Patents

Literature

111results about How to "Reduce resonance noise" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pneumatic tire and method of designing tread pattern of the tire

ActiveUS20070051448A1Large sound-absorbing effectDeterioration of steering stability can be preventedTyre tread bands/patternsNon-skid devicesEngineeringGround contact

A pneumatic tire reduces the columnar resonance noise of the tire while controlling the lowering of wet performances, wherein four circumferential grooves continuously extending in the circumferential direction of the tire are disposed in a treading face and a plurality of lateral grooves each having one end opened to the circumferential groove and terminated in a land portion are formed with respect to two circumferential grooves among the four circumferential grooves, and these lateral grooves and the respective circumferential grooves have such a groove width that both groove walls of the groove do not contact with each other in a ground contact face and one or more lateral groove are always completely included in the ground contact face, and an extending length of a portion of each lateral groove in the ground contact face having a groove width of the lateral groove corresponding to not less than 30% of a groove width of the circumferential groove is made not less than 40% of an extending length of the circumferential groove in the ground contact face.

Owner:BRIDGESTONE CORP

Ultrasonic self-cleaned extractor hood and method thereof

ActiveCN106439960ARealize automatic cleaningFast cleaningDomestic stoves or rangesLighting and heating apparatusUltrasonic sensorEngineering

The invention discloses an ultrasonic self-cleaned extractor hood and a method thereof. The ultrasonic self-cleaned extractor hood comprises a controller, a machine shell and a centrifugal fan arranged in the machine shell. A cleaning liquid sucking and discharging pump and a cleaning liquid sucking and discharging port are formed in the machine shell. One connector of the cleaning liquid sucking and discharging pump communicates with the cleaning liquid sucking and discharging port through a pipeline. The other connector of the cleaning liquid sucking and discharging pump directly communicates with the bottom of a volute through a pipeline. At least two through holes are formed in the bottom of the volute. Ultrasonic transducers are fixed to the lower sides of the through holes. The fan, the cleaning liquid sucking and discharging pump and the ultrasonic transducers are connected with the controller. The problem that an extractor hood in the prior art is hard to clean or the cleaning effect is not ideal is effectively solved. The ultrasonic self-cleaned extractor hood is high in automation degree, automation cleaning of the extractor hood is truly achieved, and very high practical value is achieved.

Owner:HANGZHOU ROBAM APPLIANCES CO LTD

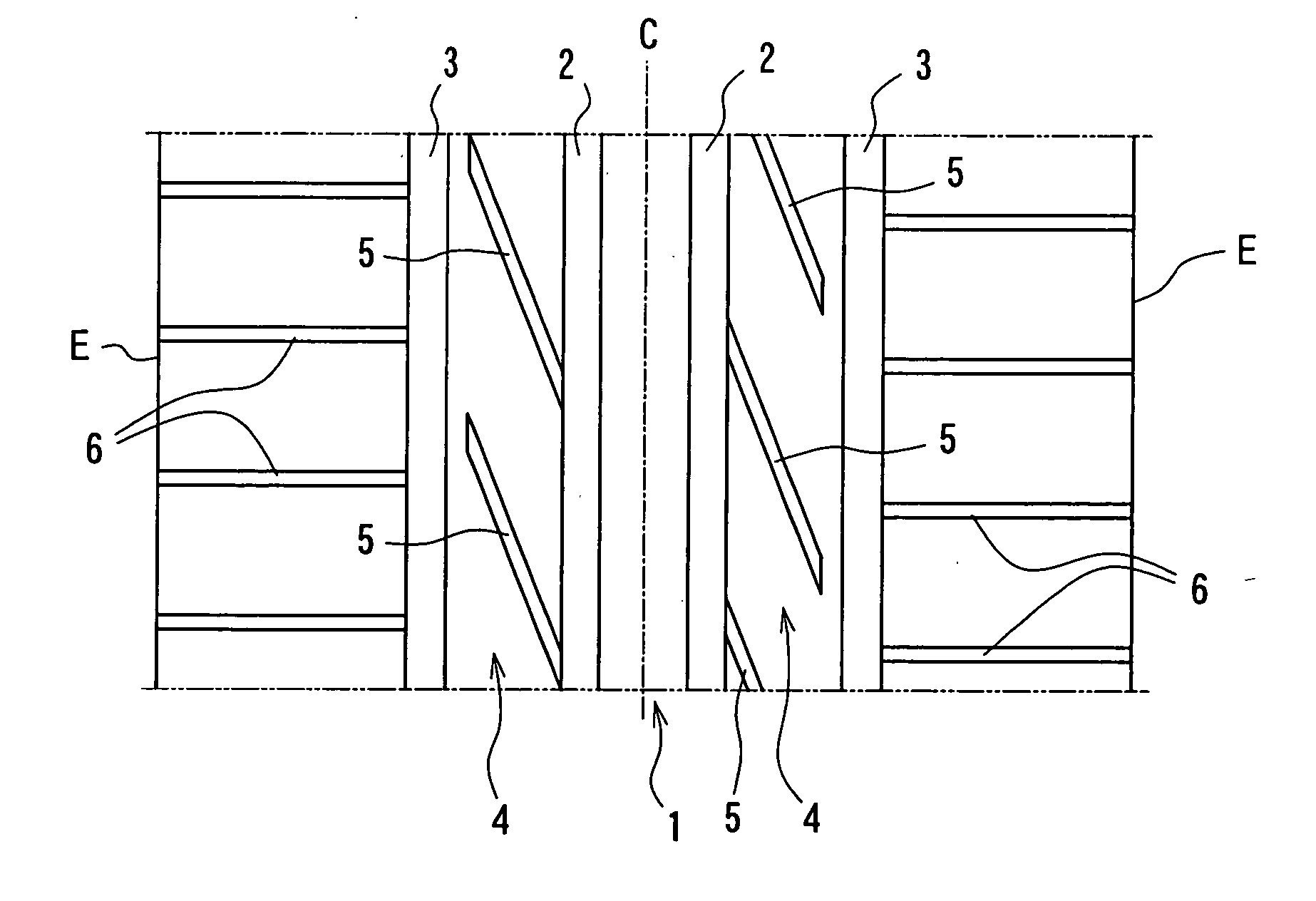

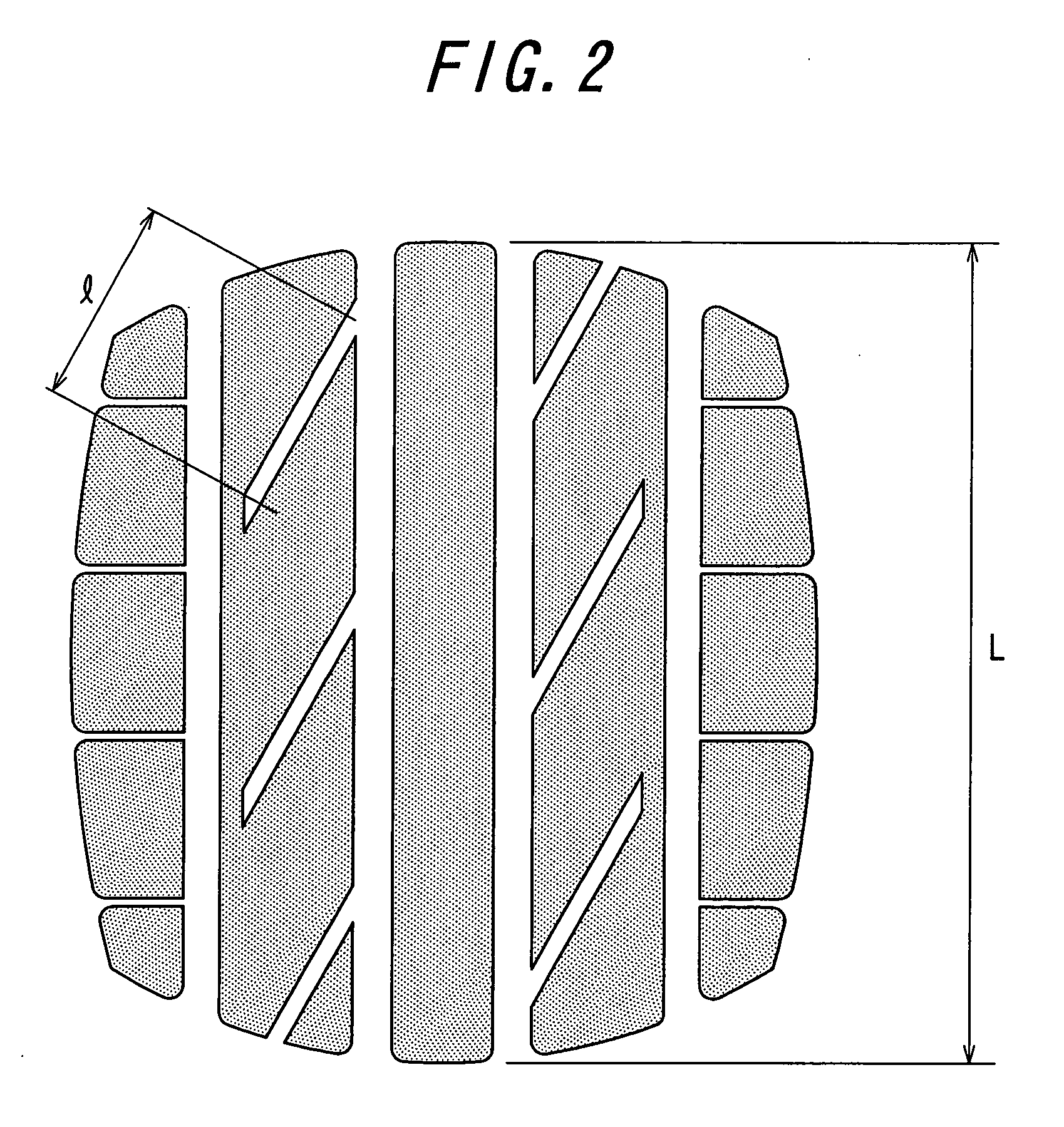

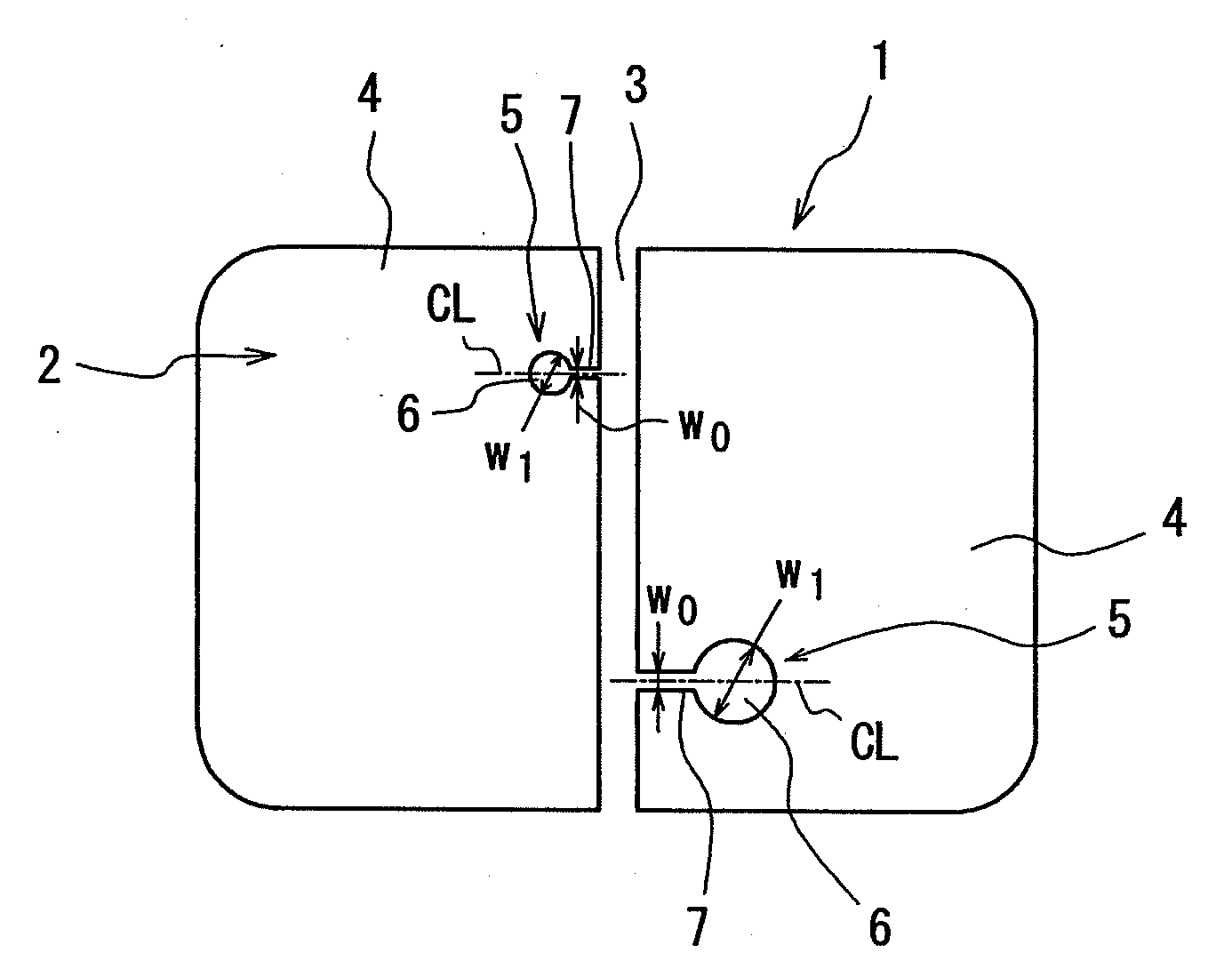

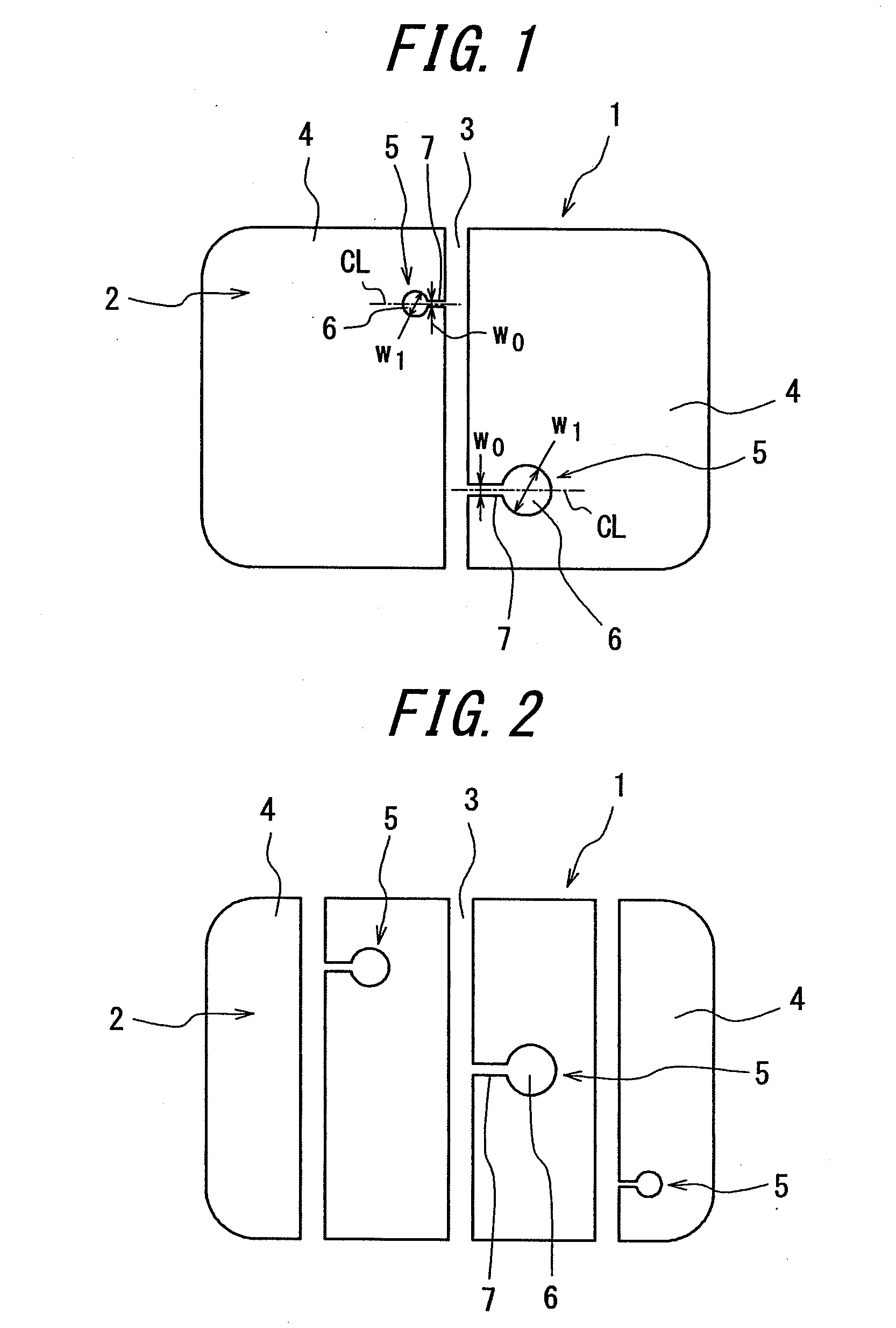

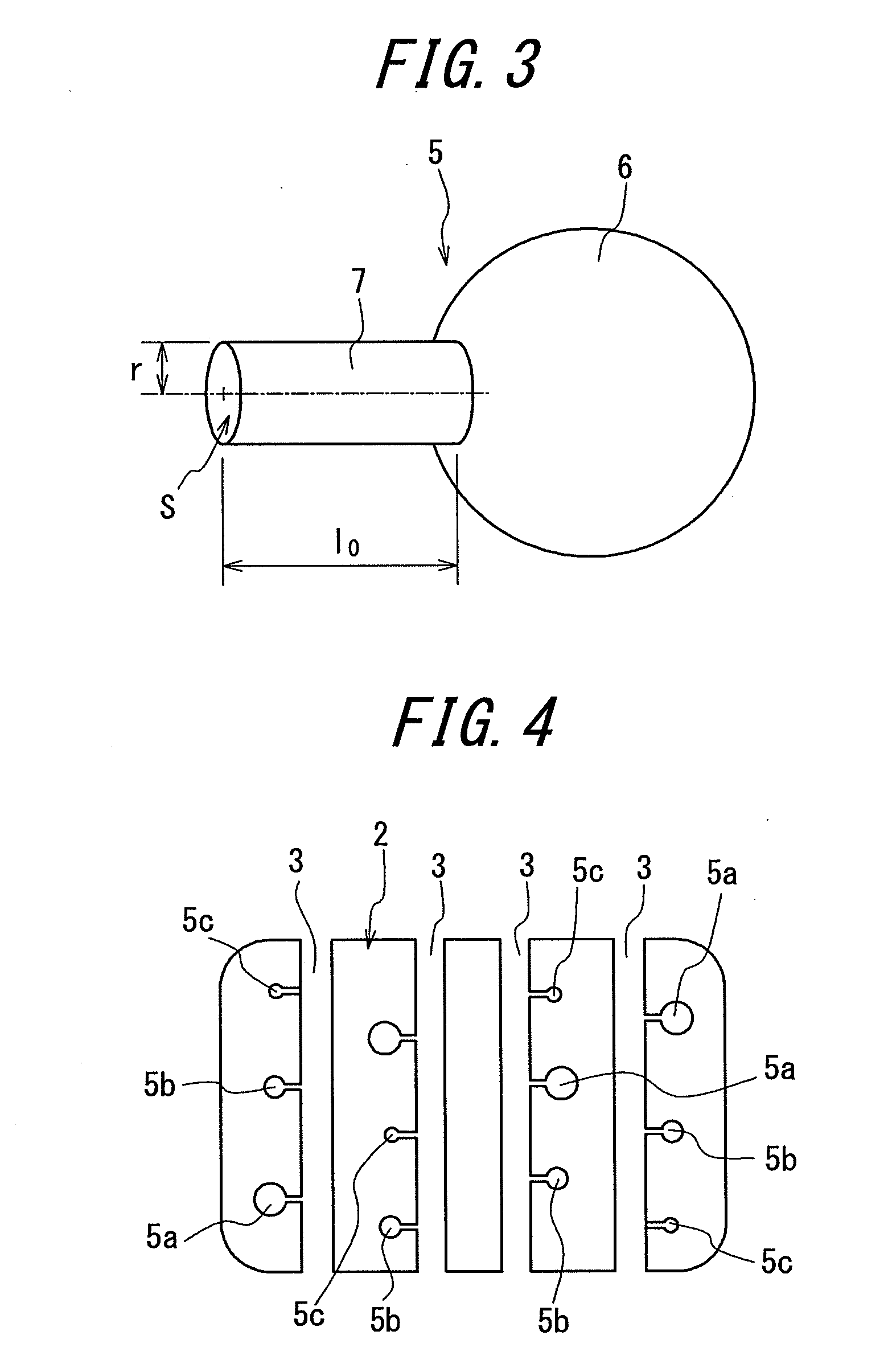

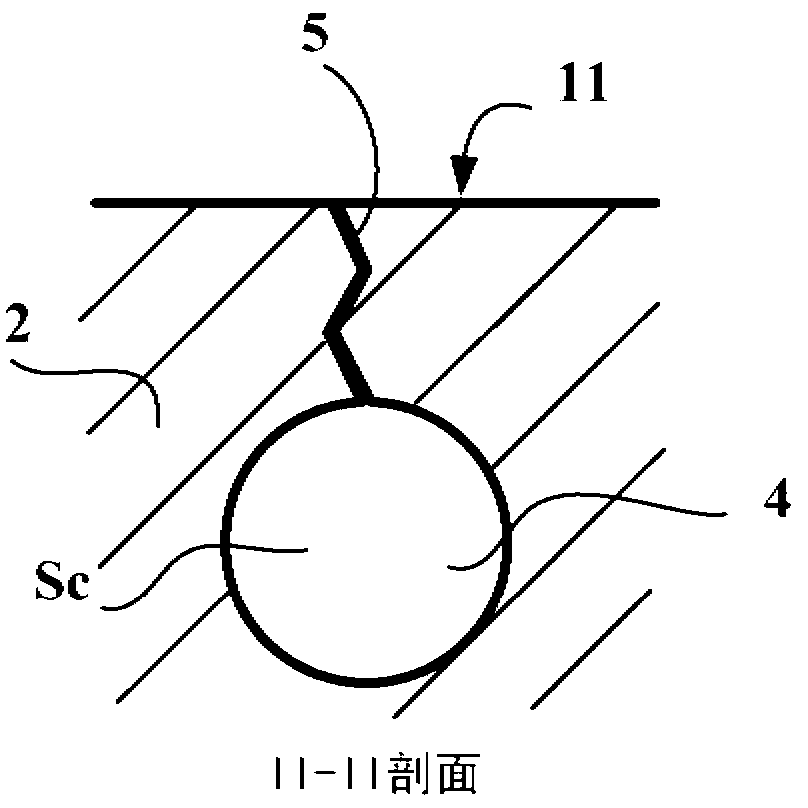

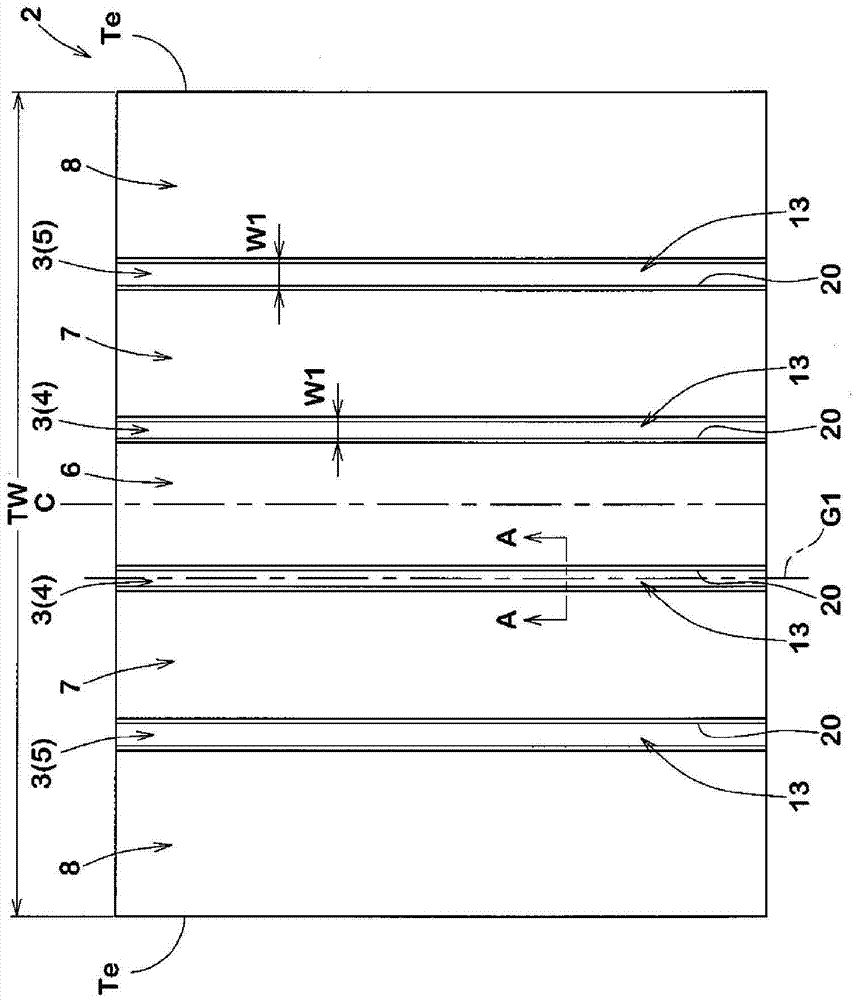

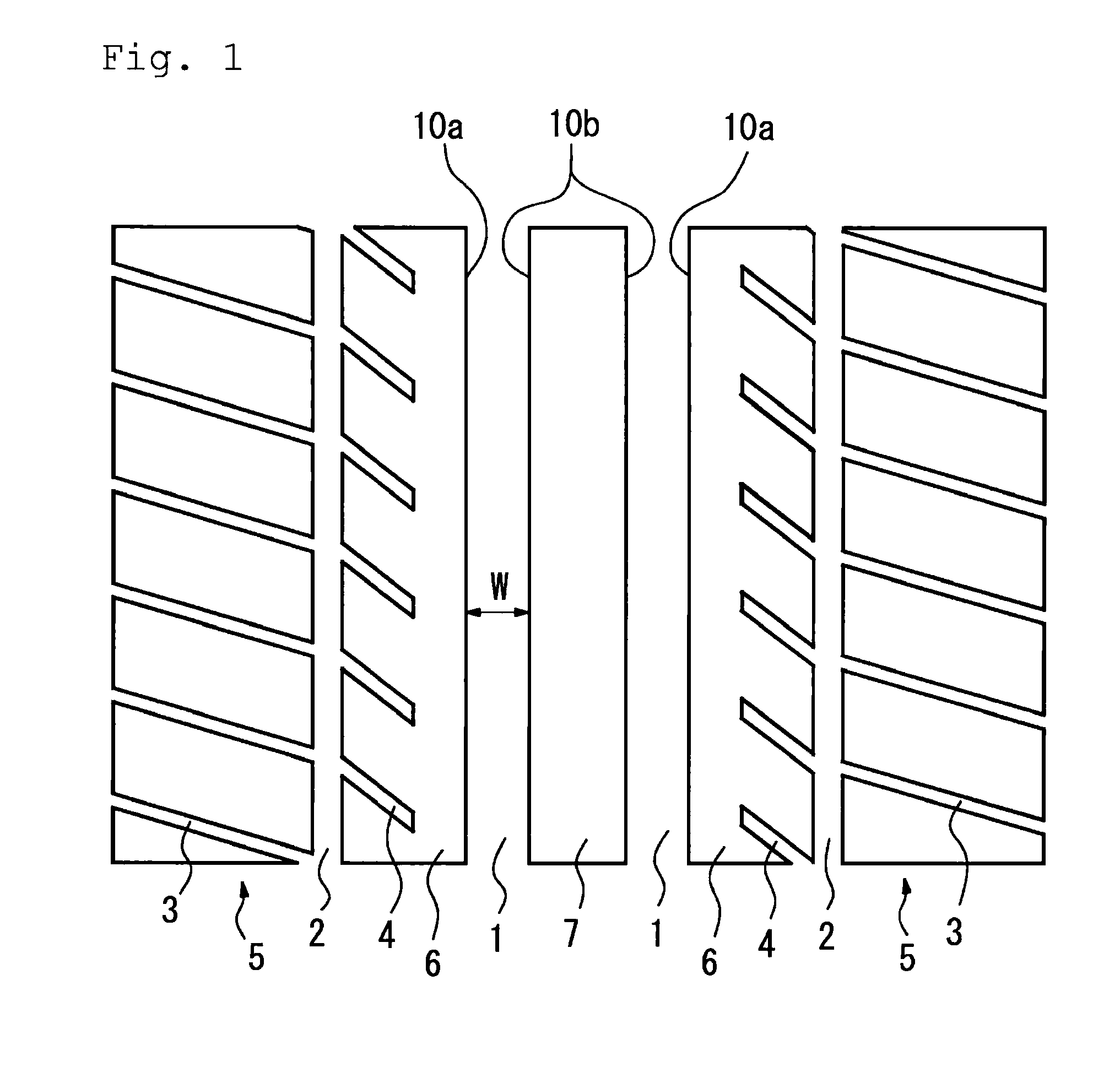

Pneumatic tire

ActiveUS20090165908A1Decrease effectSufficient productivityTyre tread bands/patternsNon-skid devicesResonatorEngineering

A pneumatic tire is provided which has sufficient total properties and mass productivity of a tire without reducing drainage capability due to narrowed circumferential grooves, achieves high design flexibility of tread patterns and stiffness of land portion as intended, and also effectively reduces undesired air column resonance noise produced by the circumferential grooves. The pneumatic tire includes a circumferential groove 3 which continuously and circumferentially extends in a straight line and arranged on a tread 1, and resonators 5 which are open to the circumferential groove 3 and terminate in a land portion 4, each of the resonators 5 being configured with an air chamber 6 open toward a land portion surface, and a narrowed neck 7 for communication between the air chamber 6 and the circumferential groove 3, and the narrowed neck 7 has the plane maximum width w0 which is within a range of from 3 to 50% of the plane maximum width w1 of the air chamber 6.

