Patents

Literature

69results about How to "Play a role in dust removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

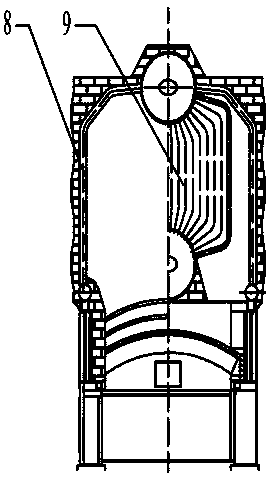

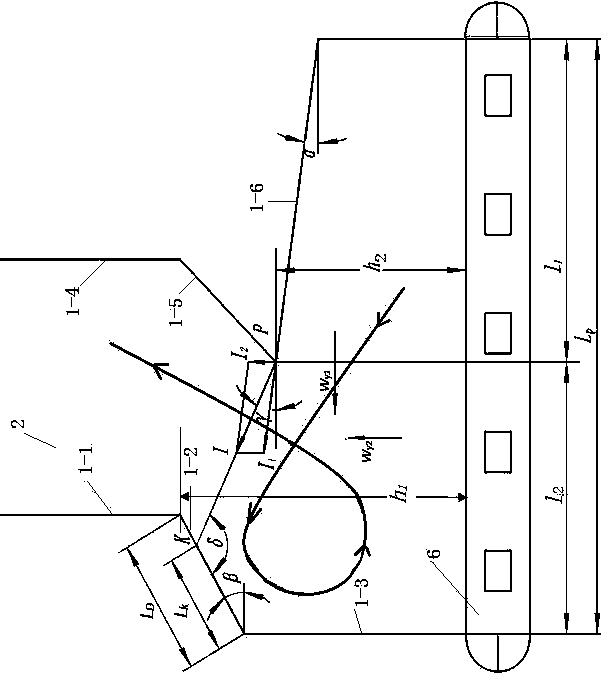

Design method for cutterheads of high-pressure water jet full-face rock tunnel boring machine

InactiveCN105736006AImprove processing efficiencyReduce energy consumptionTunnelsRock tunnelWater jet

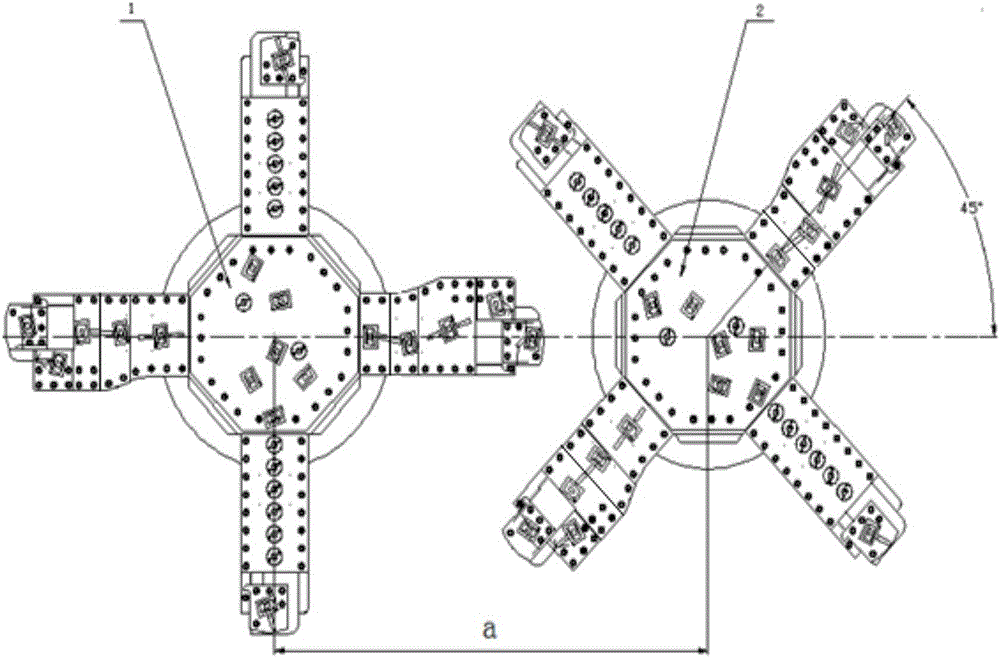

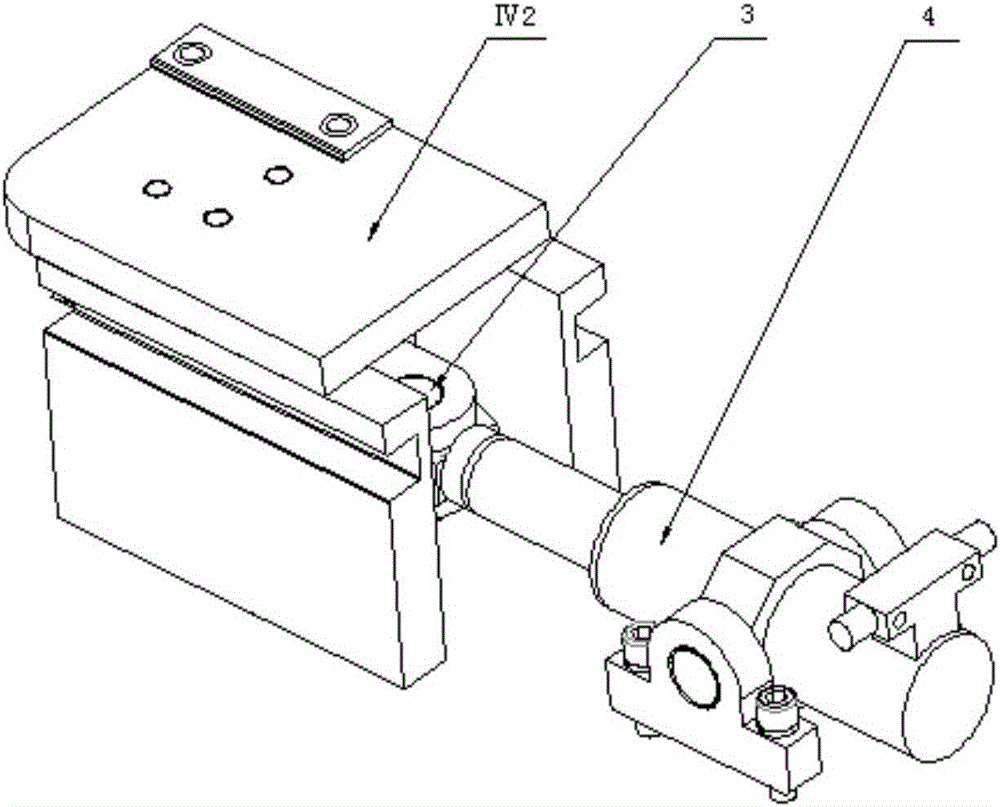

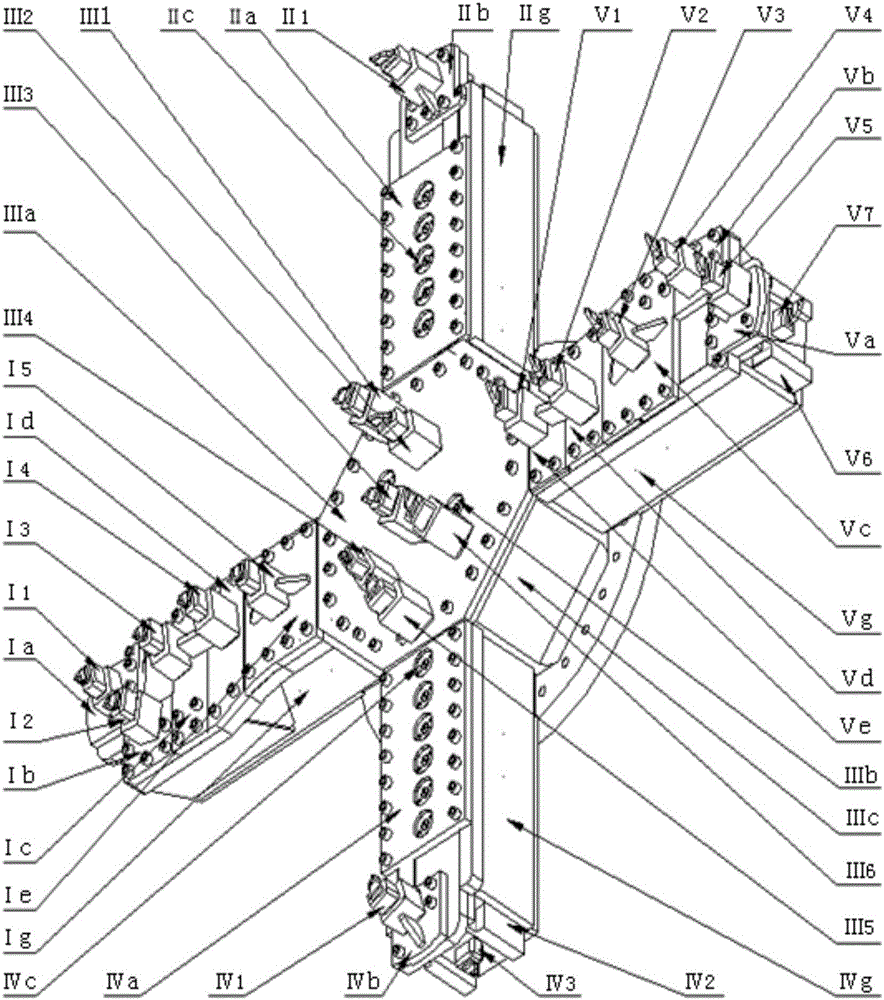

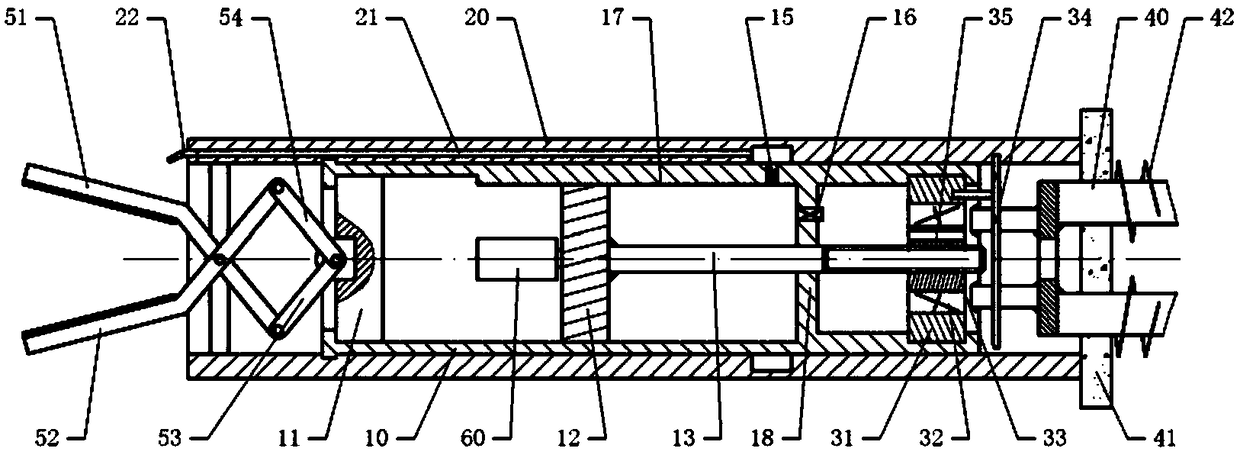

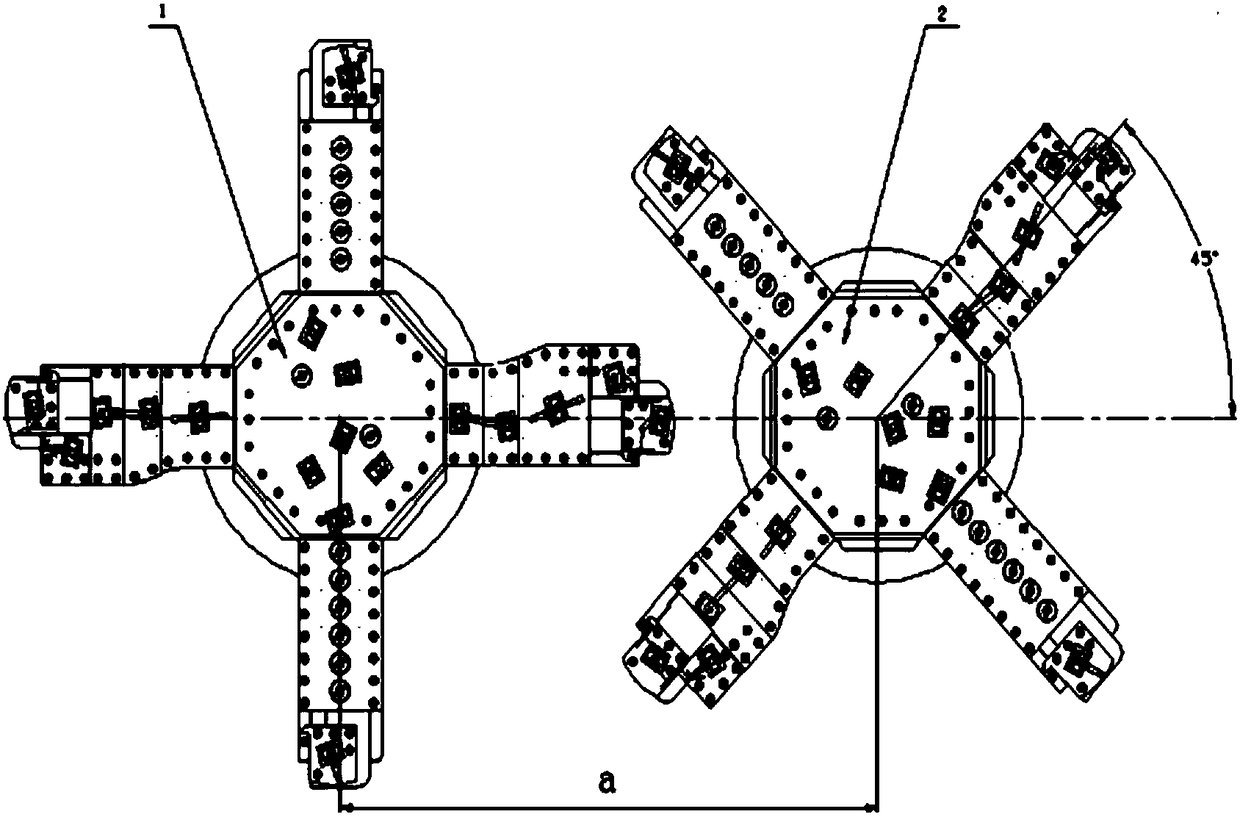

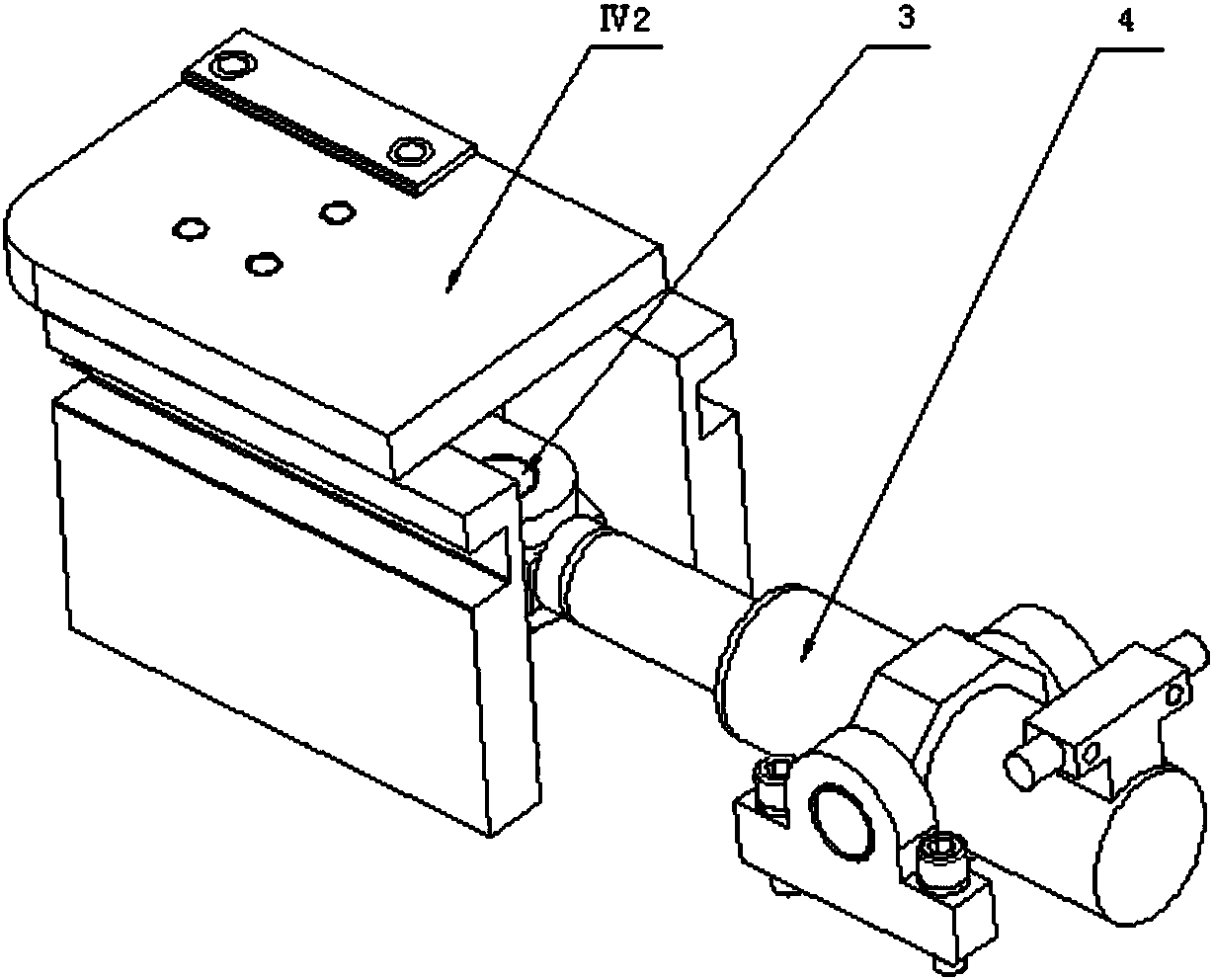

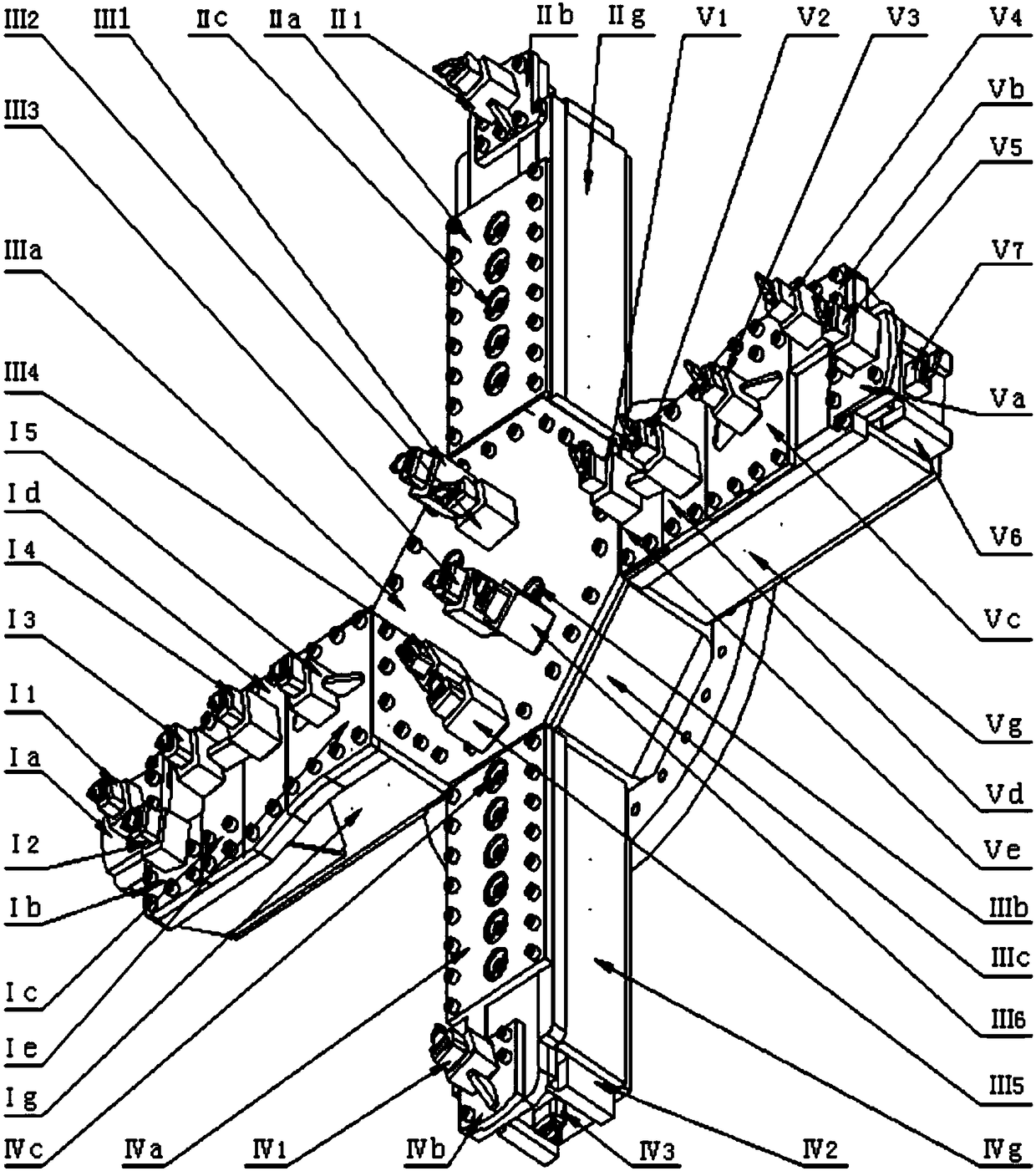

The invention discloses a high-pressure water jet full-section rock boring machine cutterhead design method, which belongs to the technical field of full-section rock boring machine excavation, and relates to a high-pressure water jet full-section rock breaking cutterhead design method. In the design method, the overall layout of the cutterhead adopts two cutterheads in the form of synchronously rotating cross-shaped spokes with the same structure. The second cutterhead is installed counterclockwise by 45° relative to the first cutterhead. Each cutterhead is composed of five Component composition. The design method has changed the integral hob structure of the traditional TBM cutter head. Two cross-shaped spoke layouts are adopted. The rock is broken through the impact of water jets on the four spokes and the rotary extrusion of the cutter. It utilizes the high processing efficiency of water jets. , low energy consumption, and easy to implement, using high-pressure water to make rocks crack and expand or even break, which reduces the resistance of the tool to breaking rocks and prolongs the life of the tool.

Owner:DALIAN UNIV OF TECH

Venturi cyclone dust extractor

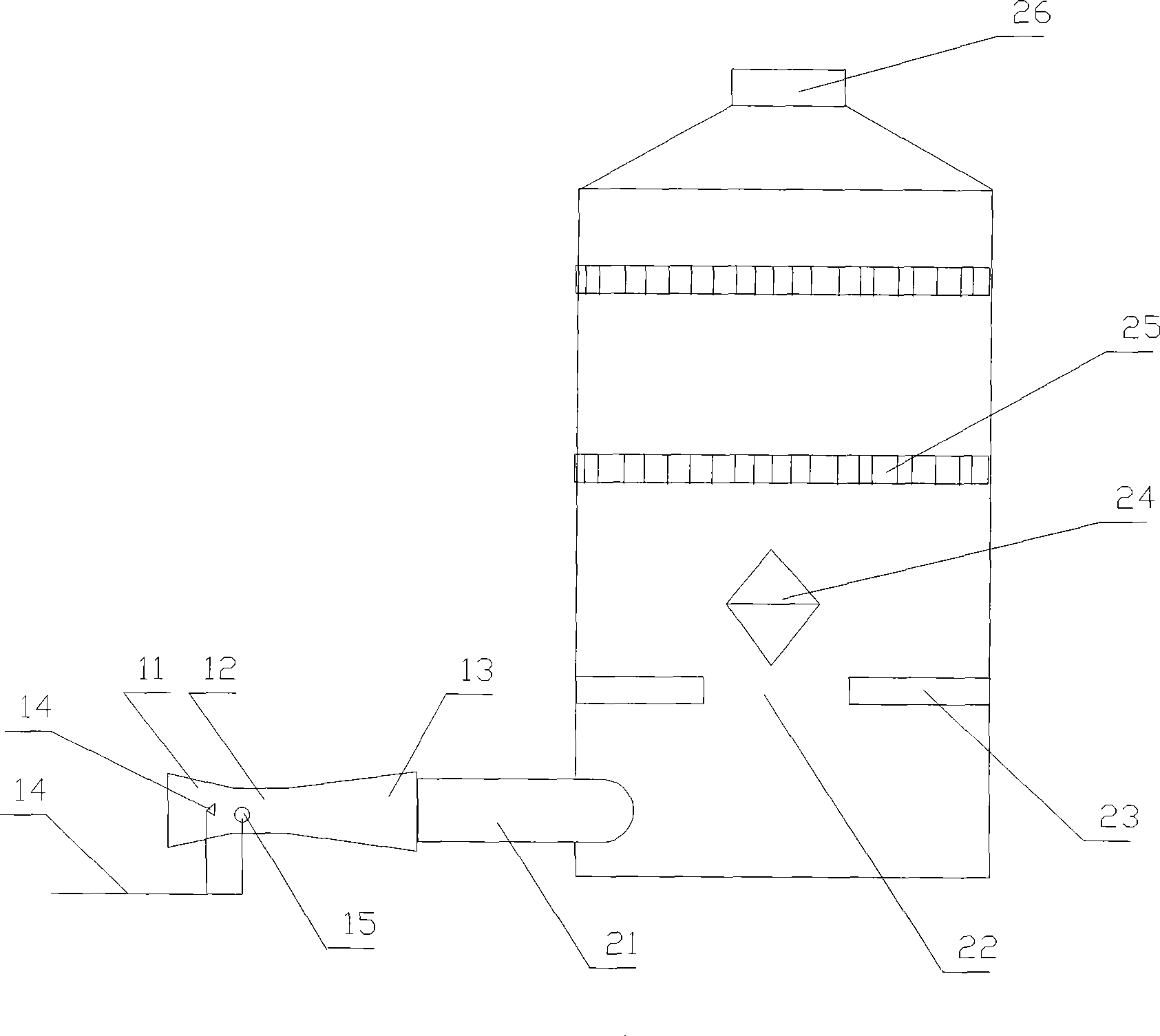

InactiveCN101468276AOvercome the defect of small quantityAchieve separationCombination devicesCrystallization separationCycloneEngineering

The invention relates to a venturi tube cyclone dust collector, which is characterized by comprising a venturi tube and a cyclone sedimentation tower, wherein outlet gas of the venturi tube tangentially enters a cyclone area on the lower part of the cyclone sedimentation tower through an air inlet pipe of the cyclone sedimentation tower; the venturi tube consists of a contraction section, a throat section and a diffusion section; the side wall of the throat section is provided with a plurality of through holes, and the outer side of the through hole are connected with a pressure water supply pipe; a port of the diffusion section forms an air outlet of the venturi tube; a port of the contraction section forms an air inlet of the venturi tube; the lower part of the cyclone sedimentation tower is a cyclone area, the upper part is a sedimentation and dehydration area, and the middle part is provided with an annular clapboard; and the upper part of the sedimentation and dehydration area is provided with a plurality of gas-liquid separating layers. The venturi tube cyclone dust collector has the advantages of small investment, high dust removing efficiency, comparatively longer service life, small water consumption and low running cost, and can be mainly applied to the dust removal of high density flue gas and industrial dust in various industrial furnaces.

