Conveying plate for large area panel

A conveying plate, large-size technology, applied in the field of conveying plates, can solve the problems of poor process, unsuitable manufacturing from an economic point of view, and difficult processing of scroll pins, and achieves the advantages of suppressing local sagging, good suspension flatness, and reducing jitter. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] The preferred embodiments of the invention will be described in detail below with reference to the accompanying drawings. The description content and the actual same component in each drawing are indicated by the same symbol, and the description will not be repeated. Furthermore, when describing the present invention, if a specific description of a known function or structure obscures the gist of the present invention, the description will be omitted.

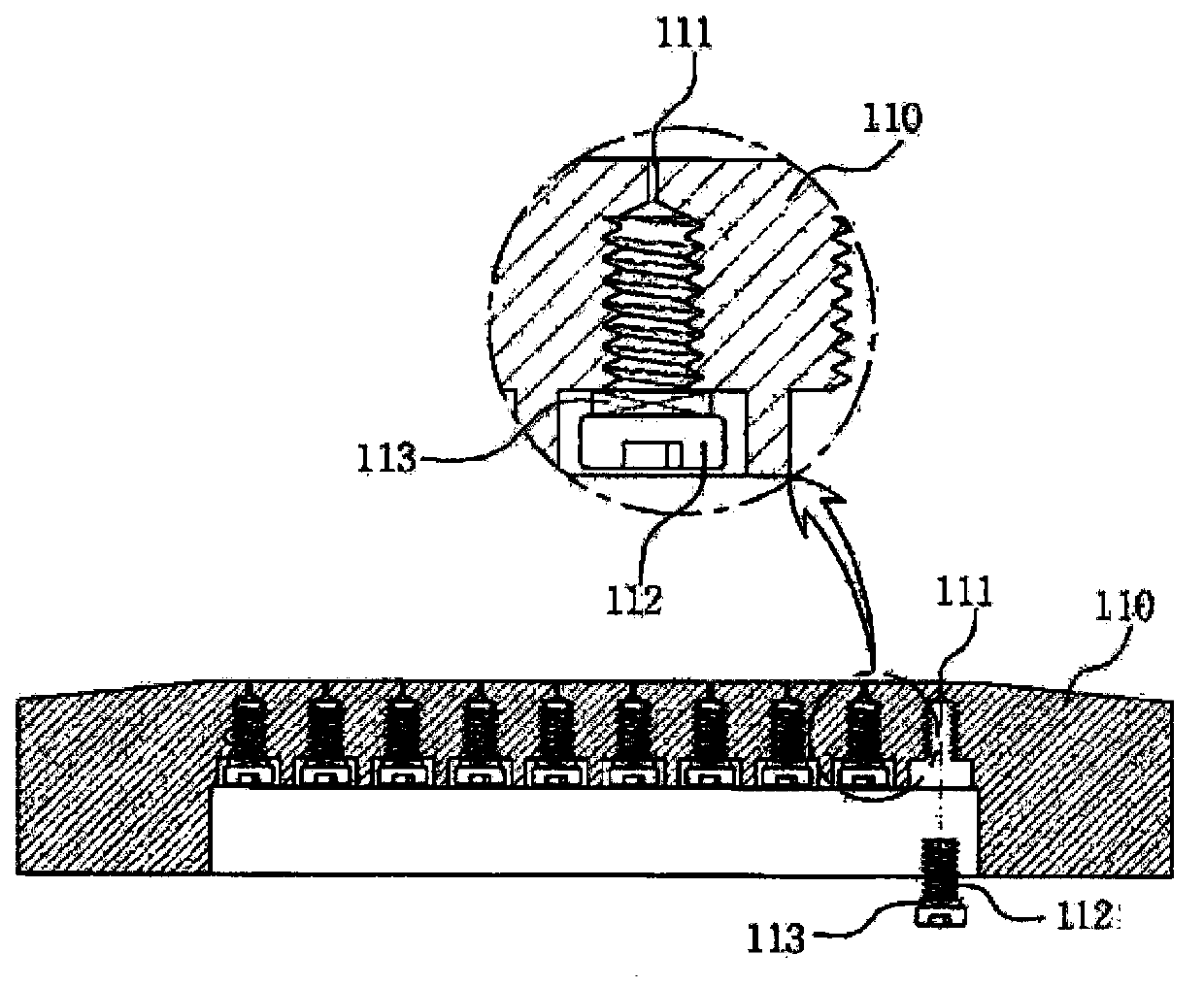

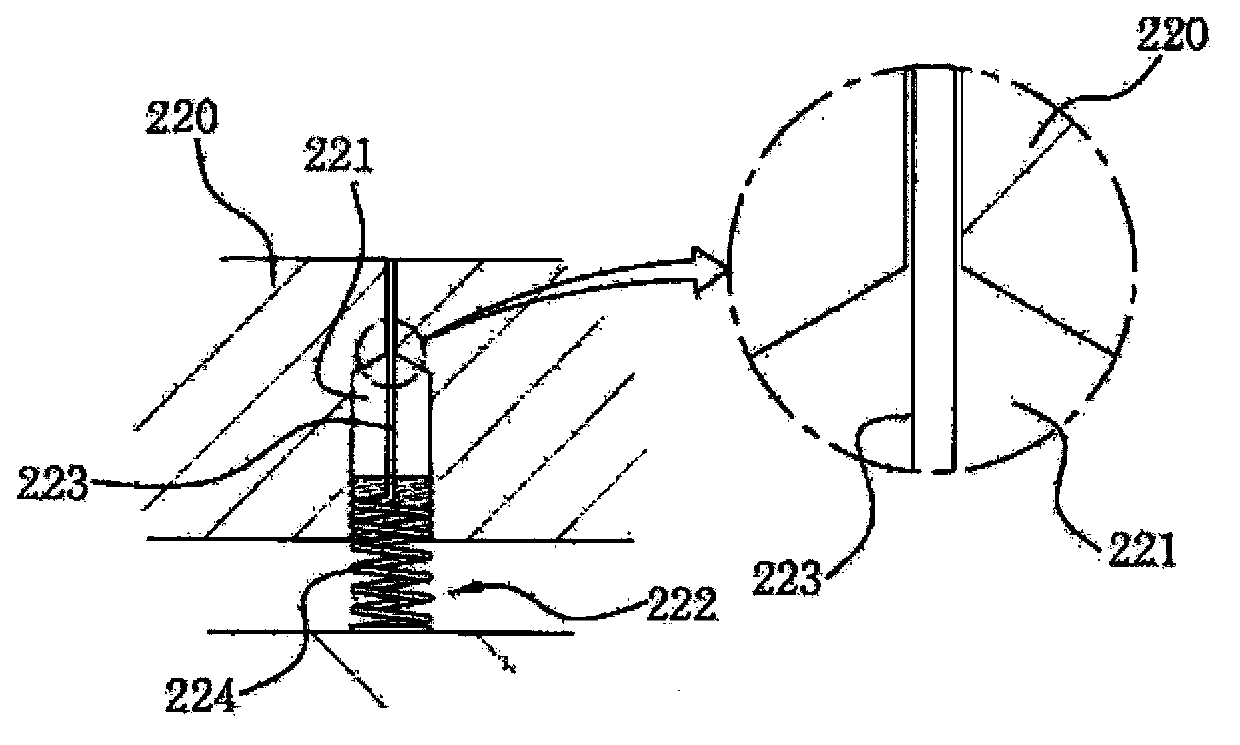

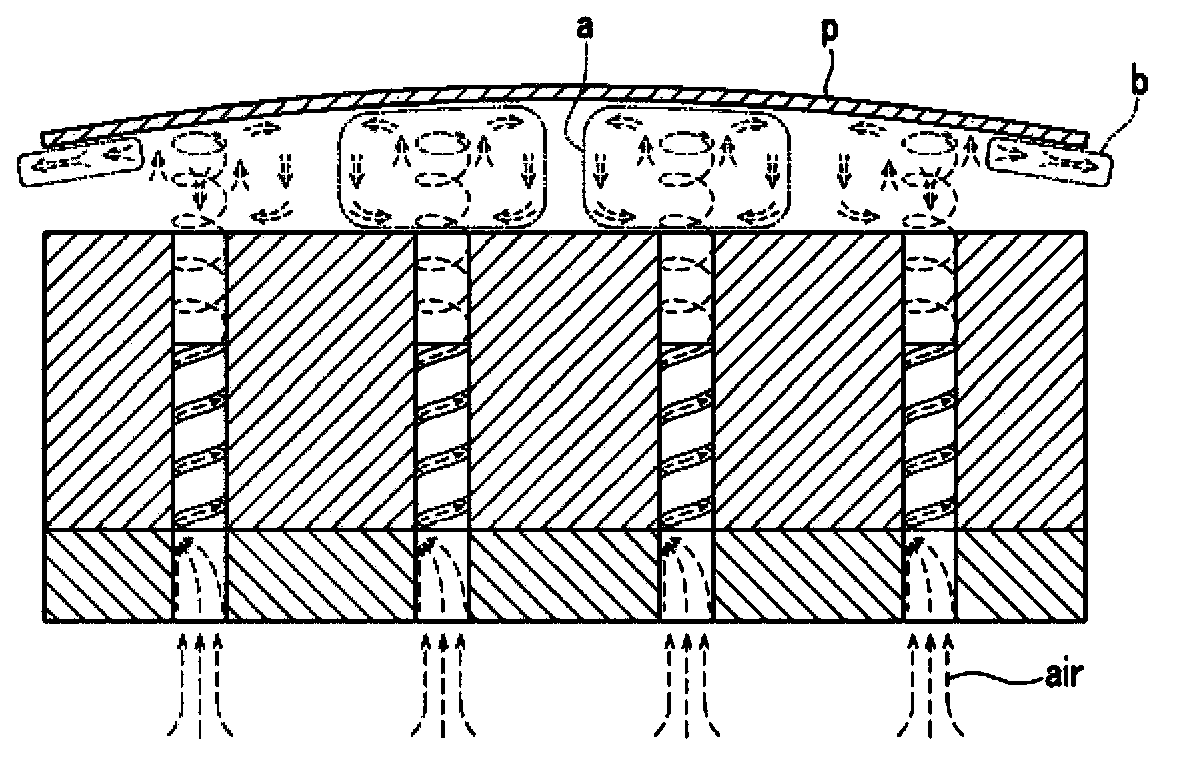

[0065] Figure 4 It is a perspective view of a conveyor plate for large-sized panels according to an embodiment of the present invention. In the figure, an air branch plate with a thin metal plate is interposed in the middle, and an upper plate with a plurality of air holes 33 is arranged on the upper side. The lower side of the air branch plate 20 shows a large-sized panel with a structurally configured lower plate 10. plate 1.

[0066] Figure 5 It is an exploded perspective view of a conveyor plate for large-sized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com