Patents

Literature

366results about How to "To achieve the purpose of dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

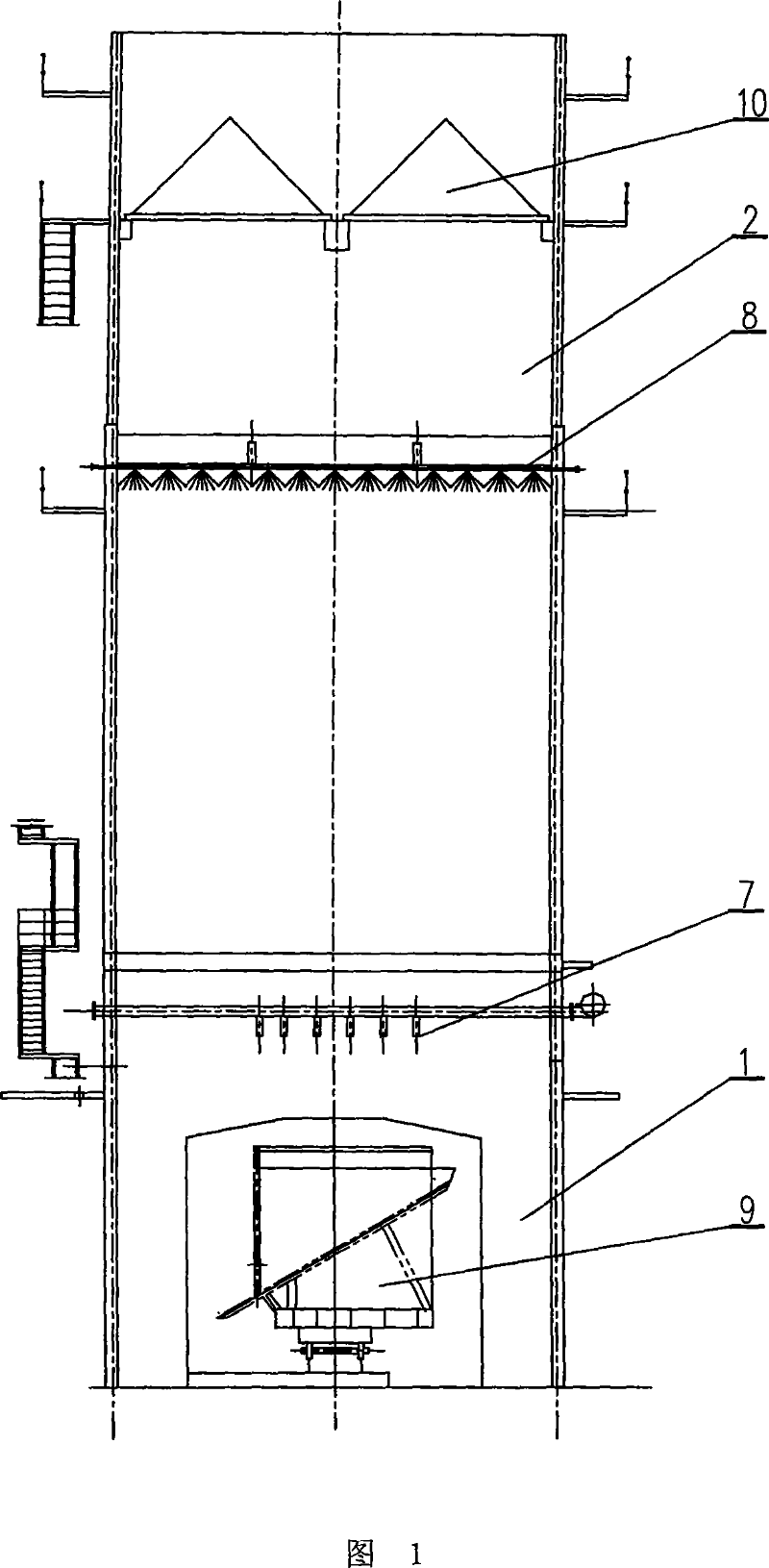

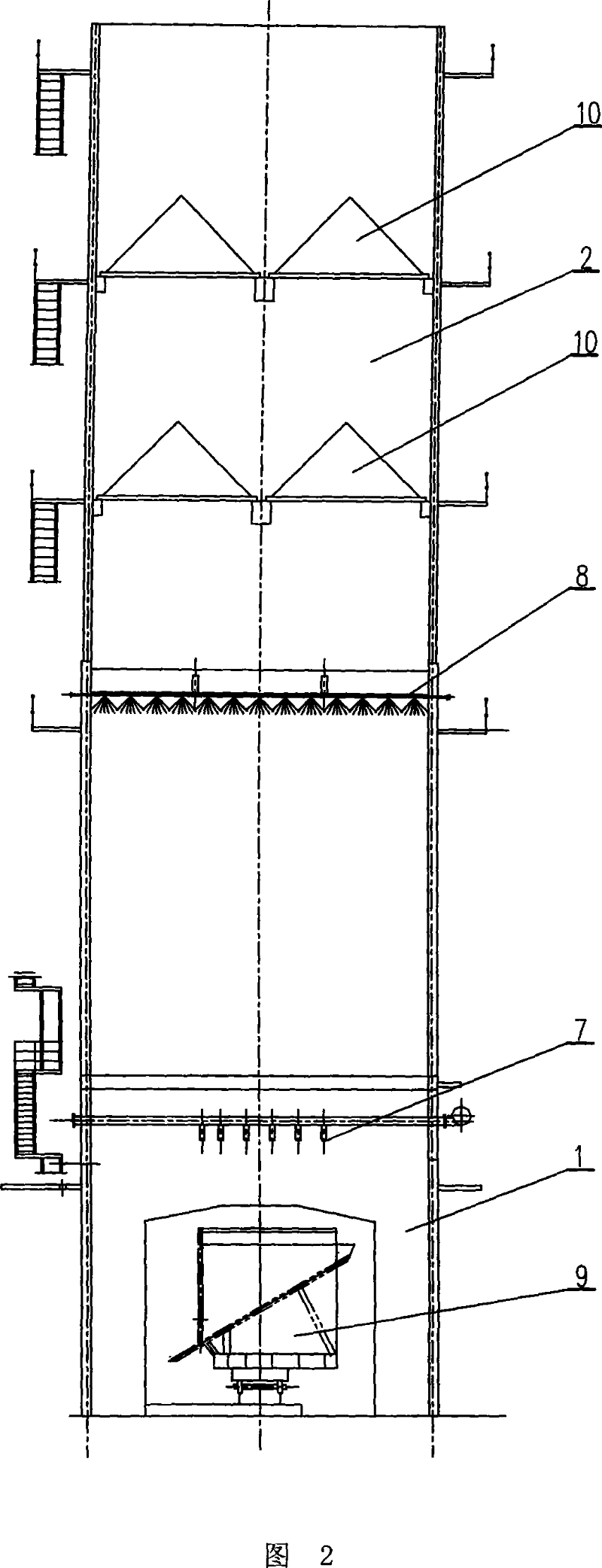

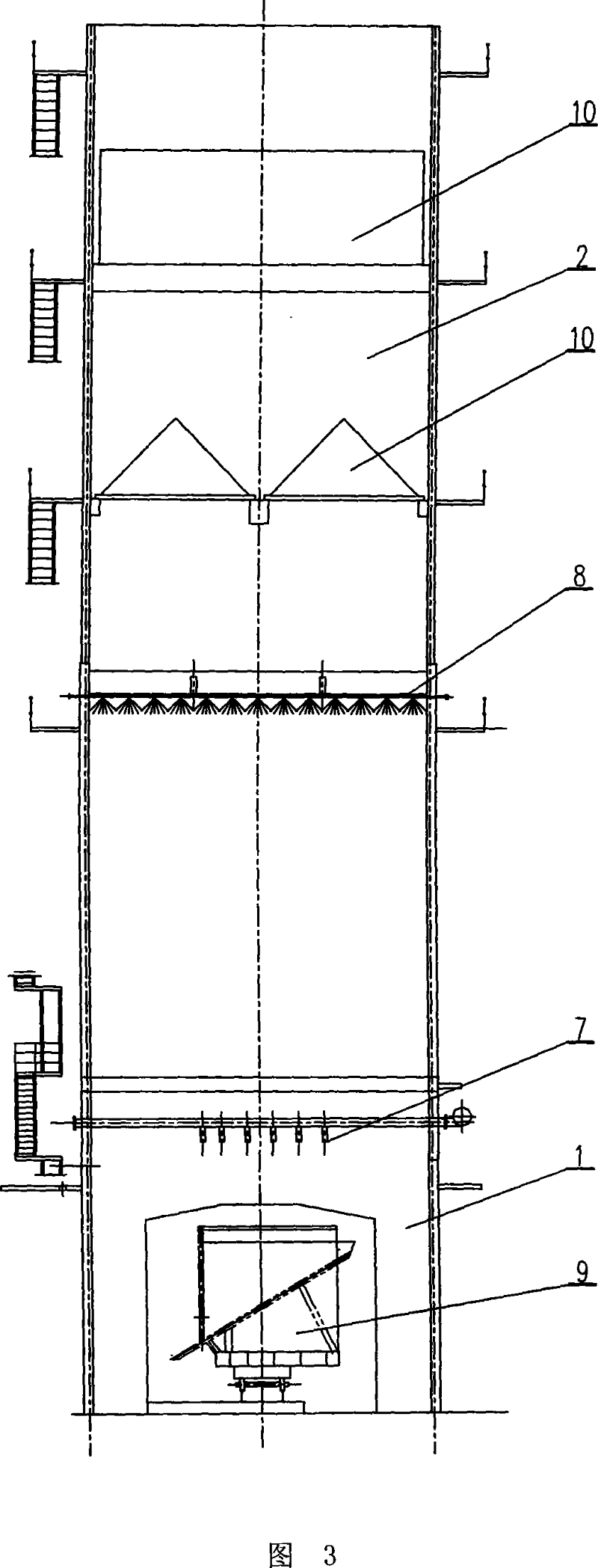

High-effective dust-removing coke quenching tower

ActiveCN101037603AEasy dust removal effectGuaranteed dust removal performanceCoke quenchingSingle stageTower

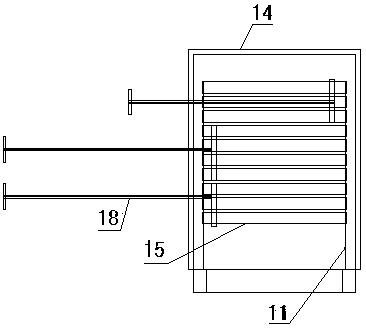

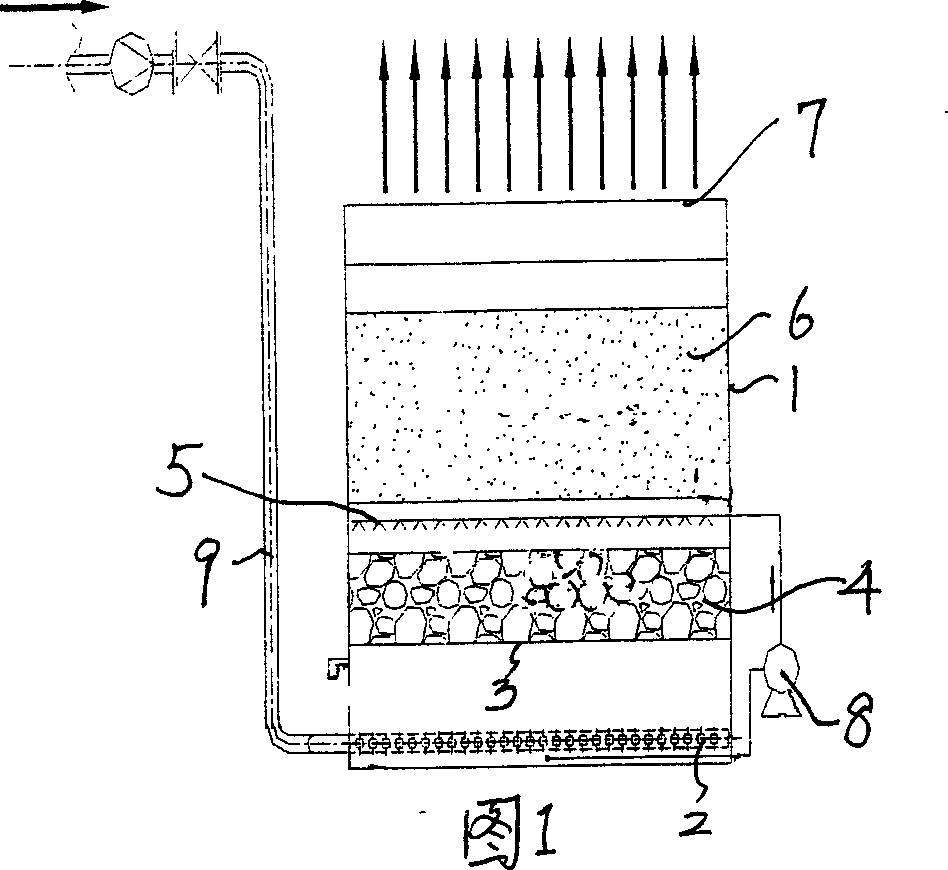

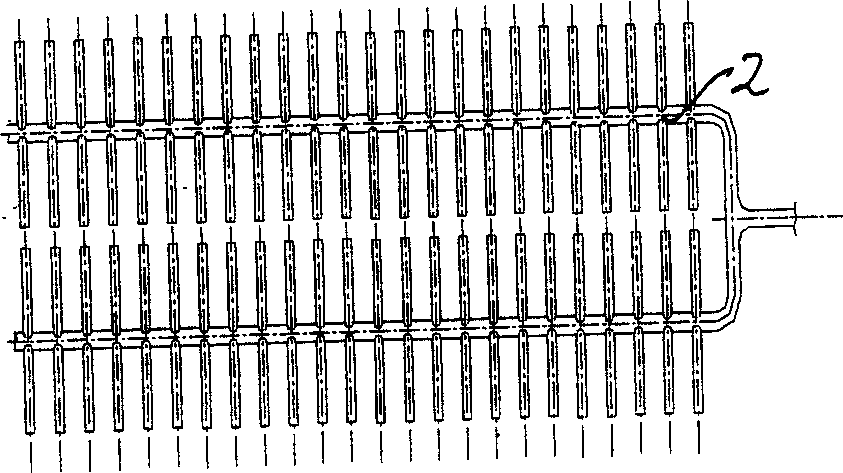

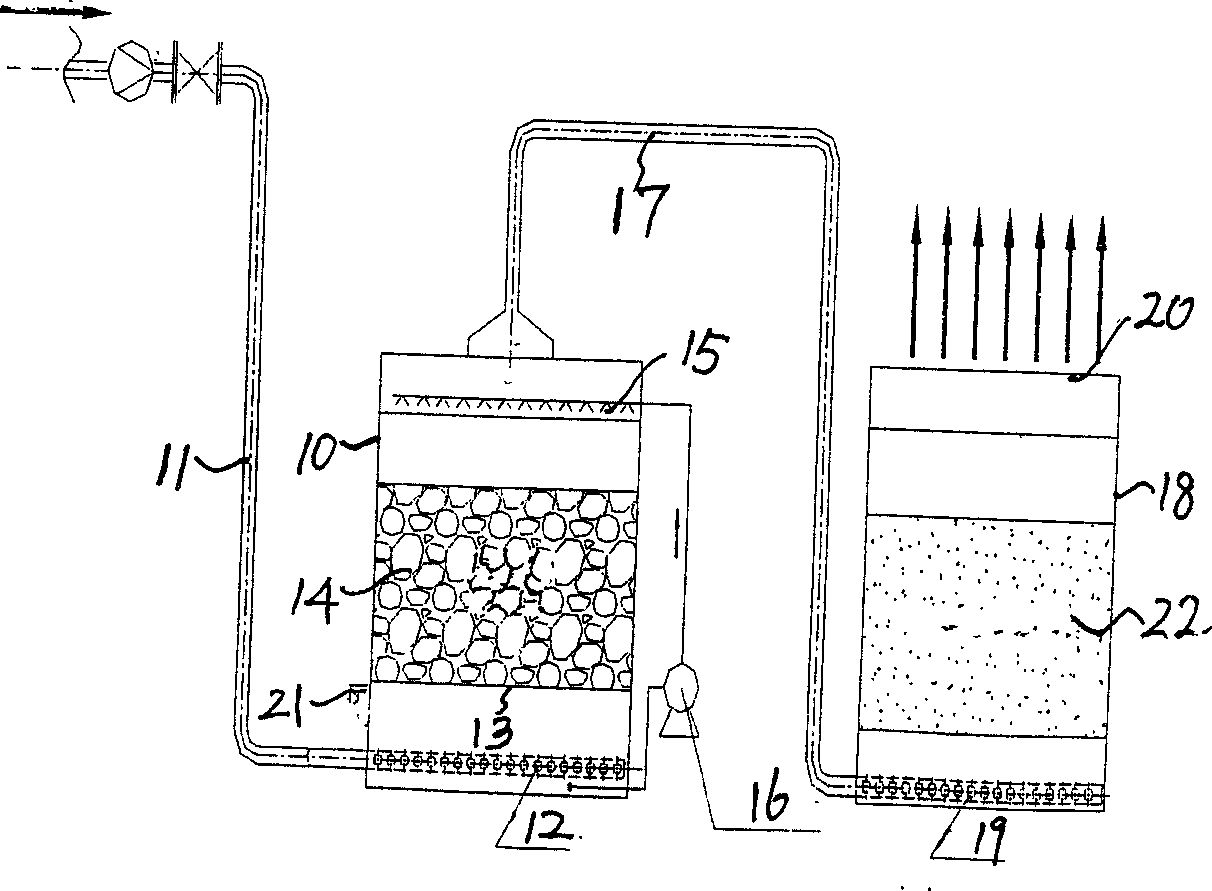

The invention relates to a highly effective dust removal coke quenching machine, which includes a coke quenching injection pipe, a washing and cooling device, and a dust removal device. The dust removal device, which is disposed single-stage or two-stage, includes a structural framework, a dust removal plate, a dust removal pipe and nozzles, wherein the dust removal plate, which is constituted of a heterotypic baffle sheet folded with a certain angle and a dust removal plate support, is disposed on the structural framework and forms angle of 45-60 DEG with horizontal plane; the dust removal pipe is equably equipped with a plurality of nozzles and is arranged parallel with the dust removal plate. Dust content of stream generated at coke quenching process is greatly reduced by water fog washing, cooling, gravitational settling and purifying of baffle plate type dust removal device, amount of coking powder discharged into air of per ton coke is lower than 50g. Moreover, the baffle plate employs industrial plastic, thereby possessing advantages of corrosion resistance, high strength, aging resistance, good dust removal effect, convenient installation and maintance, and easy cleaning.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

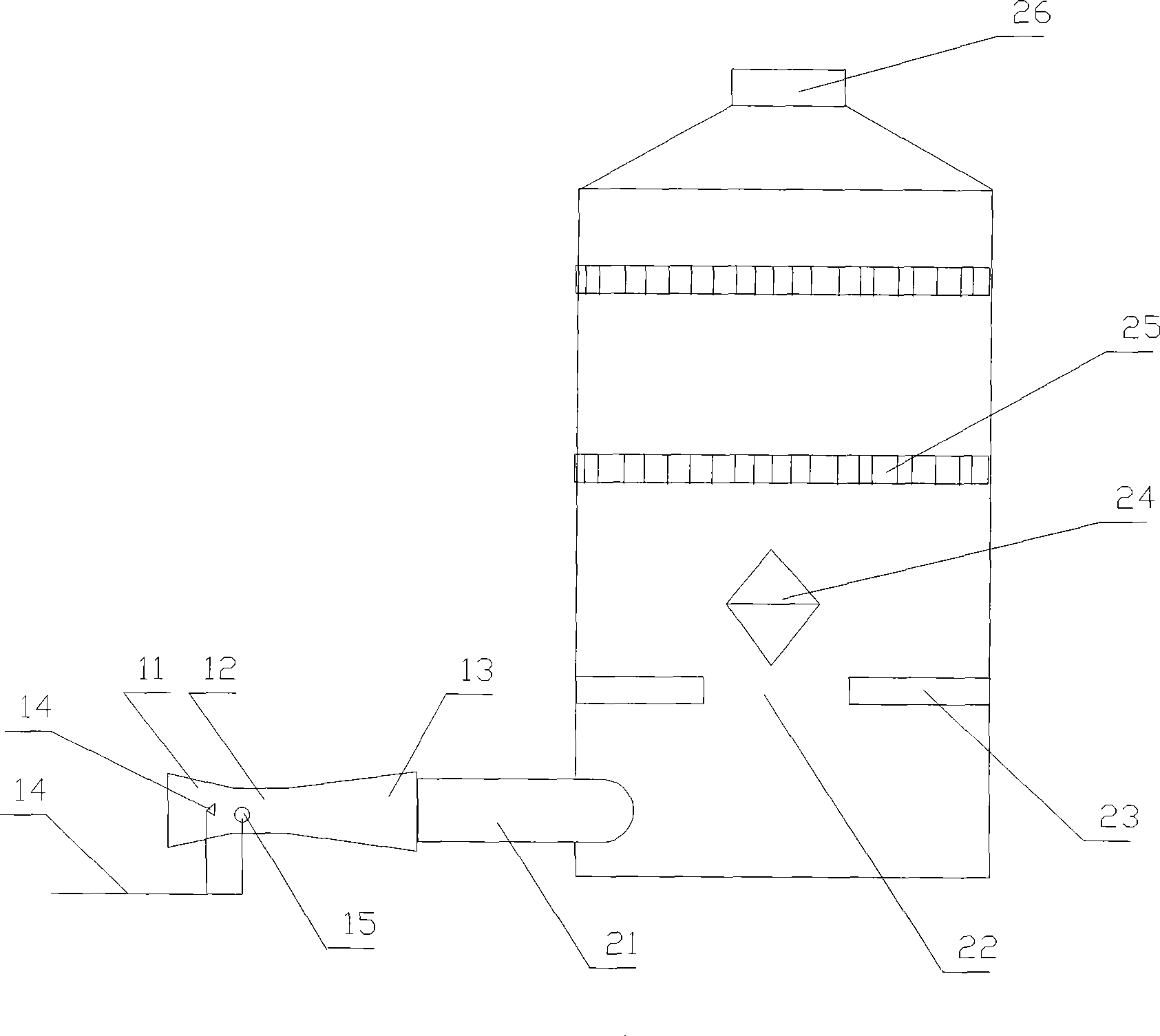

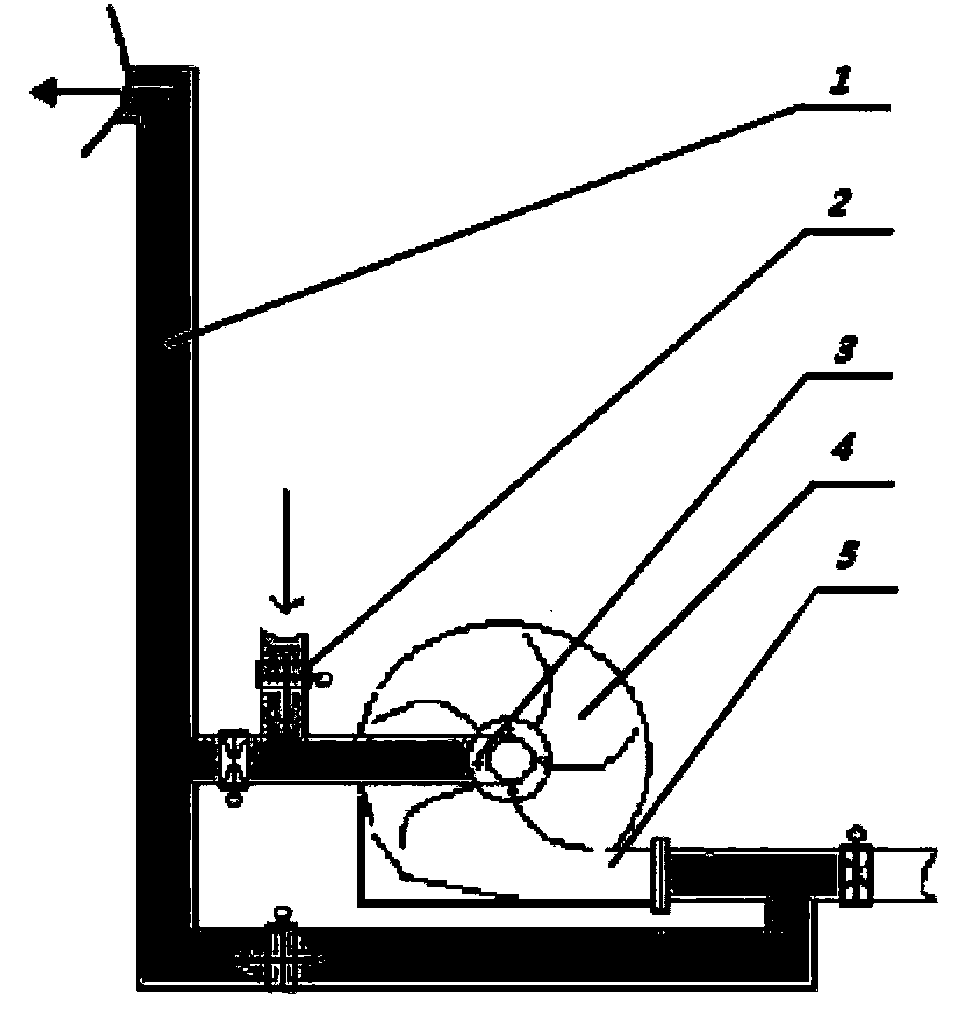

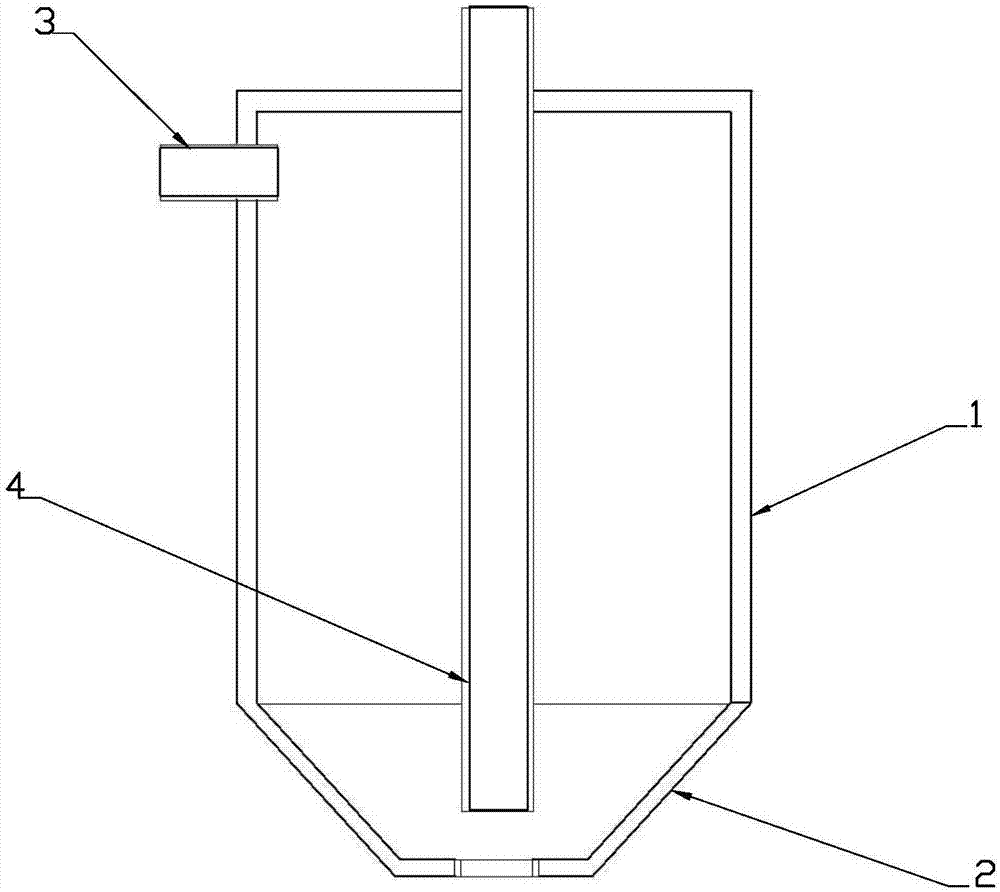

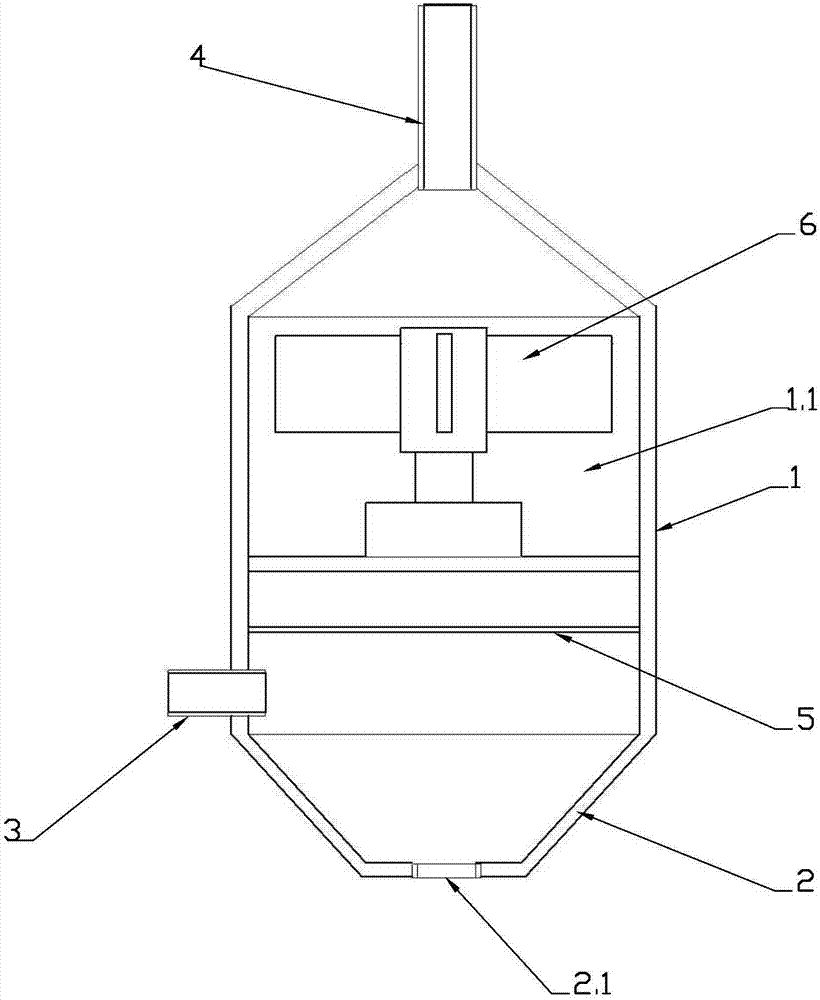

Venturi cyclone dust extractor

InactiveCN101468276AOvercome the defect of small quantityAchieve separationCombination devicesCrystallization separationCycloneEngineering

