Low-noise air pump

A low-noise, air-pump technology, applied in pump components, variable-capacity pump components, and liquid-variable-capacity machinery, etc., can solve the problems of high noise, large impact, and short airflow passages of the air pump, and reduce operating noise and reduce Operating noise and impact reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

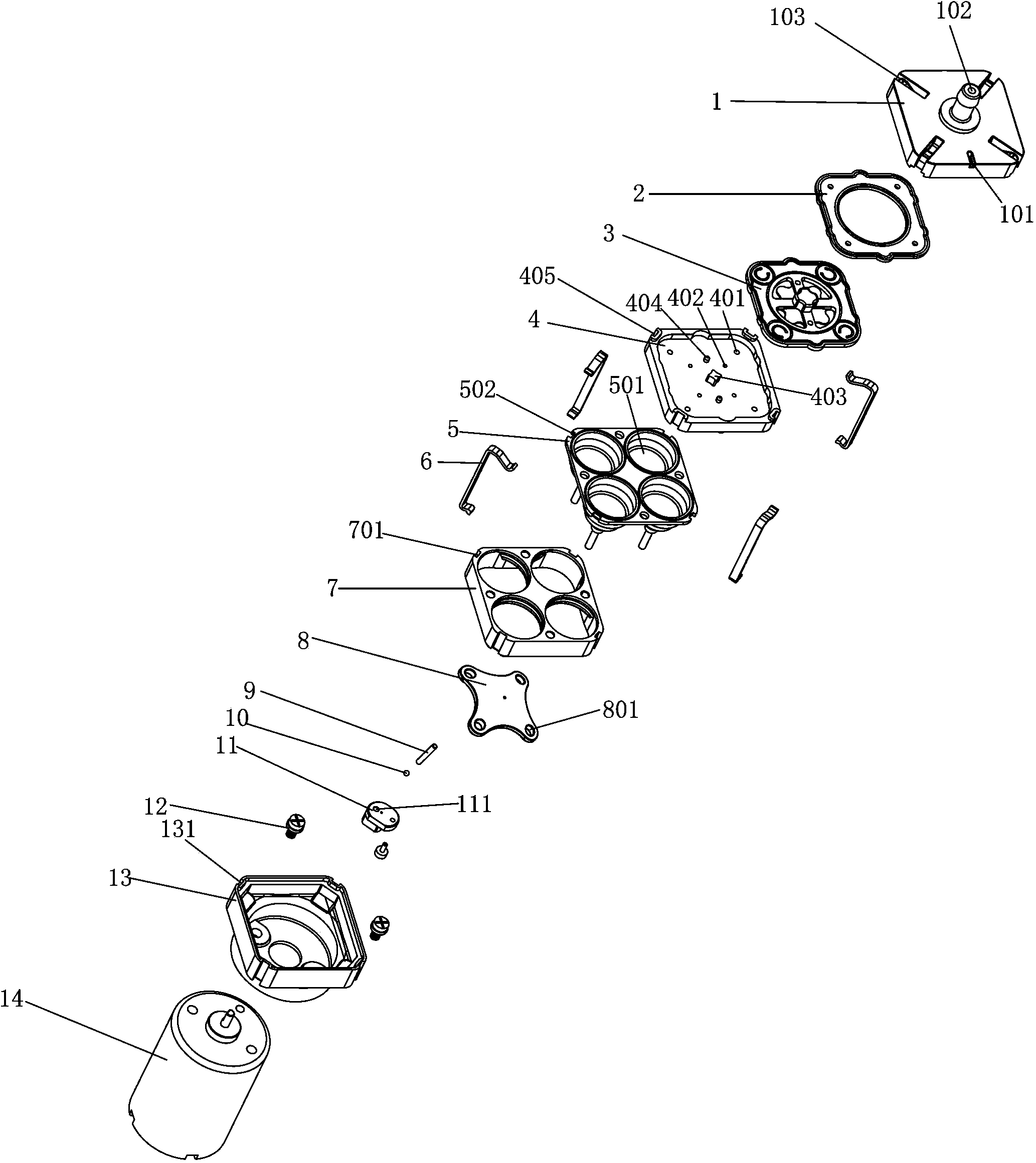

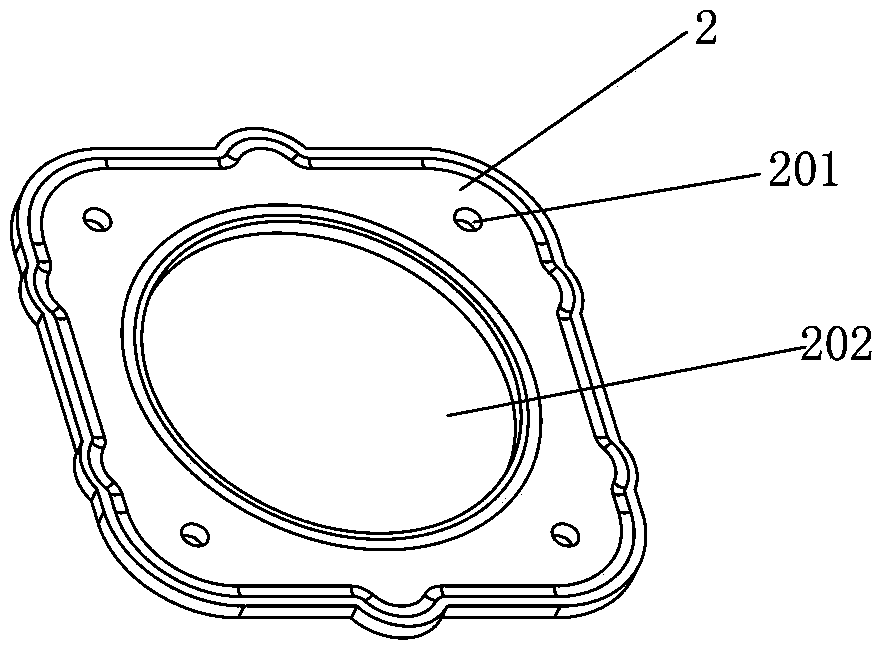

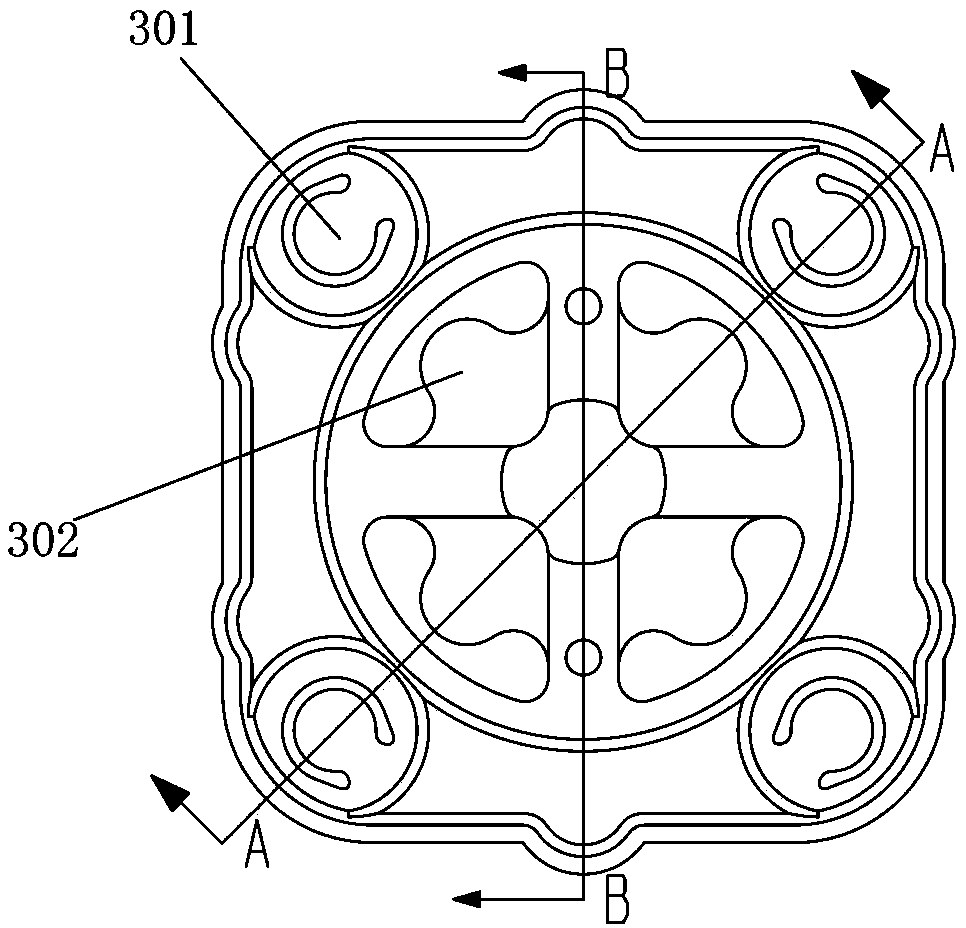

[0024] Embodiments, please refer to the accompanying drawings, a low-noise air pump of the present invention includes an upper cover 1 provided with an exhaust port 102 and an air inlet 101, a cylinder body 7, and a piston 5 integrally provided with four air bags 501 , base 13, air inlet and outlet one-way flow distribution device, motor 14, connecting rod mechanism and partition plate 2; upper cover 1, air inlet and outlet one-way flow distribution device, top of piston 5, cylinder body 7 and base 13 are fixed in sequence from top to bottom , the cylinder body 7 is correspondingly provided with four through holes, each airbag 501 of the piston 5 is respectively sleeved in the corresponding through holes of the cylinder body 7, the connecting rod mechanism and the motor 14 are installed on the base 13 respectively, and the drive shaft of the motor 14 is connected with the The connecting rod mechanism is connected by transmission, and the connecting rod mechanism and the air bag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com