Improvement to noise attentuator devices for tyres

A tire and resonance noise technology, which is applied to tire parts, tire tread/tread pattern, wheels, etc., can solve the problem of reducing the lateral stiffness of the tread and achieve the effect of reducing resonance noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

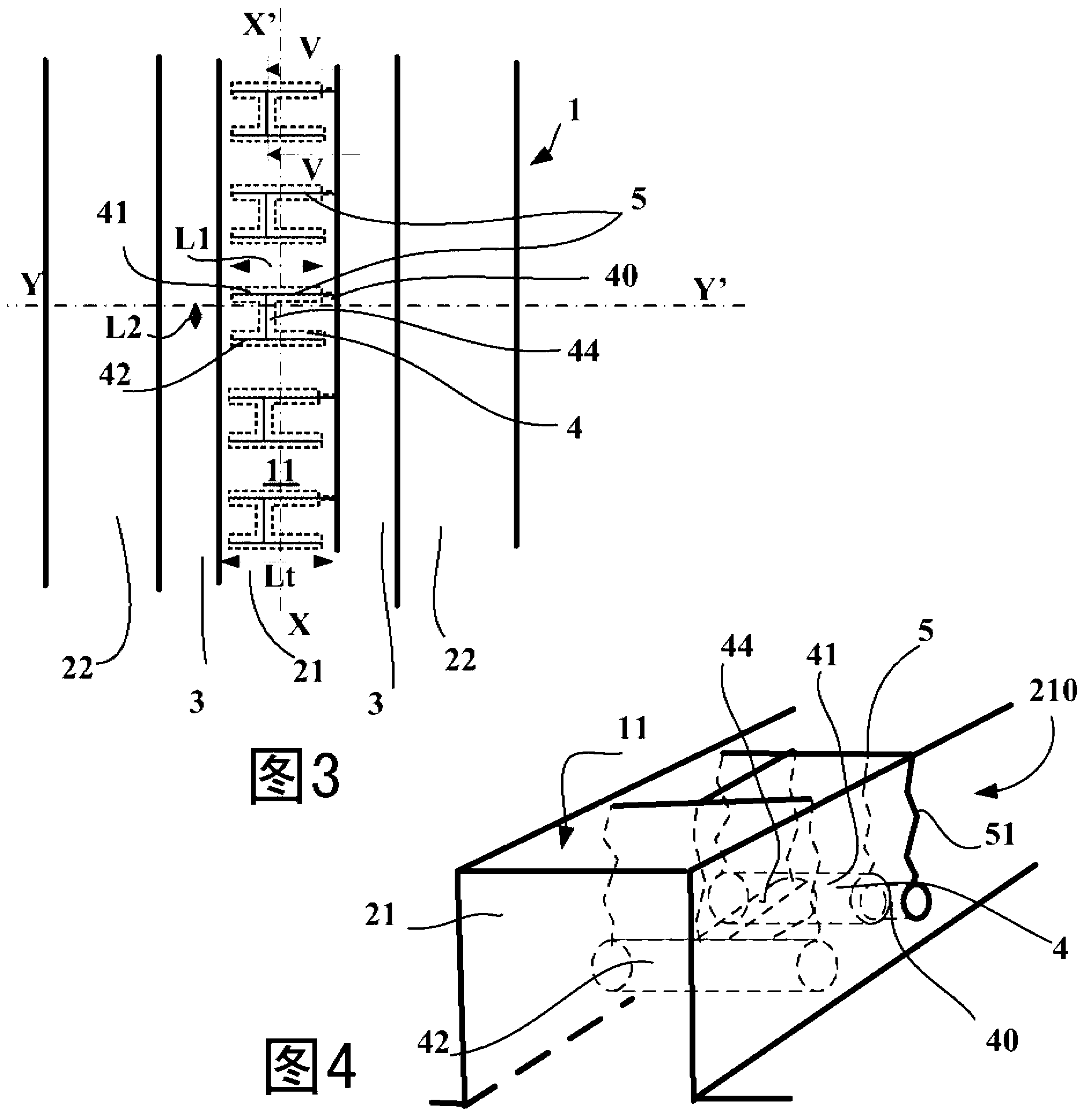

[0047] To make the drawings easier to understand, the same reference signs are used for the description of the different variants of the invention when they designate the same kind of structural or functional elements.