The invention relates to a venturi tube cyclone dust collector, which is characterized by comprising a venturi tube and a cyclone sedimentation tower, wherein outlet gas of the venturi tube tangentially enters a cyclone area on the lower part of the cyclone sedimentation tower through an air inlet pipe of the cyclone sedimentation tower; the venturi tube consists of a contraction section, a throat section and a diffusion section; the side wall of the throat section is provided with a plurality of through holes, and the outer side of the through hole are connected with a pressure water supply pipe; a port of the diffusion section forms an air outlet of the venturi tube; a port of the contraction section forms an air inlet of the venturi tube; the lower part of the cyclone sedimentation tower is a cyclone area, the upper part is a sedimentation and dehydration area, and the middle part is provided with an annular clapboard; and the upper part of the sedimentation and dehydration area is provided with a plurality of gas-liquid separating layers. The venturi tube cyclone dust collector has the advantages of small investment, high dust removing efficiency, comparatively longer service life, small water consumption and low running cost, and can be mainly applied to the dust removal of high density flue gas and industrial dust in various industrial furnaces.

Owner:HAISIBOTE BEIJING SCIENE & TECH

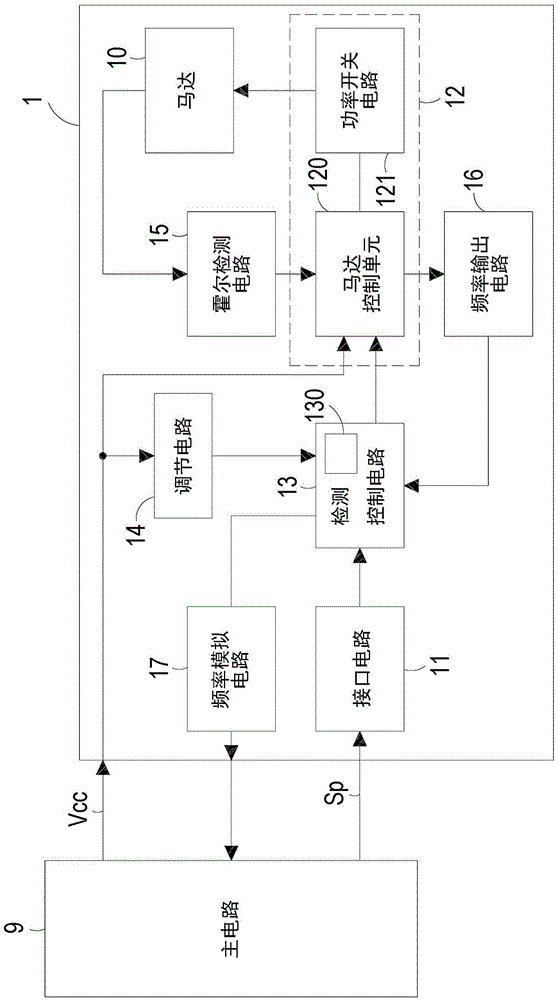

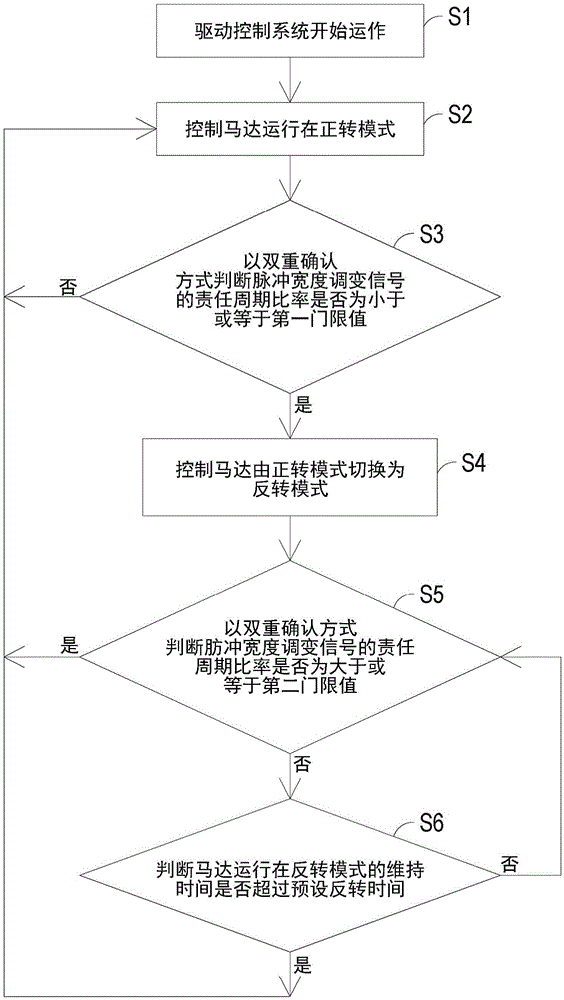

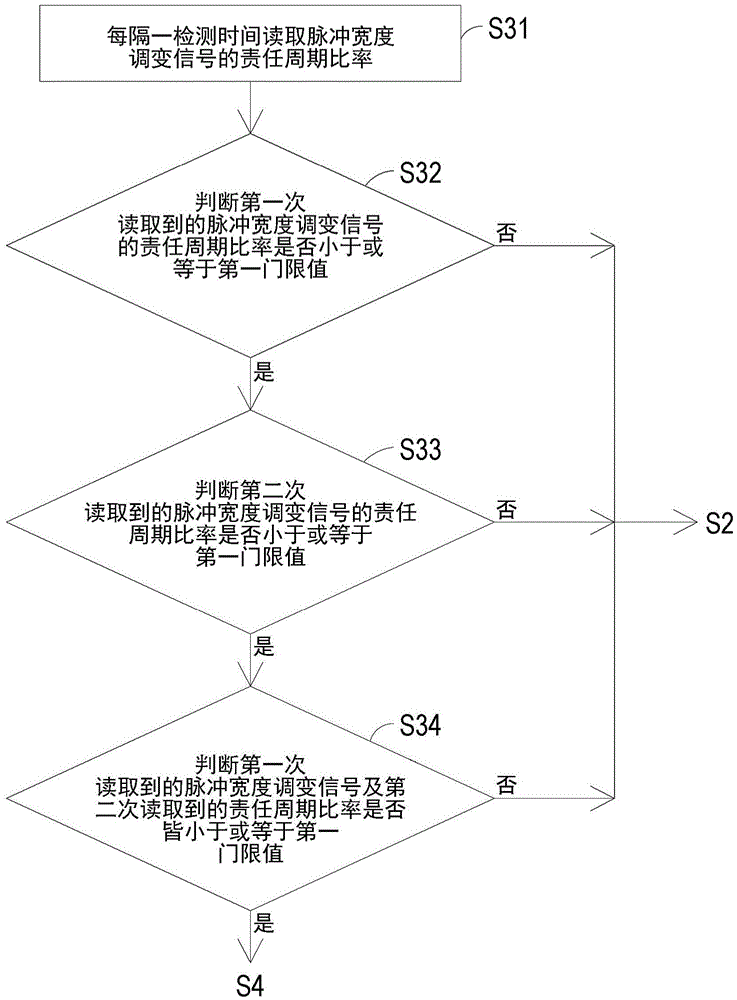

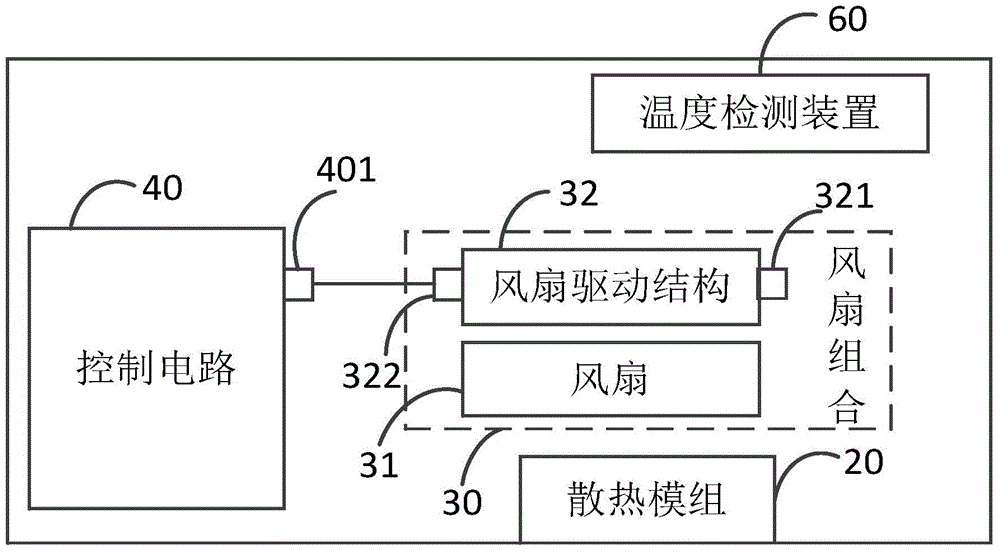

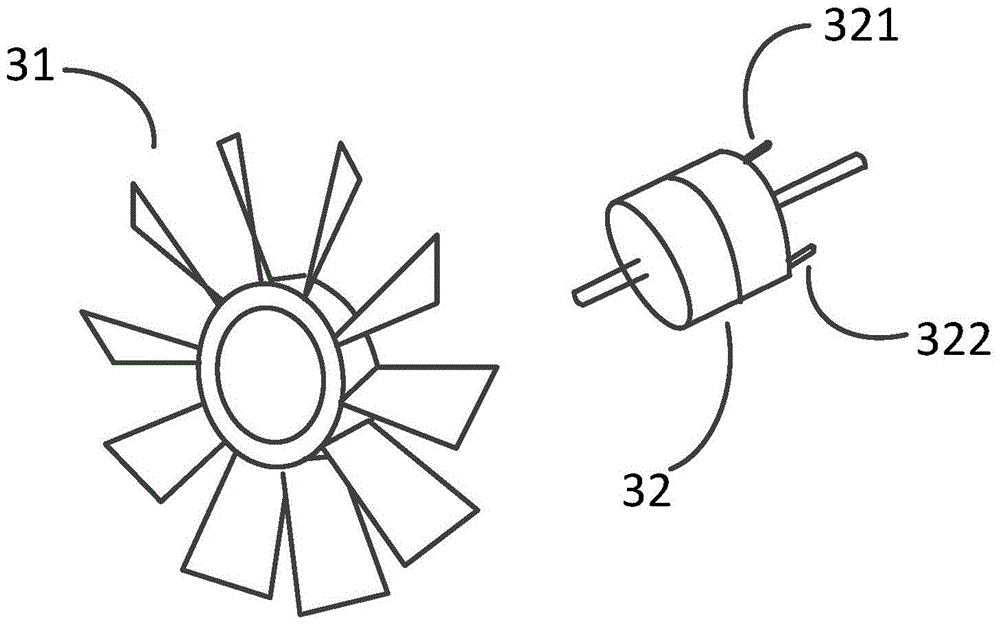

System And Method For Controlling Forward/Reverse Rotation Of Fan

ActiveCN105889109AEfficient heat dissipationTo achieve the purpose of dust removalPump componentsPump controlInterface circuitsElectricity

The invention provides a system and method for controlling forward / reverse rotation of fan. The control system includes a motor, an interface circuit, a motor controller and a detection control circuit. The interface circuit receives and converts a pulse width modulation signal. The fan dissipates heat when the motor is operated in a forward rotation mode and eliminates dust when the motor is operated in a reverse rotation mode. The detection control circuit reads a duty cycle of the converted pulse width modulation signal in real time. When the motor is operated in the forward rotation mode, the detection control circuit drives the motor controller to control the rotation speed of the fan according to the duty cycle. If the duty cycle is lower than or equal to a first threshold value, the detection control circuit drives the motor controller to switch operation mode of the motor from the forward rotation mode to the reverse rotation mode. The control system can dynamically control the motor and the fan to carry out forward rotation for blowing and reverse rotation for ventilation, in order to realize radiation and dust removal purposes with high efficiency.

Owner:DELTA ELECTRONICS INC

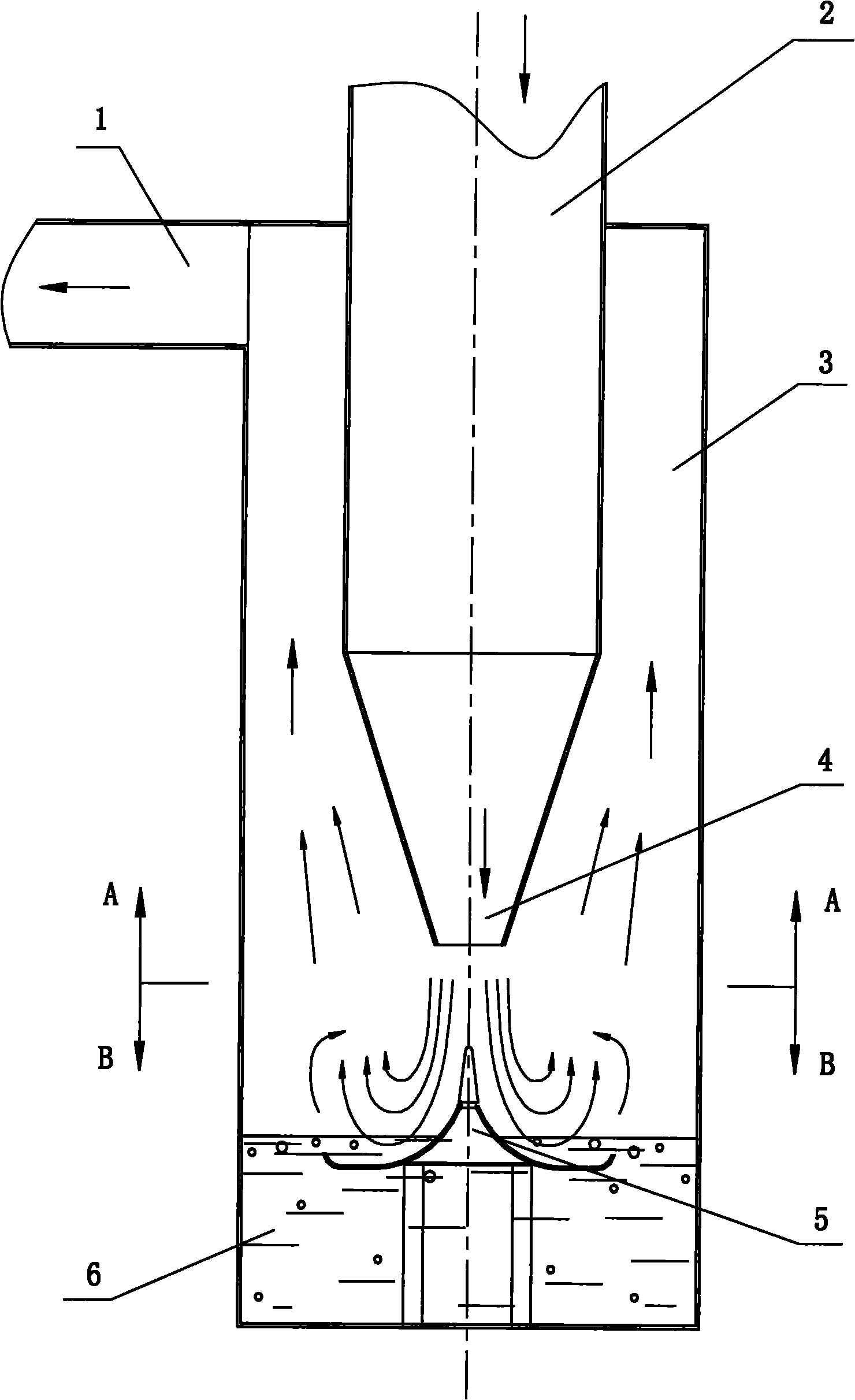

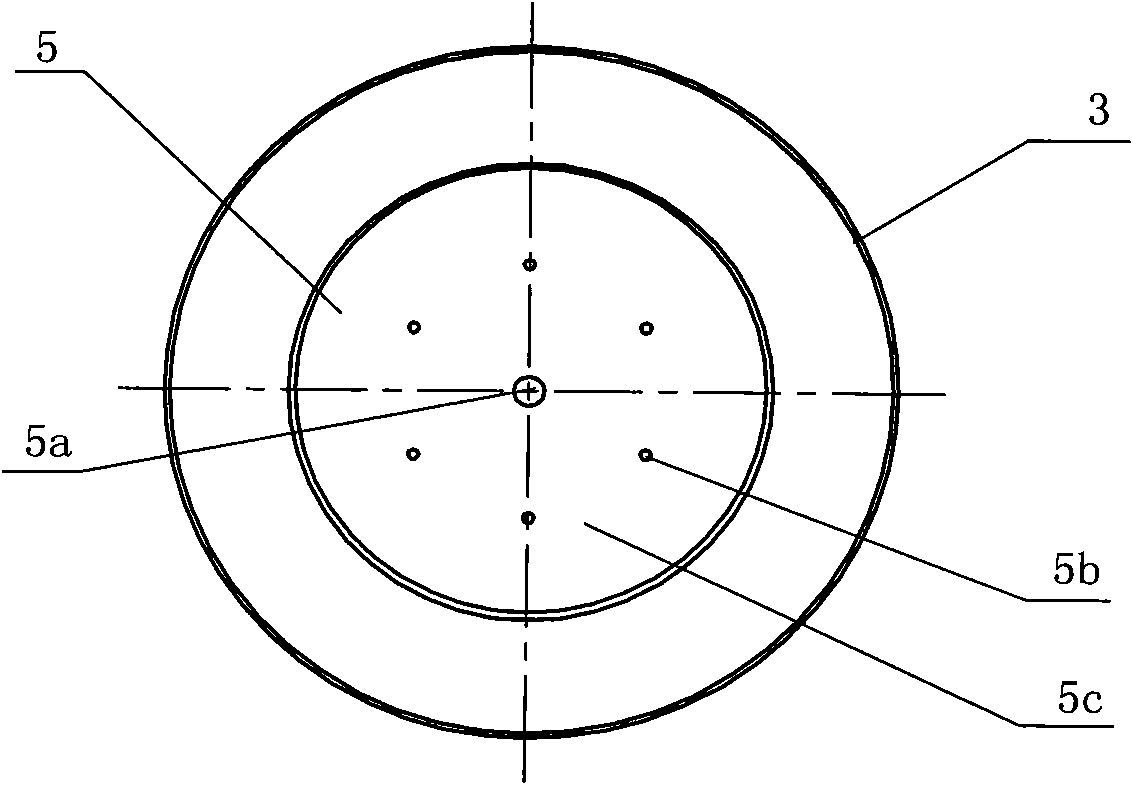

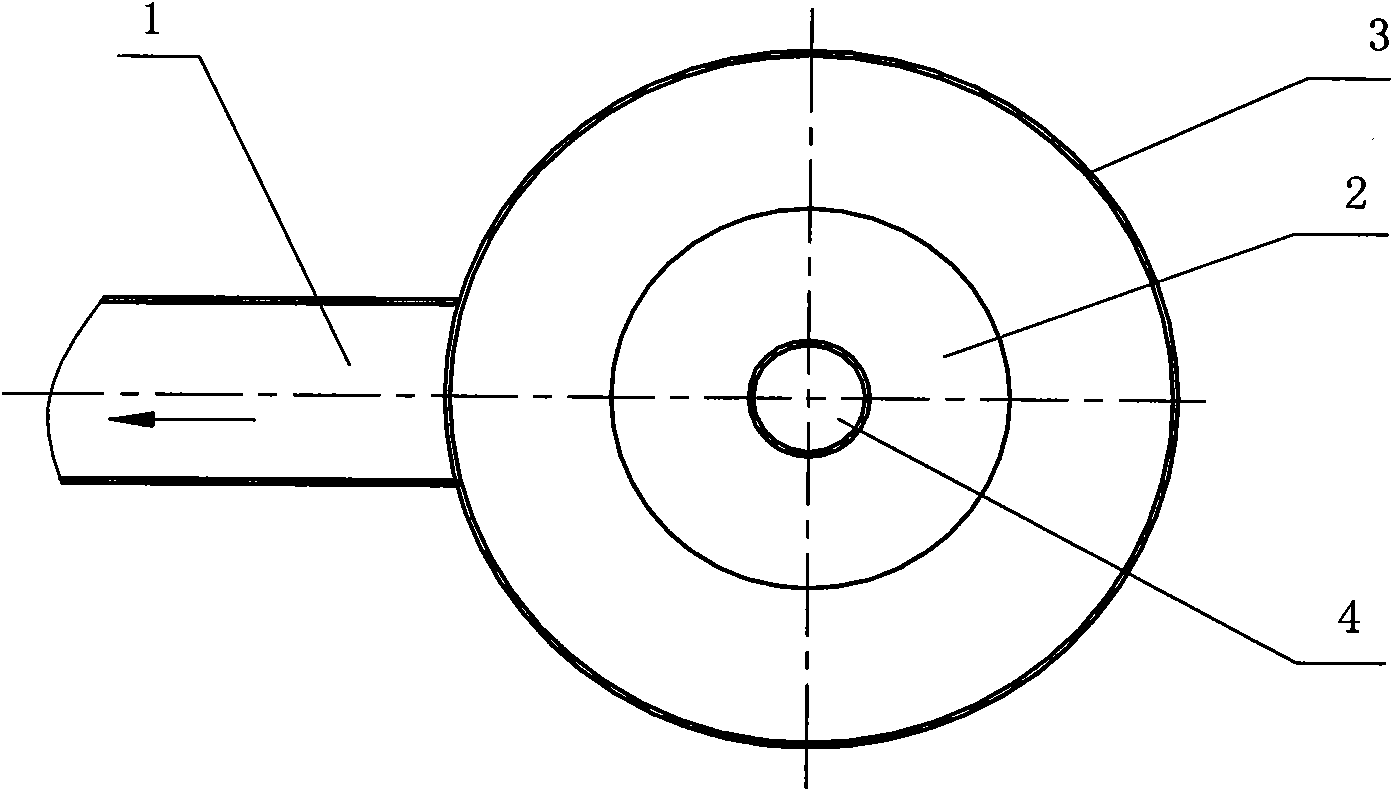

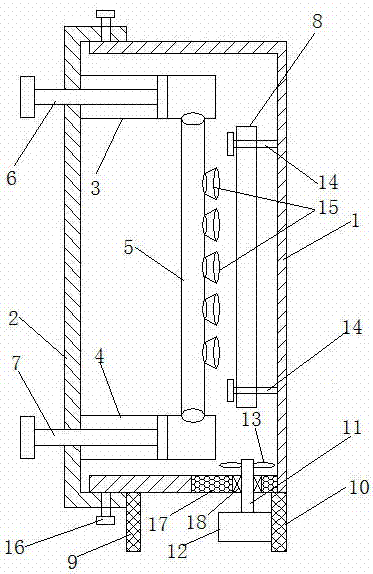

Device for guiding airflow to impact liquid level in tangential direction for forming moisture-containing airflow

InactiveCN101799169AEnsure safetyImprove heat transfer performanceLiquid fuel feeder/distributionUsing liquid separation agentEngineeringCurve line

The invention relates to a device structure used in the fields of liquefied natural gas heating gasification, natural gas heating, dust removal, central air-conditioning systems and the like. A device for guiding airflows to impact the liquid level in a tangential direction for forming moisture-containing airflows is characterized in that a conical spraying opening (4) communicated with a vertical downward airflow air inlet pipe (2) is arranged in a container (3), liquid (6) is arranged under the spraying opening (4), the lower part of an airflow swirl water element (5) in a reverse umbrella shape is soaked in the liquid (6), an airflow outlet (1) is led out on a passage formed between the inner wall of the container (3) and the outer walls of the air inlet pipe (2) and the spraying opening (4), the middle of the airflow swirl water element (5) is an upwards projected pointed top (5a) and then is an arc-shaped curve surface (5c) formed by being upwards bended a little after firstly going downwards to an edge by a curve line shape extending from the pointed top to the edge, and the horizontal projection of the outer ring of the airflow swirl water element (5) has the same shape as the horizontal cross section of the spraying opening (4) and is in a circular shape or a polygon shape. The invention has the advantages of simple structure and no movable component, is applicable to various kinds of strengthened heat transfer, has the functions of dust removal, humidifying purification and the like, and improves the heat efficiency and the dust removing efficiency.

