Patents

Literature

43results about How to "The transfer process is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

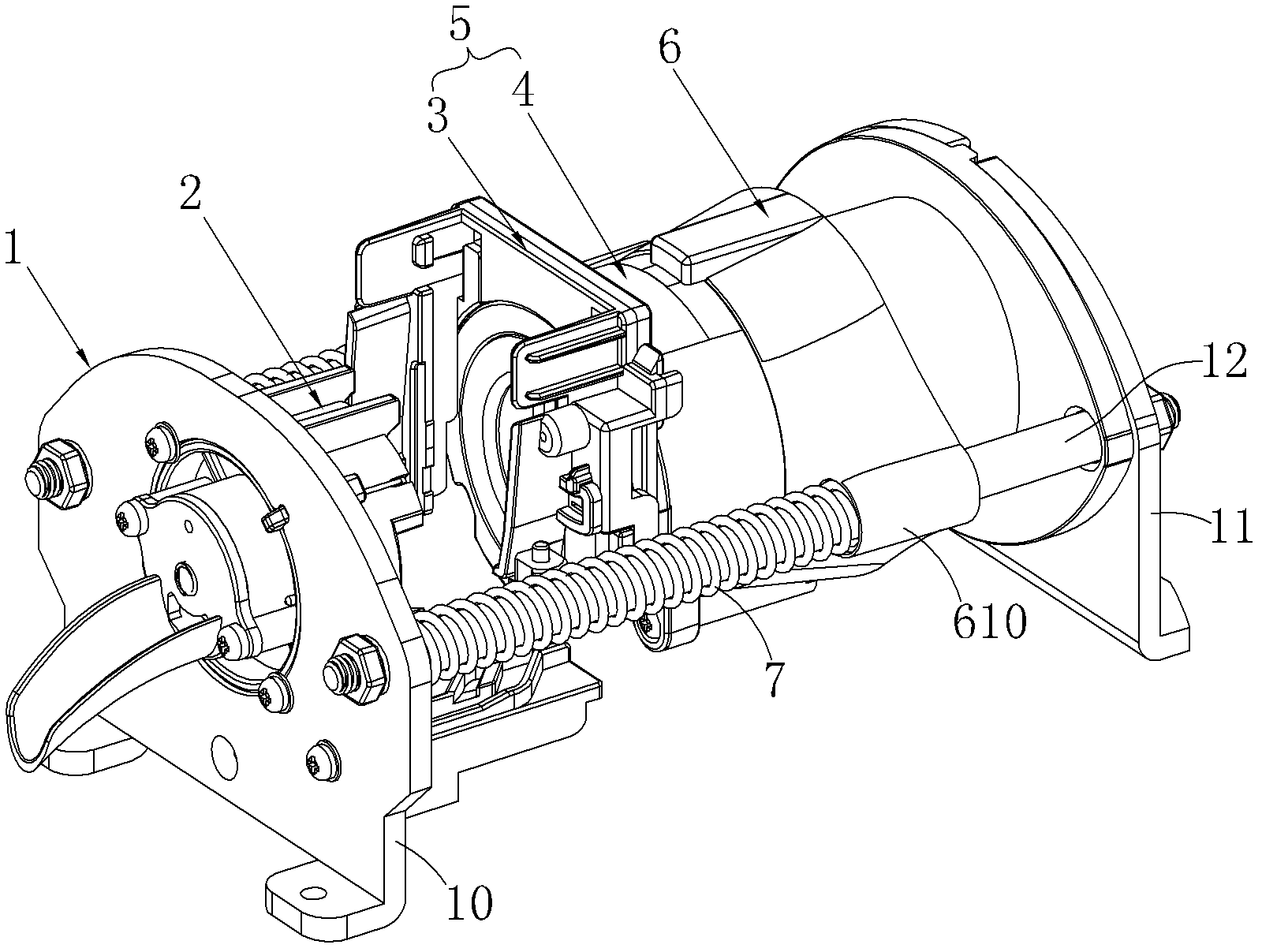

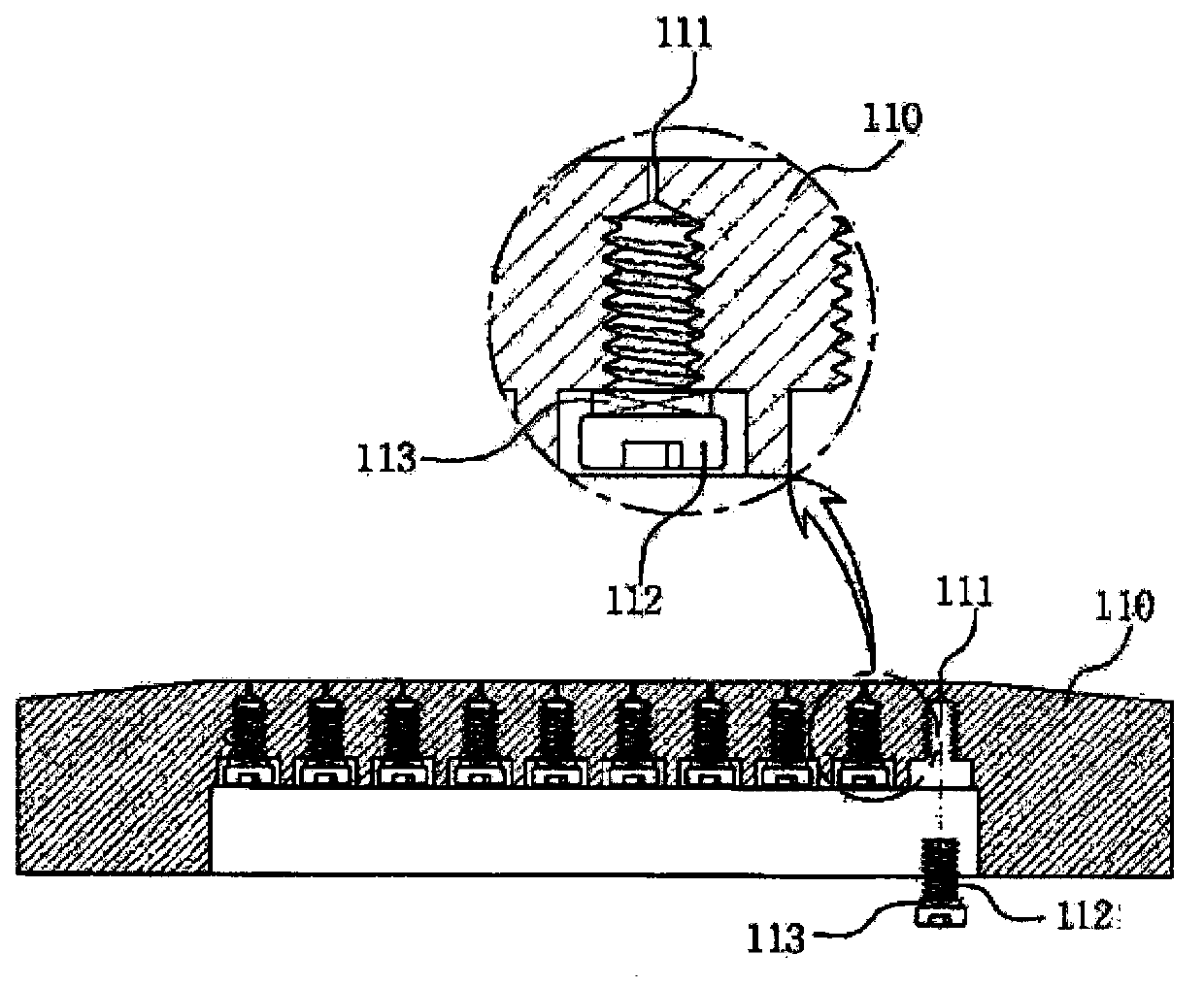

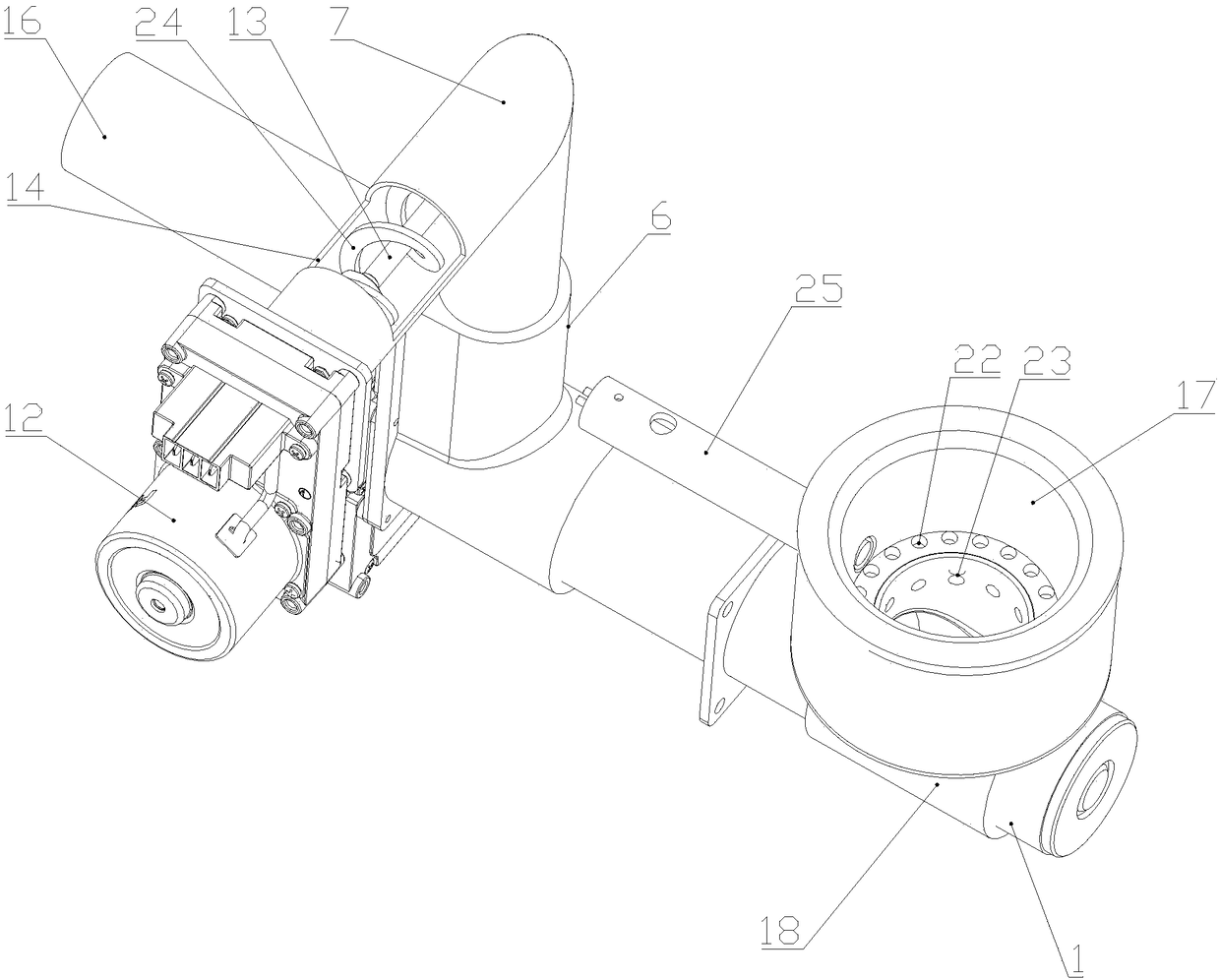

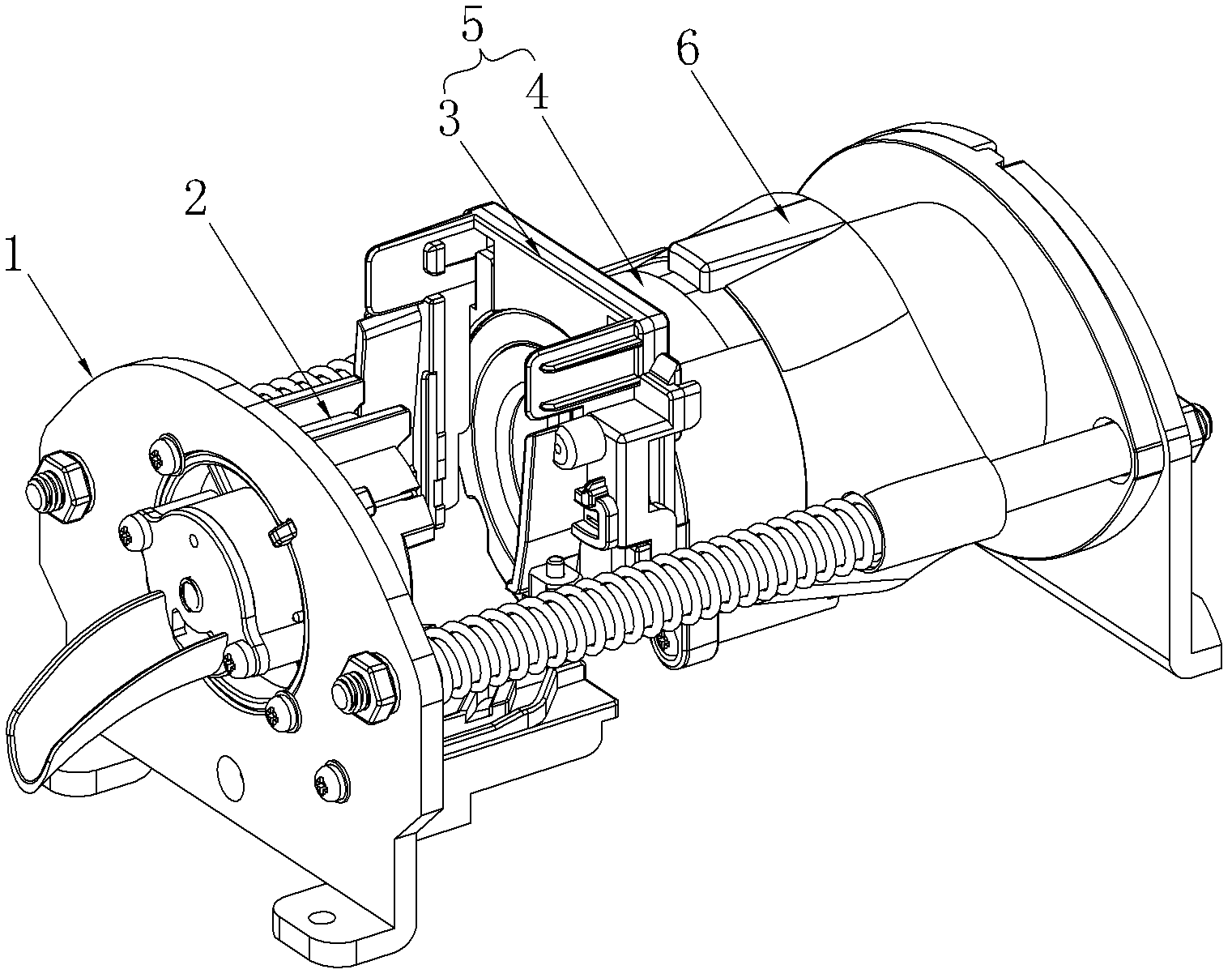

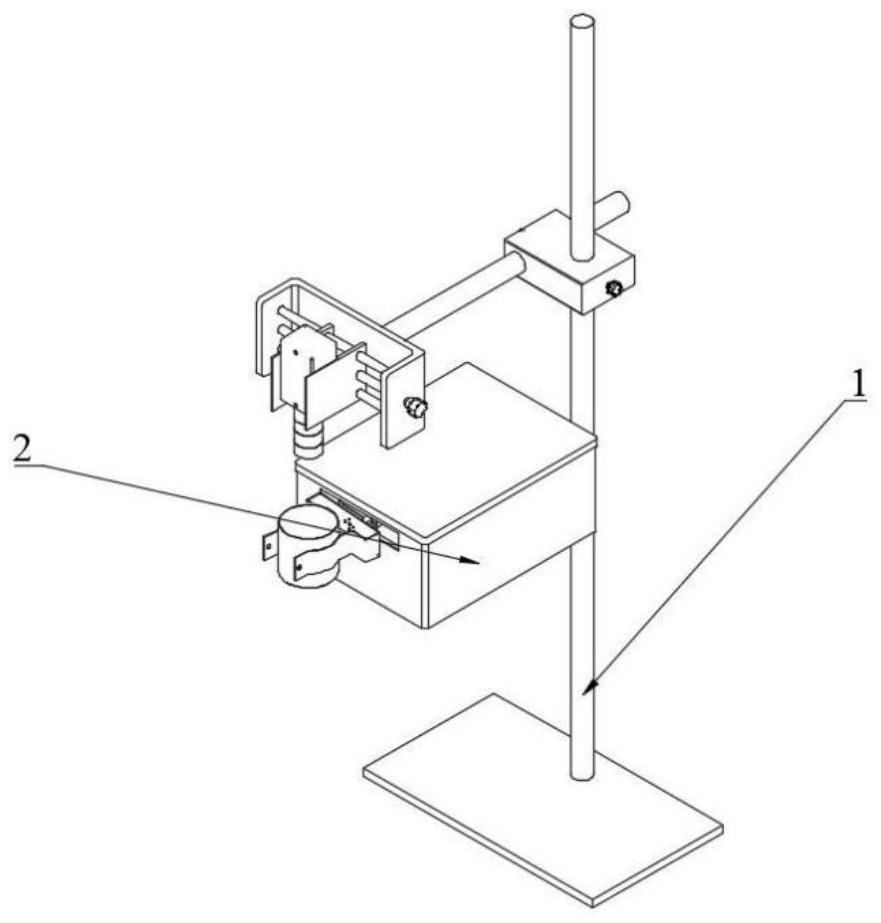

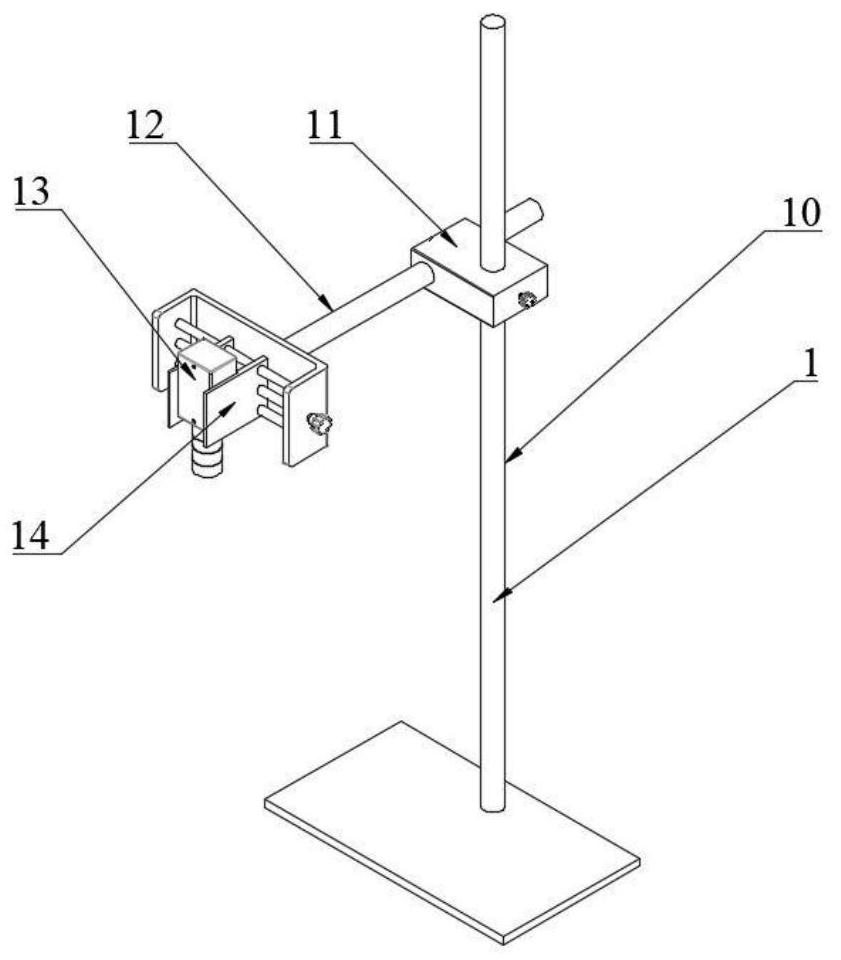

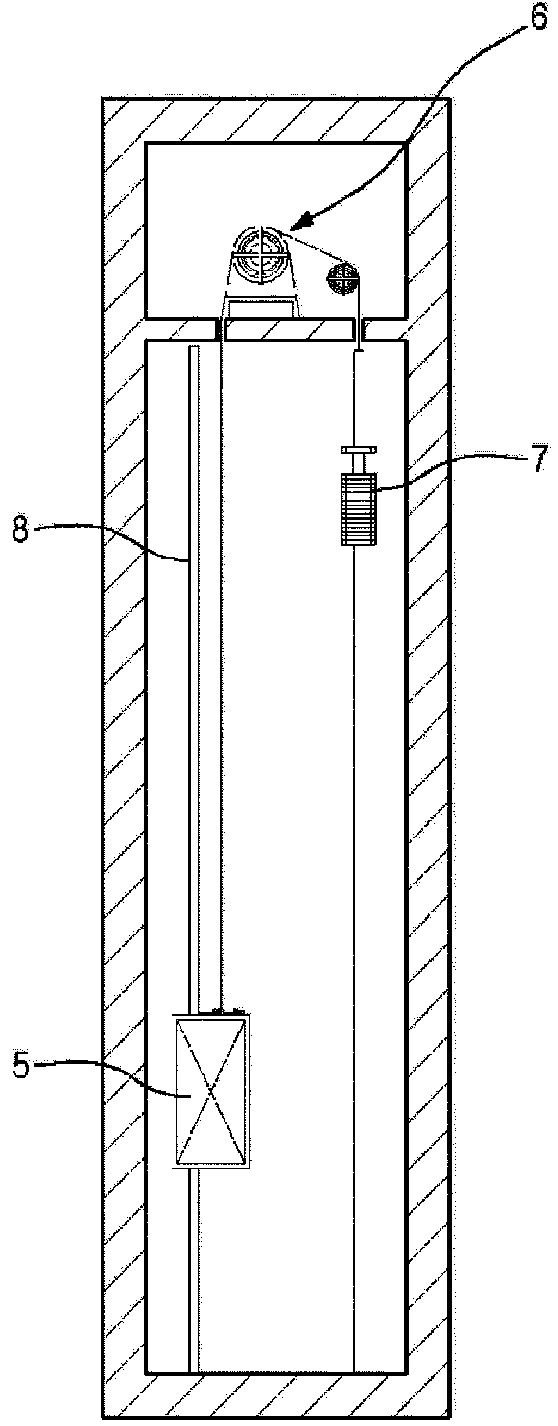

Making device of coffee capsule maker

The invention discloses a making device of a coffee capsule maker, which comprises a framework, a making component, a driving component and a making chamber used with the making component to make coffee. The making component comprises a guide-in mechanism and a brewing mechanism, the guide-in mechanism comprises a guide-in rack, a separation blade and a guide track, the upper end of the separation blade is in transfer connection onto the guide-in rack, the lower end of the separation blade is connected with the guide track via a slide pin component, the guide track is provided with a one-way advancing slide way and a one-way withdrawing slide way, when the making component approaches the making chamber, the slide pin component slides along the one-way advancing slide way and drives the separation blade to expand so as to release a capsule, when the making component resets, the slide pin component slides along the one-way withdrawing slide way and drives the separation blade to be folded after the capsule drops, and an elastic component which drives the capsule to be separated from the making chamber when the making component resets is arranged in the making chamber. The coffee capsule maker is simple in structure, convenient in use and fine in universality, coffee capsules can smoothly drop assuredly after being made, and reliability of products is improved.