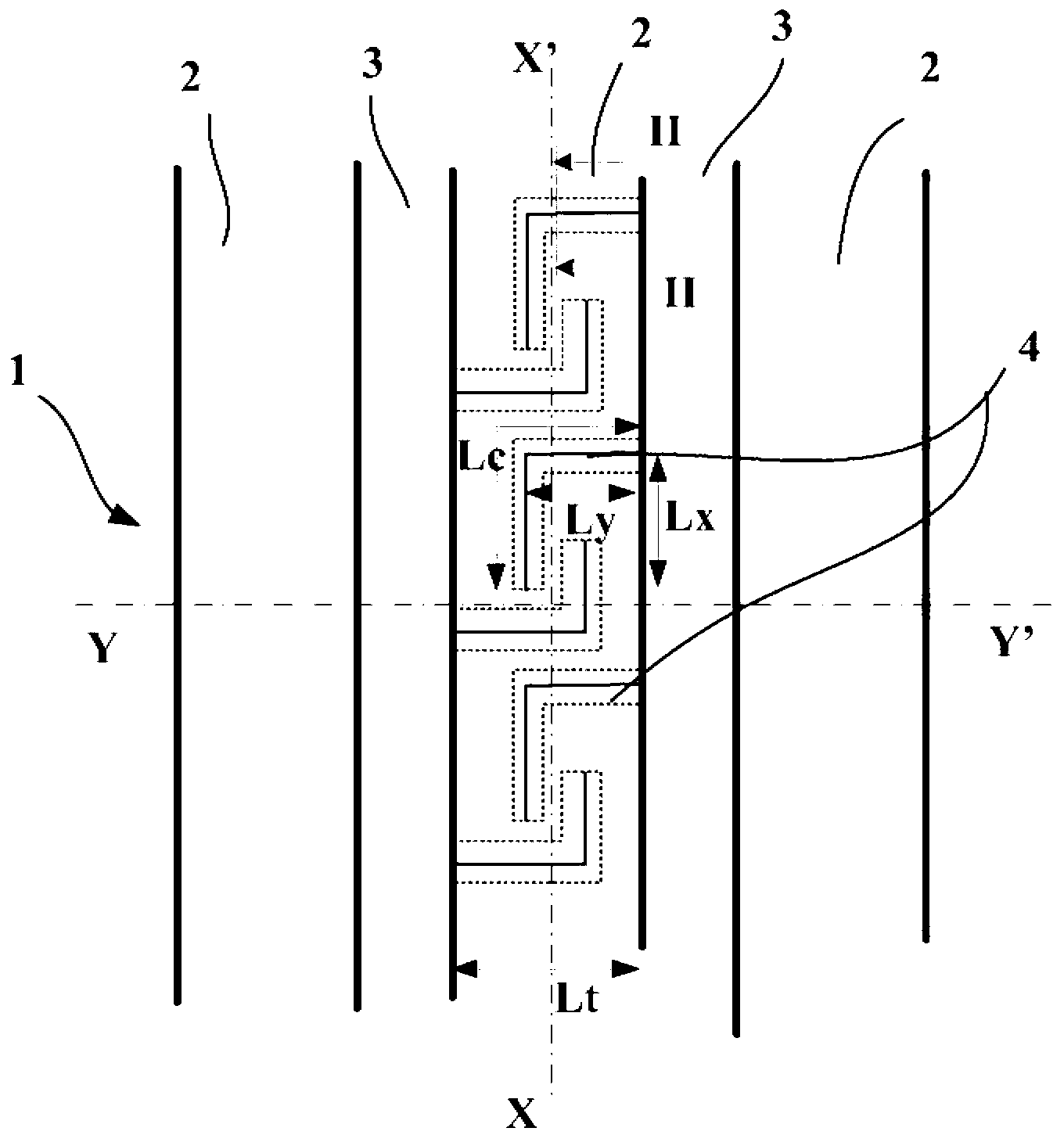

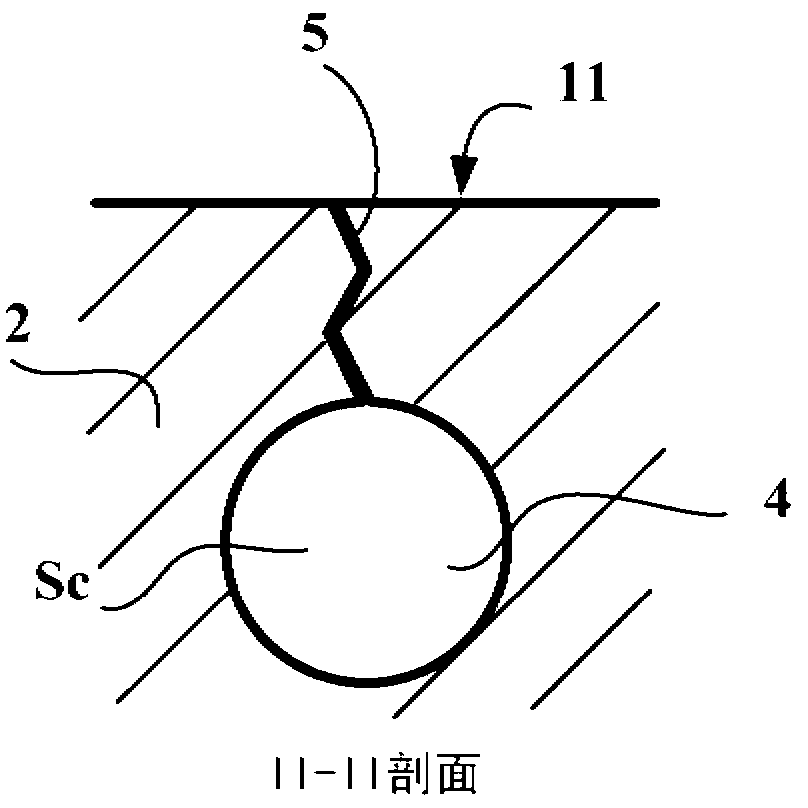

[0048] Figure 1 shows a part of a tread 1 according to the prior art described in the application with publication number WO 2009 / 095288. This FIG. 1 shows three ribs 2 with a circumferential orientation defining two grooves 3 . Each rib has a width Lt. In order to reduce the noise level caused by the resonance of the air in the two grooves 3, a plurality of cavities 4 in the shape of the letter "L" are formed in the central rib, each of the two branches of this cavity has a substantially same length. Thus, the total length Lc of this cavity in the circumferential direction (indicated by the direction YY'' in Figure 1) and the sum Ly is substantially equal to the total length Lc of this cavity in the transverse direction (indicated by the direction XX in Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com