Owner:SHANGHAI UNIV OF ENG SCI

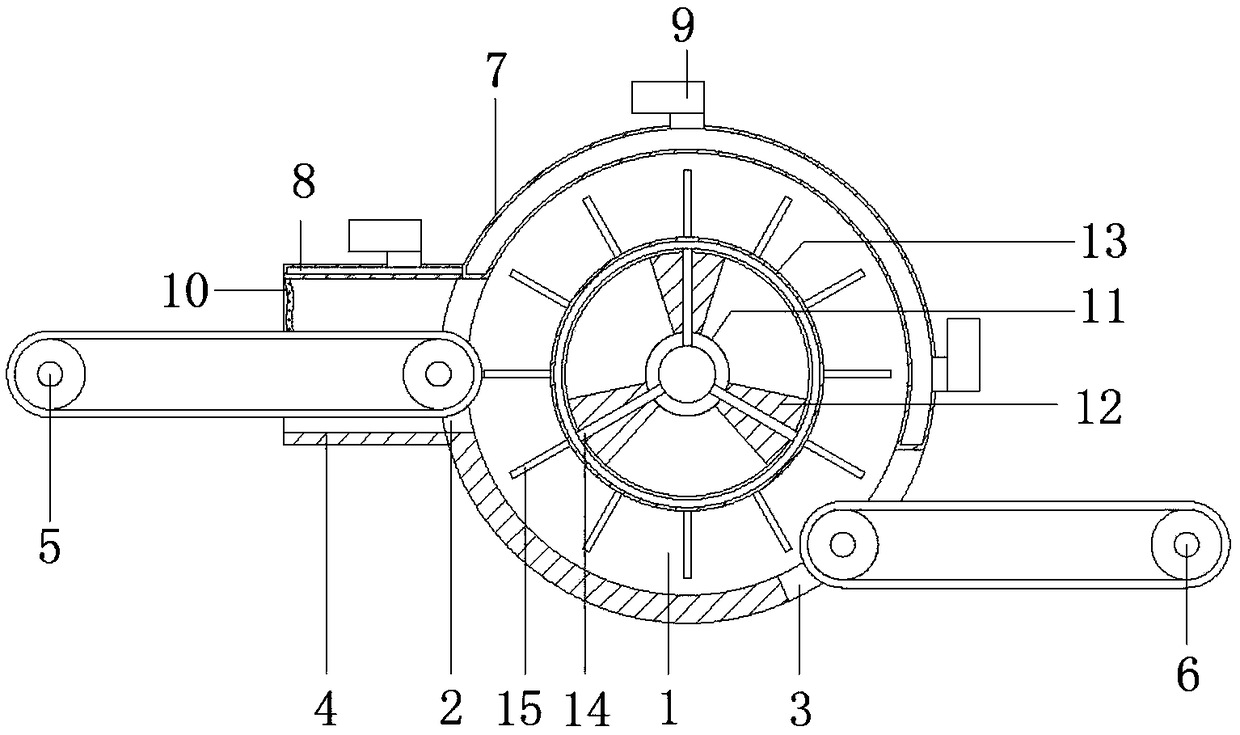

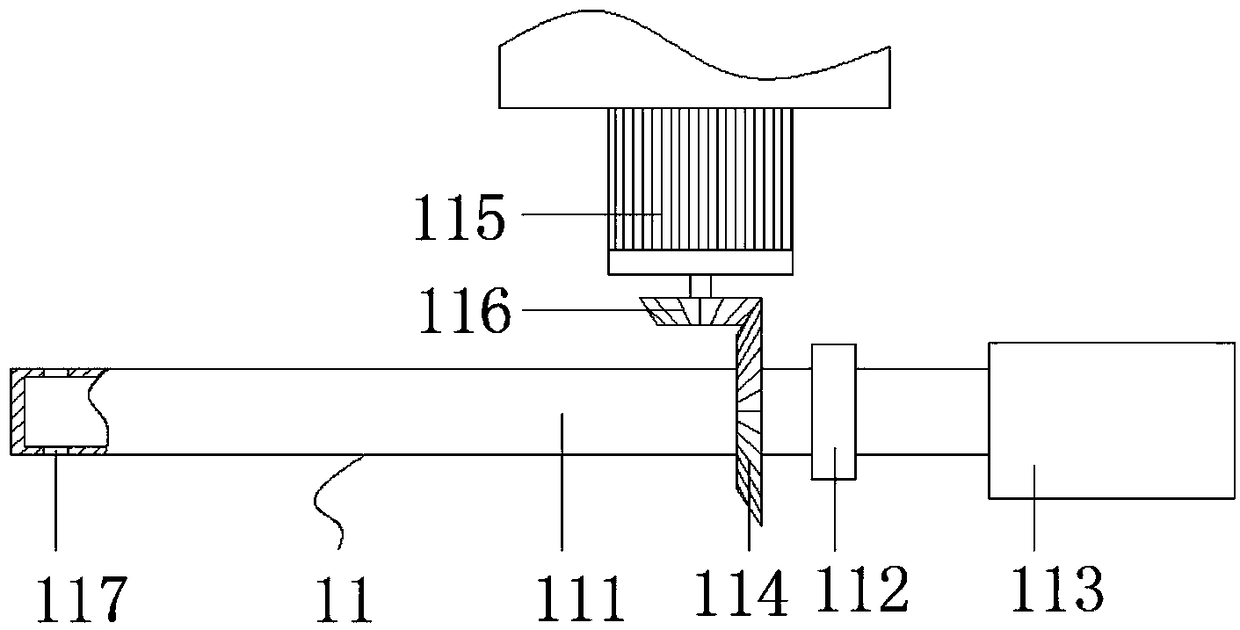

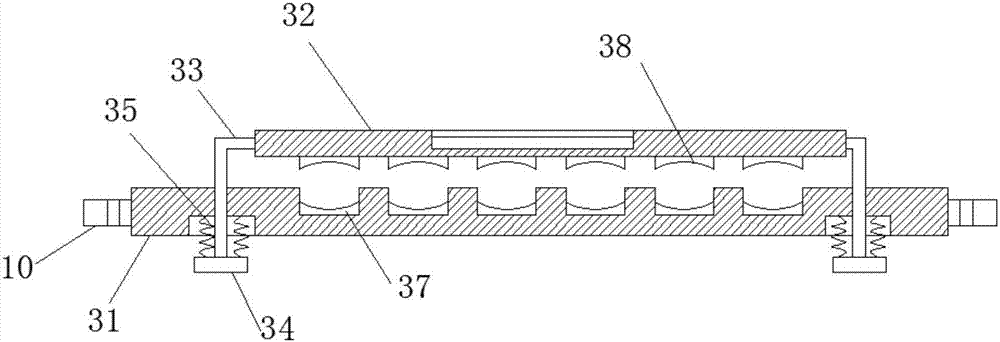

Dust removal device for cement packaging bag

InactiveCN108995911AEfficient removalTurn overDirt cleaningPackaging protectionAir blowerMaterials science

The invention discloses a dust removal device for a cement packaging bag in the technical field of cement processing. The dust removal device comprises a dust removal frame, wherein a cement bag inletis formed in the left side of the dust removal frame, a cement bag outlet is formed in the lower right side of the dust removal frame, and a feeding frame communicating with the cement bag inlet is arranged on the left side of the dust removal frame; a feeding conveyor belt driven by a conveyor motor is arranged on the left side of an inner cavity of the feeding frame in a penetrating manner; a discharging conveyor belt driven by the conveyor motor is arranged on the right side of the cement bag outlet in a penetrating manner; and a circular arc dust removal chamber is arranged at the top ofan inner cavity of the dust removal frame. The dust removal device is simple in structure and convenient to operate, dust on the cement packaging bag can be effectively removed, the cement bag can beturned over through rotation of cement bag supporting plates, dust removal of the cement bag is facilitated, the dust on the cement bag can be blown up by an air blower, the blown-up dust can be absorbed by a suction fan, and the purpose of dust removal is realized.

Owner:HUBEI BAIZHAOSHAN CEMENT CO LTD

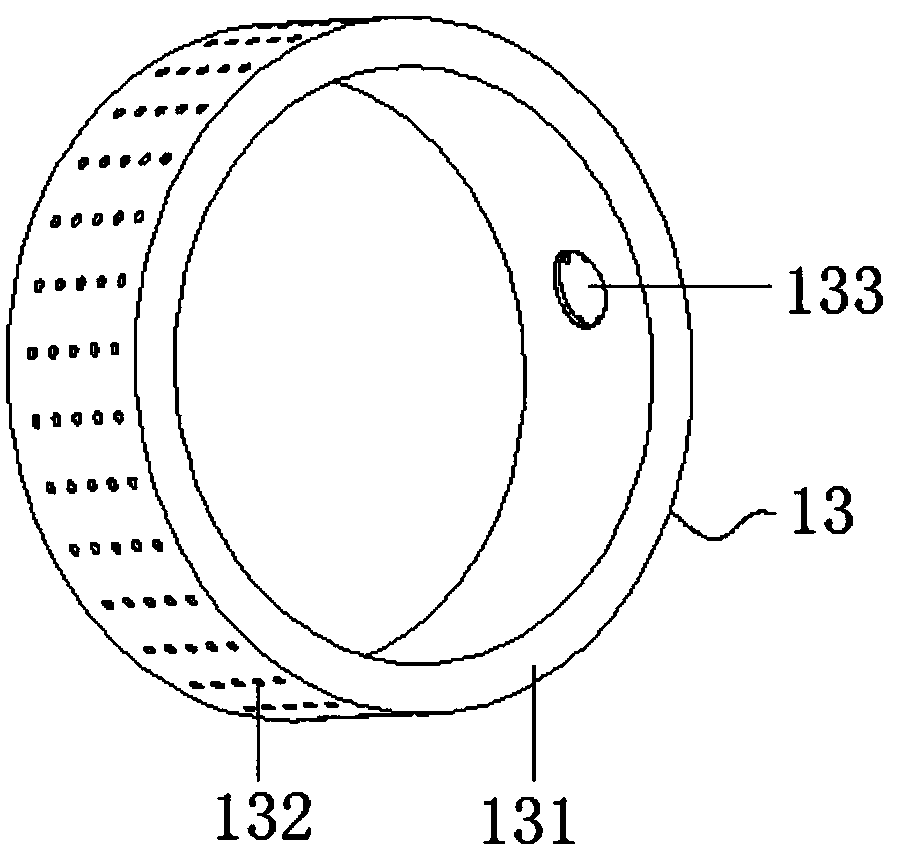

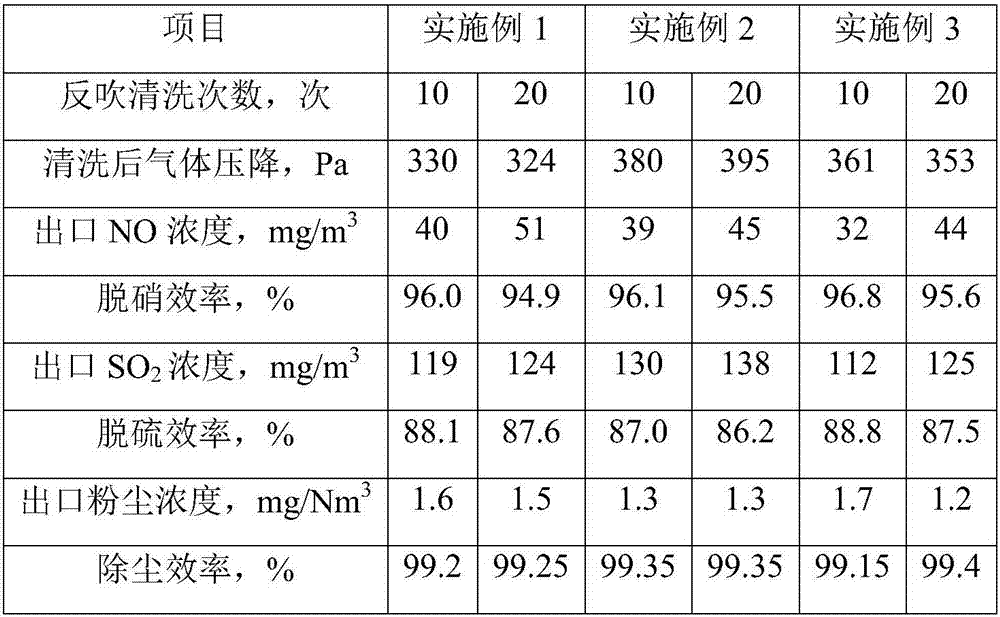

Ceramic catalytic filter element for flue gas purification and flue gas desulfurization and denitrification integrated dust removal method

ActiveCN107876043AExtended service lifeReduce loadDispersed particle filtrationTransportation and packagingActive matrixFlue gas

The invention relates to a ceramic catalytic filter element for flue gas purification and a flue gas desulfurization and denitrification integrated dust removal method. The ceramic catalytic filter element is prepared from the following steps that a microporous alumina ceramic filter tube with a pore diameter of 40-80 microns is taken as a matrix; the matrix is immersed in a mixed sol made of zincacetate, and after the matrix is impregnated under a negative pressure, the matrix is roasted to obtain a modified matrix modified by zinc oxide; an equal volume impregnation method is adopted, and the modified matrix is impregnated with an mixed oxalic acid solution containing ammonium metavanadate and ammonium metatungstate, so that total loading mass of V2O5 and WO3 in pores of the matrix reaches 4.0%-6.0% to obtain an active matrix; the active matrix is immersed in a mixed sol made of Al2O3-SiO2-TiO2, the active matrix is dried and roasted after the active matrix is taken out, and a densefilm with a thickness of 0.2-0.6 millimeter and a pore diameter of 1-10 microns is formed on the outer surface of the active matrix to obtain the ceramic catalytic filter element. A denitrification catalyst of the ceramic catalytic filter element has the advantages of being strong in load, high in denitrification efficiency, long in service life and applicable to popularizing and using.

Owner:济南玉泉生物发电有限公司

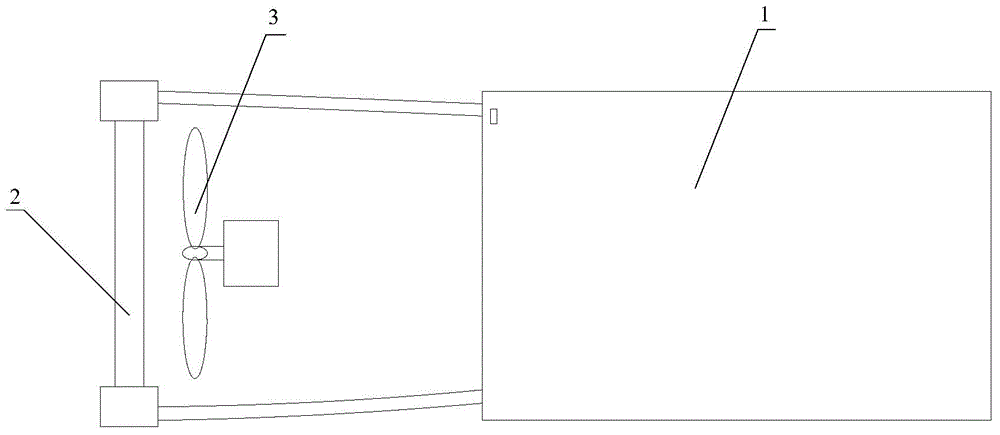

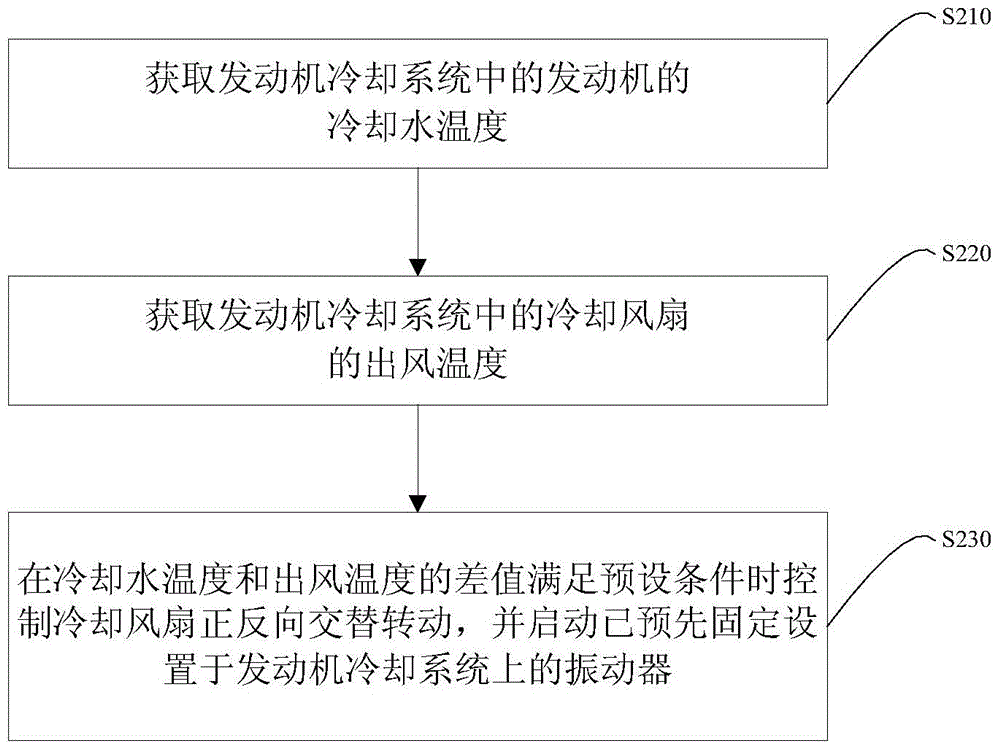

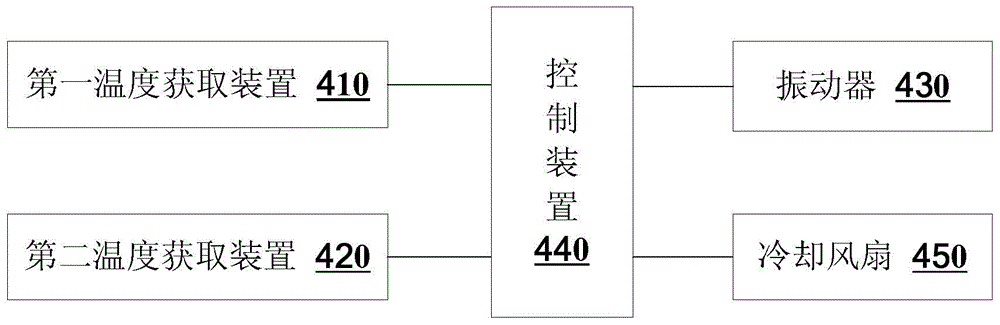

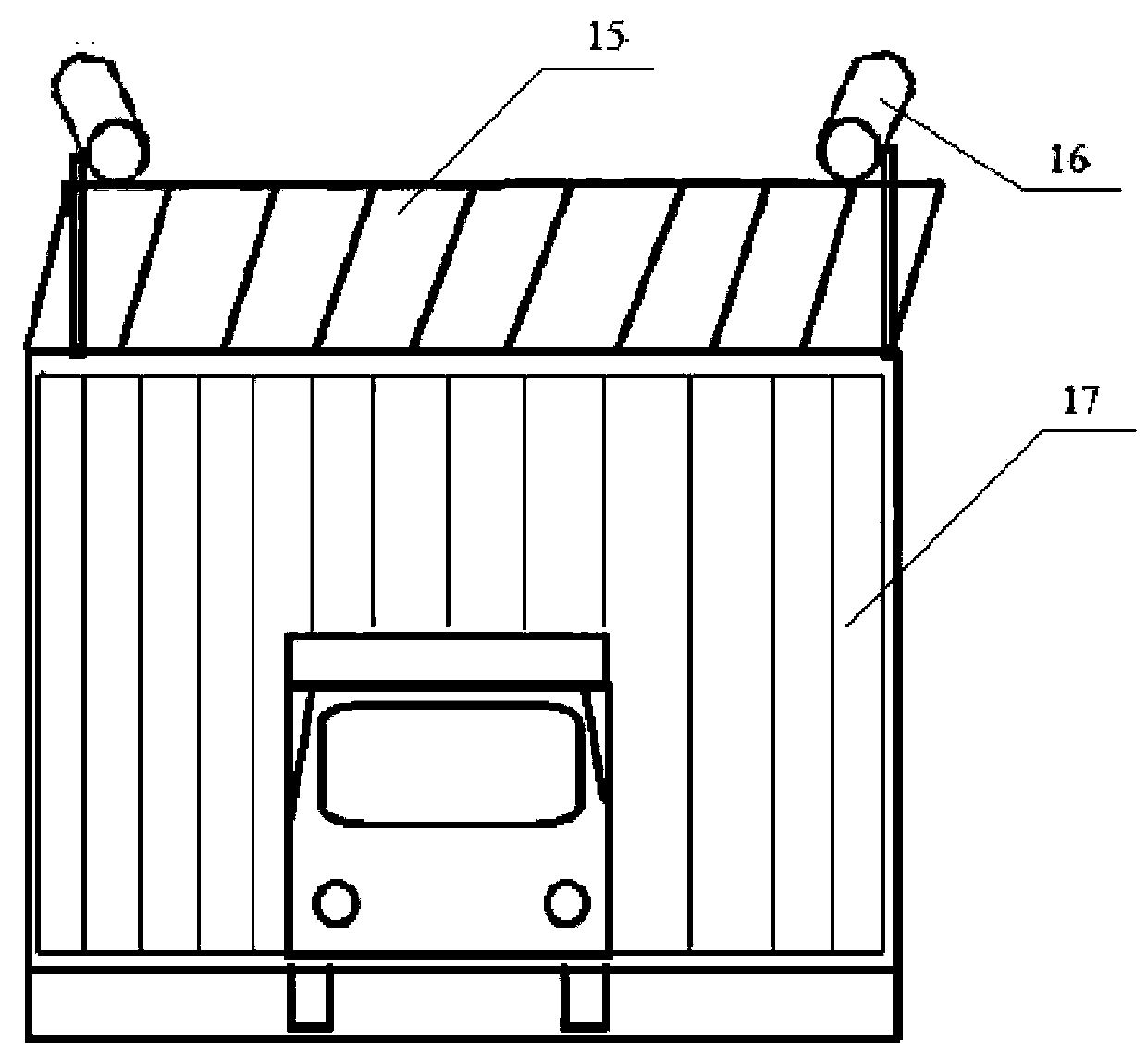

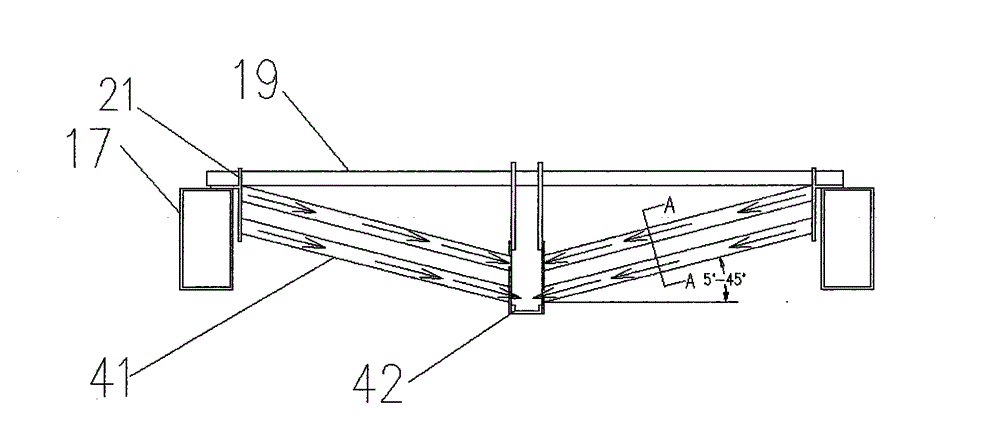

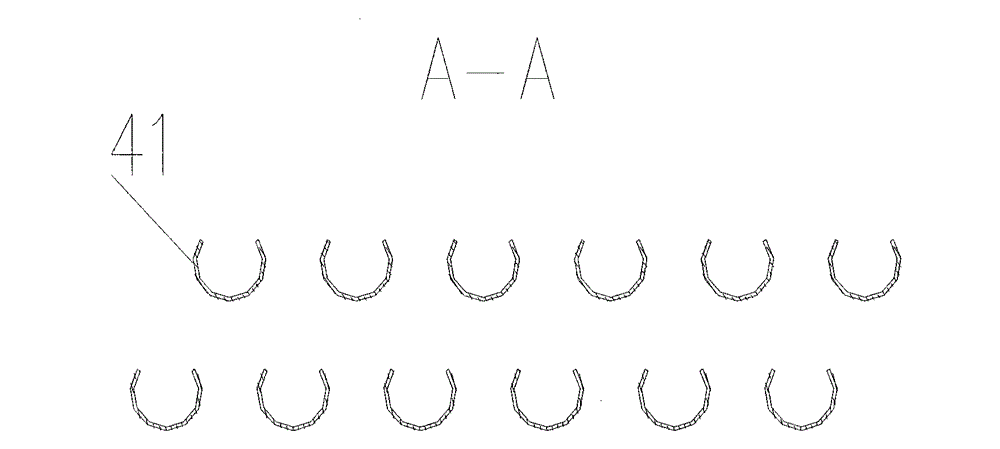

Automatic dust removing method, automatic dust removing system and vehicle

ActiveCN104832270ATo achieve the purpose of dust removalEasy to operateMachines/enginesEngine cooling apparatusLiquid temperatureWorking temperature

The invention provides an automatic dust removing method, an automatic dust removing system and a vehicle. The automatic dust removing method comprises the steps of obtaining cooling liquid temperature of an engine in an engine cooling system, obtaining the air outlet temperature of a cooling fan in the engine cooling system, and when the difference value of the cooling liquid temperature and the air outlet temperature is larger than the preset temperature, controlling the cooling fan to alternatively rotate forwards and reversely. Alternative air generated by rotation in the forward and reverse direction of the cooling fan is utilized for completing automatic dust removing of the engine cooling system; the heat dissipation efficiency of the engine cooling system is improved, and meanwhile, it is also ensured that when the engine operates under the normal working temperature, the service life of the engine is prolonged.