Owner:HAISIBOTE BEIJING SCIENE & TECH

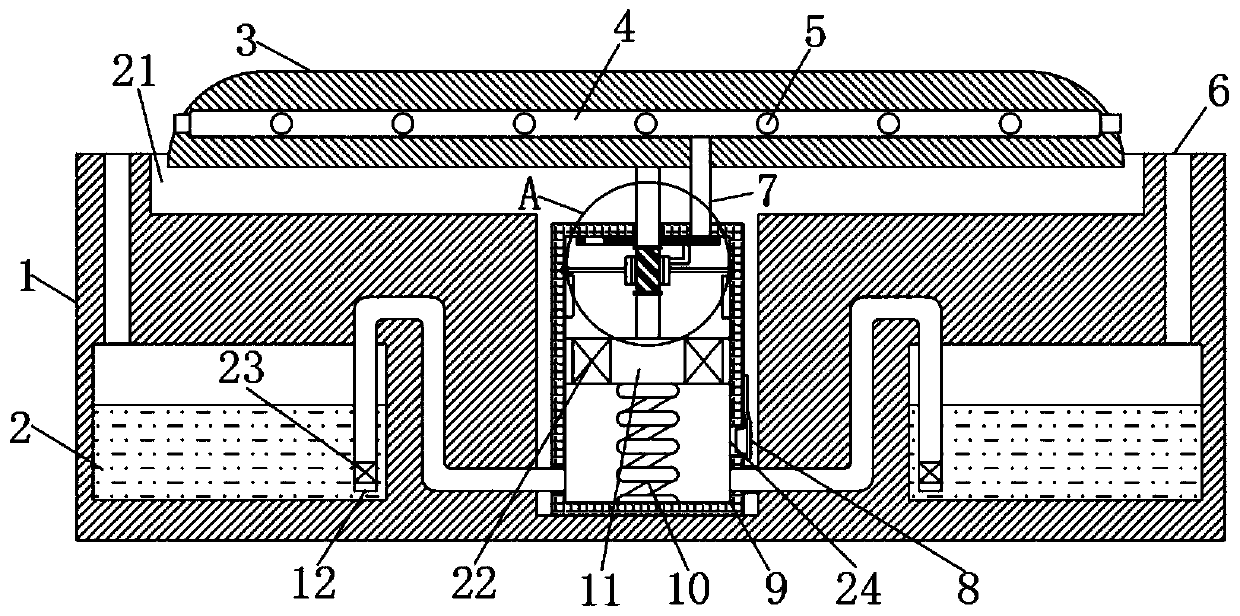

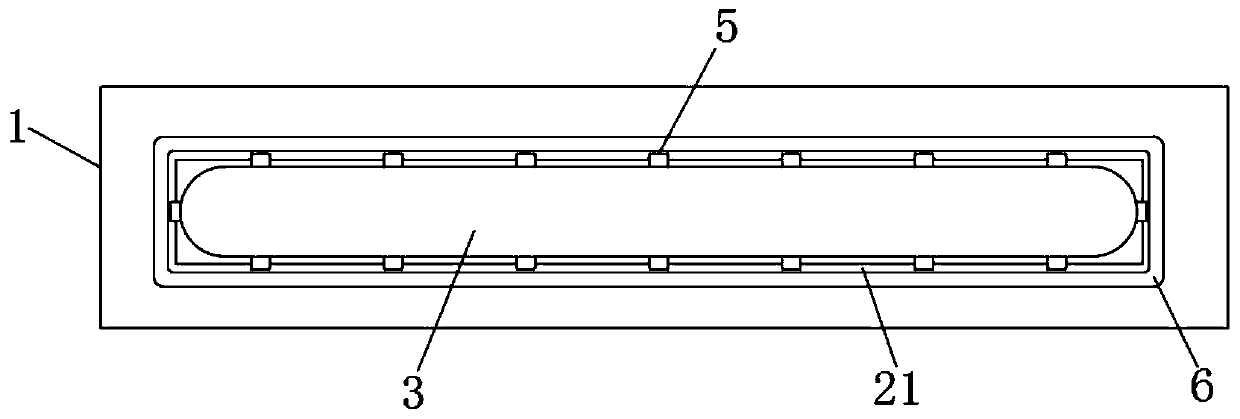

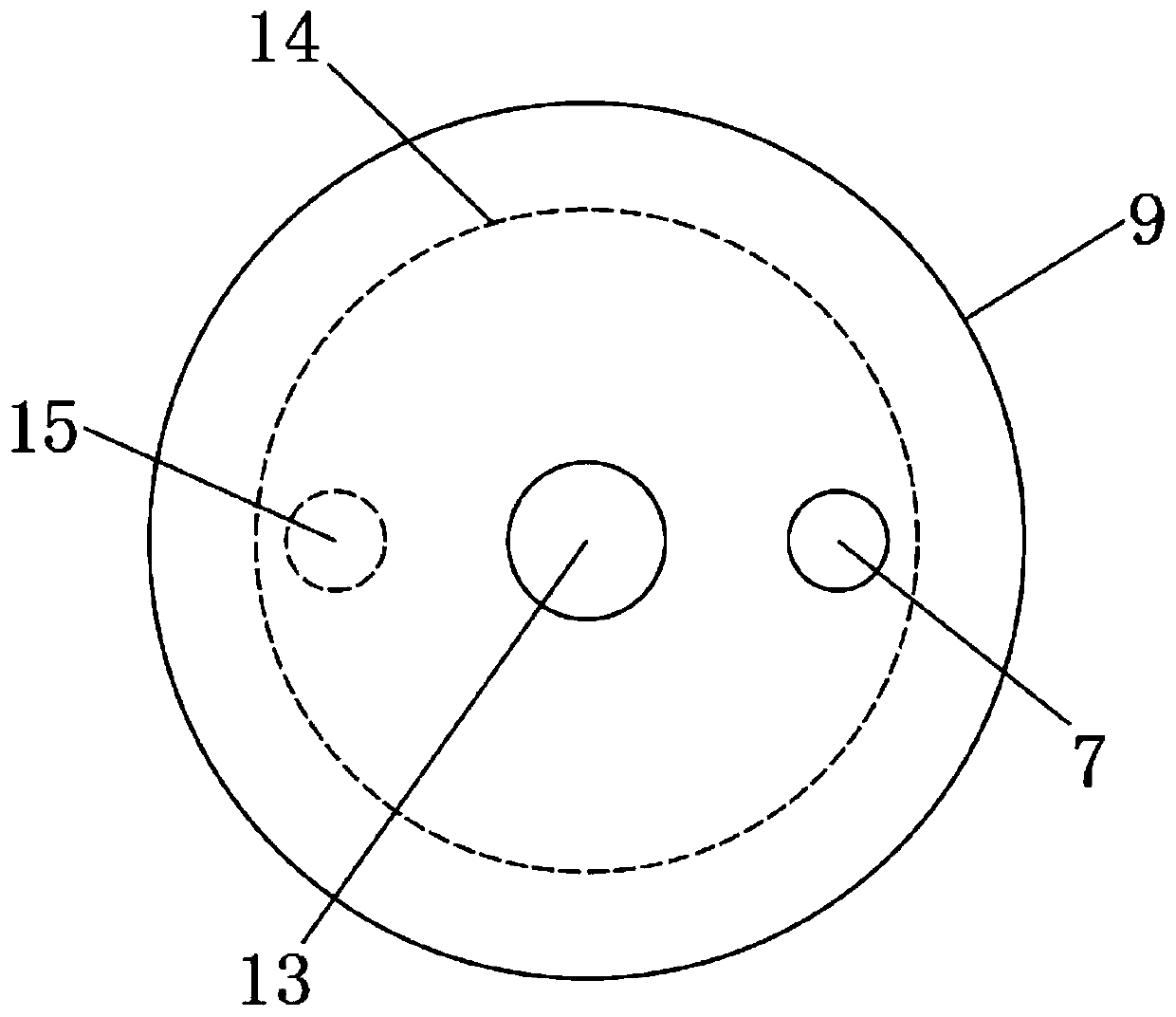

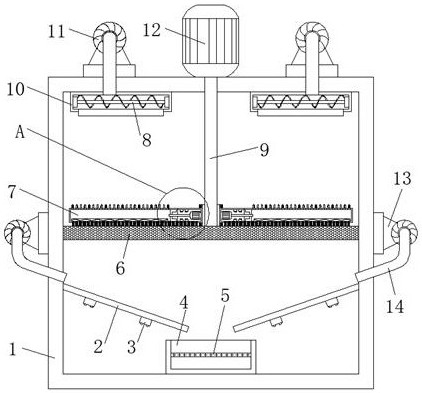

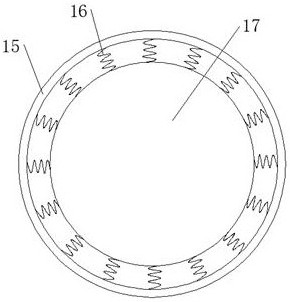

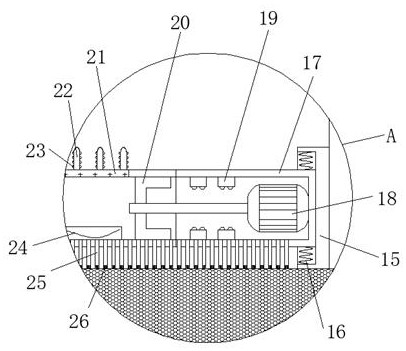

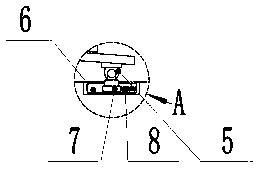

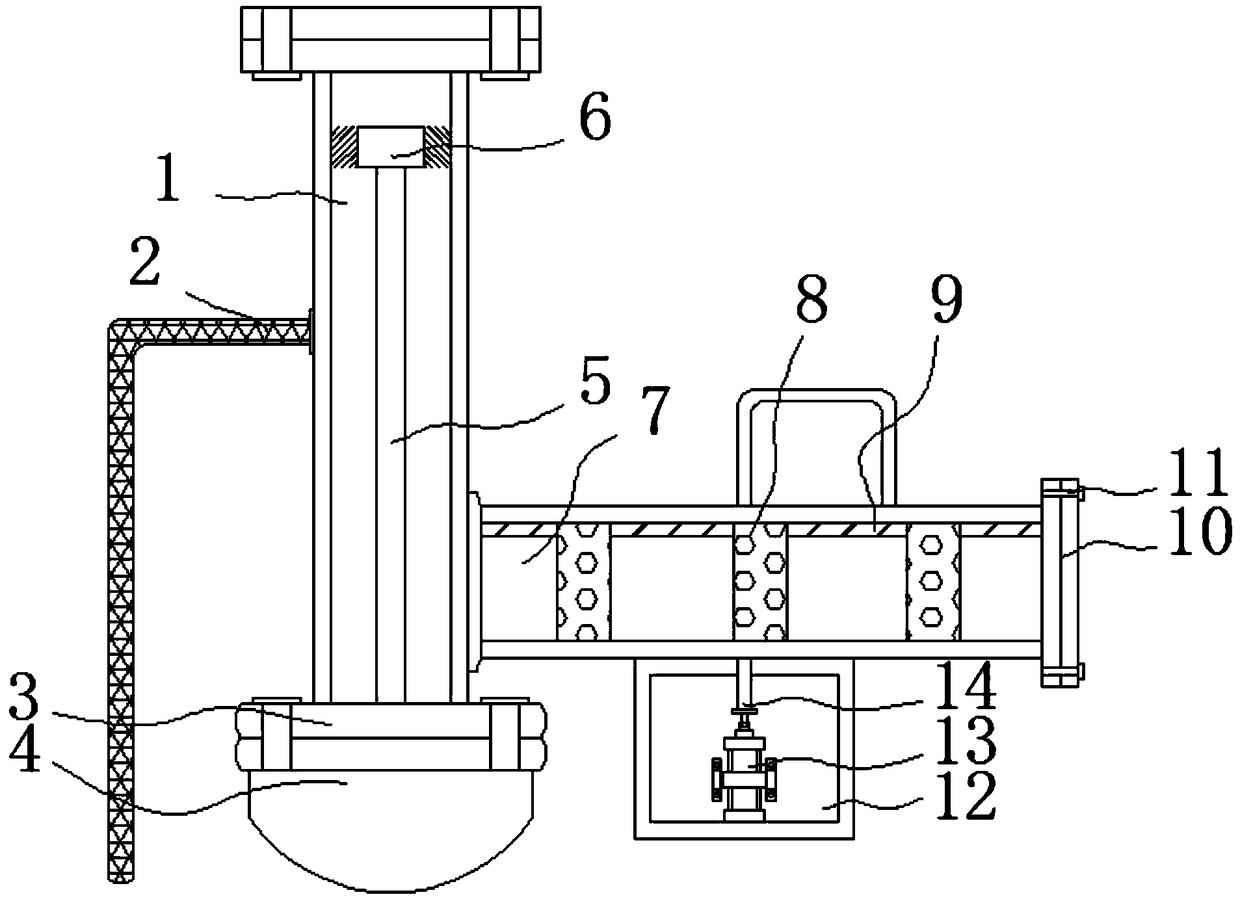

Road traffic sprinkling dust removing device

ActiveCN110075642APlay a role in dust removalPrevent slippingUsing liquid separation agentSpeed bumpWater storage

The invention discloses a road traffic sprinkling dust removing device. The road traffic sprinkling dust removing device comprises a foundation, wherein a sliding groove is formed in the foundation, aspeed bump is connected to the inside of the sliding groove in a sliding manner, a sprinkling groove is formed in the speed bump, sprinkling holes are uniformly distributed in the side walls of the speed bump, and are communicated with the sprinkling groove, a water storage groove is formed in the foundation, a piston groove is formed in the foundation, a piston barrel is fixedly connected to thebottom of the inside of the piston groove, and the piston barrel is communicated with the sprinkling groove through a water outlet pipe. Due to arrangement of the piston barrel, an intermittent wateroutlet mechanism and a temperature change mechanism, on the premise that traffic is not affected, sprinkling dust removing actions on a road surface can be completed when an automobile runs through the speed bump for a certain number of times, it can be ensured that the sprinkling actions are not carried out in winters to prevent the road surface from freezing, accumulated water on road sides canbe collected and utilized, the circumstance of water accumulation of the road sides is improved, and water resources are saved.

Owner:陕西正光建设工程有限公司

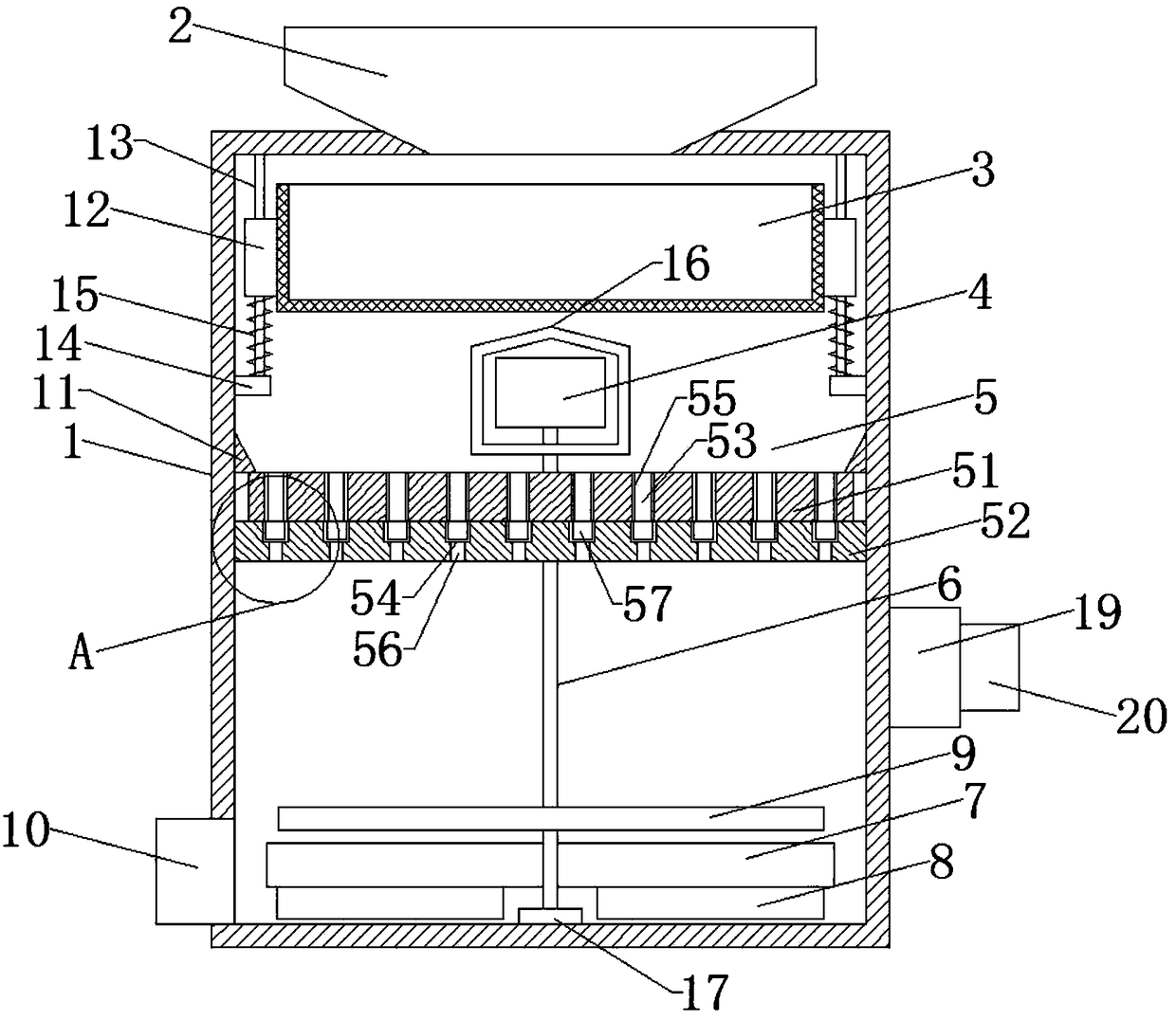

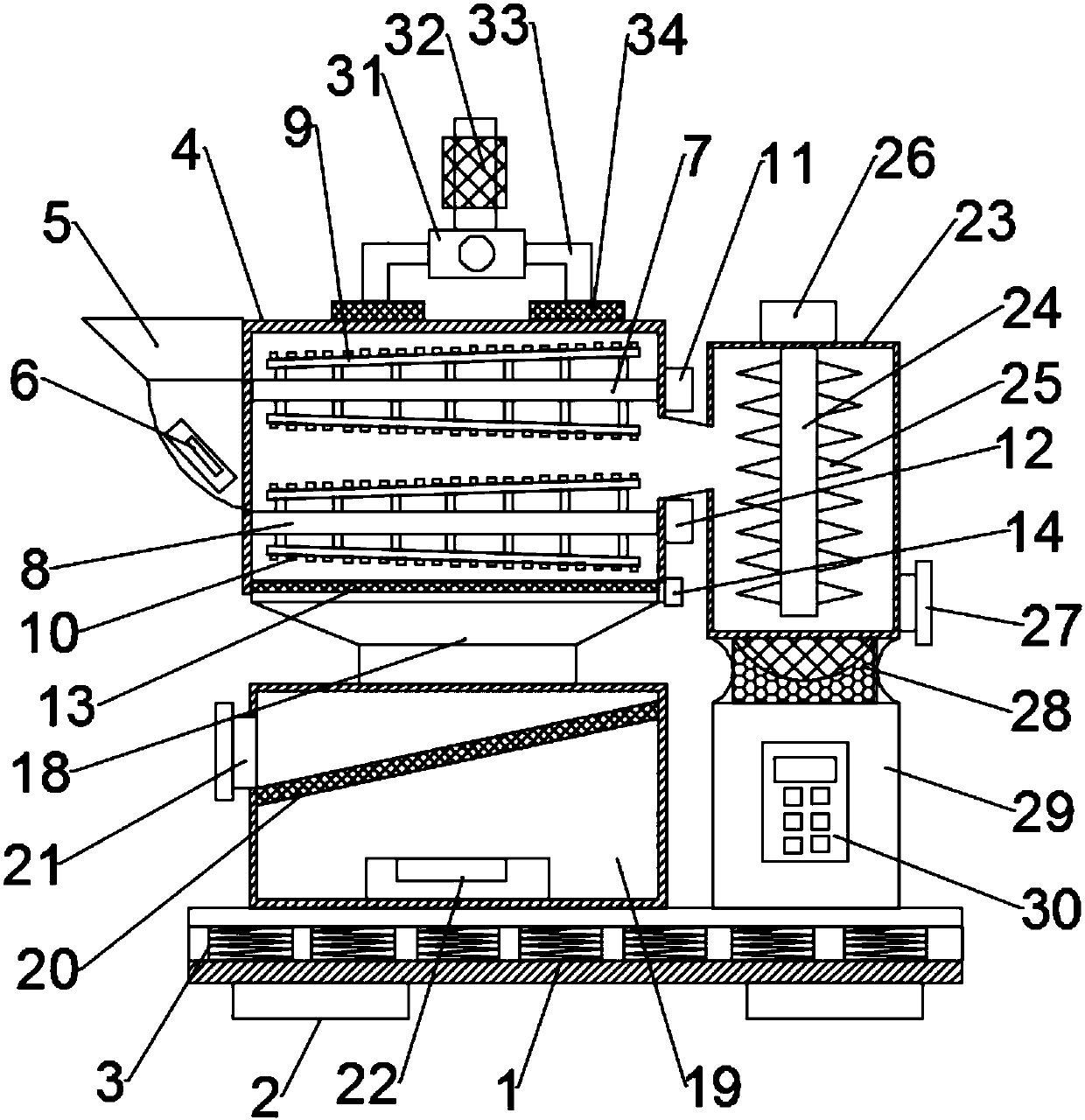

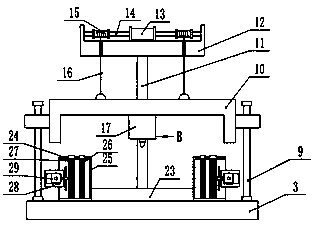

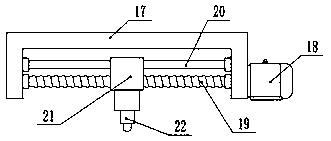

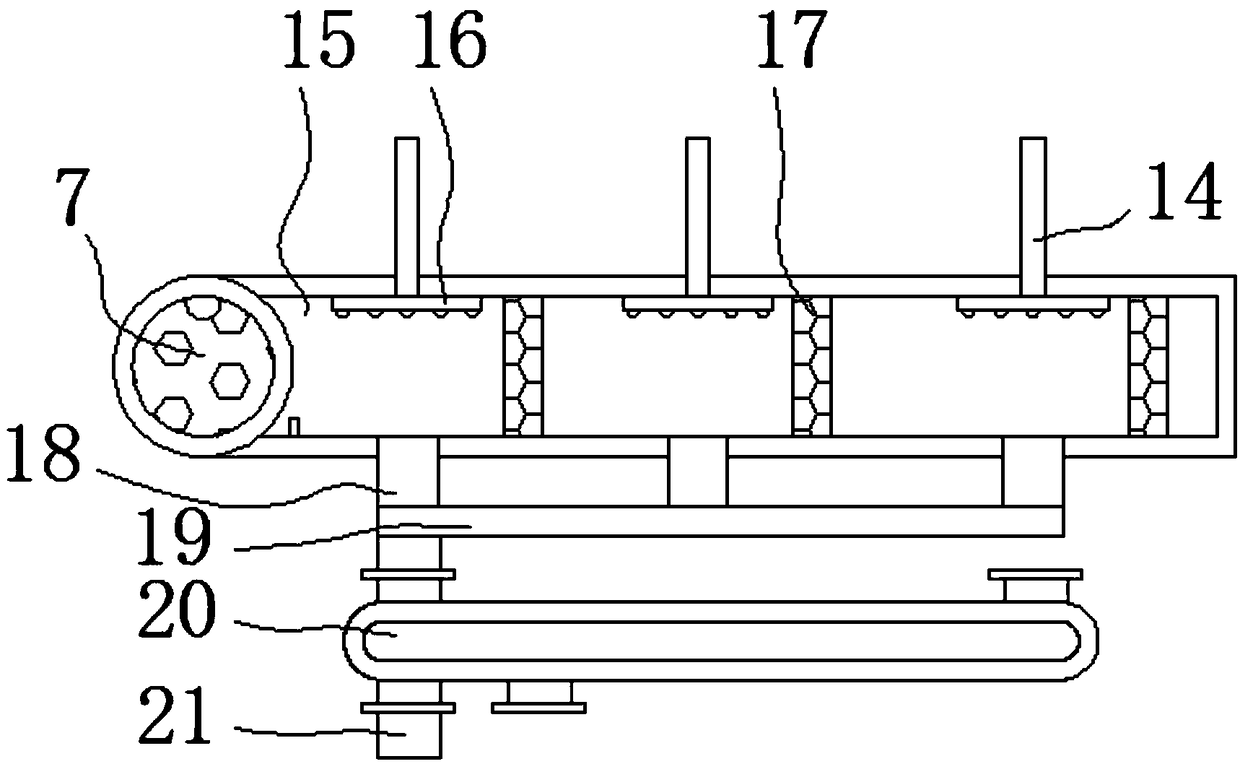

Continuously-feeding grinding device for medicinal material processing

InactiveCN108479938AEasy to take awayPlay a role in dust removalGas current separationCocoaElectric machineryEngineering

The invention discloses a continuously-feeding grinding device for medicinal material processing. The continuously-feeding grinding device for medicinal material processing comprises a shell, a feeding hopper, a sieving box and a motor. The sieving box is arranged on the upper portion in the shell. The middle portion of the shell is provided with a smashing mechanism. The smashing mechanism comprises a rotary grinding disk, a fixed grinding disk, discharging holes, grinding grooves, abrasion-resisting layers, falling holes and bulge loops. The lower side of a fixing block is fixedly provided with an oblique plate extending to the bottom of the shell. The corresponding side wall, below the smashing mechanism, of the shell communicates with the sieving box, and the sieving box communicates with an exhaust fan. According to the continuously-feeding grinding device for medicinal material processing, the two grinding disks in the smashing mechanism are mutually extruded, the grinding grooves and the bulge loops arranged in the smashing mechanism carry out extrusion grinding, medicinal materials are refined, the smashed medicinal materials fall down from the falling holes in the bottomsof the grinding grooves, the medicinal materials on the upper portion continuously enter from the discharging holes, and smashing is continuously carried out; and the medicinal material particles meeting requirements are stirred on the bottom under the action of the oblique plate, the medicinal materials are separated from dust in the medicinal materials, and the dust removing effect is achieved.