Owner:BRIDGESTONE CORP

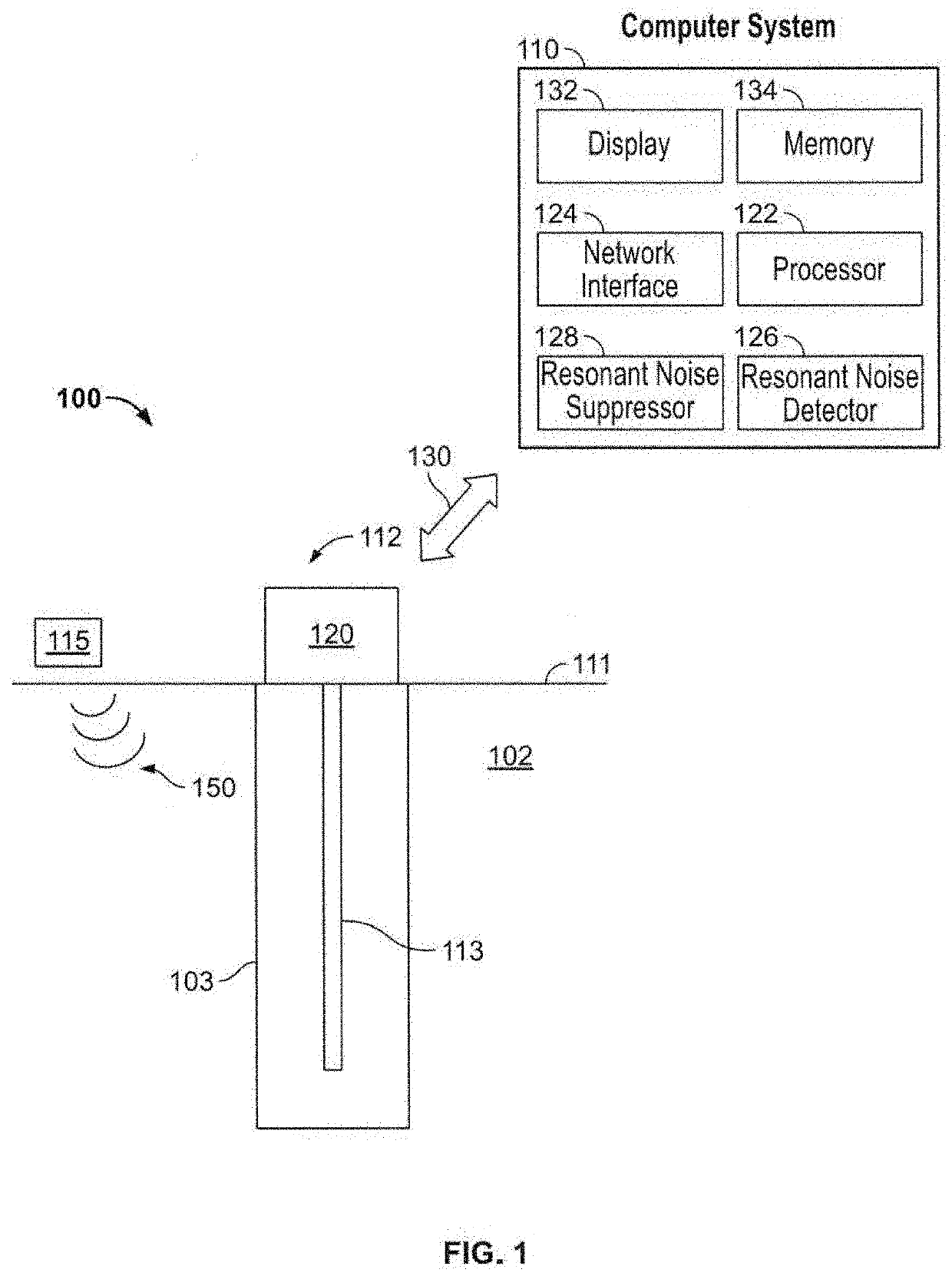

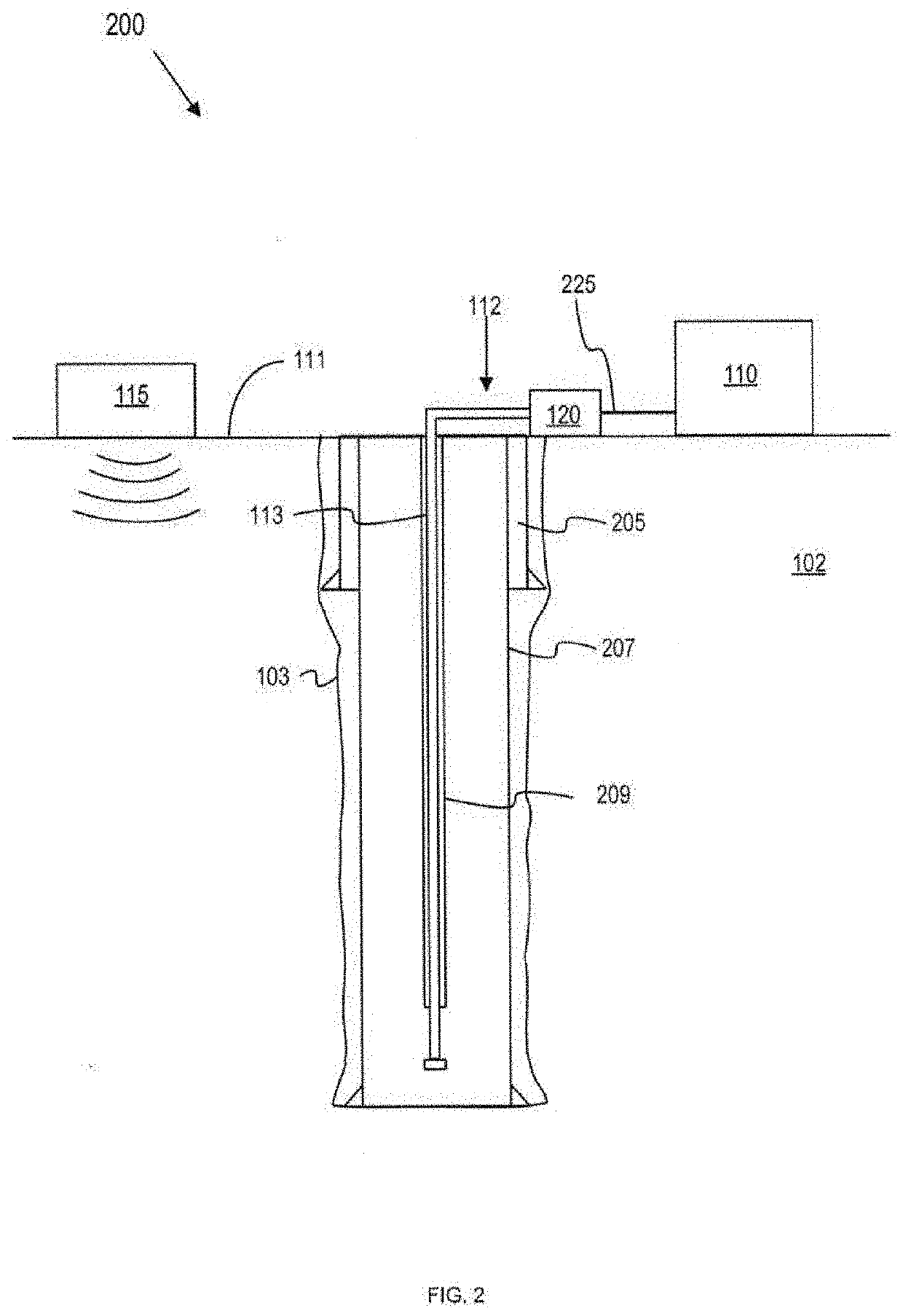

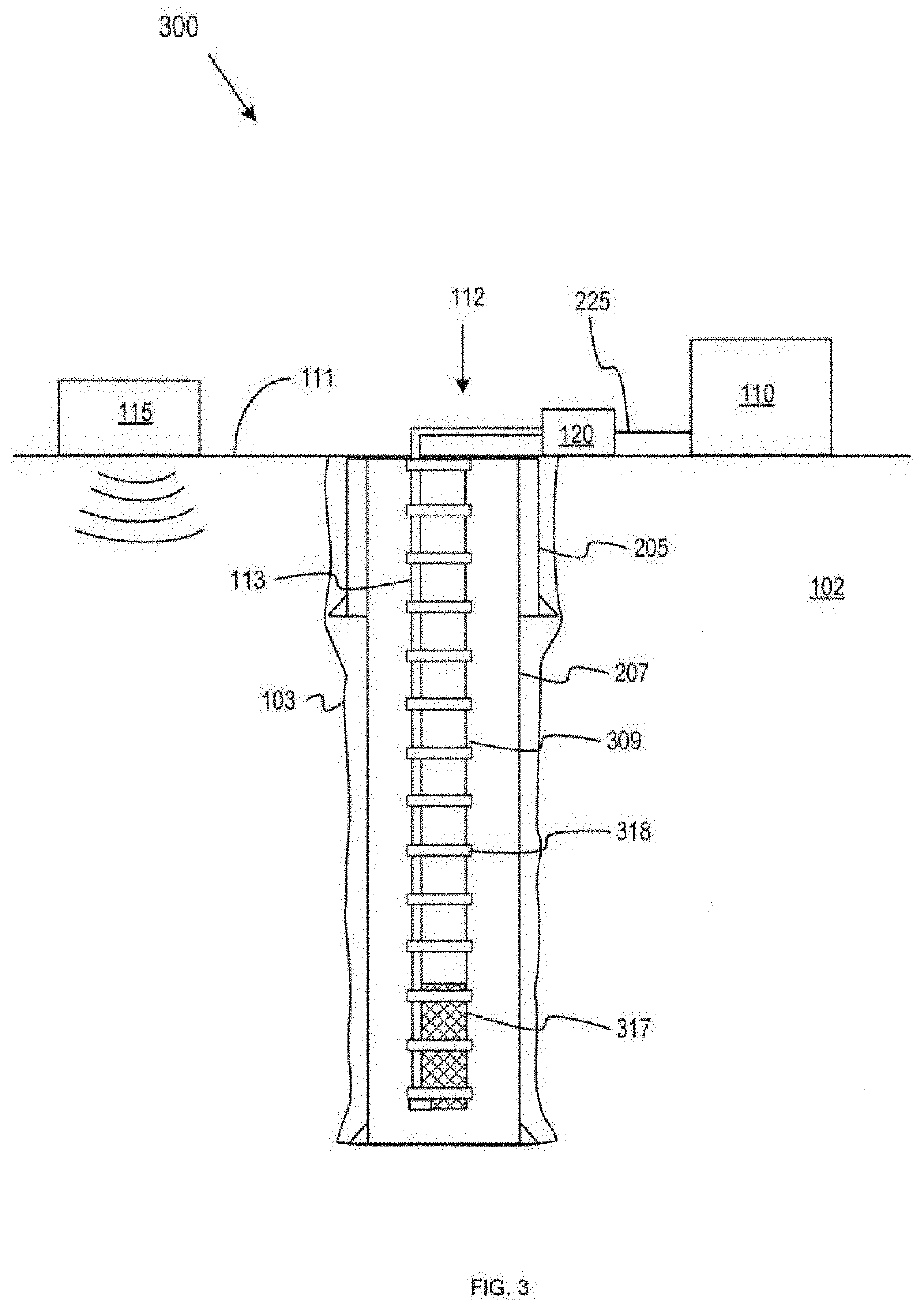

Reducing resonant noise in seismic data acquired using a distributed acoustic sensing system

ActiveUS20200102821A1Reduce resonance noiseSeismic signal processingSeismology for water-loggingDistributed acoustic sensingNoise

A distributed acoustic sensor is positioned within a wellbore of a geologic formation. Seismic waves are detected using the distributed acoustic sensor. A raw seismic profile is generated based on the detected seismic waves. Resonant noise is identified and reduced in seismic data associated with the raw seismic profile.

Owner:HALLIBURTON ENERGY SERVICES INC

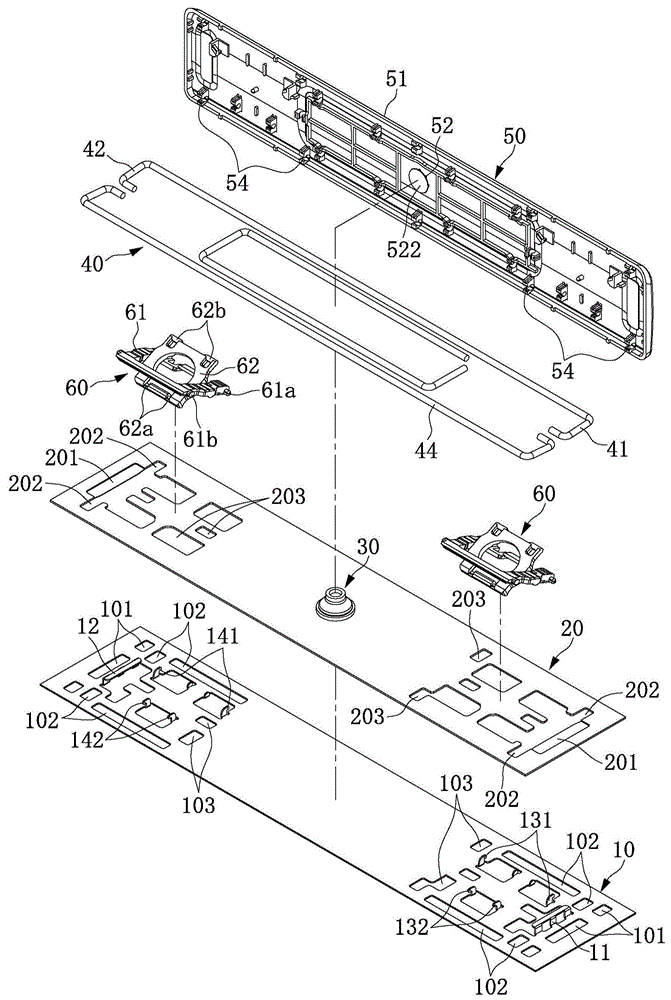

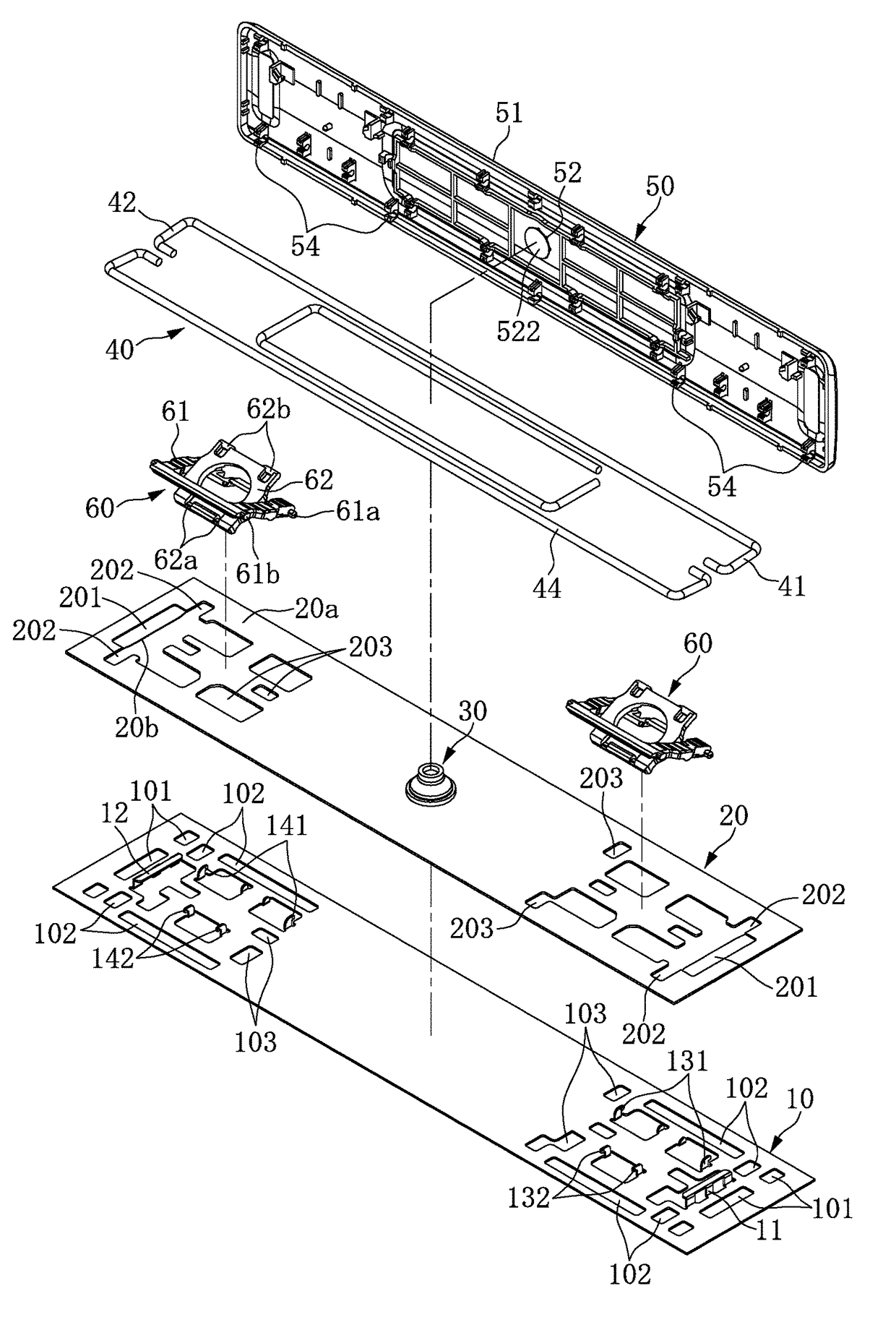

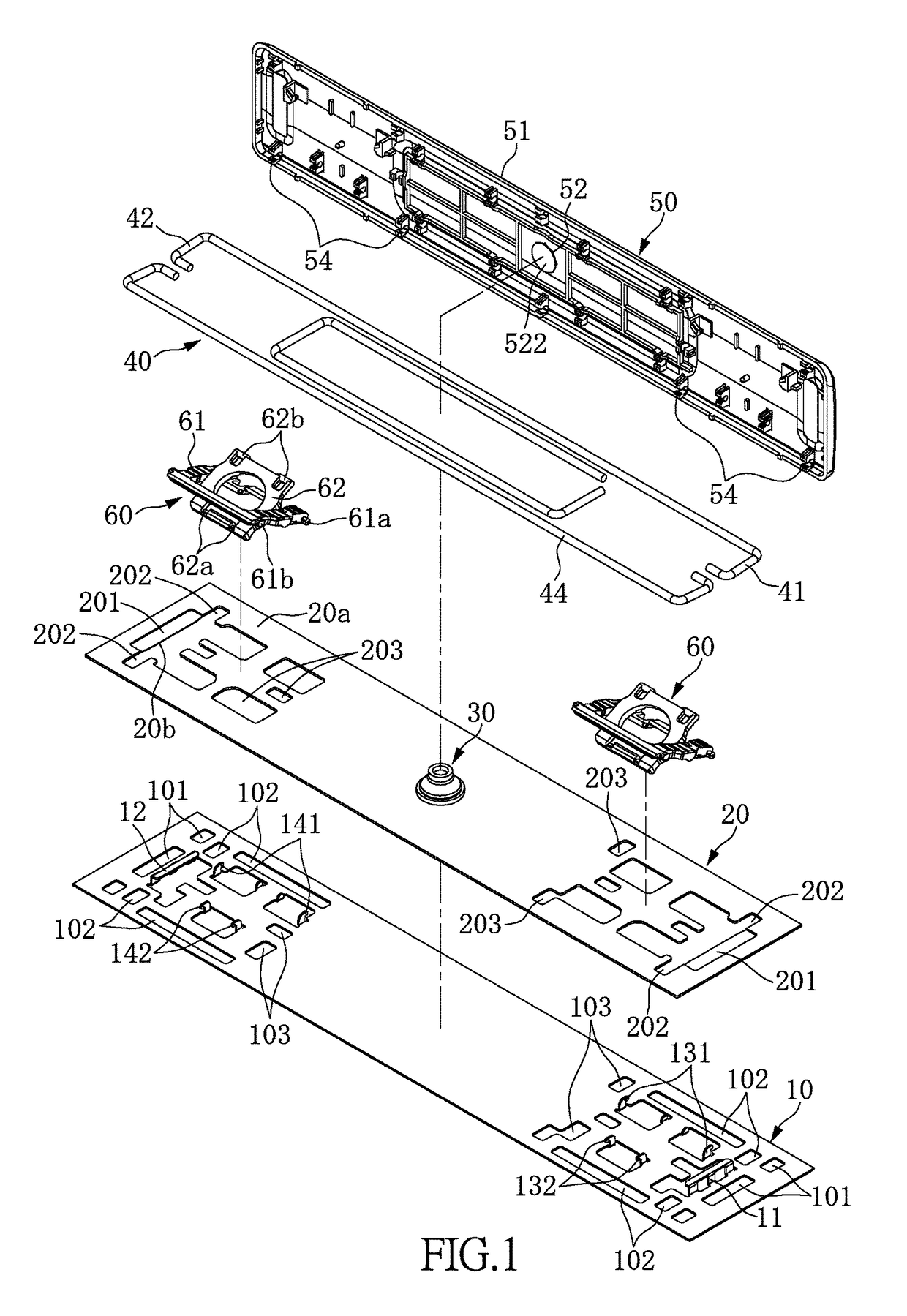

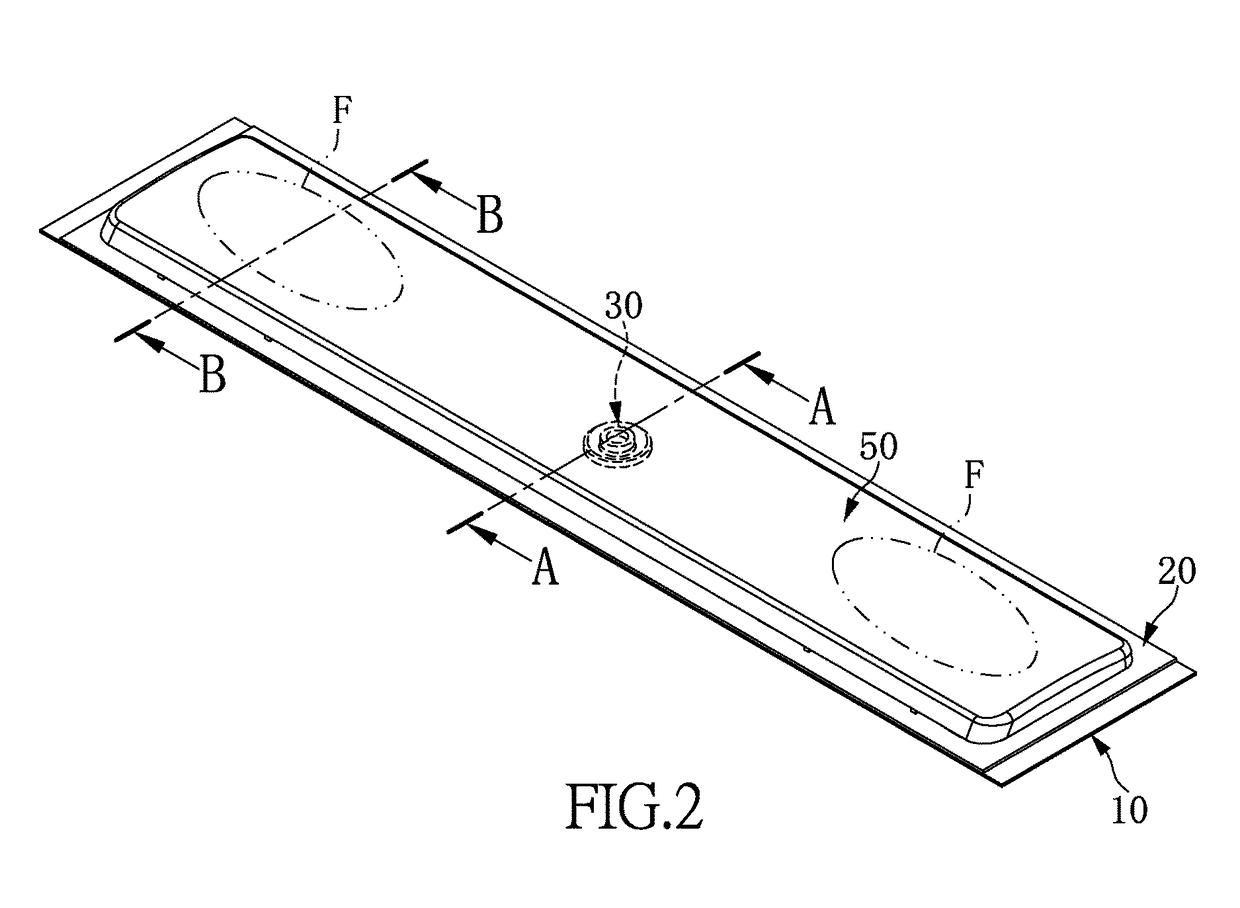

Key with reduced resonant noise

ActiveCN105719875AReduce resonance effectReduce noiseEmergency actuatorsContact mechanismsEngineeringElectrical and Electronics engineering

A key with reduced resonant noise includes a base plate formed with a first supporting portion and a second supporting portion, a conductive film layer, an elastic conducting element, a linking rod, and a keycap on the linking rod. The linking rod has a main portion, a first arm extended from one end of the main portion and pivotally connected to the first supporting portion, and a second arm extended from the other end of the main portion and pivotally connected to the second supporting portion. The key cap has a bottom surface pivotally connected to the main portion of the linking rod. The base plate has openings under the linking rod and adjacent to the first supporting portion and the second supporting portion. The openings are adjacent respectively to the two ends of the main portion and adjacent to the first arm and the second arm, thereby reducing resonant effect of clapping sound in the keycap, when the keycap is pressed.

Owner:LITE ON TECH CORP

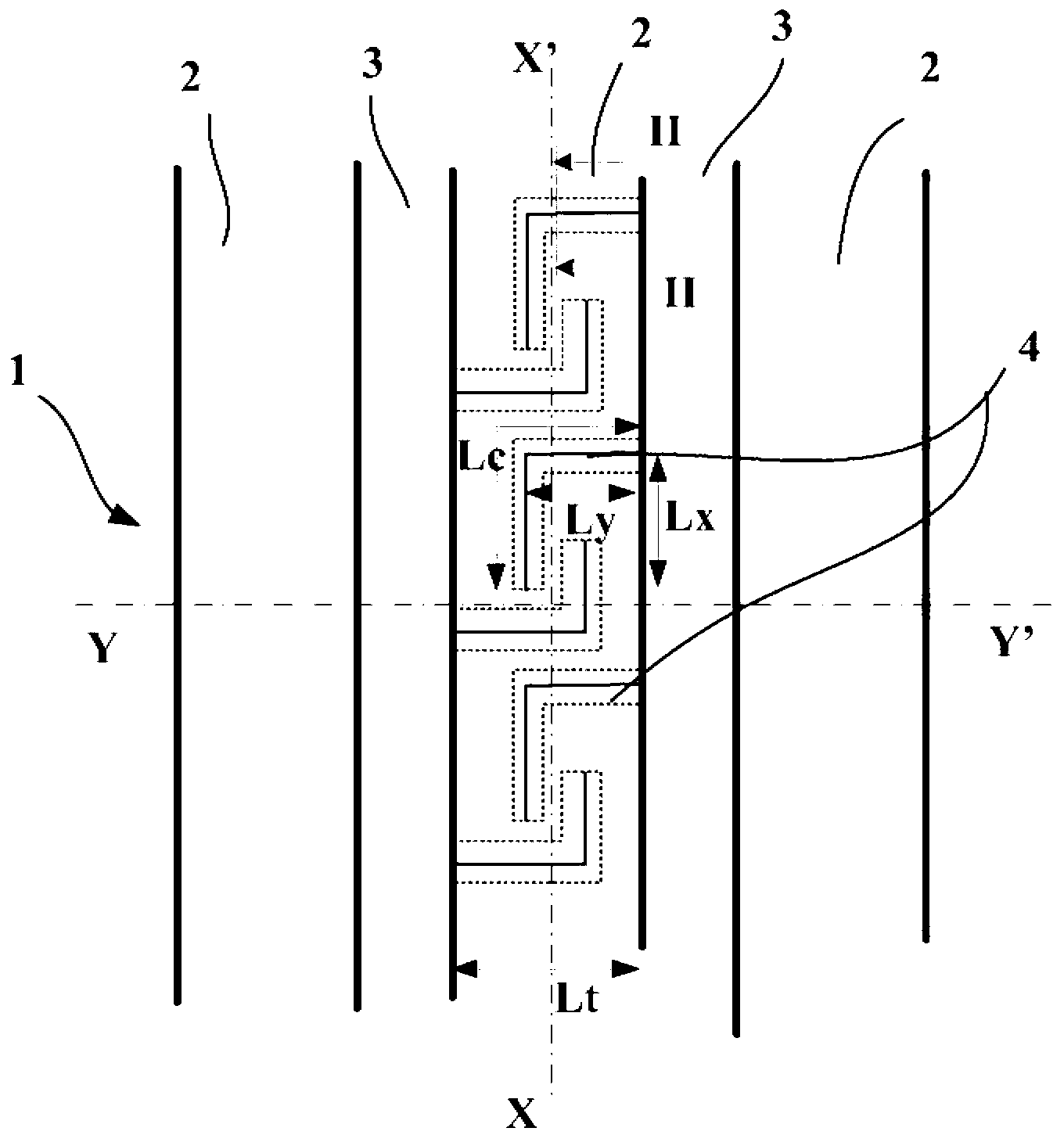

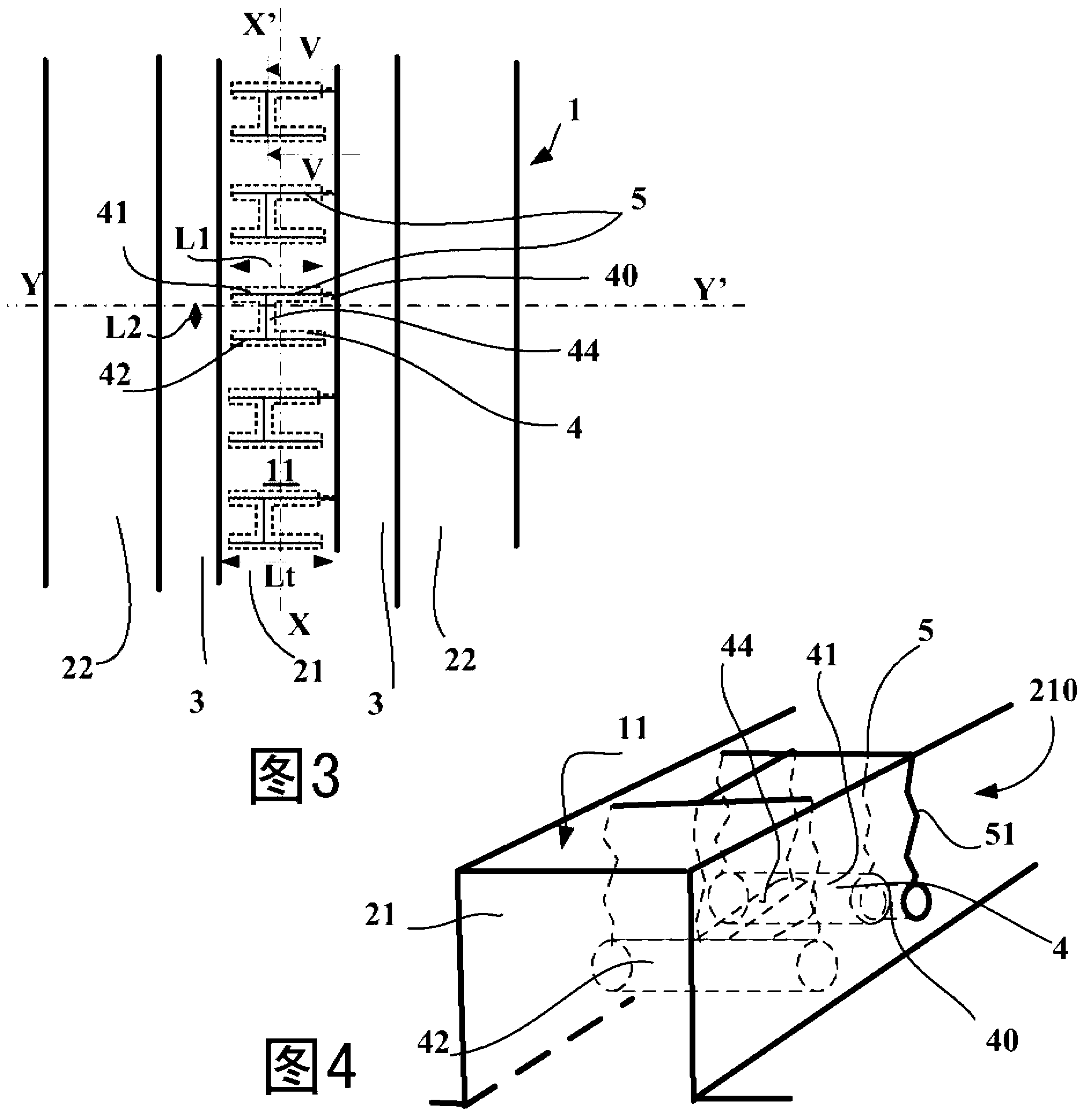

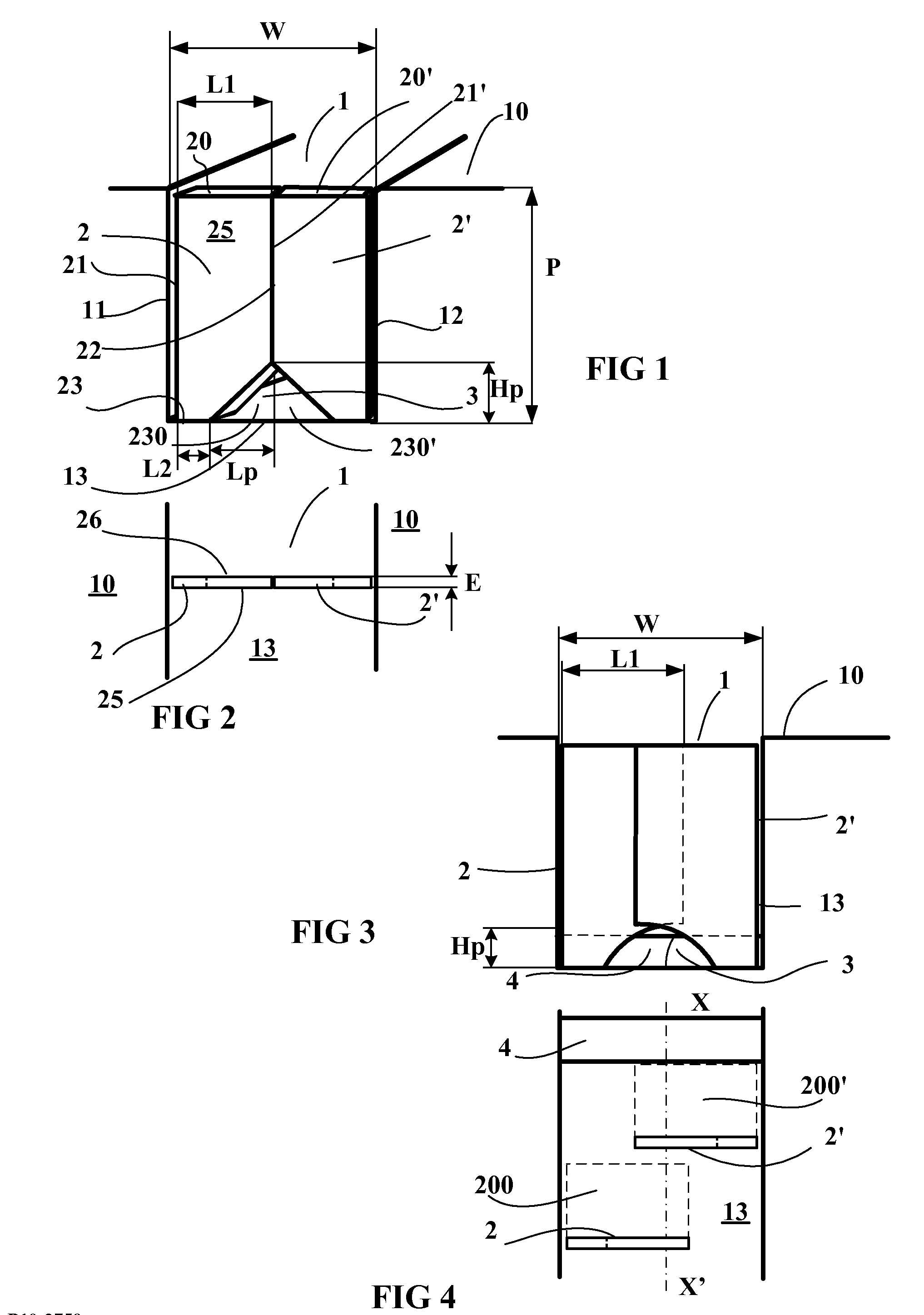

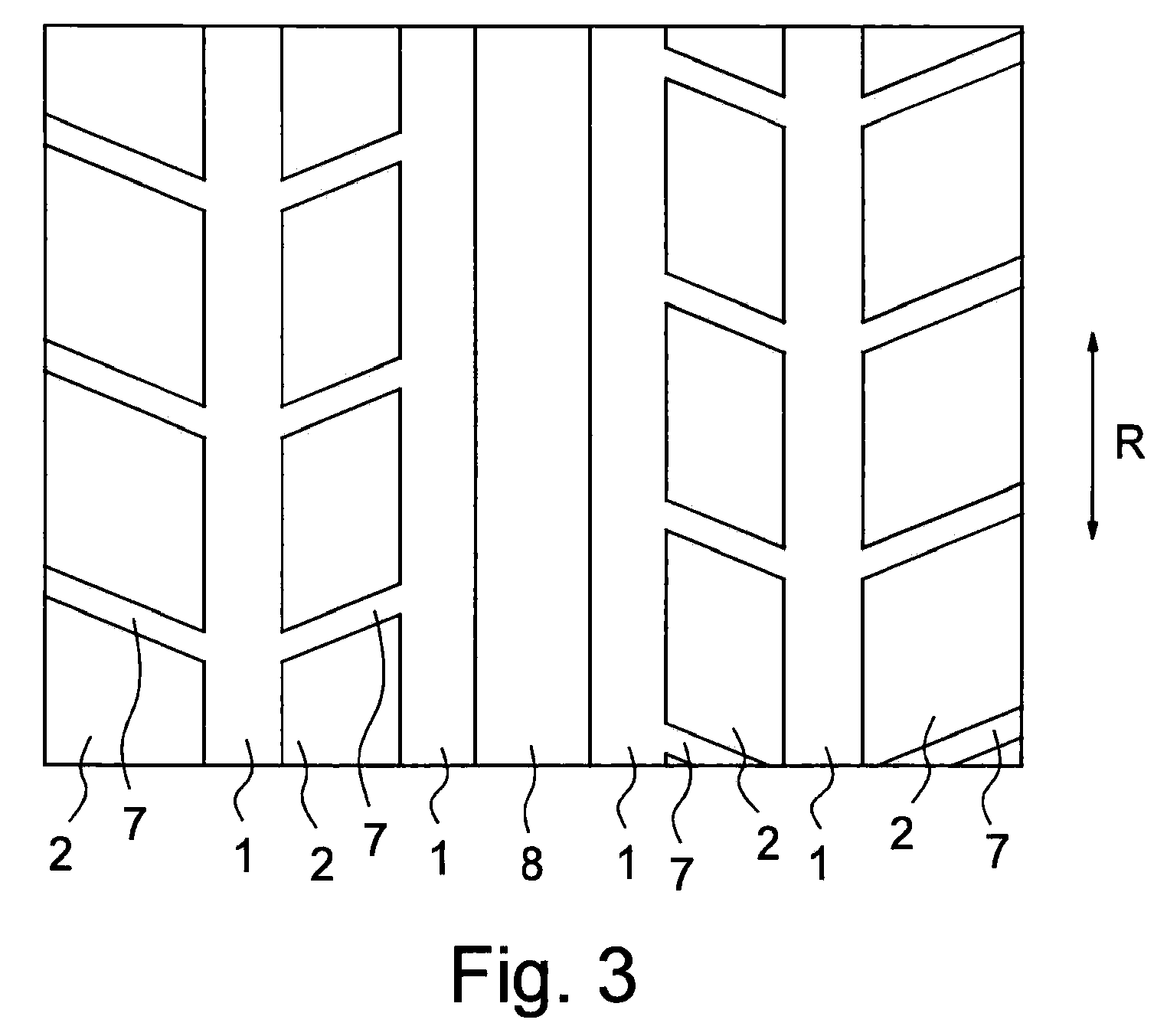

Improvement to noise attentuator devices for tyres

InactiveCN103153653AReduce resonance noiseSatisfied with balanceTyre tread bands/patternsWheelsEngineeringMechanical engineering

Tyre comprises a tread (1) having at least one generally circumferentially orientated groove (3) and a plurality of raised elements (21, 22), each of these raised elements comprising a contact face (11) of transverse width Lt and side walls (210), at least one raised element being provided with a plurality of resonant-noise attenuating devices, each device comprising a cavity (4) of elongate shape having a total volume Vc and opening onto a sidewall (210), this cavity (4) having a total length Lc which is greater than the transverse width Lt of the raised element and a geometry comprising several cavity parts (40, 41, 42, 43, 44, 45) joined together, the length Lc being equal to the sum of the lengths of all the cavity parts, each cavity (4) being extended over its entire length Lc by an incision (5) extending radially outwards to open onto the tread surface, this tread being such that the sum Ly of the lengths projected in the transverse direction, of each cavity is at least 1.5 times greater than the sum Lx of the lengths, projected in the circumferential direction, of each cavity.