Owner:BEIQI FOTON MOTOR CO LTD

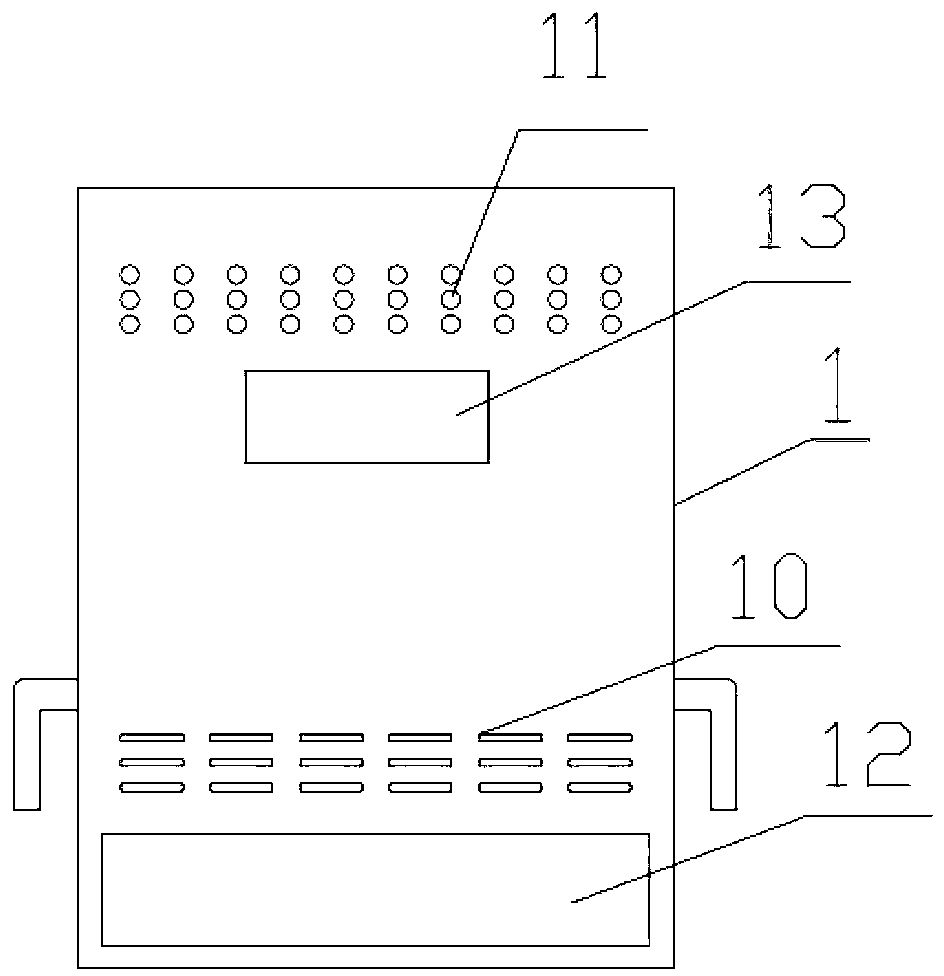

Dust removal type computer case using air flow for dust blowing

InactiveCN107219904ATo achieve the purpose of dust removalScientific and reasonable designDigital processing power distributionCleaning using gasesDrive shaftComputer engineering

The invention discloses a dust removal type computer case using air flow for dust blowing. A computer mainboard is installed at the right side wall of the computer case, a case cover is installed on the computer case through fastening bolts, an upper inflator is welded to the upper portion of the case cover, a lower inflator is welded to the lower portion of the case cover, the top of an air flow pipe is communicated with the upper inflator, the bottom of the air flow pipe is communicated with the lower inflator, a screen plate is embedded into the bottom surface of the computer case, a dust-collection drive shaft is installed on the screen plate through a bearing, a dust-collection motor is installed at the bottom of the dust-collection drive shaft, and a dust-collection fan is installed on the upper portion of the dust-collection drive shaft. The dust removal type computer case is scientific and reasonable in design, simple in structure and convenient to use.

Owner:ANHUI TECHN COLLEGE OF MECHANICAL & ELECTRICAL ENG

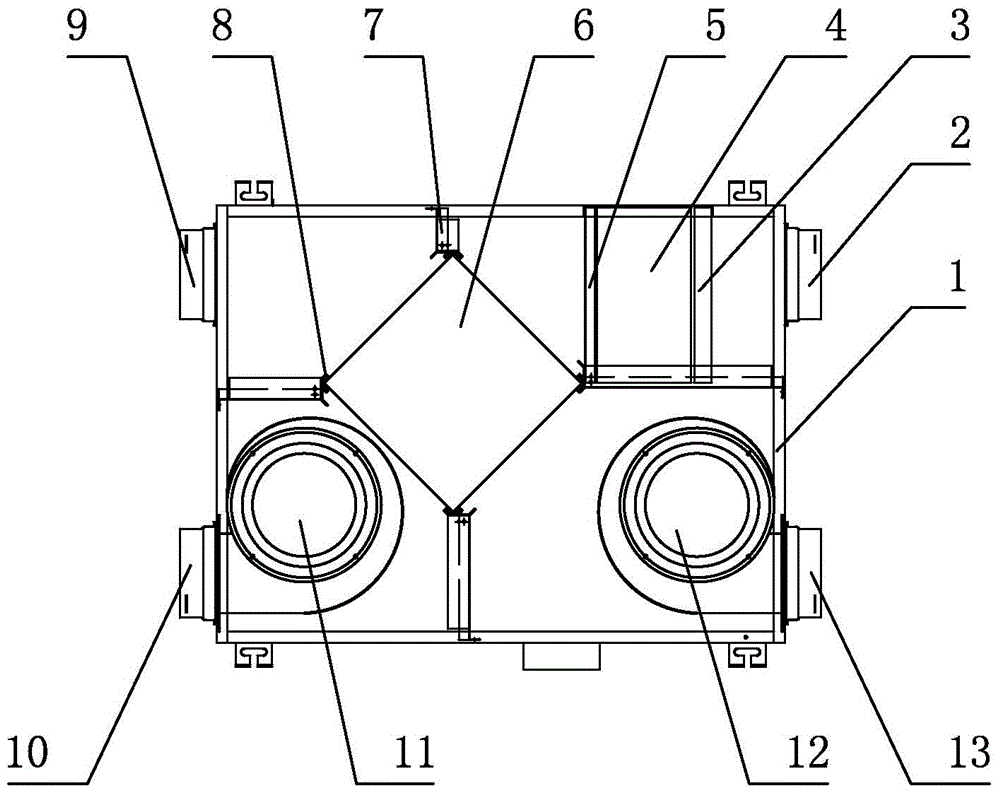

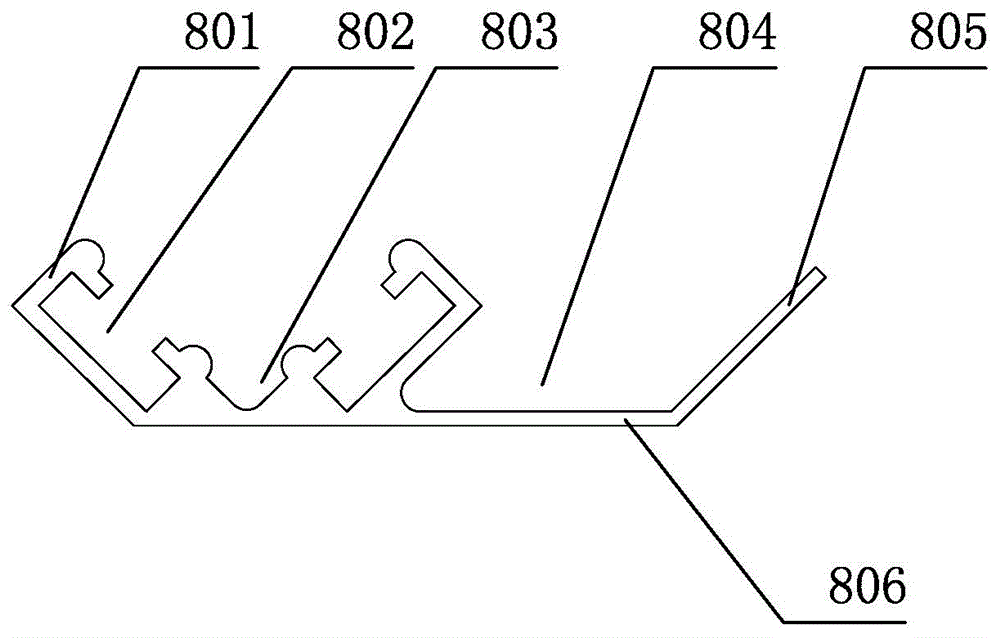

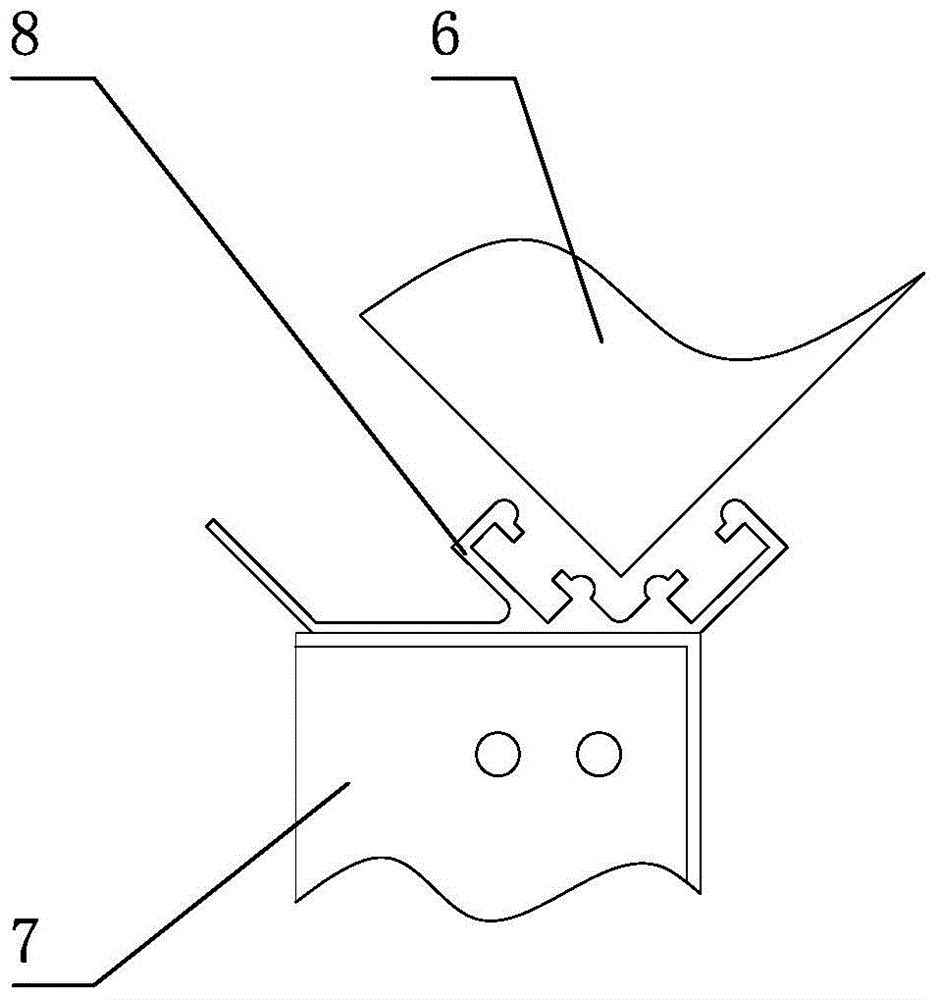

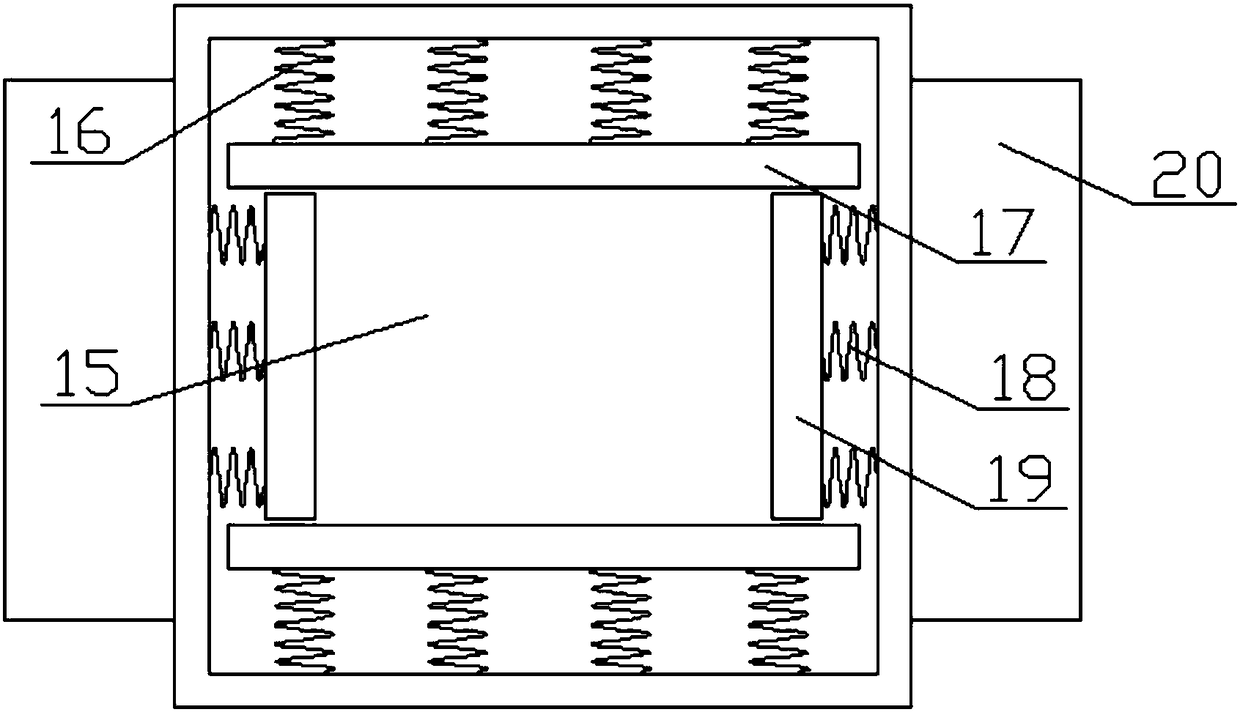

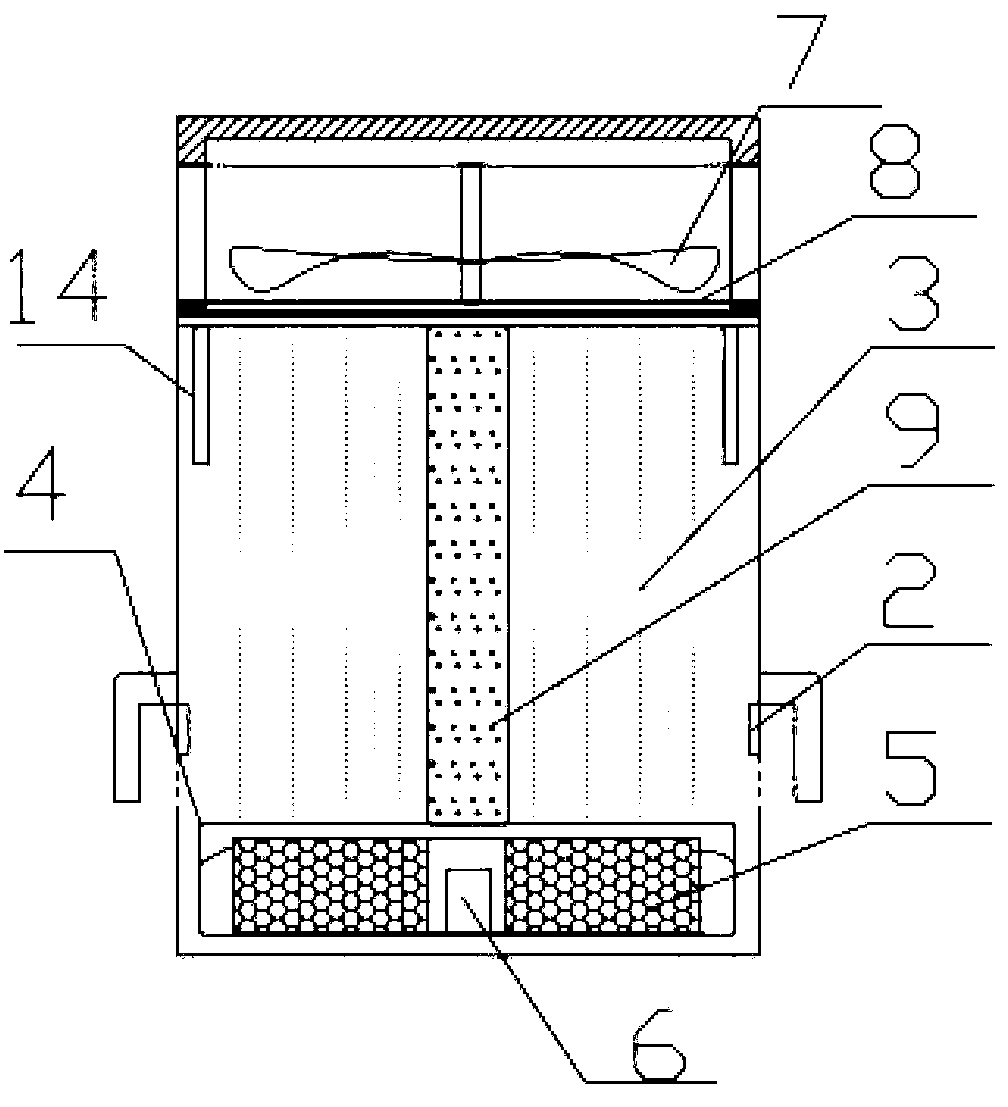

Fresh air ventilator

InactiveCN104315601AKeep freshEasy to installEnergy recovery in ventilation and heatingLighting and heating apparatusPlate heat exchangerFresh air

The invention relates to a fresh air ventilator and belongs to the field of vented exhaust equipment. The fresh air ventilator comprises an enclosure and a partition plate support in the enclosure; space in the enclosure is divided into a fresh air inlet passage, a fresh air outlet passage, an exhaust air inlet passage and an exhaust air outlet passage through the partition plate support; a filter, a high-voltage static box and an ozone filter are arranged in sequence along an air inlet direction in the fresh air inlet passage; a fresh air fan is arranged in the fresh air outlet passage; an exhaust air fan is arranged in the exhaust air outlet passage; a plate heat exchanger is arranged at the hubs of the fresh air inlet passage, the fresh air outlet passage, the exhaust air inlet passage and the exhaust air outlet passage, and is fixedly arranged on the partition plate support through mounting buckles. The fresh air ventilator disclosed by the invention has the advantages that substances, such as impurities, dust and ozone, in air can be effectively filtered out to ensure the freshness of the air; the energy is saved, and the environment is protected; the heat exchanger is convenient to install and maintain.

Owner:ZIBO QIYU AIRCONDITION ENERGY RECOVERY EQUIP

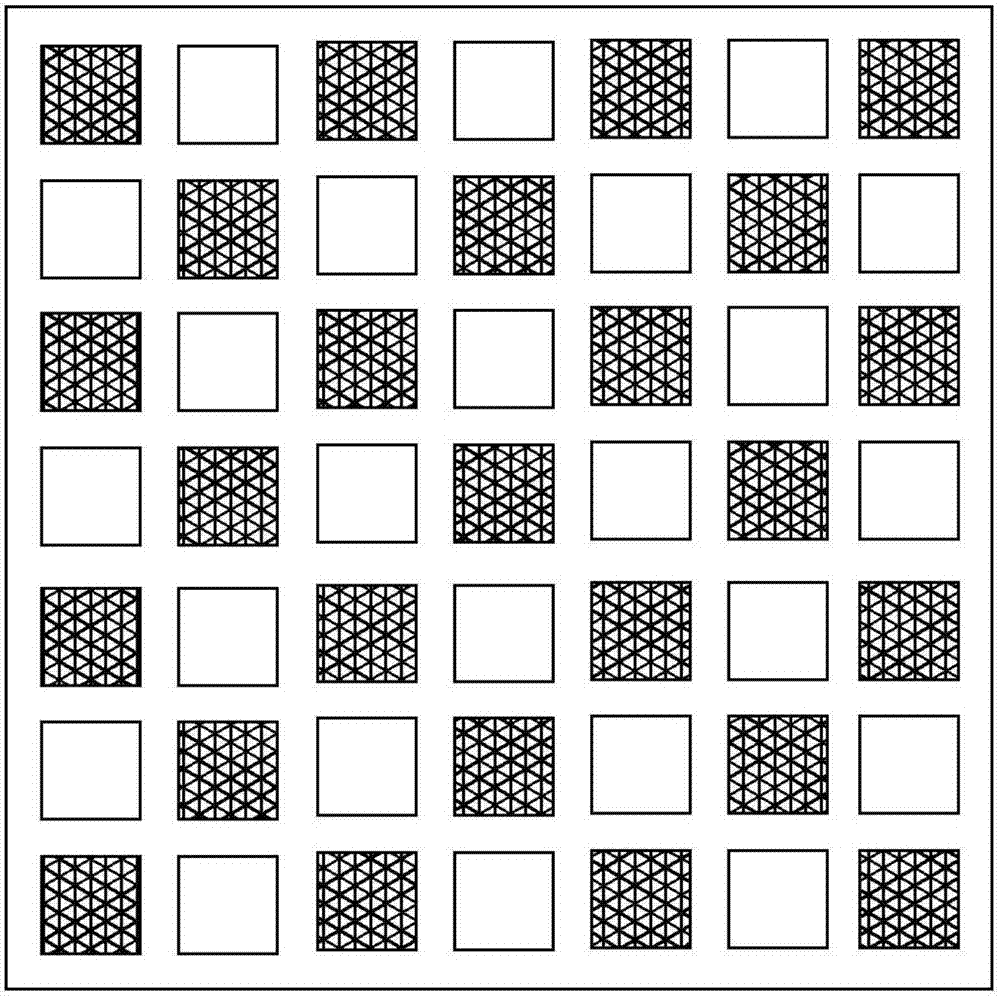

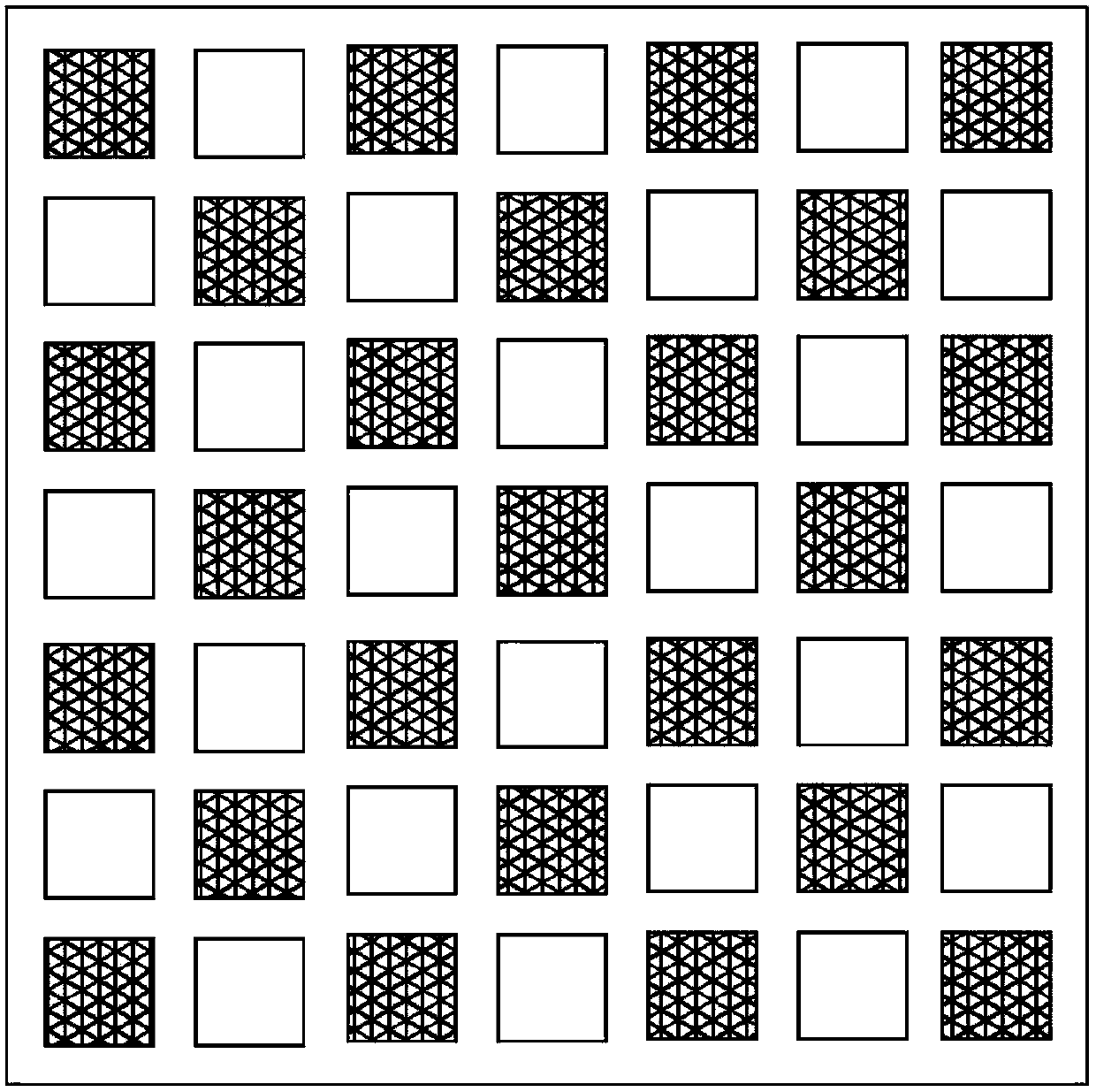

Honeycomb wall-flow ceramic catalyst for flue gas denitration and dust extraction, and preparation method thereof

InactiveCN107970917AExtended stayHigh strengthGas treatmentHeterogenous catalyst chemical elementsRetention timeFlue gas

The invention relates to a honeycomb wall-flow ceramic catalyst for flue gas denitration and dust extraction, and a preparation method thereof, which belong to the technical field of catalysts. The method comprises five processes of preparing and mixing, extruding, drying, blocking and calcining. Through a blocking technology, a state of each through hole in a traditional honeycomb SCR (SelectiveCatalytic Reduction) catalyst is changed, so that flue gas enters from one end of the honeycomb catalyst and passes through a side wall of an adjacent hole of an unsealed hole in an inlet end, smoke dust is filtered and removed through the side wall, the retention time of the flue gas is prolonged, and the catalyst efficiency is improved. Meanwhile, according to the catalyst, by adding a vanadium-tungsten-titanium nanotube, not only is the mechanical strength of a honeycomb ceramic improved, but also the adhesive strength of a vanadium-tungsten active substance is improved; by a special structure of the nanotube, a specific surface area of the catalyst is improved, and the denitration activity of the catalyst is promoted. Meanwhile, poisonous metals are isolated through a tube wall of thevanadium-tungsten-titanium nanotube, so that the alkali (soil) metal resistance of the catalyst is improved, and the service life of the catalyst is prolonged.