Owner:曹桂林

Plasma waste gas treatment device and method

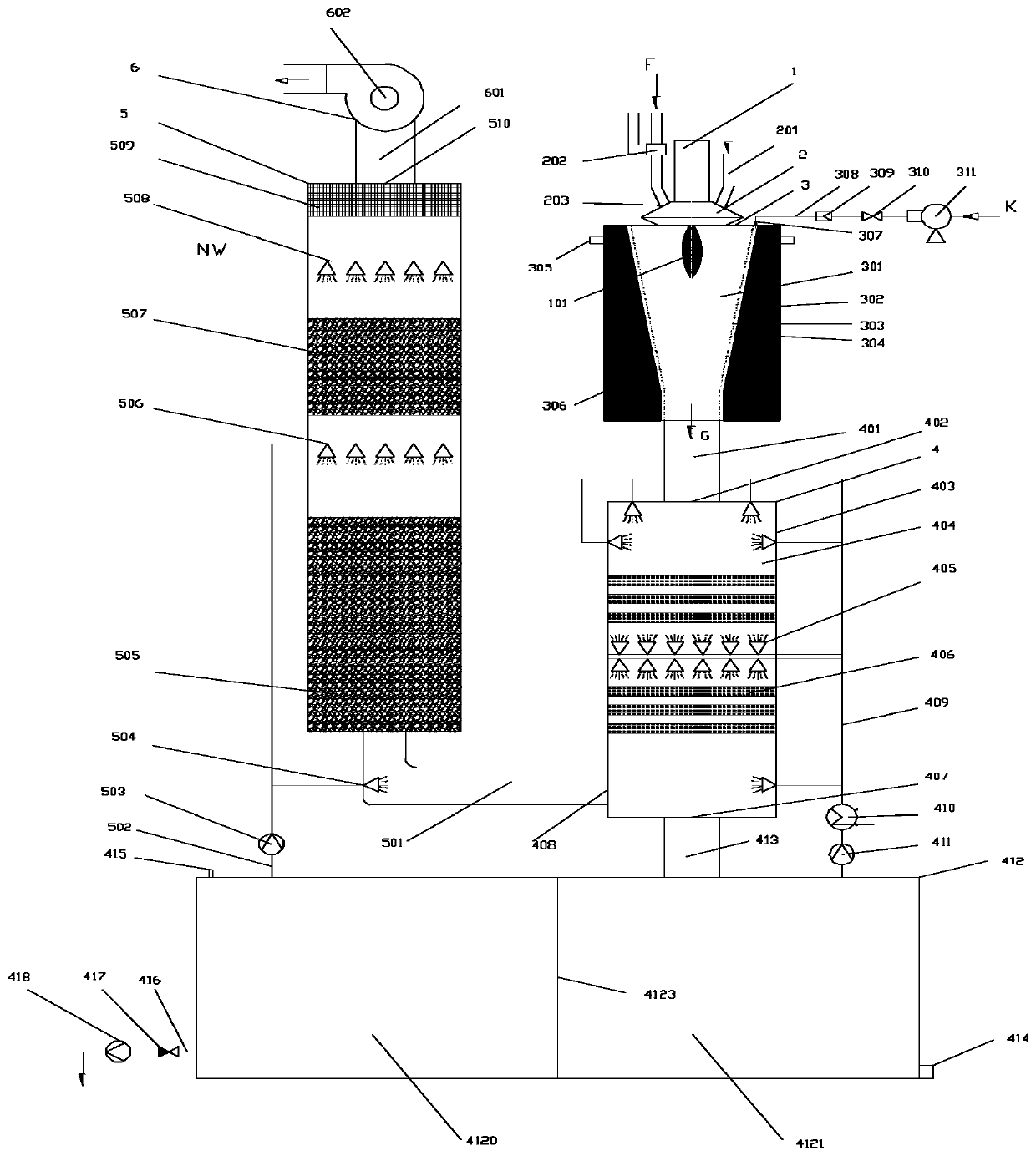

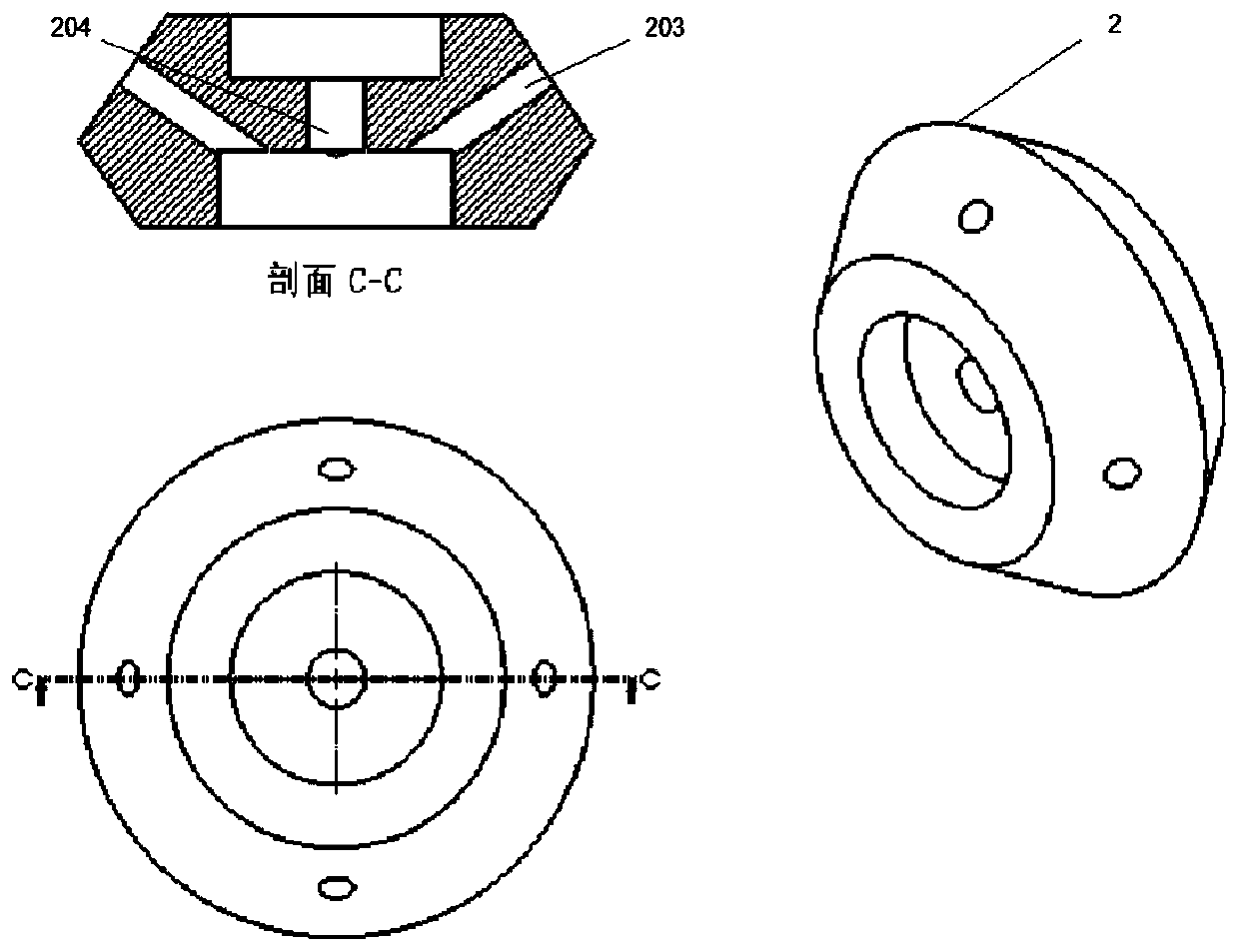

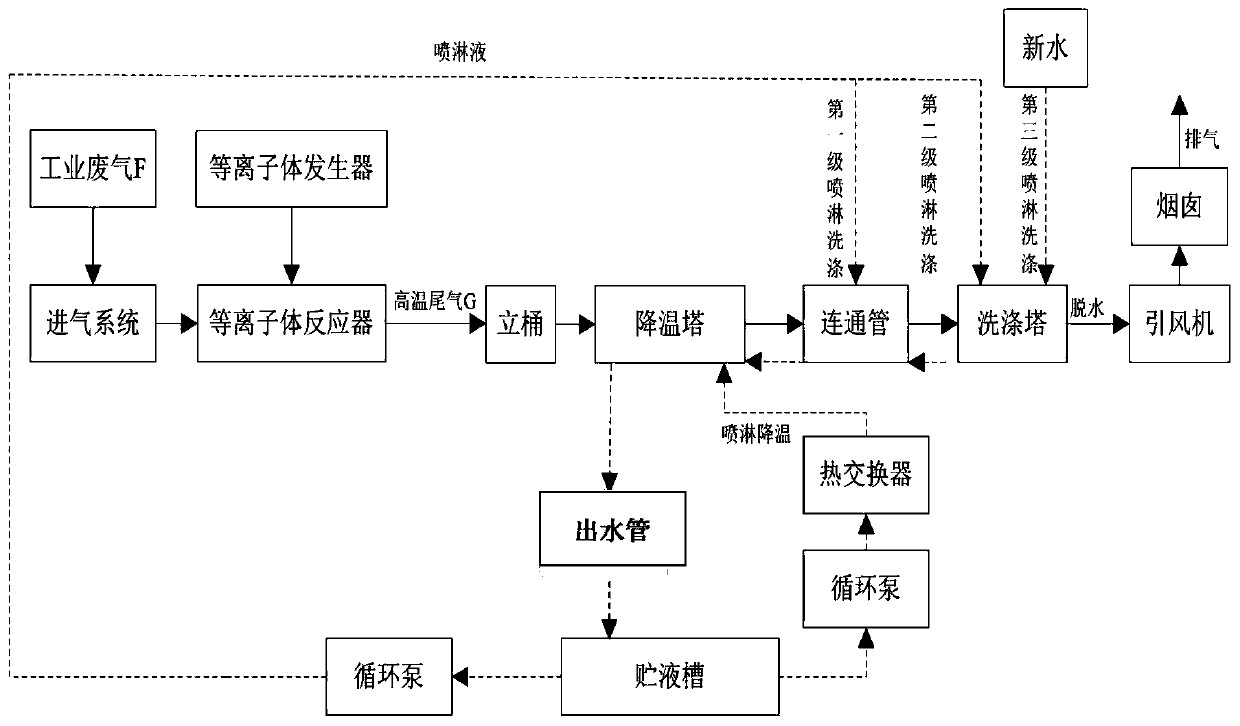

ActiveCN109821373AFully contactedAdequate responseUsing liquid separation agentEnvironmental engineeringQuenching

The invention provides a plasma waste gas treatment device and method, and belongs to the technical field of waste gas treatment.The plasma waste gas treatment device comprises a thermal reaction system, an air inlet system, a cooling system, a multistage purification washing system, an exhaust system and a liquid circulating system, and the structureis compact, safe and reliable.The plasma wastegas treatment method comprises the following steps of: carrying out high-temperature cracking reaction after waste gas to be treated enters into the thermal reaction system through the air inlet system, and carrying out quenching and preliminary purification after entering the cooling system; carrying out washing and purification for a plurality of times after entering the multistage washing system; finally discharging the waste gas from a chimney through a dehydration layer under the action of an induced draft fan.The waste gas is subjected to high-temperature cracking, cooling, preliminary purification and multistage purification, so that the purification speed is obviously improved; and the waste gas which can be treated by the method comprises perfluorides, inflammable substances, corrosion, poisons and the like, the purification is thorough, the method is safe and reliable.

Owner:上海高笙集成电路设备有限公司

Controller with cleaning function

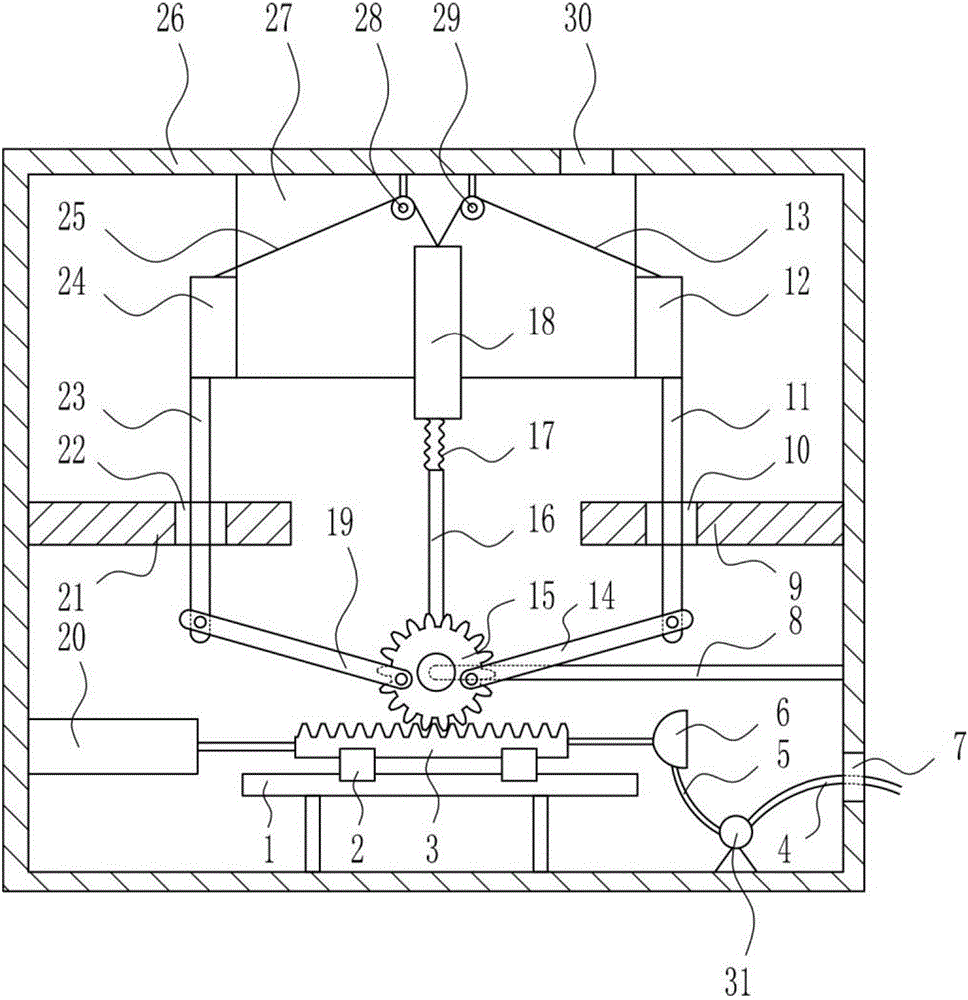

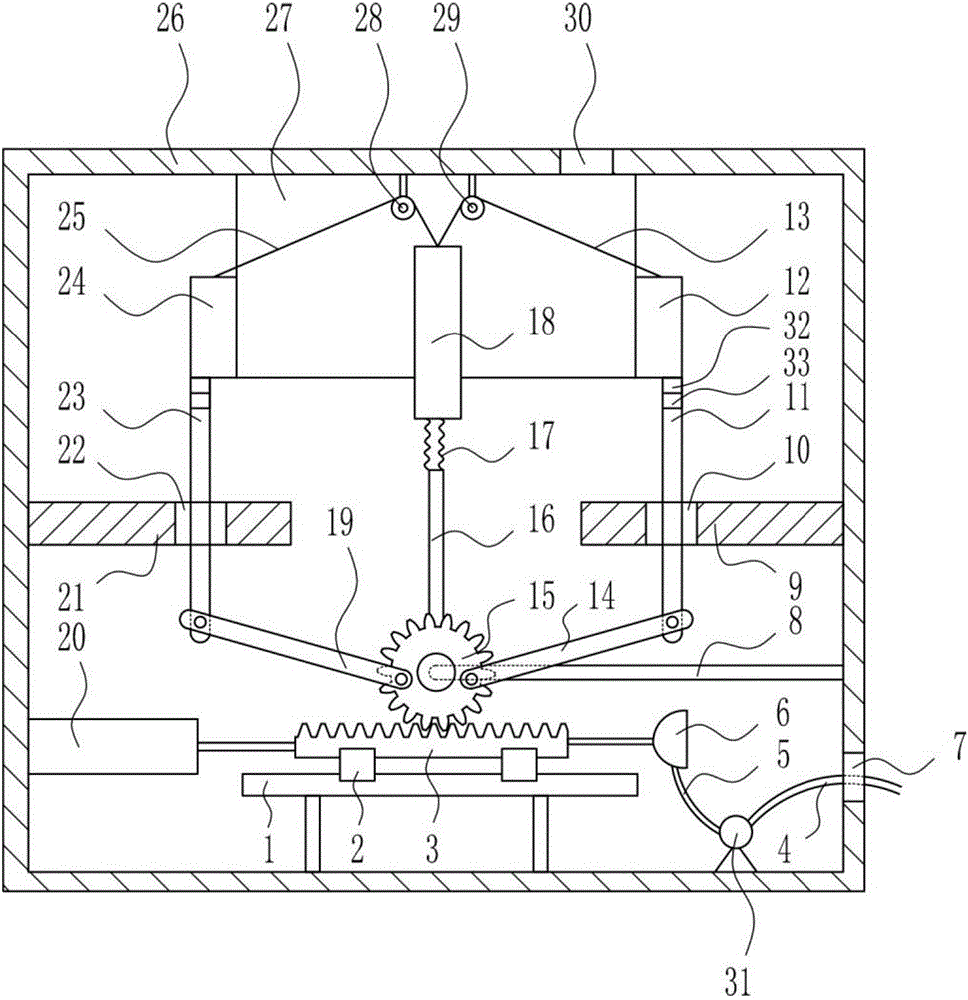

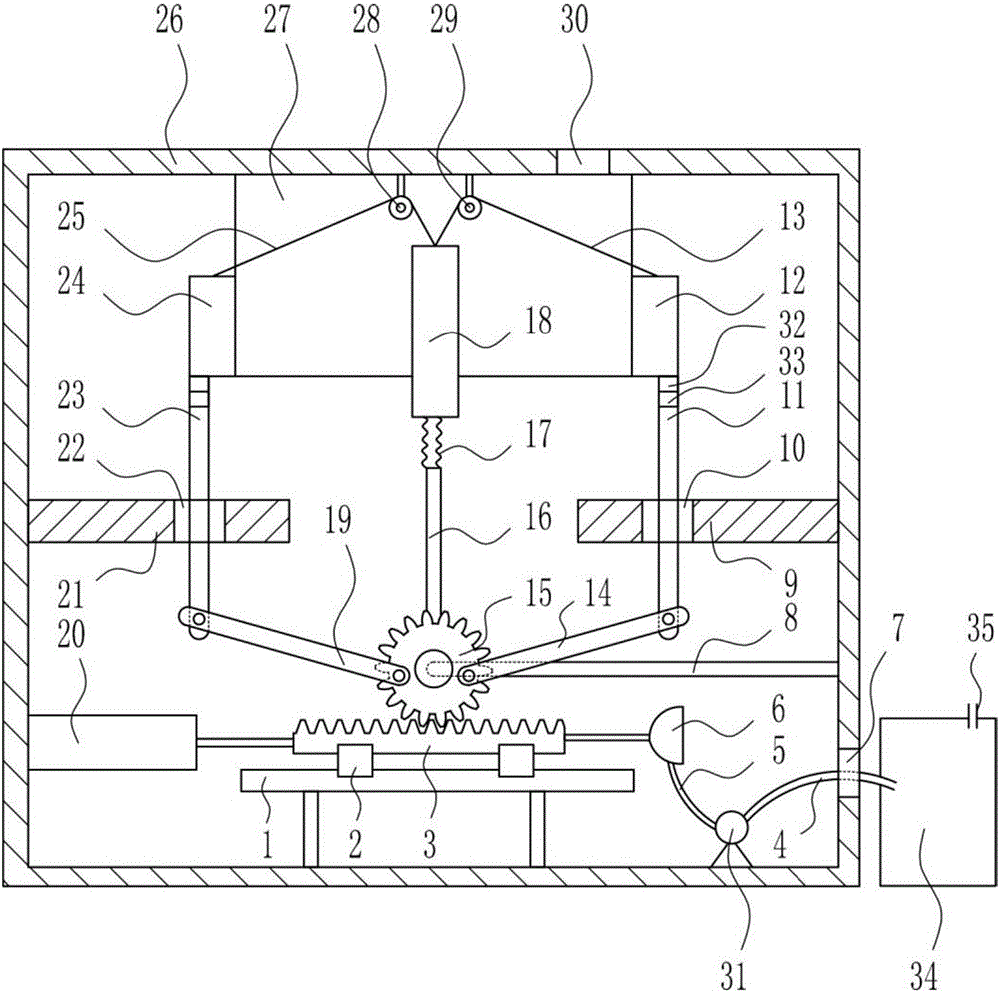

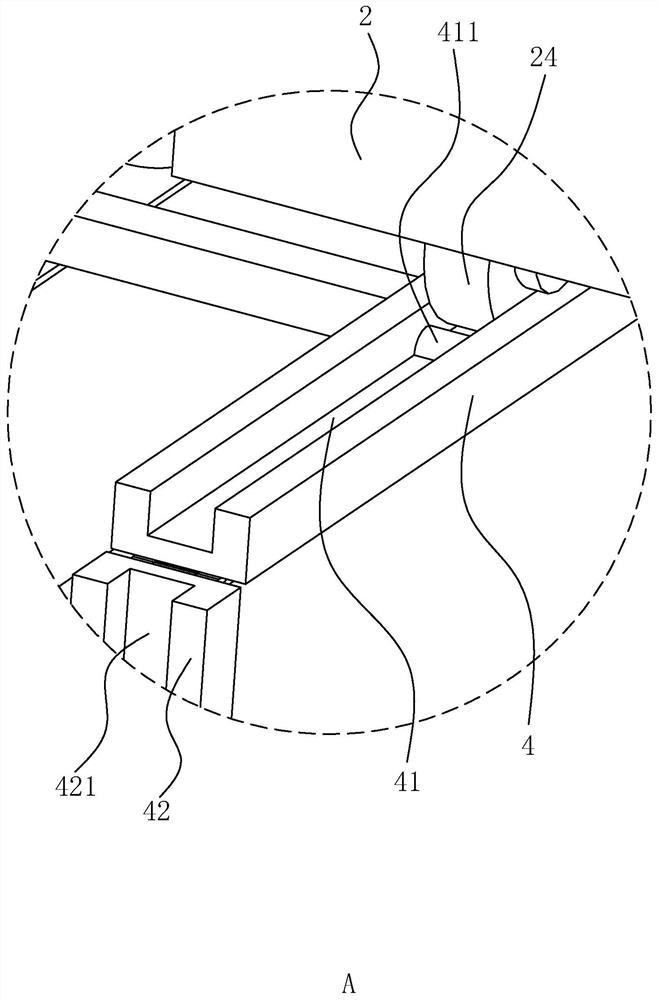

ActiveCN106563652APlay a role in dust removalAvoid destructionDirt cleaningCleaning using toolsAir pumpControl theory

The invention relates to a controller and especially to a controller with the cleaning function. The technical problem to be solved by the present invention is to provide a controller having a cleaning function which is simple in cleaning process and saves time and labor and has long service life. To solve the above technical problem, the invention provides a controller with the cleaning function. The controller comprises a slide rail, sliding block, a rack, a first air outlet pipe, an intake pipe, a suction hood, a support rod, a first guide plate, a first guide rod, a first sponge, a first stay wire, a first link, a gear, a swing rod, an elastic member, a third sponge, a second link, an electric push rod, a second guide plate, a second guide rod, a second sponge, a second stay wire, a cabinet body, a controller, a second pulley, a first pulley and an air pump; the lower part of the right wall of the cabinet body is provided with a through hole. The controller with cleaning function in the invention has simple cleaning process, saves time and labor, has long service life, and saves large labor and financial resources.

Owner:GUANGDONG POLYTECHNIC NORMAL UNIV

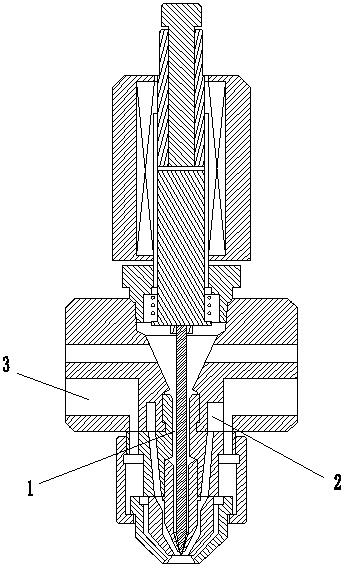

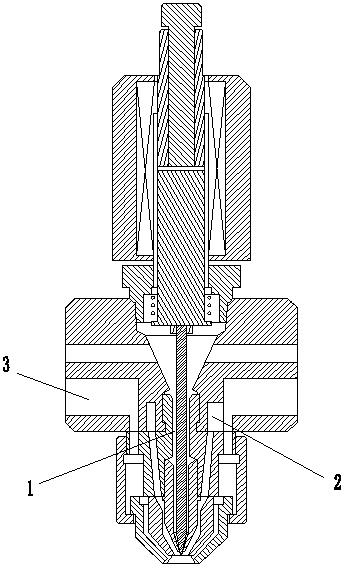

Spraying method for preventing steel plate hot mark machine spray head from being blocked

ActiveCN102166561ALow failure rateAvoid cloggingLiquid surface applicatorsSpraying apparatusFailure rateSpray nozzle

The invention discloses a spraying method for preventing a steel plate hot mark machine spray head from being blocked. The method comprises the following steps of: a, starting spraying for the first time, namely continuously filling compressed air into an atomization air cavity of the spray head; b, opening a spray head paint nozzle and spraying paint; c, after finishing the paint spraying for the first time, closing the spray head paint nozzle; d, stopping filling the compressed air, continuously filling cooling water into the atomization air cavity, and stopping filling the cooling water when the spraying for the next time is started; and e, repeating the steps from a to d until marking operation is finished. In the spraying method, the spray head is cooled by the continuous compressed air in a spraying process, and the spray head is cooled by the continuous cooling water after the spraying is finished, so the temperature of the paint in the spray head paint cavity is kept in a lower range, the solidification of the paint is not affected by high temperature of a steel plate, and the failure rate of the spray head is low; and besides cleaning and cooling the spray head, the continuously sprayed cooling water also plays a role in removing dust in the air from the paint at the same time, so the air in the working environment is cleaner.

