Air port adjustable static pressure box with uniform outlet air

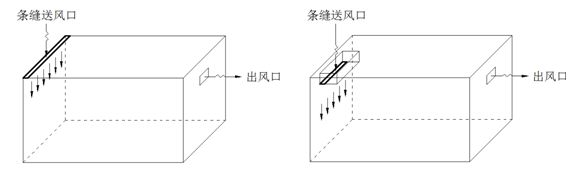

A technology of uniform air outlet and static pressure box, which is applied in the direction of pipeline layout and noise suppression, which can solve the problems of cumbersome installation, inapplicability, and high cost, and achieve the goals of reducing equipment operating noise, realizing adjustability, and extending flow distance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

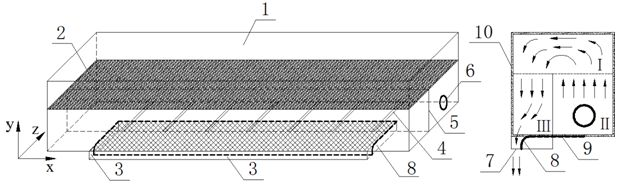

Embodiment 1

[0023] The numerical calculation model of the static pressure box is established according to the actual use situation. The length × width × height of the static pressure box shell is 2600 × 500 × 500mm; the length × width of the orifice plate is 2600 × 500mm, and the opening rate is 23.7%. The height of the bottom surface of the plenum is 300mm; the length × height of the partition is 2600 × 300mm, and it is installed vertically at a distance of 200mm from the front side of the plenum; 400mm, welded on the inner side of the lower wall of the rear lower area of the static plenum along the width direction of the plenum, and each card slot is arranged at equal intervals, with an interval of 300mm, a total of 7; In the slot; the diversion arc section of the slit air outlet is 1 / 4 of a circle with a radius of 50mm, and the arc section is connected to a 10mm vertical section. The adjustment plate, the diversion arc section, and the vertical section connected to the arc section are...

Embodiment 2

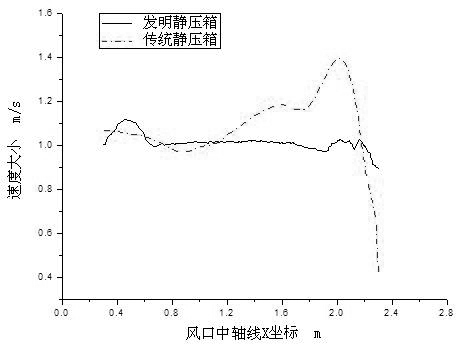

[0046] Others are the same as in Embodiment 1, and the width of the slit air outlet is 100 mm. It is calculated that the turbulent flow intensity at the air outlet of the plenum device of the present invention is 4.3%, and the turbulent flow intensity of the air outlet of the traditional shell-type plenum device is 10.4%, and the uniformity of the air outlet of the former is 242% higher than that of the latter.

Embodiment 3

[0048] Others are the same as in Embodiment 1, and the air outlet speed of the slit air outlet is 1.5m / s. It is calculated that the turbulent flow intensity at the air outlet of the plenum device of the present invention is 4.7%, and the turbulent flow intensity of the air outlet of the traditional shell-type plenum device is 10.9%, and the uniformity of the air outlet of the former is 232% higher than that of the latter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com