Owner:OCIETE DE TECH MICHELIN +1

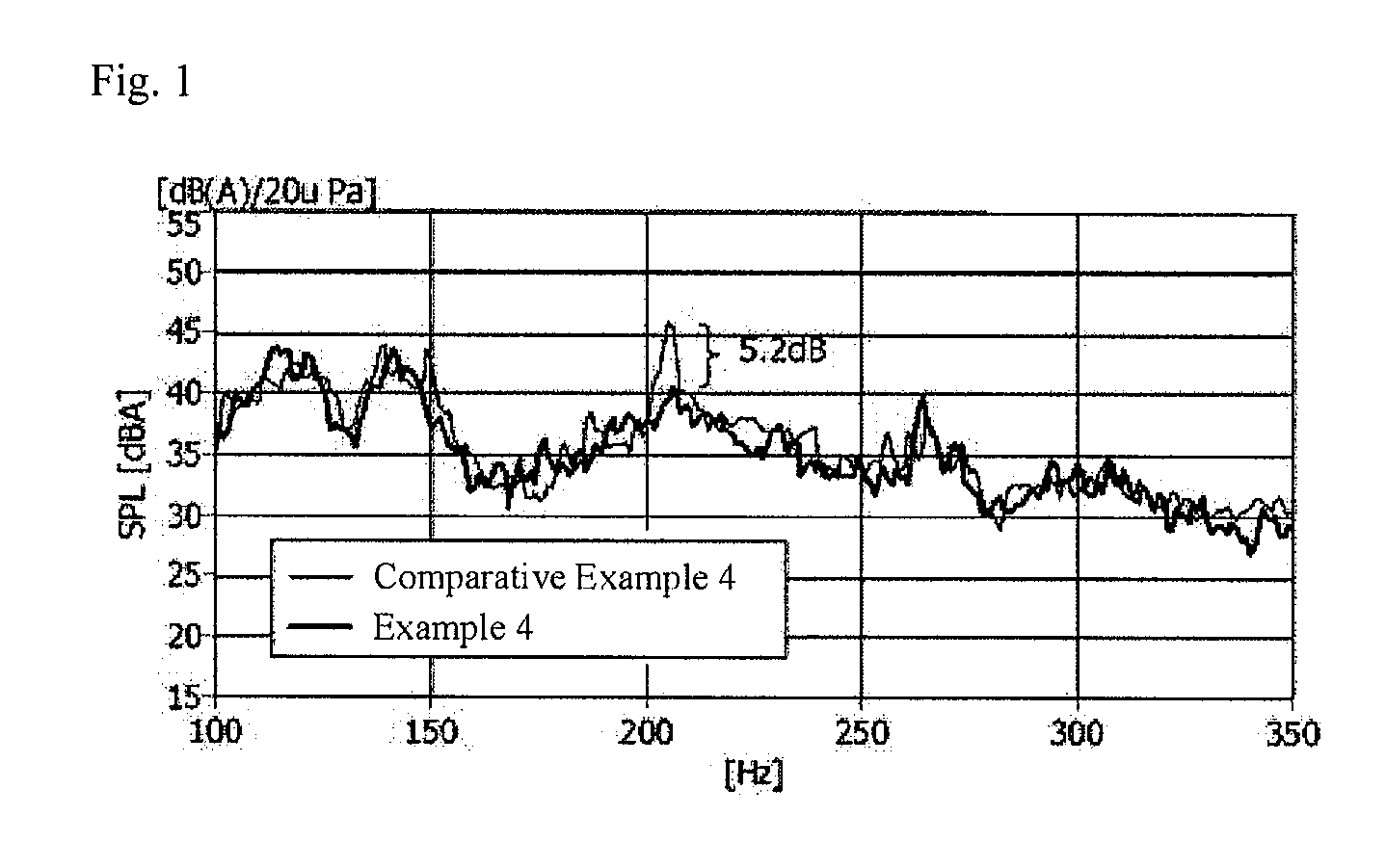

Polyurethane foam and pneumatic tire

A polyurethane foam which is obtained by a reaction between a diol component and a diisocyanate component, with the diol component being a mixture of a polyether-based diol and a polyester-based diol, and a pneumatic tire to which the polyurethane foam is applied are provided. When a soft polyurethane foam is produced using a mixture of a polyether-based diol and a polyester-based diol as the diol component, and by varying the content of the expanding agent during the production process, and when the polyurethane foam is disposed in the cavity of a pneumatic tire, the polyurethane foam thus produced has an effect of reducing the resonance noise generated in the cavity of the tire and improving durability of the tire.

Owner:HANKOOK TIRE WORLDWIDE

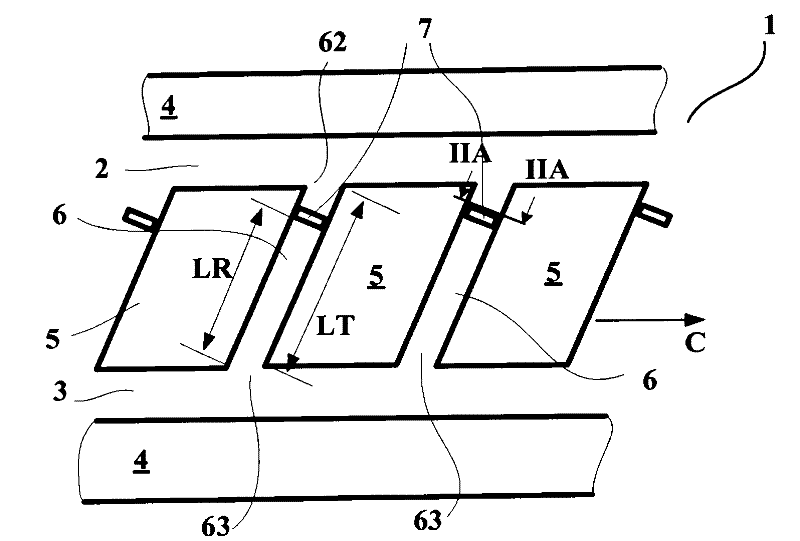

Sound suppressing device for tire tread

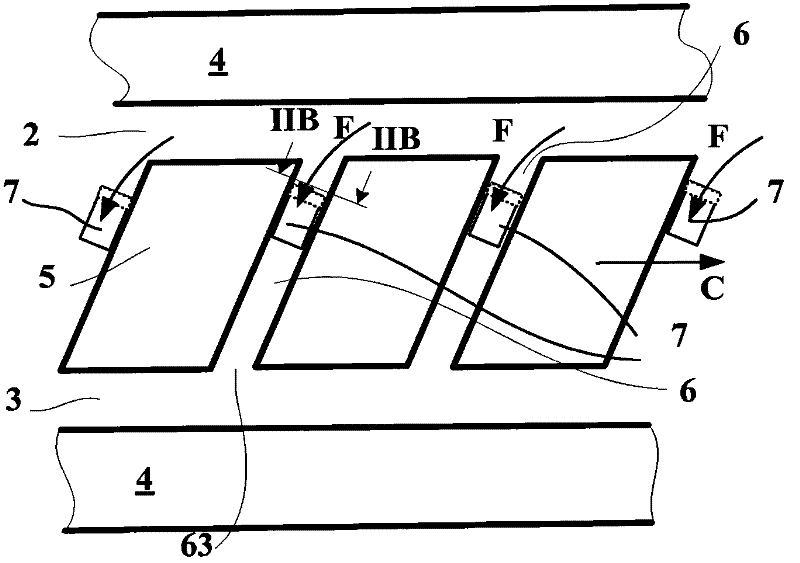

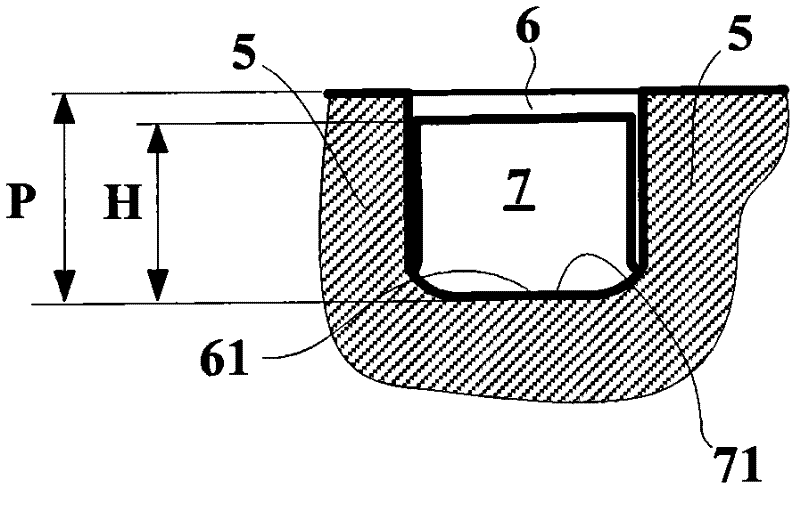

ActiveCN102227326AReduce resonance noiseOccupy the preferredTyre tread bands/patternsNominal conditionEngineering

The present invention relates to a tire having a tire tread (1) that includes: at least two grooves (2, 3) in a general circumferential direction; a plurality of transverse grooves (6), each transverse groove leading into two circumferential grooves via openings (62, 63), the circumferential and transverse grooves having transverse sections suitable for enabling liquid on the road to flow while the wheels are turning; and a plurality of closing devices (7) located in said grooves, each closing device at least partially closing the transverse section of a groove, each closing device (7) defining, with the end (62, 63) of the transverse groove end (6), a groove length LR from one half to three quarters of the length of an in contact circumferential groove and measured under nominal conditions for load and pressure. Said tire is characterized in that each closing device (7) is designed to bend and open the groove section in which the device is placed, being moved by a liquid flow so as to enable the flow of said liquid when the wheels are turning on a road covered with water.

Owner:OCIETE DE TECH MICHELIN

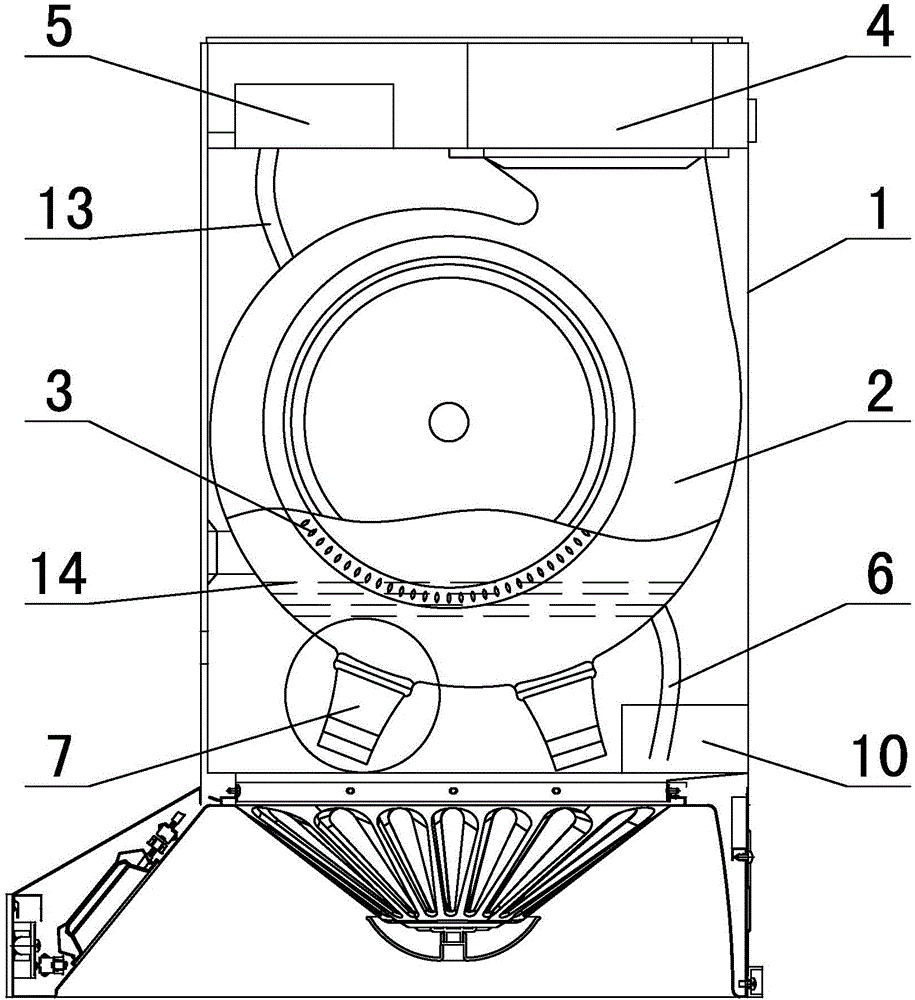

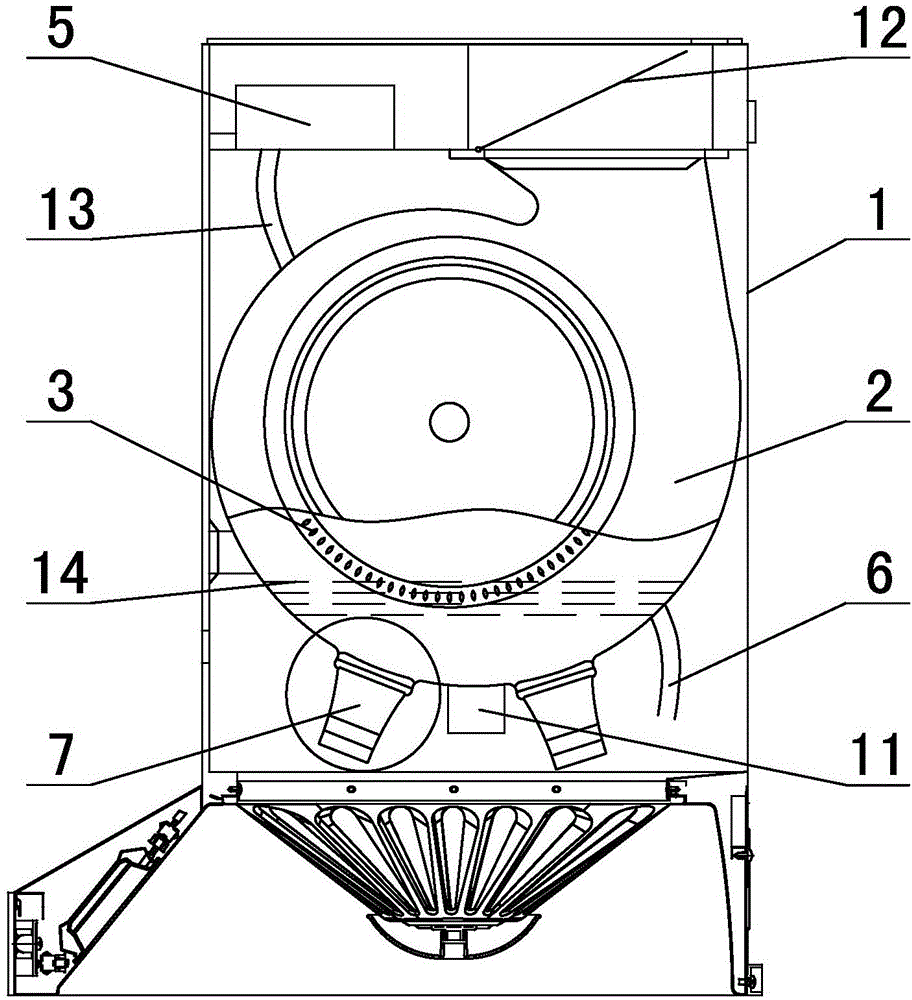

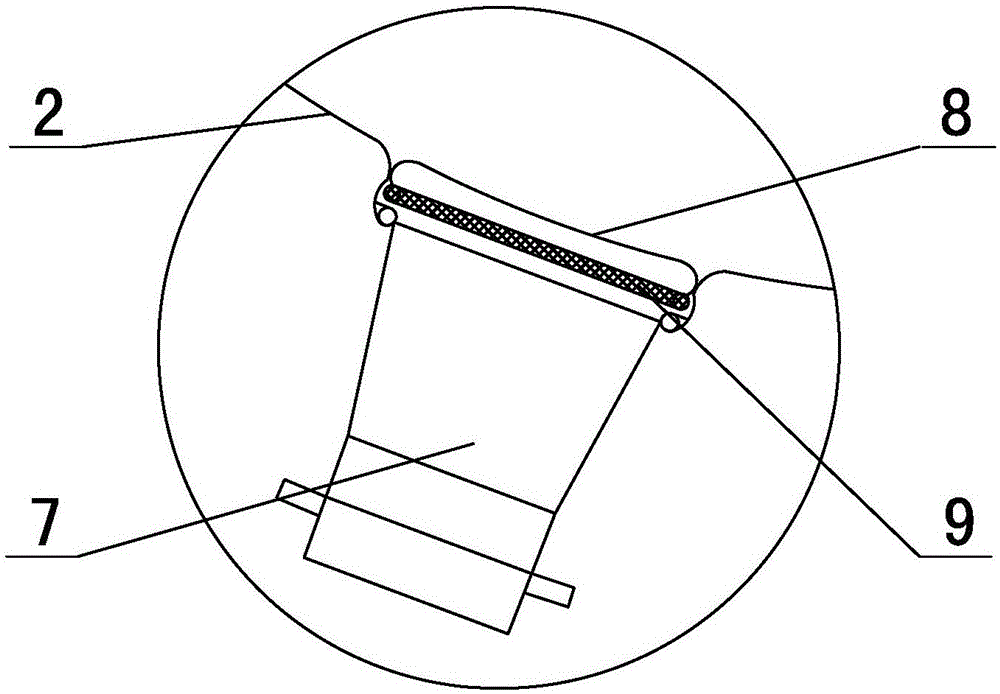

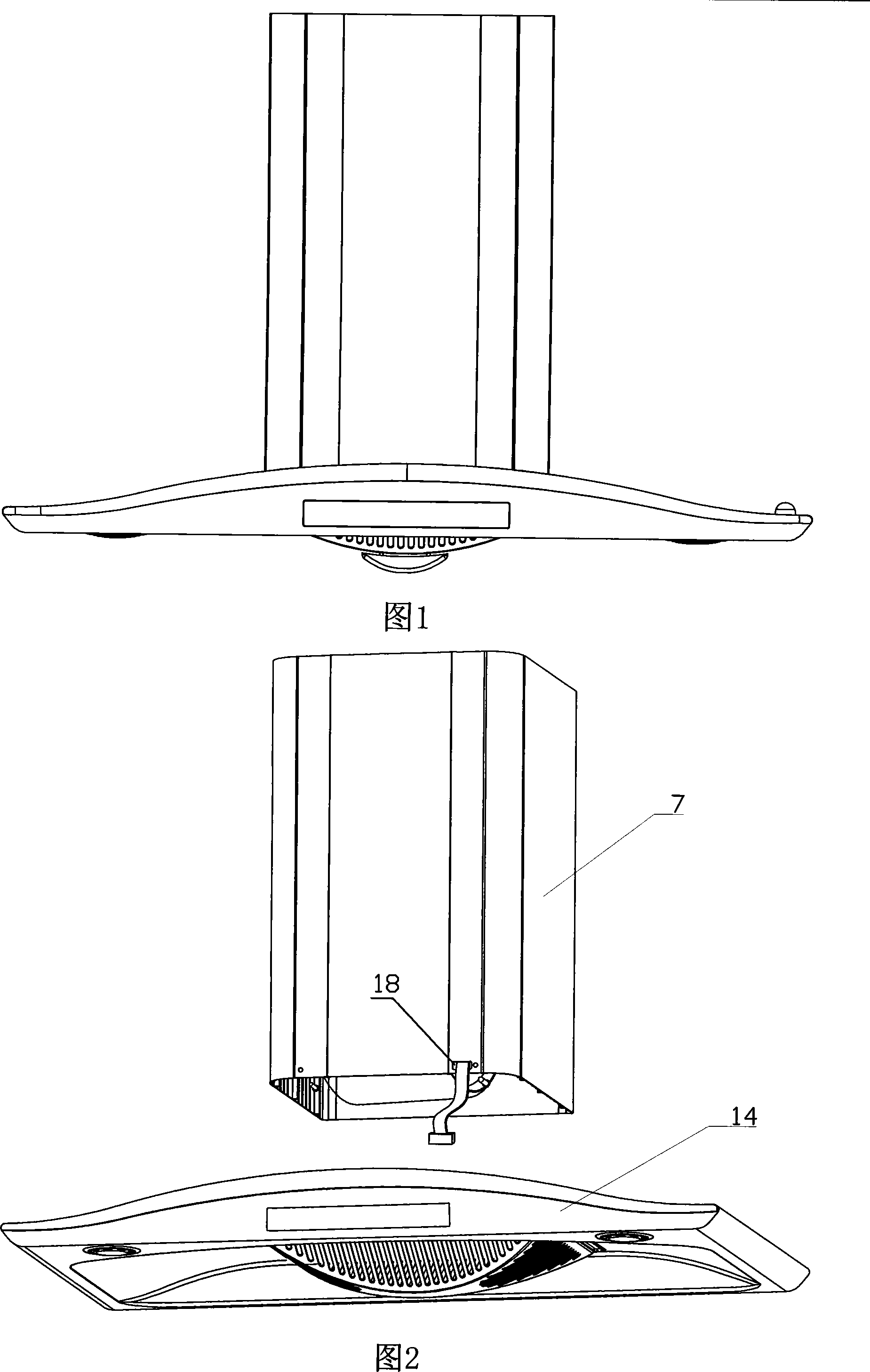

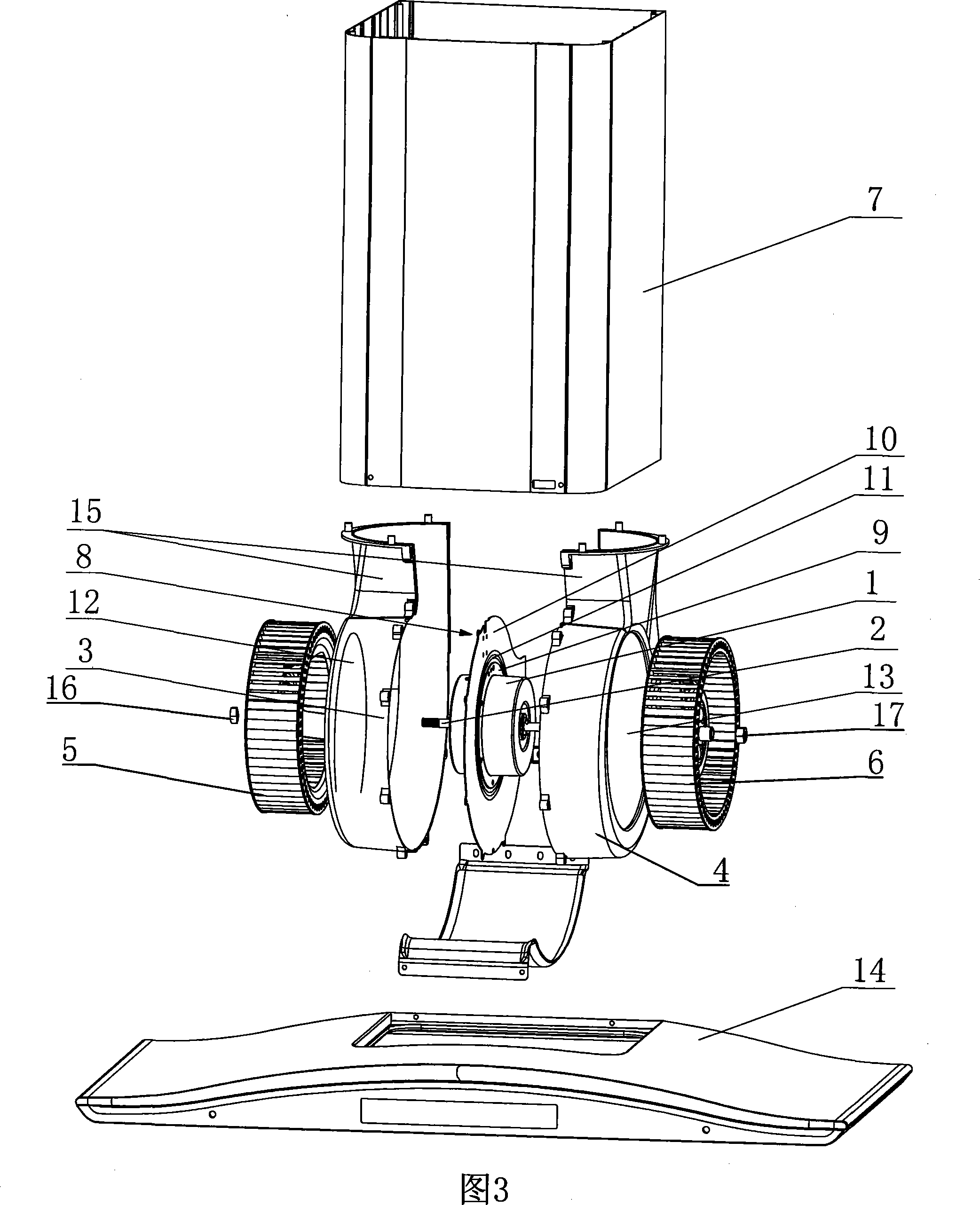

Cooker hood

InactiveCN101201187APackage structure is simpleReduced packaging volumeDomestic stoves or rangesLighting and heating apparatusEngineeringJoint surface

The invention provides a double-wind wheel ventilator which comprises a lower body and an upper body. The upper body is provided with an electric motor as well as a rotor shaft, a left spiral case, a right spiral case, a left wind wheel and a right wind wheel arranged on the electric motor. A shockproof fixing ring is arranged between the electric motor and the spiral cases. The shockproof fixing ring consists of an inner ring, an outer ring and a shockproof elastic ring. The shockproof elastic ring is arranged between the inner ring and the outer ring. The electric motor is fixedly arranged on the inner ring end surface of the shockproof elastic ring. The rotor shaft of the electric motor extends out to the two side of the electric motor. The left end and the right end of the rotor shaft are fixedly provided with the left wind wheel and the right wind wheel correspondingly. The joint surface of the left spiral case and the right spiral case and the outer ring in the shockproof fixing ring are movably connected. The left spiral case and the right spiral case are respectively provided with a suction opening corresponding to the left wind wheel and the right wind wheel. After adopting the scheme, the invention can reach the advantages of increasing the air suction and exhaust amount, reducing the noise and being easy to disassemble and wash.

Owner:苏润本

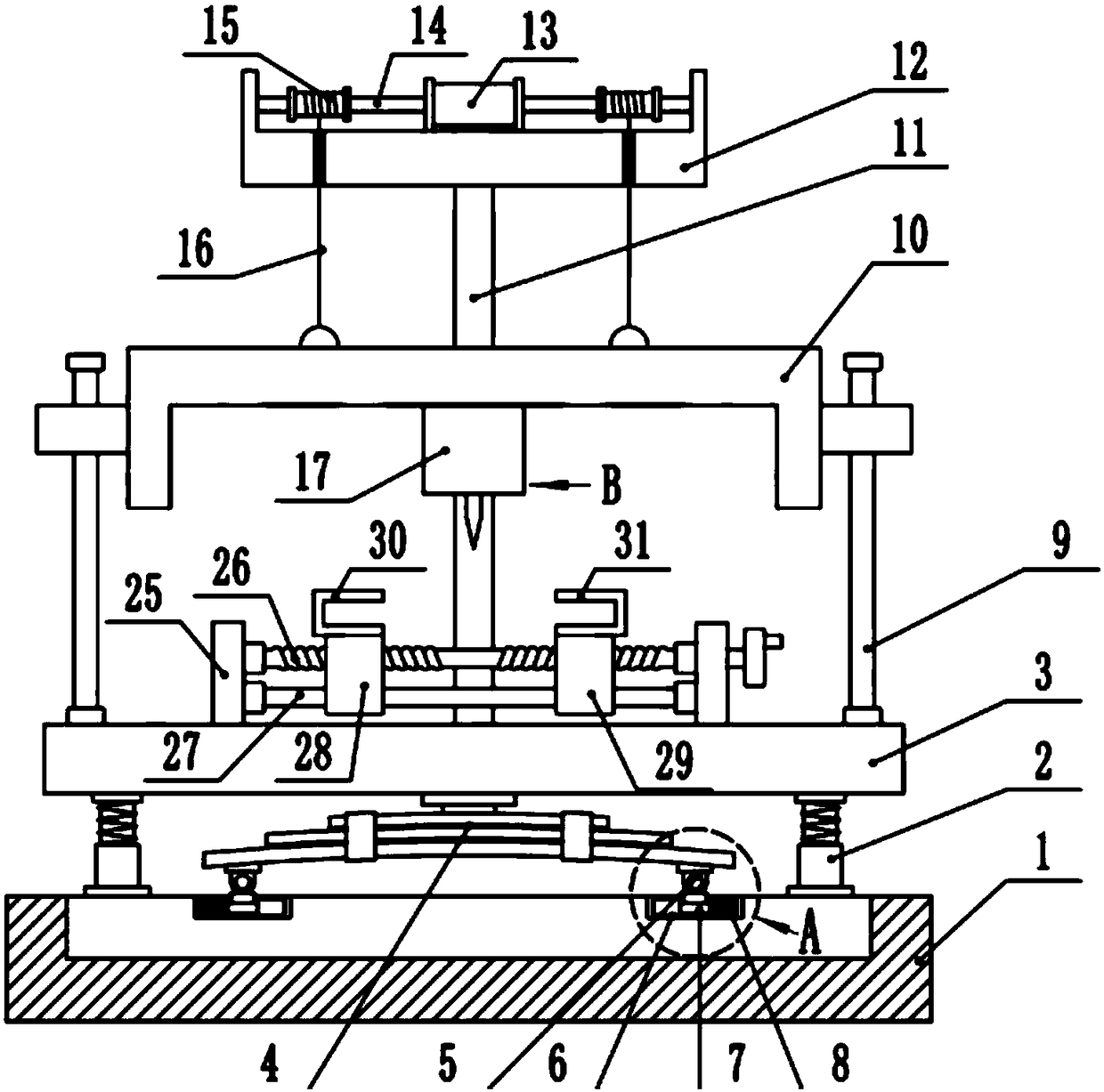

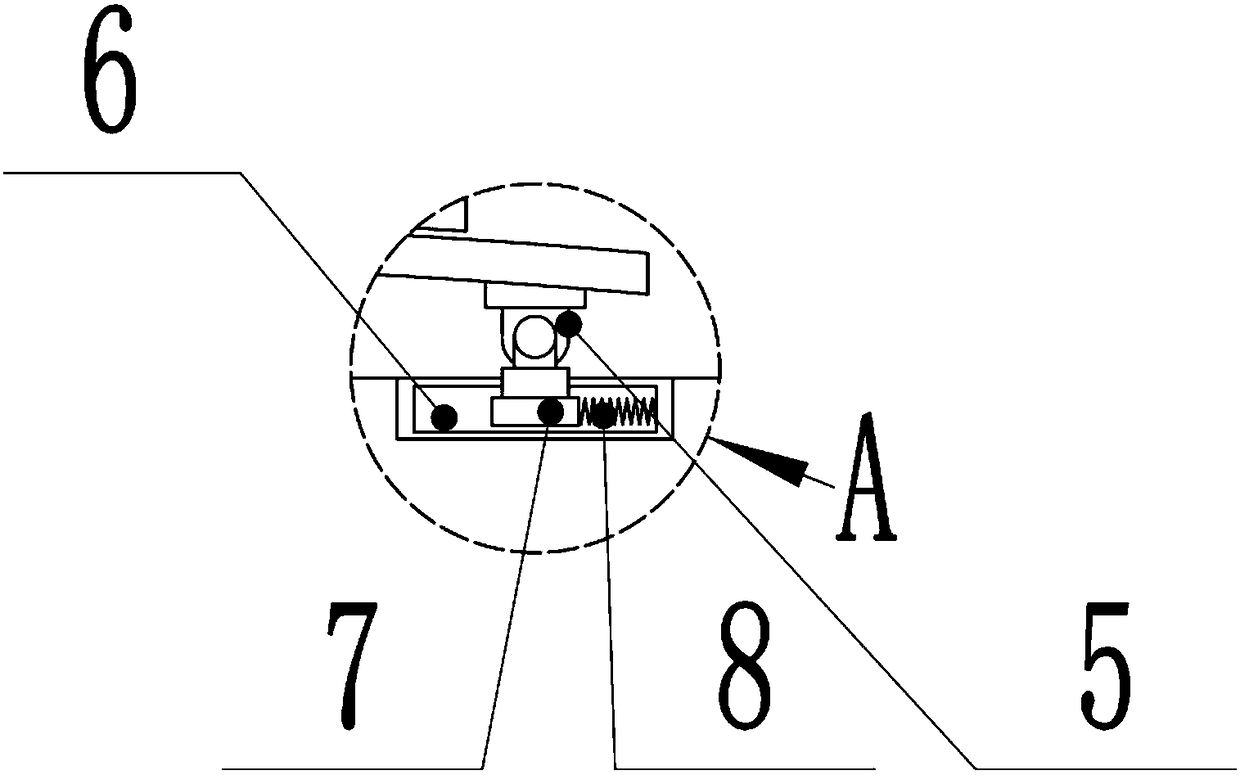

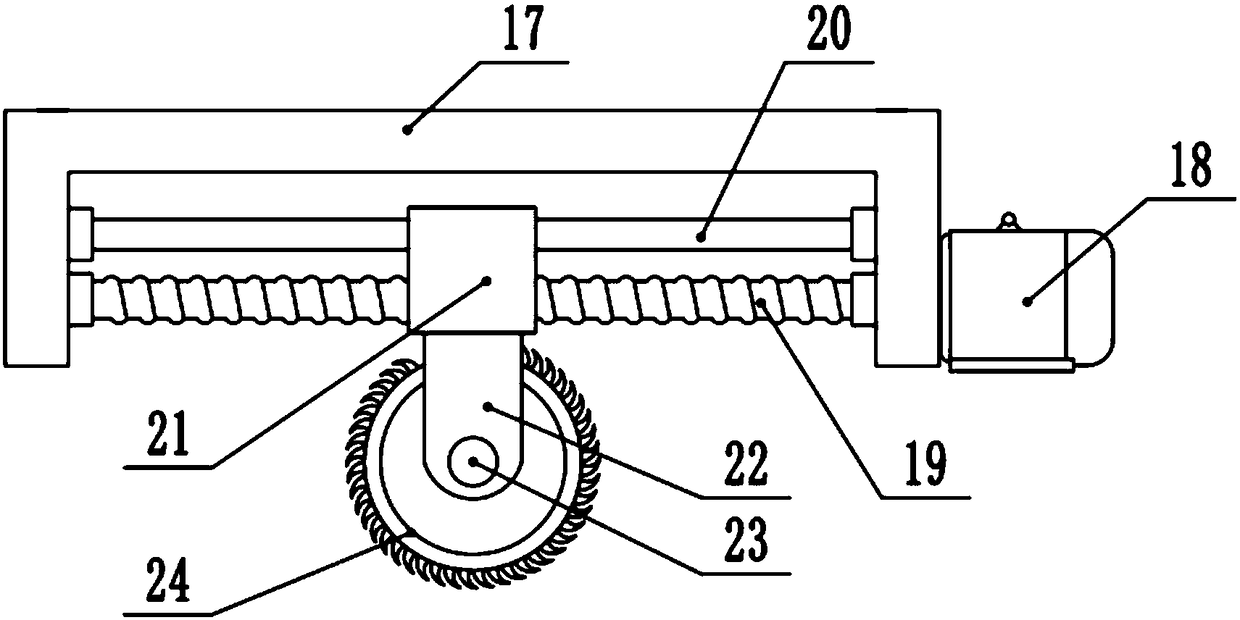

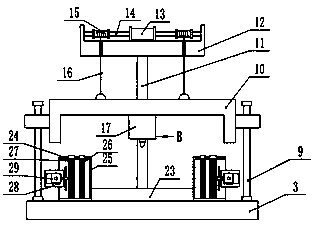

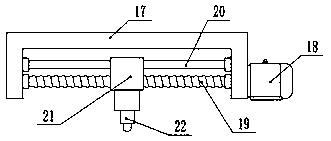

Bathroom anti-skid ceramic tile equally-dividing cutting device

InactiveCN108481584ASatisfy clamping and cutting workImprove versatilityNon-rotating vibration suppressionWorking accessoriesInterference fitCoupling

The invention discloses a bathroom anti-skid ceramic tile equally-dividing cutting device, comprising a base, a dual-axle motor, a cutting wheel, a left clamping jaw and a right clamping jaw. Connecting shafts are connected to output shafts on both ends of the dual-axle motor through shaft couplings. A wire winding wheel is fixedly mounted on each connecting shaft. The wire winding wheels are wound with pull wires. A lifting plate is connected with the other ends of the pull wires. A first screw rod is provided with a threaded sliding block in a threaded mode. The threaded sliding block is further arranged on the first screw rod in a sliding mode. A motor frame is fixedly arranged on the lower side of the threaded sliding block through bolts. A cutting motor is fixedly arranged on the rearside of the motor frame. An output shaft of the cutting motor is provided with the cutting wheel in an interference fit mode. Moving up and down of the lifting plate is realized, so that the cuttingwheel on the cutting motor is driven indirectly to go down and anti-skid ceramic tiles are subjected to equally-dividing cutting, and equally-dividing cutting of the anti-skid ceramic tiles with different thicknesses is achieved.