Owner:CHONGQING IRON & STEEL CO LTD

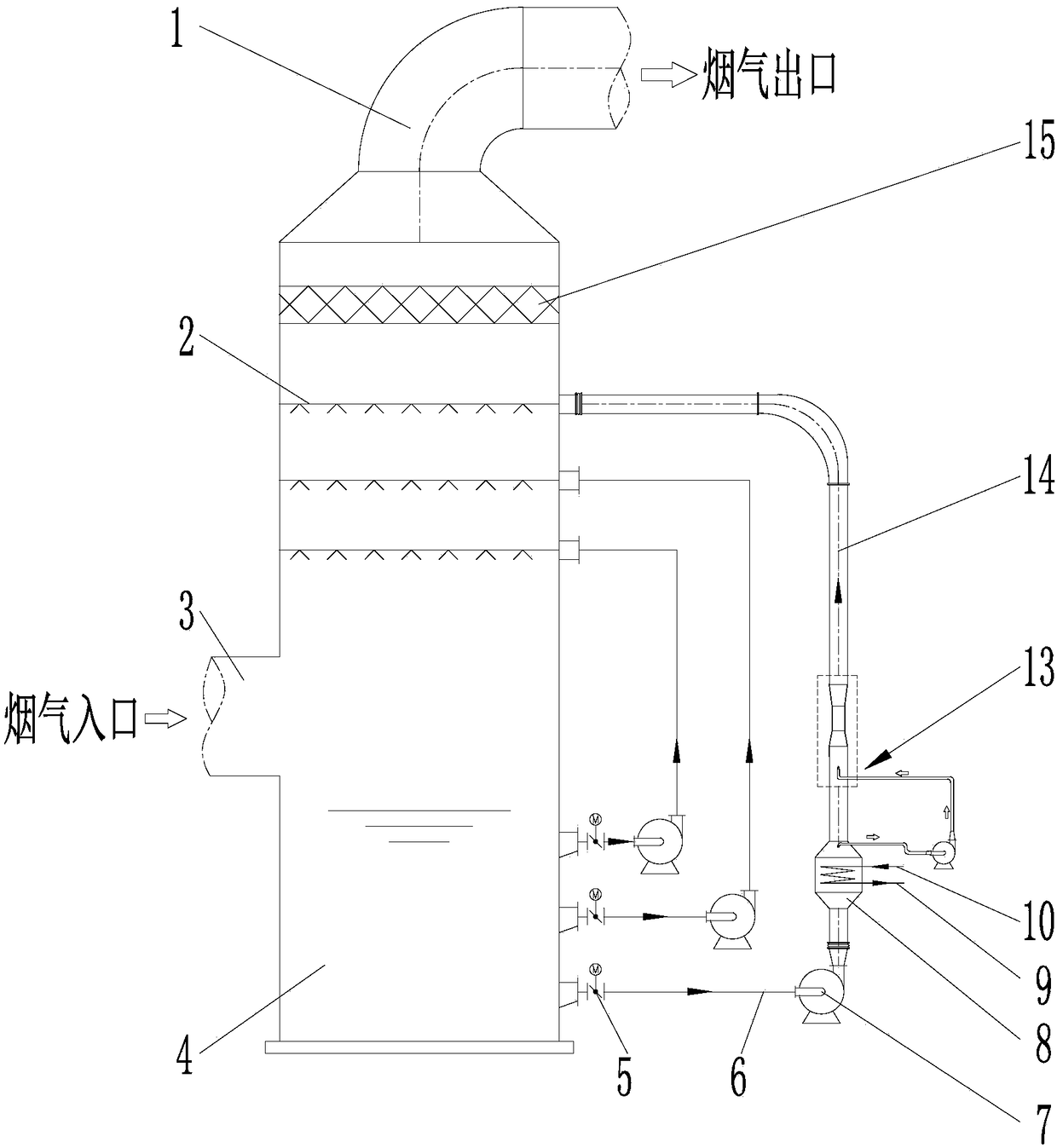

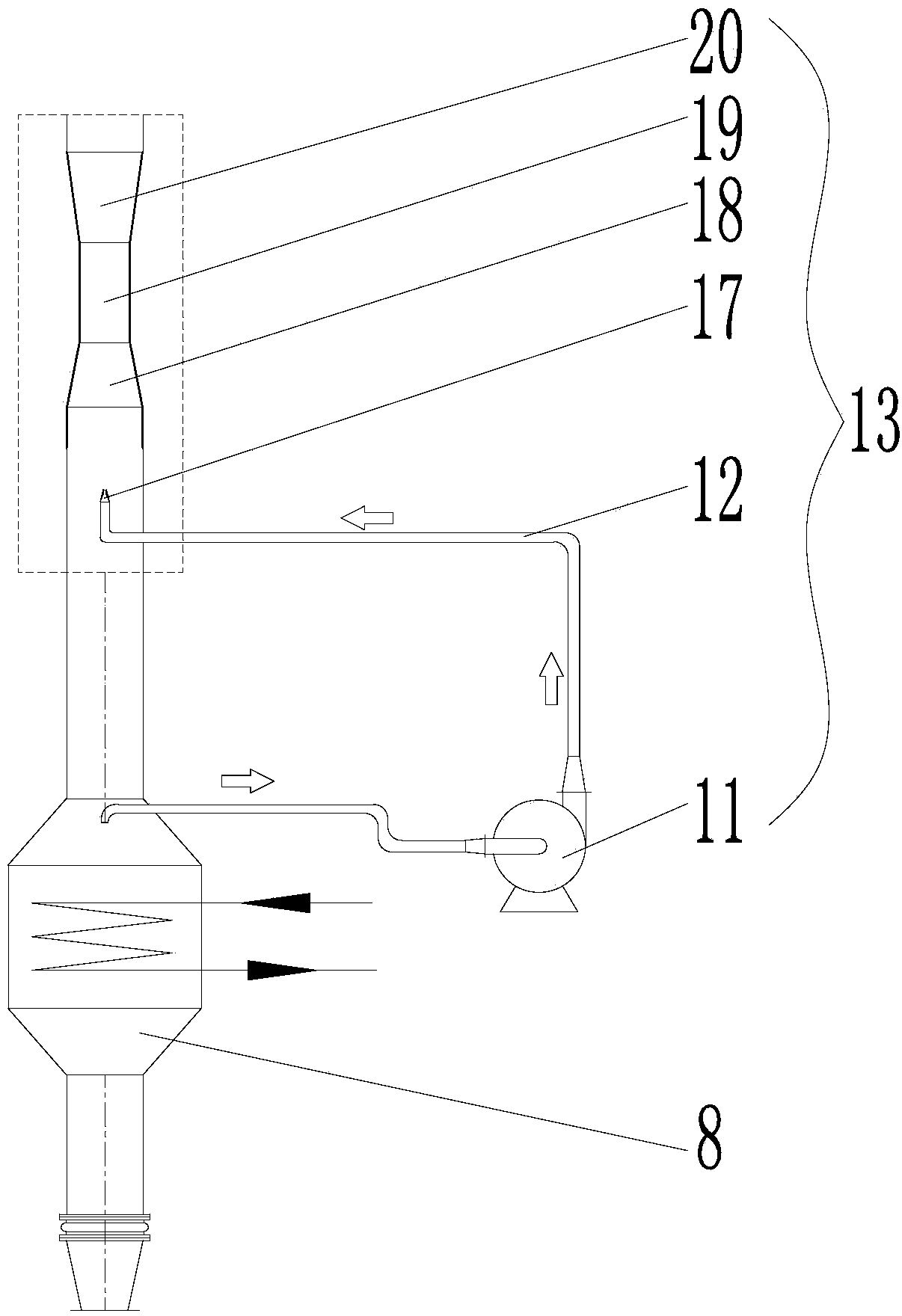

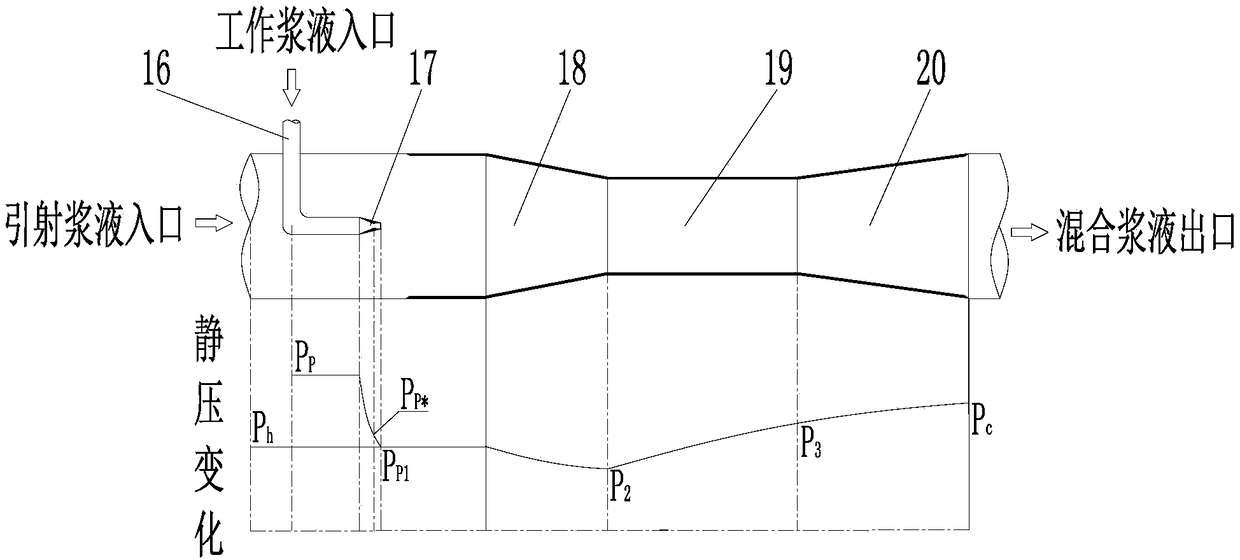

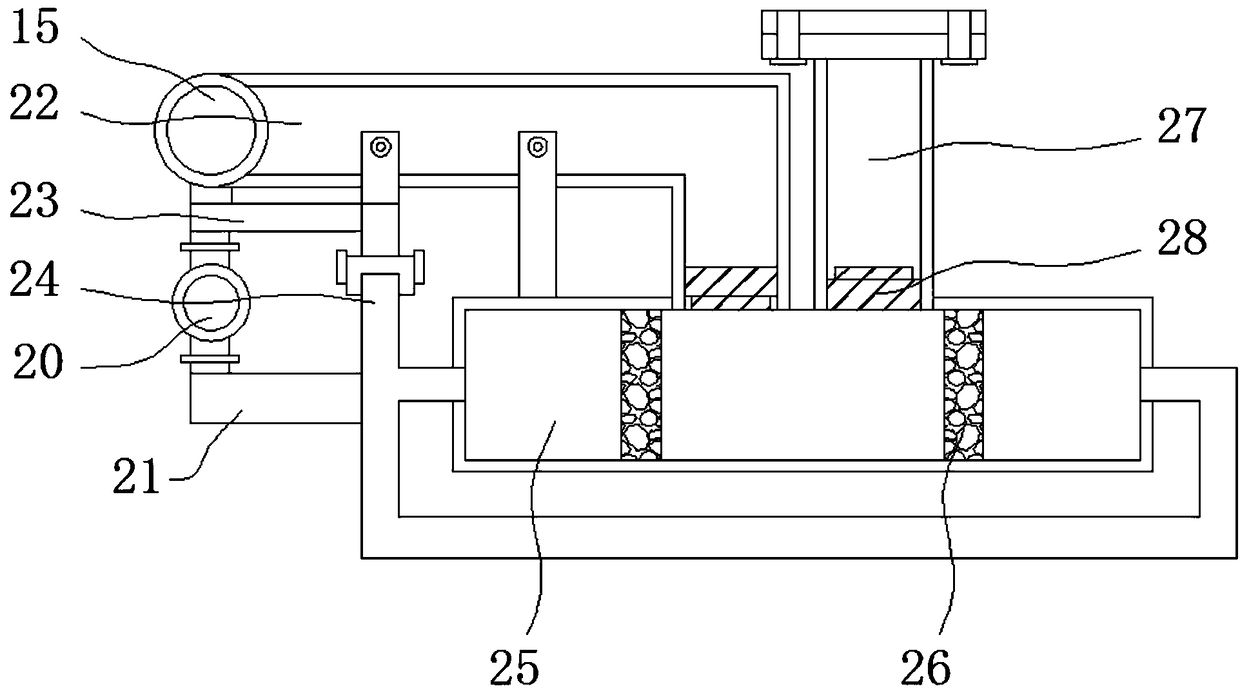

Cooling and white smoke eliminating device and method for circulating slurry for desulfurizing tower of thermal power plant

ActiveCN108295633ASimple crafting systemShort transformation periodUsing liquid separation agentCombustion technology mitigationSlurryButterfly valve

The invention discloses cooling and white smoke eliminating device and method for circulating slurry for a desulfurizing tower of a thermal power plant, and belongs the fields of the flue gas purification and the white smoke elimination of utility boilers and metallurgical coking and relevant industrial boilers, and the like. The side surface of the bottom of the desulfurizing tower in the deviceis provided with electric butterfly valves; the electric butterfly valves, slurry circulating pump inlet pipes, slurry circulating pumps, a slurry cooler, a slurry jetting and boosting device, a slurry circulating pump outlet pipe and top-layer spray layers are connected in sequence. The device can be used for reducing the water replenishing amount of the desulfurizing tower, is used for decreasing the moisture content of flue gas, and is used for further eliminating white smoke. Meanwhile, the invention also provides the cooling and white smoke eliminating method for the circulating slurry for the desulfurizing tower of the thermal power plant. The latent heat of vaporization in the flue gas is recovered; the heat loss of the smoke exhausted from a boiler is further decreased; the moisture carried in the flue gas is reduced; the water resource is saved, and the white smoke from a chimney outlet is eliminated.

Owner:CHINA HUADIAN ENG +1

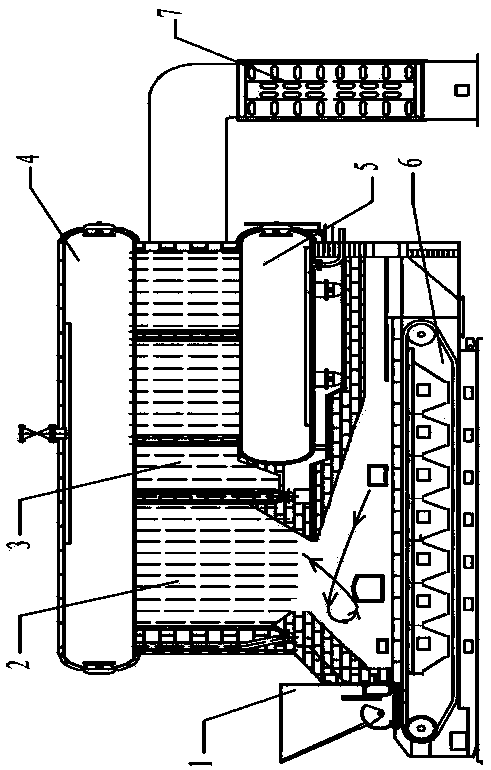

Biomass chain boiler

InactiveCN103925592AImprove combustion conditionsImprove combustion efficiencySolid fuel combustionCasings/liningsCombustion chamberEngineering

The invention discloses a biomass chain boiler. The biomass chain boiler comprises a boiler body provided with a feed port. An upper boiler barrel, a lower boiler barrel, a hearth, a combustion chamber, a front arch, a back arch and a chain grate stoker are arranged in the boiler body. The front end of the upper boiler barrel stretches to the front side of the front end of the lower boiler barrel. The upper boiler barrel and the lower boiler barrel are connected through a convection bank, and the combustion chamber is formed between the upper boiler barrel and the lower boiler barrel. The hearth is located on the lower side of the front of the upper boiler barrel and located on the front side of the combustion chamber and is communication with the combustion chamber. A throat is formed between the front arch and the back arch, and located under the hearth and on the front side of the lower boiler barrel. The chain grate stoker sequentially penetrates through the feed port, the lower portion of the front arch, the lower portion of the back arch and the lower portion of the lower boiler barrel from front to back. The biomass chain boiler can make biomass briquette fully combust and improve combustion efficiency.

Owner:HENAN AGRICULTURAL UNIVERSITY

Cleaning device for mobile phone mainboard

PendingCN108856148ARelieve pressureAvoid destructionCleaning using gasesTerminal equipmentComputer terminal

The invention relates to the field of communication mobile terminal equipment and particularly discloses a cleaning device for a mobile phone mainboard. The cleaning device comprises a seat body and acylinder body; the cylinder body is internally provided with a first piston, a second piston, a partition plate and a torsion mechanism from left to right in sequence; an air cavity is formed betweenthe second piston and the partition plate, and a driving rod is fixed to the right end of the second piston; the torsion mechanism comprises a torsion ring and a driving ring which is connected withthe torsion ring through a one-way bearing, and when the driving rod moves leftwards and rightwards relative to the driving ring, the driving ring rotates in a reciprocating mode; the cylinder body isexternally provided with a sleeve pipe, a torsional spring is arranged in the torsion ring and the sleeve pipe, the right end of the cylinder body is provided with a friction disc, and the friction disc abuts against the end of the sleeve pipe through a compression spring; and the left end of the sleeve pipe is provided with clamping jaws, the clamping jaws are connected with the first piston through a parallelogram mechanism; the side wall of the cylinder body is provided with pores, the side wall of the sleeve pipe is internally provided with an air channel communicating with the pores, andthe air channel extends to the left ends of the first clamping jaw and the second clamping jaw. The cleaning device can blow air to the mainboard while rotating, and accordingly, dust is blown away.

Owner:重庆金茂联合电子有限公司

Agricultural efficient corn processing mechanical equipment with impurity removal function

The invention discloses an agricultural high-efficiency corn processing machinery and equipment with impurity removal function, comprising a fixed chassis, a support seat and a shock absorbing mechanism. A filter screen plate is provided, a discharge port is provided on the left side of the trash removal box, and a threshing box is arranged on the upper end of the trash removal box. The side is provided with a corn cob crushing box. This equipment is used for corn processing. It can thresh and remove impurities, and can pulverize the corn cob. After threshing, the corn kernels pass through the vibrating screen at the lower end and enter the lower end of the removal box from the feeding channel. And the eccentric runner at the lower end of the vibrating screen rotates under the drive of the vibrating motor, which can make the vibrating screen go up and down and form regular vibration, which helps the corn kernels to pass through the vibrating screen and fall into the lower end. And can effectively prevent the clogging of the mesh.

Owner:安徽豪嘉亿装饰工程有限公司

High-temperature sterilization device for tea production and sterilization method thereof

PendingCN112970870ADry insideEasy to sterilizePre-extraction tea treatmentElectrostatic separationElectric machineryEngineering

Owner:安徽精一茶业有限公司

Laser marking machine with smoke and dust removing functions

InactiveCN108941902ARealize moving up and downPrecise positioningLaser beam welding apparatusResonanceEngineering

The invention discloses a laser marking machine with smoke and dust removing functions. The laser marking machine comprises a base, a platform, a double-shaft motor, a laser marking head and smoke anddust removing mechanisms, wherein a marking table is further arranged at the center of the upper surface of the platform, the smoke and dust removing mechanisms are arranged on the two sides of the marking table, a dust removing screen and a smoke removing filter screen are sequentially arranged inside each smoke and dust removing mechanism, a shell is fixedly installed in each smoke and dust removing mechanism, and a dust suction machine is arranged in each shell. Meanwhile, the dust suction machines work in the marking process, and dust and smoke which are generated in the marking process are adsorbed into the dust removal screens and the smoke removing filter screens, so that the functions of removing dust and removing smoke are achieved, and the environment of a processing site is improved. Meanwhile, the dust removing screens and the smoke removing filter screens are all inserted, so that cleaning is convenient to achieve. In the marking process, damping columns and damping spring pieces can play a role in damping, so that resonance noise generated in the marking process is reduced, the operation site environment is improved, and the ear hearing capacity of operators can be protected.

Owner:珠海横琴新区辉腾电子科技有限公司

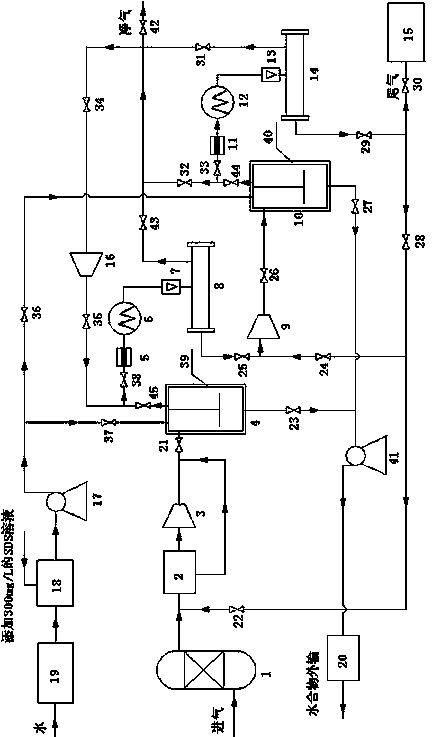

Membrane separation and hydrate combined gas desulfuration and deacidifying device and method

ActiveCN103484185AReduce loadPlay a role in dust removalGaseous fuelsTransportation technologyProduct gas

The invention belongs to the field of oil and gas storage and transportation technology engineering, and particularly relates to a membrane separation and hydrate combined gas desulfuration and deacidifying device and method. According to the device, hydrate reactors are adopted for processing feed gas under appropriate pressure before the feed gas enters a membrane assembly, and nearly all hydrogen sulfide and most of carbon dioxide can be removed; meanwhile, the dust removal function is achieved, the load of the follow-up membrane assembly is reduced greatly, and the replacement frequency of membranes is reduced. By the adoption of the method that acid gas is fixed in a hydrate mode and unreacted gas is used as net gas to be circulated, loss of light hydrocarbon can be reduced, and gas can be directly used as net gas to be transported out through a gas outlet of the second hydrate reactor after being up to the standard. The hydrogen sulfide and the carbon dioxide which exist in a solid hydrate form can be conveniently transported to a centralized processing device to be processed, and acid gas processing independence is enhanced.

