Wet type dust collector for mining drilling orifice

A wet dust collector and drilling hole technology, which is used in dust prevention, mining equipment, earth-moving drilling, etc., can solve the problems of physical injury of operators and endanger the health of operators, so as to improve dust removal efficiency and improve drilling operations. The effect of high environmental and dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

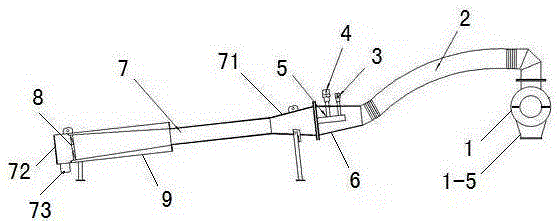

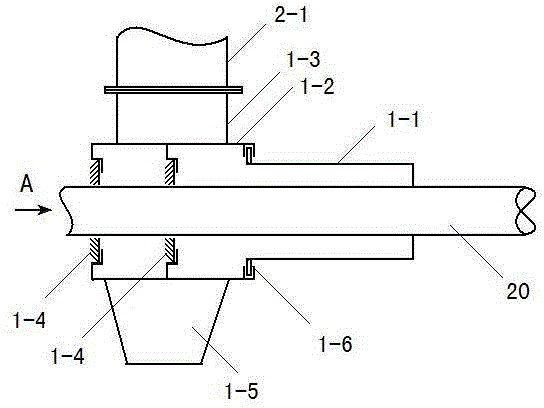

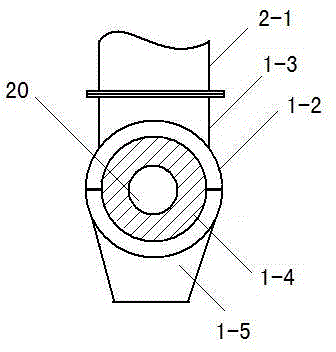

[0023] Such as figure 1 , figure 2 , image 3 As shown in the figure, a wet dust collector for mining drilling holes, the dust cover connecting pipe 1-3 on the upper part of the dust collector 1 is connected to the hose connecting pipe 2-1 through the flange, and the hose connecting pipe 2-1 is connected to the hose 2 ( The hose can be a soft steel wire pipe), the hose 2 is connected to the jet disc 6, and the jet disc 6 is a funnel-shaped tube (that is, the thickness is uneven), and the water-air nozzle 5 is arranged in the center (dust and gas can pass through the surrounding area) , the water-air nozzle 5 is respectively connected with a water interface 3 and an air interface 4 leading to the outside of the jet plate 6 ( figure 1 This place is a sectional view), water and air can be passed into the water and air nozzle 5 through the water interface 3 and the air interface 4; the jet disc 6 is connected to the atomization chamber 71 (the front thick and the rear thin tube...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com