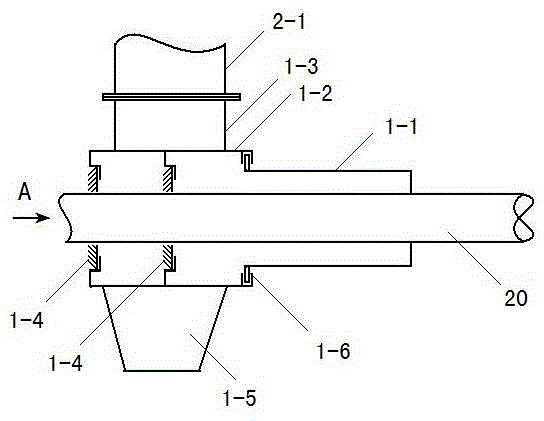

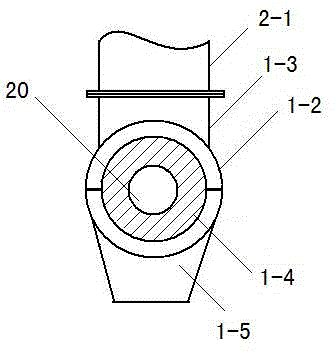

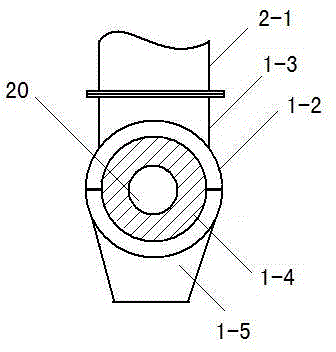

Multifunctional grain sampling machine

InactiveCN105628447ASimple structureFunction increaseWithdrawing sample devicesPreparing sample for investigationFilter systemEngineering

A multifunctional grain sampling machine comprises a sampling part (1) and a sample separating part (2), wherein the sampling part (1) is fixedly arranged at the top of the sample separating part (2); the multifunctional grain sampling machine is characterized in that an air inlet / outlet (7) is formed in a central position of a barrel bottom (5) of the sampling part (1) in a penetrating way; a cylindrical filter core tank (4) is arranged inside the barrel bottom (5) in a connecting way; a filter casing (3) sleeves the filter core tank (4). The multifunctional grain sampling machine is integrally simple in structure, and multifunctional; the multifunctional grain sampling machine can skillfully integrate a sampling system, a dust-filtering system, a dust-removing system and a sample-separating system, so that operations of the four systems are completely at one time; the multifunctional grain sampling machine ensures trueness of an obtained sample; especially, under the premise that a sealing cap is not opened, a dust-removing problem is solved relatively well; the cost in the using process is reduced, deformation of a barrel cover is prevented, frequent replacement of a dust separator is not required, and the problems of air leakage caused by dropping of a sealing ring and the like are avoided.

Owner:CHUZHOU HUALIANG STORAGE TECH CO LTD

Device for sterilization and dust removal of medical air purifier

InactiveCN112361510ASolve the sterilization effectSolve the problem of dust removalMechanical apparatusLighting and heating apparatusAir purifiersThreaded pipe

The invention relates to the technical field of medical apparatuses and instruments, and discloses a device for sterilization and dust removal of a medical air purifier. The device comprises a shell.The shell is used for supporting the whole device to ensure the stability of the whole device, and a negative ion filter is fixedly connected to the interior of the shell. Negative ions can be generated through the negative ion filter, a threaded pipe is fixedly connected to the outer side of the negative ion filter, through cooperative use of a brush, a first gear and a second gear, automatic dust removal is achieved when the device is used for operation, the situation that a filter plate needs to be frequently disassembled for cleaning is avoided, and more time and labor are saved; and through cooperative use of a push plate, a moving block, a first rotating disc, a second rotating disc, a limiting plate and a baffle, air can stay in the device for equal time, so that enough time is reserved for disinfection and sterilization, the mode that a traditional disinfection device only allows air to pass through temporarily is changed, and the disinfection and sterilization effect is further improved.