Owner:南通东湖国际商务服务有限公司

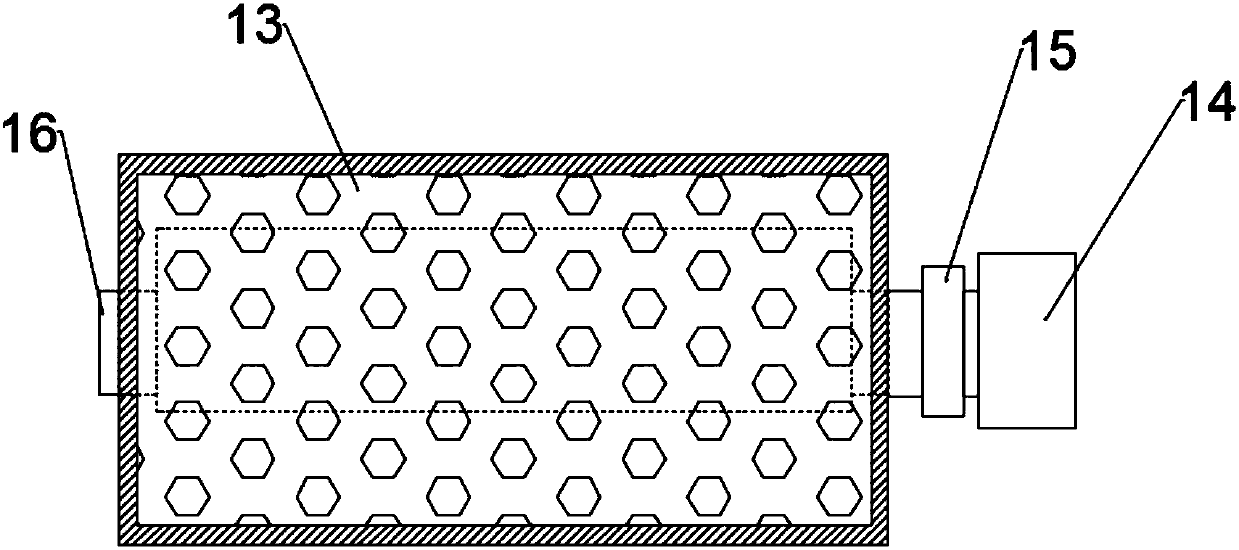

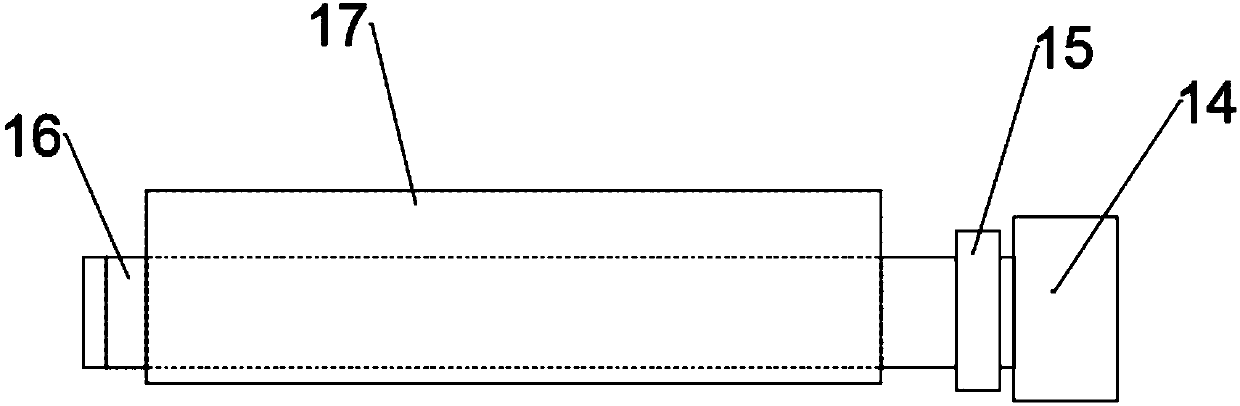

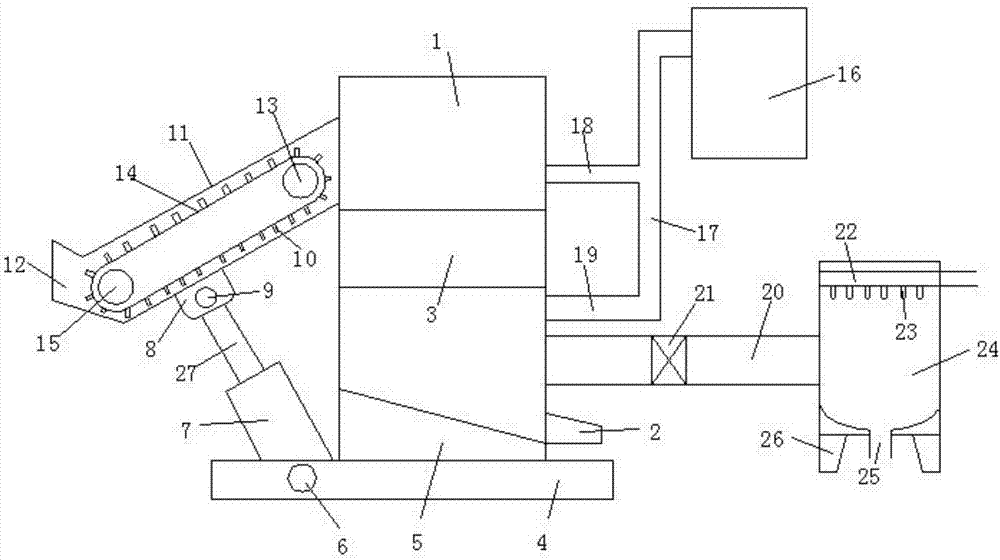

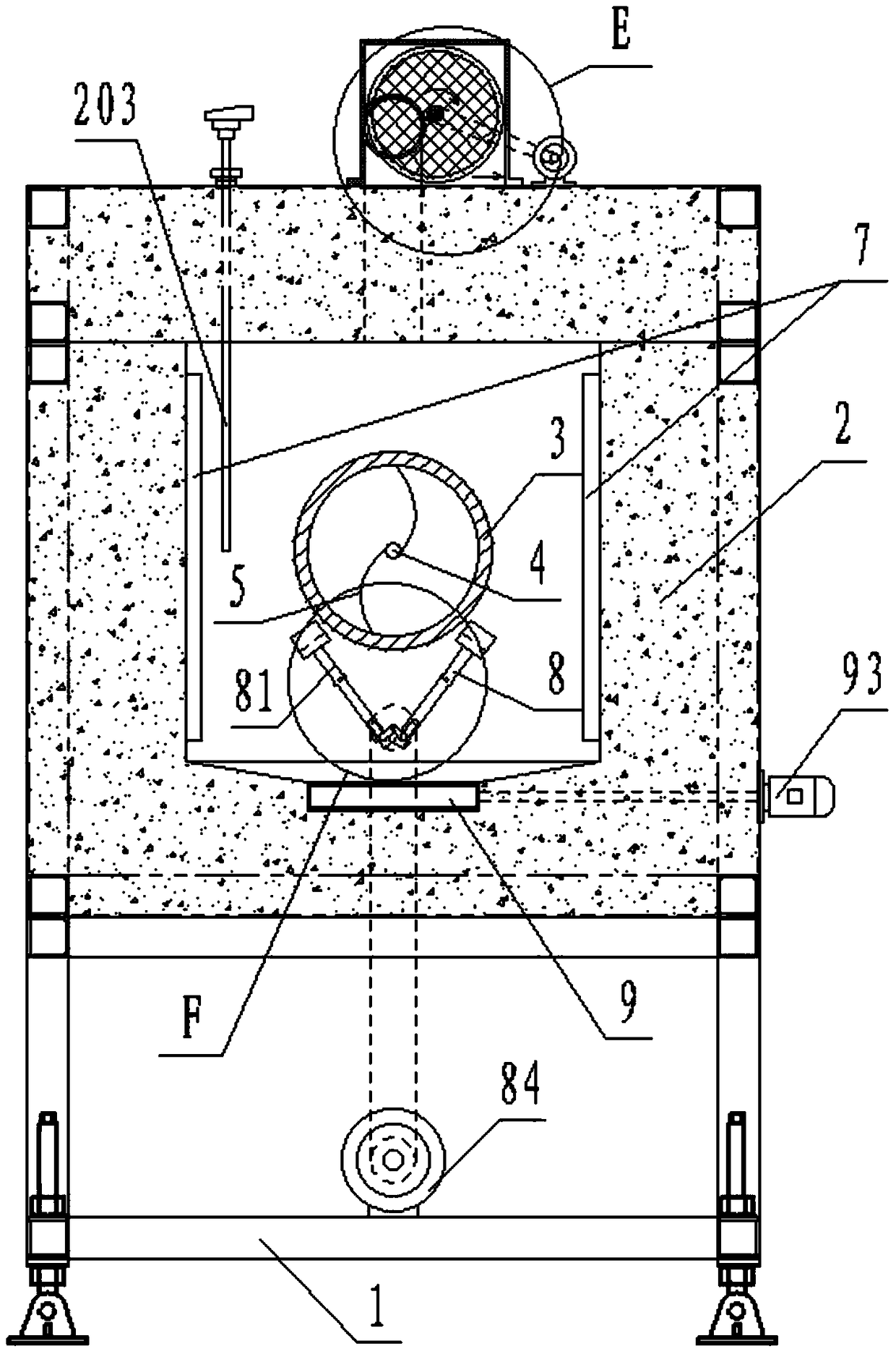

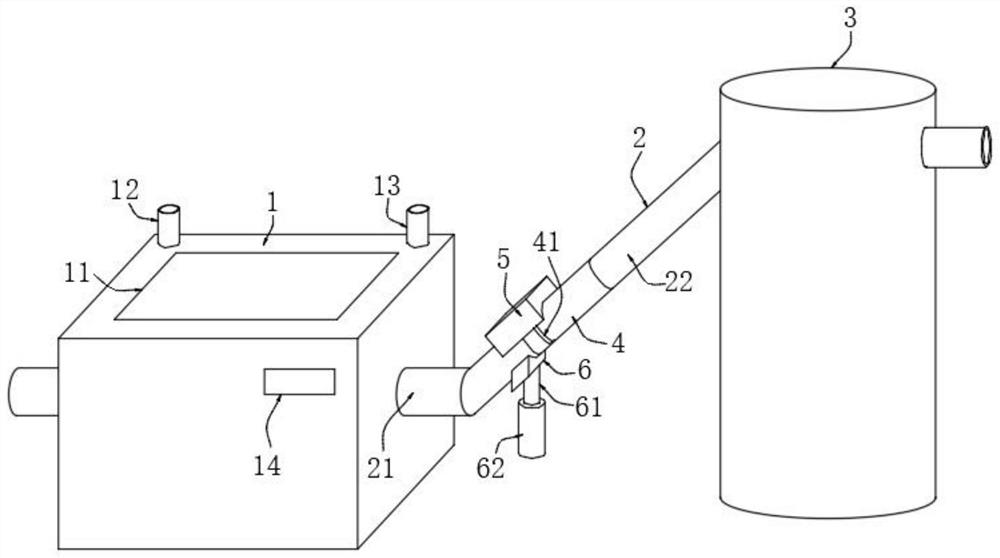

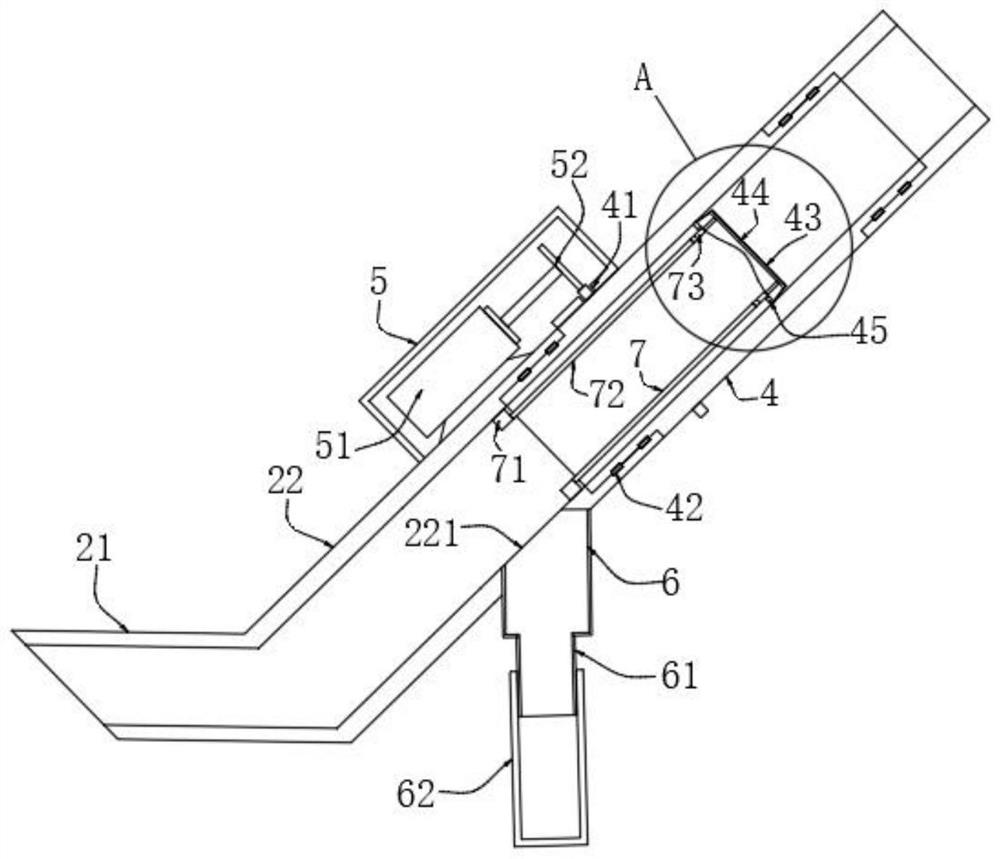

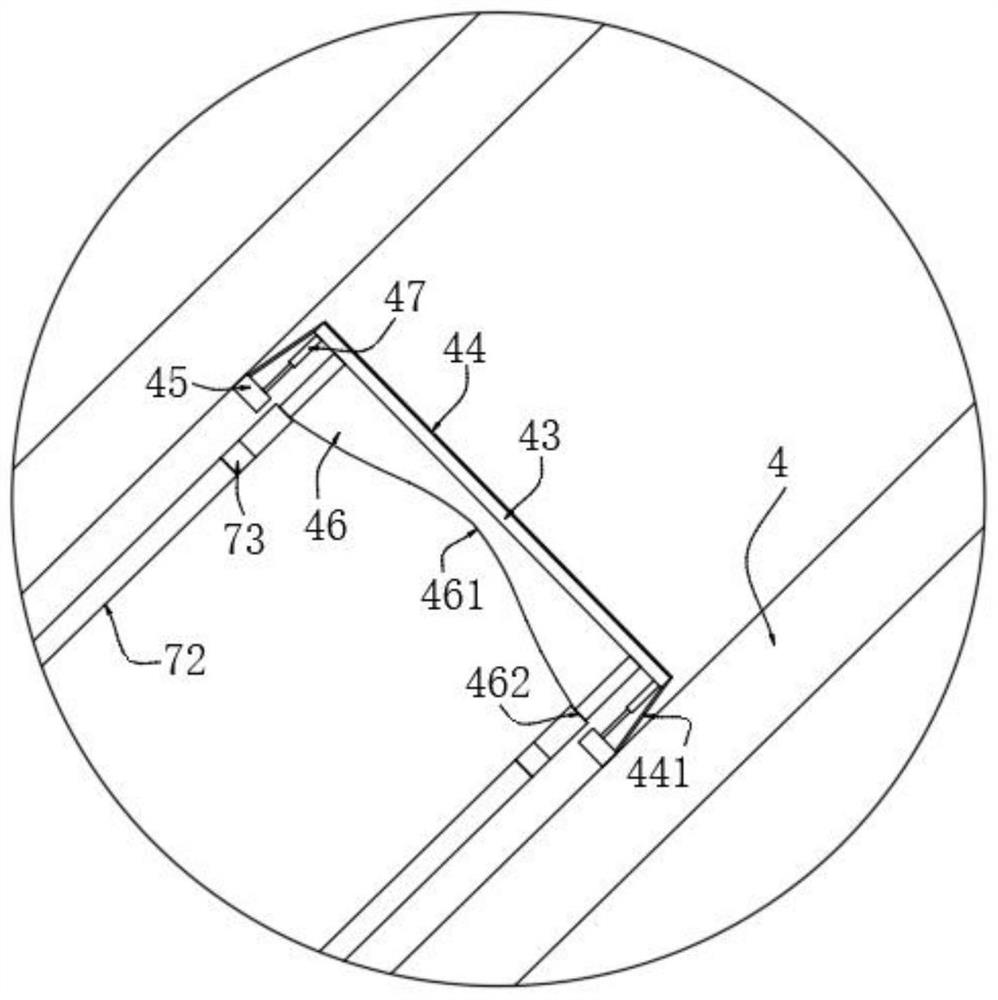

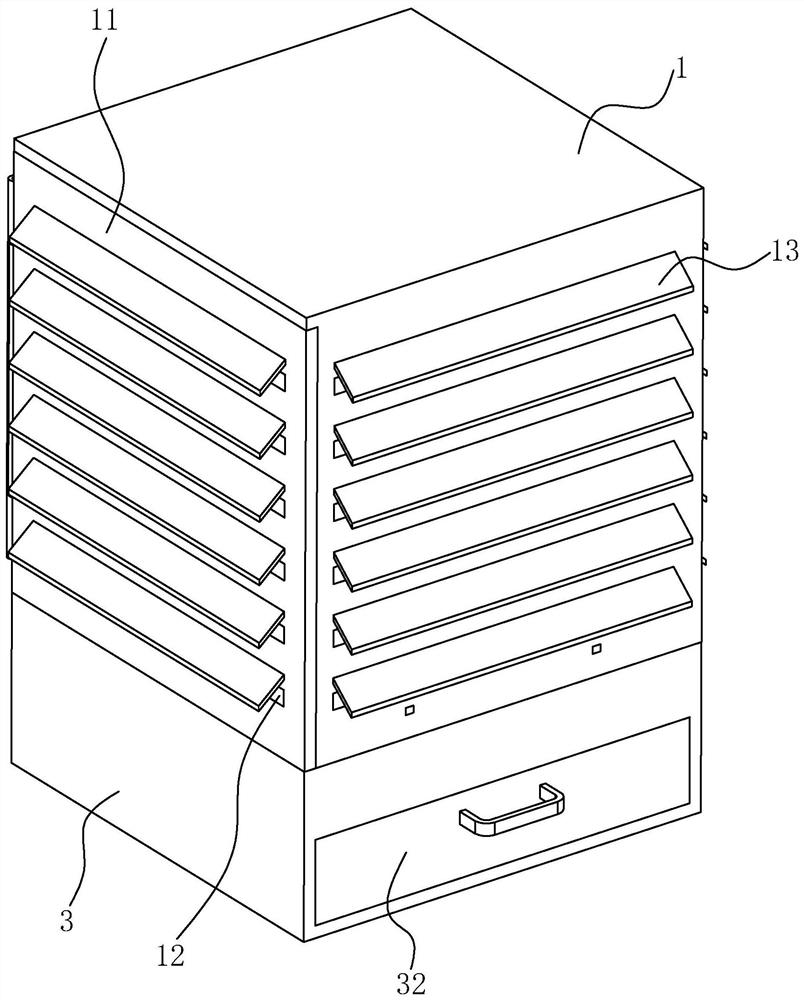

Grain drying device and use method thereof

InactiveCN107183174AEasy loadingImprove drying effectSeed preservation by dryingAgricultural engineeringGrain drying

The invention discloses a grain drying device, which comprises a base, a hot air furnace and a dust removal tank, wherein a drying box is arranged at the upper end of the right side of the base; a grain leaking box is arranged in the middle part of an inner cavity of the drying box; a grain feeding box is movably connected onto the upper part of the left side of the drying box; a piston rod is connected with a connecting plate through a second pin shaft; a main air guide pipe is arranged at the left side of the upper part of the hot air furnace; a water inlet pipe is arranged at the upper part of the inner cavity of the dust removal tank. The angle and the height of a grain feeding opening are adjustable; the grain feeding can be convenient; when the grain falls to the pipeline, under the effect of bulges, the grain is scattered; in the process that the grain falls into a funnel, the grain is dried; when the grain is leaked out through the pipeline, the grain is dried; the drying is performed twice; the grain drying effect is good; an air draft works for conveying dust mixed in the grain to an inner cavity of the dust removal tank through a dust suction pipe; at the moment, water sprayed out from a spray head is mixed with the dust; a dust removal effect is achieved.

Owner:合肥朝霞机械科技有限公司

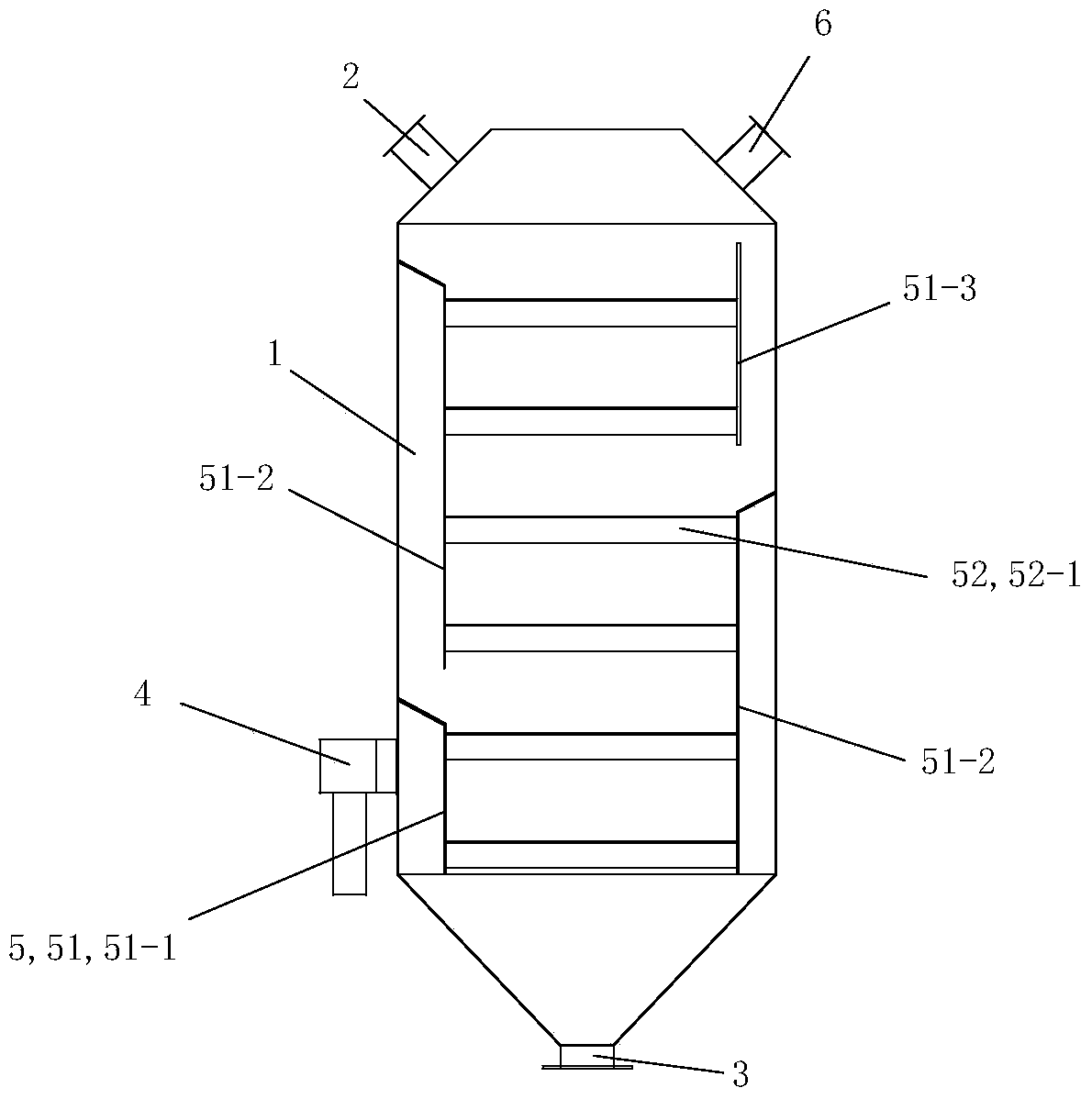

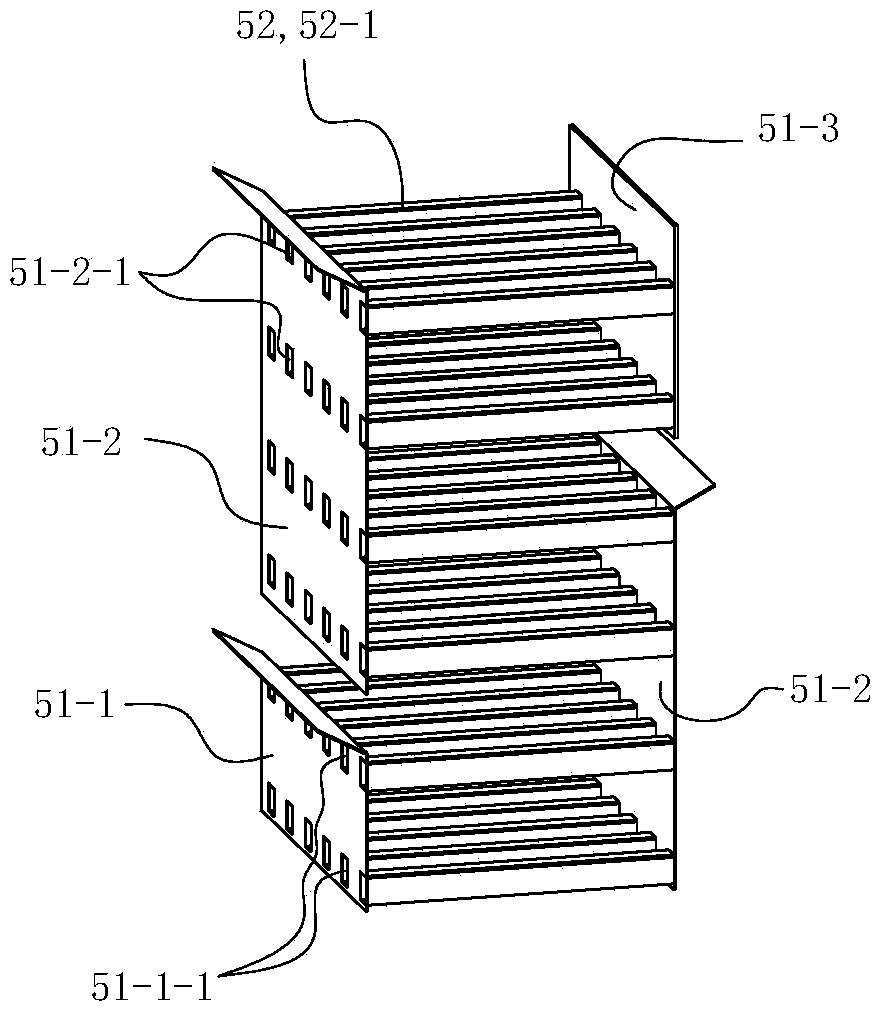

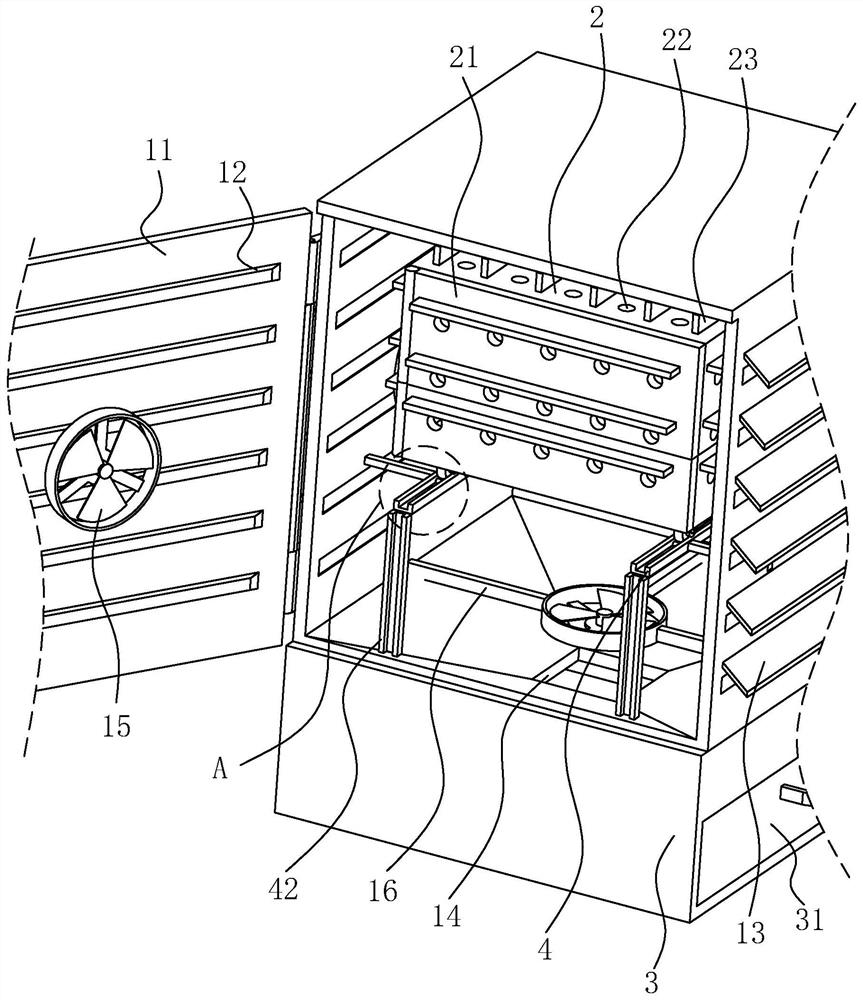

Laminated adsorption type gas filtering tower for industrial waste gas treatment

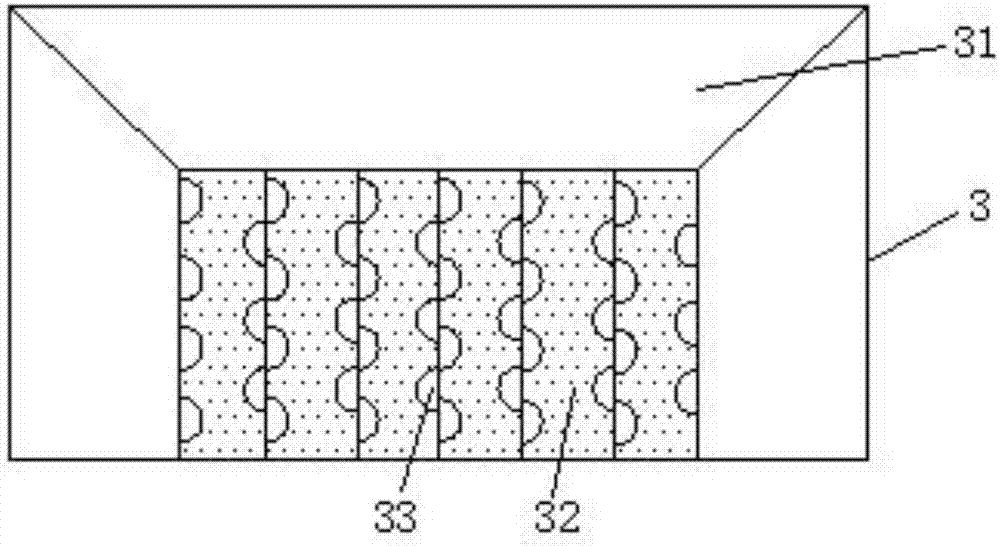

InactiveCN111921368AImprove the effect of adsorption treatmentLarge handling spaceCombination devicesGas treatmentIndustrial wasteExhaust fumes

The invention discloses a laminated adsorption type gas filtering tower for industrial waste gas treatment, and belongs to the technical field of waste gas treatment. Spraying cavities and adsorptioncavities which are arranged in a staggered manner are arranged in a cylindrical tower body; handling large contact space is large, waste gas is guided into the spraying cavities through gas inlet sleeves and gas inlet holes to be subjected to dust removal spraying treatment of a spraying mechanism. The treated waste gas is guided into the adsorption cavities from the spraying cavities through ventilation layers; the waste gas guided into the adsorption cavities is subjected to multi-layer adsorption treatment through a laminated gas filtering mechanism; the laminated gas filtering mechanism comprises a gas filtering adsorption layer and a bioactive filler layer which are arranged up and down; a plurality of groups of porous adsorption balls on the gas filtering adsorption layer and an active biological filler on the bioactive filler layer are matched to adsorb and decompose some water-insoluble harmful and difficult-to-remove impurities in the waste gas; the treated waste gas is discharged from the top end of the adsorption cavity, and wastewater generated after spraying treatment downwards passes through a filter bed filled at the bottom end part of the cylindrical tower body to be treated.

Owner:杨正新

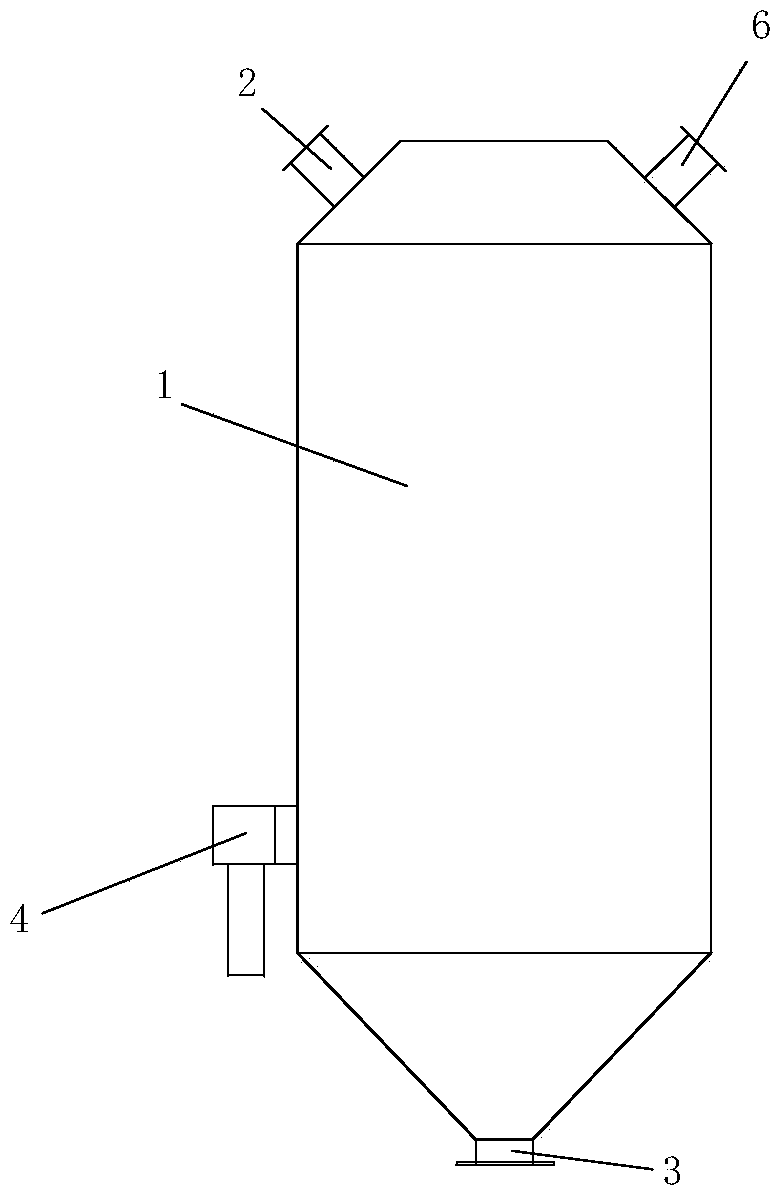

Sand cooling apparatus

ActiveCN104107877ASimple structureLow retrofit costMould handling/dressing devicesEngineeringAirflow

The invention discloses a sand cooling apparatus. The sand cooling apparatus comprises a vertical casing, a material inlet and a material outlet. The apparatus also comprises a gas inlet, a guiding device and a gas outlet. The lower portion of the casing plate of the vertical casing is provided with gas inlet holes. The gas inlet is arranged outside the lower portion of the vertical casing, completely covers the gas inlet holes, and has a closed connection with the outer wall of the vertical casing. The upper right portion of the gas outlet is fixedly connected to the right side of the upper portion of the vertical casing in a closed manner, and is connected with the internal of the vertical casing. The guiding device is arranged in the vertical casing, the guiding device, the vertical casing and molding sand in the vertical casing form an S-shaped gas channel, and the gas channel connects the gas inlet with the gas outlet.