Owner:杨美龄

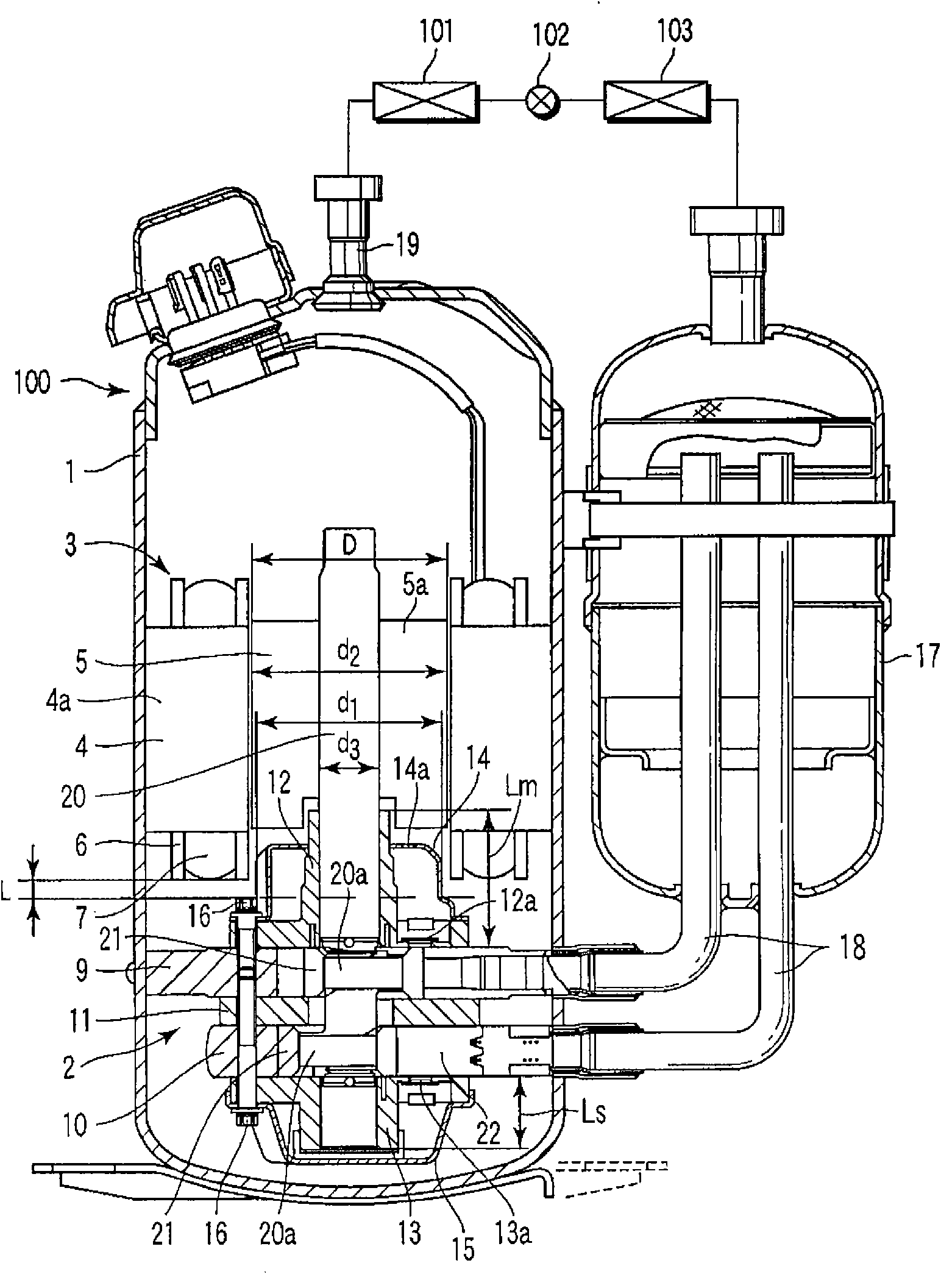

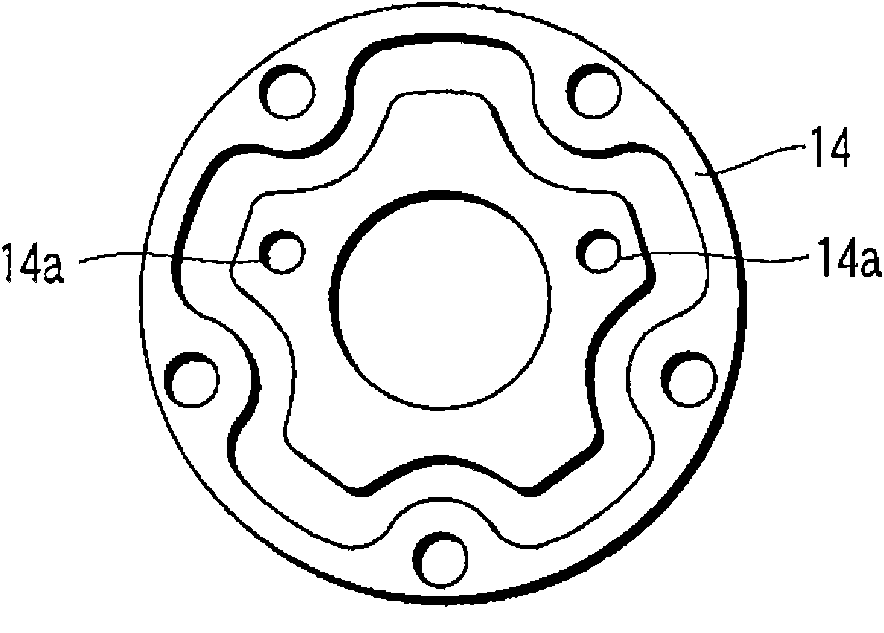

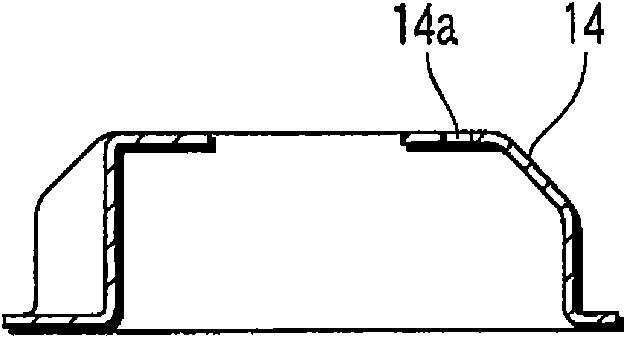

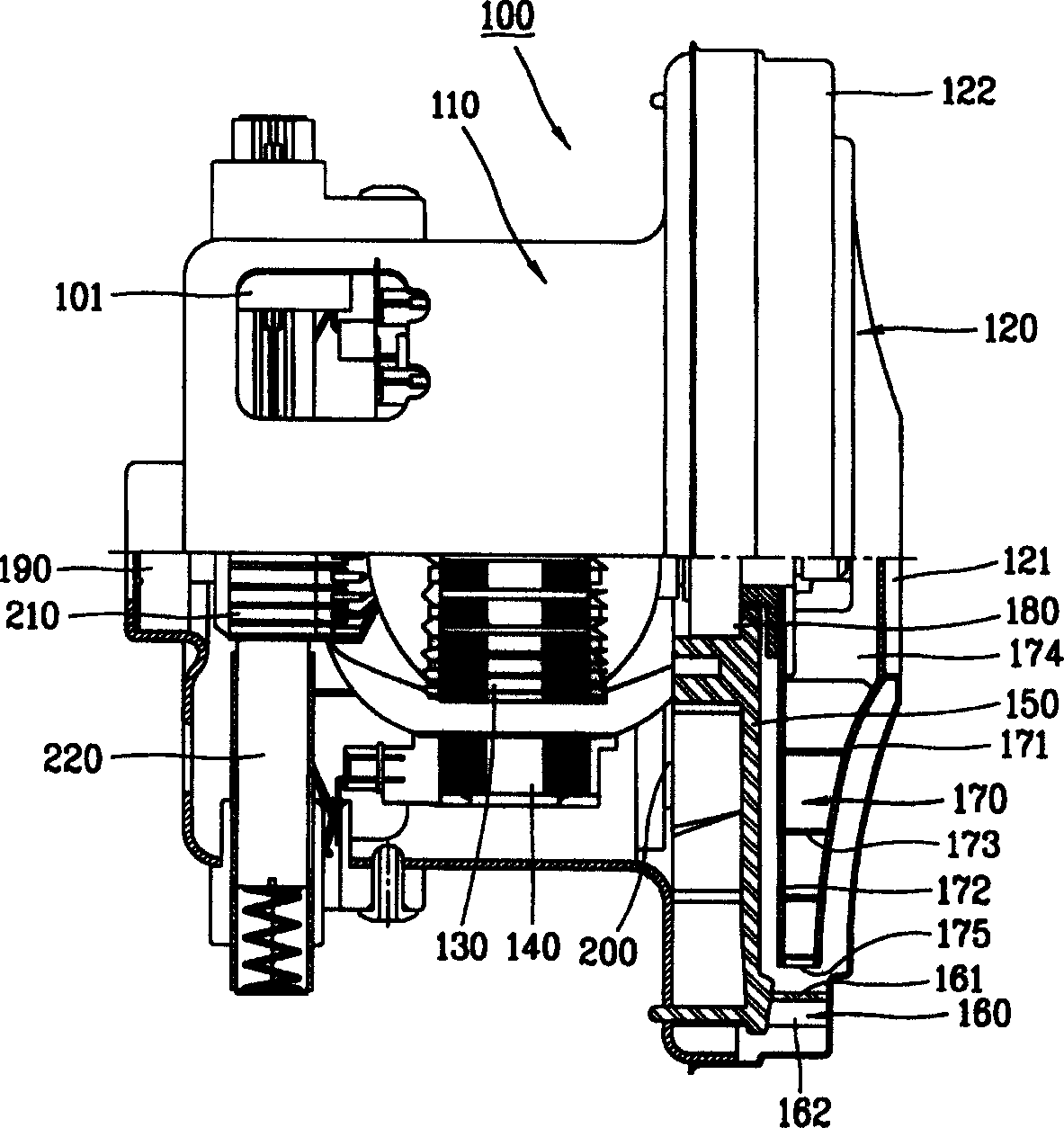

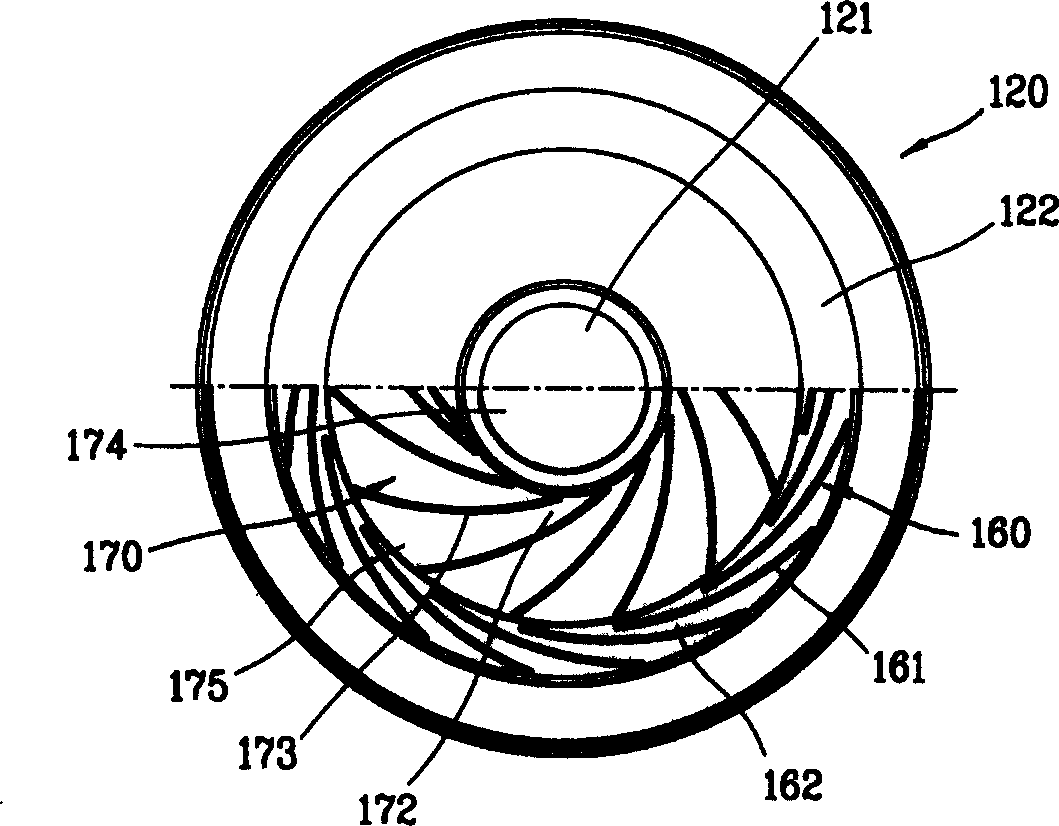

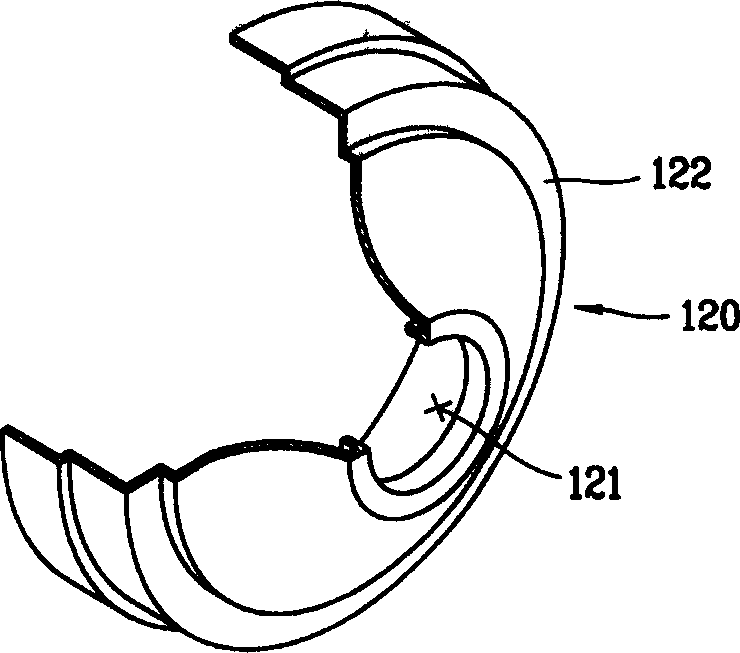

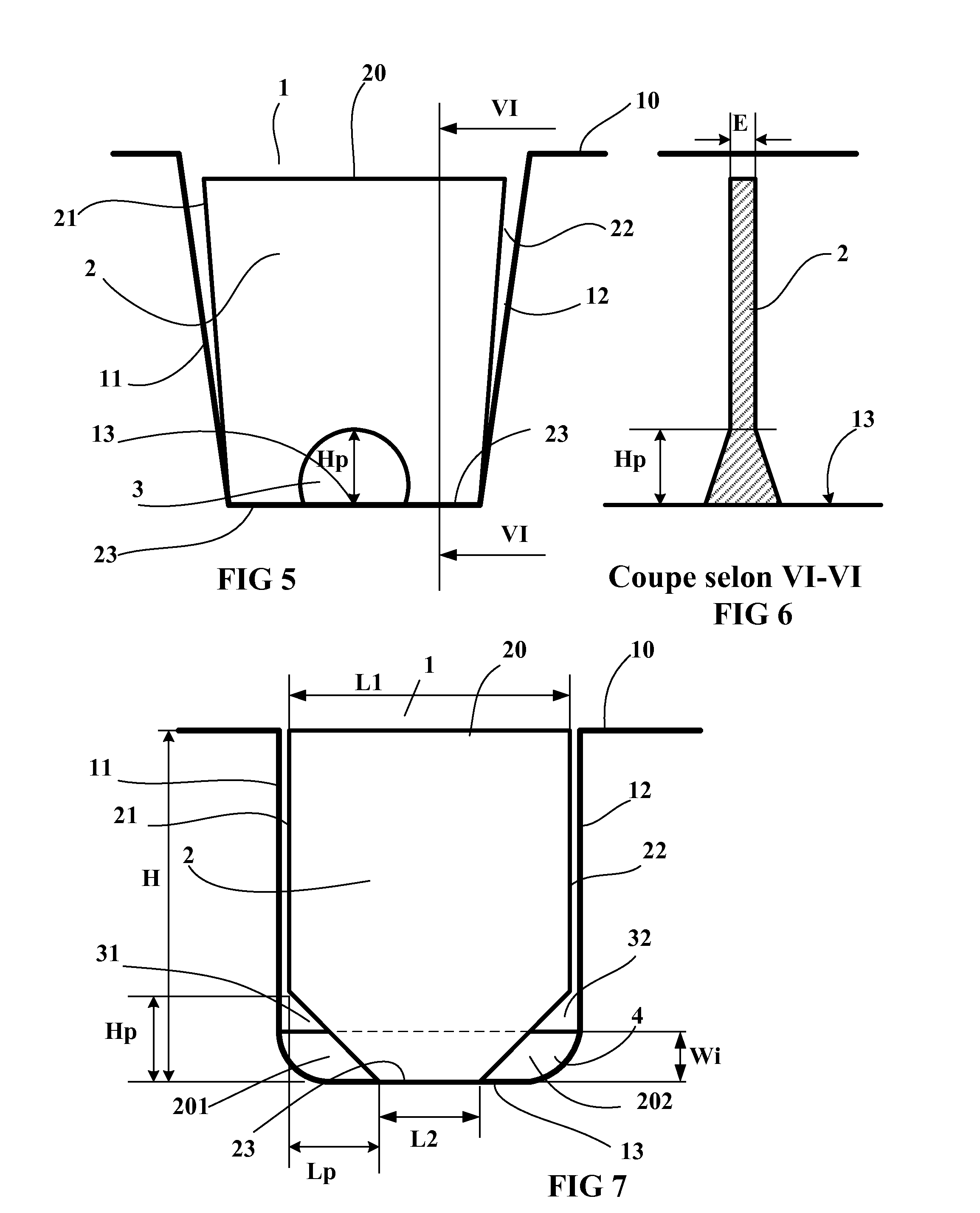

Rotary compressor and refrigeration cycle device

InactiveCN101529098AReduce electromagnetic noiseReduce resonance noiseRotary/oscillating piston combinations for elastic fluidsRotary piston pumpsEngineeringRefrigeration

A rotary compressor is provided with a hermetic case (1); a motor section (3) arranged in the hermetic case (1); a compression mechanism section (2) driven by the motor section (3) through a main shaft (20) to eject a compressed gas from an ejection valve (12a) facing the motor section (3); and an upper valve cover (14) fixed to the compression mechanism section (2) with a bolt (16) to cover the ejection valve (12a). The motor section (3) and the compression mechanism section (2) are arranged to face each other with an interval of 2-8mm between the motor section (3) and the bolt (16) of the upper valve cover (14).

Owner:TOSHIBA CARRIER CORP

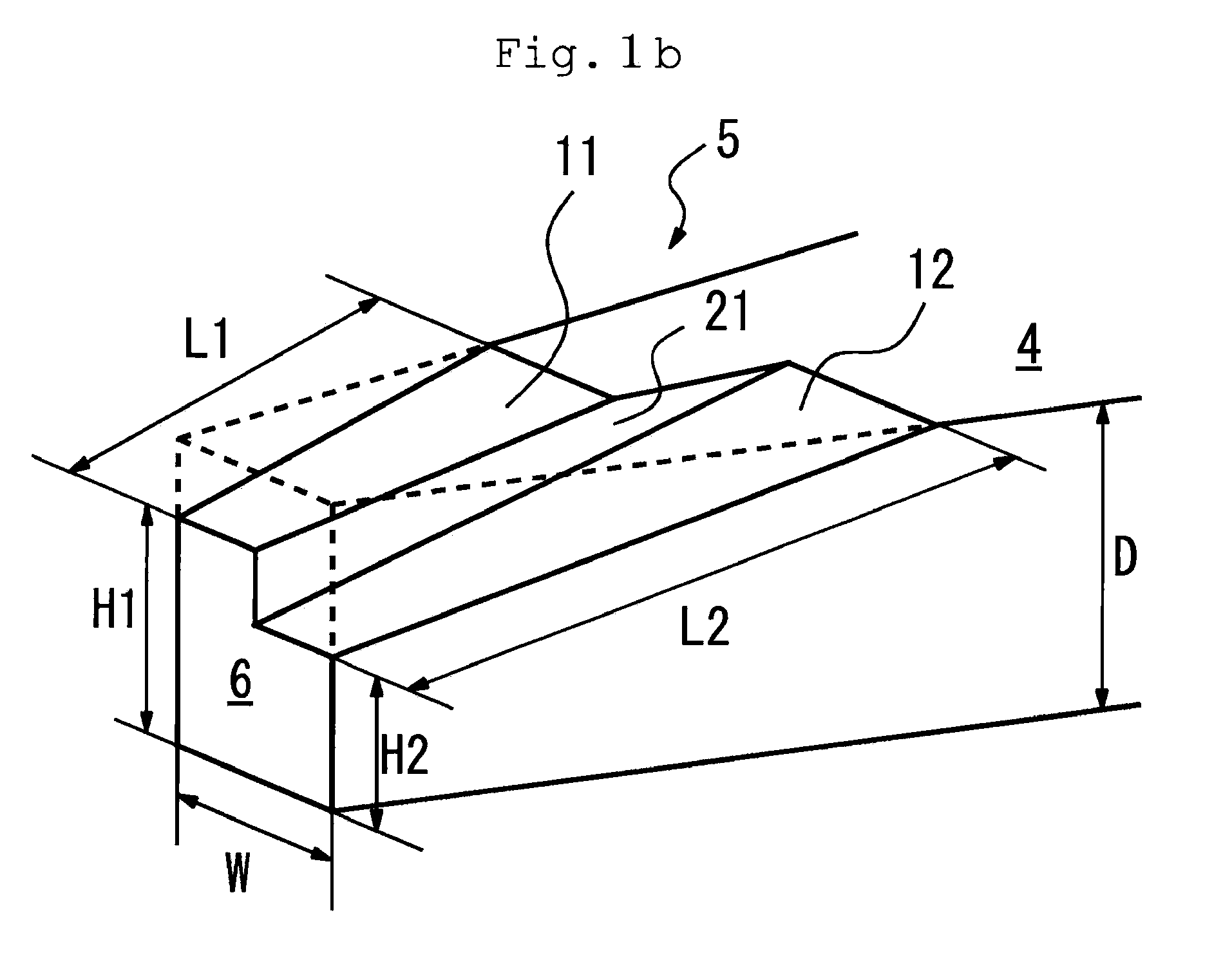

Pneumatic Tire

ActiveUS20100236679A1Same uneven wear resistance propertyReduce noise levelTyre tread bands/patternsNon-skid devicesAcute angleEngineering

A pneumatic tire comprises grooves 1 to 3 formed in a tread and land portions 4 each having an acute angle portion 5 formed by the grooves 2 and 3. The acute angle portion 5 is chamfered by a plurality of chamfered surfaces 11 and 12 to form into a step shape by the chamfered surfaces 11 and 12 and a connecting surface 21 that connects the adjacent chamfered surfaces 11 and 12. Furthermore, from one sidewall to the other sidewall of the acute angle portion 5 at an end 6 of the acute angle portion 5, a height H1 of the chamfered surface 11 and a height H2 of the chamfered surface 12 are gradually decreased while a length L1 of the chamfered surface 11 and a length L2 of the chamfered surface 12 are gradually increased.