Owner:CHONGQING YUANDA CATALYST MFG

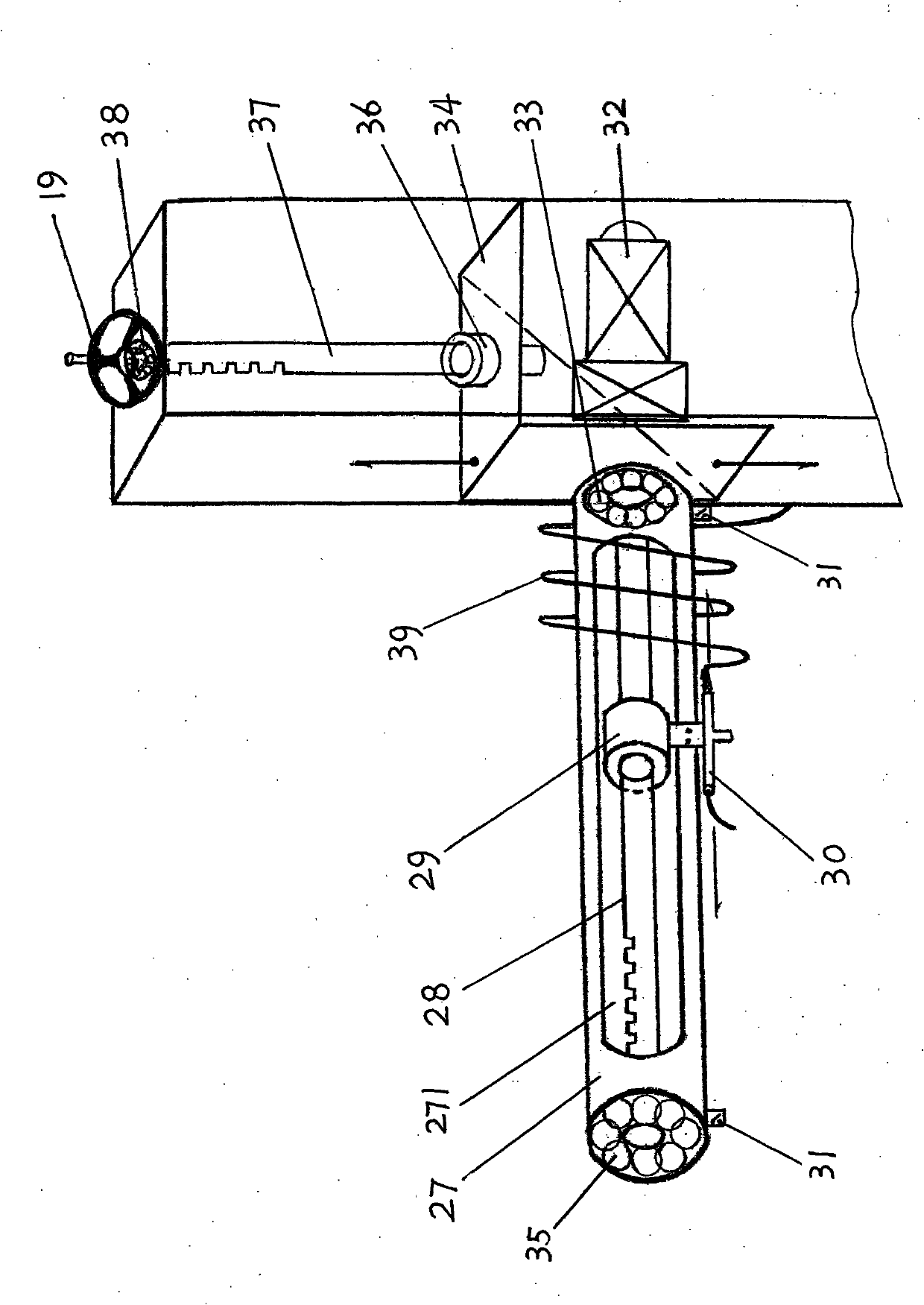

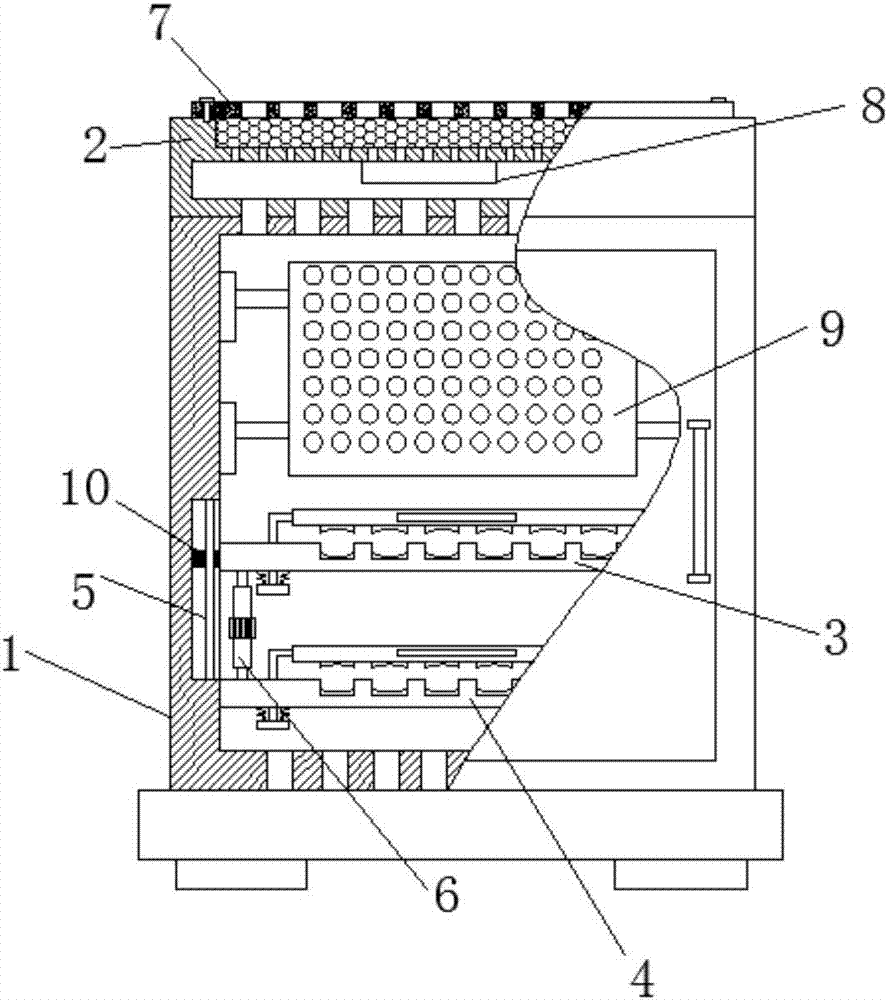

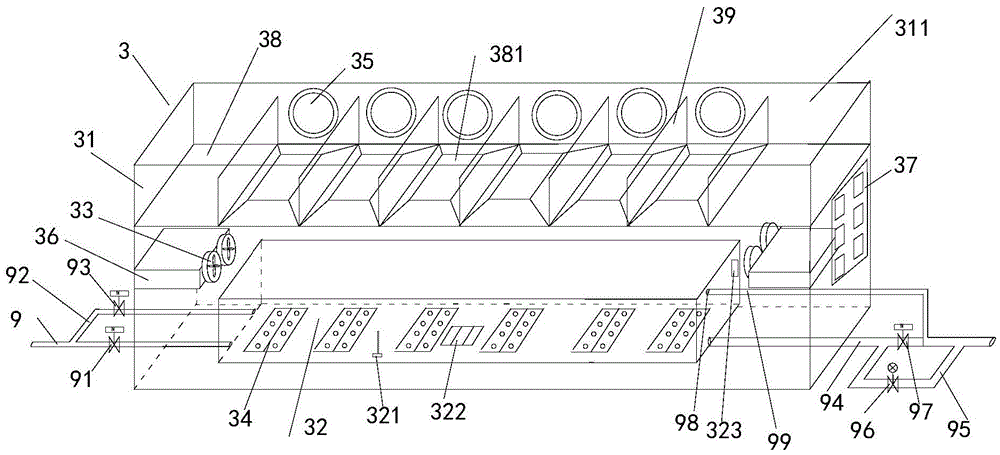

Dust removal device for air filter cartridge

InactiveCN101994614AAdapt to dust removal needsEasy to useAir cleaners for fuelElectricityAir filter

The invention relates to a dust removal device for an air filter cartridge. The dust removal device is provided with a frame, an electric control panel, a dust removal chamber with a closed structure, and a sealed dust collection device, wherein a double-roller mechanism and a nozzle guide rod mechanism capable of spraying air to remove dust inside and outside are arranged in the dust removal chamber; under the drive of an speed-adjustable motor and a feed screw nut, an inner nozzle and an outer nozzle in the nozzle guide rod mechanism can do uniform rectilinear motion to and fro inside and outside the air filter cartridge to be dedusted and uniformly apply compressed air to the internal and external surfaces of the air filter cartridge for dust removal; the dust collection device consists of a vacuum pump and a dust collection chamber positioned below the vacuum pump; and one side of the frame is provided with a detection platform for detecting whether the filter cartridge is broken or not. The dust removal device has the dust removal rate of over 95 percent, can realize dust removal and detection functions, is easy to operate and control, can blow the air uniformly in multiple directions, does not damage the air filter cartridge, is labor-saving, time-saving, safe and environmental-friendly, is favorable for protecting the body health of workers and improving labor efficiency, saves production and operation cost, and can clean and maintain various types of cylindrical air filter cartridges in engines of all Europe III buses and other transport vehicles, ships and the like.

Owner:FUZHOU PUBLIC TRANSPORT GROUP

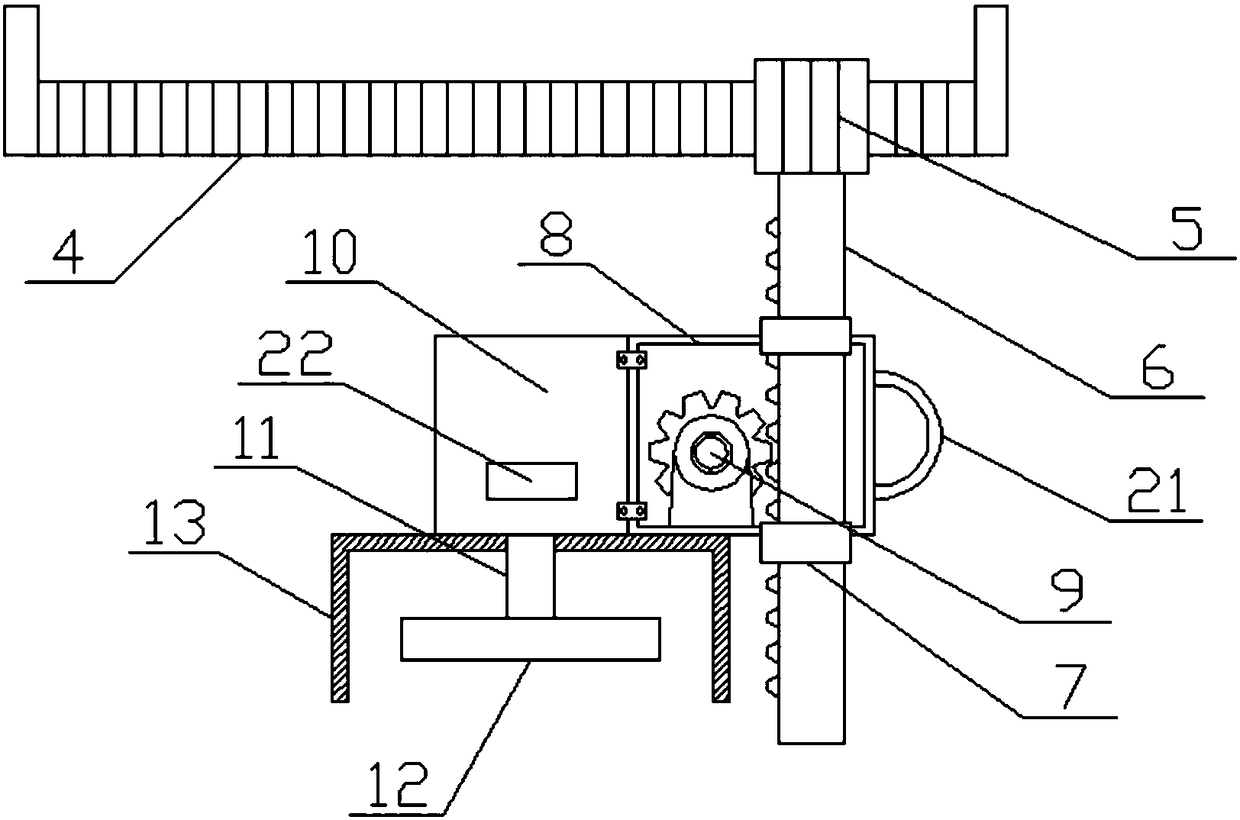

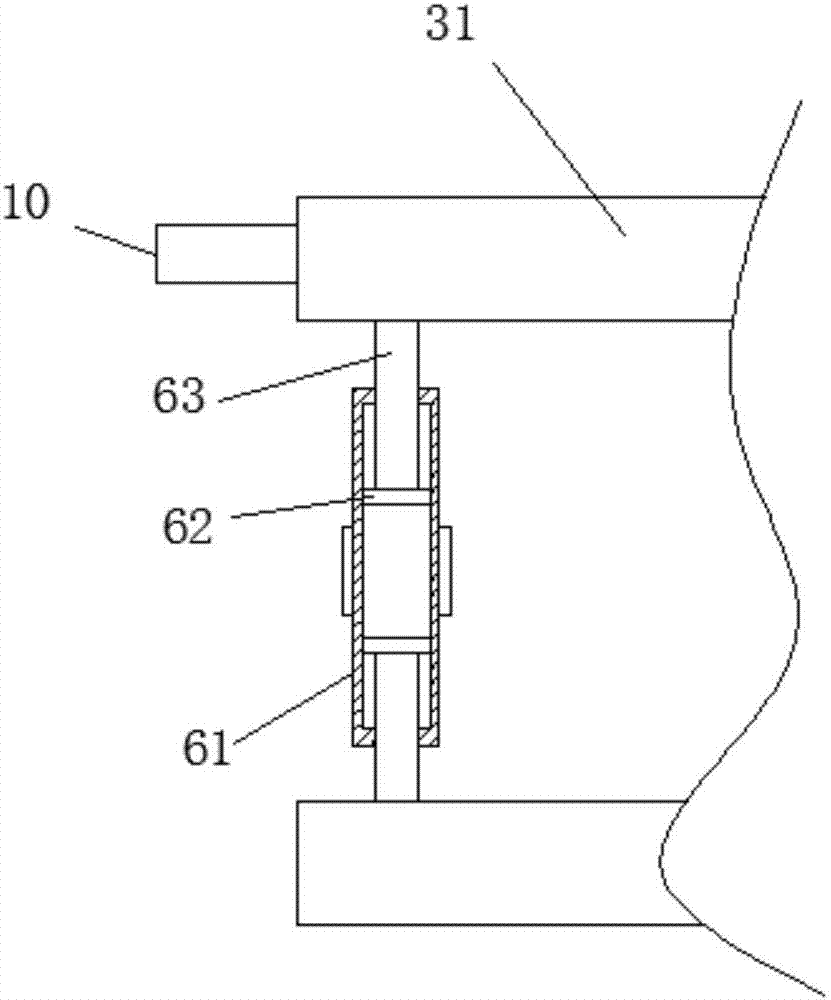

Hardware fitting grinding device

InactiveCN108406488AImprove grinding efficiencyPlay the role of cushioning and shock absorptionEdge grinding machinesGrinding carriagesArchitectural engineeringDrive motor

The invention discloses a hardware fitting grinding device comprising a workbench. The middle of the workbench is covered with a first dust cover. A grinding unit is arranged in the middle of a cavityof the first dust cover, and a sliding bar is arranged at the upper end of the grinding unit. The right outer wall of the sliding bar is sleeved with a first sliding block, and a straight rack is fixed to the lower end of the first sliding block. The middle portion of the outer wall of the straight rack is sleeved with a second sliding block, and a moving frame is fixed to the outer wall of the second sliding block. A driving motor is fixed to the left side of the outer wall of the moving frame, and a grinding disc is rotatably connected to the lower end of the outer wall of the driving motorthrough a rotating shaft and covered with a second dust cover. A hardware fitting clamping device is arranged in the middle of the upper surface of the workbench. The invention relates to the technical field of hardware fitting grinding. The hardware fitting grinding device achieves the purposes of good grinding effect, good fixing effect and dust removal, and hardware fitting grinding efficiencyis improved.

Owner:湖州吉斯安机械有限公司

High-low voltage wire split-type high-voltage cabinet

InactiveCN107394613AReduce mutual interferenceAvoid clutterBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationLow voltageFire risk

The invention discloses a high-voltage and low-voltage wiring split-type high-voltage cabinet, which includes a cabinet body, a fan installation box is fixed on the top of the cabinet body, and a component installation plate is arranged inside the cabinet body, and one side of the component installation plate is below There are high-voltage line branching structures and low-voltage line branching structures arranged up and down, and a distance adjustment structure is provided between the high-voltage line branching structure and the low-voltage line branching structure, and the structures of the high-voltage line branching structure and the low-voltage line branching structure are consistent , and the high-voltage line branching structure includes a movable rod located in the cabinet, a pressure rod is arranged above the movable rod, and symmetrically arranged L-shaped connecting rods are fixed at both ends of the pressure rod. The present invention not only can separate the high-voltage wiring and the low-voltage wiring through the combined use of the high-voltage line branching structure, the low-voltage line branching structure, and the distance adjustment structure, but also the wiring is orderly and tidy, thereby avoiding the messy winding of the high-voltage and low-voltage wiring and reducing the fire risk.

Owner:ZHEJIANG MAILANG ELECTRIC

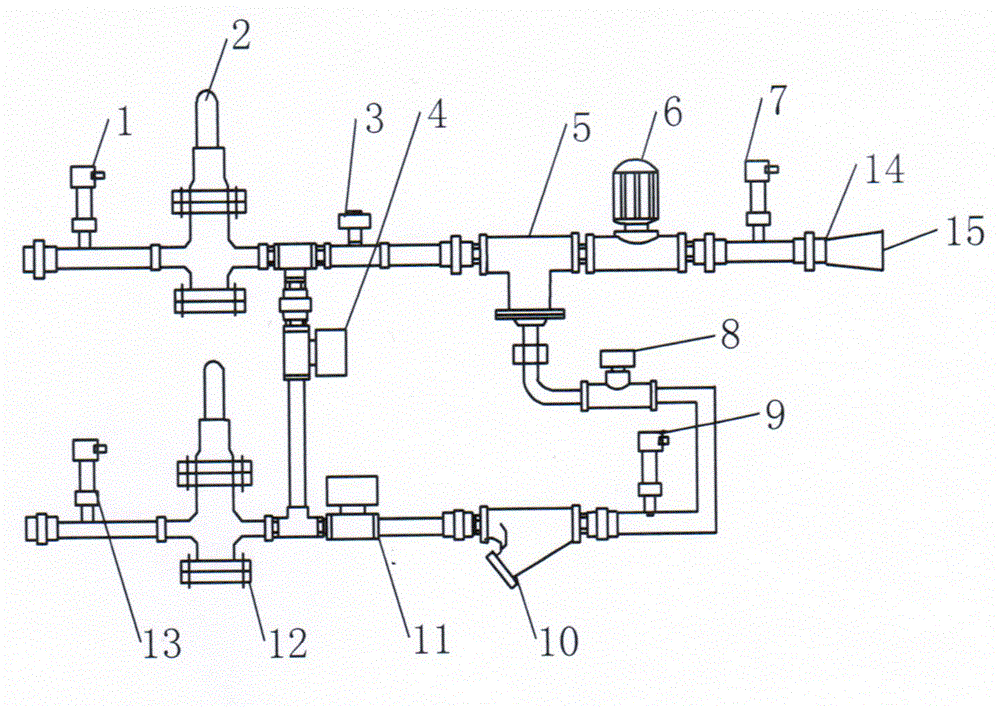

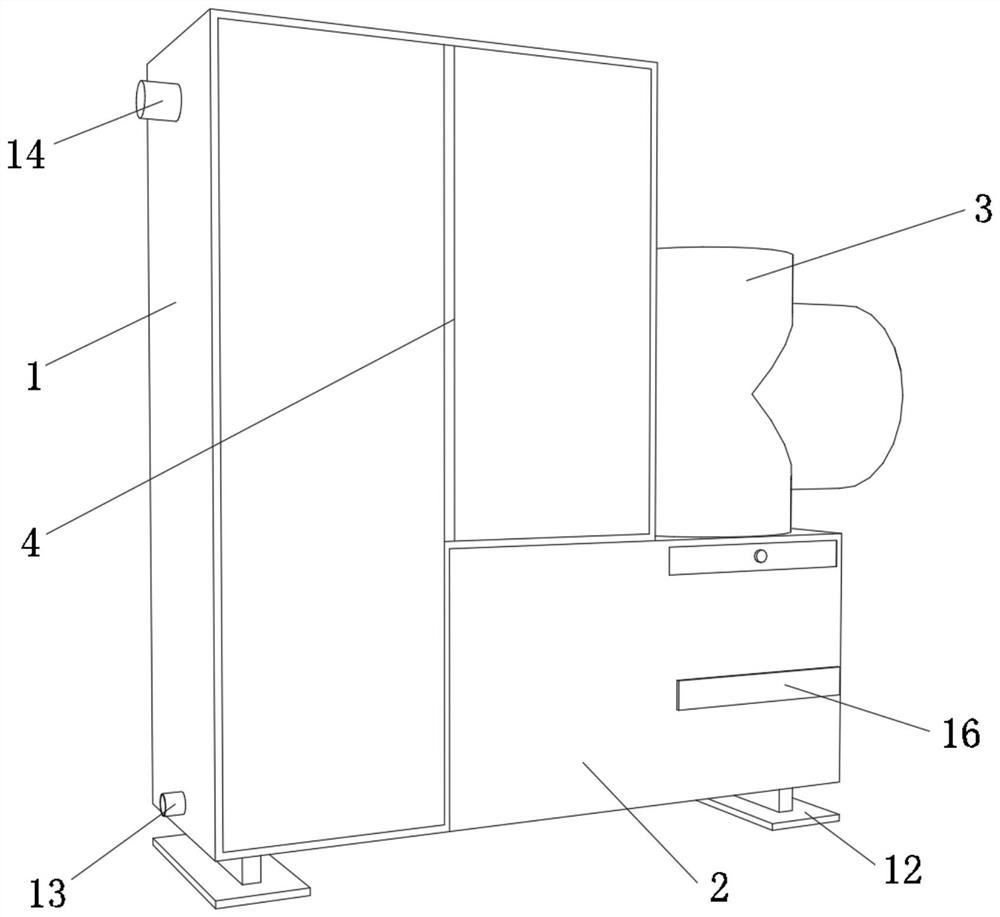

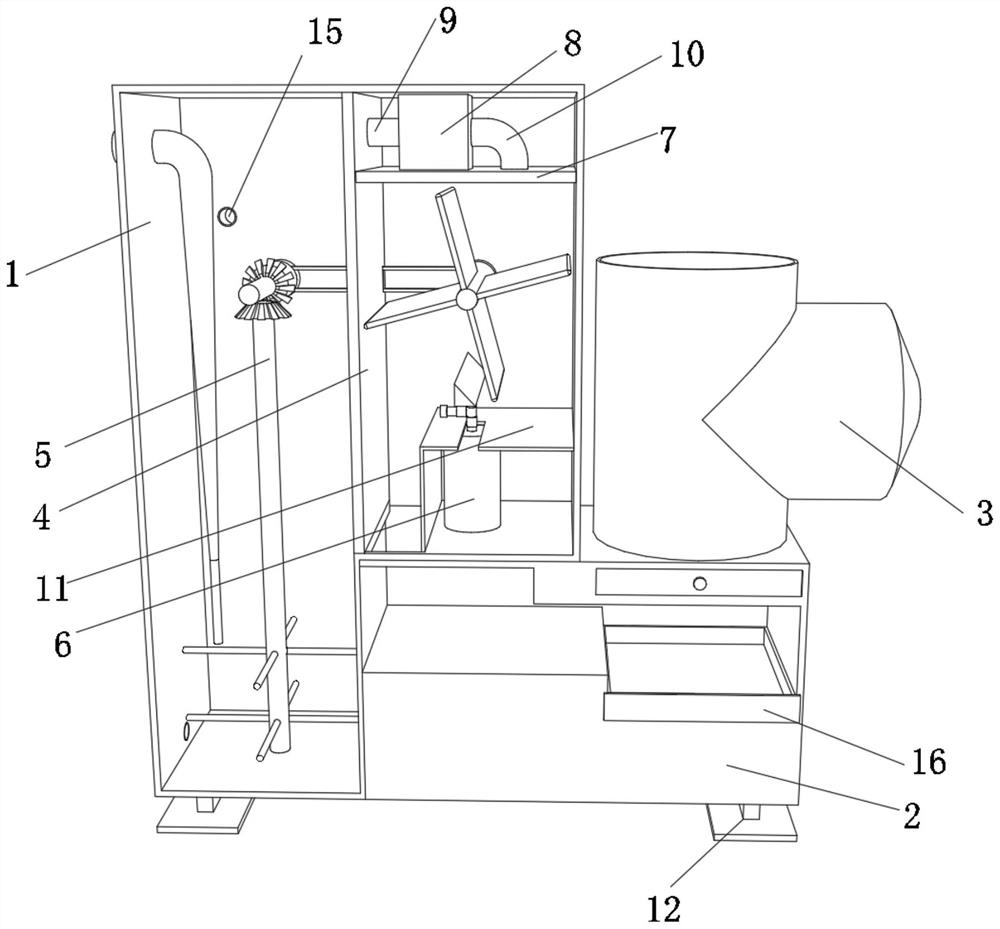

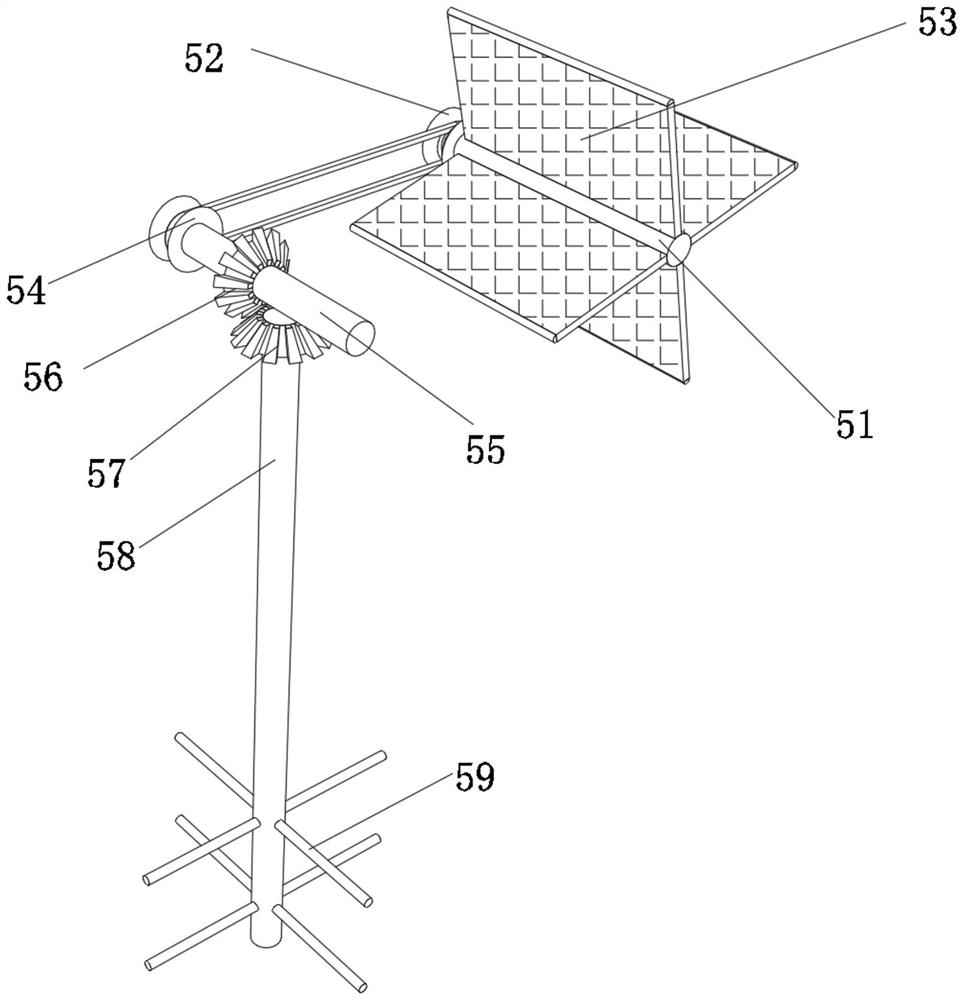

Intelligent self-cleaning dry fog de-dusting equipment

InactiveCN104623998ARealize self-cleaningAchieve anti-cloggingUsing liquid separation agentSeparation devicesProcess engineeringInlet pressure

The invention provides intelligent self-cleaning dry fog de-dusting equipment. A water supply pipe and an gas supply pipe are connected respectively with a water gas mixer; a water inlet pressure sensor, a water supply adjusting valve and a water control electromagnetic valve are connected to the water supply pipe; a gas inlet pressure sensor, a gas supply adjusting valve, a gas storage tank filter and a gas outlet pressure sensor are connected sequentially to the gas supply pipe; the gas supply pipe is connected with the water gas mixer by the gas pressure adjusting valve; an fog spraying box, an outlet pressure sensor and a sprayer are arranged on the pipe of the rear part of the water gas mixer; a spraying vibrator is arranged on the sprayer. A connecting pipe is arranged between the gas supply adjusting valve pipe on the gas supply pipe and the water supply adjusting valve pipe, and a back blow valve is arranged on the connecting pipe. The equipment is controlled by a PLC. By utilizing the equipment, the water gas mixed vibrating fog spraying can be realized, the self-cleaning and blockage prevention of pipelines and sprayer can also be realized. The equipment has the advantages of good de-dusting effect and high reliability. And the equipment is suitable for being used as the dry fog de-dusting equipment.

