Dry type dust collector for mining drilling orifice

A technology of dry dust collector and drilling hole, which is applied in the direction of construction, etc. It can solve the problems that the dust collector cannot withstand the impact of high-pressure air flow, the dust collector and drilling rig, drilling tools are damaged, and the working environment is smoky, so as to improve the drilling operation environment , High dust removal efficiency, good for physical and mental health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

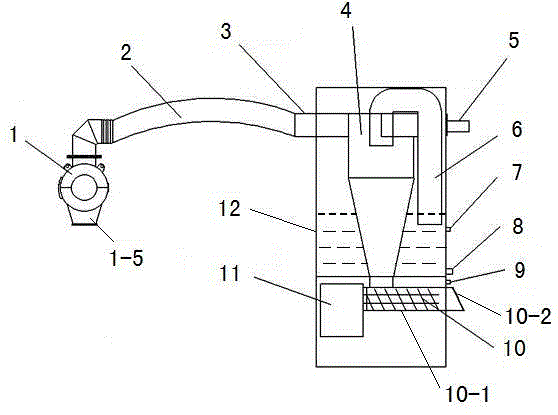

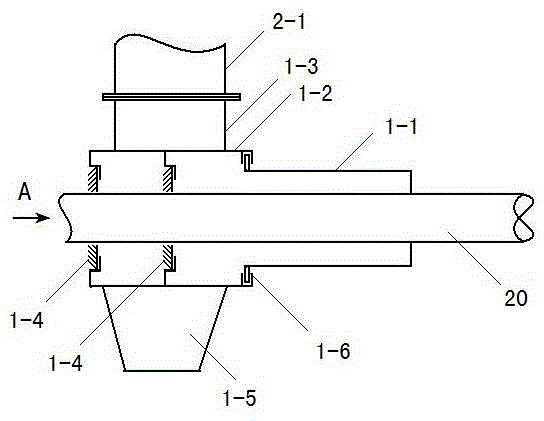

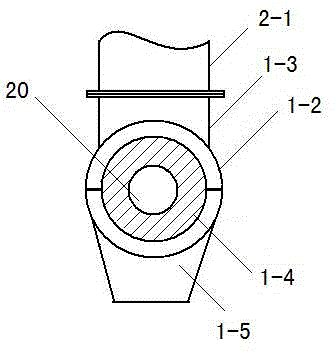

[0021] Such as figure 1 , figure 2 , image 3 As shown, a dry-type dust collector for drilling holes for mining, the back of the dust collector 1 is connected to the inlet 3 of the cyclone dust collector through a hose 2, and the inlet 3 of the cyclone dust collector is placed on the top of the slag discharge box 12, and the slag discharge The box 12 is a closed box, which can be round, oval or square; a gas outlet 5 is also provided on the upper part of the slag discharge box 12, and a cyclone dust collector 4 (Sacron cyclone dust collector, It is a kind of dust removal device. The mechanism of dust removal is to make the dust-laden air flow rotate, and the dust particles are separated from the air flow by centrifugal force and collected on the wall of the device, and then the dust particles fall into the ash hopper by gravity), and the air duct 6. The air motor 11 (flameproof air motor, the same below) and the auger 10, the slag discharge box 12 is divided into three part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com