Owner:TOYO TIRE & RUBBER CO LTD

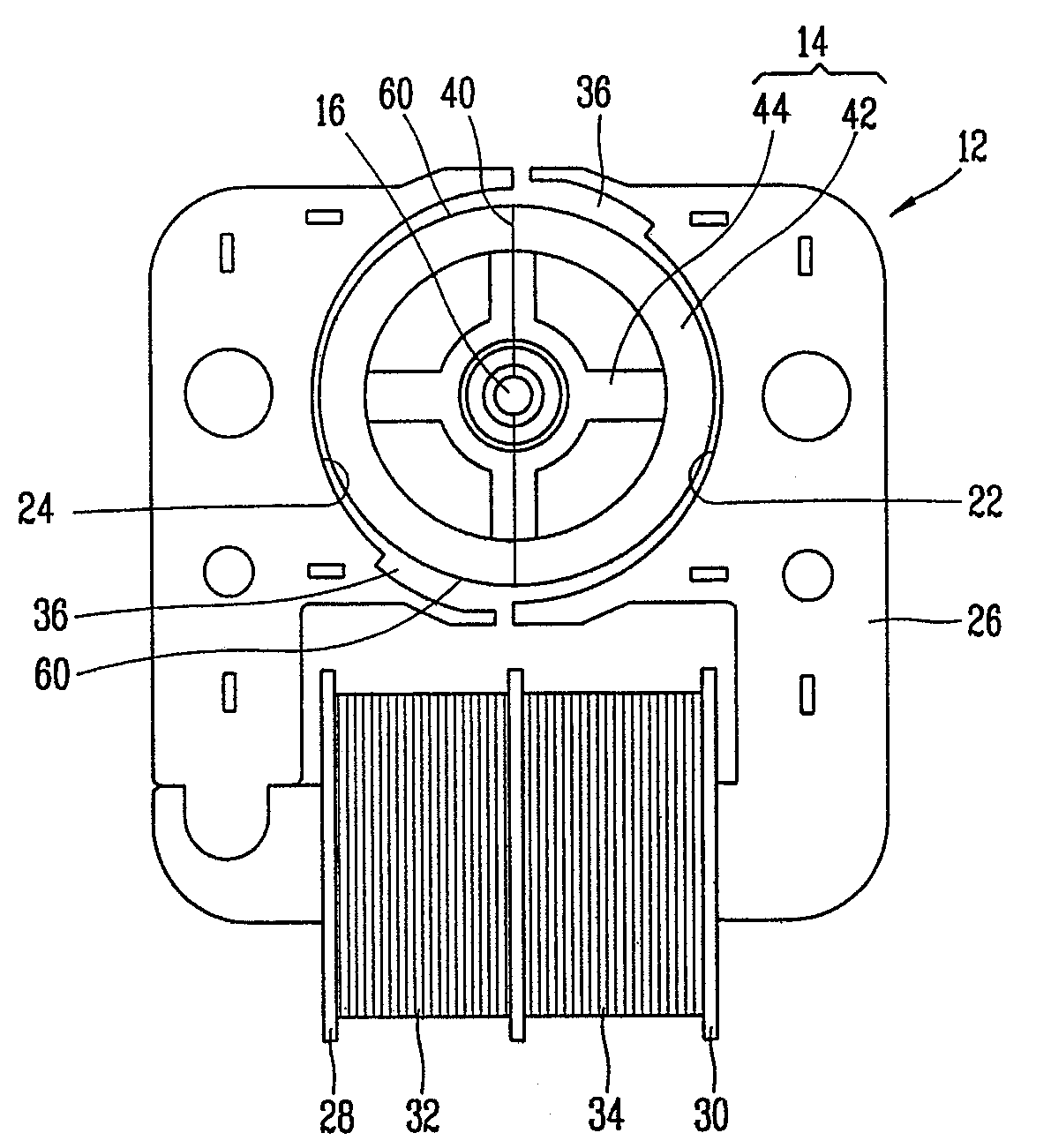

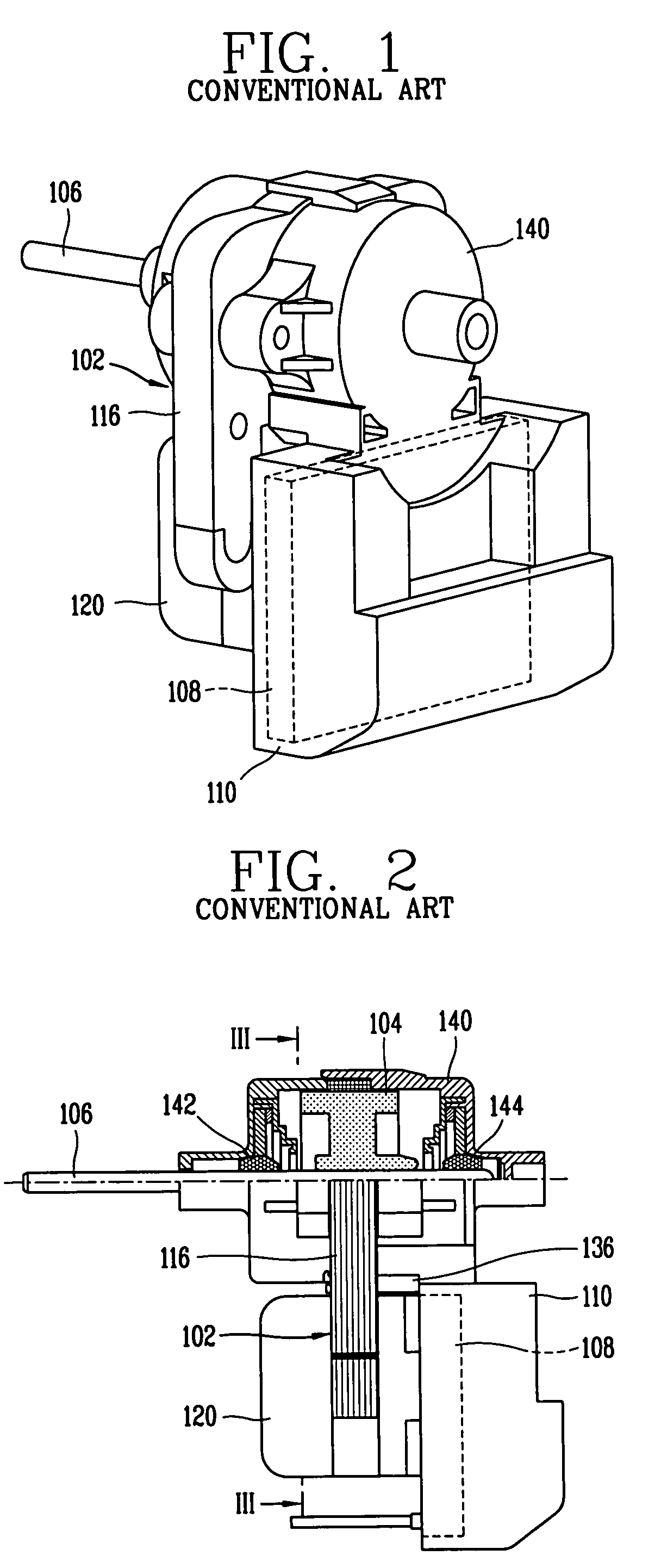

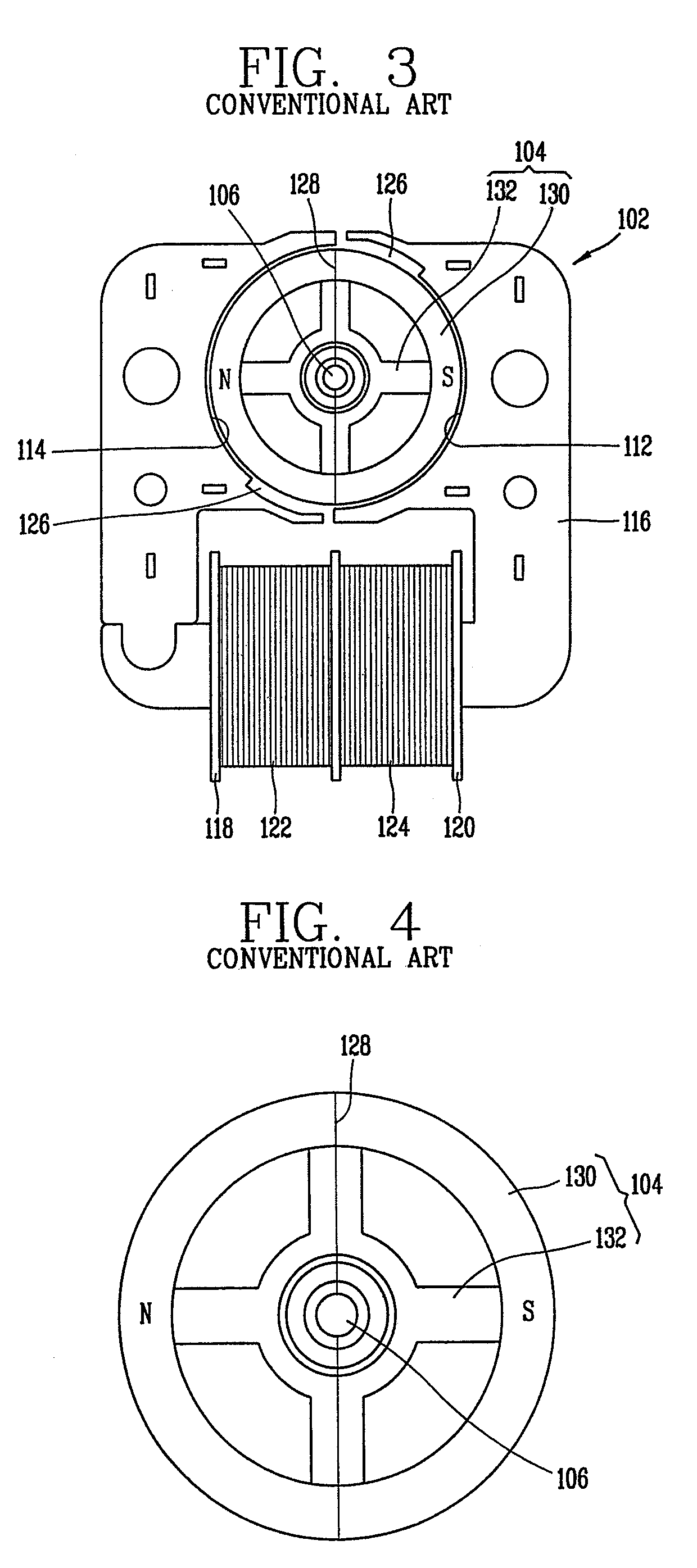

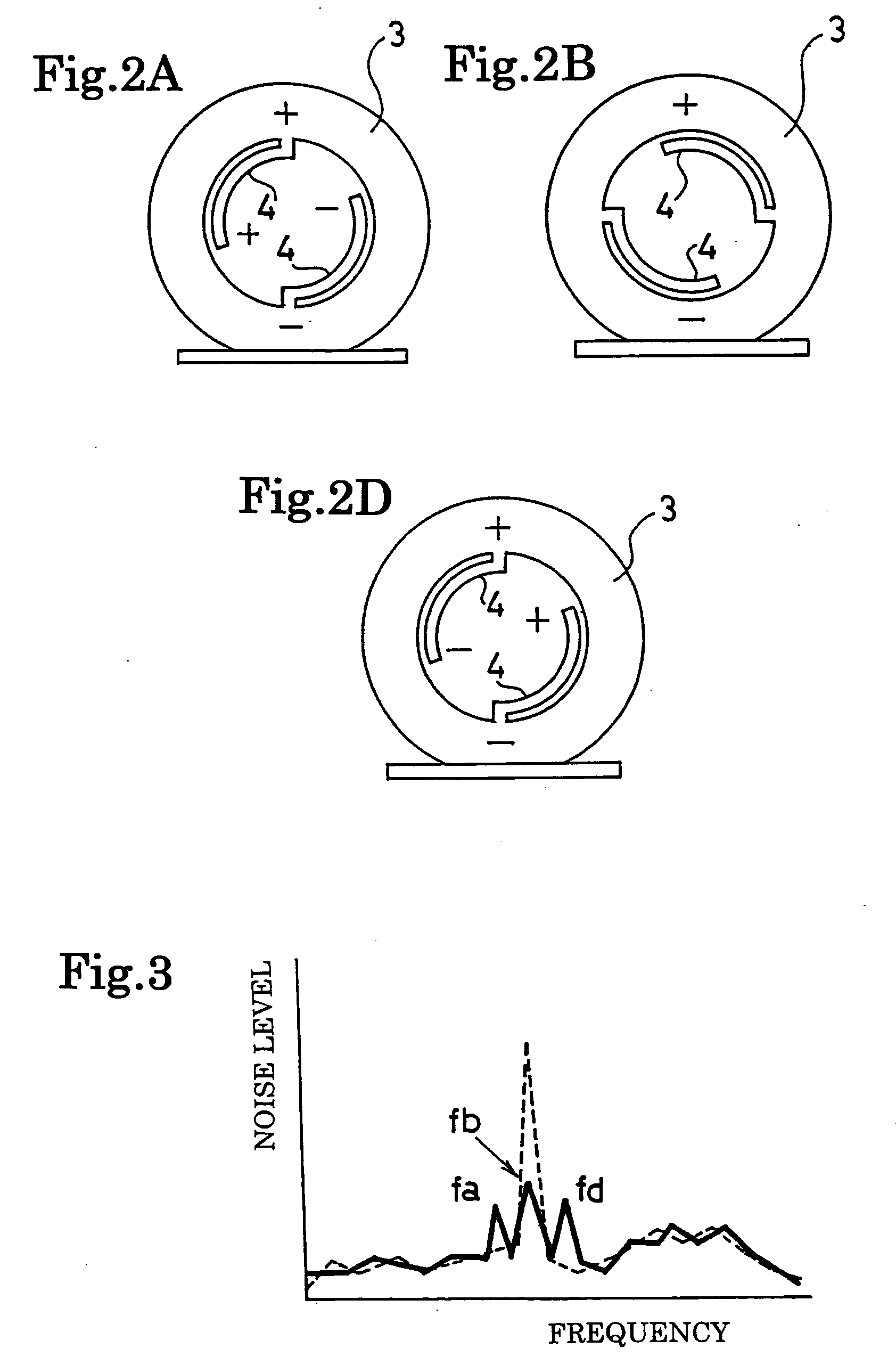

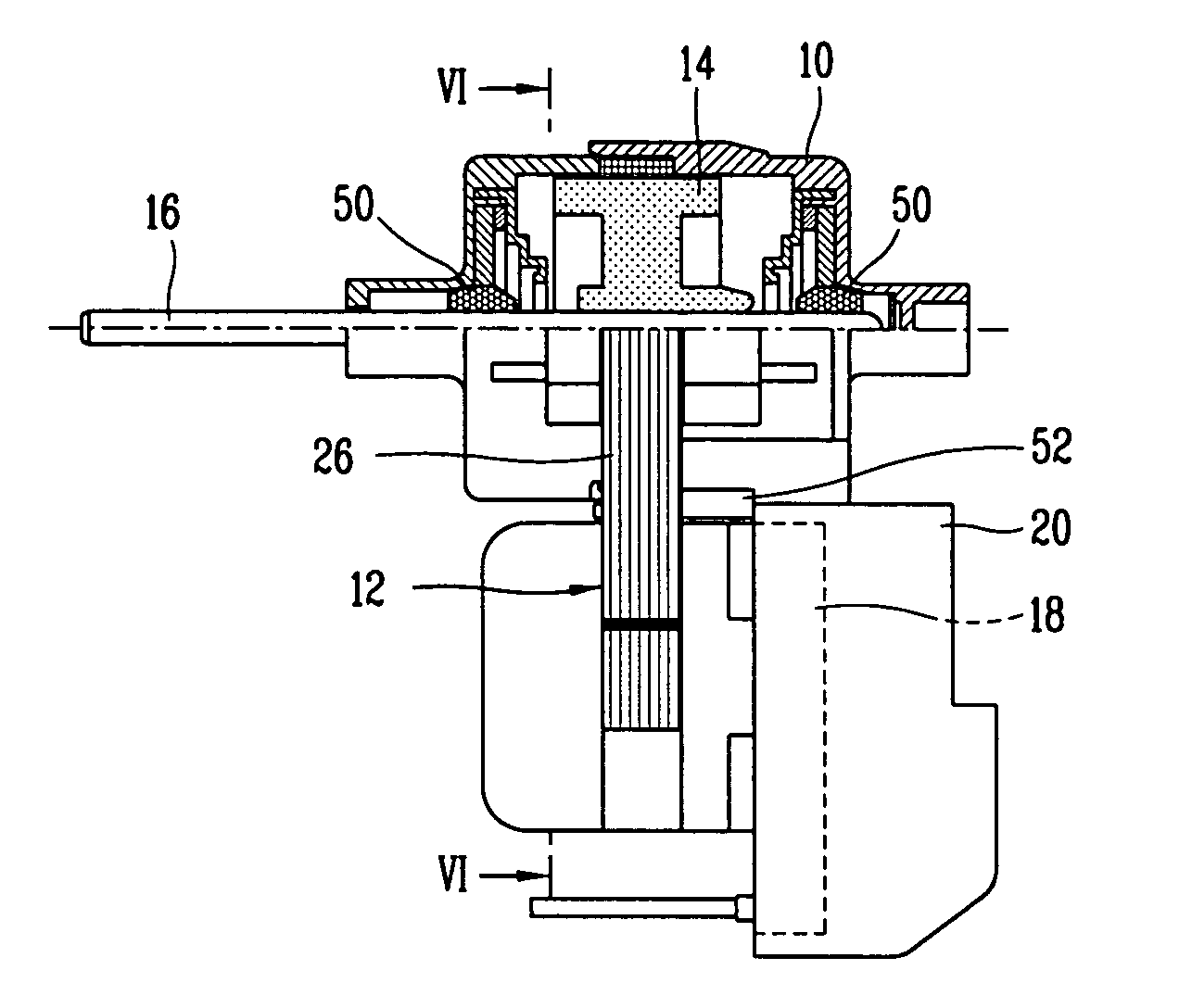

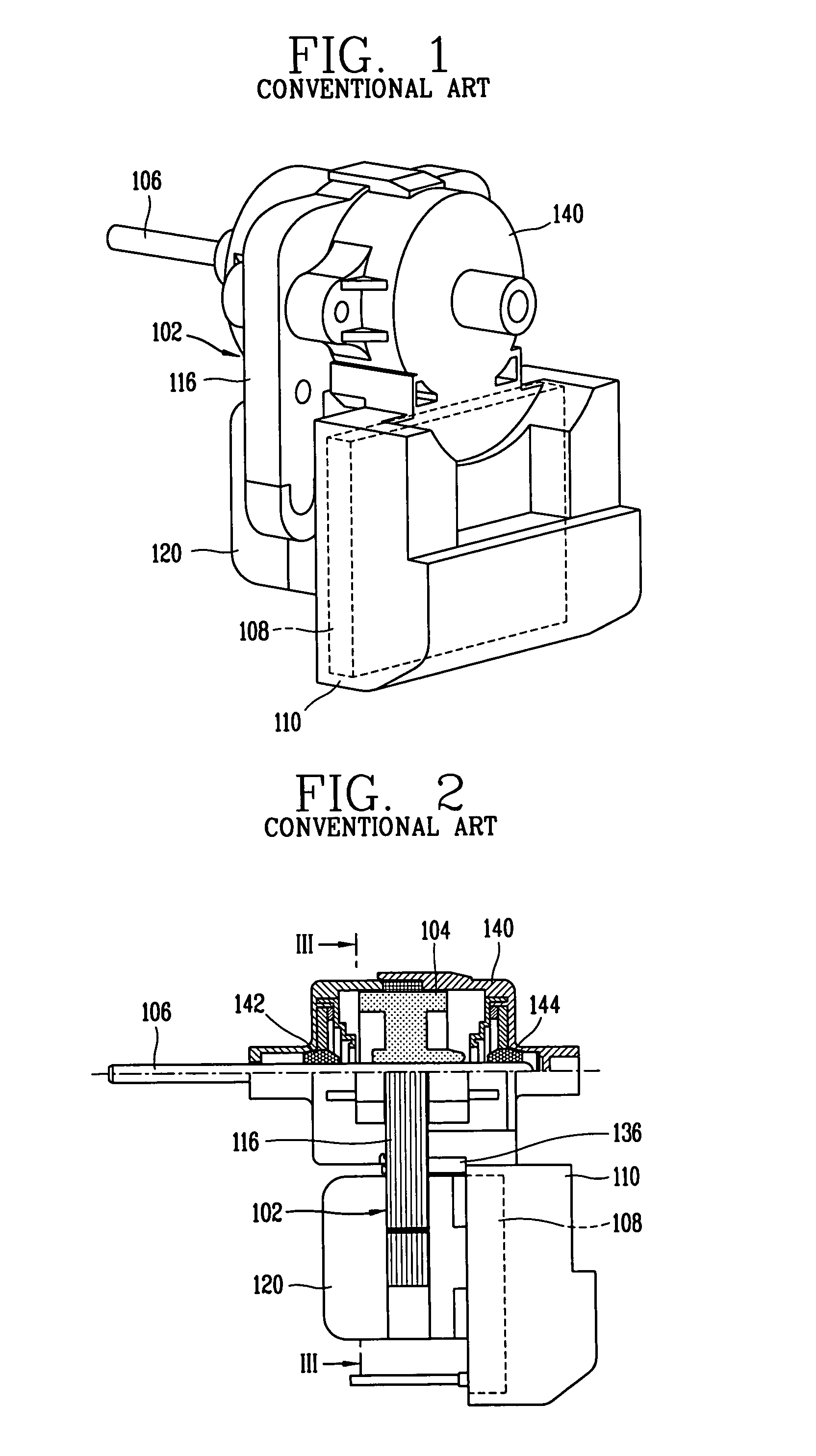

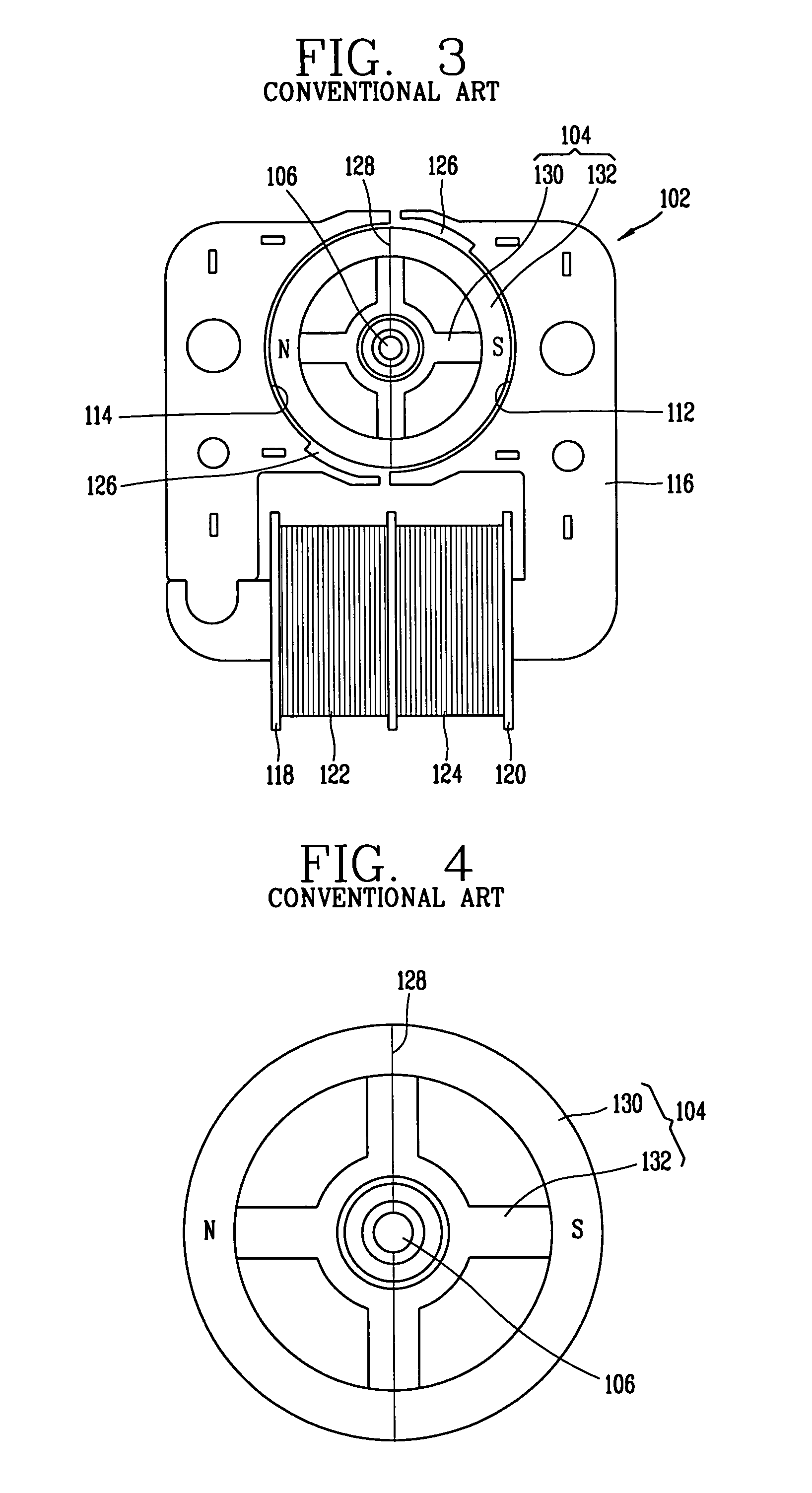

Skeleton type BLDC motor

A rotor of a BLDC motor includes: a rotor divided into a north pole and a south pole on the basis of a magnetic pole separating line; and a stator at which the rotor is disposed with an air gap, the stator having a first pole shoe, a second pole shoe and a pair of detent grooves at its inner surface, wherein an air gap forming portion for enlarging an air gap between the rotor and the detent grooves is formed at both end portions of the rotor where the magnetic pole separating line passes, so that the rotor can maintain the motor performance and reduce resonance noise by reducing only higher degree of cogging torque from cogging torque generated when the motor is driven.

Owner:LG ELECTRONICS INC

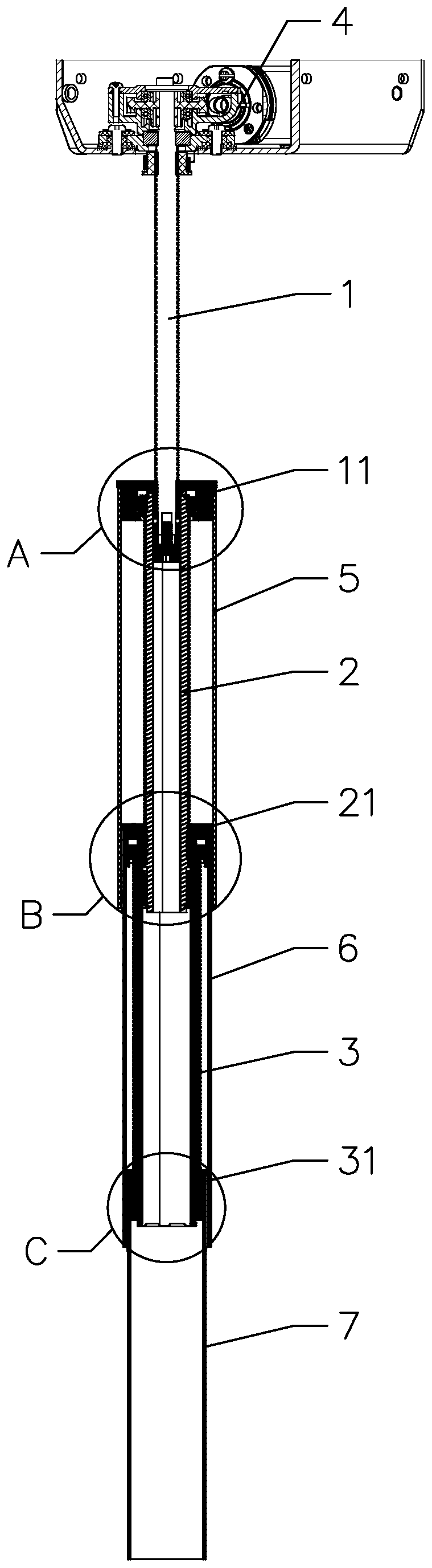

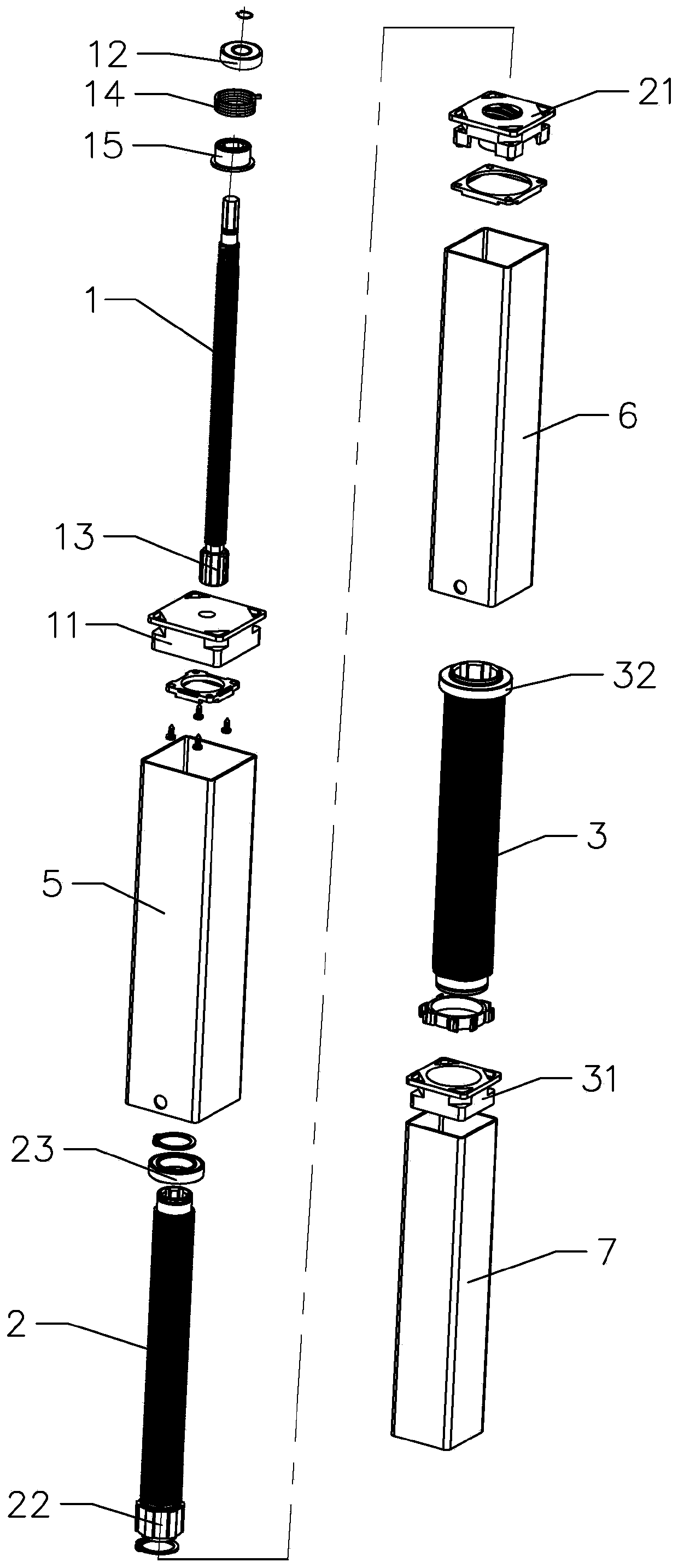

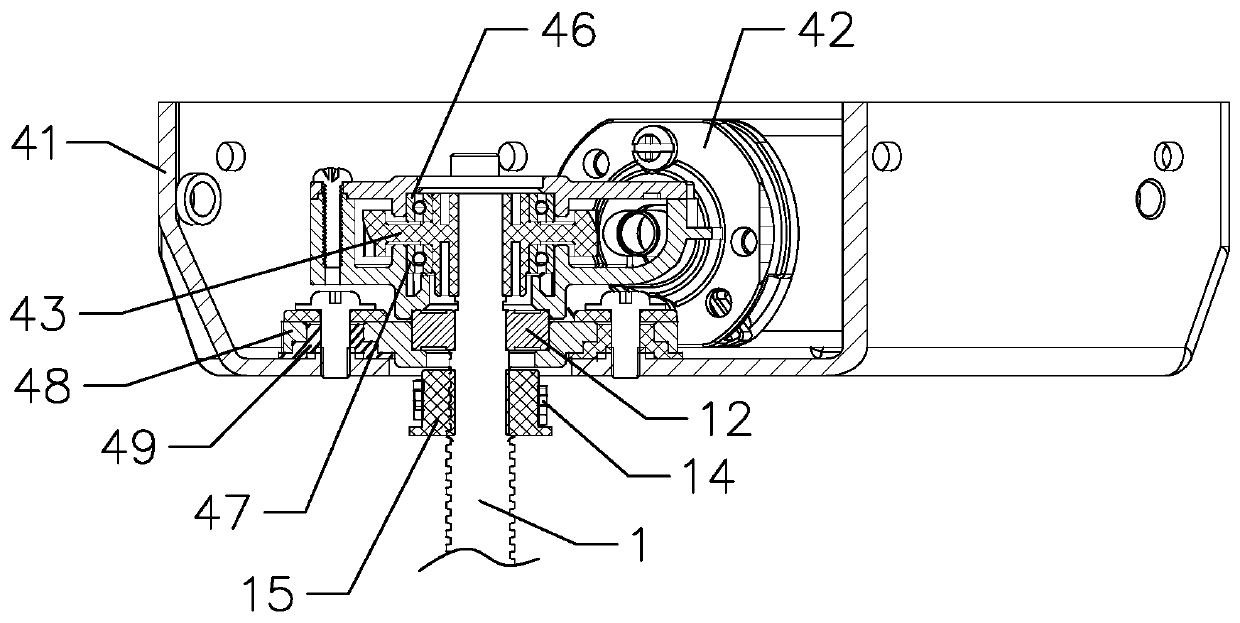

Transmission assembly and lifting vertical column

PendingCN109812556ASmooth transmissionReliable transmissionGearingMechanical energy handlingEngineeringMechanical engineering

The invention provides a transmission assembly and a lifting vertical column. The transmission assembly comprises a first screw rod, a second screw rod, a third screw rod, a driving device, a first nut which is in transmission fit with the first screw rod, a first sleeve fixedly connected with the first nut, a second nut which is in transmission fit with the second screw rod, a second sleeve fixedly connected with the second nut, a third nut which is in transmission fit with the third screw rod, and a third sleeve fixedly connected with the third nut; the first nut, the second nut and the third nut are fixedly arranged in the circumferential direction, the second screw rod and the third screw rod are hollow, the first screw rod and the second screw rod can rotate synchronously and expand and contract relatively in the axial direction, and the second screw rod and the third screw rod can rotate synchronously and expand and contract relatively in the axial direction; and the four-sectiontransmission assembly achieves driving through rotation of the screw rods, the sleeves are driven by the nuts to achieve expanding and contracting, and thus, transmission of the transmission assemblyis stable and reliable.

Owner:NINGBO HAISHIKAI DRIVER TECH CO LTD

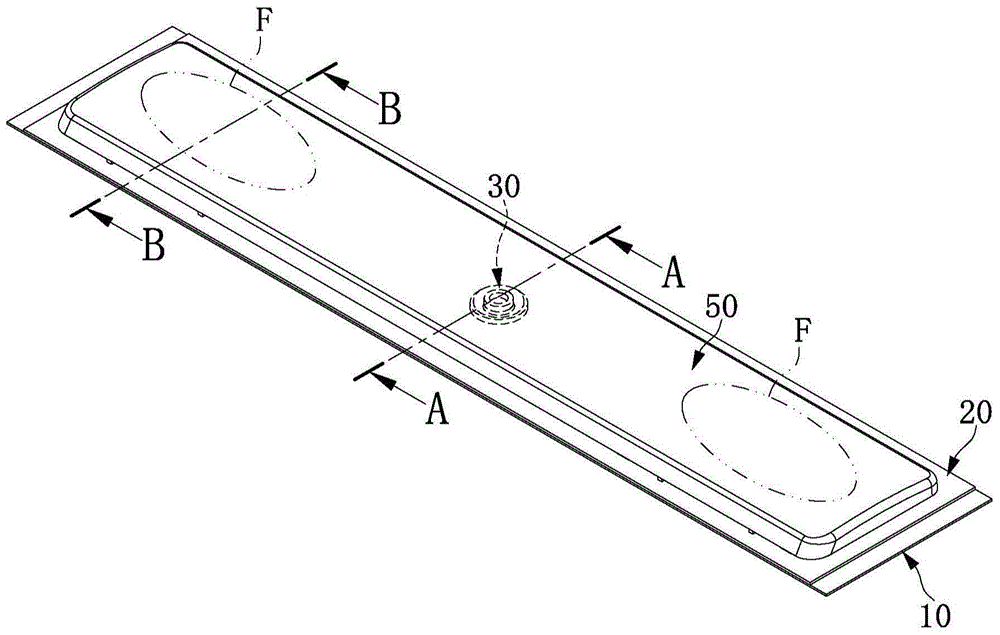

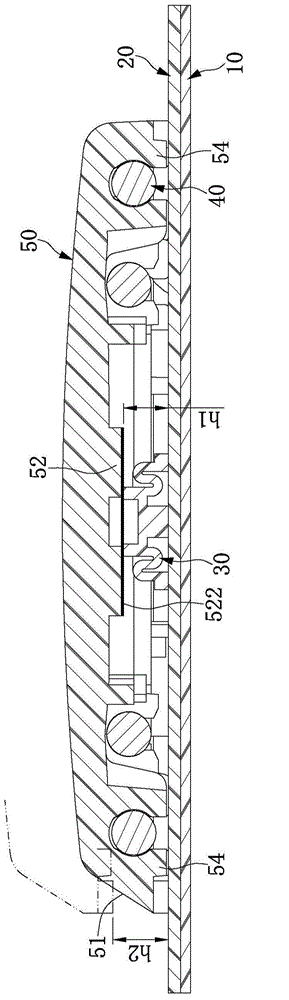

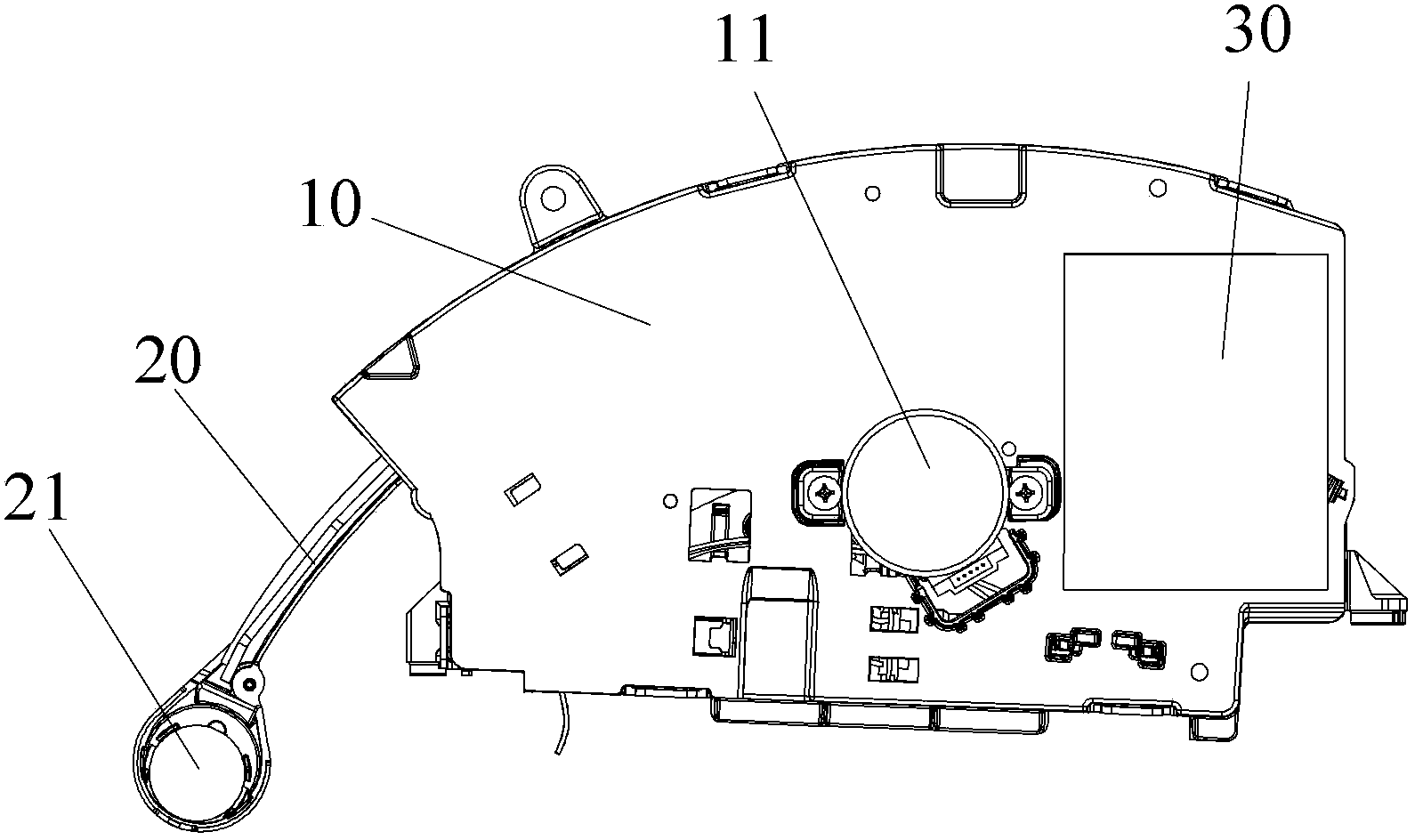

Air deflector drive structure and air conditioner comprising same

ActiveCN103486715AWeight increaseReduce resonance noiseNoise suppressionElectric machineStructure based

The invention provides an air deflector drive structure and air conditioner comprising the same. The air deflector drive structure comprises a driving box (10), a driving box motor (11) and a connecting rod assexcelsior boardembly (20), the driving box motor (11) is arranged on the driving box (10), the first end of the connecting rod assembly (20) is connected with the driving box motor (11) and can be driven by the driving box motor (11), and a vibration-damping block (30) is arranged on the driving box (10). The resonant noise of the air deflector drive structure based on the invention can be effectively reduced in the process of operation.