Owner:SUIZHONG ZHONGWEI TECH

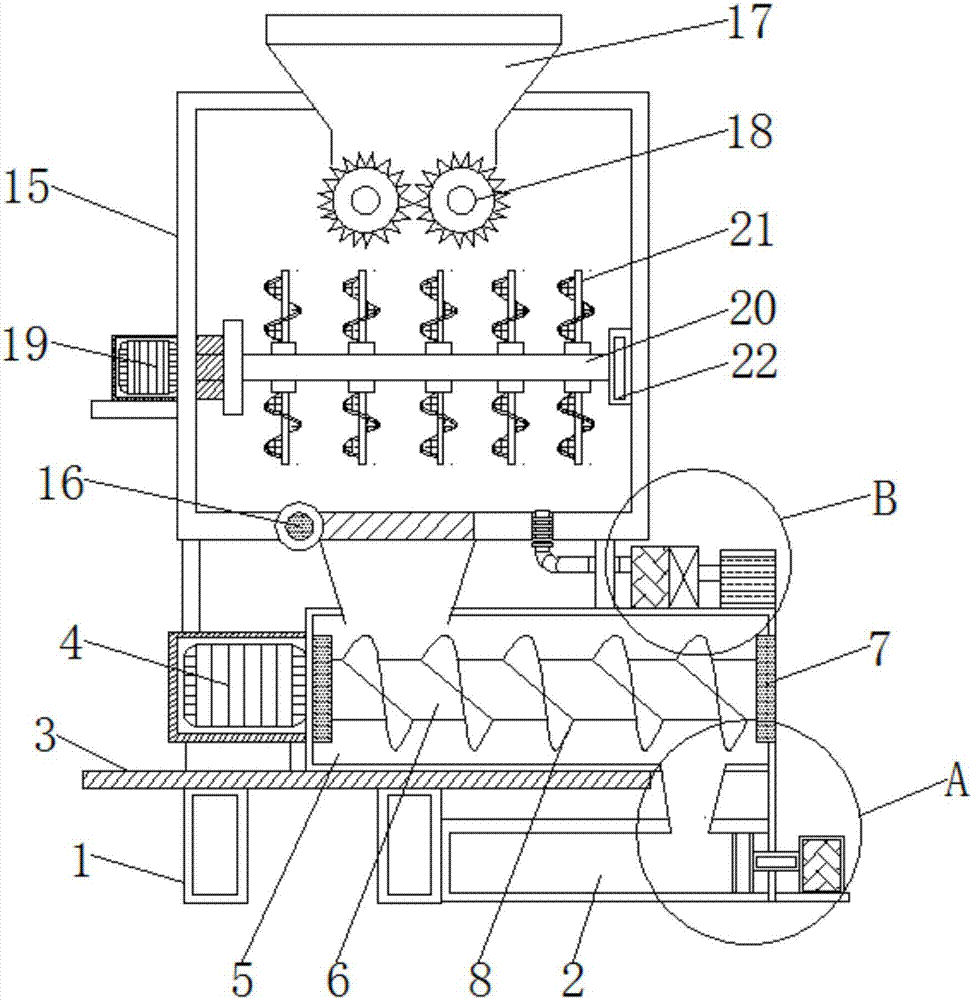

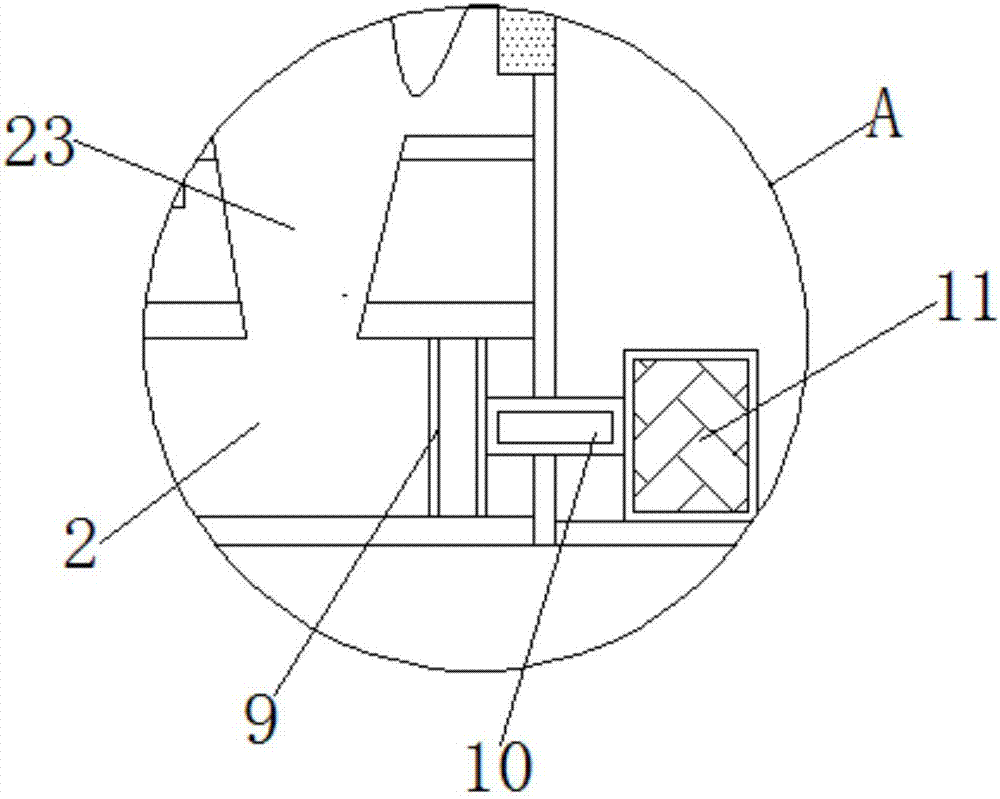

Straw feed grinder

The invention provides a straw feed grinder. The straw feed grinder comprises supporting columns, wherein one side of a supporting column is fixedly connected with a collection box; the top parts of the supporting columns are fixedly connected with a supporting plate; the top part of the supporting plate is successively provided with an auxiliary motor and a discharge box from left to right; the output shaft of the auxiliary motor is fixedly connected with an auxiliary rotating shaft which penetrates through and extends into the interior of the discharge box; the surface of the auxiliary rotating shaft is fixedly connected with spiral disks which are located in the interior of the discharge box; and one end of the auxiliary rotating shaft far away from the auxiliary motor is provided withan auxiliary bearing. The straw feed grinder provided by the invention has the following advantages: through arrangement of grinding rollers and grinding blades, straw enters the grinding rollers forpreliminary grinding through a feeding funnel, and grinded straw falls into the bottom part of a frame and undergoes secondary grinding through rotation of grinding blades which are arranged on a mainrotating shaft and driven by a main motor, so the grinding effect of the straw is greatly improved; meanwhile, a dust collector is utilized to timely absorb dust in the interior of the frame in the process of grinding, so the purpose of dedusting is achieved.

Owner:建始惠万农生物科技有限公司

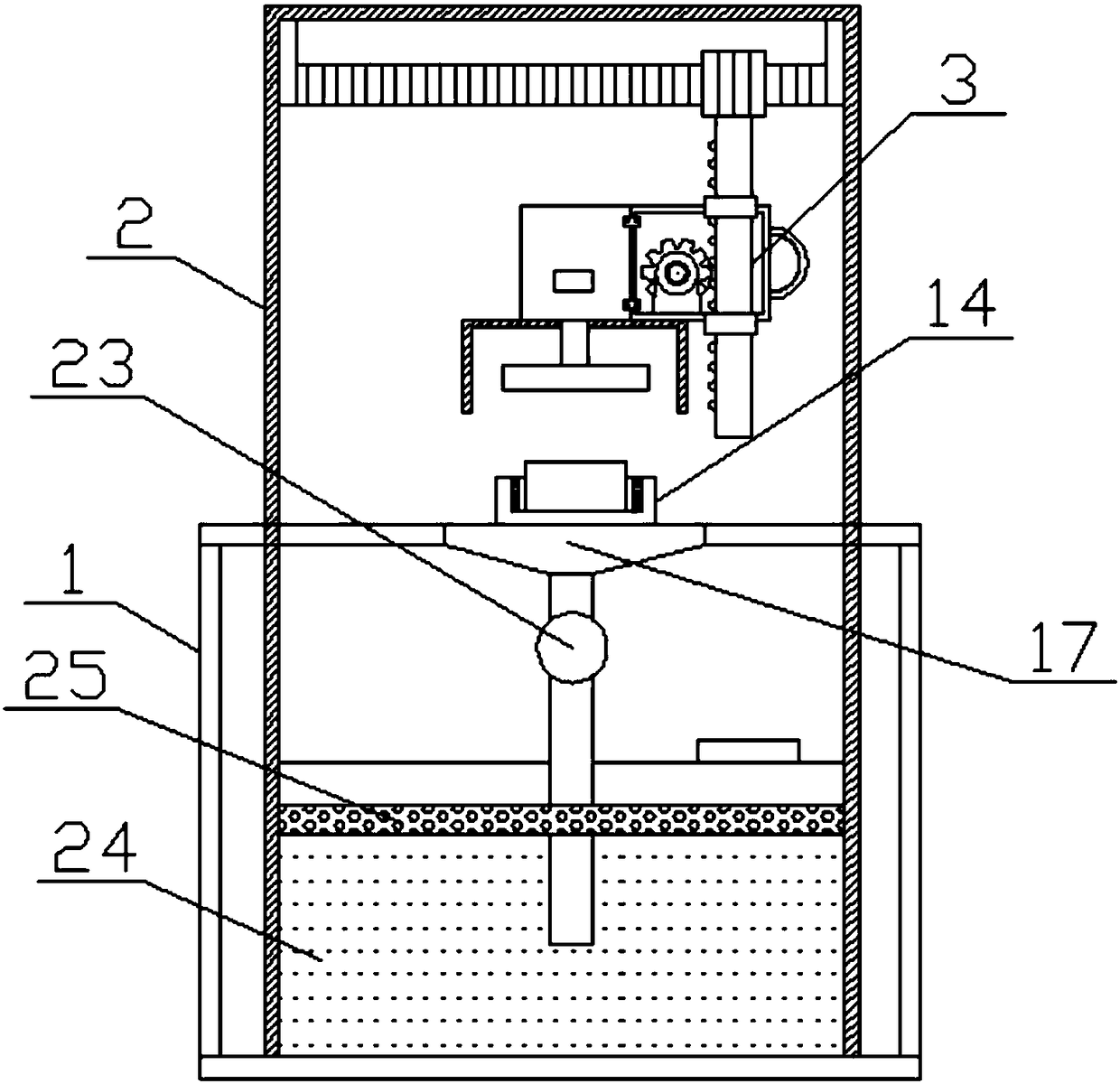

Dust removing device for crushing building wastes

InactiveCN107321067AGood dust removalTo achieve the purpose of dust removalCombination devicesGas treatmentEngineeringWater tanks

The invention discloses a dust removing device for crushing building wastes. The dust removing device comprises a building-waste crushing box and also comprises a connecting pipeline, a cloth-bag dust remover, a drying device, a water tank, a ring-shaped exhausting pipe and a fan, wherein the top part of the building-waste crushing box is communicated with a dust conveying pipeline; the bottom part of an inner cavity of the connecting pipeline is communicated with the other end of the dust conveying pipeline; the inner cavity of the connecting pipeline is provided with a primary filtering net and a secondary filtering net in sequence from bottom to top; the top part of the inner cavity of the connecting pipeline is communicated with the air inlet end of the cloth-bag dust remover by a communicating pipe; the ring-shaped exhausting pipe is erected at the lower part of the inner cavity of the water tank; a grid is fixedly erected at the middle part of the inner cavity of the water tank; and the air outlet end of the cloth-bag dust remover is communicated with the ring-shaped exhausting pipe by a conveying pipeline. The dust removing device disclosed by the invention has the advantages that the structure is simple, the production cost is low, the use is convenient, the dust removing effect for dusts exhausted by the building-waste crushing box is good, and the influence of the dust on the atmospheric environment is avoided, so that the dust removing device is suitable for promotion and use.

Owner:曾玉琼

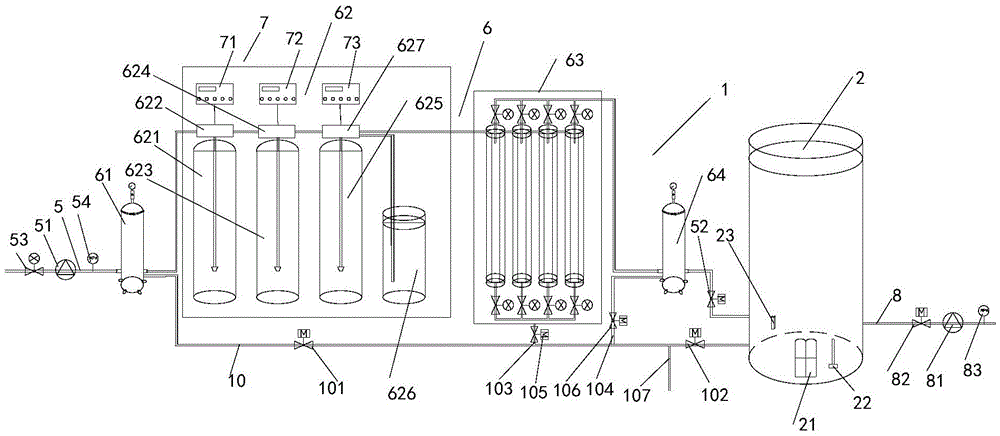

Air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method

InactiveCN105617798APrecision FiltrationEasily brokenGas treatmentUsing liquid separation agentWater storage tankWater source

The invention relates to an air-conveying type ultrasonic wave micron-grade dry fog dust suppression system and method. The system comprises a water quality filtering and softening device, a water storage tank, a dry fog dust suppression device and a local controller. An adjustable atomization plate in the dry fog dust suppression device scatters and atomizes a constant-temperature water source which is filtered and softened through the water quality filtering and softening device in the water storage tank, a large amount of micron-grade dry fog and negative ions are produced, a frequency conversion high pressure centrifugal fan in the dry fog dust suppression device blows the large amount of micron-grade dry fog and negative ions out of the dry fog dust suppression device, then the dust is adsorbed, condensed and precipitated, and therefore the purpose of dust removal is achieved. Millimeter-grade visible dust particles can be effectively treated, micrometer-grade inhalable dust particles can also be effectively treated, pollution of dust on the atmosphere is lowered, the work environment of on-site workers is improved, and occupational disease occurrence rate is lowered; the system is small in occupied area, safe and convenient to operate and high in practicability and is controlled in a full-automatic mode.

Owner:刘坤

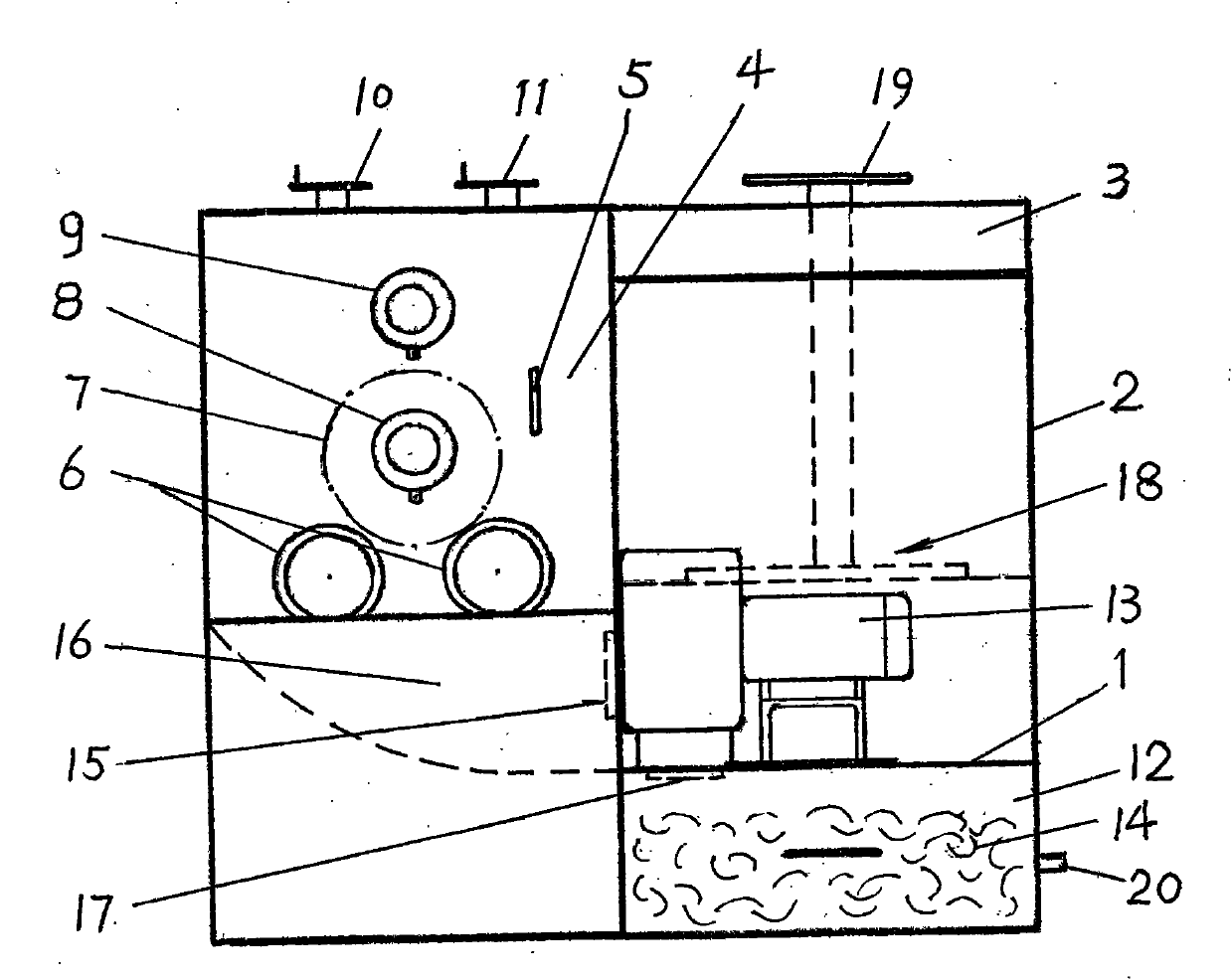

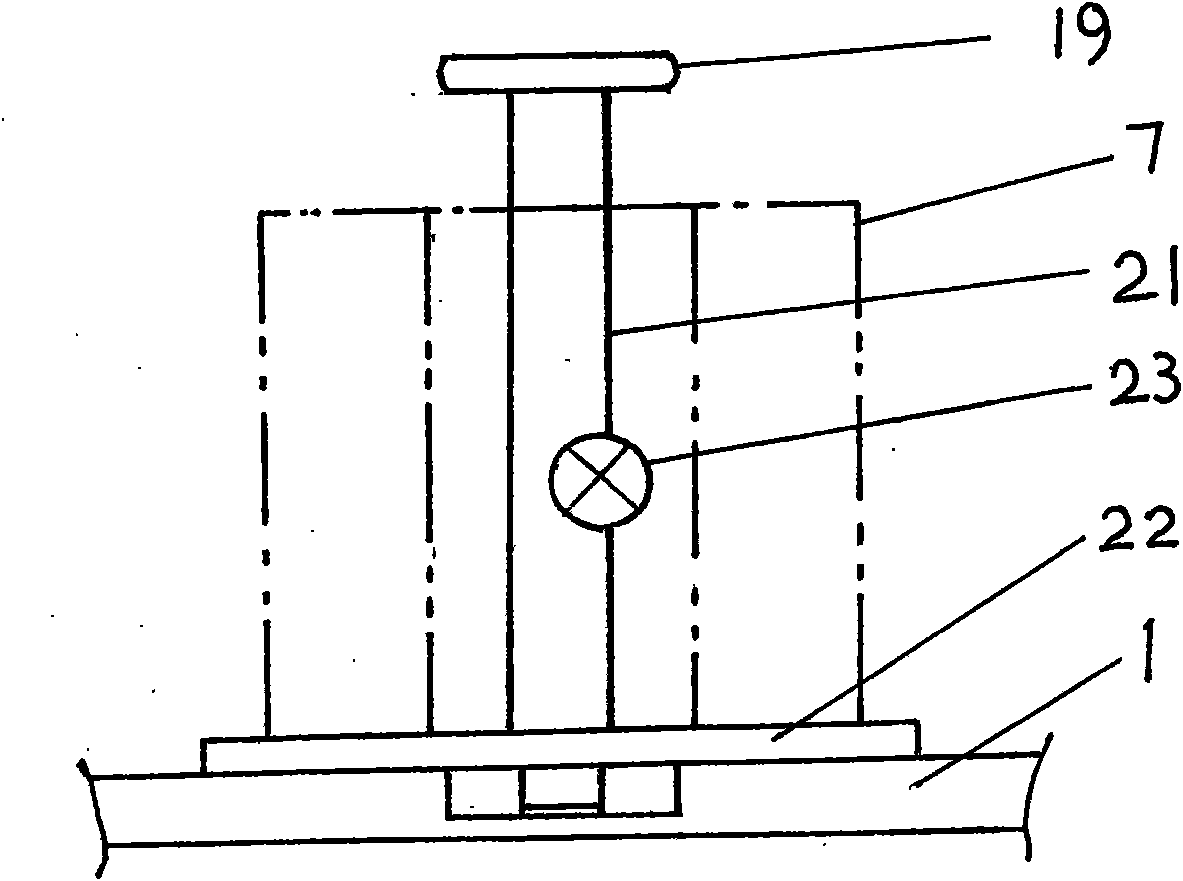

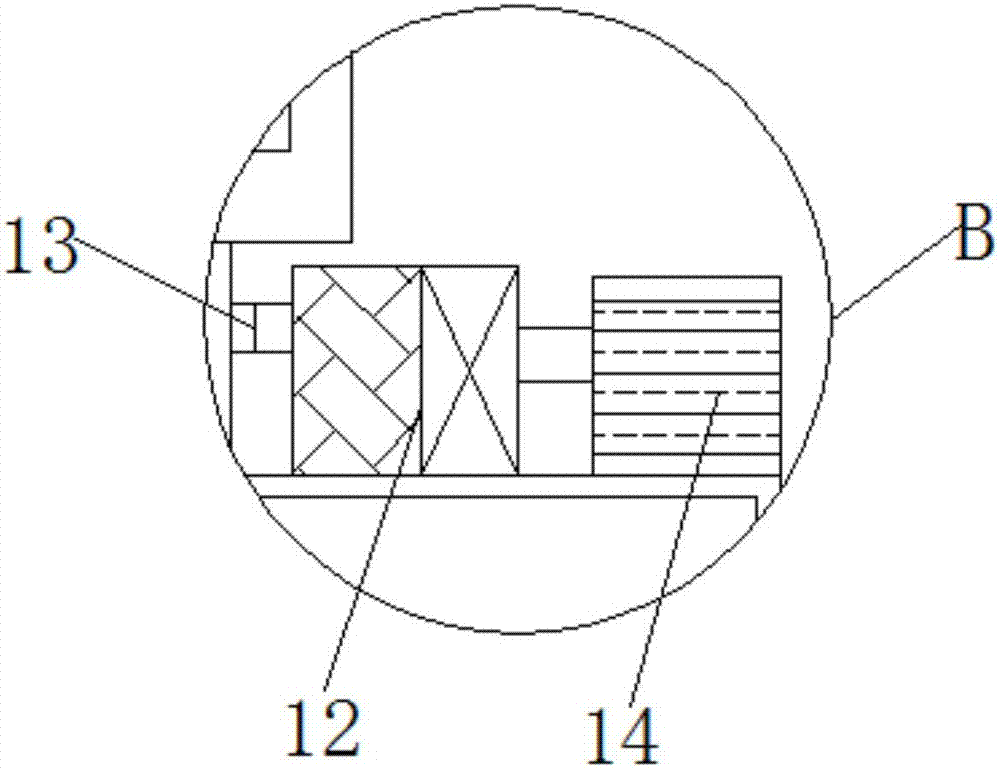

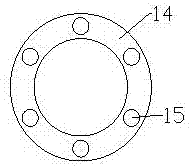

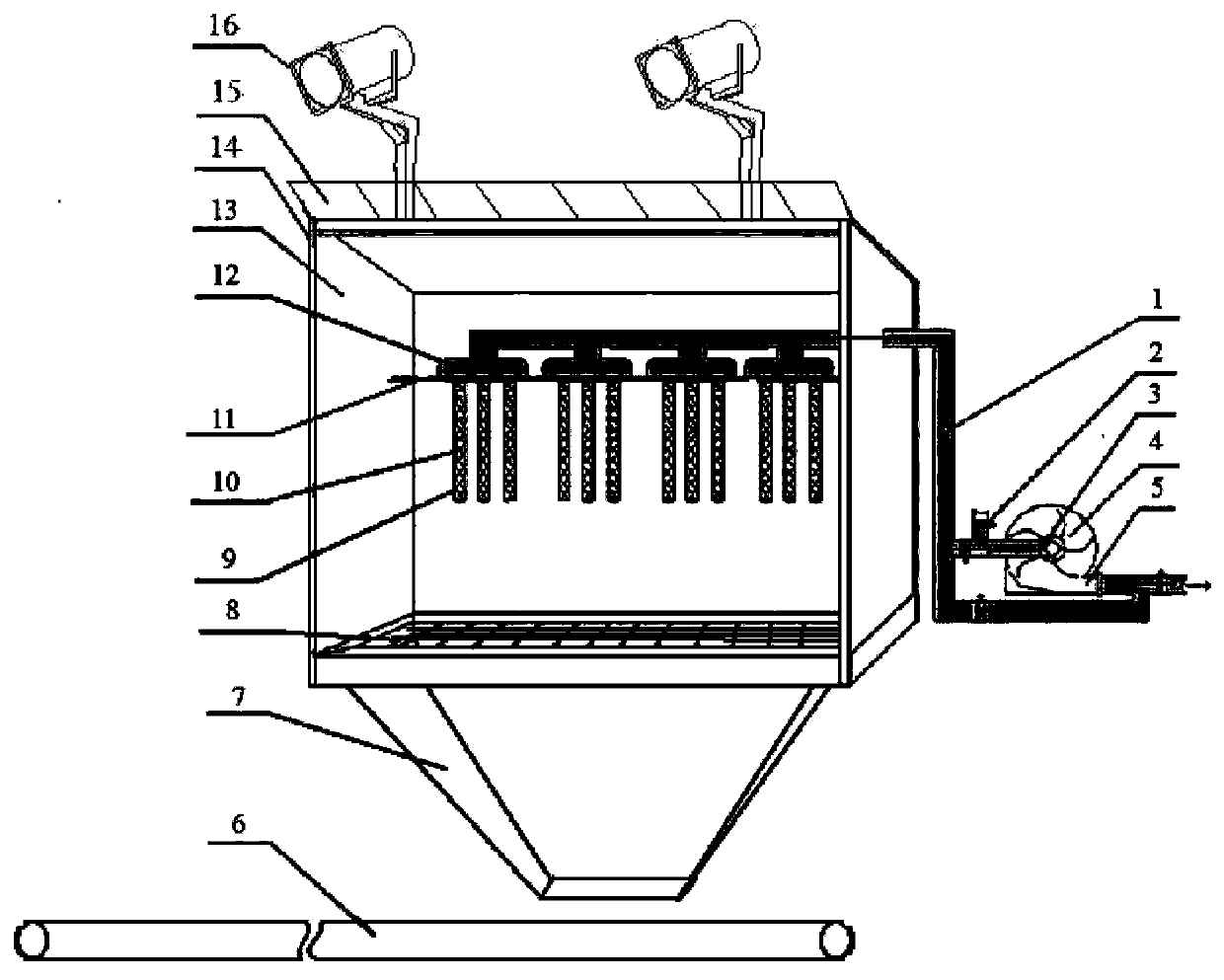

Collecting and dedusting device

InactiveCN104208954AControllable spillageReduce spillageDispersed particle filtrationDust controlEngineering

The invention discloses a collecting and dedusting device. The collecting and dedusting device comprises an unloading chamber (14) and is characterized in that the inside of the unloading chamber (14) is provided with a dedusting device for dedusting, the side portion of the unloading chamber (14) is provided with an air sucking dedusting device, which is connected with the dedusting device; the unloading chamber (14) also comprises a feeding port (13) at the side portion and a collecting hopper (7) at the bottom for collecting materials and dust. By means of a semi-tight structure, the collecting and dedusting device can achieve rapidity during unloading of a machine tool body and obtain dedusting effects. Meanwhile, the collecting and dedusting device is simple in structure, convenient to operate and good in dedusting effects.