Owner:ZHEJIANG KUFEER ELECTRICAL APPLIANCE

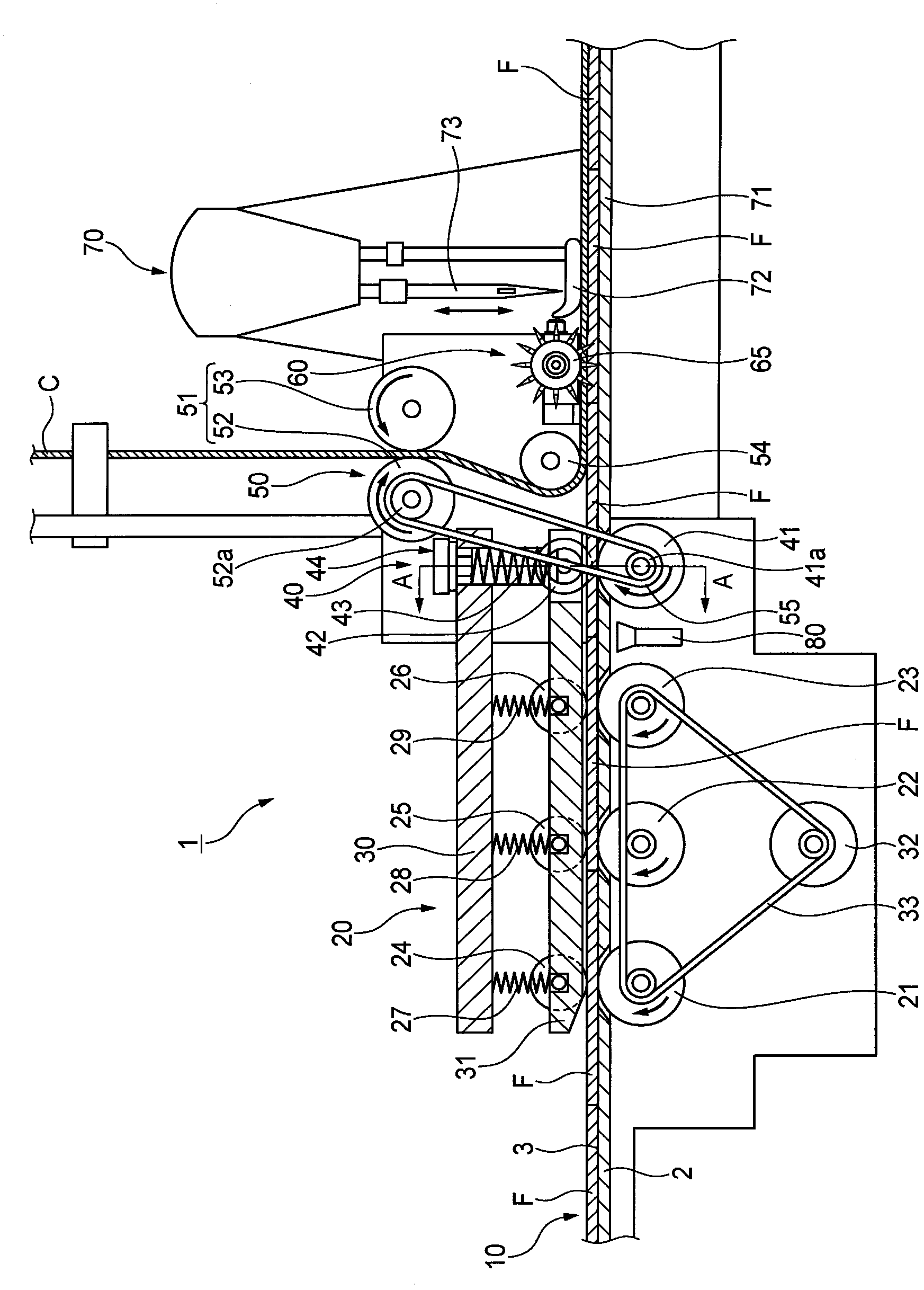

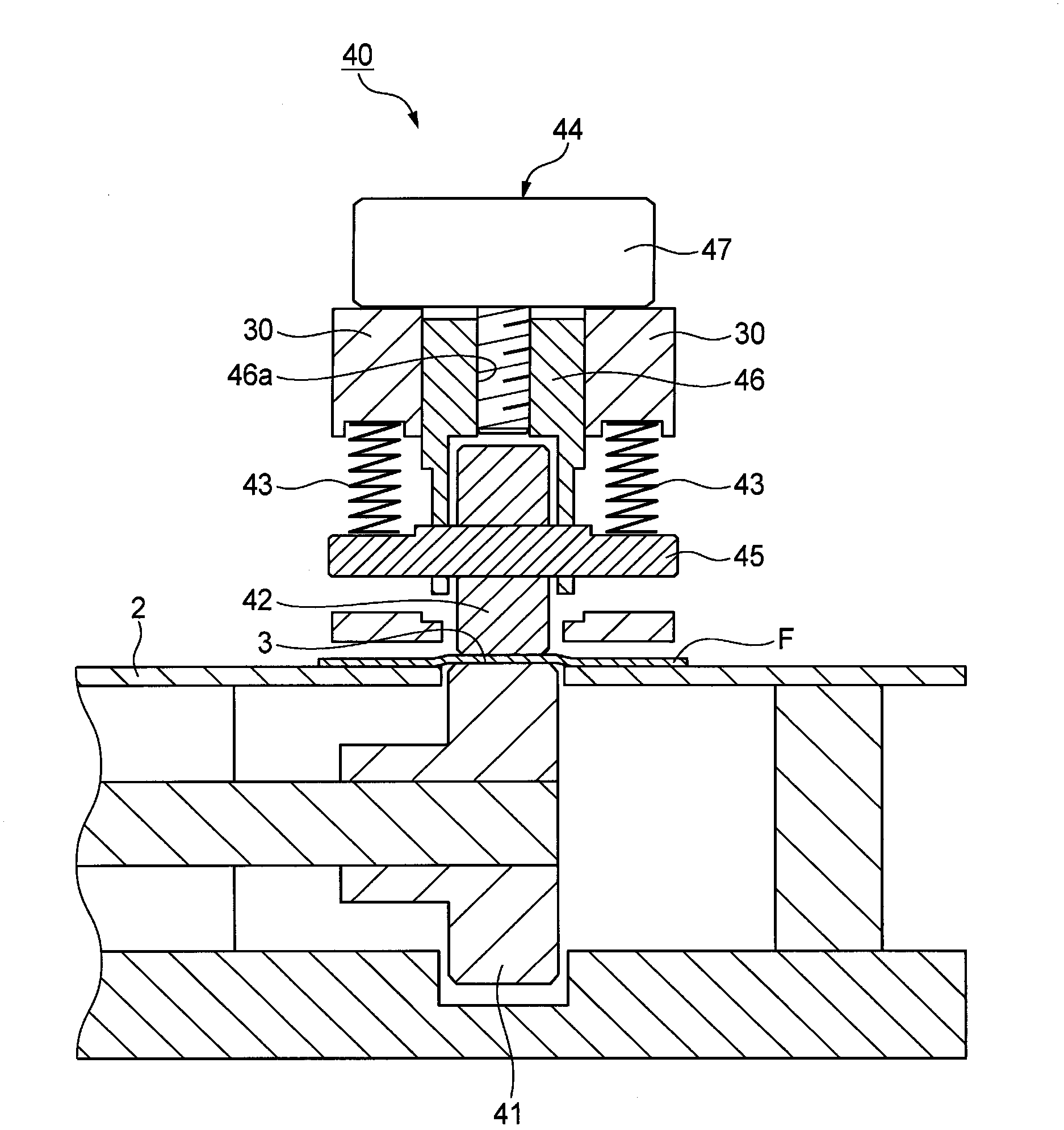

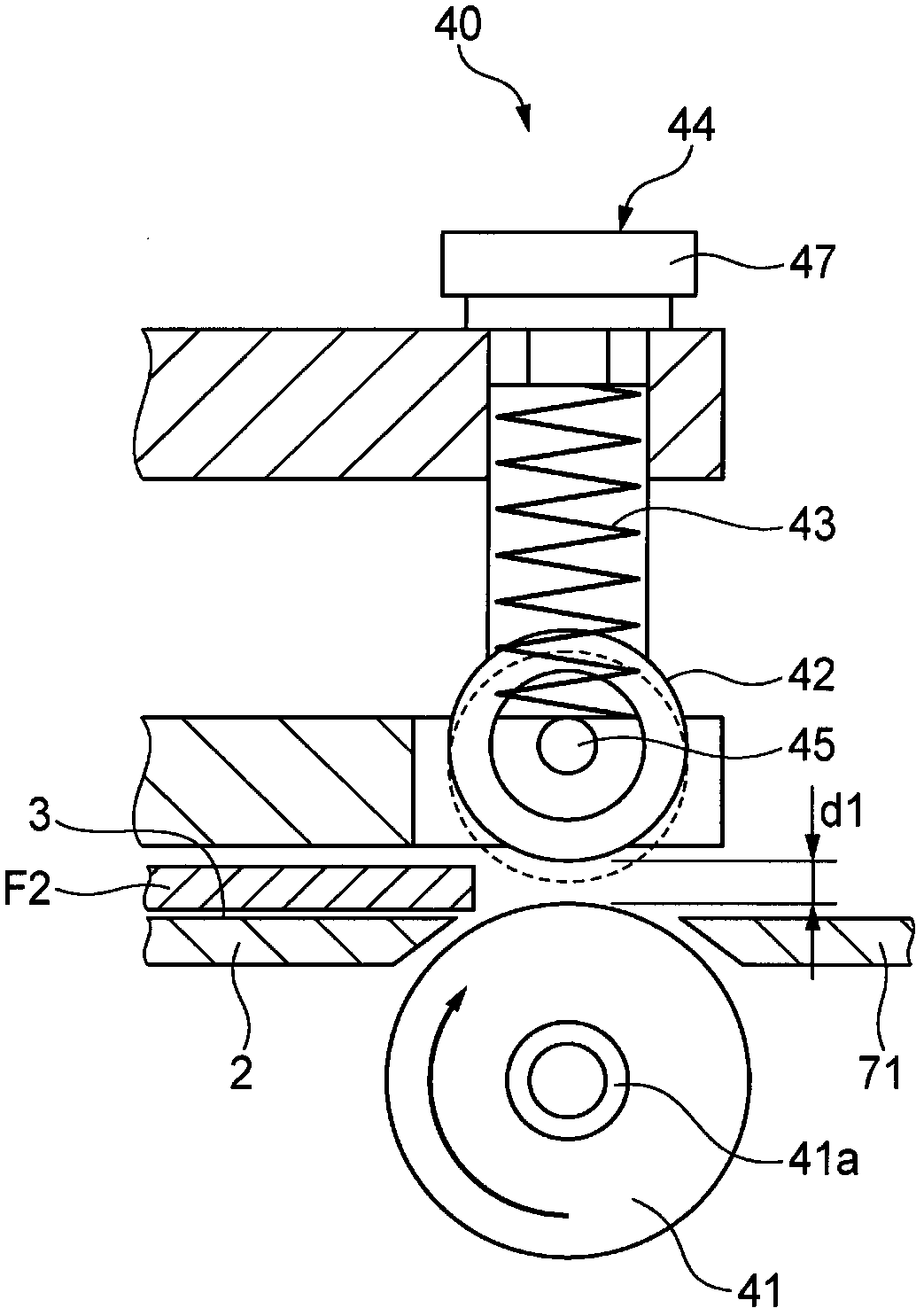

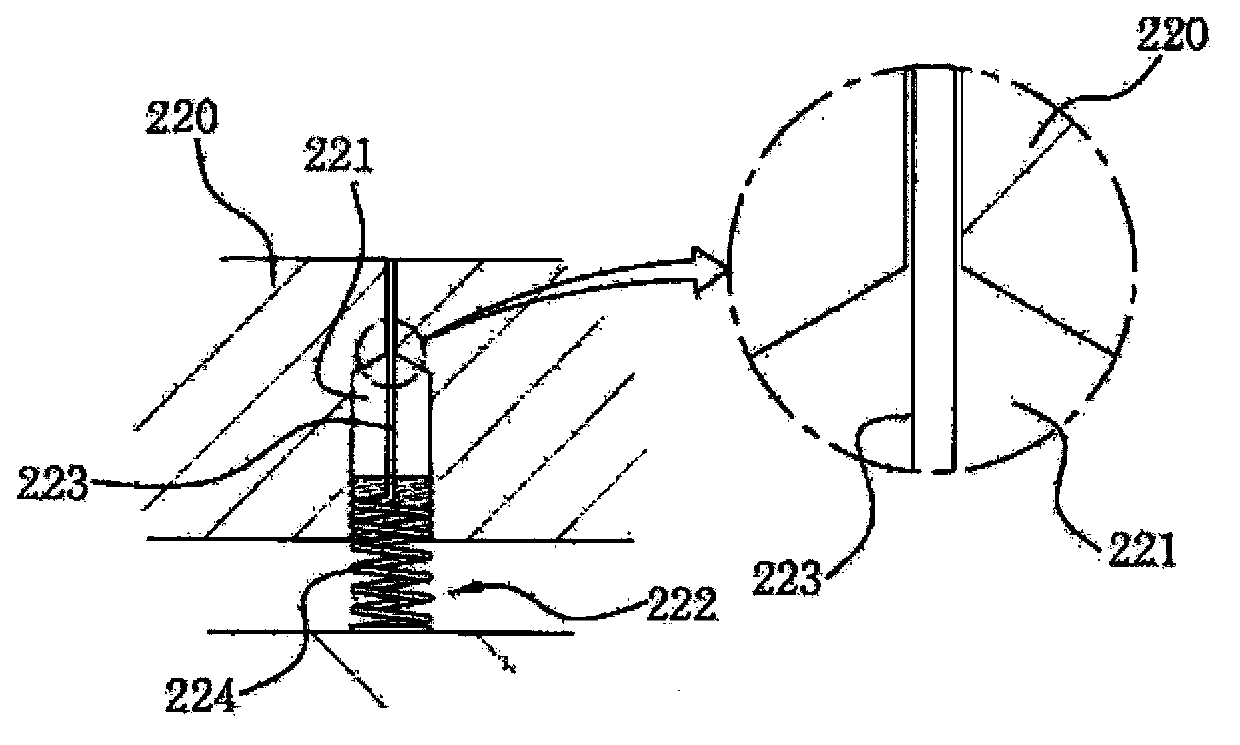

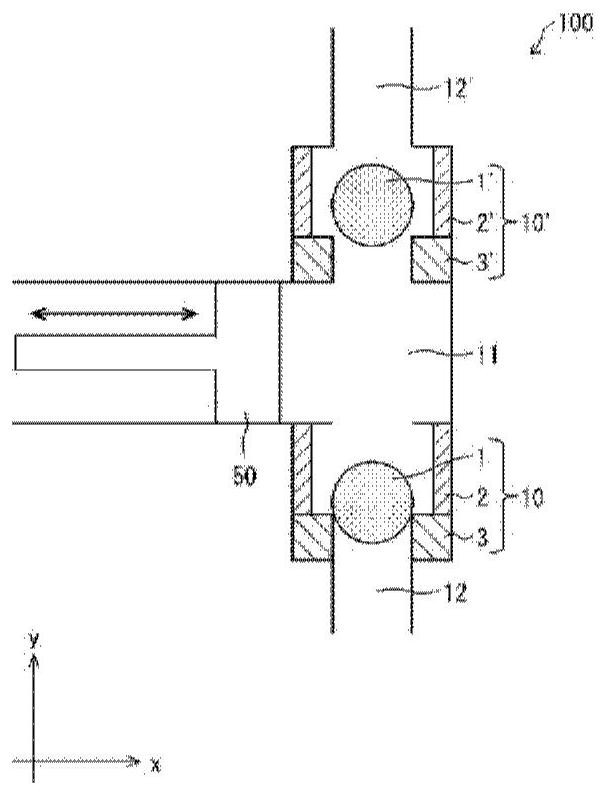

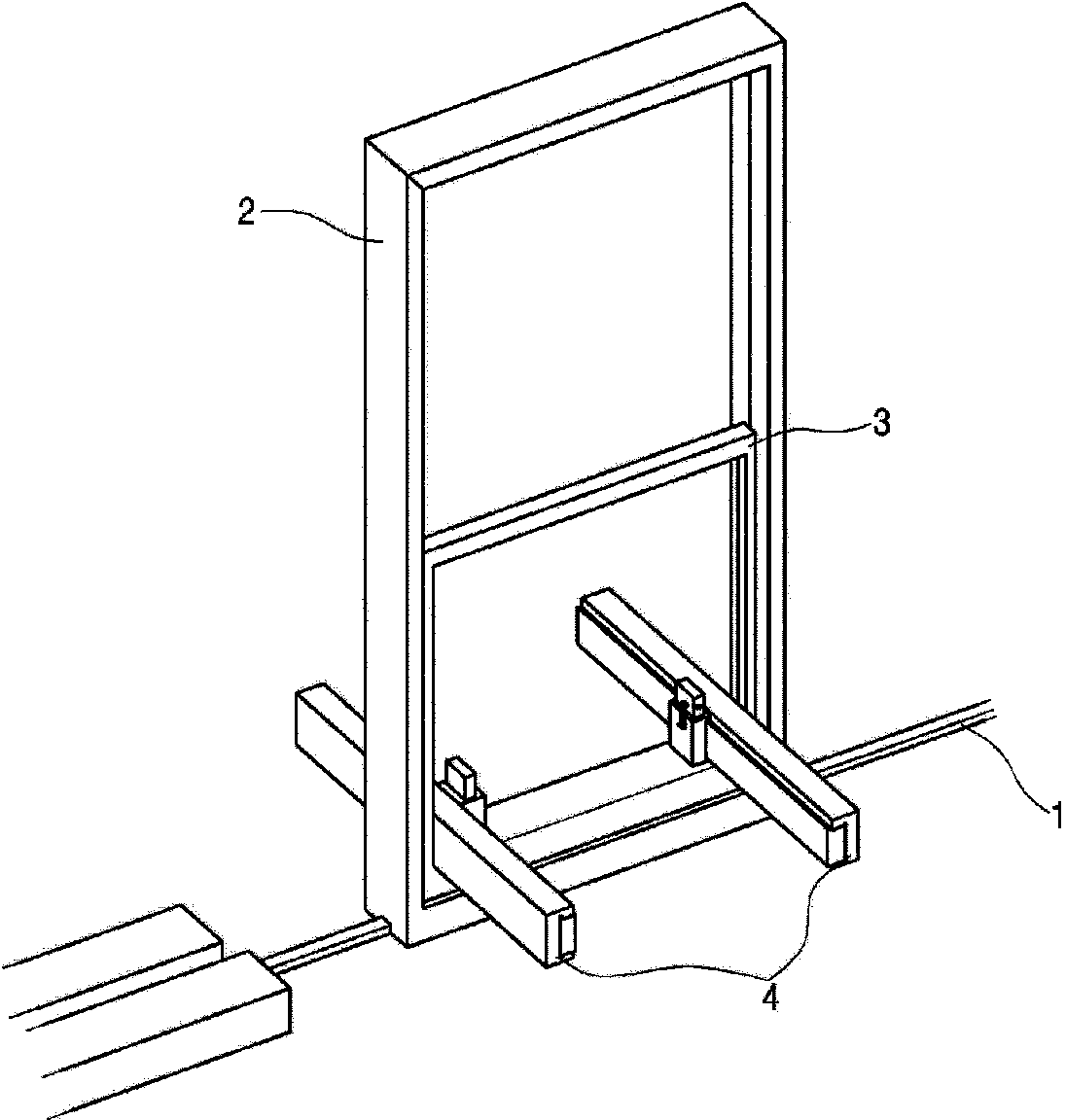

Fly sewing machine

Provided is a fly sewing machine that ensures stable fly feeding, and makes it possible to properly attach a fly to a slide fastener chain, even if the fly is short. The fly sewing machine is equipped with: a fly supply unit (10) that supplies a fly (F) to a transfer passage (3); a fly transfer unit (20) that transfers and sends the fly (F) that has been supplied by the fly supply unit (10) toward the downstream side; a chain feed unit (50) that feeds a slide fastener chain (C) to the fly (F) that has been sent by the fly transfer unit (20); an auxiliary conveyance unit (60) that presses the fly (F) and the slide fastener chain (C), which have been aligned overlappingly by the chain feed unit (50), from above or below, and sends the fly (F) and the slide fastener chain (C) toward the downstream side; and a sewing machine part (70) that sews together the fly (F) and the slide fastener chain (C), which have been sent by the auxiliary conveyance unit (60).