Owner:GREE ELECTRIC APPLIANCES INC

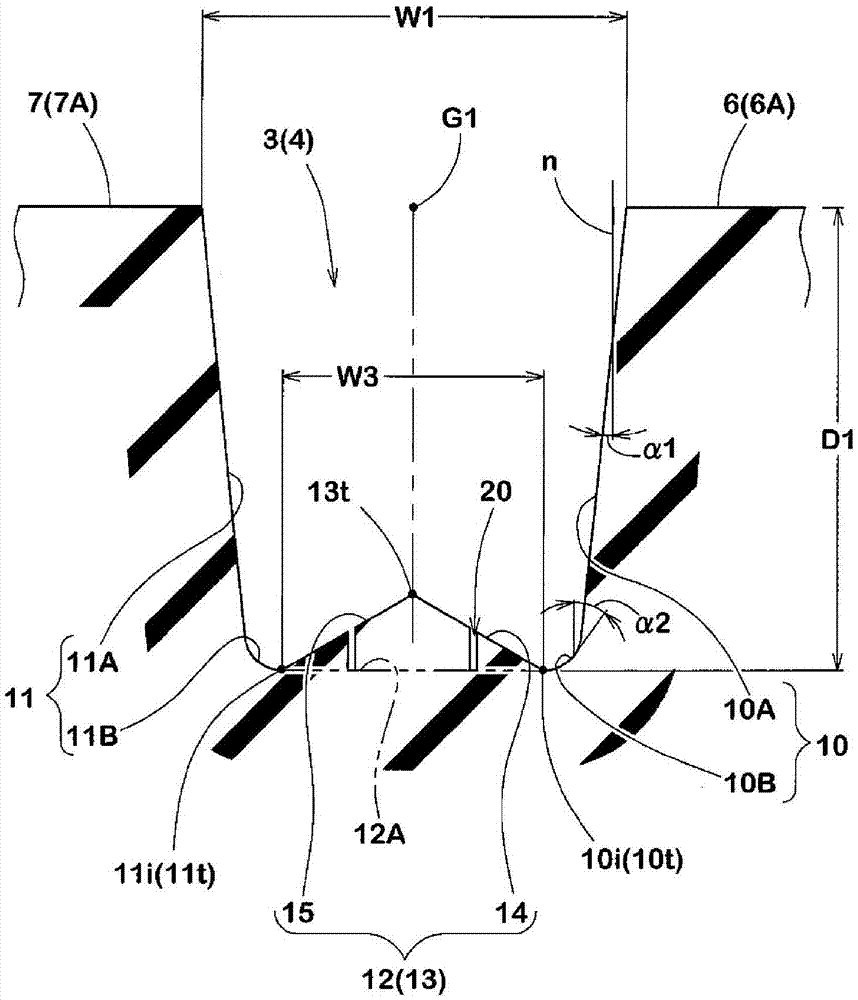

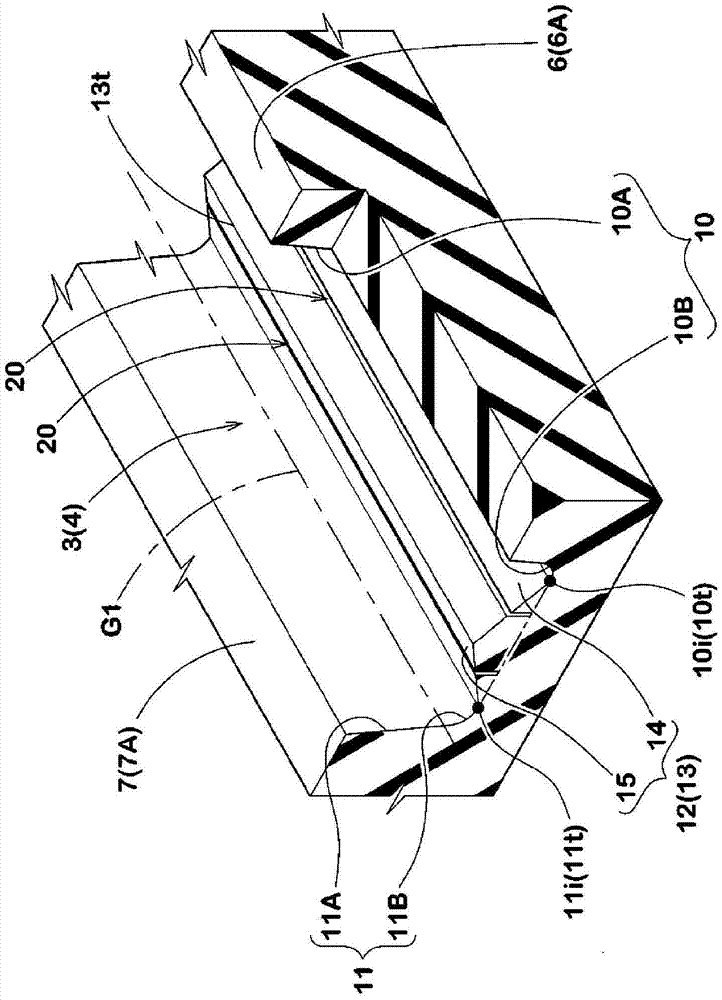

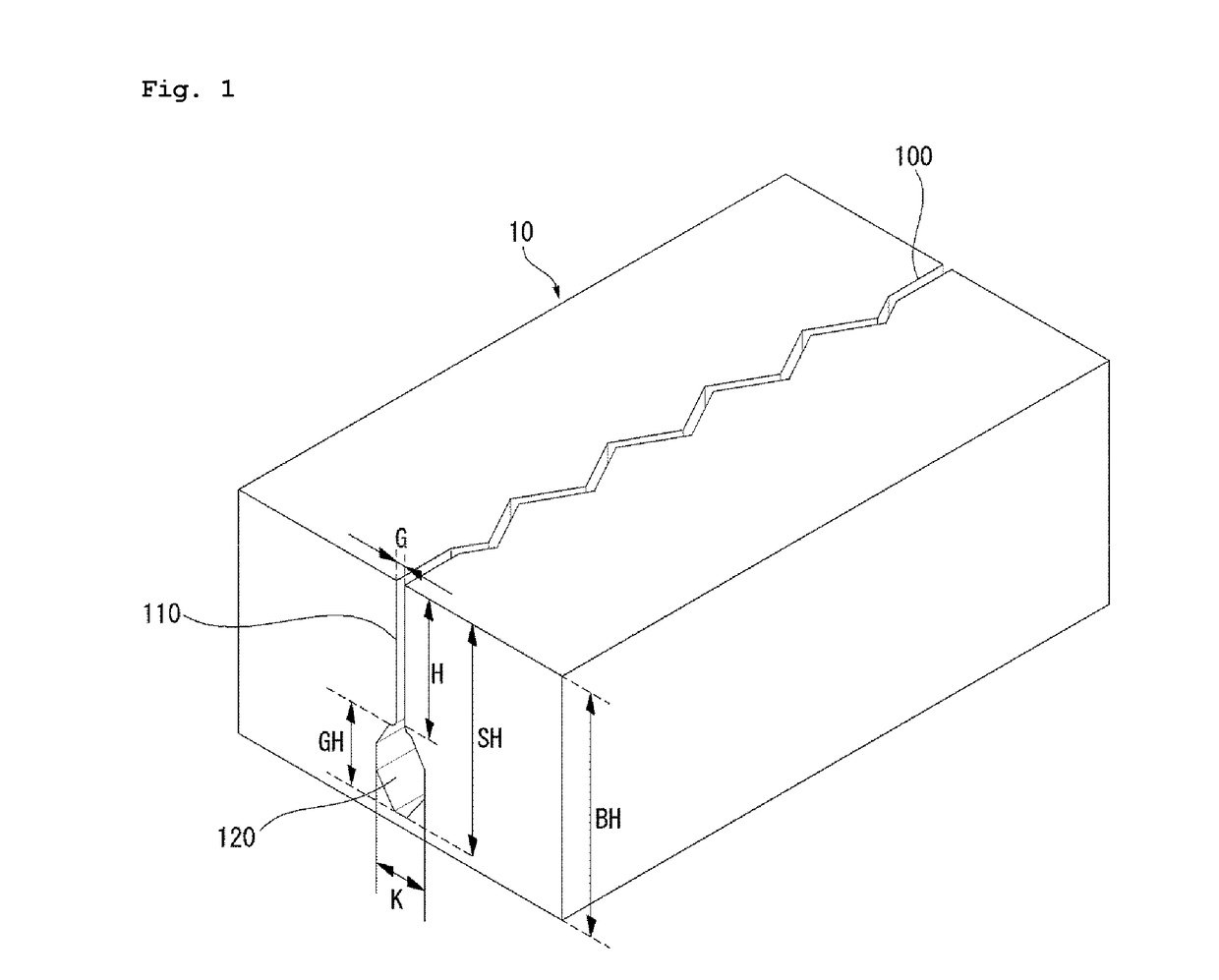

Pneumatic tire

ActiveCN105452018AIncrease stiffnessReduce vibrationTyre tread bands/patternsGroove widthWater discharge

Water discharge performance and noise performance are improved in a balanced manner. A pneumatic tire has a major groove (3) provided to a tread part (2). In a transverse cross section, the major groove (3) has a first groove wall (10), a second groove wall (11), and a groove floor (12). The groove floor (12) includes a protruding part (13) that is convex outward in a tire radial direction. The protruding part (13) continues along the major groove (3). The width (W3) of the protruding part (13) in a direction perpendicular to a groove center line (G1) of the major groove (3) is 50% to 100% of the groove width (W1) of the major groove (3). The protruding part (13) juts outward in the tire radial direction from an imaginary groove floor (12A) that connects an inner end (10i) of the first groove wall and an inner end (11i) of the second groove wall in a straight line, and the cross-sectional area of the protruding part (13) is 3% to 15% of the transverse cross-sectional area of the major groove (3).

Owner:SUMITOMO RUBBER IND LTD

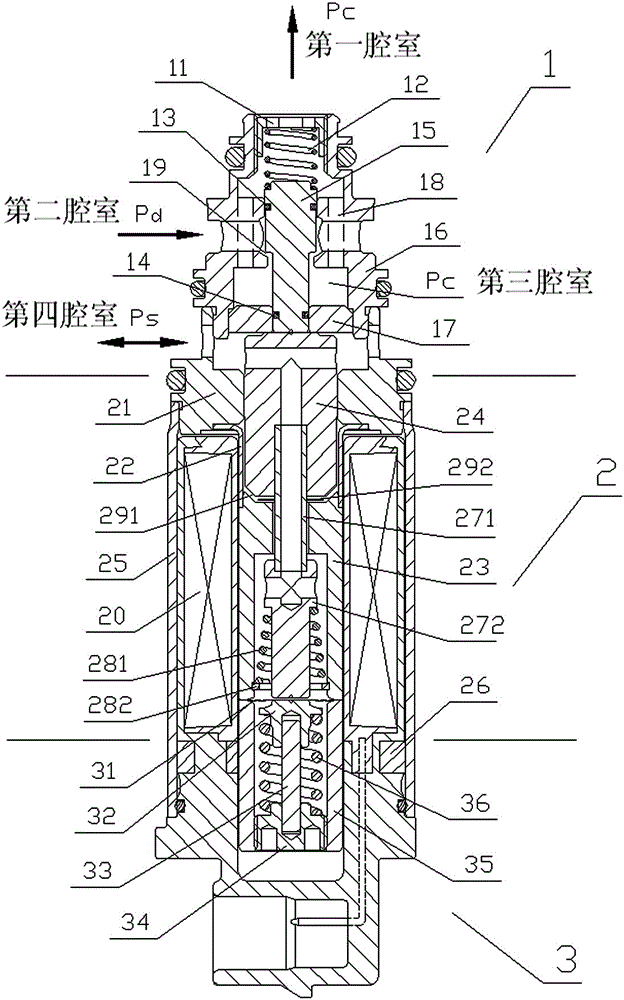

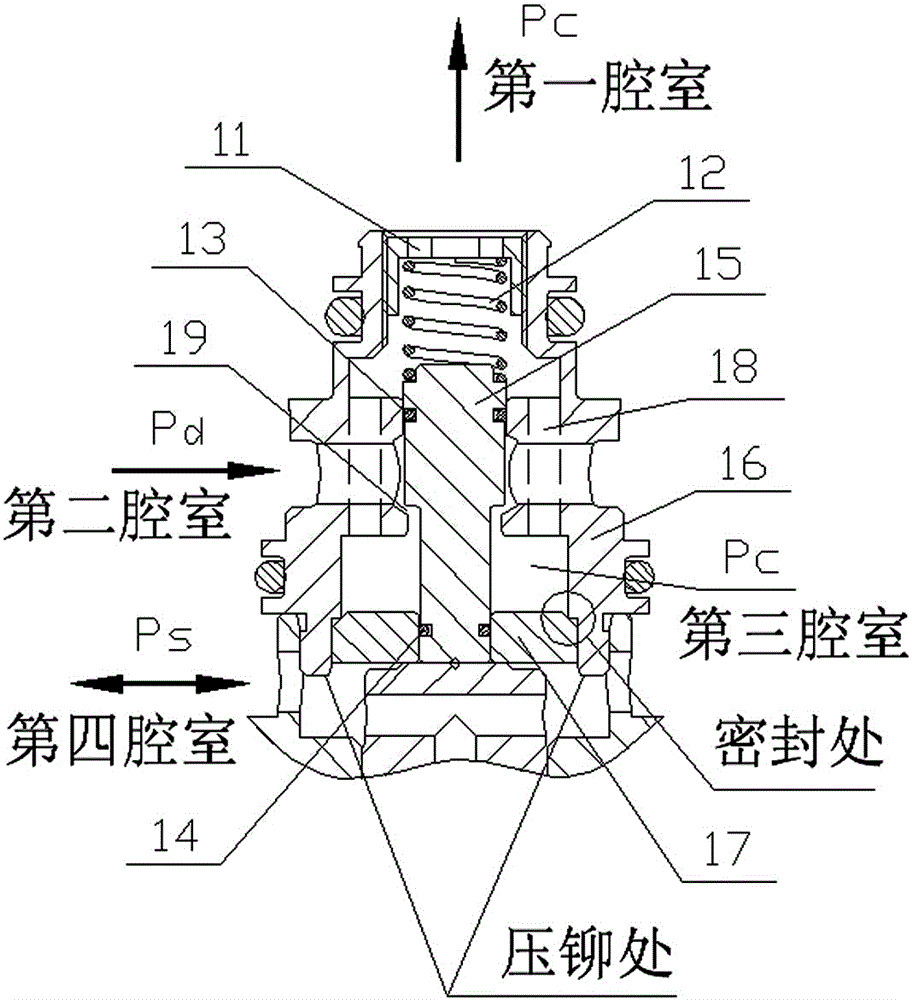

Electromagnetic control valve for variable displacement compressor

ActiveCN105041630AEliminate the effects ofHigh control precisionPump controlPositive-displacement liquid enginesPhysicsClutch

An electromagnetic control valve for a variable displacement compressor is mainly composed of valve parts, electromagnet parts and pressure sensing parts which are arranged on the same axis. The electromagnet parts are arranged between the valve parts and the pressure sensing parts, and each valve part comprises a valve body and a valve element arranged in the valve body, wherein the opening end of the lower end of the valve body is connected with a valve element support plate in an interference fit mode, the lower end of the valve element is contained in a middle through hole formed in the valve element support plate, and an inner cavity of the valve body is provided with multiple through holes which are used for communicating the exhaust pressure, the suction pressure and the crank pressure; the electromagnet parts can generate an electromagnetic force used for driving the adjacent valve element arranged over the electromagnet parts to move after being powered on; the pressure sensing parts can also generate a force used for driving the valve element to move due to the change of the suction pressure. The electromagnetic control valve for the variable displacement compressor has the advantages of being reasonable in structure, capable of improving the control precision and being used for the variable displacement compressor without a clutch, beneficial for the lightweight design of a car and the like.

Owner:ZHEJIANG SANHUA AUTOMOTIVE COMPONENTS

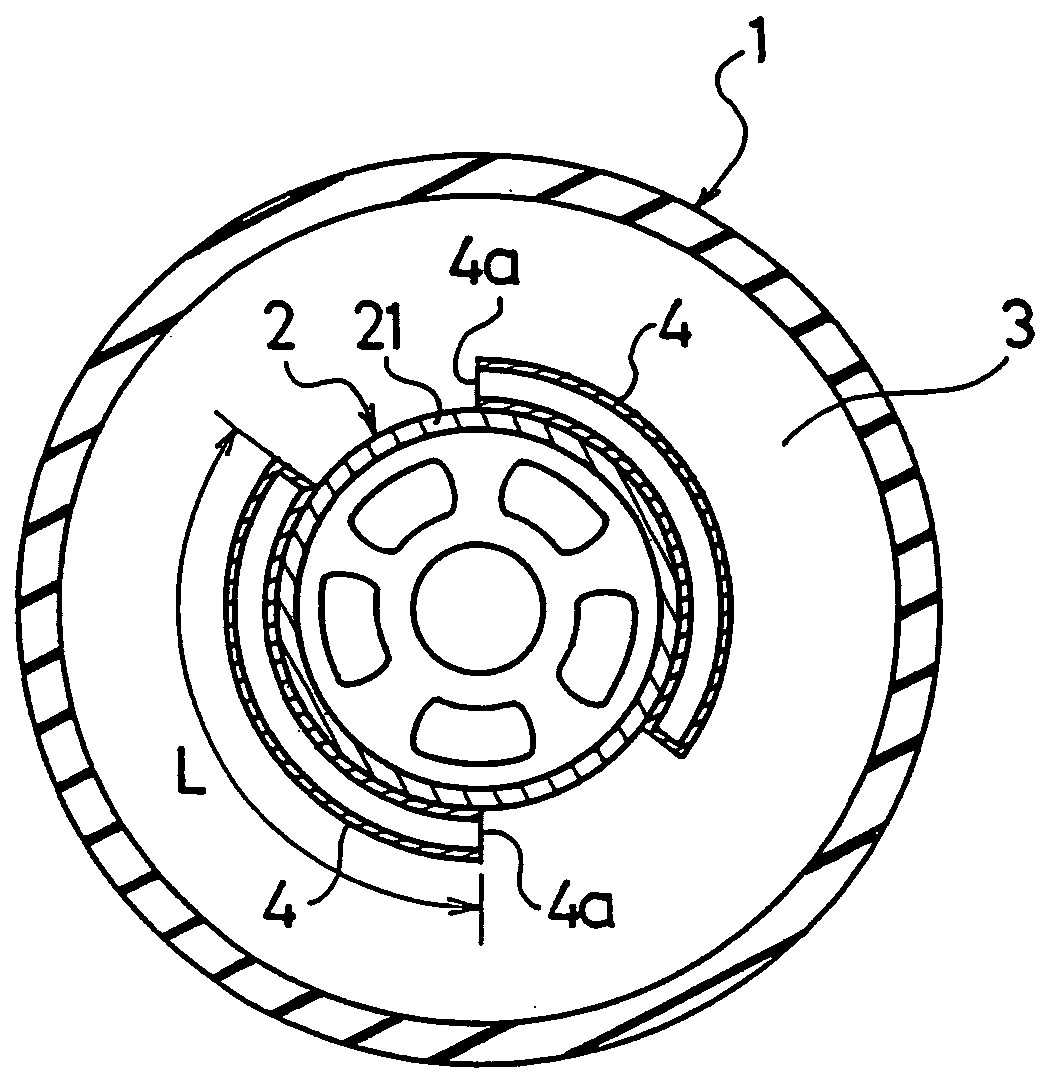

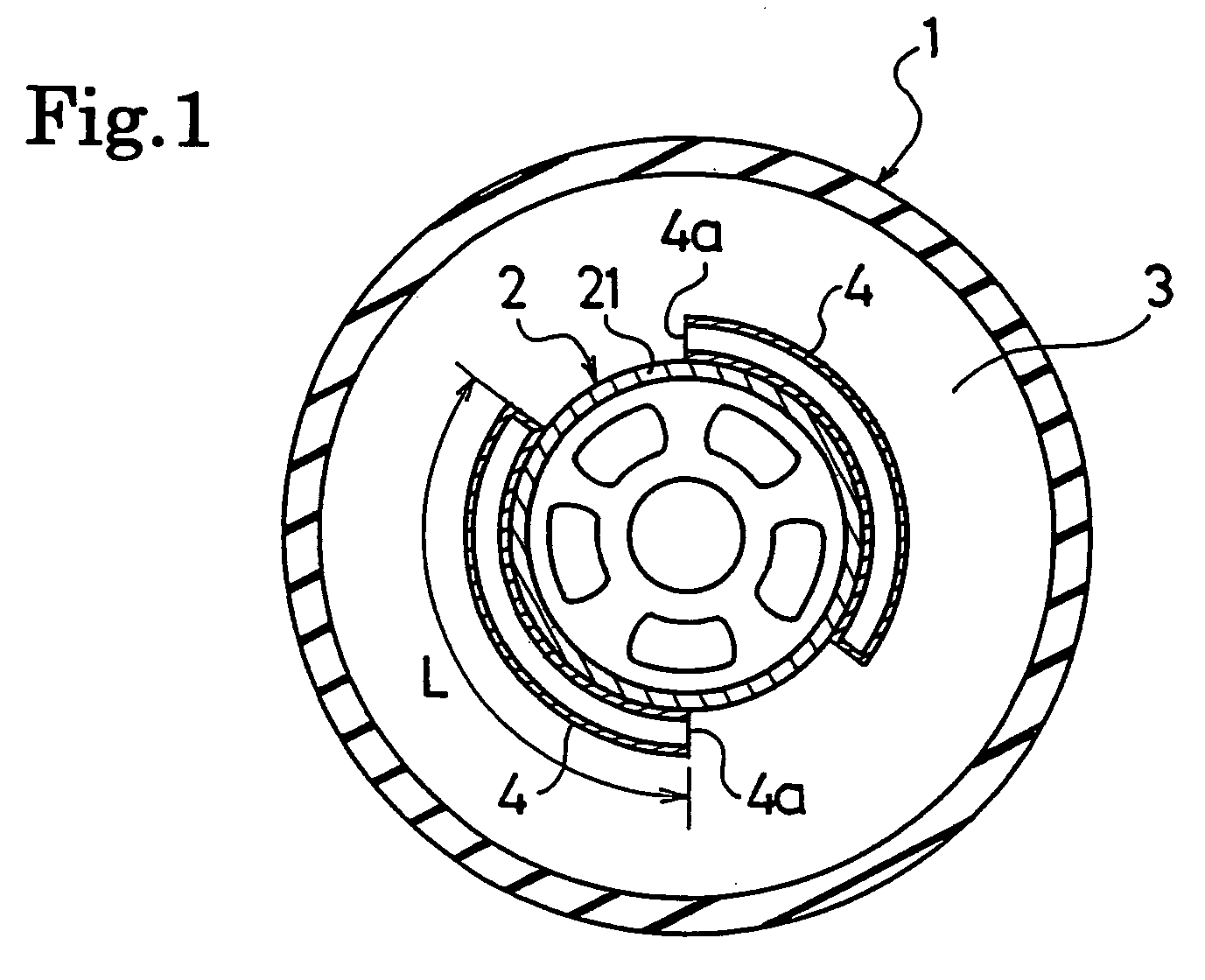

Tire wheel assembly

InactiveUS20090151836A1Easy to calculateGood effectRimsWith separate inflatable insertsCavity resonanceEngineering

Provided is a tire wheel assembly making it possible to effectively reduce cavity resonance noise without causing either negative influence on deformation of a tire or deterioration in rim assembling workability. A tire wheel assembly of the present invention includes a pneumatic tire, and a wheel provided with a rim fitted with the pneumatic tire, and forms a cavity portion between the pneumatic tire and the rim. The tire wheel assembly comprises at least one tube, which has one end thereof closed while having a length of 55% to 110% of a reference length L0 corresponding to one fourth of a cavity resonance wavelength, is provided so as to open to the cavity portion.

Owner:YOKOHAMA RUBBER CO LTD

Structure for reducing resonance noise of external shell of fan for motor of vaccum dust collector

InactiveCN1536235AReduce resonance noisePrevent noise from stackingPump componentsSuction cleanersResonanceEngineering

The present invention discloses a structure for reducing resonace noise of fan case for vacuum cleaner motor. Said structure includes fan outer protector which is connected with front side opening position of outer shell of vacuum cleaner motor and can be used for protecting fan, diffuser placed on the peripheral surface of the fan and diffuser sealing surface which is connected together with fan outer protector, sectional extended space which is tightly fixed on the front face of diffusion vane formed into diffuser and can reduce flow rate of air high-speed flower out from the fan and resonace-resisting circular groove which is forward projected and formed on the above-mentioned diffuser sealing surface. In the vacuum cleaner provided by said invention the structure capable of reducing motor noise is adopted, so that its product reliability also can be raised.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

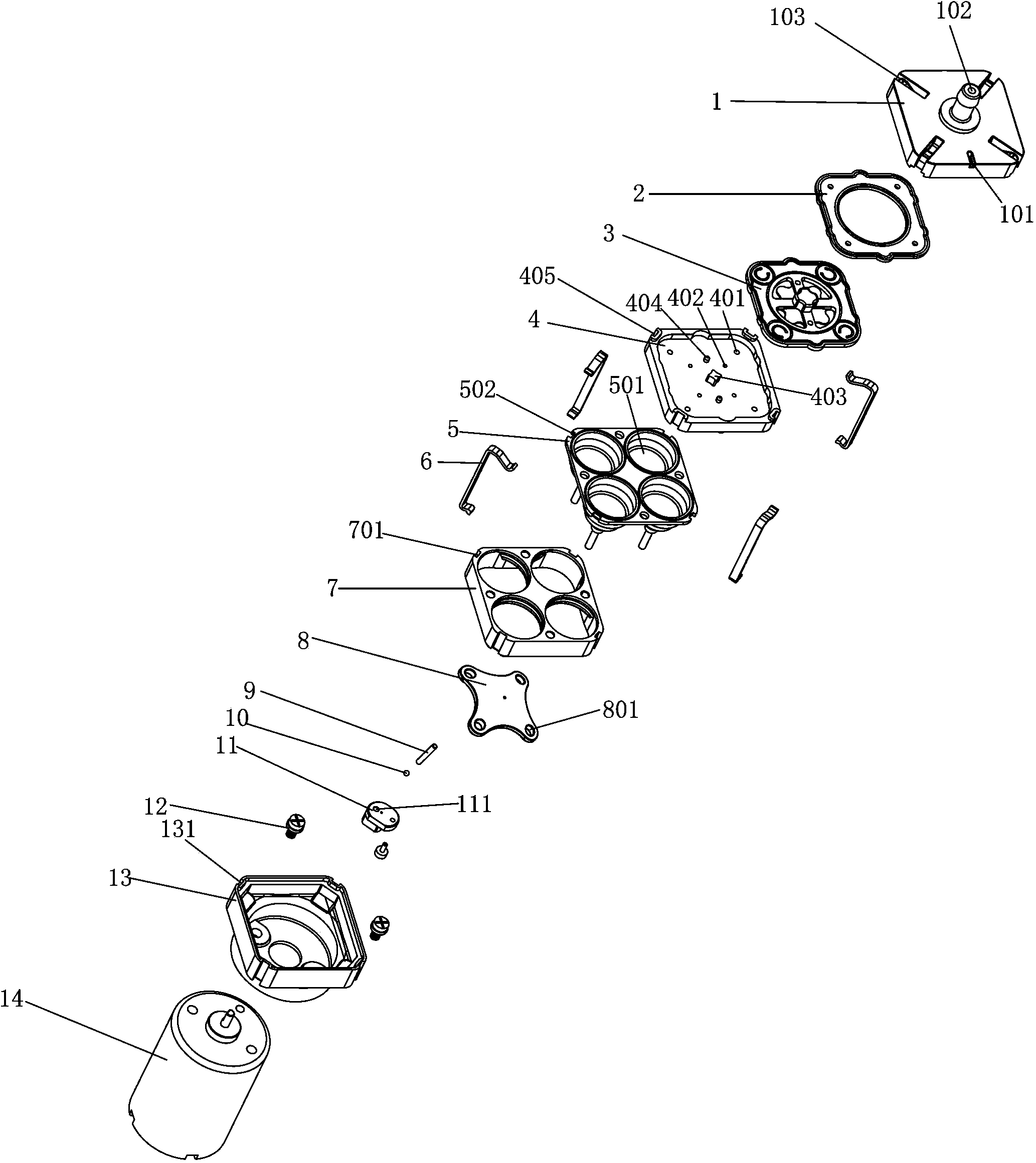

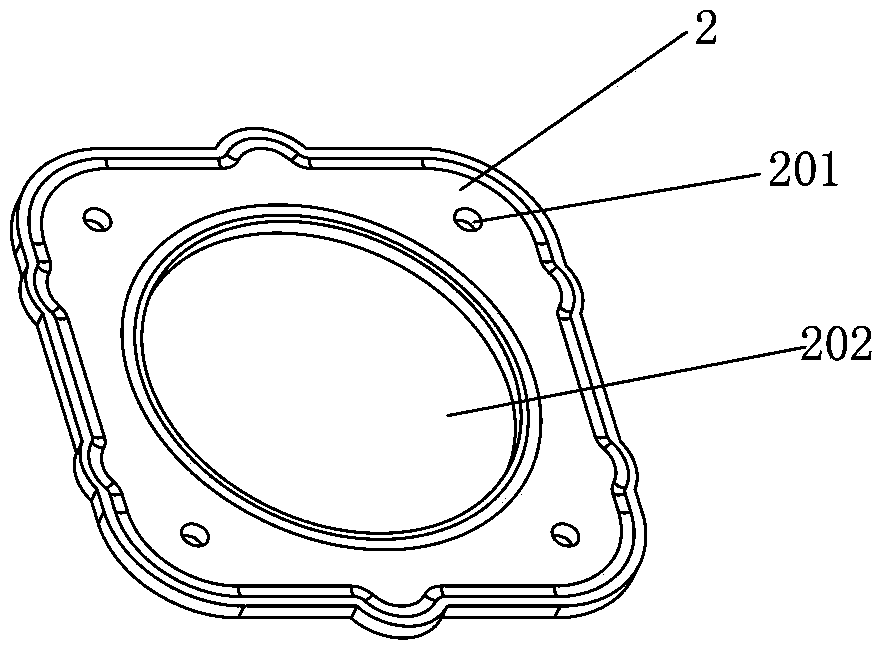

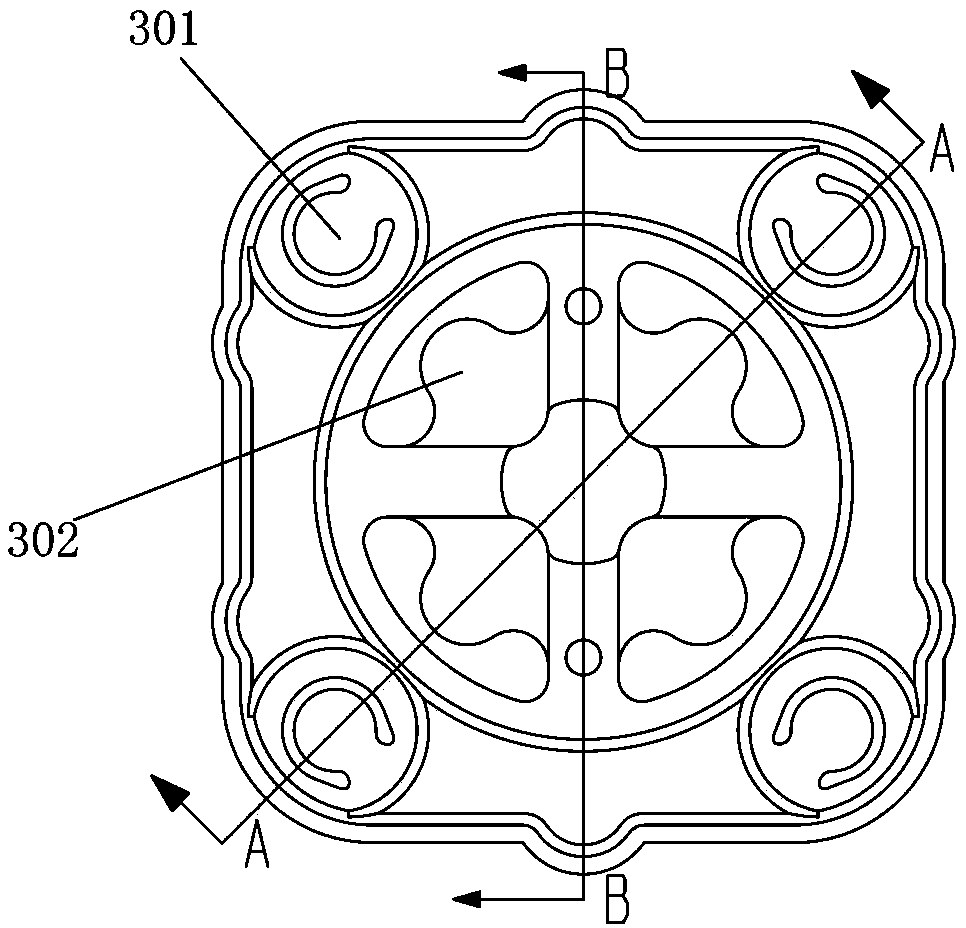

Low-noise air pump

ActiveCN103452806AReduce running noisePrevent warping and deformationPositive displacement pump componentsPositive-displacement liquid enginesLow noiseAir pump

The invention discloses a low-noise air pump which comprises an upper cover, a cylinder, a piston, a base, a unidirectional inlet and outlet air distributing device, a motor, a linkage mechanism and a partition plate. The upper cover is provided with an exhaust port and an air inlet, and the piston is integrally provided with at least two air bags; the partition plate is provided with a first air outlet hole and first air inlet holes; the partition plate is fixed to a position between the upper cover and the unidirectional inlet and outlet air distributing device, the partition plate and the upper cover are hermetically matched with each other to form a sealed cavity, the air inlet of the upper cover and the first air inlet holes of the partition plate are respectively communicated with the sealed cavity, the first air outlet hole of the partition plate is communicated with the exhaust port of the upper cover, and the first air outlet hole and the first air inlet holes are respectively correspondingly matched with the unidirectional inlet and outlet air distributing device to realize a unidirectional outlet air distributing effect and a unidirectional inlet air distributing effect. The low-noise air pump has the advantages that owing to the partition plate, an airflow passage is prolonged, inlet air can be buffered, impact force is reduced, accordingly, running noise of the air pump is greatly reduced, and tilting deformation of an air inlet check valve of the unidirectional inlet and outlet air distributing device due to long-term direct stress can be prevented.