Owner:GUANGXI DADU CONCRETE GROUP

Efficient automatic waste gas treatment method

ActiveCN113019042ATo achieve the purpose of dust removalAffect the effect of dust removalCombination devicesDispersed particle filtrationParticulatesWater source

The invention relates to waste gas treatment, and discloses an efficient automatic waste gas treatment method. The treatment method is based on waste gas treatment equipment. The treatment equipment comprises a water tank, a bottom box is welded to the surface of the water tank, a dust removal mechanism is arranged in the bottom box, a vertical plate is welded in the water tank, a crushing mechanism is arranged on the rear wall of the water tank, a spraying mechanism is arranged on the bottom wall of the water tank and located on the right side of the vertical plate, and the right side of the vertical plate is fixedly connected with the inner wall of the water tank through a transverse plate. According to the waste gas treatment equipment with a dust removal function and the use method thereof, waste gas can be subjected to preliminary dust removal through a water source to reduce the existence rate of dust in the waste gas, then the waste gas is conveyed into the bottom box and a dust removal pipe through an air pump, the waste gas subjected to dust removal through a water adsorption method is filtered again through a filter screen, a filter plate and a filter box, and therefore, particulate matters in the waste gas are reduced again, and the purpose of removing dust from the waste gas is achieved.

Owner:湖南利苍环保科技有限公司

Device and method for purifying air using biological enzymolysis

ActiveCN103344012AHas the effect of sterilization and disinfectionHas the effect of adsorptionCombination devicesLighting and heating apparatusAgricultural engineeringOrganic matter

The invention discloses a device and method for purifying air using biological enzymolysis. The device comprises a shell and a fan arranged in the shell. An air inlet and an air outlet are formed in the side wall of the shell, the air inlet is arranged below the air outlet, a drum-shaped filter body and a water channel containing a biological enzymolysis adsorption module are arranged in the shell, and the drum-shaped filter body comprises an upper flat plate, a lower flat plate and a plurality of hollow ventilation pipes, wherein the upper flat plate and the lower flat plate are horizontally arranged, and the hollow ventilation pipes are vertically arranged between the upper flat plate and the lower flat plate. The side wall of each hollow ventilation pipe is provided with a filter net where biological enzymes are located, through holes communicated with openings of the hollow ventilation pipes are formed in the upper flat plate and the lower flat plate, the upper flat plate is arranged between the air inlet and the air outlet, the lower flat plate is arranged below the air inlet, and the water channel is arranged below the lower flat plate. The invention further discloses a method for purifying air using biological enzymolysis. According to the method, the biological enzymes are used for indoor environment purification processing, formaldehyde and other organic matter harmful to a human body can be effectively degraded, a bacteriostatic effect also can be achieved, and secondary pollution can not occur.

Owner:山东德源中天科贸有限公司

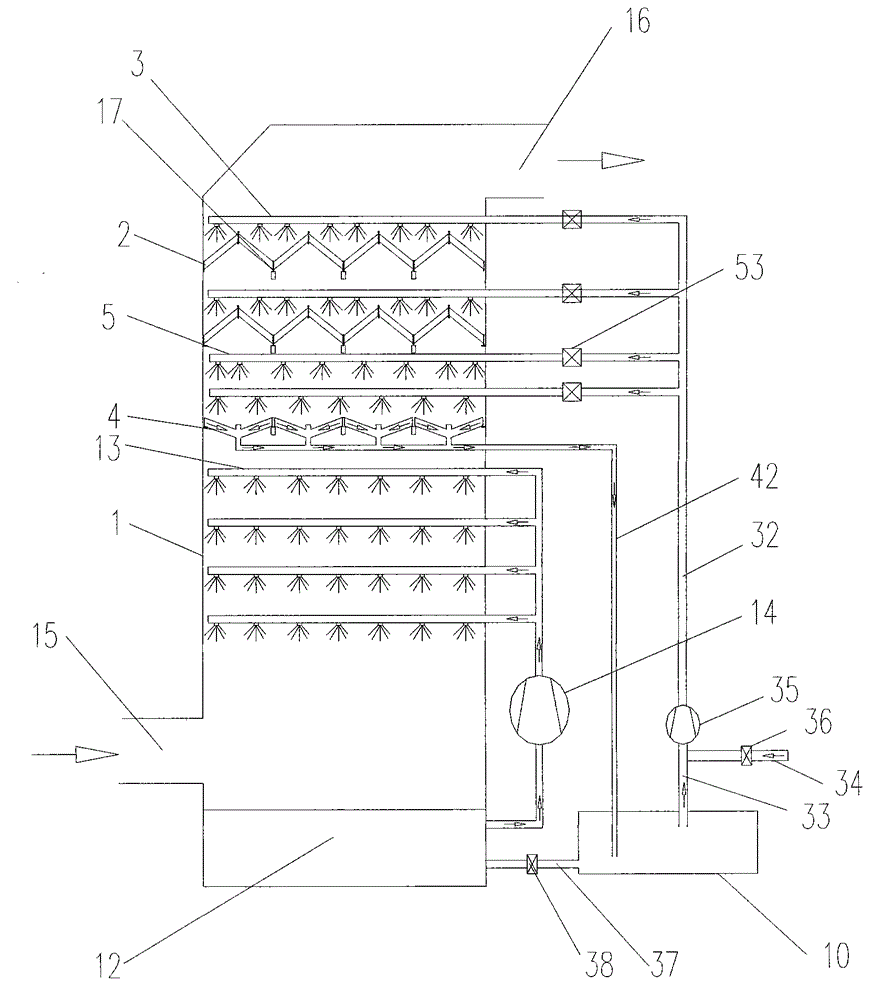

Multi-return-stroke heat-exchanging type biomass boiler

ActiveCN104373923ACompact structureSmall footprintWater-tube boilersSolid fuel combustionCombustion chamberThermal insulation

The invention discloses a multi-return-stroke heat-exchanging type biomass boiler. The biomass boiler comprises a boiler body and an air blowing and inducing system, and is characterized in that the boiler body comprises a feeder, a double-combustion-chamber mechanism, a multi-return-stroke densely distributed water pipe boiler furnace, a smoke exhausting pipe, a water tank arranged outside the double-combustion-chamber mechanism and the boiler furnace, and a thermal insulation layer arranged on the exterior of the water tank. The inlet of the double-combustion-chamber mechanism is connected with the feeder and an air blower, and the outlet of the double-combustion-chamber mechanism is connected with the inlet of the boiler furnace. The outlet of the boiler furnace is connected with the smoke exhausting pipe and an induced draft fan. The multi-return-stoke heat-exchanging type biomass boiler is high in heat efficiency, safe, reliable, convenient to install and small in occupied area.

Owner:HUAIHUA QIXIAO ENERGY SAVING TECH +1

Combined type deodorization arrangement

InactiveCN1736565AIncrease humidityEasy to adjustDispersed particle separationDeodrantsDistribution systemEngineering

The invention discloses a built-up device for deodorization, which comprises a housing, the bottom of which is equipped with a distribution system, an air inlet pipe linked to the distribution system, the top of which is equipped with a grid holder, the first filler layer placed above the grid holder, a spray unit on the filler layer, not less than one active filler layers equipped behind the spay unit, and a air outlet equipped behind the other active filler layers. The invented device has a rational structure and a well deodorization effect.

Owner:顾建

Cyclone type flue gas dust removal device

An existing flue gas dust removal device comprises a casing and an ash bucket arranged on the lower side of the casing, wherein an air inlet pipe is connected into a cavity of the casing from the upper side of the casing; an air outlet pipe is connected into the cavity from the upper side of the casing and extends to the bottom of the cavity; flue gas enters the upper part of the cavity from the air inlet pipe, rotational flow is formed and enters the air outlet pipe from an air outlet pipe orifice at the lower part of the cavity, and when the flue gas forms the rotational flow, relatively large particles in the flue gas are thrown to the wall of the cavity under the action of centrifugal force and discharged from an ash falling port in the lower end of the ash bucket. To solve the existing technical problem, the invention provides the cyclone type flue gas dust removal device. The device comprises the casing, the ash bucket, the air inlet pipe and the air outlet pipe and is characterized in that a fan is further arranged in the casing and supplies air from bottom to up, the air inlet pipe is arranged on the lower side of the fan, the air outlet pipe is arranged on the upper side of the fan, and a filter net is further arranged on the upper side of the air inlet pipe. Due to arrangement of the fan, the cyclone effect of flue gas in the cavity is better, and the flue gas dust treatment capacity is further improved.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

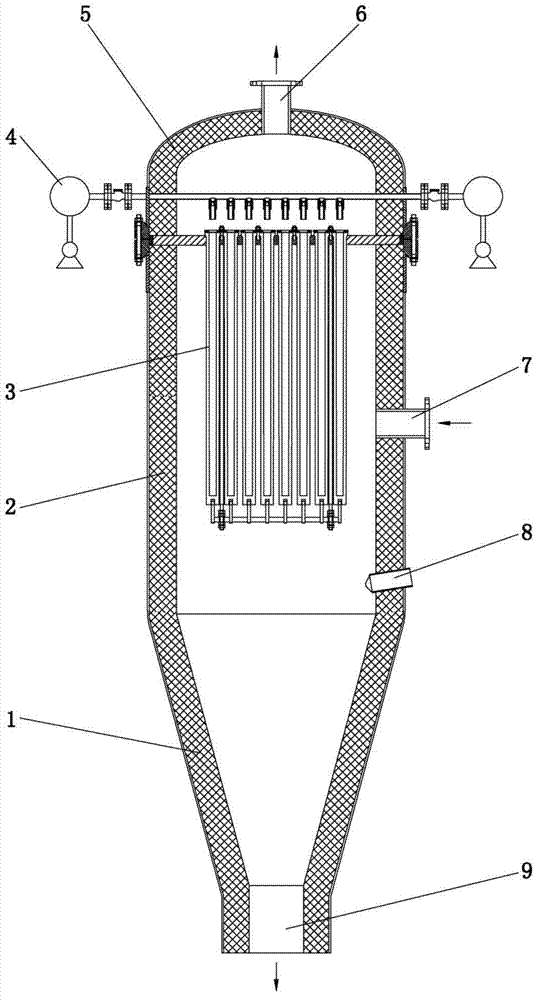

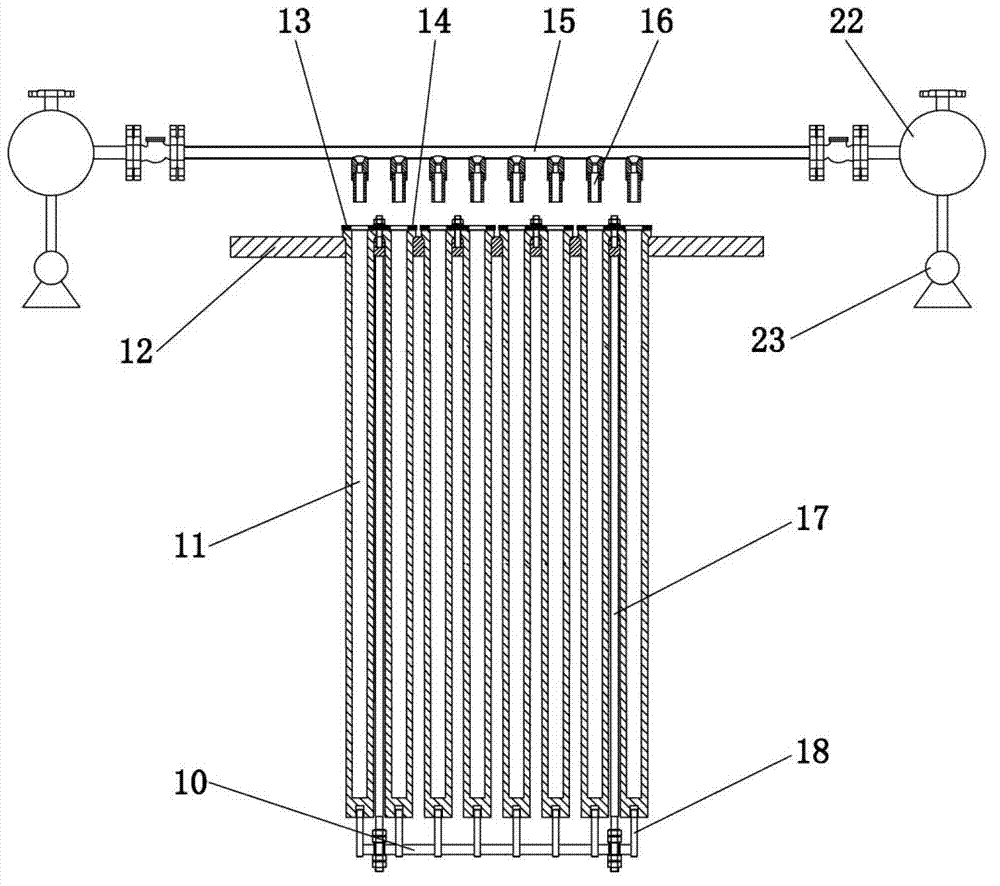

Biogas filter

InactiveCN103041652ARestore the dust removal functionSmall pressure dropDispersed particle filtrationGas dust removalMetallurgyCombustible gas

The invention disclose a biogas filter, wherein a filtrating unit composed of a plurality of ceramic filter cores for filtrating ash impurity and impurities in the biogas, is arranged in a cylinder. When the high-temperature biogas passes through the ceramic membrane filter cores of the filter, the dust in gas flow impacts the ceramic membrane filter cores and is held up. The high-temperature combustible gas with tar passes through the ceramic membrane filter cores, to separate the gas flow and a grain flow for removing dust in gas. The filter has the characteristics of high temperature resistance and good filtrating effect.

Owner:GUANGZHOU DEVOTION THERMAL TECH

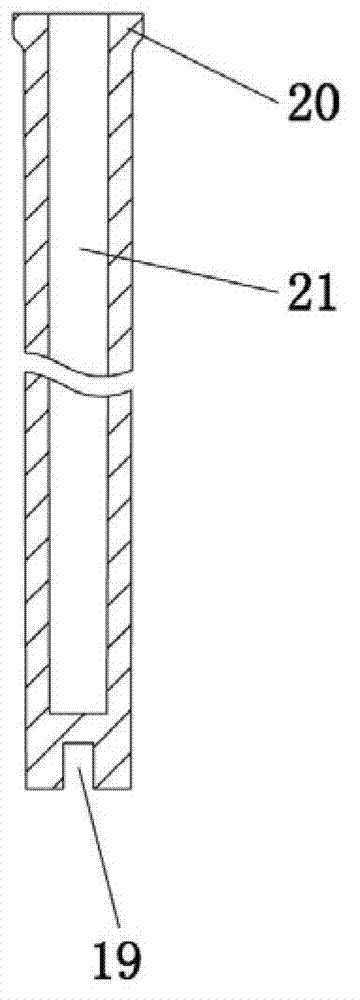

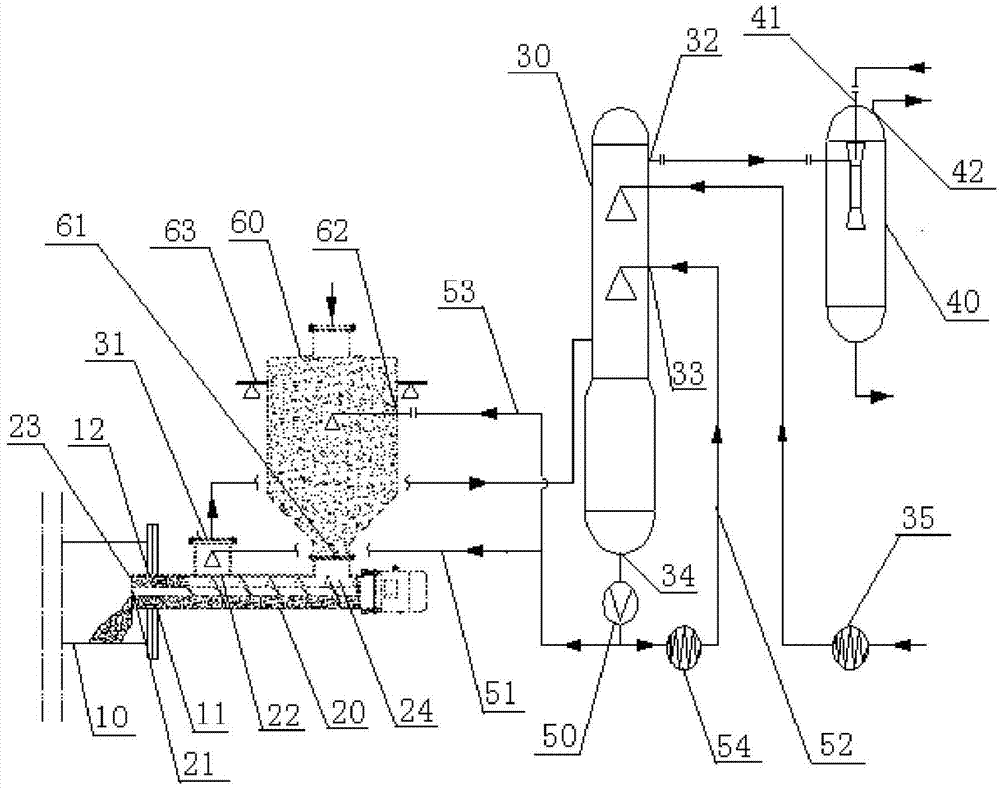

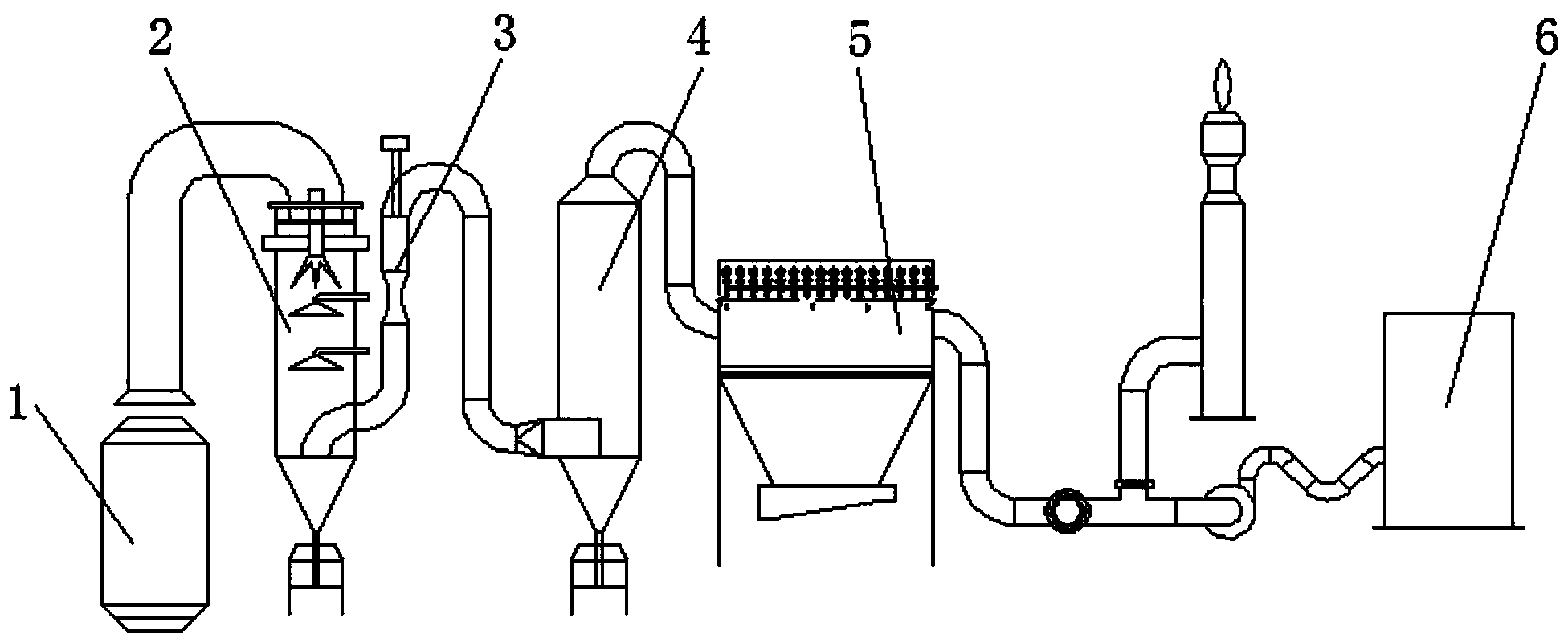

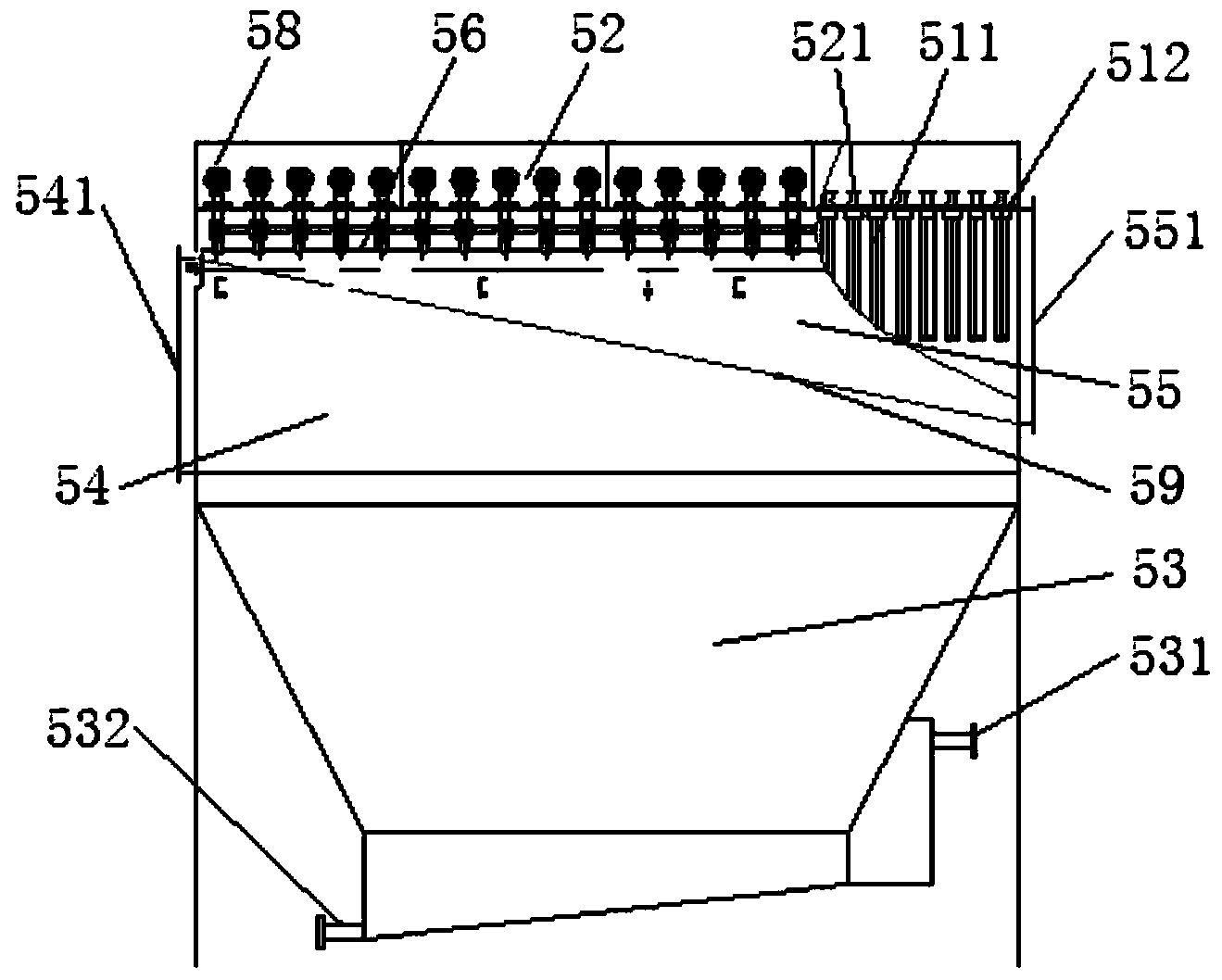

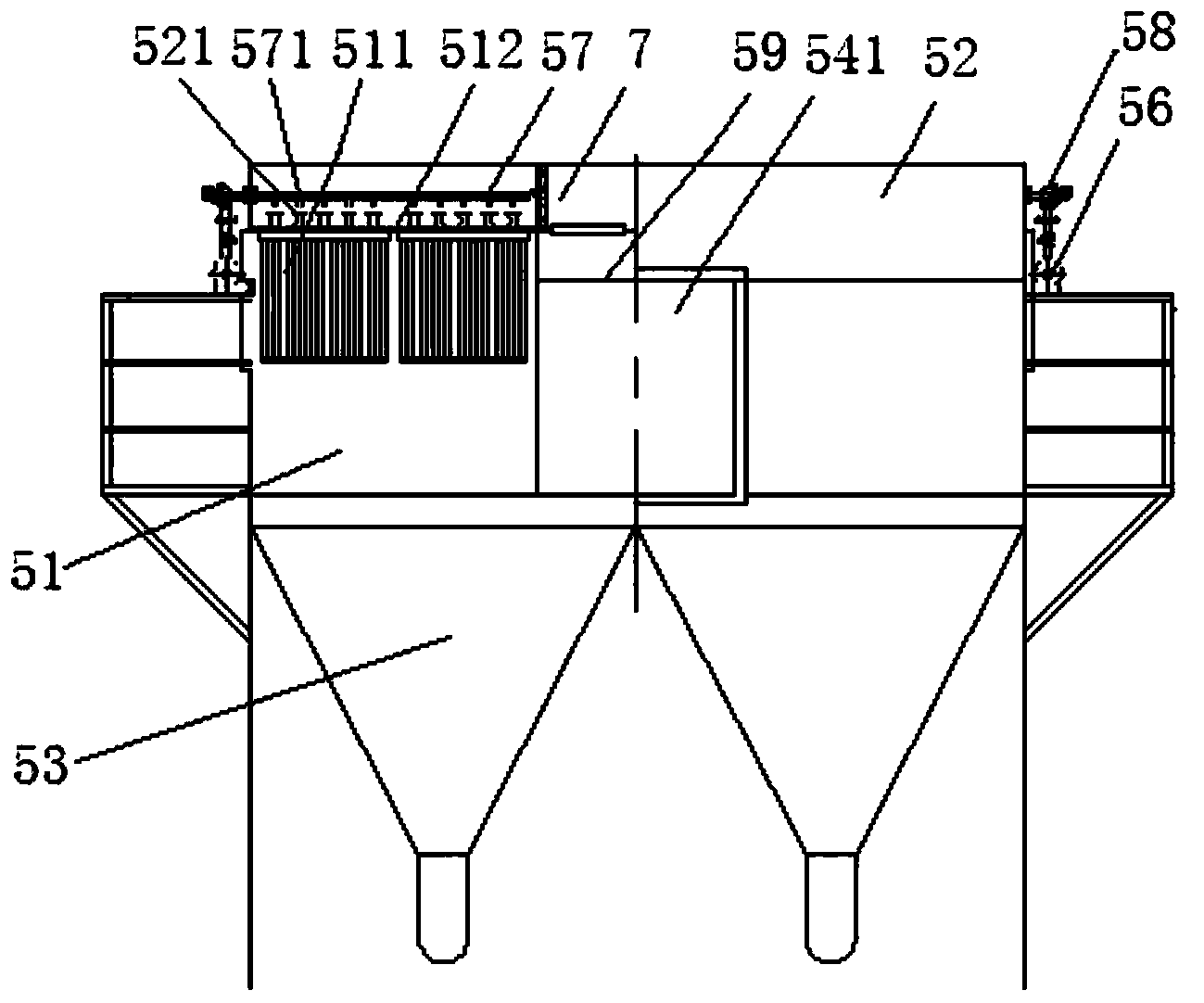

Combined process and device for dust removal for pyrolysis coal gas and delayed coking for heavy oil

ActiveCN104762109AAdvantages of dust removal processEasy to operateGas purification by treating with solidsGas dust removalProcess engineeringMoving bed

The invention provides a process and a device for dust removal for a pyrolysis coal gas, and a combined process and device for dust removal for a pyrolysis coal gas and delayed coking for heavy oil. The process for dust removal for the pyrolysis coal gas comprises the following steps: (1) enabling the pyrolysis coal gas to reversely pass through a moving bed particle layer formed by dry coal to obtain primary dust removal coal gas; and (2) carrying out a secondary dust removal treatment on the primary dust removal coal gas by the heavy oil with fractions with temperature of 350 DEG C or above to obtain dustless coal gas. Compared with the prior art, the process for dust removal disclosed by the invention is simple to operate and low in energy consumption and facilitates large-scale running; in addition, the process for dust removal for the pyrolysis coal gas is perfectly coupled together with delayed coking for heavy oil for the first time, thus greatly simplifying the process flow, reducing the operation difficulty, and reducing the cost investment and the energy consumption of a production device.