Owner:YKK CORP

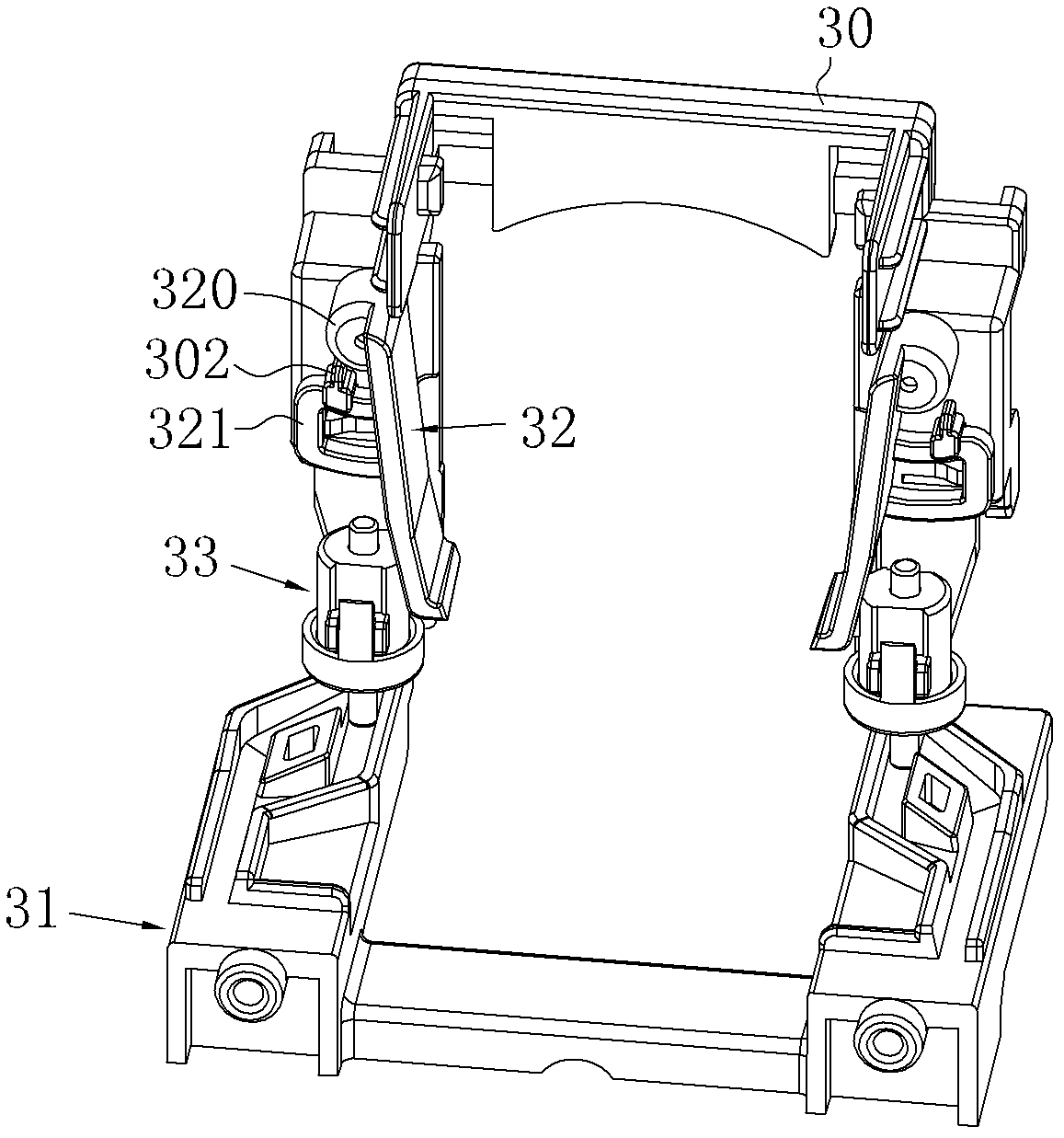

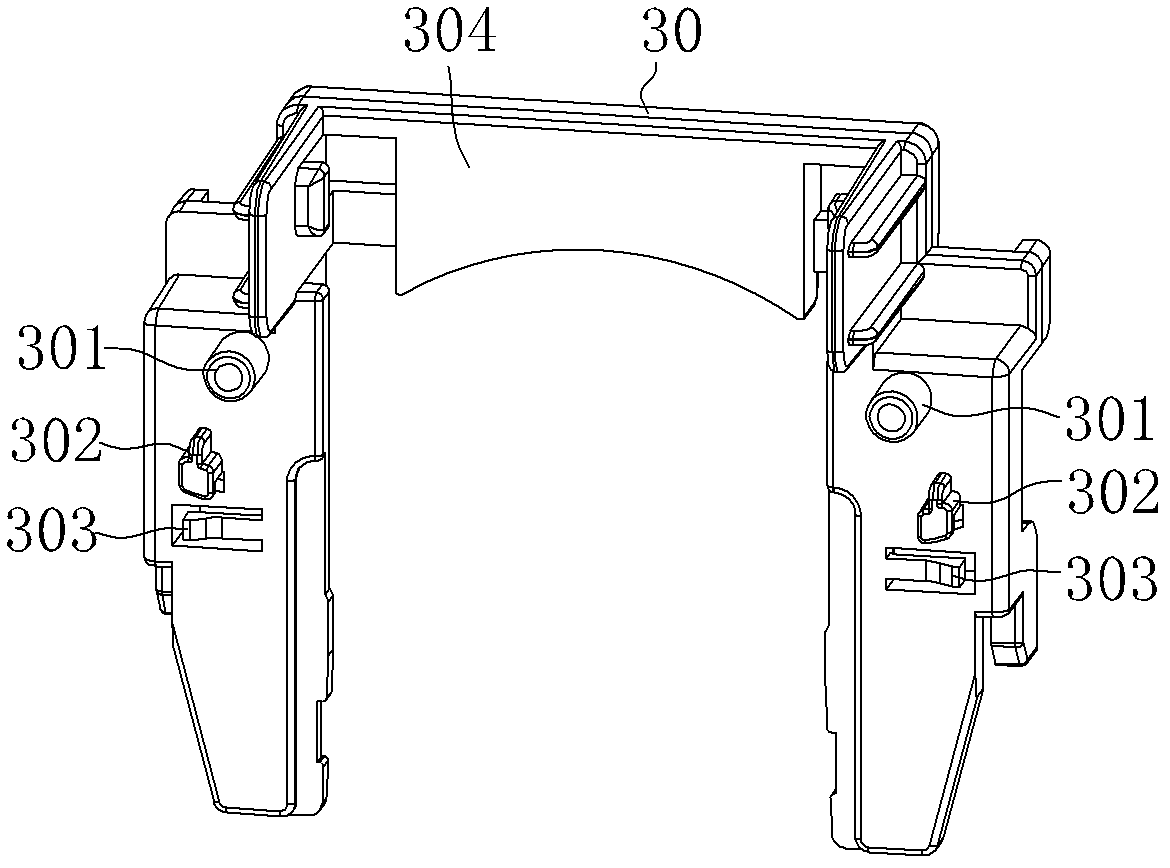