Owner:常州市姚氏铸造材料有限公司

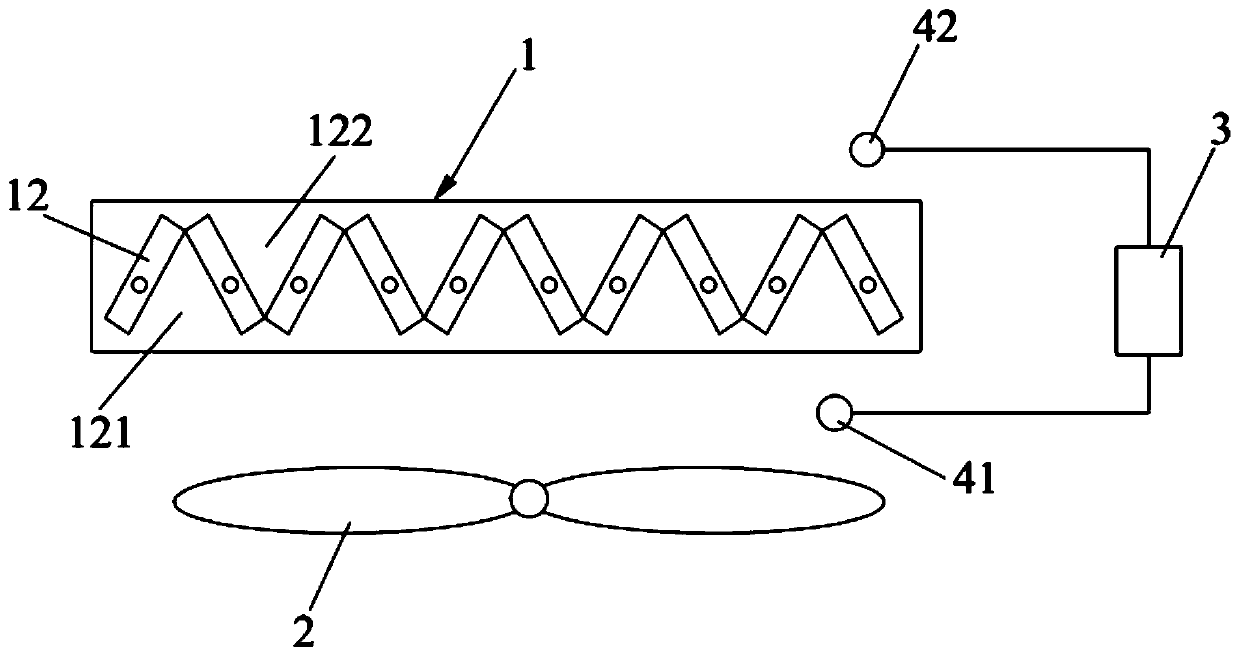

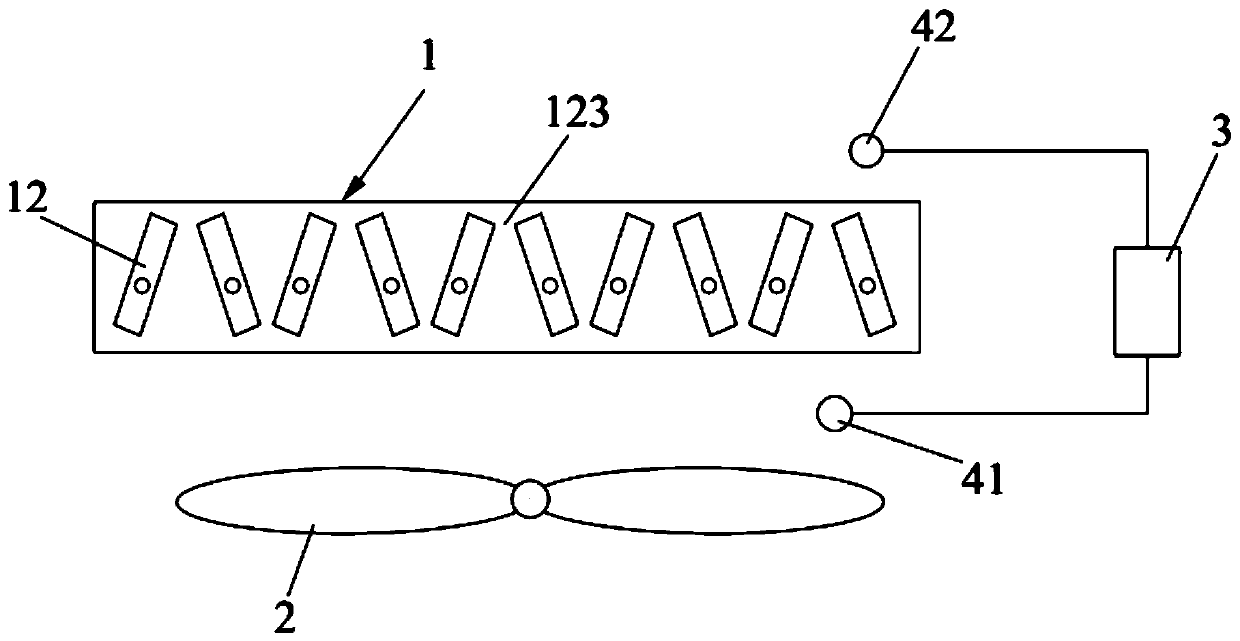

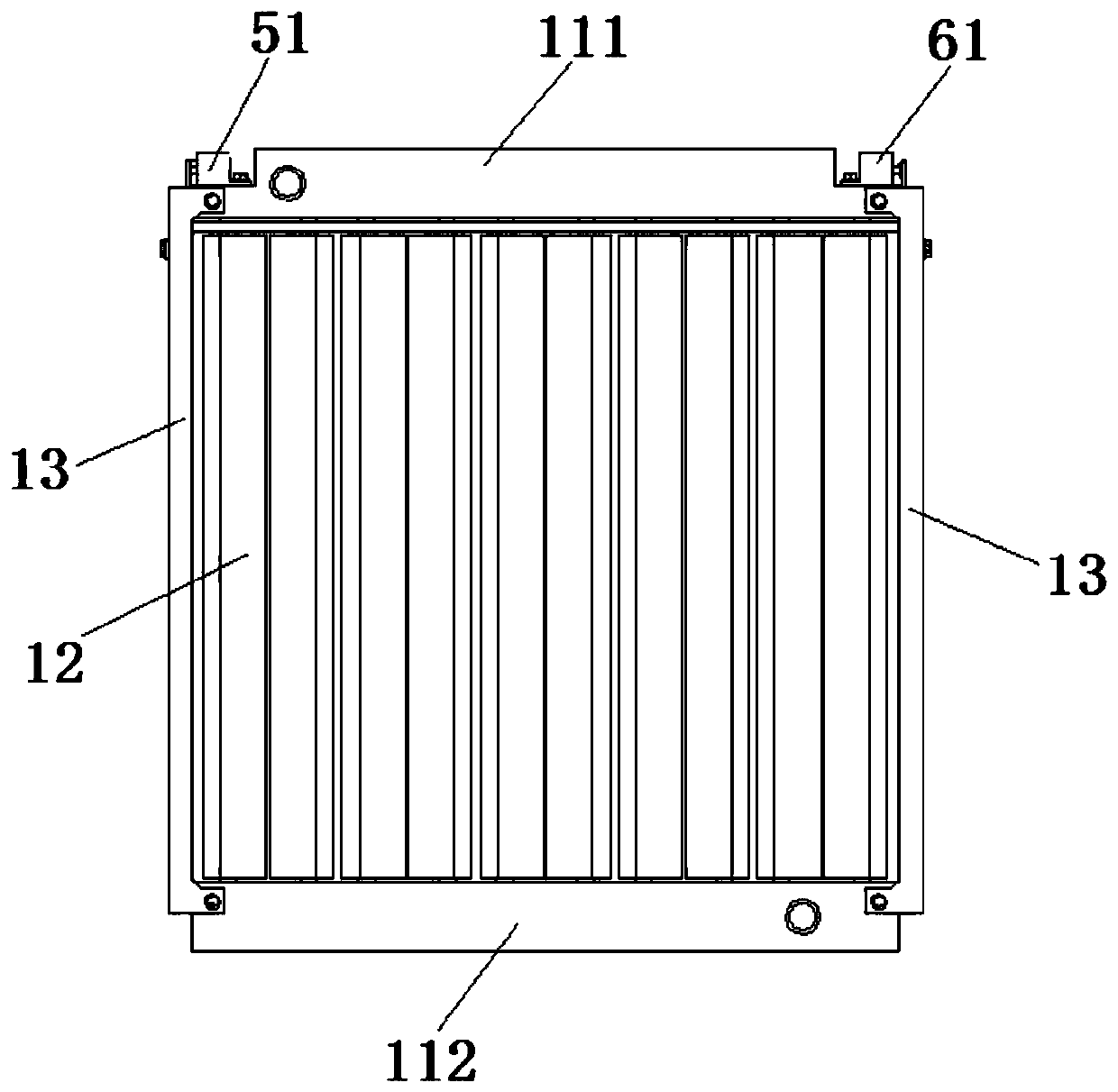

Heat dissipation system and control method thereof

ActiveCN110318855APlay a role in dust removalEasy to peelMachines/enginesEngine cooling apparatusWater sprayComputer engineering

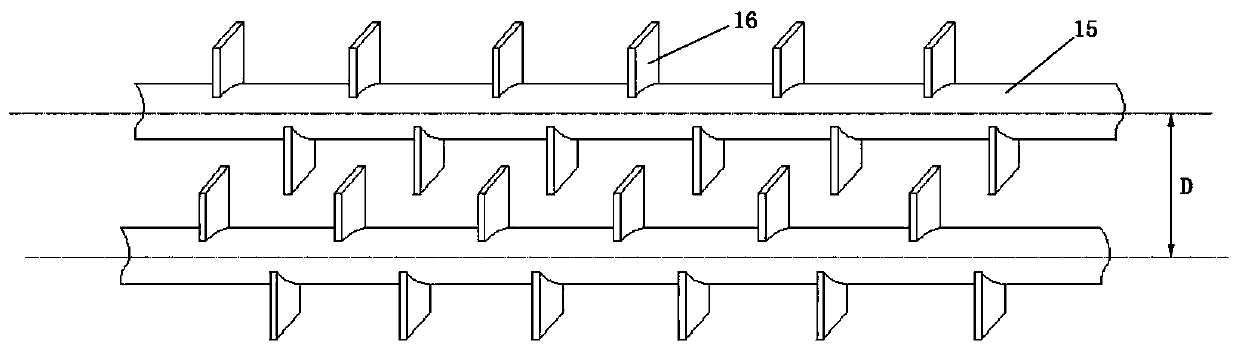

The invention relates to the technical field of heat dissipation systems, in particular to a heat dissipation system and a control method thereof. The heat dissipation system involves a radiator and afan, wherein the radiator comprises a heat dissipation chamber and a plurality of heat dissipation core bodies which are arranged at intervals in the first direction and are rotationally arranged inthe heat dissipation chamber, the fan faces the heat dissipation core bodies, the fan is used for dissipating heat of the heat dissipation core bodies, the radiator is provided with a first state anda second state, when the radiator is in the first state, any two adjacent heat dissipation core bodies are abutted against each other, when the radiator is in the second state, a dust removal gap is formed between every two adjacent heat dissipation core bodies, when air blown out by the fan passes through the dust removal gap, the flow speed of the air flow is accelerated, dust or floccules on the surface of the heat dissipation core body can be stripped, the dust removal effect is enhanced, compared with the prior art., the heat dissipation system does not need to be disassembled when the heat dissipation system is used for removing dust, the fan does not need to rotate reversely, and a water spraying device does not need to be arranged.

Owner:SHANTUI CONSTR MASCH CO LTD

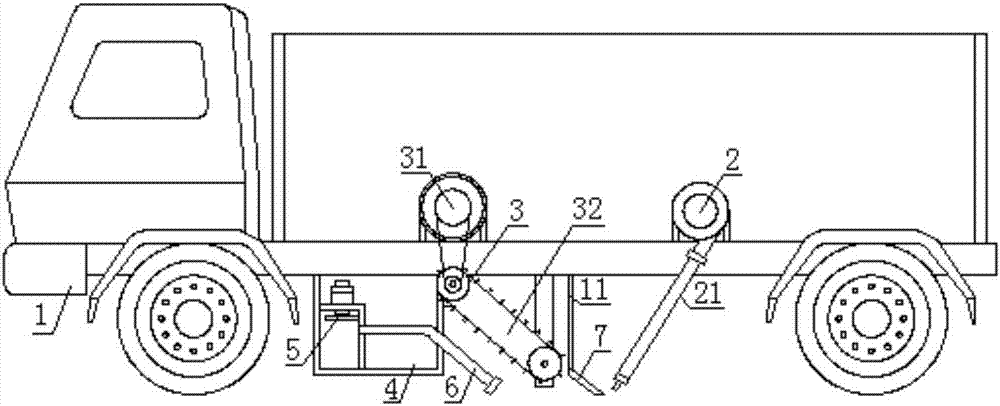

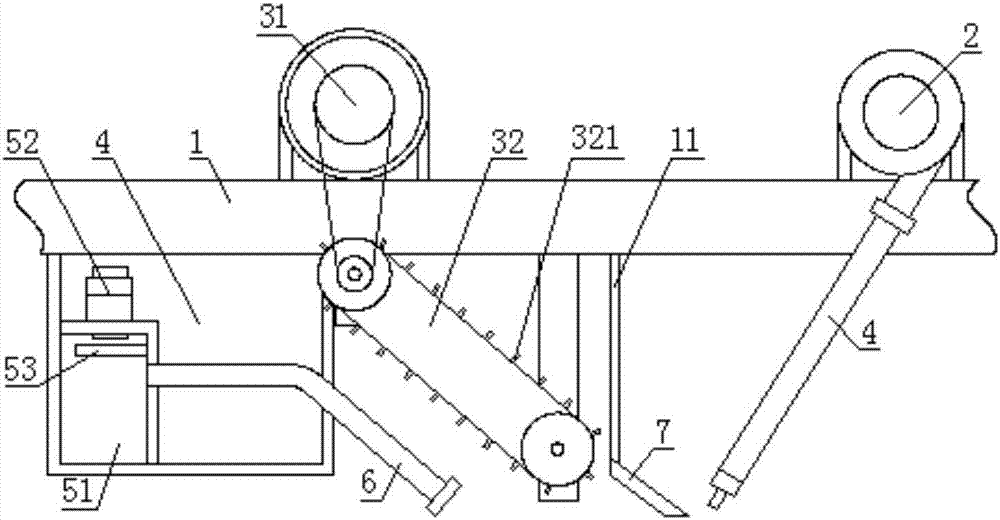

Cleaning vehicle capable of clearing up fallen leaves and removing duct

The invention relates to the field of environmental sanitation equipment, in particular to a cleaning vehicle capable of cleaning fallen leaves and removing dust. The technical solution is: a cleaning vehicle capable of cleaning and dedusting fallen leaves, including a vehicle body, on which a blower for blowing up fallen leaves and a conveying mechanism for transporting fallen leaves on the road are respectively installed, and the air outlet of the blower is connected to There is an air outlet pipe, and the conveying mechanism and the air outlet pipe are arranged obliquely to each other. A collection box for collecting fallen leaves transported by the conveying mechanism is also installed on the car body. A dust suction mechanism is installed in the collection box, and a suction suction mechanism is connected to the dust suction mechanism. dust pipe. The invention provides a cleaning vehicle for automatically clearing and transporting large pieces of rubbish and dust on the road surface at the same time, which solves the problems of low efficiency and unsafety in manual cleaning of fallen leaves on the road surface or manual dust removal.

Owner:弘毅天承知识产权股份有限公司

Recycling device and recycling method for a mold material for alumina brick production

InactiveCN108970781AEfficient removalImprove the film removal effectSolid waste disposalGrain treatmentsBrickEngineering

The invention discloses a recycling device and recycling method for a mold material for alumina brick production. The recycling device comprises a frame, wherein a hearth is arranged on the frame, a sleeve is arranged in the hearth, and a blanking hole is provided at the bottom of the sleeve; one end of the sleeve is provided with a feeding port, and the other end thereof is provided with a discharging port; a feeding rotating shaft is arranged inside the sleeve; a feeding screw is arranged on the feeding rotating shaft; the feeding rotating shaft is in drive connection with a feeding motor; aheating plate is arranged inside the hearth; a tapping device is arranged at the lower part of the sleeve; a conveying device is arranged at the lower part of the sleeve; the conveying device comprises a conveying roller, a conveying belt and a conveying motor; an outgoing hole is formed on the hearth below one end of the conveying device; and a material blocking plate is arranged at the discharging port. The object of the invention is providing a recycling device and recycling method for a mold material for alumina brick production. The device can perform heating pretreatment of used sand toimprove the film removing effect, and then effectively remove the residue on the surface of the sand by mechanical friction.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

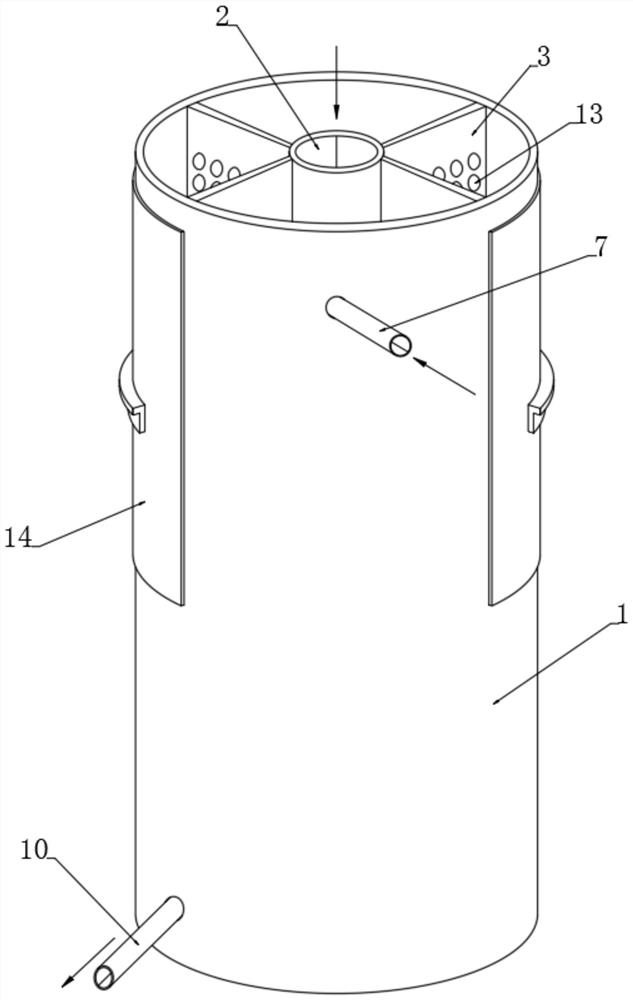

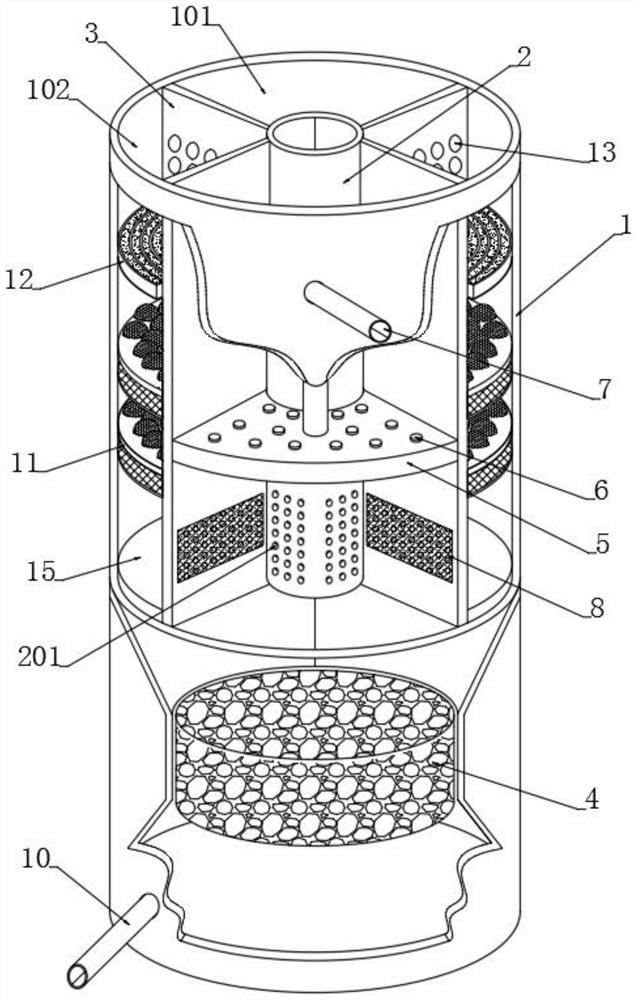

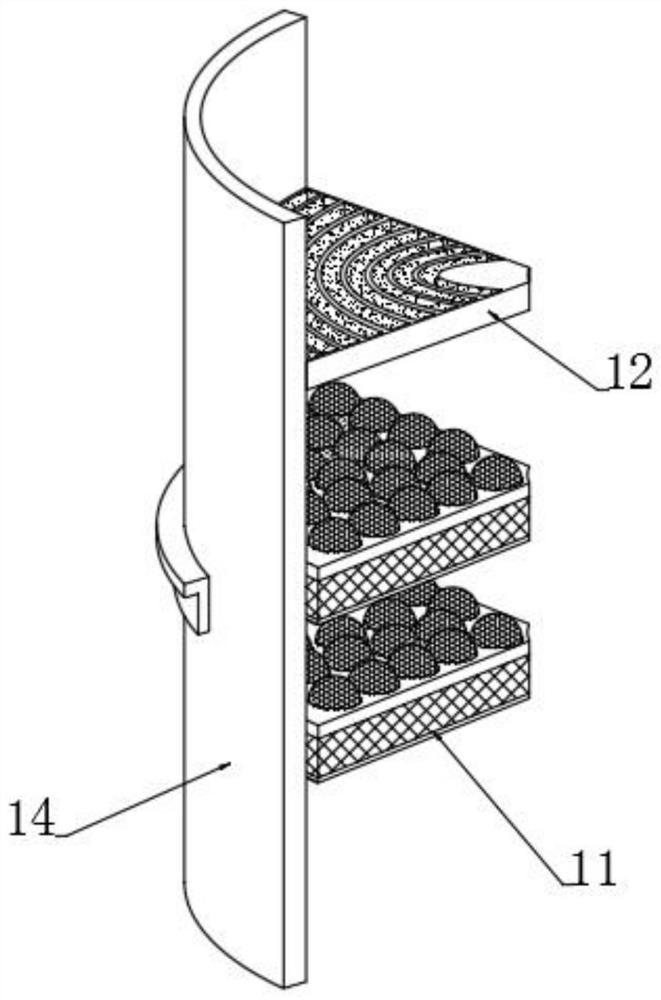

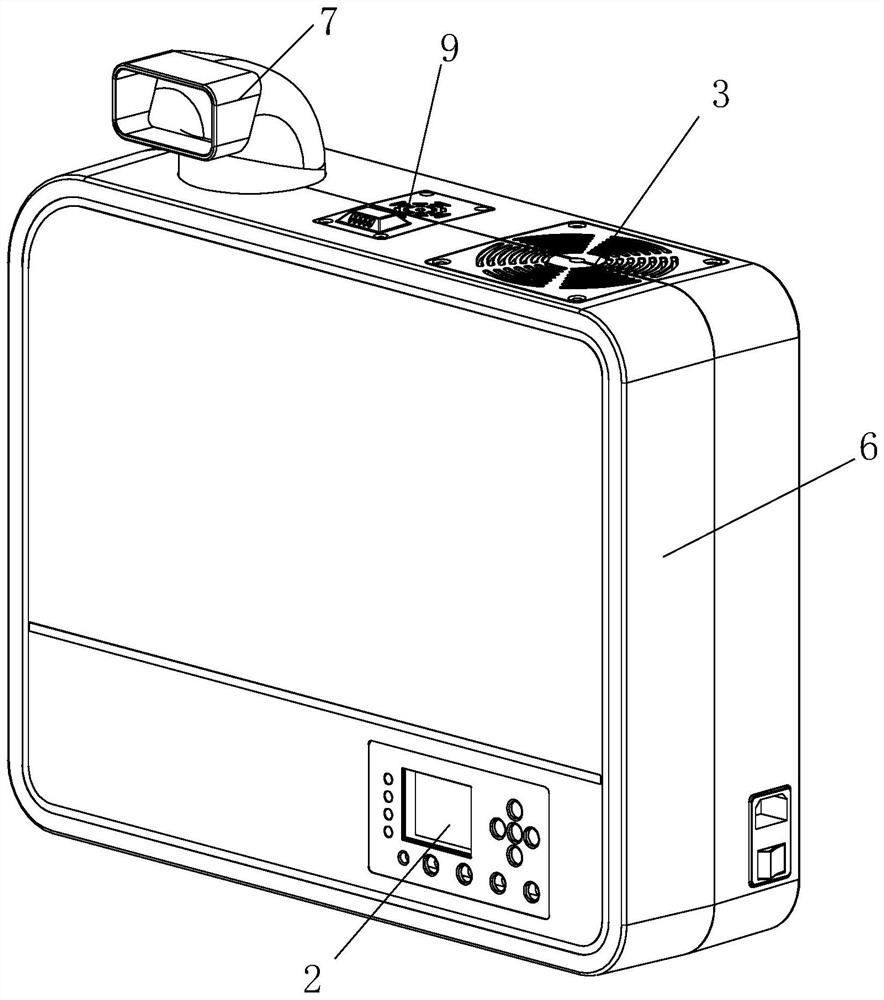

Biological air purifier

InactiveCN111678221APlay a role in dust removalBactericidalMechanical apparatusLighting and heating apparatusWater tanksLiving place

The invention discloses a biological air purifier, belongs to the technical field of purifiers, and solves the problem of the dissatisfied using effect of the existing purifier. The main point of thetechnical scheme comprises a water tank, an intelligent controller, a fan, a fragrance spraying device, a floating ball and an atomizer, wherein the fan can adjust air intake, the water tank is used for containing purified liquid, the floating ball is arranged in the water tank and floats on the purified liquid, the atomizer is located in the floating ball and below the draft of the floating ballso as to be in contact with the purified liquid, at least one opening is formed in the water tank, the intelligent controller is connected with the atomizer for work control, the assisting effects ofatomization and dust reduction, deodorization, sterilization, antibacterial, and fragrance spraying are achieved, and working and living places with good air environment are provided to people.