Owner:广州胡丽娟科技有限公司

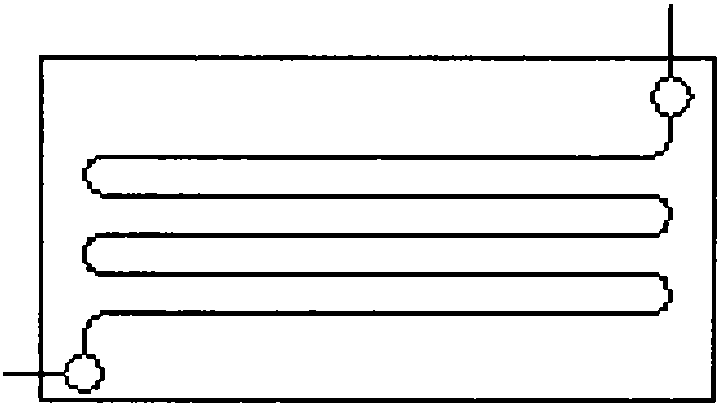

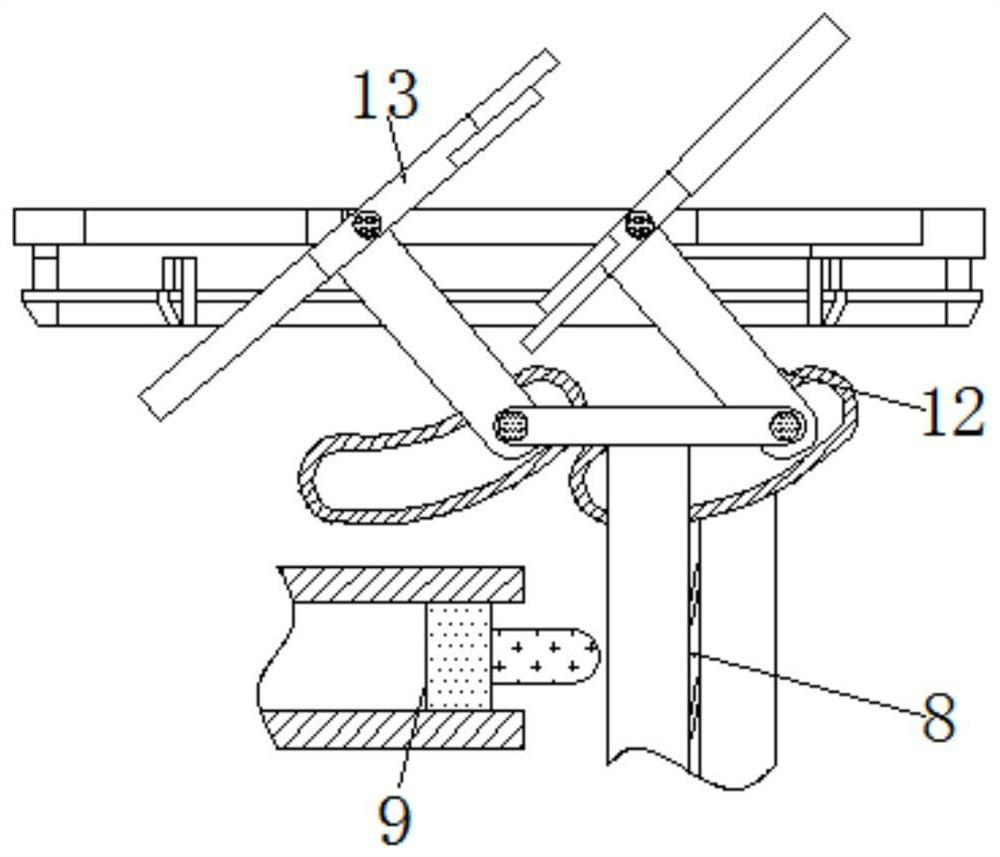

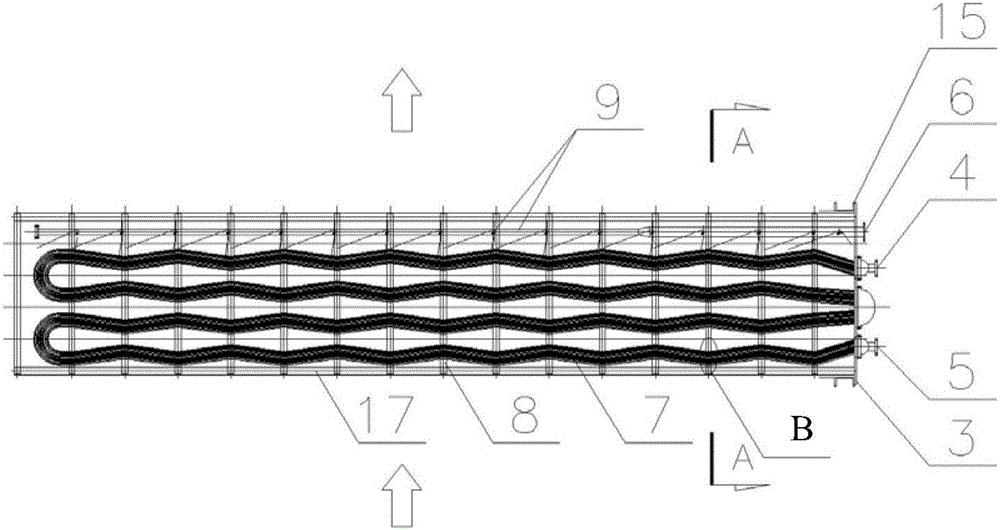

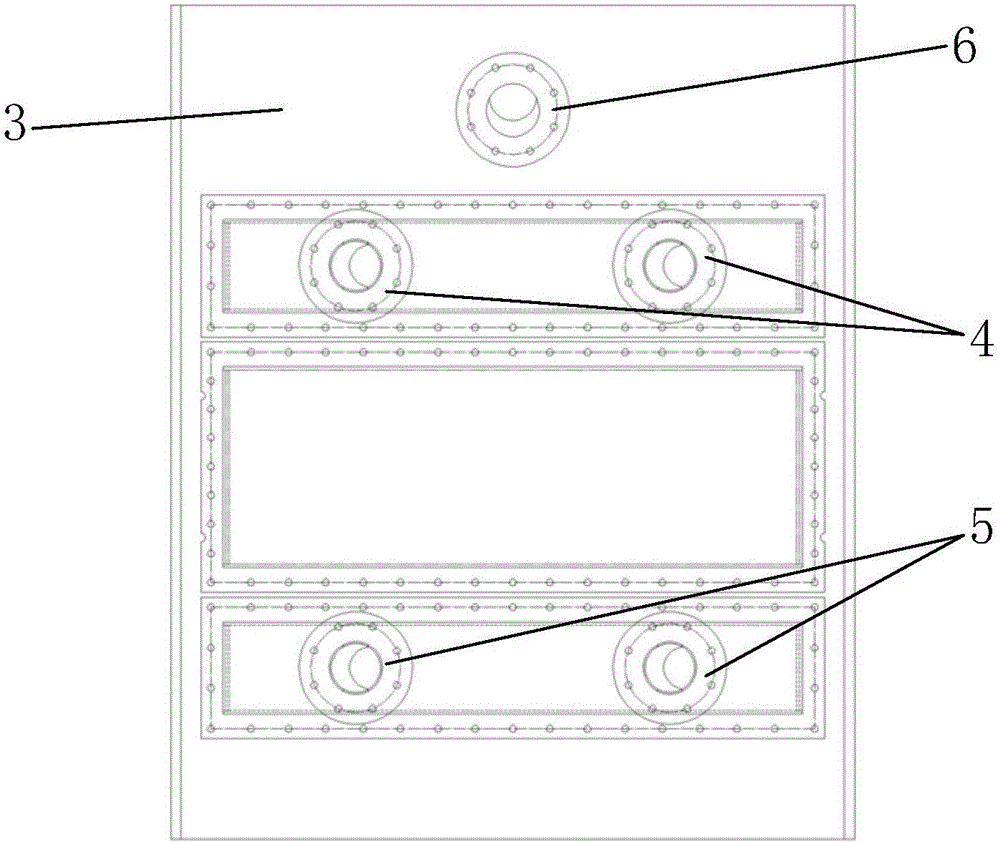

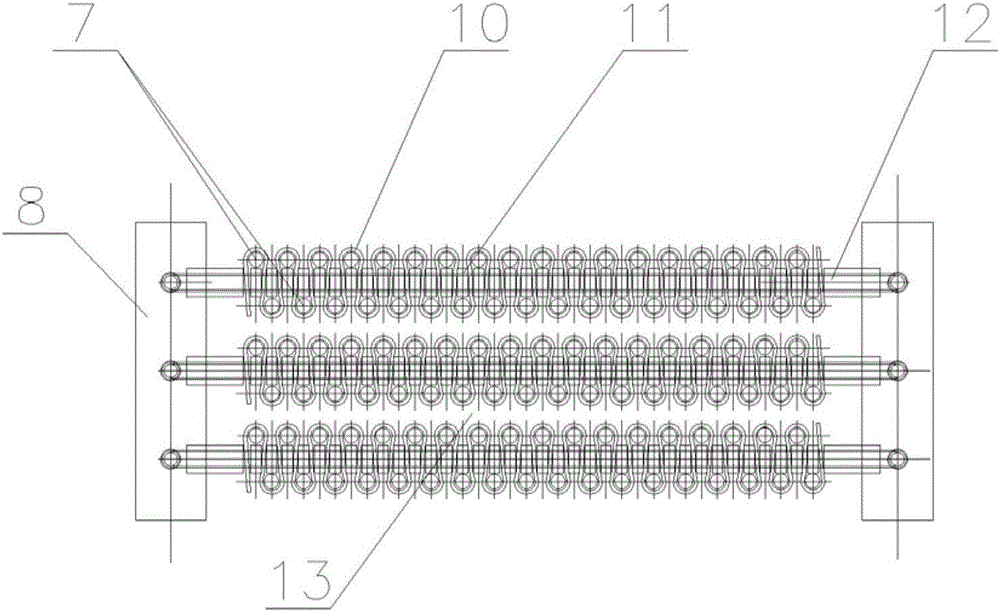

Horizontal fluorine plastic tube type dust and mist collection device mounted inside absorption tower

InactiveCN106582153ASolve the problem of "ultra-clean emission" transformationAchieve clean emissionsUsing liquid separation agentLiquid waterEngineering

The invention belongs to the technical field of waste gas purification, and in particular relates to a horizontal fluorine plastic tube type dust and mist collection device mounted inside an absorption tower. The horizontal fluorine plastic tube type dust and mist collection device is mounted inside an absorption tower (1) and comprises dust and mist collection tube bundles (7), a support unit and a water flushing unit, wherein the dust and mist collection tube bundles (7) consist of ''U''-shaped tubes and are arranged in a wave manner in a horizontal direction; a plurality of the horizontal fluorine plastic tube type dust and mist collection devices are