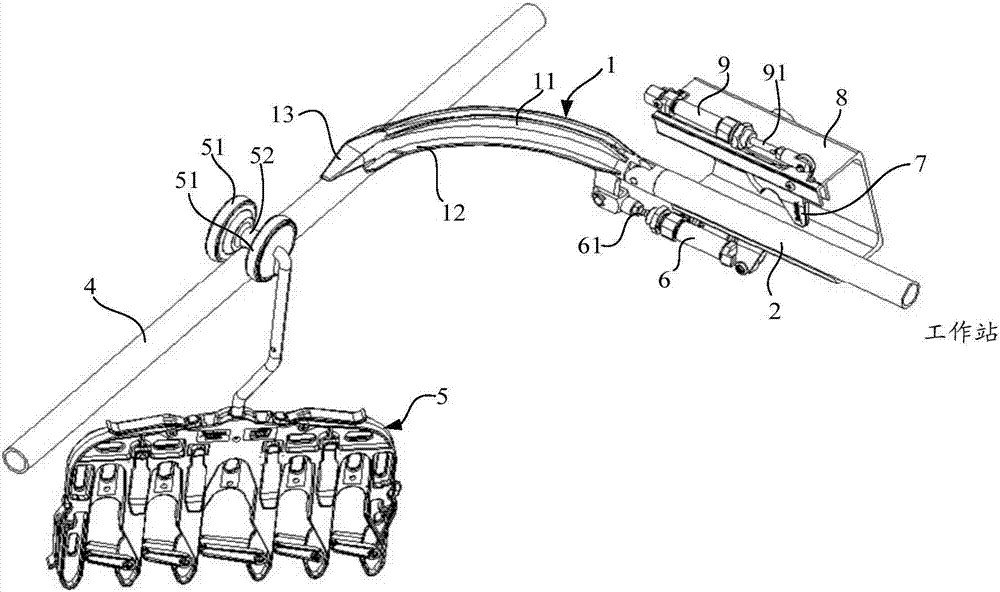

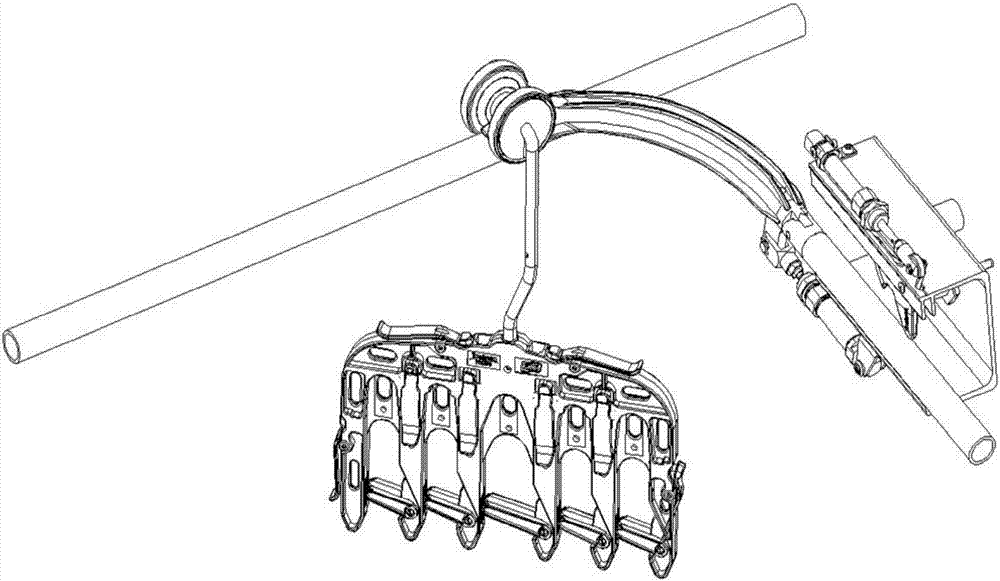

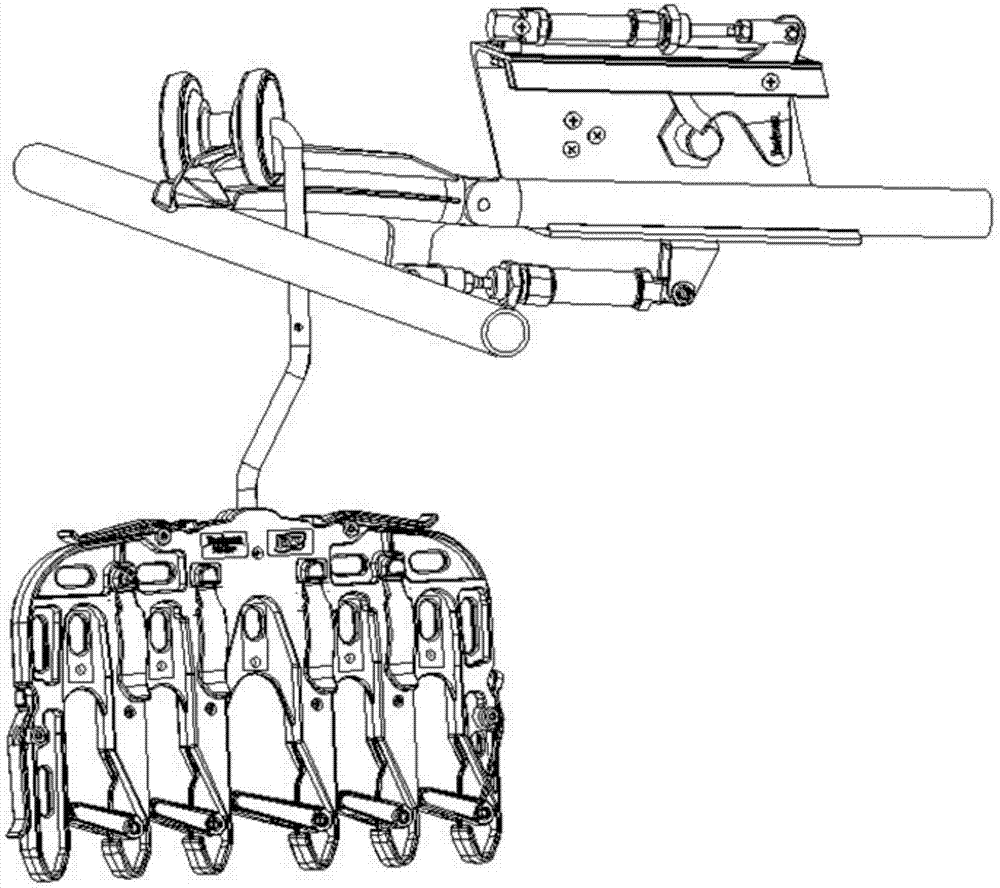

