Laser marking machine with smoke and dust removing functions

A laser marking machine and laser marking head technology, applied in laser welding equipment, manufacturing tools, welding equipment, etc., can solve problems such as physical hazards, unfavorable long-term work of operators, and heavy smoke and dust, so as to improve the environment and protect ears Hearing, the effect of reducing resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

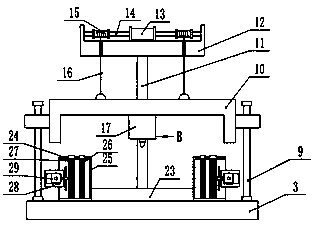

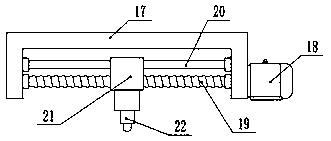

[0027] see figure 1 and image 3 , a laser marking machine with smoke and dust removal functions, including a platform 3, a biaxial motor 13, a laser marking head 22 and a smoke and dust removal mechanism 24, the upper surface of the platform 3 is symmetrically provided with sliding columns 9, The sliding column 9 and the platform 3 are fixedly connected by threads, and a lifting plate 10 is slidably installed between the sliding columns 9 on the left and right sides. The base 1 is fixedly connected with a main support rod 11 by a thread, and the main support rod 11 The top is fixedly connected with a top cover 12 by screws, and the upper center of the top cover 12 is fixed with a double-axis motor 13 through a bracket. The type of the double-axis motor 13 is not limited. All output shafts at both ends are connected with a connecting shaft 14 by a coupling, and a winding wheel 15 is also fixedly installed on the connecting shaft 14, and a traction line 16 is wound on the wind...

Embodiment 2

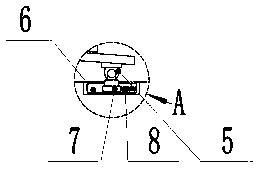

[0032] see Figure 3-4 , a laser marking machine with smoke and dust removal functions, including a base 1, a biaxial motor 13, a laser marking head 22 and a smoke and dust removal mechanism 24, and shock absorbing columns 2 are arranged on both sides of the upper surface of the base 1 , a shock absorbing spring is installed on the shock absorbing column 2, and the upper side of the shock absorbing column 2 is provided with a platform 3, and the lower center position of the platform 3 is fixedly equipped with a shock absorbing spring sheet 4, and the lower side of the shock absorbing spring sheet 4 The left and right parts are welded with connectors 5, and the lower side of the connectors 5 is welded with a slider 7. The surface of the base 1 is provided with a chute 6, and the slider 7 is slidably installed in the inside of the chute 6. The slider 7 and the The first spring 8 is connected between the chute 6, and the slider 7 can slide left and right inside the chute 6, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com