Owner:XIAMEN KOGE MICRO TECH

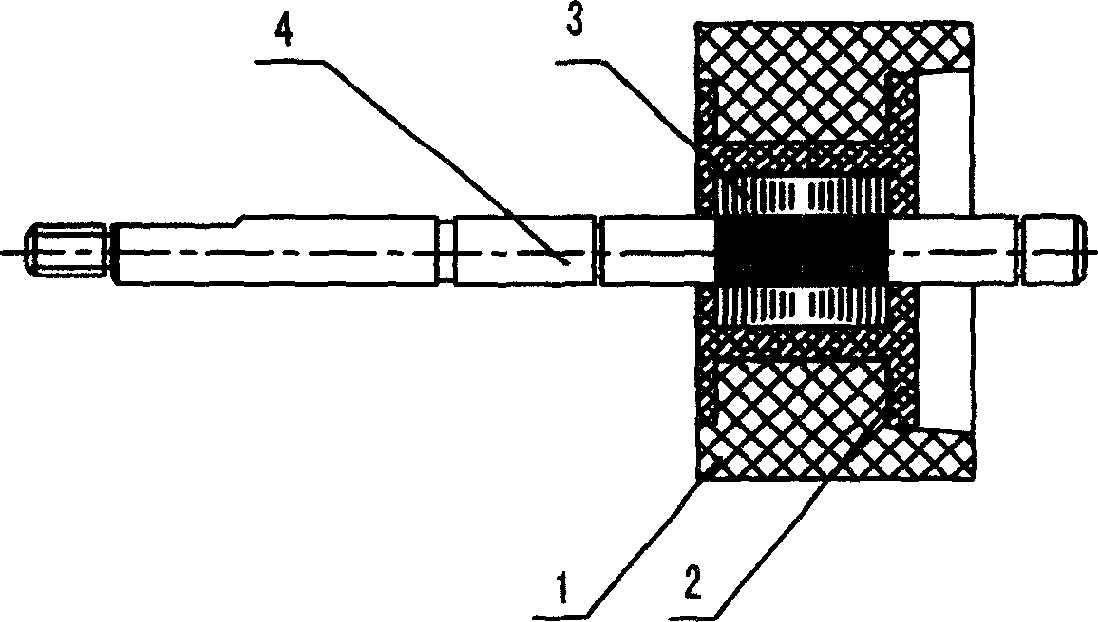

Permanent magnetic rotor for electromotor and method for making same

InactiveCN1671025AAutomatically adjust the amount of compressionIngenious designMagnetic circuit rotating partsManufacturing stator/rotor bodiesPermanent magnet rotorHigh volume manufacturing

A permanent magnetic rotor for motor and making method thereof, which contains permanent magnetic ring, rotor core, rotor axle, axle hole for rotor axle penetrating rotor core, high temperature liquid rubber filled between permanent ring and rotor core, the rubber consolidated with permanent magnetic ring and rotor core after cooling. Said invention can effectively eliminate the resonance between motor and fan blade and noise.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG

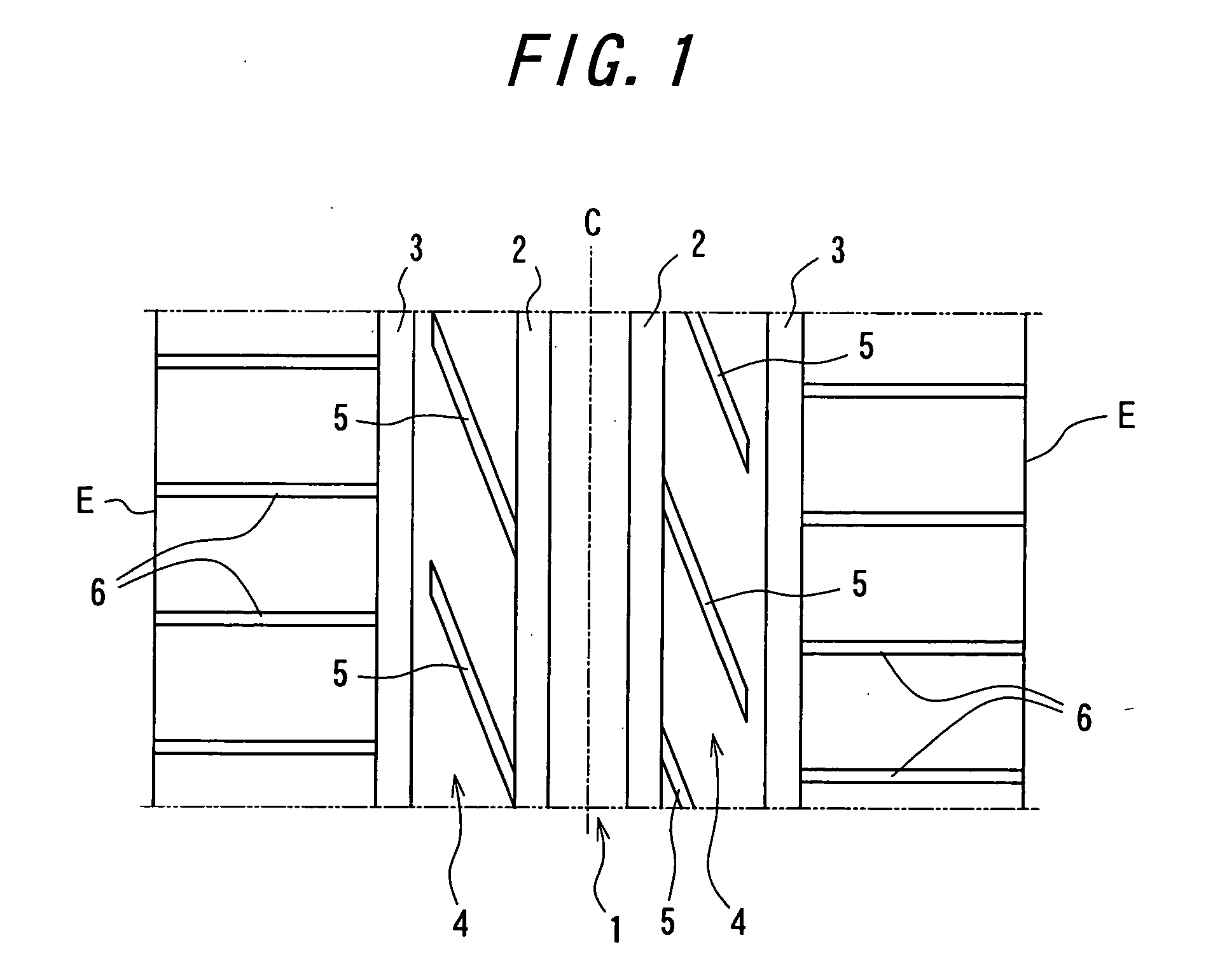

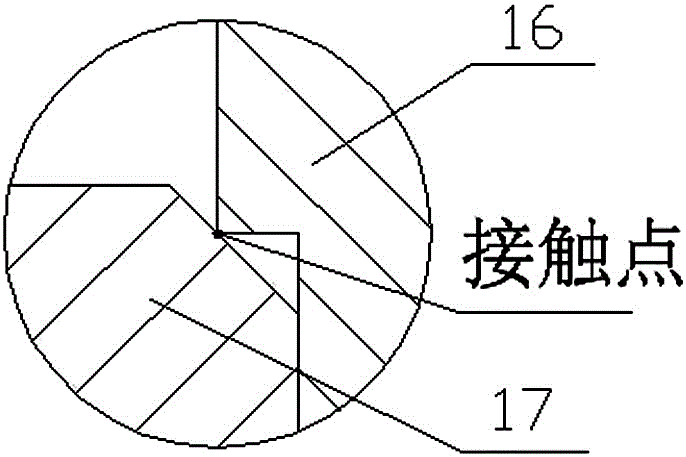

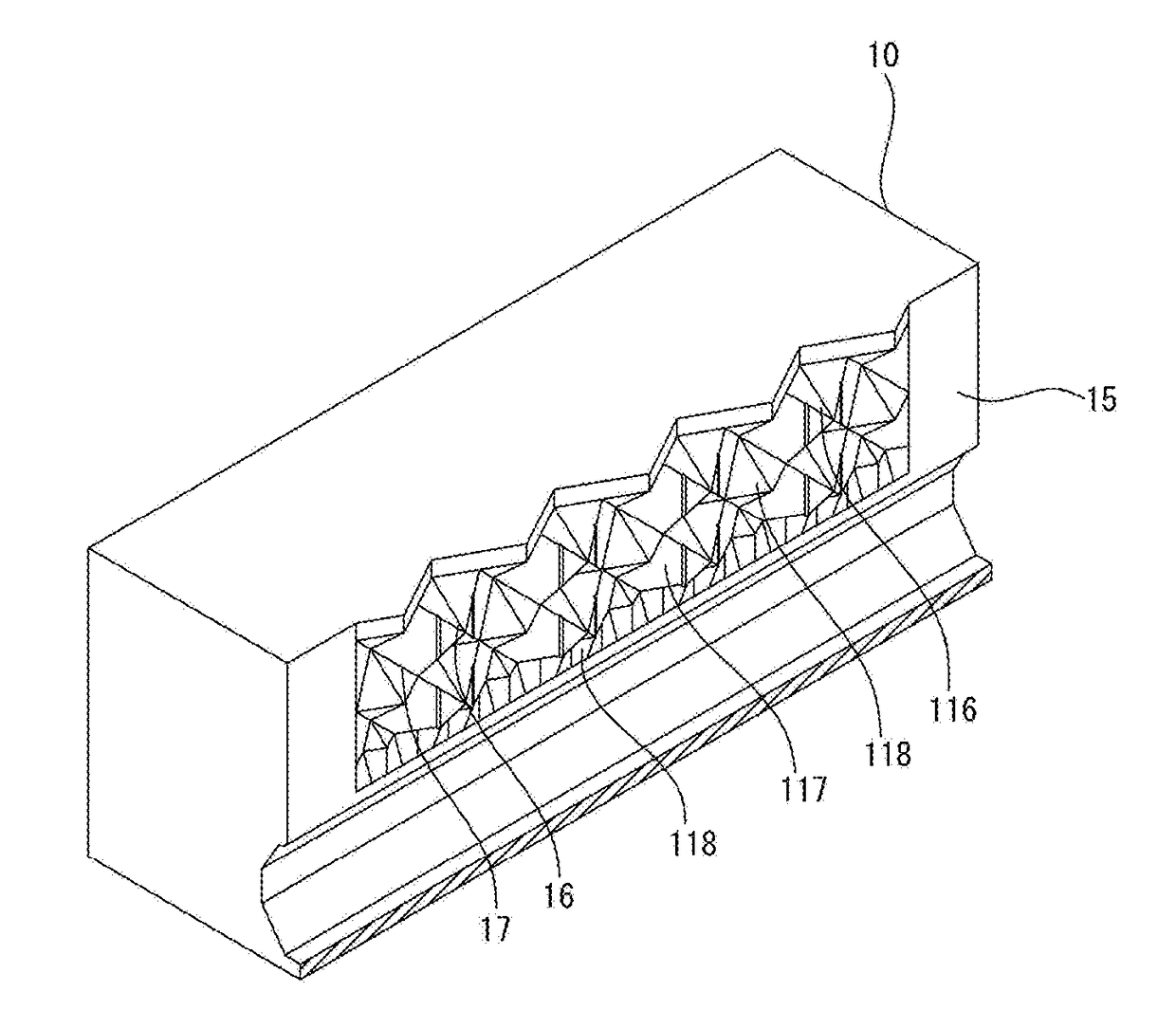

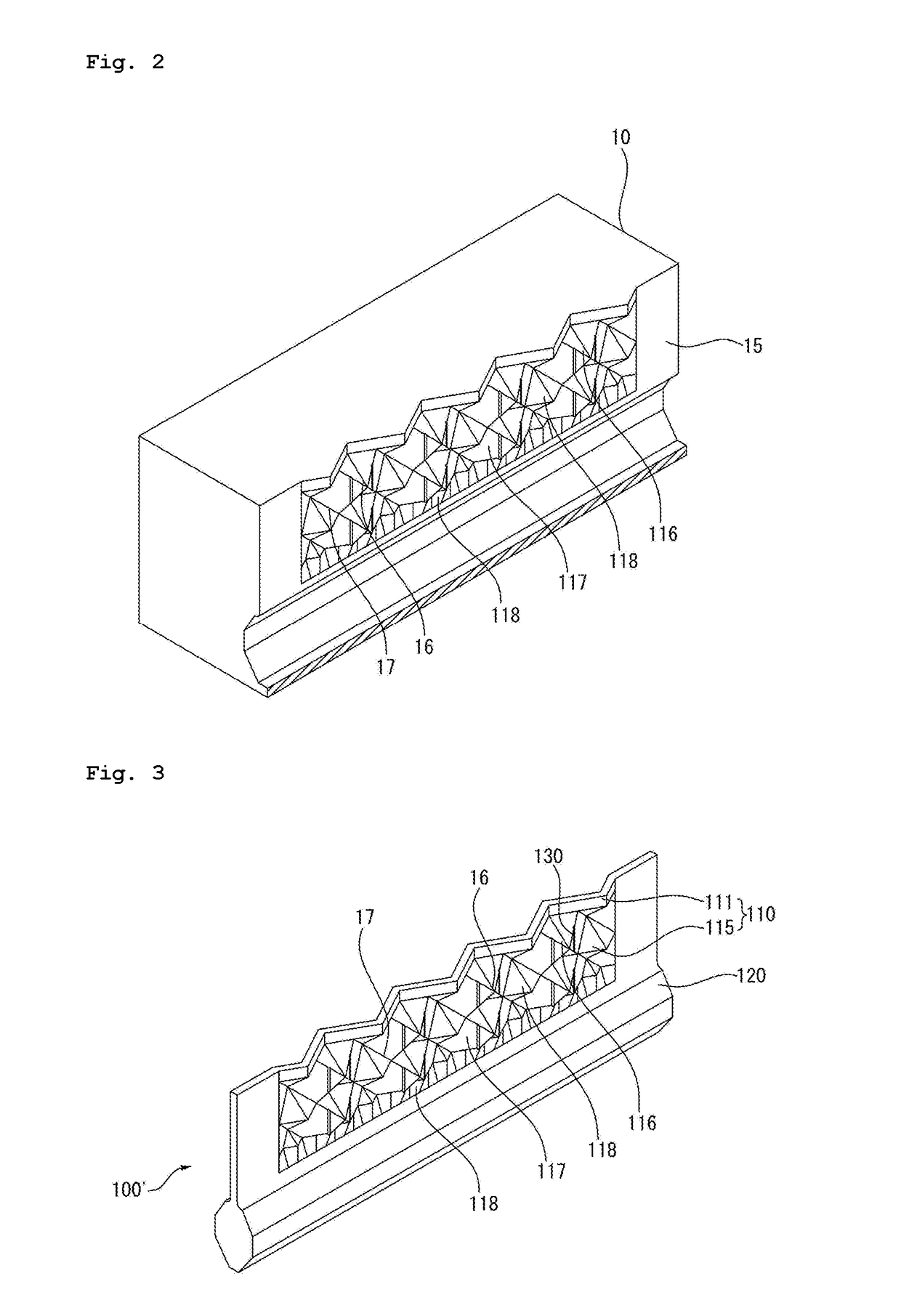

Pneumatic tire

ActiveUS20170182851A1Minimize movementEasy to manufactureTyresTyre tread bands/patternsForeign matterResonance

The present invention provides a pneumatic tire including a tread block 10 having a sipe 100 formed therein. A three-dimensional inclined surface groove 110 is formed at an upper portion of the sipe 100 formed in the tread block 10, such that three-dimensional inclined surface protrusions 16 and inclined surface grooves 17 respectively formed on both sipe side wall surfaces 15 forming the sipe 100 so as to correspond to each other may minimize a movement of the tread blocks 10 due to a stress generated from the tire contacting with a ground during driving, so as to increase a traction force. In addition, a lower through groove is formed at a lower portion of the sipe 100 formed in the tread block 10, such that it is possible to reduce a resonance noise of the tire occurring when driving, more easily and automatically discharge the foreign matters caught in the sipes 100 of the tire during driving, and improve a traction performance of the tire in the latter half of the tire lifespan by dividing the remaining tread block 10 after the upper portion of the tread block 10 is worn.

Owner:KUMHO TIRE CO INC

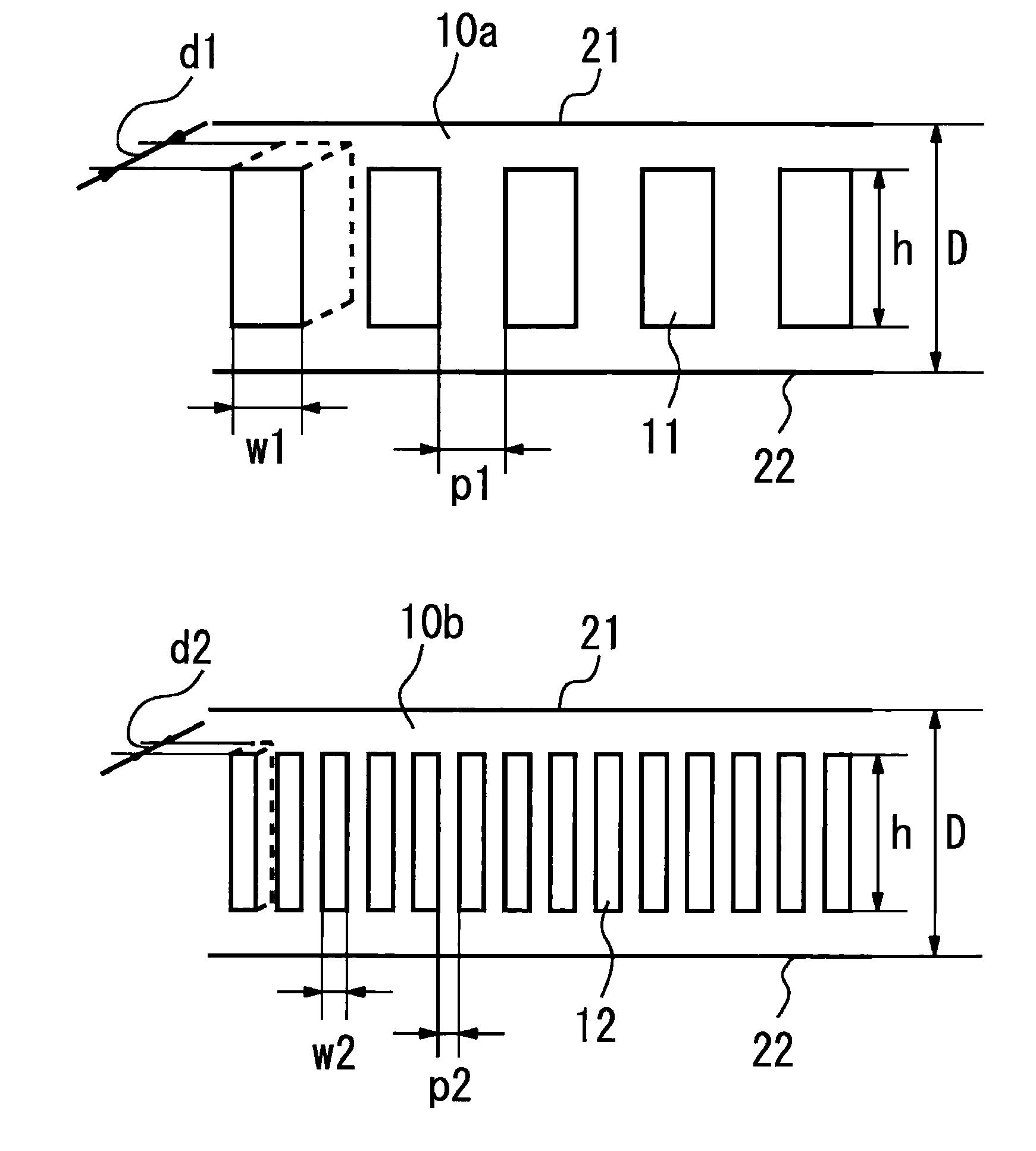

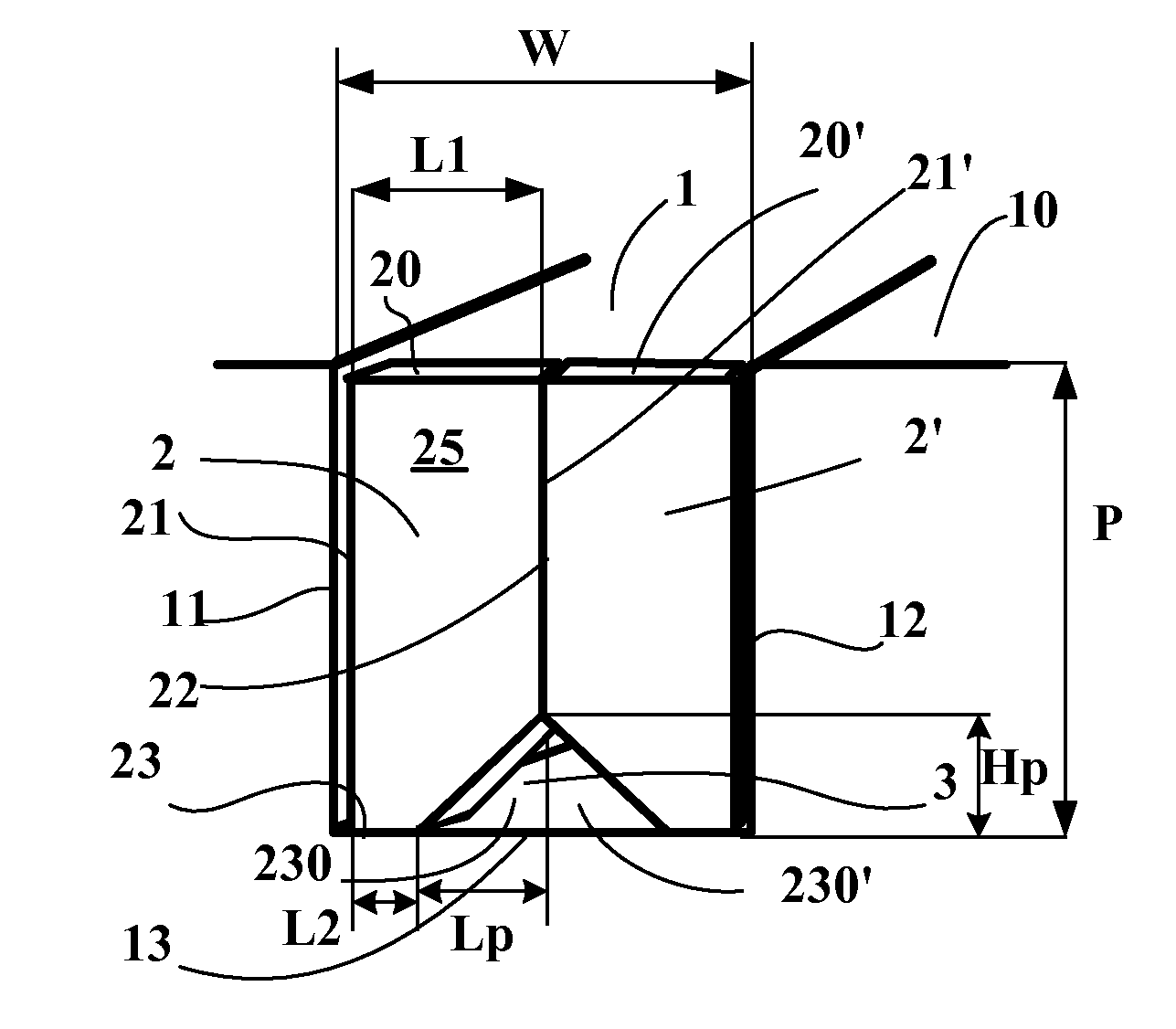

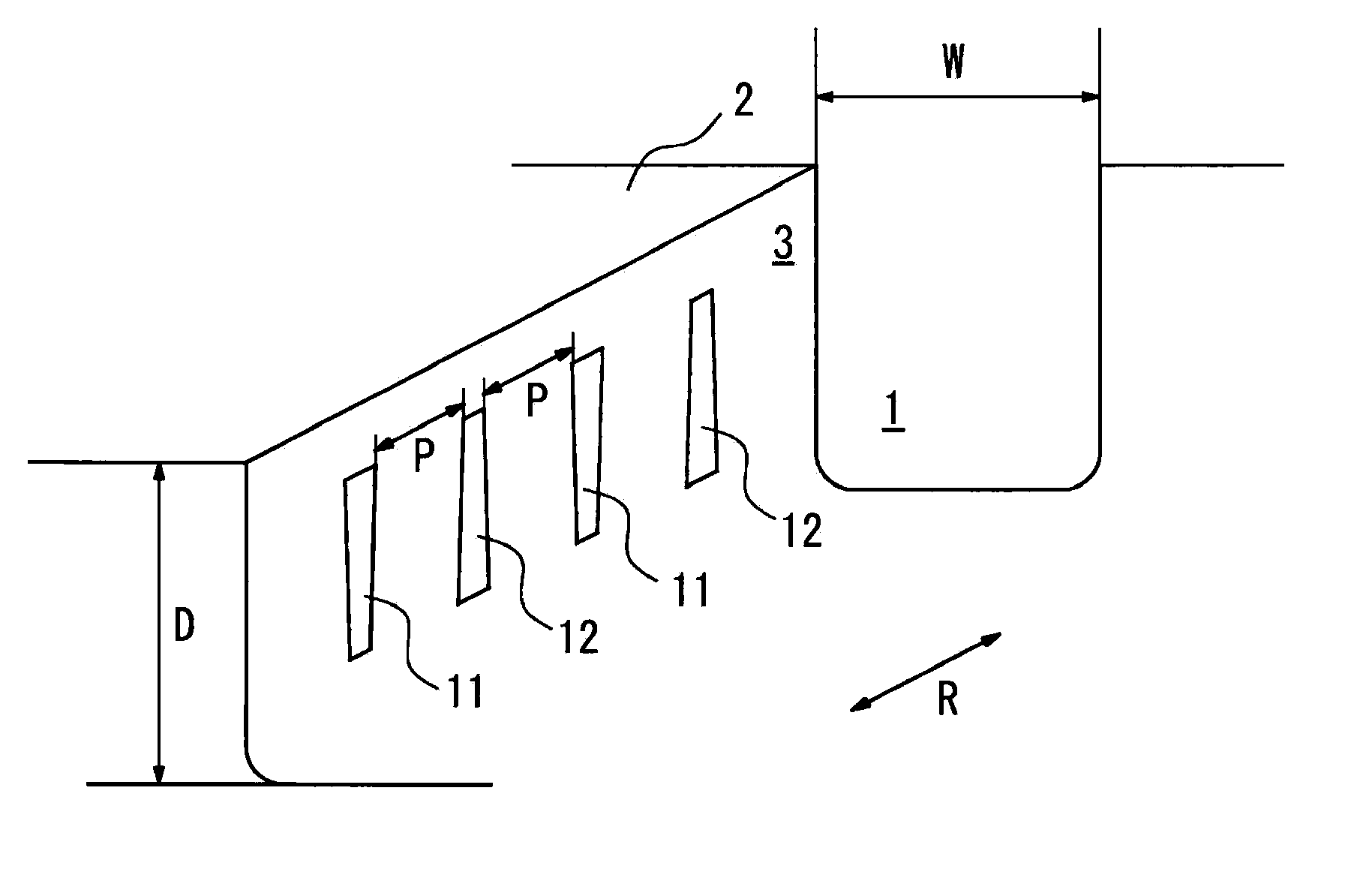

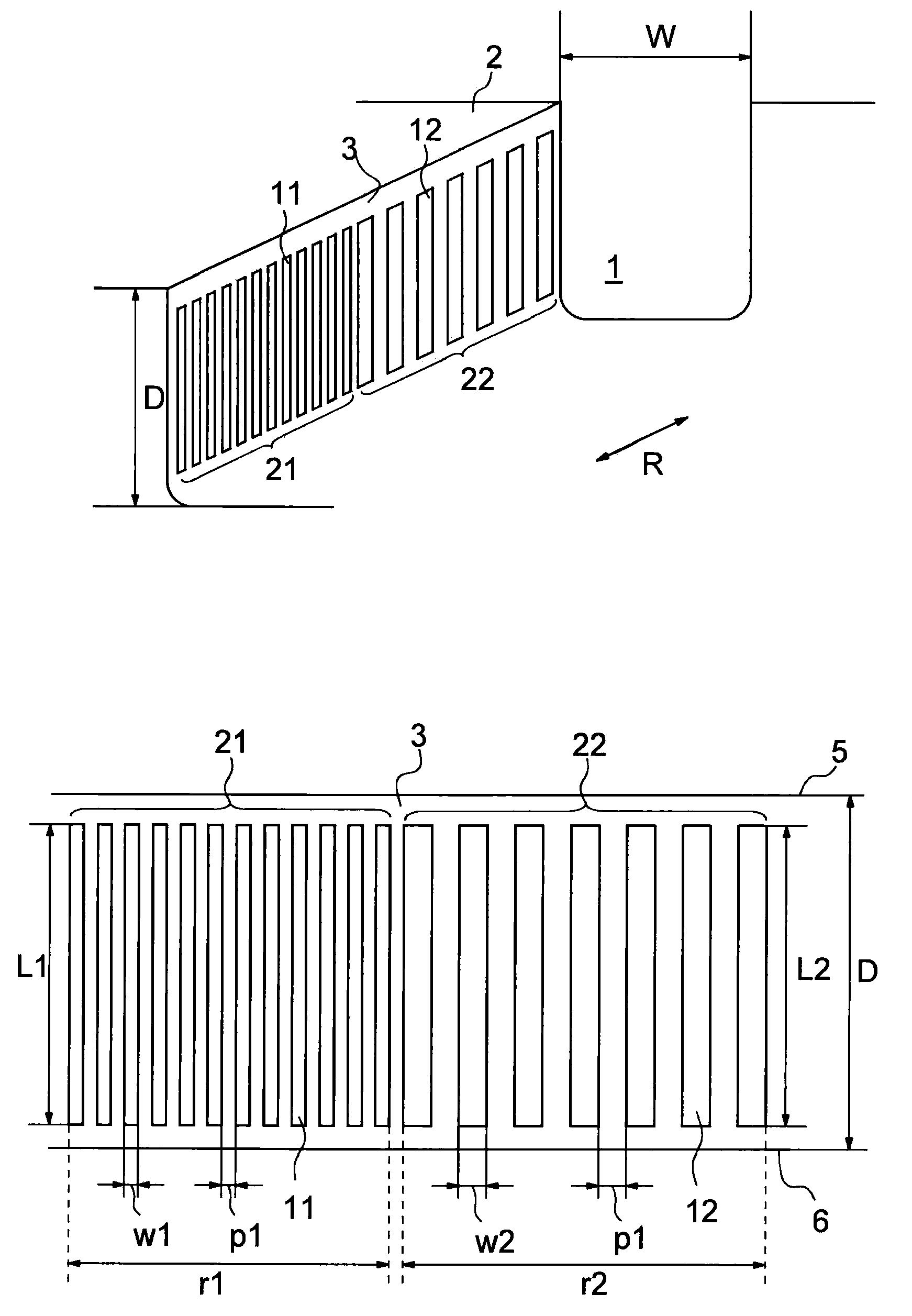

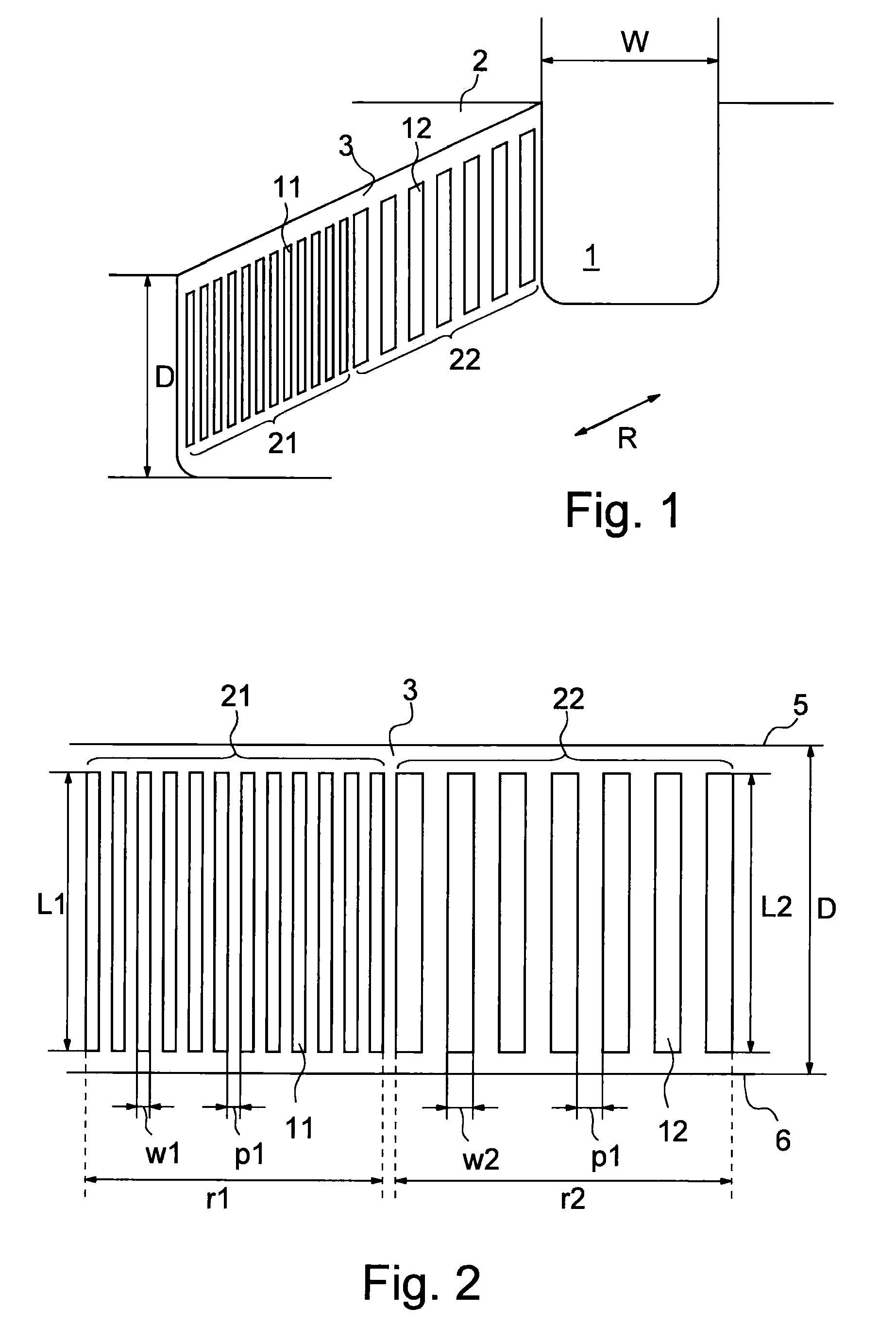

Pneumatic tire with tread having oblong holes

ActiveUS8439093B2Increase resistanceReduce resonance noiseTyre tread bands/patternsNon-skid devicesNoise levelEngineering

The present invention provides a pneumatic tire with reduced air columnar resonance noise level in comparison with the conventional pneumatic tires. The pneumatic tire comprises large-volume oblong holes 11 formed in a sidewall 10a on one side of a main groove 1 and small-volume oblong holes 12 formed in a sidewall 10b on the other side thereof, respectively, in which a width w1 and a depth d1 of the large-volume oblong hole 11 are at least not less than 0.4 mm and more than 0.05 times but less than 0.25 times a width W of the main groove 1, and a space p1 between the large-volume oblong holes 11 is at least not less than 0.8 mm and more than 0.2 times but less than 1.0 times the width W, a width w2 and a depth d2 of the small-volume oblong hole 12 are at least not less than 0.2 mm and more than 0.01 times but less than 0.05 times the width W, and a space p2 between the small-volume oblong holes 12 is at least not less than 0.4 mm and more than 0.04 times but less than 0.2 times the width W, and each height h of the oblong holes 11 and 12 in the depth direction of the main groove 1 is 50 to 80% of a depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

Key structure with reduced resonant noise

ActiveUS9697965B2Reduce resonance noiseSimple structureEmergency actuatorsContact operating partsEngineeringElectrical and Electronics engineering

Owner:LITE ON ELECTRONICS (GUANGZHOU) LTD +1

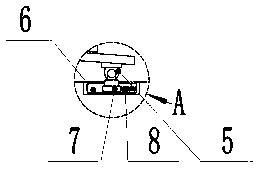

Noise-reducing device for a tire

ActiveUS20140338805A1Reduce resonance noiseSimple moldingTyre tread bands/patternsNon-skid devicesRoad surfaceMechanical engineering

Tread having a tread surface intended to come into contact with a road surface and comprising at least one groove of width W and of depth P delimited by two walls facing one another, these walls being joined together by a groove bottom, at least one groove comprising at least one closure device for at least partially closing this groove as it passes through the contact patch, each closure device comprising at least one flexible blade of suitable thickness that allows it to flex under the effect of a circulation of liquid, this at least one flexible blade projecting from the bottom of the groove, each flexible blade being delimited by a contact wall intended to come into contact with the road surface and by end walls each facing a wall delimiting the groove and lateral walls, this tread further comprising at least one passage between the bottom of the groove and each blade of the device, this passage being intended to ensure a minimal flow of water when driving on a water-covered road surface.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

Skeleton type BLDC motor

A rotor of a BLDC motor includes: a rotor divided into a north pole and a south pole on the basis of a magnetic pole separating line; and a stator at which the rotor is disposed with an air gap, the stator having a first pole shoe, a second pole shoe and a pair of detent grooves at its inner surface, wherein an air gap forming portion for enlarging an air gap between the rotor and the detent grooves is formed at both end portions of the rotor where the magnetic pole separating line passes, so that the rotor can maintain the motor performance and reduce resonance noise by reducing only higher degree of cogging torque from cogging torque generated when the motor is driven.