Owner:ZHEJIANG CHAOLI MECHANICAL TOOLS

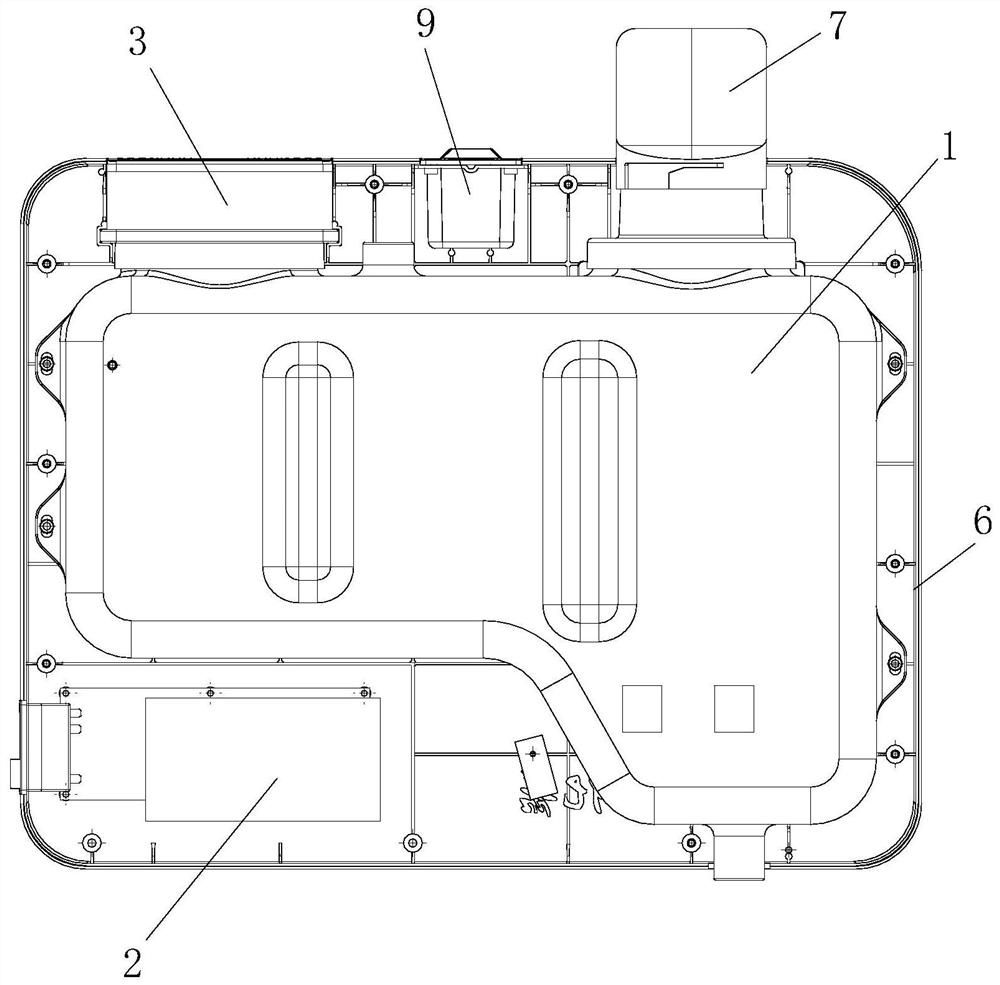

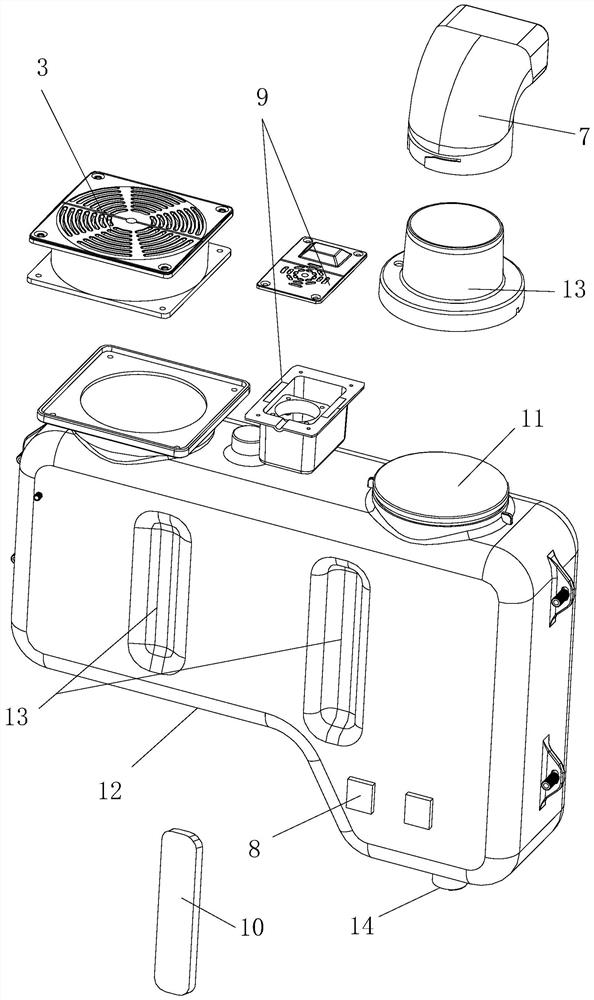

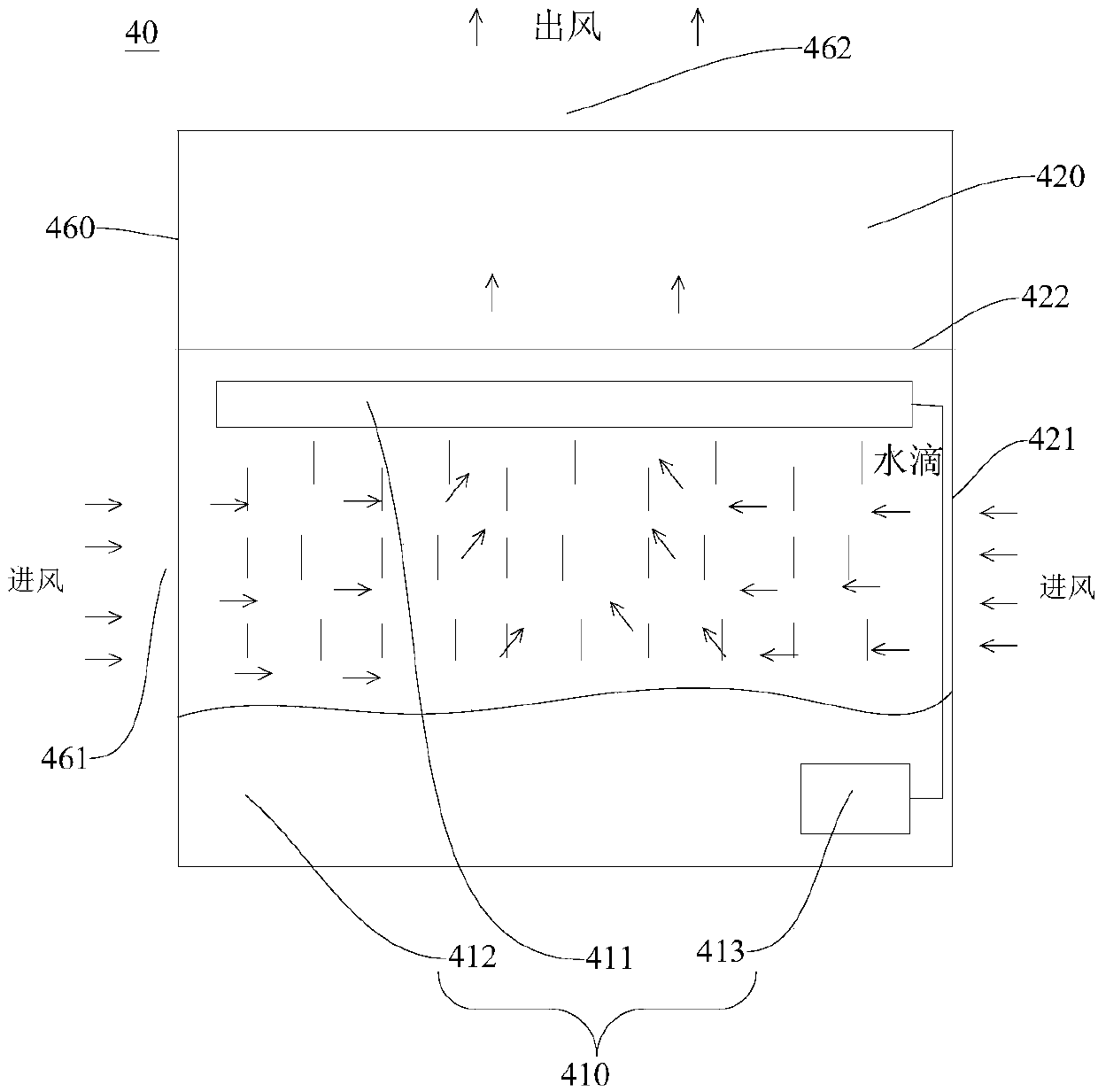

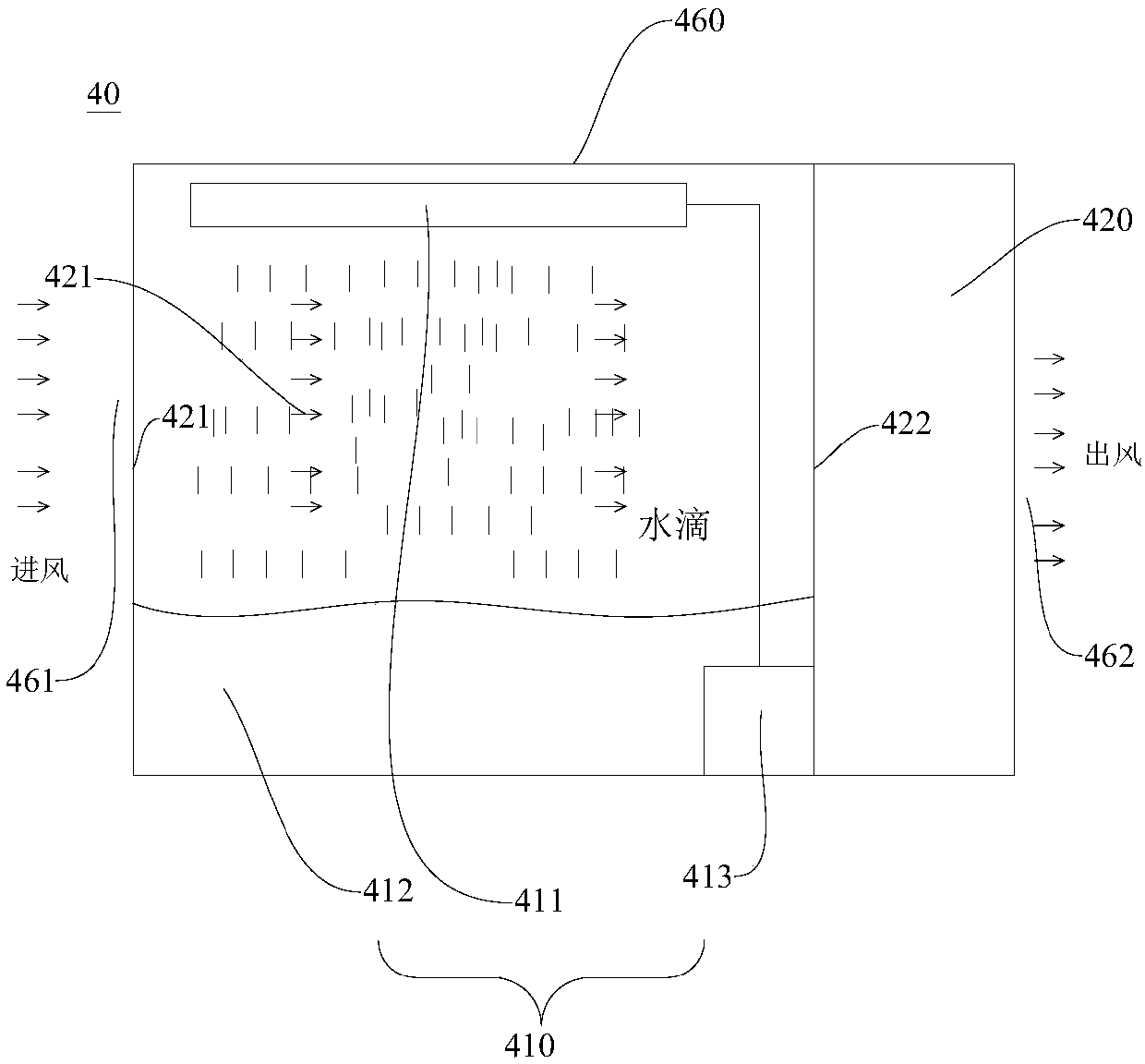

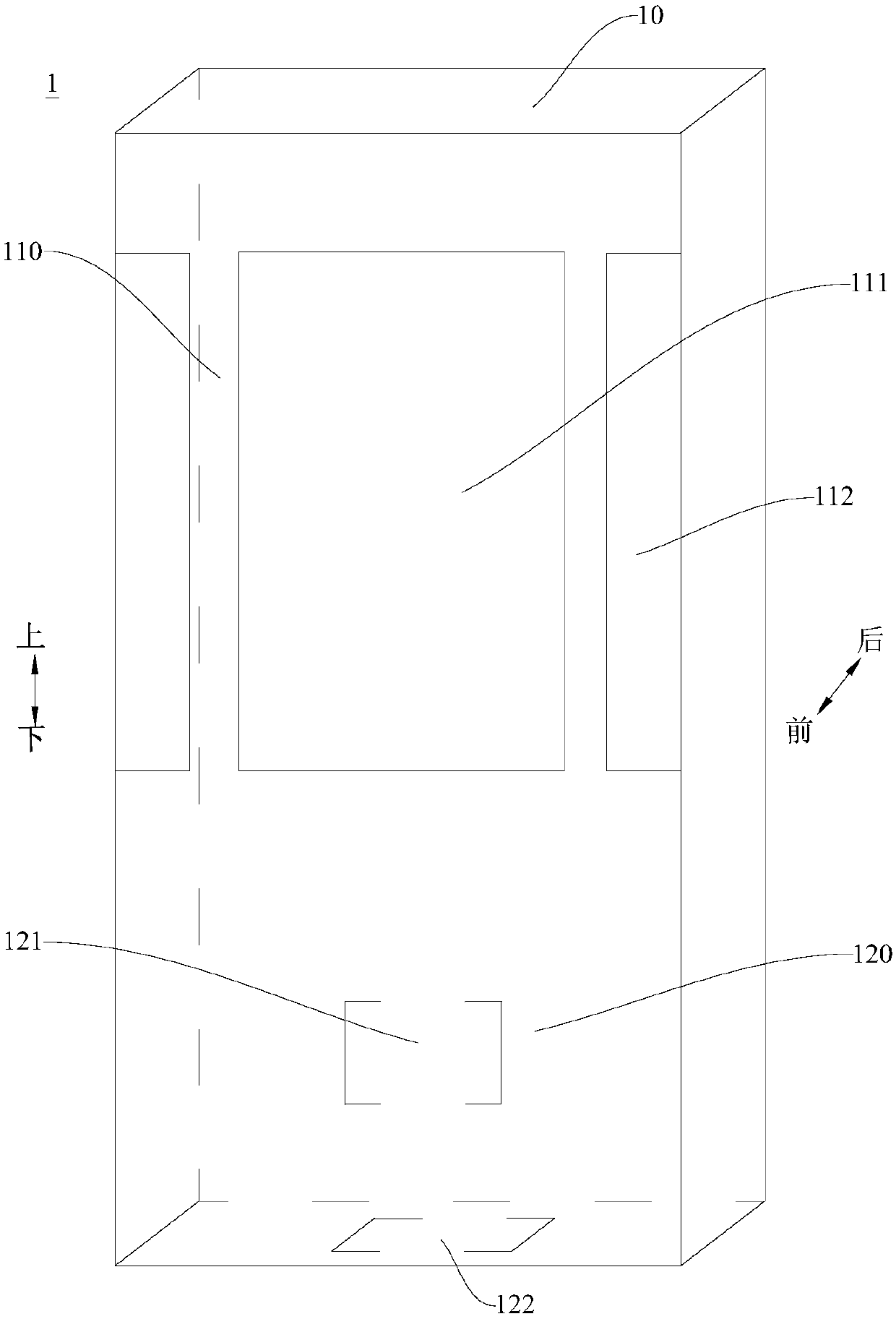

Air treatment device for air conditioner, air conditioner indoor unit and air conditioner outdoor unit

PendingCN109539394AWork efficiency impactDoes not affect cooling/heating efficiencyMechanical apparatusLighting and heating apparatusAir treatmentEngineering

The embodiment of the invention discloses an air treatment device for an air conditioner, an air conditioner indoor unit and an air conditioner outdoor unit. The air treatment device comprises a shell, a guide fan and a water treatment module, the guide fan and the water treatment module are arranged in the shell, the shell is provided with an indoor air inlet and an indoor air outlet, the shell is internally provided with an air treatment air duct isolated from a heat exchanging air duct of the air conditioner indoor unit, at least part of the air treatment air duct extends transversely, thewater treatment module comprises a water container and a water application piece, the water container is connected with the water application piece so as to supply water to the water application piece, and the water application piece is constructed to apply the water to the transverse extending part of the air treatment air duct. According to the air treatment device for the air conditioner, the air treatment air duct of the air treatment device is isolated from the heat exchanging air duct of the air conditioner indoor unit, and thus the work efficiency of the air conditioner indoor unit cannot be affected when the air treatment device treats air.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Oxygenation barrel grate

PendingCN110748922AOvercome the weakness of single direction upward ventilationAvoid cloggingDomestic stoves or rangesSolid fuel combustionThermodynamicsMechanical engineering

The invention discloses an oxygenation barrel grate which comprises grate teeth and an oxygenation barrel. The oxygenation barrel is fixedly arranged at the center of the grate teeth, the top of the oxygenation barrel is closed, the bottom of the oxygenation barrel is open, and a through hole is formed in the position, above the grate teeth, of the peripheral wall of the oxygenation barrel. The oxygenation barrel grate has the advantages that the mixed-direction oxygen supply effect is achieved, a certain ash removal function is achieved, an upward ventilation channel of the furnace teeth is prevented from being blocked and influencing the oxygen supply effect, good heating and smoke eliminating effects are achieved, the wood consumption is greatly saved, and the overall temperature of a furnace is improved.

Owner:夏常涛

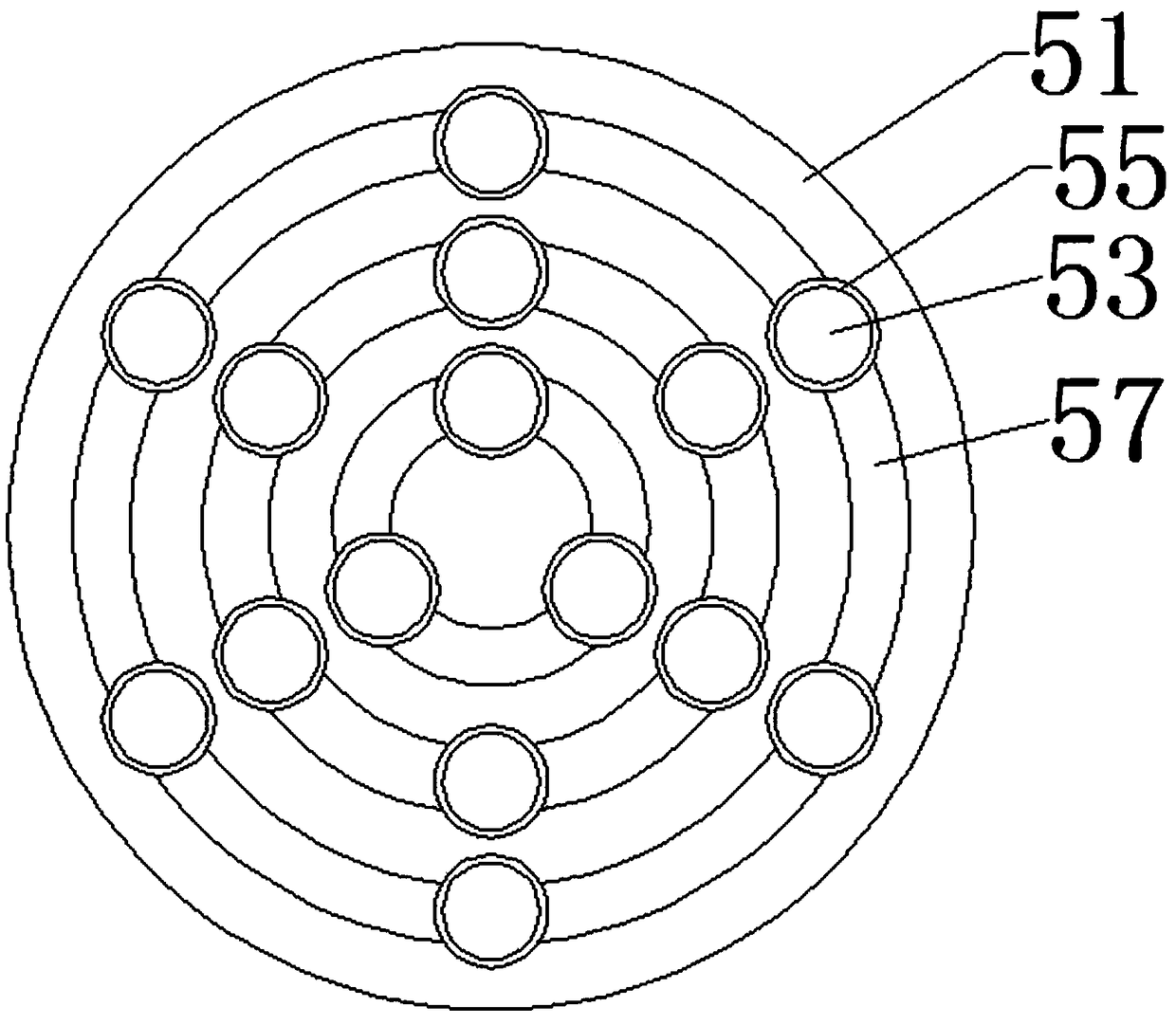

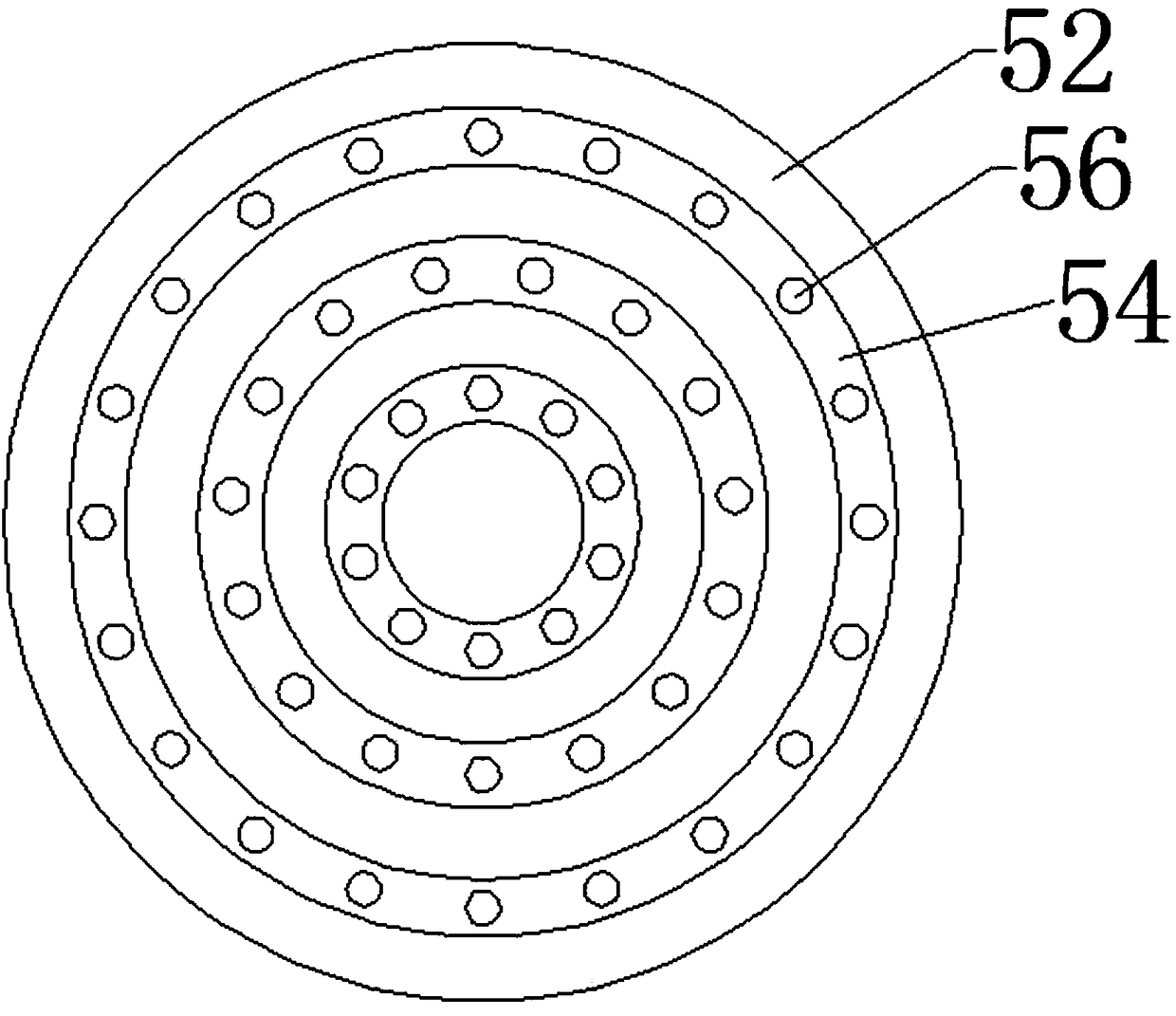

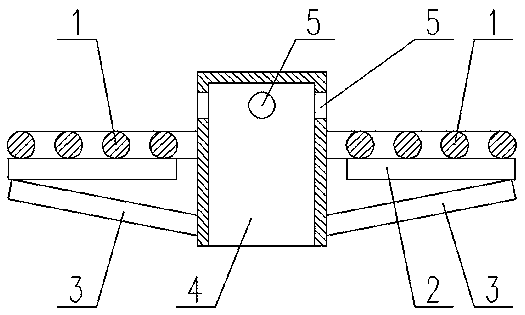

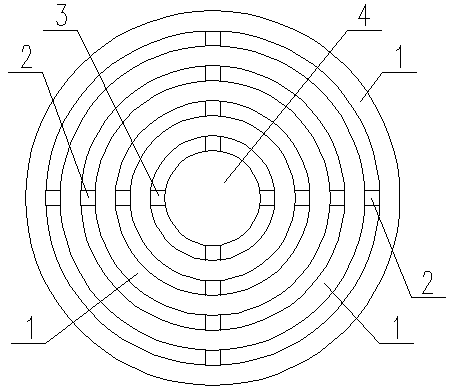

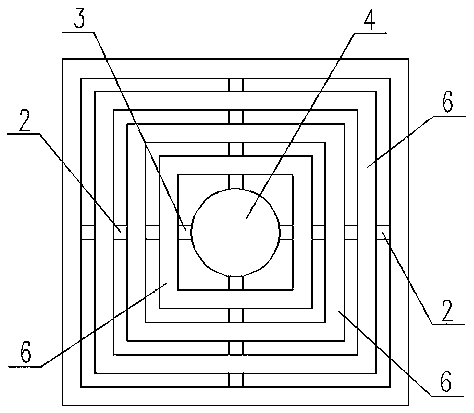

Design method of cutter head for full-face rock tunneling machine with high-pressure water jet

The invention discloses a design method for cutterheads of a high-pressure water jet full-face rock tunnel boring machine and belongs to the technical field of tunneling of full-face rock tunnel boring machines. In the design method, according to the overall arrangement of the cutterheads, the two cutterheads which are of the completely identical structure, rotate synchronously and arranged in a cross-shaped spoke mode are adopted, the second cutterhead rotates anticlockwise relative to the first cutterhead by 45 degrees so as to be installed, and each cutterhead is composed of five components. According to the design method, the integral hob structure of traditional TBM cutterheads is changed, the arrangement in the form of spokes form two cross shapes is adopted, rock breaking is achieved through the impact of water jet on the four spokes and the rotary squeezing of a tool, and the characteristics that water jet machining is high in efficiency, low in energy consumption and easy to achieve are utilized; and high-pressure water is used for cracking rocks, expanding cracks and even breaking the rocks, the rock breaking resistance of the tool is reduced, and the service life of the tool is prolonged.