horizontally mounted in parallel inside the absorption tower (1); and one end with a surface plate (3), of each horizontal fluorine plastic tube type dust and mist collection device, extends outside the absorption tower through an absorption tower flange (15). The horizontal fluorine plastic tube type dust and mist collection device is applied to the power environmental protection industry and works in the absorption tower of a flue gas desulfurization (FGD) device of a thermal power plant, fume is purified by using a cold source in a cooling manner, or liquid membranes are formed on surfaces of the fluorine dust and mist collection tube bundles in a water spraying mode to capture impurities such as fine particle dust, gypsum and liquid water, and thus cleaning discharge of fume of the thermal power plant can be achieved.

Owner:北京新世翼节能环保科技股份有限公司

Textile machine dust collection device good in dust collection

InactiveCN108442025AImprove dust removal effectSolve the problem of dust removalAuxillary apparatusKnittingEngineeringWater tanks

The invention discloses a textile machine dust collection device good in dust collection. The device comprises a working table, a protection box and a dust collection box are fixedly connected to thetop of the working table in sequence from left to right, a bottom plate is fixedly connected to an inner cavity of the protection box, and a cylinder is fixedly connected to the top of the left side of the inner wall of the protection box. Accordingly, by means of cooperation of the working table, the dust collection box, a bearing table, the protection box, the bottom plate, a dust sucking pipe,the cylinder, a sleeve plate, a sliding rod, a sliding groove, a corrugated pipe, a sliding column, a delivery pipe, a draught fan, a water inlet, a water outlet, a filter screen, an output pipe, a spray head, a connecting pipe, a water tank, a spray plate and a water pump, the problem that when a textile machine is used, due to the fact that a fabric body can be accompanied with dust, if the fabric body is not treated, dust can enter the textile machine, and when an existing textile machine is used, the dust collection effect is poor is solved, use of a user is facilitated, and the practicability of the textile machine is improved.