Owner:SHAANXI COAL & CHEM IND GRP SHENMU TIANYUAN CHEM IND +1

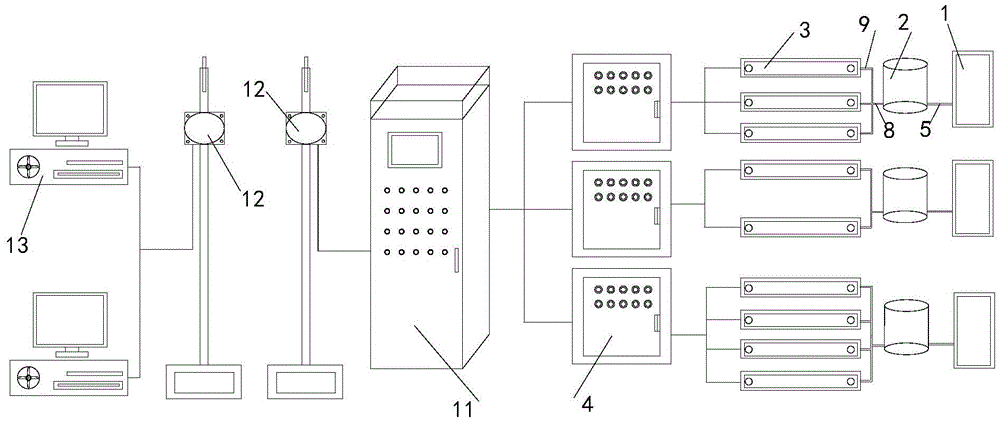

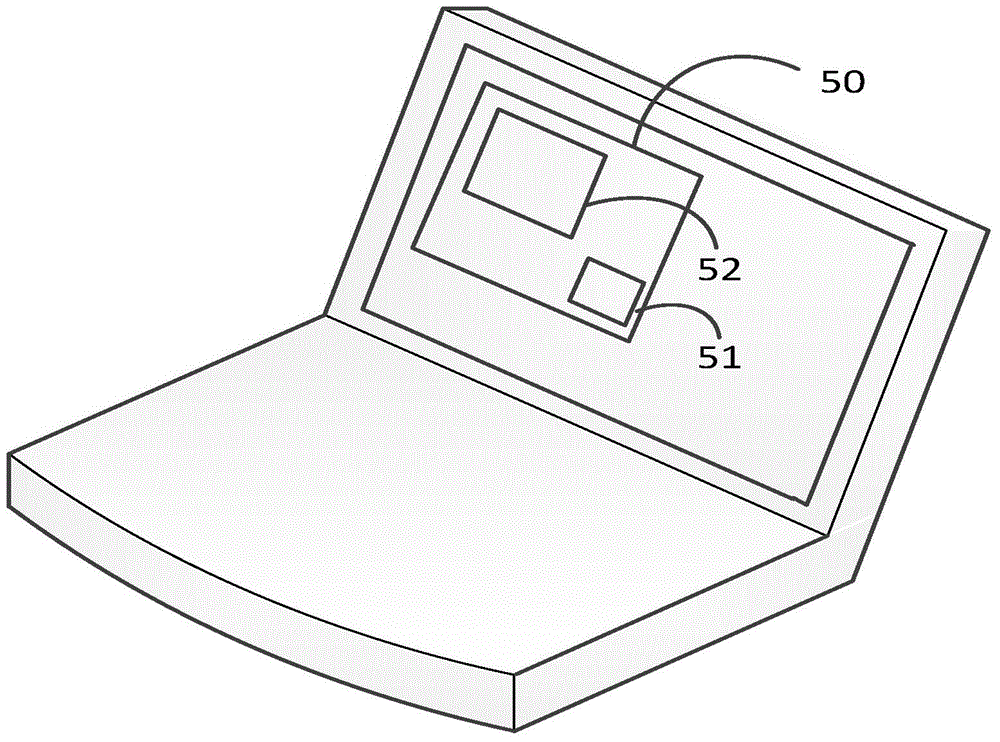

Electronic device and fan assembly

ActiveCN105446436ASimple circuit designTo achieve the purpose of dust removalDigital data processing detailsCircuit designControl circuit

The present invention discloses an electronic device and a fan assembly. The electronic device comprises a cooling device, a fan assembly and a control circuit; the fan assembly comprises a fan and a fan drive structure, and the fan drive structure comprises a power port and a first fan port different from the power port; the control circuit comprises a second fan port, and is connected with the fan drive structure through the first fan port and the second fan port; and the control circuit generates a fan revolution control instruction, and transmits the instruction to the fan drive structure through the first fan port and the second fan port, and the fan drive structure receives and executes the fan revolution control instruction to control the fan to carry out a corresponding revolution operation. According to the electronic device, by setting the first fan port, the technical problems of the complicated fan circuit design structure and the high cost of the electronic device in the prior art are solved.

Owner:LENOVO (BEIJING) CO LTD

Demisting system with dedusting, demisting and water recovery functions

InactiveCN104874255AGood effect of dust removal and fog removalIncrease workloadCombination devicesWater dischargeSpray nozzle

The invention relates to a demisting system with dedusting, demisting and water recovery functions. The demisting system with the dedusting, demisting and water recovery functions comprises a demister, a supporting plate and a flushing device, wherein the demister is arranged in an absorption tower; the supporting plate is used for fixing the demister; the flushing device is used for flushing the demister; the demister comprises a plurality of demister blades which are configured in parallel; the flushing device comprises a flushing water pipeline and a plurality of spray nozzles; a flushing water recovery device is arranged below the flushing device, and comprises a plurality of water collection pipes which are obliquely arranged, and a water discharge pipe which is used for communicating the water collection pipes with one another and discharging flushing water outside the tower; channels through which fumes circulate are arranged between every two adjacent water collection pipes. According to the demisting system with the dedusting, demisting and water recovery functions, through the combination of the water recovery device, a spray dedusting system and the demister, the dedusting and the demisting on the fumes and the repetitive recycling of water are realized; the purposes of energy conservation and emission reduction are realized; the requirement of near zero emissions of a heat-engine plant is met.

Owner:北京香源溪环保科技有限公司

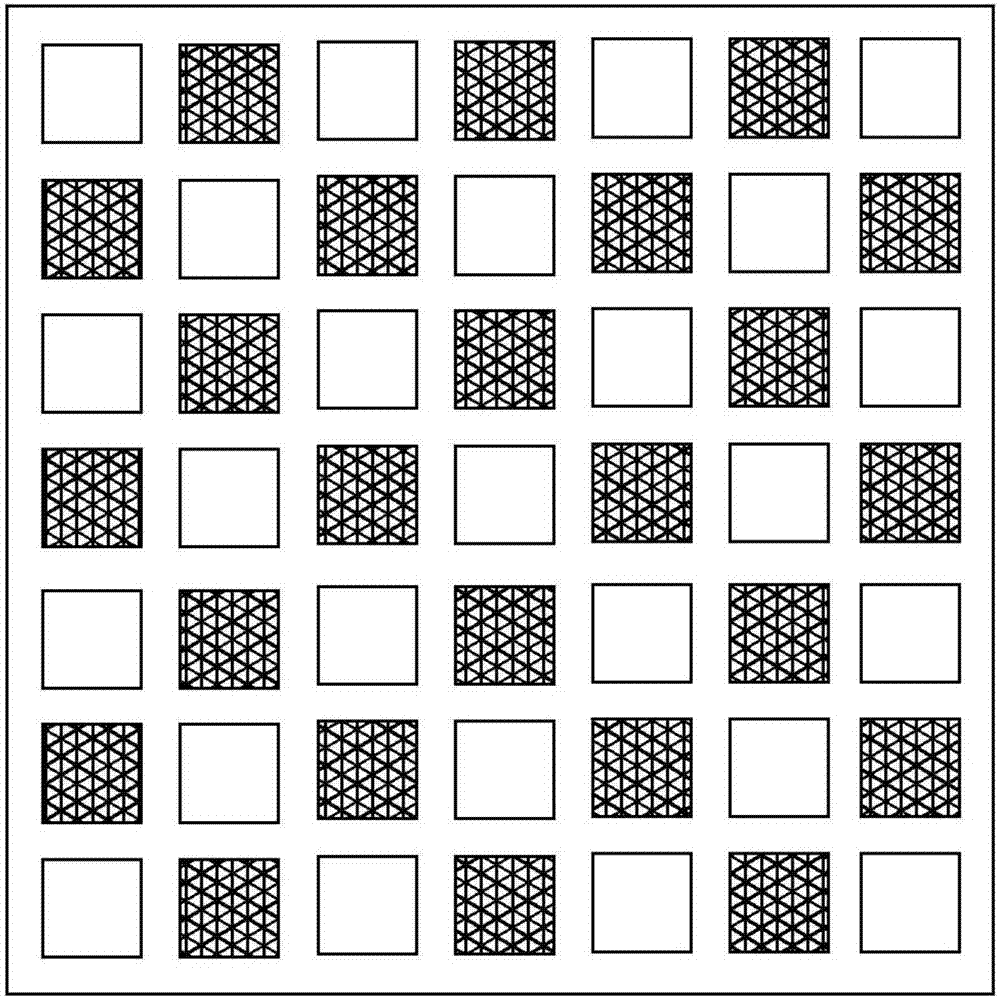

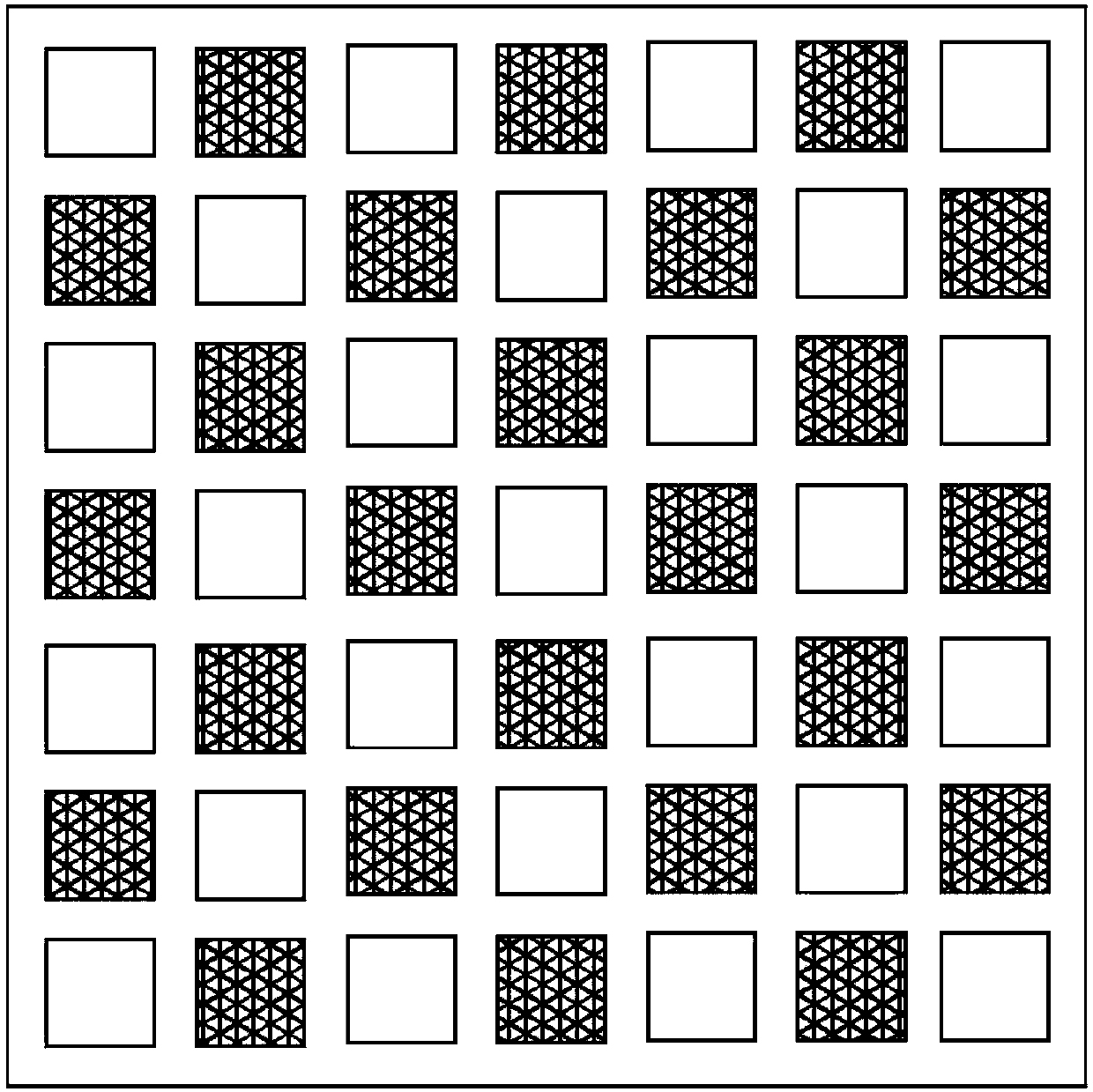

Dust-removing and denitration integrated catalyst and preparation method thereof

InactiveCN107899566AImprove denitrification efficiencyReduce poisonDispersed particle filtrationHeterogenous catalyst chemical elementsEnvironmental resistanceFlue gas

The invention relates to a dust-removing and denitration integrated catalyst and a preparation method thereof, and belongs to the technical field of a catalyst. The method comprises eight processes ofmixing, extruding, drying, blocking pores, calcining, loading an active substance, drying again and calcining. According to the method, the state of each through hole in the traditional honeycomb SCRcatalyst is changed through a pore blocking technology, flue gas enters from the inlet end of the catalyst, and the flue gas is completely filtered through the side wall of the adjacent pore of the unclosed pore at the inlet end and by utilizing the side wall. Therefore, the dust-removing aim is fulfilled, the retention time of the flue gas in the catalyst is prolonged, the contact area of the flue gas and the catalyst is increased and the efficiency of the catalyst is improved; meanwhile, the variety and the use amount of a pore forming agent are limited and the pore diameter distribution ofthe side wall in the catalyst is changed, so that the catalyst is suitable for removal of dust with various grain size, the denitration and dust-removing aims are finally achieved, dust-removing anddenitration integration is realized in true sense, and the environment-protecting investment and the operation cost of flue gas treatment of a power plant and an industrial kiln furnace are greatly reduced.

Owner:CHONGQING YUANDA CATALYST MFG

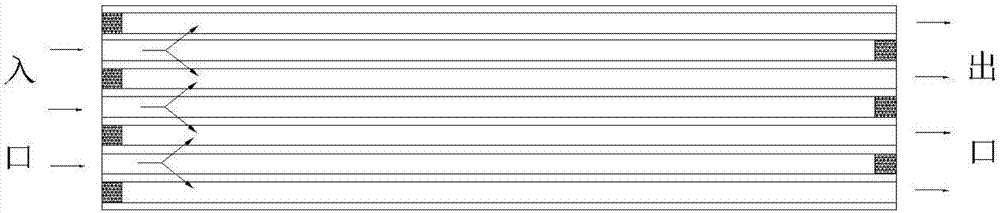

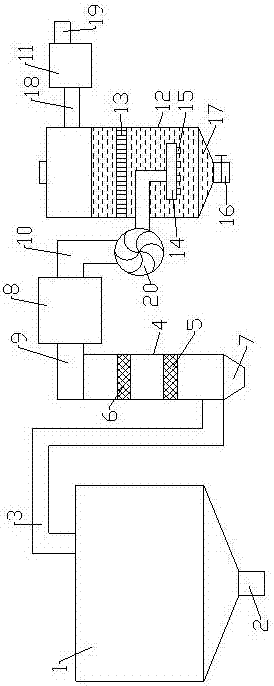

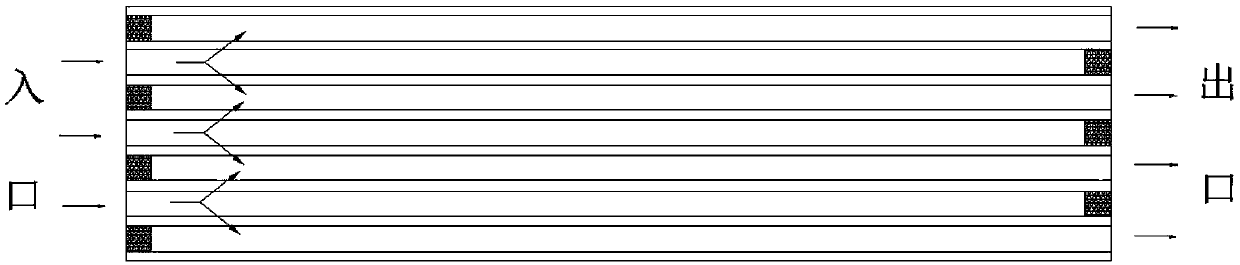

Blast furnace gas dust removal system

InactiveCN104031691AImprove dust removal efficiencySolve potential safety hazardsCombination devicesGas dust removalCombustionEngineering

The invention discloses a blast furnace gas dust removal system, belonging to the field of metallurgical furnace gas purification and dust removal. The blast furnace gas dust removal system aims to solve the problems of low dust removal efficiency, incapability of thoroughly avoiding gas explosion and the like in the existing dust removal mode. The dust removal system comprises a converter, a spray tower, a Venturi wet-process dust remover, a swirl dehydrator and a sintering board dust remover which are sequentially connected through a pipeline according to the gas flow sequence. Gas discharged from the converter enters the spray tower through the pipeline to be cooled, enters the Venturi wet-process dust remover to be subjected to rough dust removal, enters the swirl dehydrator to be dehydrated, and enters the sintering board dust remover to be subjected to fine dust removal and dehydration, and the finally obtained clean gas is classified according to needs and subjected to dispersed combustion or collected into a gasometer. By combining the rough dust removal of the Venturi wet-process dust remover and the fine dust removal and dehydration of the sintering board dust remover, the system greatly enhances the dust removal efficiency, and thoroughly solves the problem of potential safety hazard caused by gas explosion.

Owner:中节能天辰(北京)环保科技有限公司

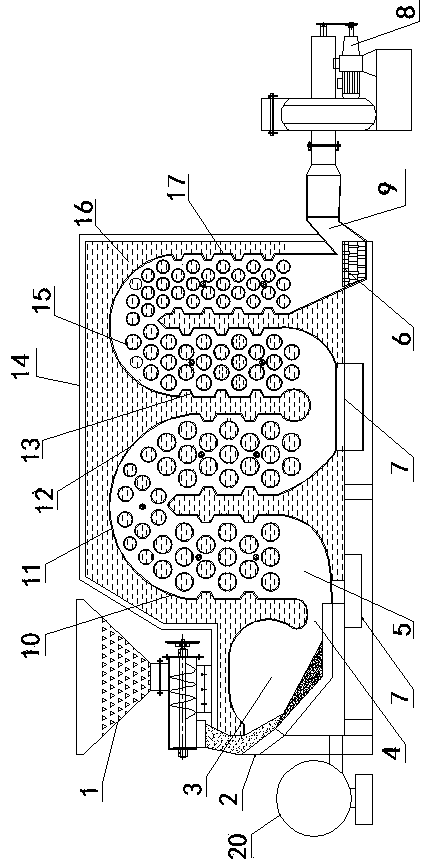

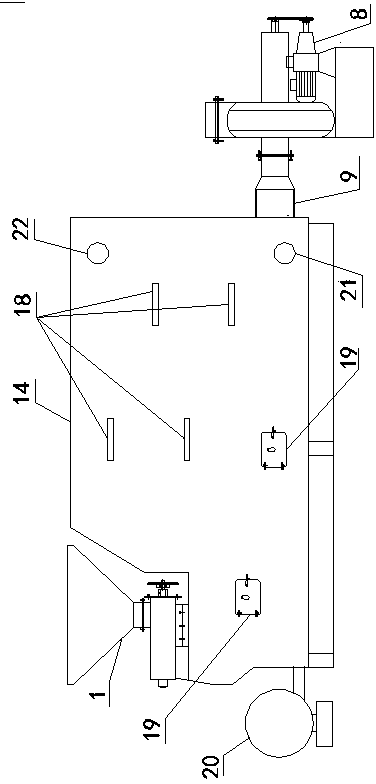

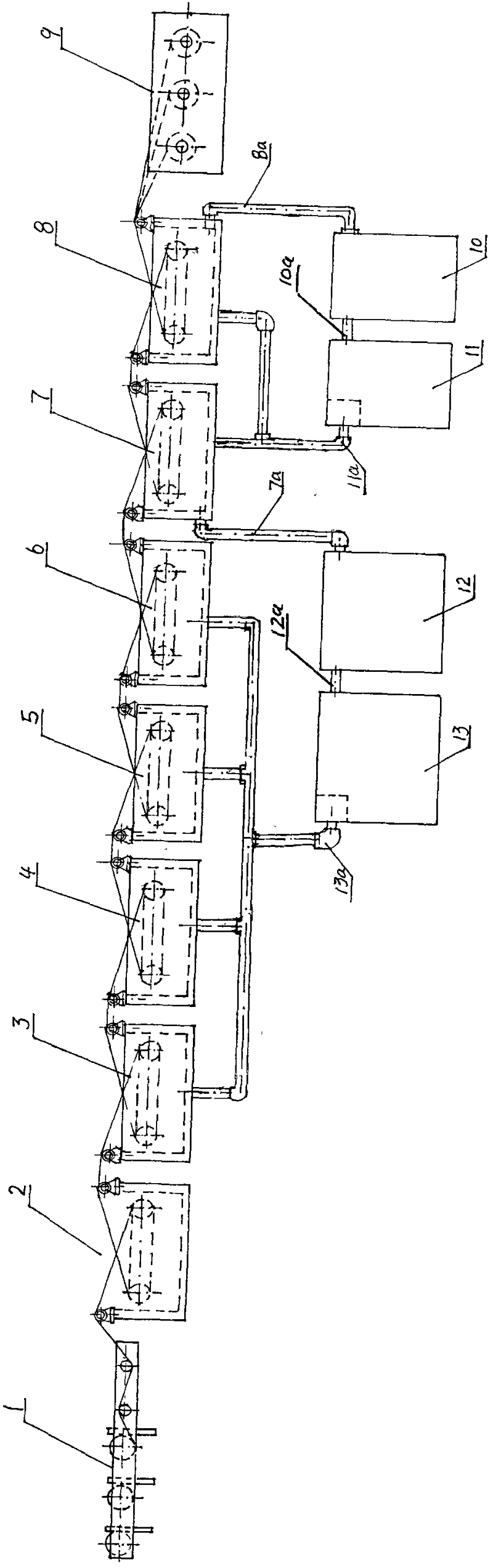

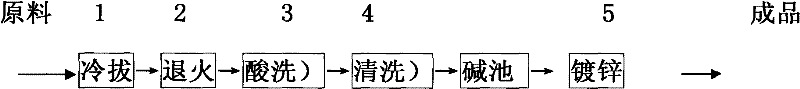

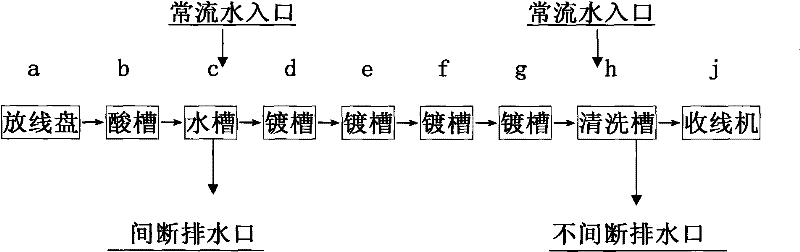

Clean and environment-friendly iron wires galvanizing apparatus and its technology

The invention relates to a clean and environment-friendly iron wires galvanizing apparatus and its technology. The iron wires galvanizing apparatus mainly comprises a paying-out machine (1), a polishing machine (2), a water tank (3), a first galvanizing tank (4), a second galvanizing tank (5), a third galvanizing tank (6), a cold water tank (7), a hot water tank (8) and a take-up machine (9), wherein, roller groups are provided on the paying-out machine (1), the polishing machine (2), the water tank (3), the first galvanizing tank (4), the second galvanizing tank (5), the third galvanizing tank (6), the cold water tank (7), the hot water tank (8) and the take-up machine (9), the iron wires of the paying-out machine (1) and the iron wires of the take-up machine (9) are connected end to endthrough each roller group. The invention also relates to a clean and environment-friendly iron wire galvanizing technology; the invention has the characteristics that no cyanogen or no pickling is contained, circulating water is not discharged which is clean and environment-friendly, the iron wires galvanizing apparatus provided in the invention can replace the traditional equipment of iron wiresgalvanizing, the invention has advantages of water saving and no environmental pollution, and the labor intensity of operators can be reduced, so that operators can get rid of work environment of strong acid mist, thereby the invention is capable of alleviating the damage of acid to operators body, reducing production cost of galvanizing iron wires and raising the competitiveness of enterprises.

Owner:秦学刚

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com