Owner:LG ELECTRONICS INC

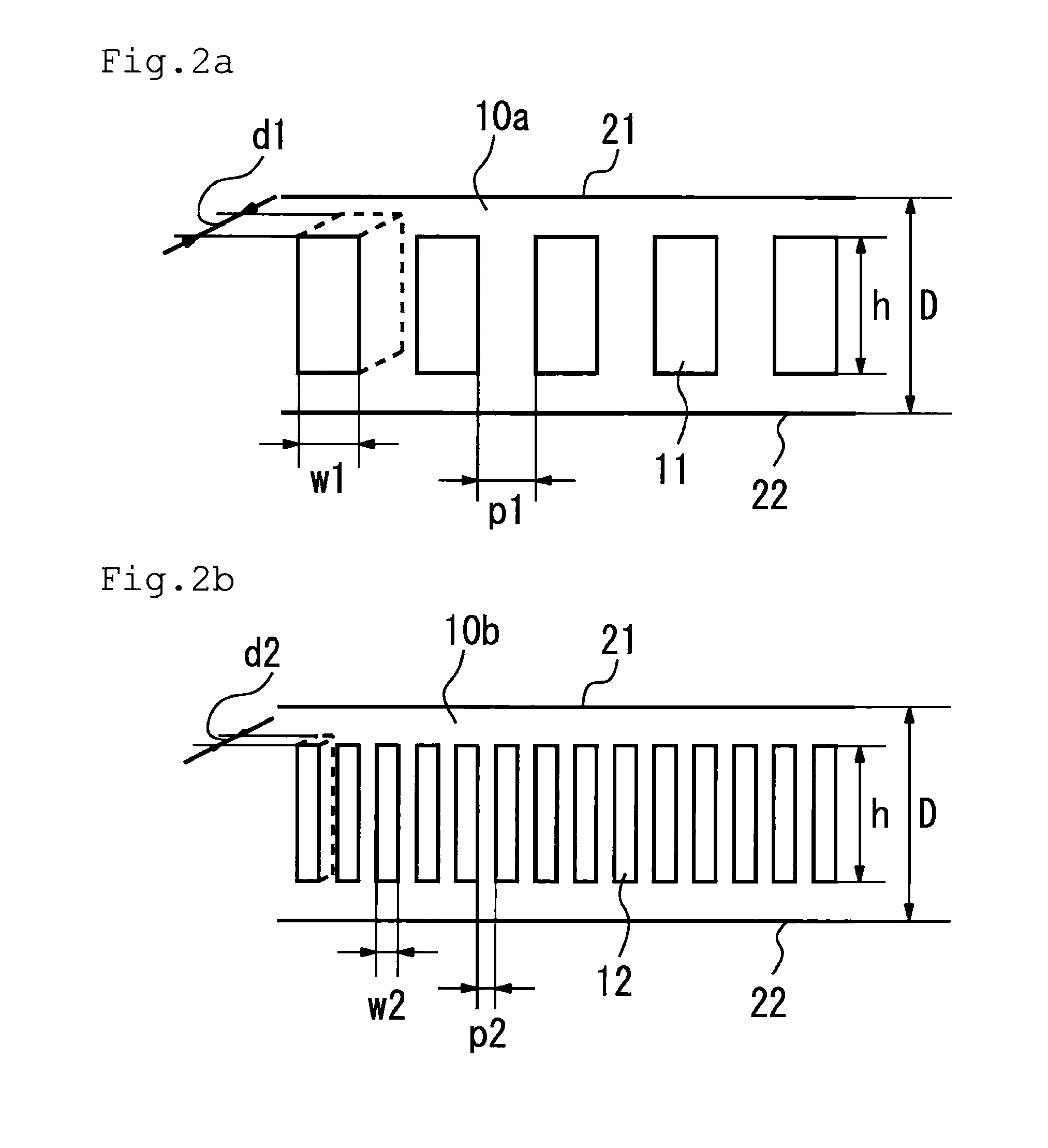

Pneumatic Tire

ActiveUS20100193100A1Decrease in rigidity of blockImprove the level ofInflatable tyresTyre tread bands/patternsEngineeringDepth direction

A pneumatic tire with improved steering stability without raising air columnar resonance noise is provided. The pneumatic tire comprises first oblong holes 11 having an opening portion of a trapezoidal shape that is elongated in the depth direction of a main groove 1 and whose depth D1 on the tread surface side is shallower than a depth D2 on the groove bottom side and second oblong holes 12 having an opening portion of a trapezoidal shape that is elongated in the depth direction of the main groove and whose depth D4 on the groove bottom side is shallower than a depth D3 on the tread surface side, wherein number of the first oblong holes 11 is 50 to 100% of the sum of oblong holes 11 and 12, the depths D2 and D3 are at least not less than 0.5 mm and 0.05 to 0.3 times a width W of the main groove 1, the depths D1, D4 are not greater than 0.1 times a depth D of the main groove 1, widths w of the oblong holes 11, 12 are at least not less than 0.5 mm and 0.05 to 0.2 times the width W of the main groove 1, and heights H of the oblong holes 11, 12 in the depth direction of the main groove are 50 to 80% of the depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

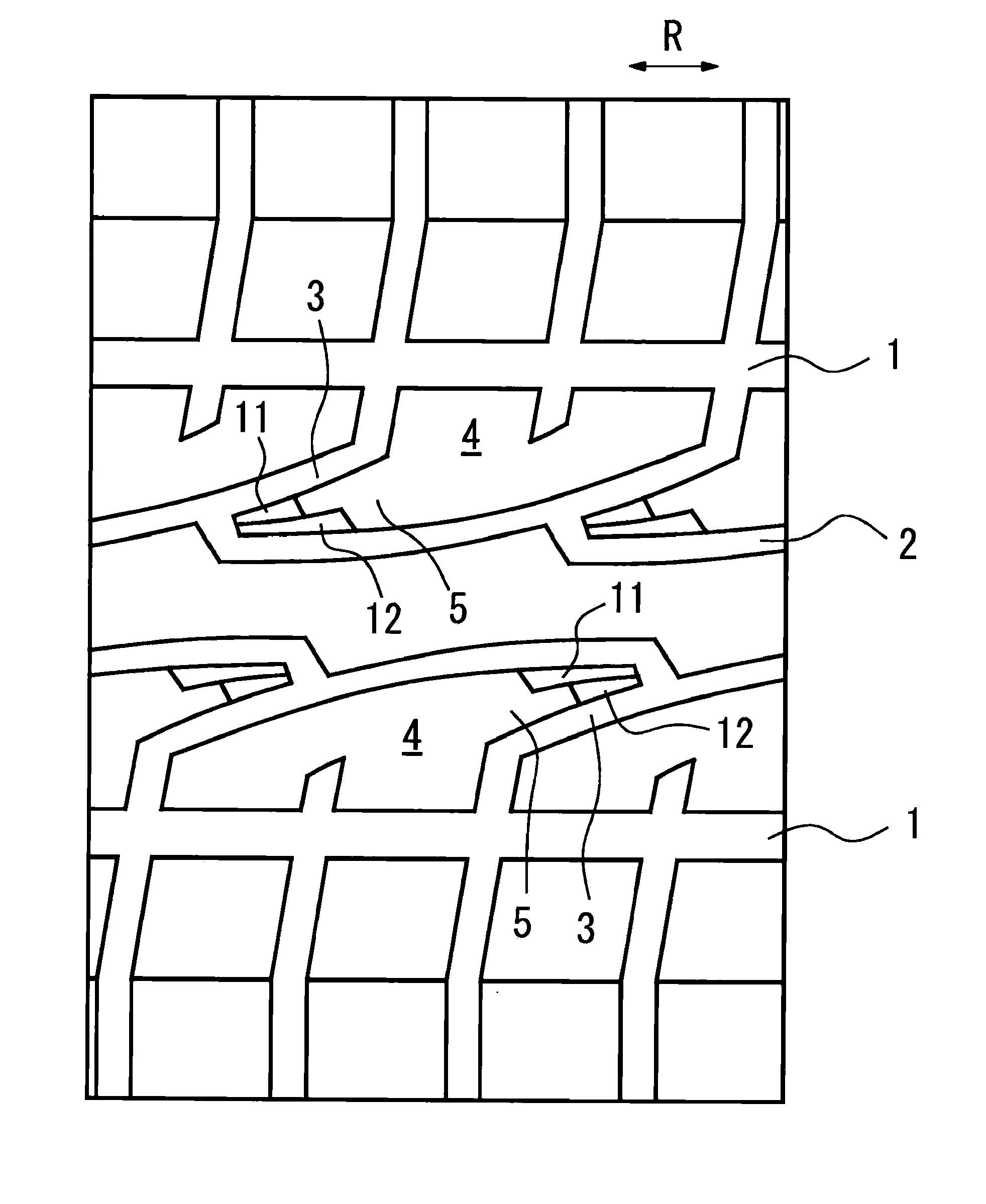

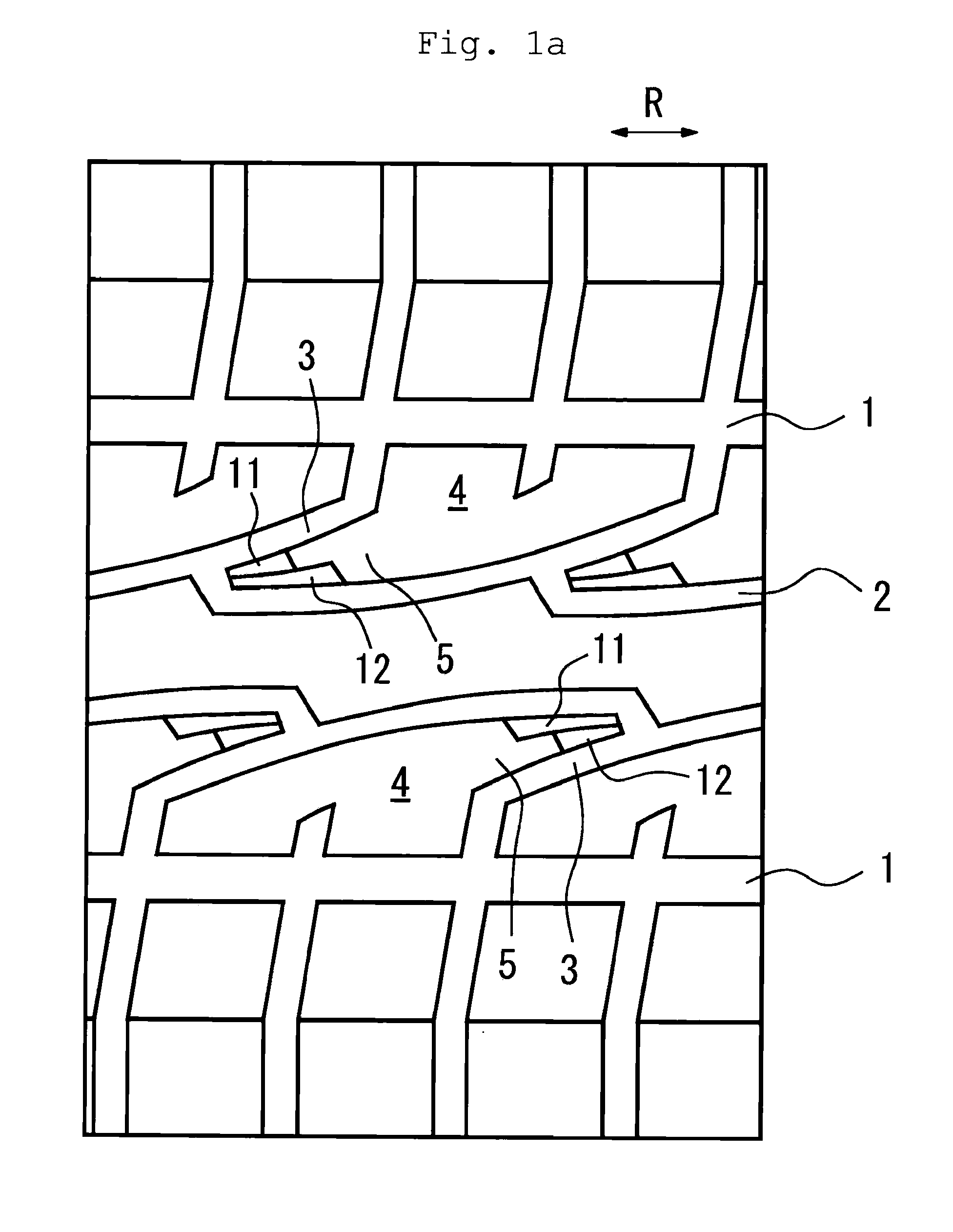

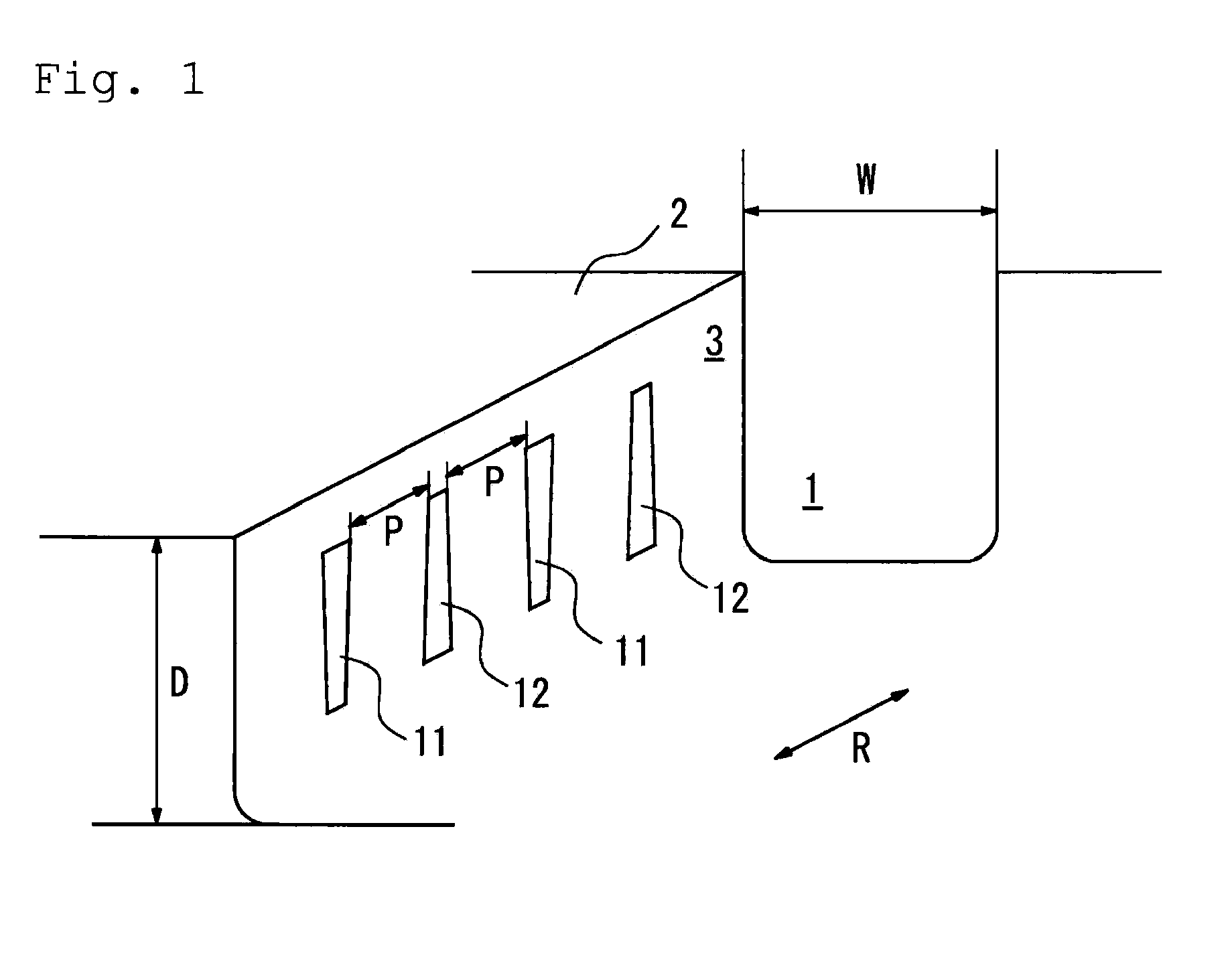

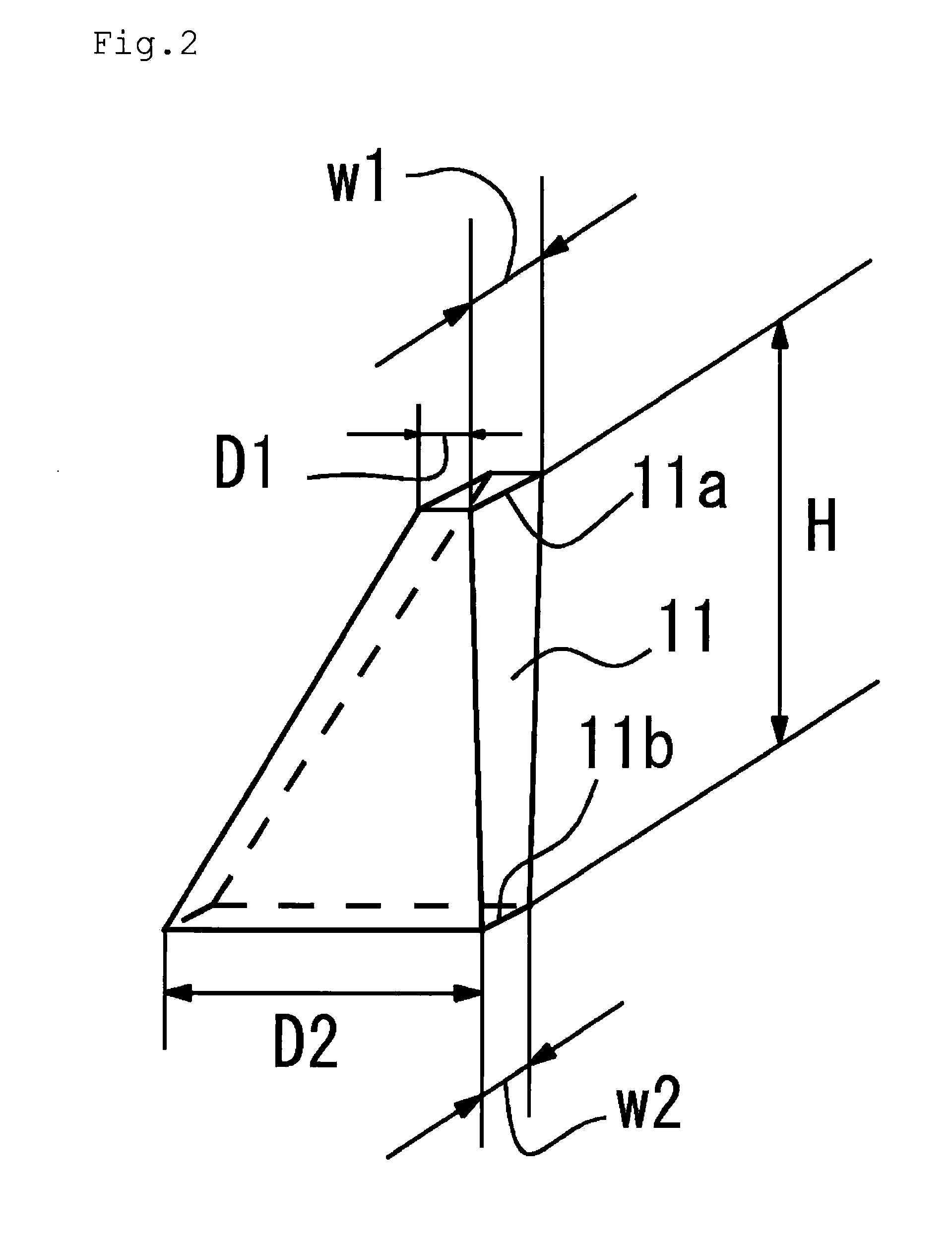

Pneumatic Tire

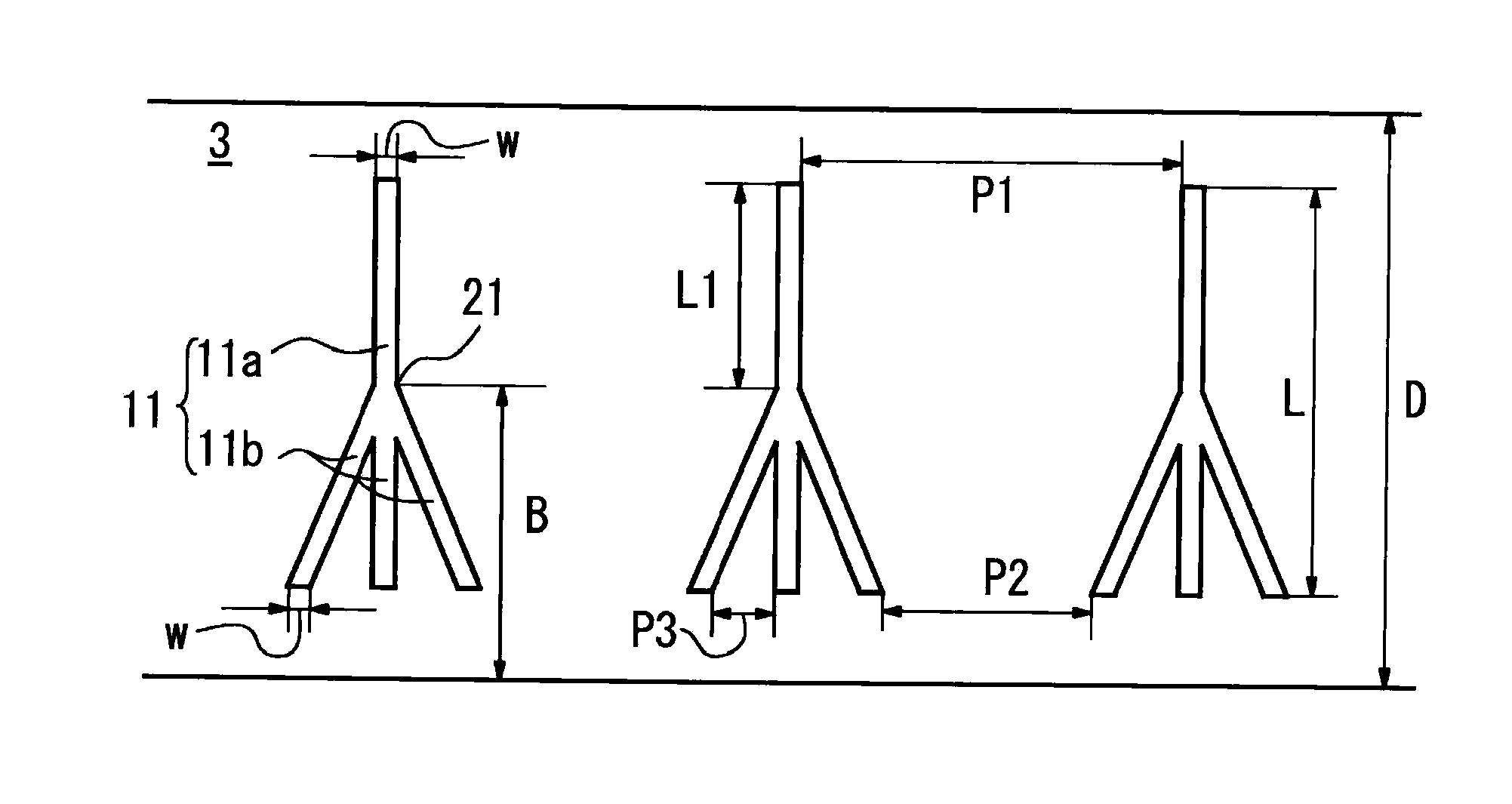

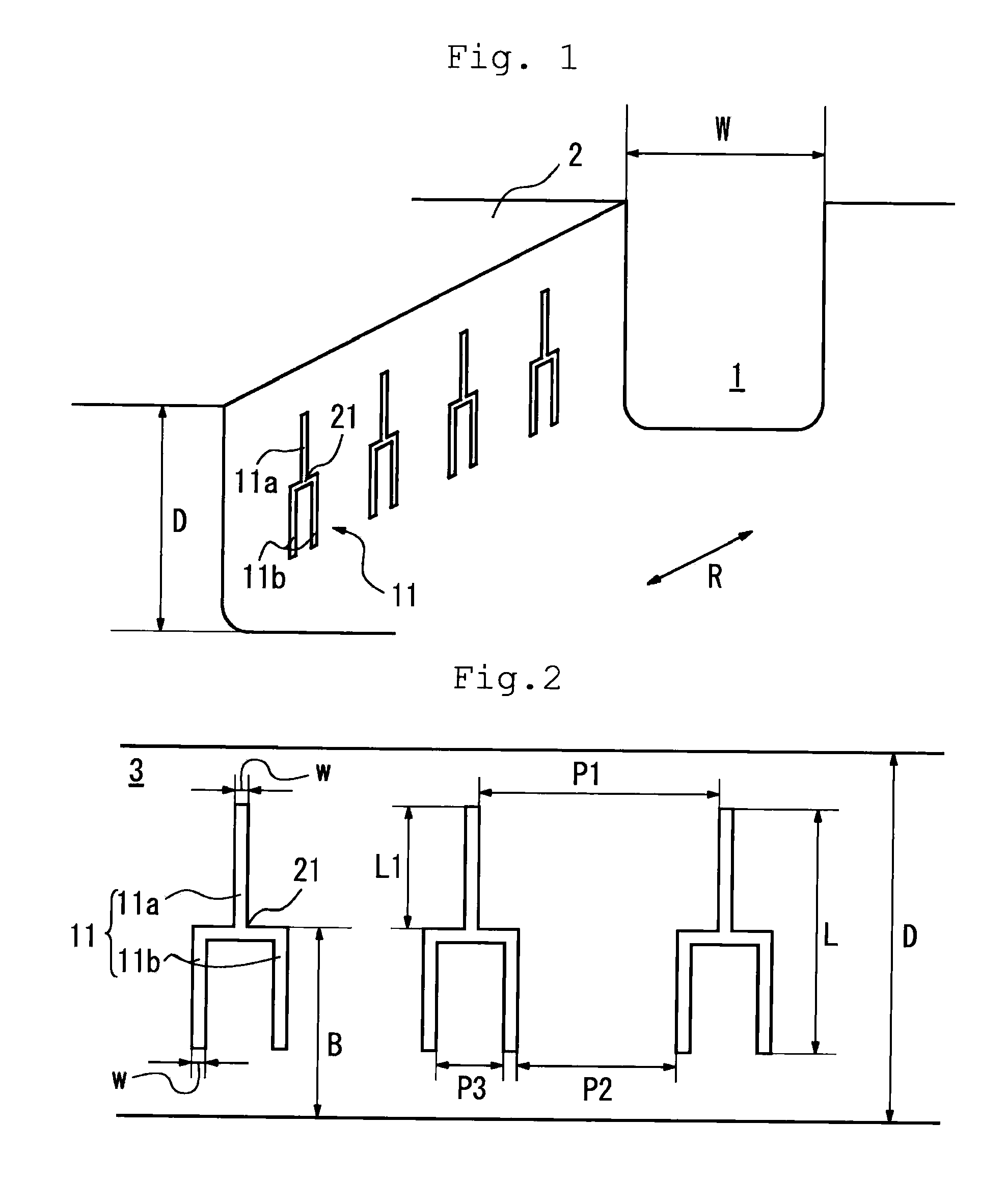

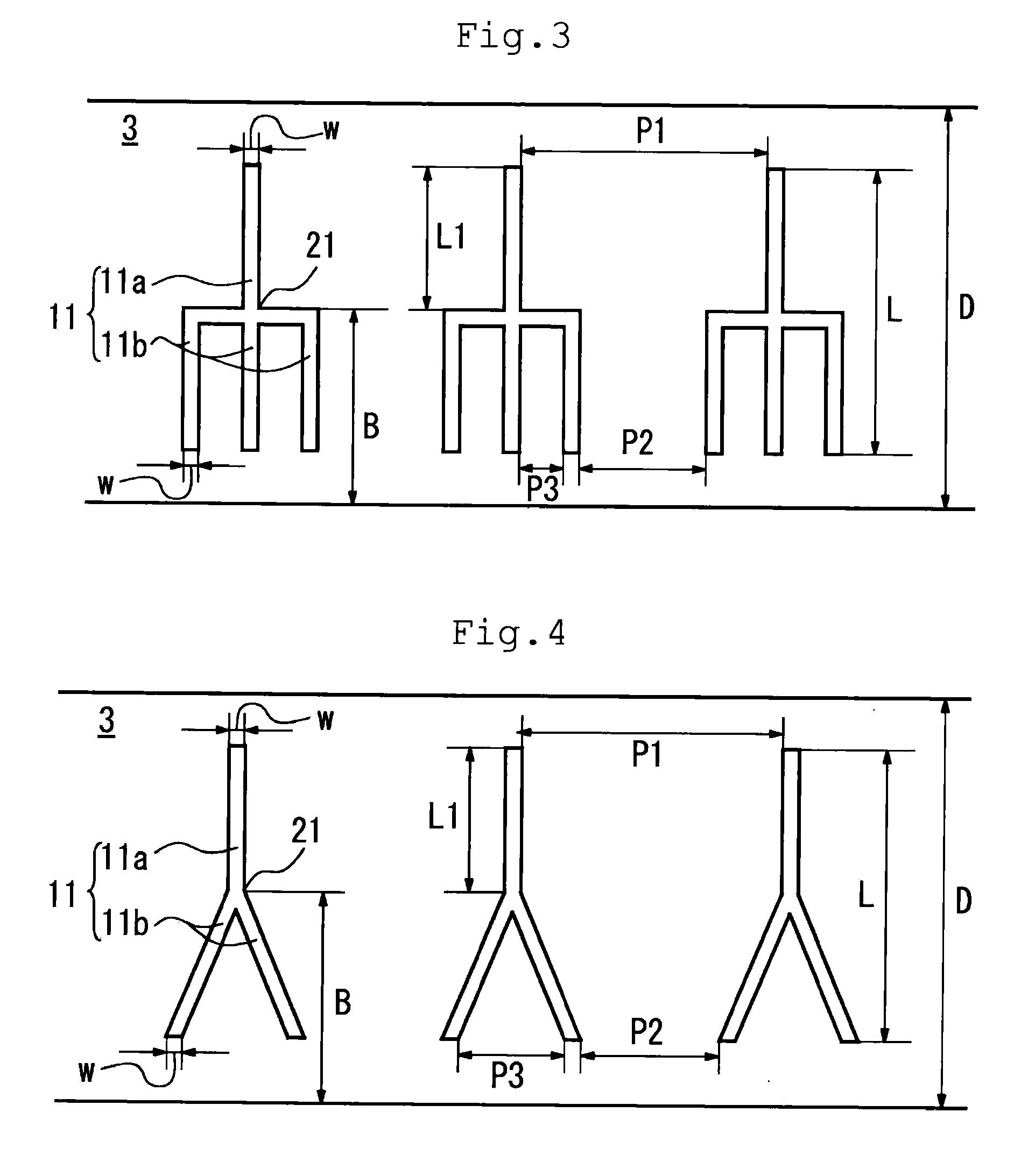

InactiveUS20100288408A1Reduce stiffnessIncrease airflowTyre tread bands/patternsNon-skid devicesResonanceNoise level

A pneumatic tire with improved steering stability without raising air columnar resonance noise level is provided. The pneumatic tire comprises upper thin grooves 11a extending from a branch point 21 in the depth direction of a main groove on the tread surface side and a plurality of lower thin grooves 11b extending from the branch point 21 in the depth direction of the main groove on the groove bottom side, which are formed at intervals along the tire circumferential direction R in a sidewall of the main groove and a distance B from the groove bottom of the main groove 1 to the branch point 21 is 30 to 60% of the depth D of the main groove 1.

Owner:TOYO TIRE & RUBBER CO LTD

Pneumatic Tire

InactiveUS20090242090A1Increase frictional resistanceSignificant changeTyre tread bands/patternsEngineeringDepth direction

A pneumatic tire has main grooves 1 extending in the tire circumferential direction, plural types of oblong hole groups 21 and 22 in the sidewall 3 of the main groove 1. The oblong hole groups have oblong holes 11 and 12 of the same shapes extending in the groove depth direction of the main groove 1 in the circumferential direction at intervals At least one of the widths w1 and w2, the depths d1 and d2, the spaces p1 and p2 of the oblong holes 11 and 12 differs from those of the other oblong hole groups by 0.1 mm or more, the circumferential lengths r1 and r2 of each oblong hole group is at least 5 mm, the circumferential length of respective oblong hole groups except the longest oblong hole group is not less than 10% of the circumferential length of the longest oblong hole group.

Owner:TOYO TIRE & RUBBER CO LTD

Laser marking machine with smoke and dust removing functions

InactiveCN108941902ARealize moving up and downPrecise positioningLaser beam welding apparatusResonanceEngineering

The invention discloses a laser marking machine with smoke and dust removing functions. The laser marking machine comprises a base, a platform, a double-shaft motor, a laser marking head and smoke anddust removing mechanisms, wherein a marking table is further arranged at the center of the upper surface of the platform, the smoke and dust removing mechanisms are arranged on the two sides of the marking table, a dust removing screen and a smoke removing filter screen are sequentially arranged inside each smoke and dust removing mechanism, a shell is fixedly installed in each smoke and dust removing mechanism, and a dust suction machine is arranged in each shell. Meanwhile, the dust suction machines work in the marking process, and dust and smoke which are generated in the marking process are adsorbed into the dust removal screens and the smoke removing filter screens, so that the functions of removing dust and removing smoke are achieved, and the environment of a processing site is improved. Meanwhile, the dust removing screens and the smoke removing filter screens are all inserted, so that cleaning is convenient to achieve. In the marking process, damping columns and damping spring pieces can play a role in damping, so that resonance noise generated in the marking process is reduced, the operation site environment is improved, and the ear hearing capacity of operators can be protected.

Owner:珠海横琴新区辉腾电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com