Owner:SUZHOU SUOBU ROBOT CO LTD

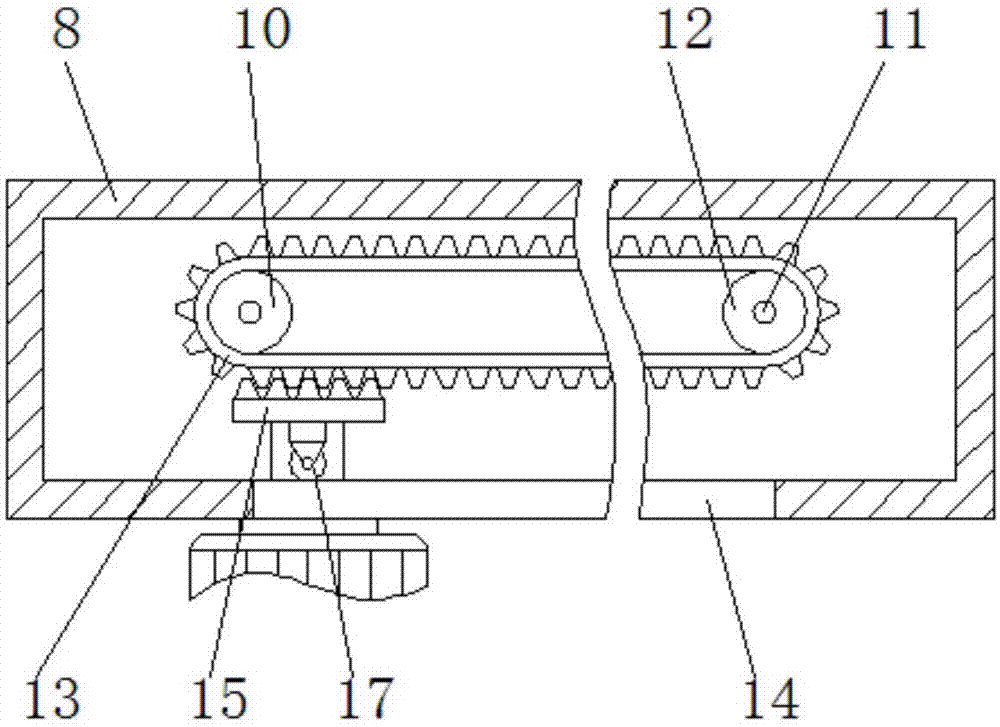

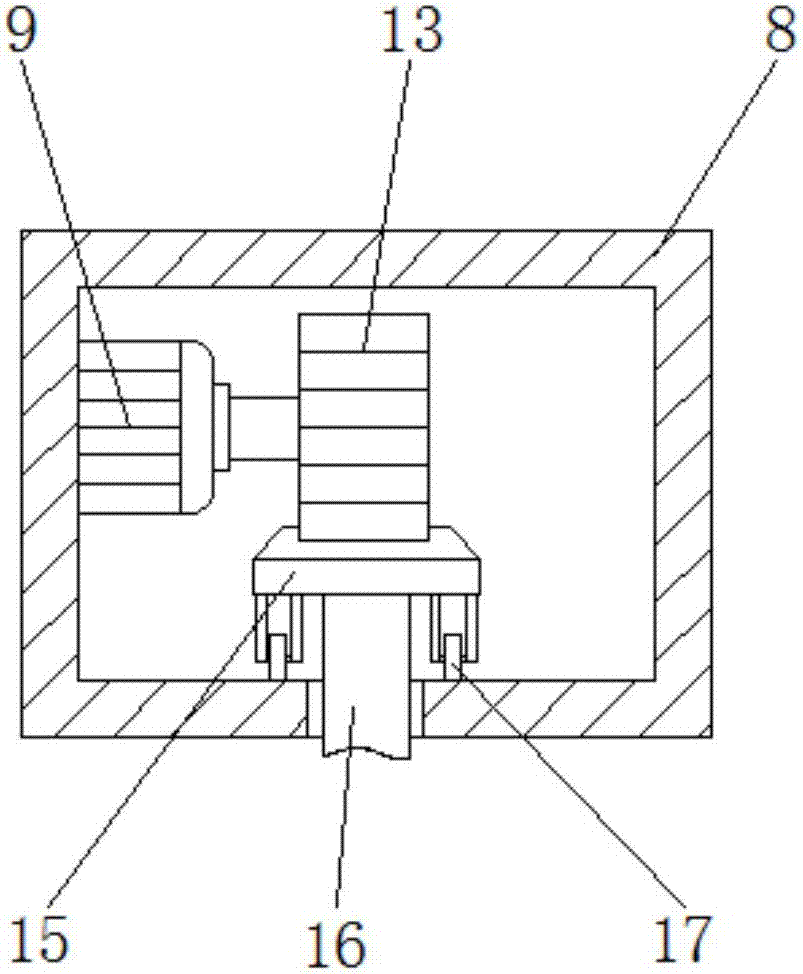

Textile rack dust removal device

InactiveCN107442477ASolve the problem of dust removalImprove dust removal effectDirt cleaningCleaning using toolsGear wheelEngineering