Owner:DALIAN UNIV OF TECH

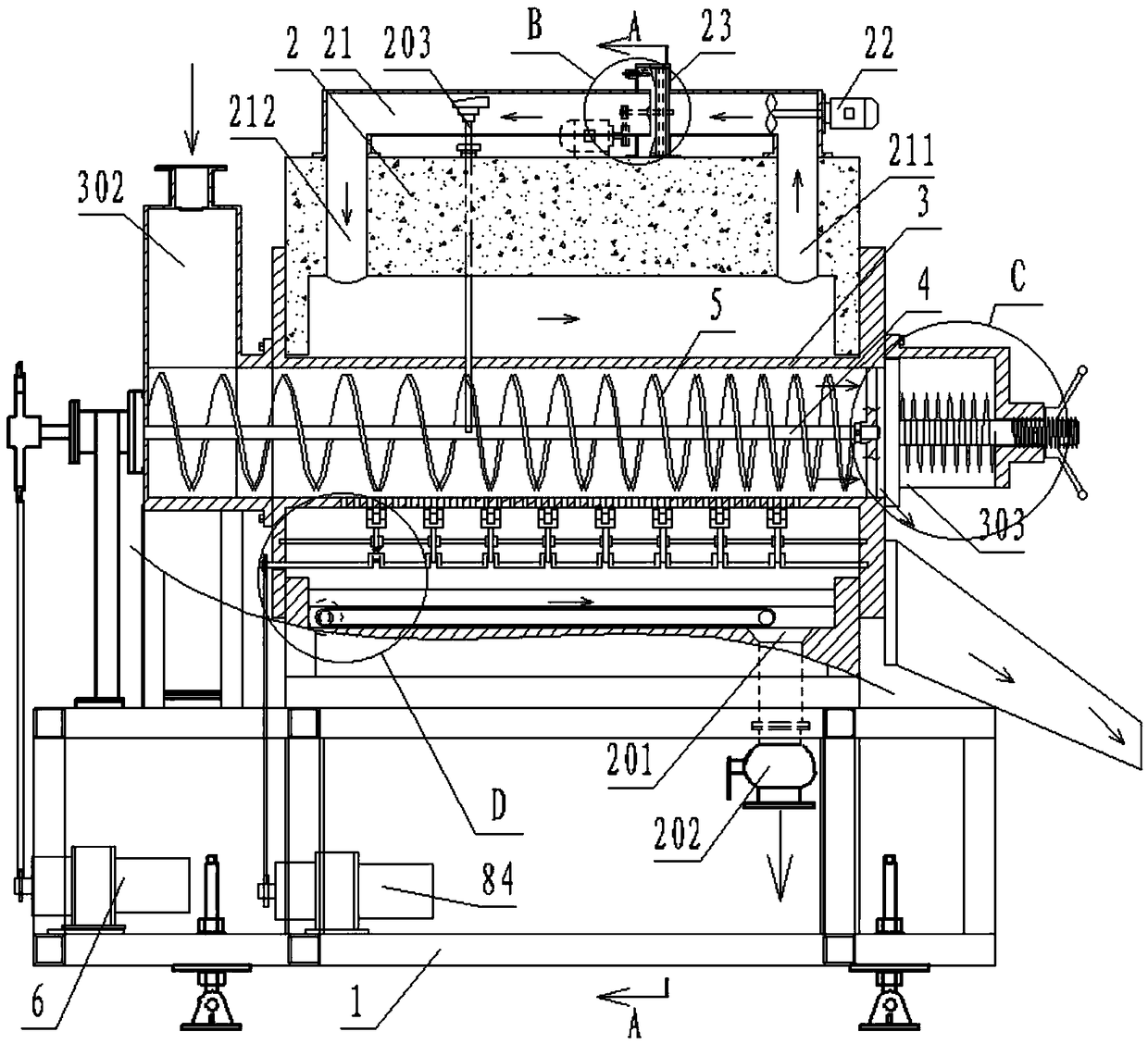

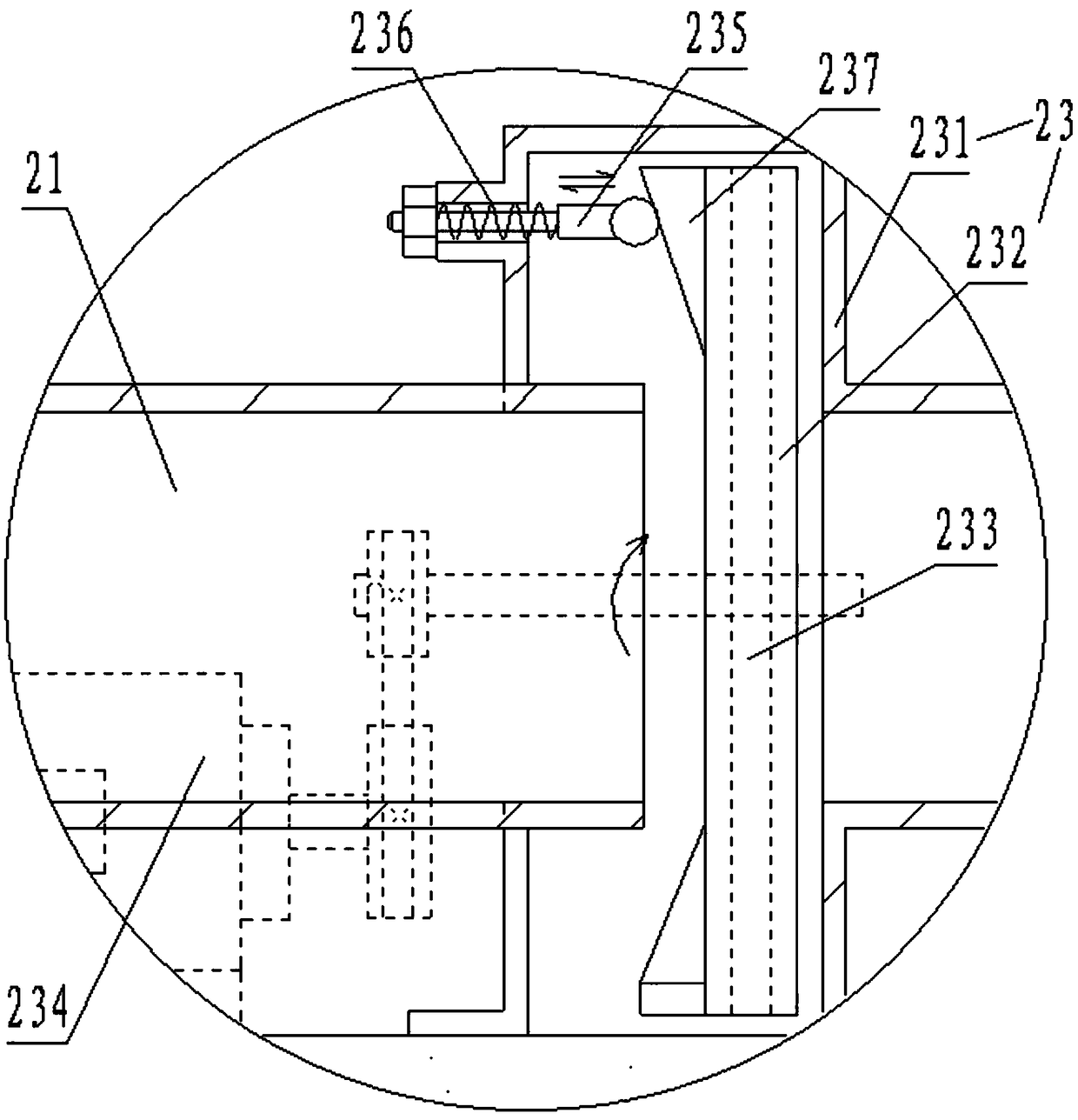

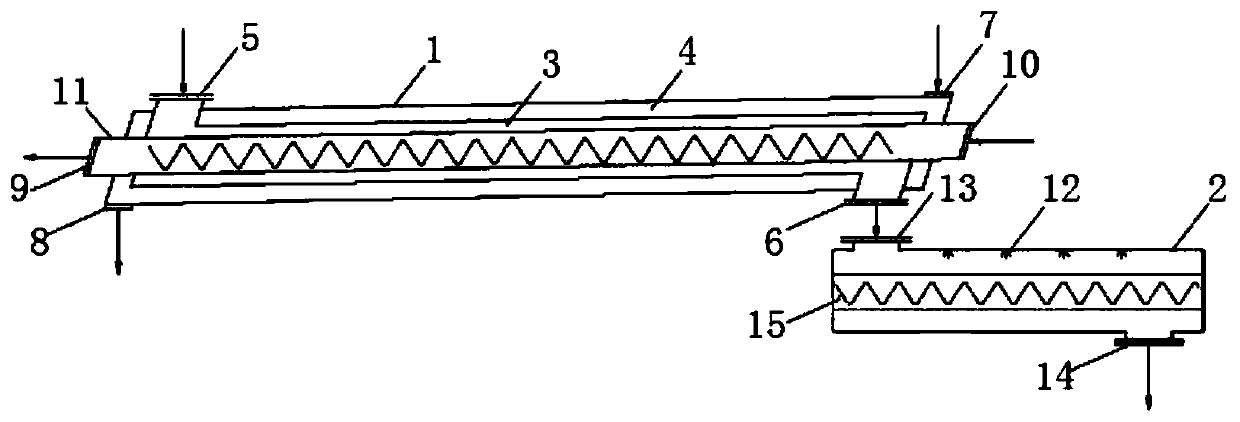

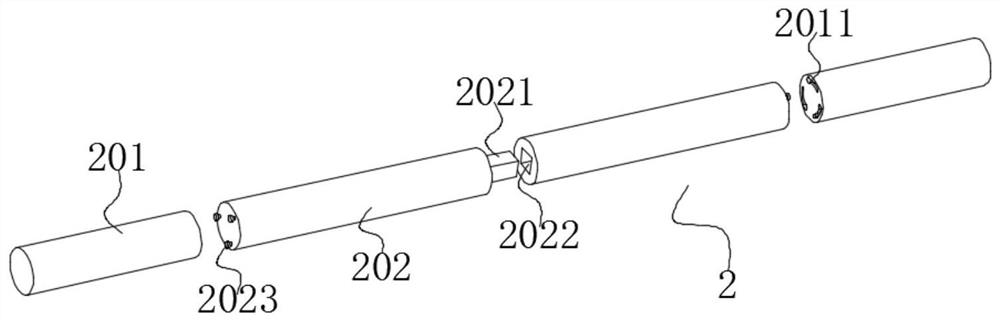

Heat-phase separation solid residue discharged material cooling dust removal device and method

PendingCN110844637AMeet the temperature requirements of the dischargeMeet temperature requirementsPackagingLoading/unloadingDust controlMechanical engineering

The invention discloses a heat-phase separation solid residue discharged material cooling dust removal device. The heat-phase separation solid residue discharged material cooling dust removal device comprises a discharged material spiral device and a discharged material spraying spiral device. The discharged material spiral device and the discharged material spraying spiral device are connected with each other. The discharged material spiral device comprises a first spiral shaft, a material cavity and a clamping sleeve cavity. The material cavity sleeves the first spiral shaft, and the clamping sleeve cavity sleeves the material cavity. The first spiral shaft is used for conveying materials in the material cavity. A first material inlet is formed in one end of the material cavity, passes through the clamping sleeve cavity and extends to the exterior of the clamping sleeve cavity. A first material outlet is formed in the other end of the material cavity, passes through the clamping sleeve cavity and extends to the exterior of the clamping sleeve cavity. A first water inlet is formed in one end of the clamping sleeve cavity, and a first water outlet is formed in the other end of theclamping sleeve cavity. Spraying assemblies are arranged in the discharged material spraying spiral device and used for spraying water to materials. The heat-phase separation solid residue dischargedmaterial cooling dust removal device has the beneficial effects that the cooling operation is conducted before the high-temperature materials are subjected to water spraying humidification and dust removal, the consumption of the spraying water is reduced, and the phenomenon that due to the fact that the moisture carries the dust, the serious secondary pollution happens is avoided.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

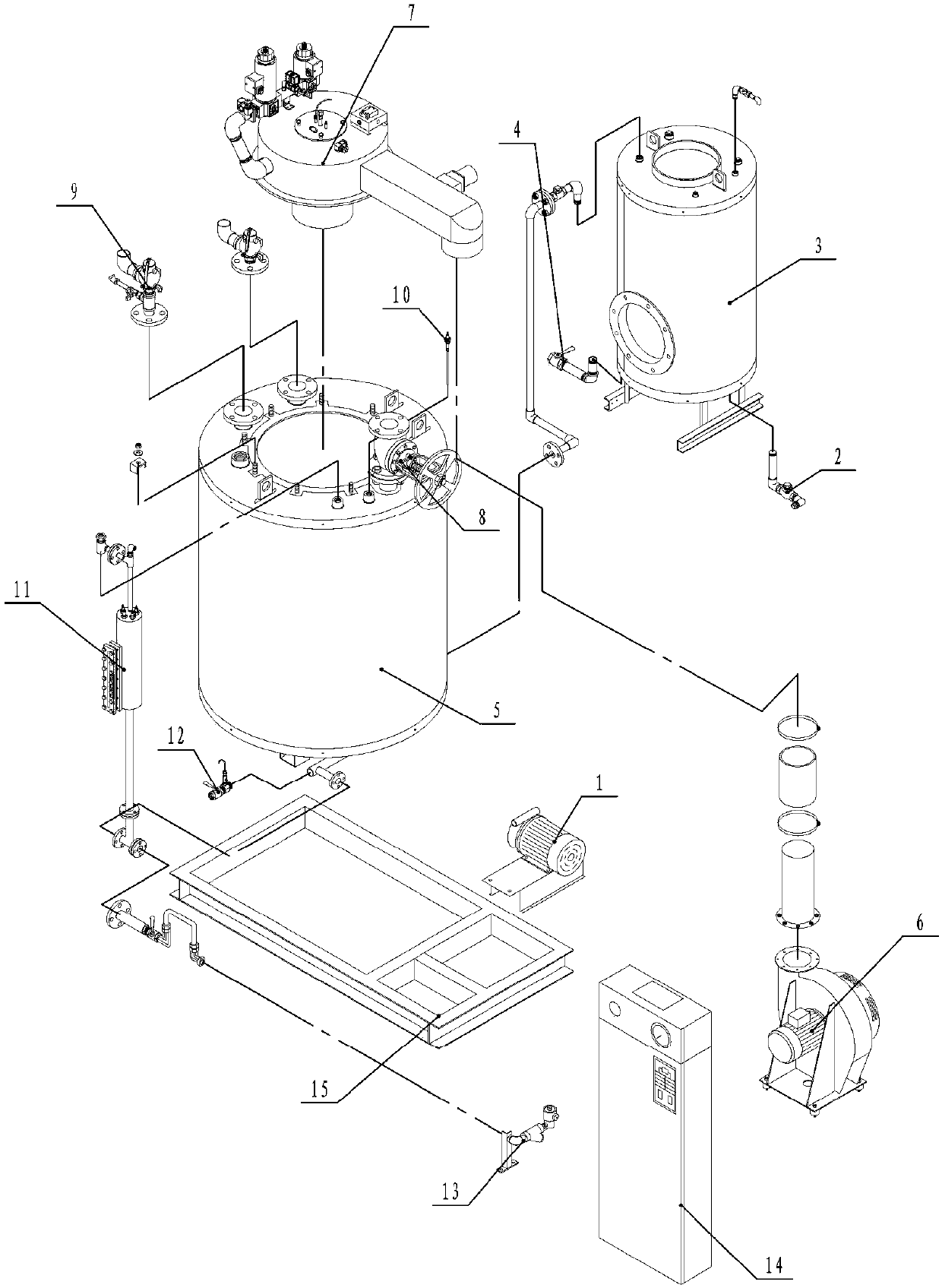

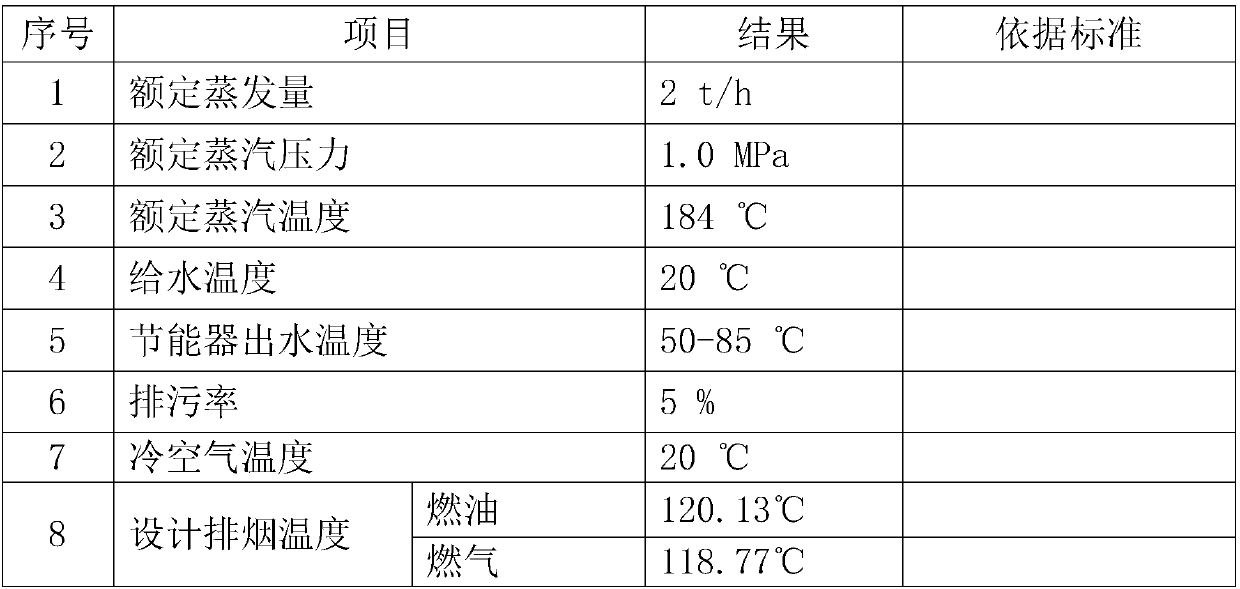

Through-flow type boiler

InactiveCN107559792ACompact structureReduce volumeSteam generation using pressureBoiler cleaning apparatusEngineeringAir blower

The invention relates to a through-flow type boiler. The through-flow type boiler comprises a water supply pump, a check valve, an energy saving device, an energy saving device drain valve, a boiler main engine, an air blower, a combustion engine, a main steam valve, a safety valve, a water level electric shock bar, a water level meter, a boiler drain valve, an automatic drain electromagnetic valve, an electric cabinet and a boiler base. The through-flow type boiler is compact in structure, small in size, low in weight and convenient to move, and has the characteristics of being high in heat efficiency and automation degree, safe and reliable, convenient to operate and the like, and the market application general reaction is good. The fuel of the boiler is clean oil or natural gas.

Owner:HENAN SITONG BOILER

Plastic compounding process organic tail gas recovery treatment system

ActiveCN111744284APlay a role in dust removalGuaranteed filtering effectDispersed particle filtrationTransportation and packagingEngineeringMechanical engineering

The invention belongs to the technical field of tail gas treatment. The invention particularly relates to a plastic composite process organic tail gas recovery treatment system. The system comprises acooling box and a secondary adsorption filtering tank, a communicating pipe comprises a cooling air outlet pipe located in the cooling box and a filtering connecting pipe located between the coolingbox and the secondary adsorption filtering tank, a driving box for driving a filtering pipe to rotate is mounted at one end, close to the cooling air outlet pipe, of the filtering connecting pipe, control mechanisms comprise control blocks fixedly connected to the inner wall of the cooling air outlet pipe and connecting rods fixedly connected to the side surfaces of the control blocks; tail gas passes through a filter screen to filter particles, dust attached to the surface layer of the filter screen can fall down towards the cooling air outlet pipe in a reverse direction, so that the dust attachment amount on the surface of the filter screen is reduced, wave crests and wave troughs of a matching ring are in sliding fit with arc-shaped blocks, then the filter screen on the surface of the supporting ring vibrates, therefore a dust removal effect on the filter screen is further achieved.

Owner:嘉兴市布雷塑胶新材料股份有限公司

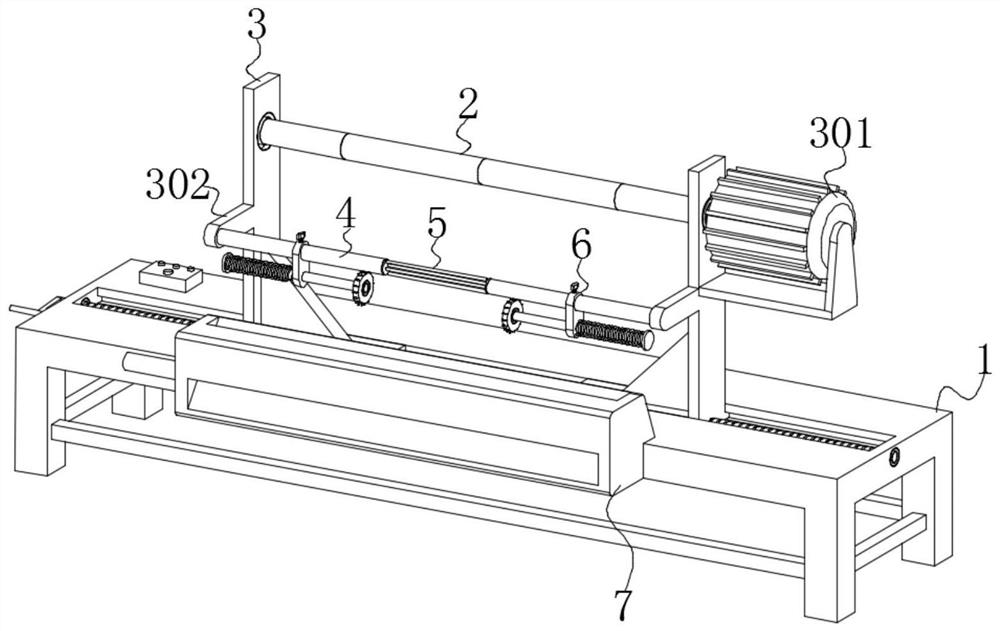

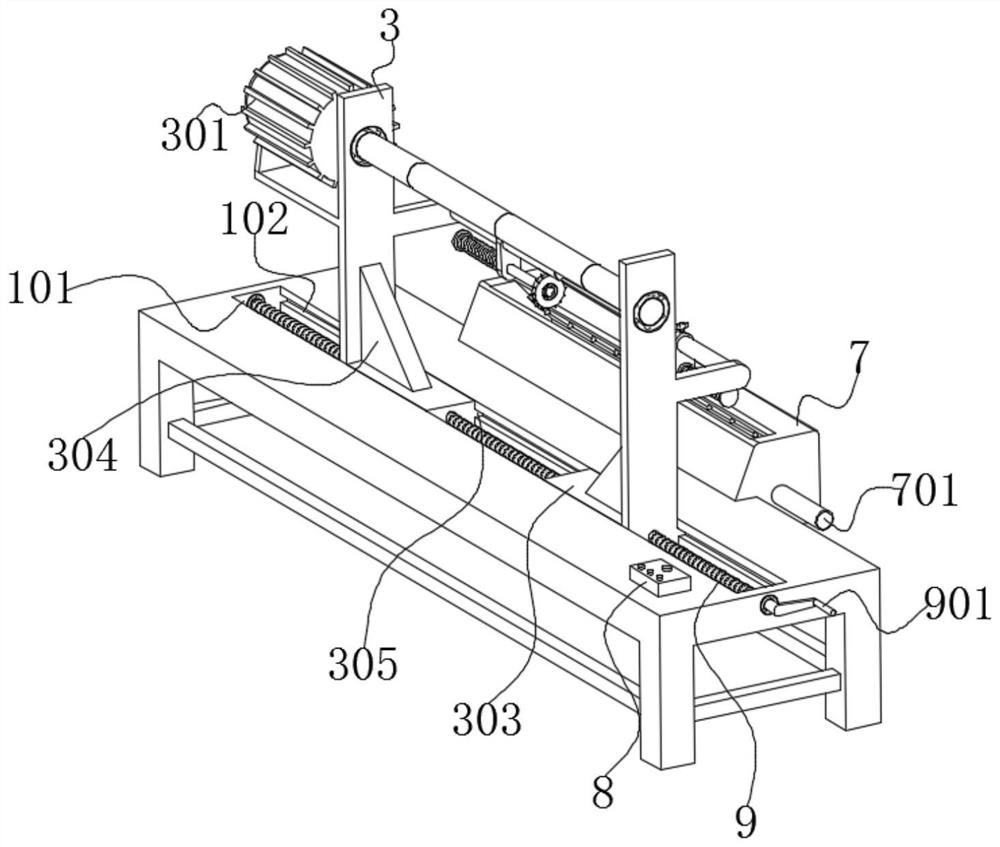

Rapid dense screen winding device for building engineering site construction

PendingCN113321025AImplementation orientationAvoid wrinklesBuilding material handlingCleaning using liquidsRolling-element bearingArchitectural engineering

The invention discloses a rapid dense screen winding device for building engineering site construction, and relates to the technical field of building construction equipment. The rapid dense screen winding device comprises an operation table, a winding rod and guide rods, wherein the two ends of the winding rod are rotationally connected to the upper end positions of supporting plates through rolling bearings; one side of each supporting plate is further fixedly connected with the corresponding guide rod through a connecting plate; each guide rod is movably matched with a positioning mechanism; the winding rod comprises rotating shafts and winding columns; the winding columns are detachably connected to the end faces, close to each other, of the two rotating shafts; and positioning assemblies used for positioning a single-layer dense screen and a multi-layer dense screen are arranged on the end faces, close to each other, of the two winding columns. According to the rapid dense screen winding device, the dense screens with different widths can be wound through the switching of the different winding columns, the positioning mechanisms can straighten and flatten each dense screen from the two sides of the dense screen, the relative movement of the two supporting plates can be achieved through the cooperation of a screw rod and moving blocks so that the dense screens can be taken out conveniently, and the dense screens can be cleaned and dedusted before being wound by arranging a cleaning box.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

Electrical control box

PendingCN112636212AReduce entryQuick releaseSubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsElectrical controlEngineering

The invention relates to an electrical control box, which relates to the field of electrical equipment and comprises an outer box body and an inner box body arranged in the outer box body, wherein a distance is reserved between each side surface of the inner box body and each side surface of the outer box body, an outer box door is hinged to one side of the outer box body, an inner box door is hinged to one side, close to the outer box door, of the inner box body, The top face, the bottom face, each side face and the inner box door of the inner box body are each provided with a plurality of heat dissipation holes, each side face and the outer box door of the outer box body are each provided with a plurality of horizontal ventilation holes in the vertical direction, the sides, away from the inner box body, of the ventilation holes incline downwards, and heat dissipation fans are fixedly arranged on the top surface, the bottom surface, each side surface and the inner side of the outer box door of the outer box body. The electric control box has the effect of improving the heat dissipation effect of the electric control box.

Owner:天津砼天建筑工程有限公司

Soot compression device having soot waste heat utilization function for electric dust removal tool

InactiveCN109173547AClean up regularlyAffect circulationCombination devicesElectricityCompression device

The invention relates to a soot compression device having a soot waste heat utilization function for an electric dust removal tool. The soot compression device comprises an air inlet pipe and a connection pipe. The left side of the air inlet pipe is provided with a grounding wire. The lower end of the air inlet pipe is provided with a connection plate. A bottom valve is inlaid in the lower end ofthe connection plate. The middle of the upper end of the bottom valve is connected to a connection rod. The upper end of the connection rod is provided with a brush ring. The lower end of the right side of the air inlet pipe is fixedly provided with a filter pipe. Through the brush ring, the connection rod is fixed above the bottom valve and the outer side of the connection rod contacts with the inner wall of the air inlet pipe. When the bottom valve is dismounted, the brush ring is driven to slide from the upper end to the lower end in the air inlet pipe and the brush ring and the inner wallof the air inlet pipe generate friction so that the dust on the inner wall of the air inlet pipe can be removed through the brush ring, dust flowing influence caused by excessive impurities inside theair inlet pipe is prevented and the interior of the air inlet pipe can be cleaned regularly.

Owner:余汉锡

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com