The invention discloses a textile rack dust removal device. The device comprises a textile rack body, supporting legs are fixedly connected with two sides of the bottom of the textile frame body, a supporting column is fixedly connected with the left side of the top of the textile frame body, and a dust inlet is formed in the right side of the supporting column; a dust removal box is fixedly connected with the left side of the supporting column, a draught fan is located on the left side of the supporting column and in the inner cavity of the dust removal box, and a dust outlet pipe is communicated with the center of the left side of the dust removal box. Through cooperation of the supporting column, the dust inlet, the dust removal box, the draught fan, the dust outlet pipe, a box body, a first motor, a first belt wheel, a fixing rod, a second belt wheel, a gear belt, a through hole, a toothed plate, a vertical plate, wheels, a second motor, a rotating rod and a brush, the problem that the dust removal effect of an existing textile rack dust removal device is poor is solved. The textile rack dust removal device has the advantage of being good in dust removal effect, dust can be prevented from floating up, and the device can be conveniently used by an operator.

Owner:HUZHOU JIACHUANG AUTOMATION TECH CO LTD

Filtering dust remover

InactiveCN107774066ASolve the problem of dust removalDispersed particle filtrationTransportation and packagingAirflowProduct gas

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Systematic dust collector

ActiveCN103961963AAvoid secondary pollutionImprove processing collection efficiencyCombination devicesEngineeringWater tanks

The invention relates to the technical field of environmental protection, in particular to a systematic dust collector, which comprises an induced draft fan, an air main and a dust chamber, wherein one end of the air main stretches into the dust chamber; the air main is located below a sprinkler; a filter layer is arranged at the upper end of a water tank; guide rails are symmetrically arranged on the transverse side walls of the water tank; a scraper is arranged above the filtering layer; the two sides of the scraper are fixedly connected with moving arms; grooves matched with the guide rails are arranged at the bottom ends of the moving arms; and the longitudinal side wall at one end of the water tank is inclined inwards, and the inward inclination angle is at least 60 degrees. The systematic dust collector further comprises a conveying device, wherein one end of the conveying device stretches into the dust chamber to contact with the inward inclined face of the water tank, and a dust collection bucket is arranged at the other end of the conveying device. When the systematic dust collector is used, not only the dust collection problem can be solved but also secondary pollution can be avoided in the collection process of dust; and meanwhile, the dust processing and collection efficiency can be improved. The systematic dust collector has the advantages of simple structure, rational setting, low manufacturing cost and the like.

Owner:FUJIAN XINLONG ENVIRONMENTAL PROTECTION CO LTD

Cloth and yarn cutting-off machine with dust removal function

ActiveCN105040393ASimple structureSolve the problem of dust removalCombination devicesSevering textilesYarnEngineering

The invention discloses a cloth and yarn cutting-off machine with a dust removal function. The cloth and yarn cutting-off machine comprises a cutting-off machine box, a feeding port, a discharging port and a rotating hob. The feeding port is formed in the front end of the cutting-off machine box. The discharging port is formed in the rear end of the cutting-off machine box. The rotating hob is arranged in the cutting-off machine box. A dust filtering plate is arranged on the portion, above the rotating hob, in the cutting-off machine box. A top dust discharge port is formed in the portion, above the dust filtering plate, of the cutting-off machine box and connected with a dust discharge pipeline. The situation that when the cloth and yarn cutting-off machine works, dust flies everywhere and has a serious impact on human bodies and environment is improved, after the technical scheme is adopted, the dust removal rate can be 90% or over 90%, and the structure is simple and practical.

Owner:绵阳光益生物科技有限公司

Dustproof system for automobile

InactiveCN102849036APrevent from bringing upSolve the problem of dust removalVehicle cleaningRoad surfaceWaste management

The invention discloses a dustproof system for an automobile. The dustproof system comprises a water tank (1), a water feeding pipe (2) and a ventilation pipe (3), wherein the water tank (1) is hung on a girder of the automobile or is erected in front of a carriage; water in the water tank (1) is guided and sprayed on tire through a pipeline; the pipeline comprises a hose arranged along the girder and a hard pipe arranged on a front axle, an intermediate axle or a rear axle of the automobile; spray heads are arranged on hard pipes; the hose is connected with the hard pipe; and a metering device (7) is arranged on one side of the water tank (1) and is used for indicating the weight of residual water in the water tank (1). According to the dustproof system of the automobile, which is disclosed by the invention, the water is sprayed on the tire, so that the dust caused by the tire is prevented, the problem in dust removal in a factory area, a harbor area and a mine area can be effectively solved, the dust can be reduced by 80-90 percent and the pavement temperature can be reduced by 2-5 degrees.

Owner:邱万

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com