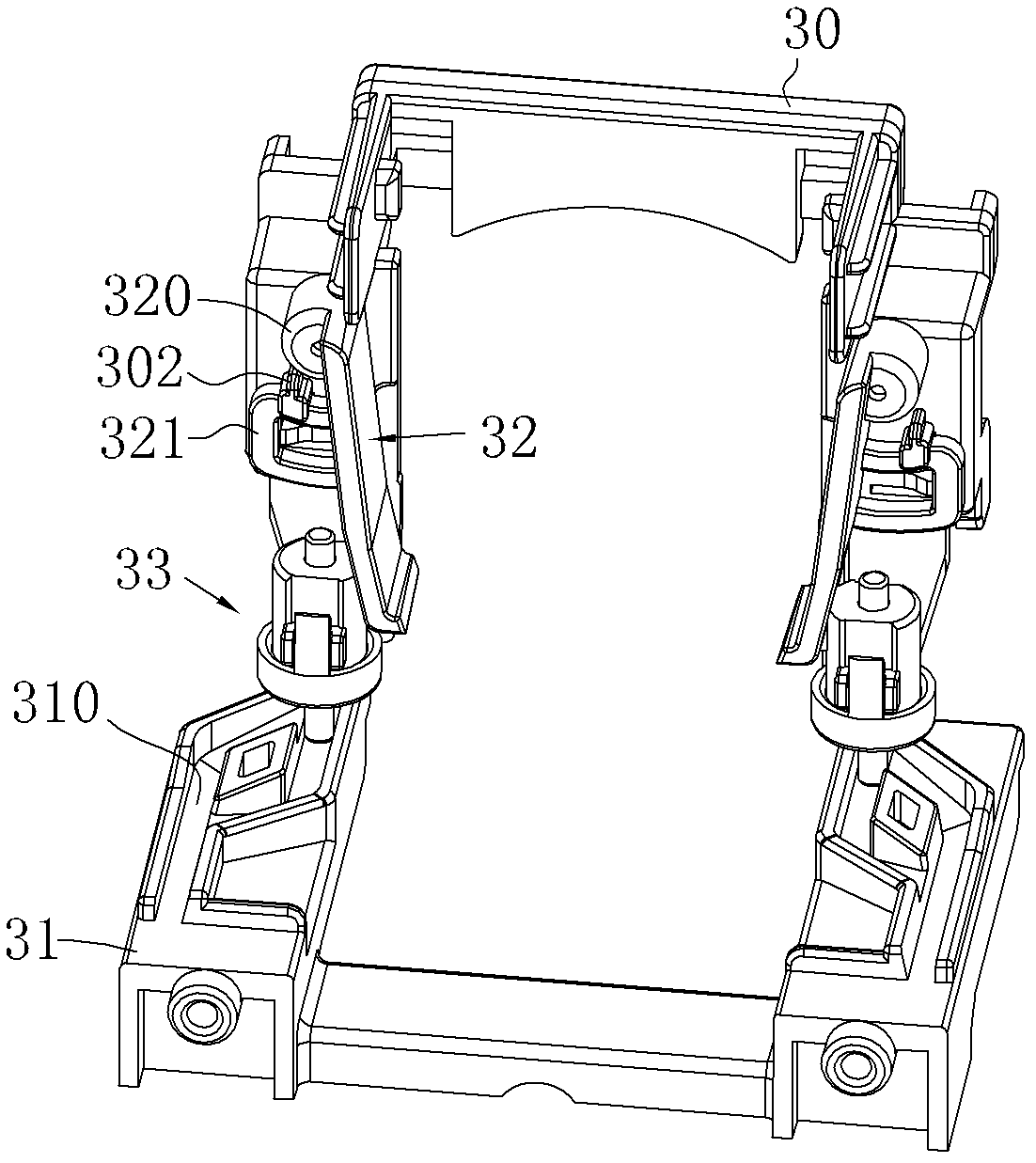

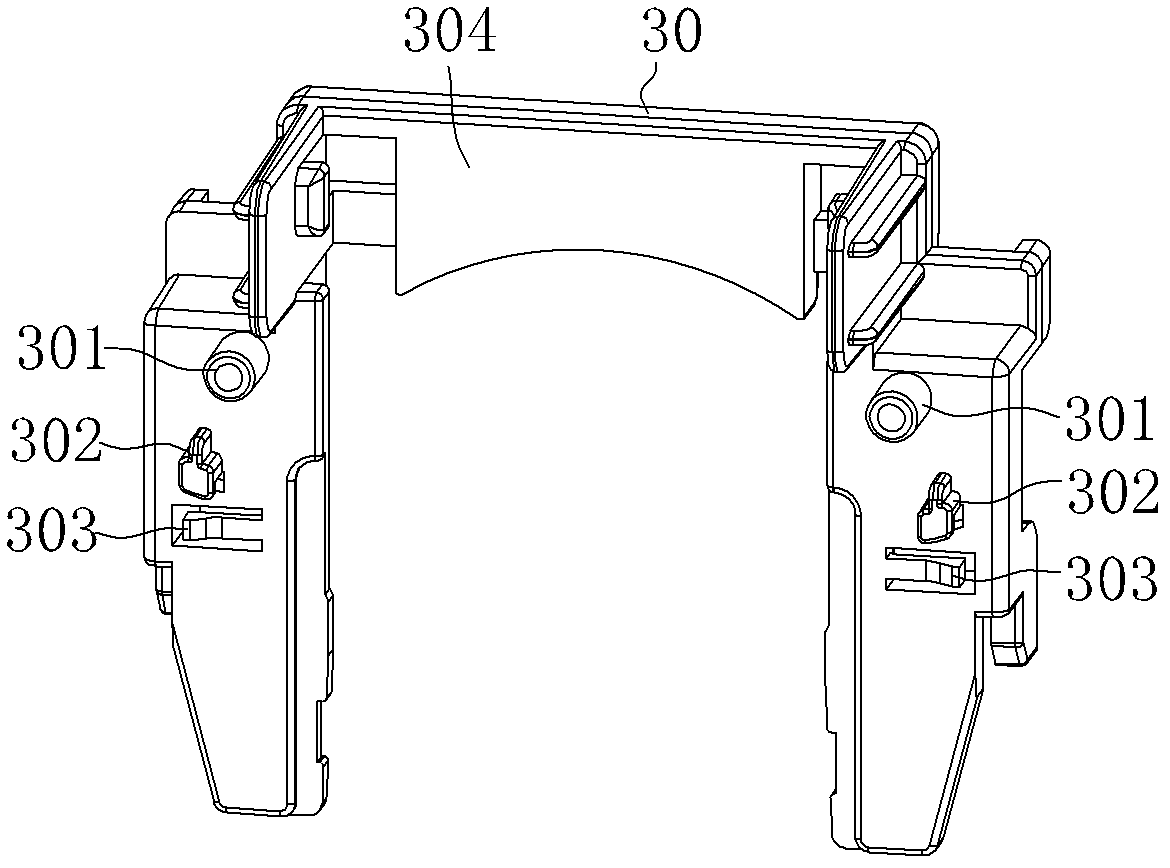

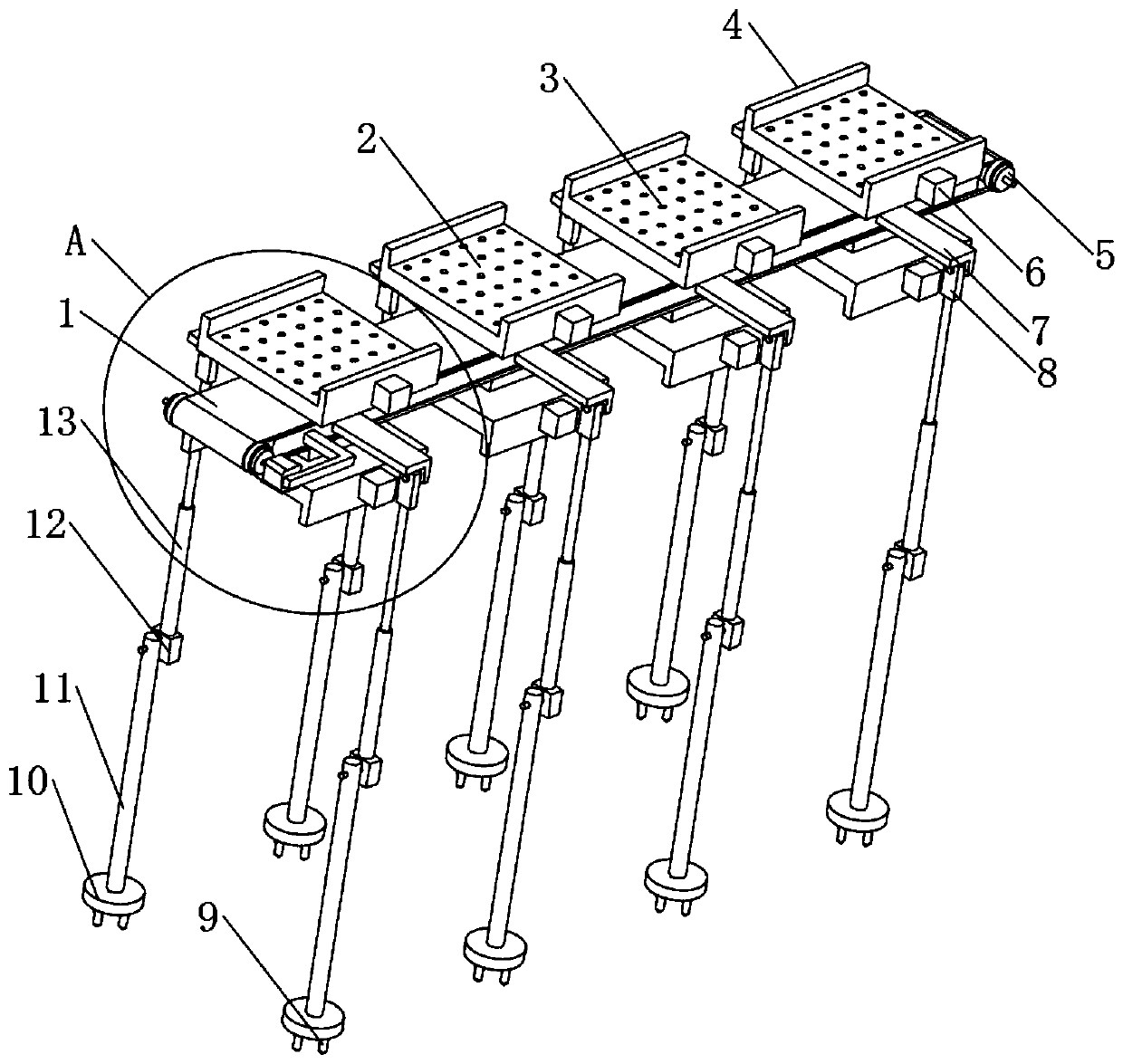

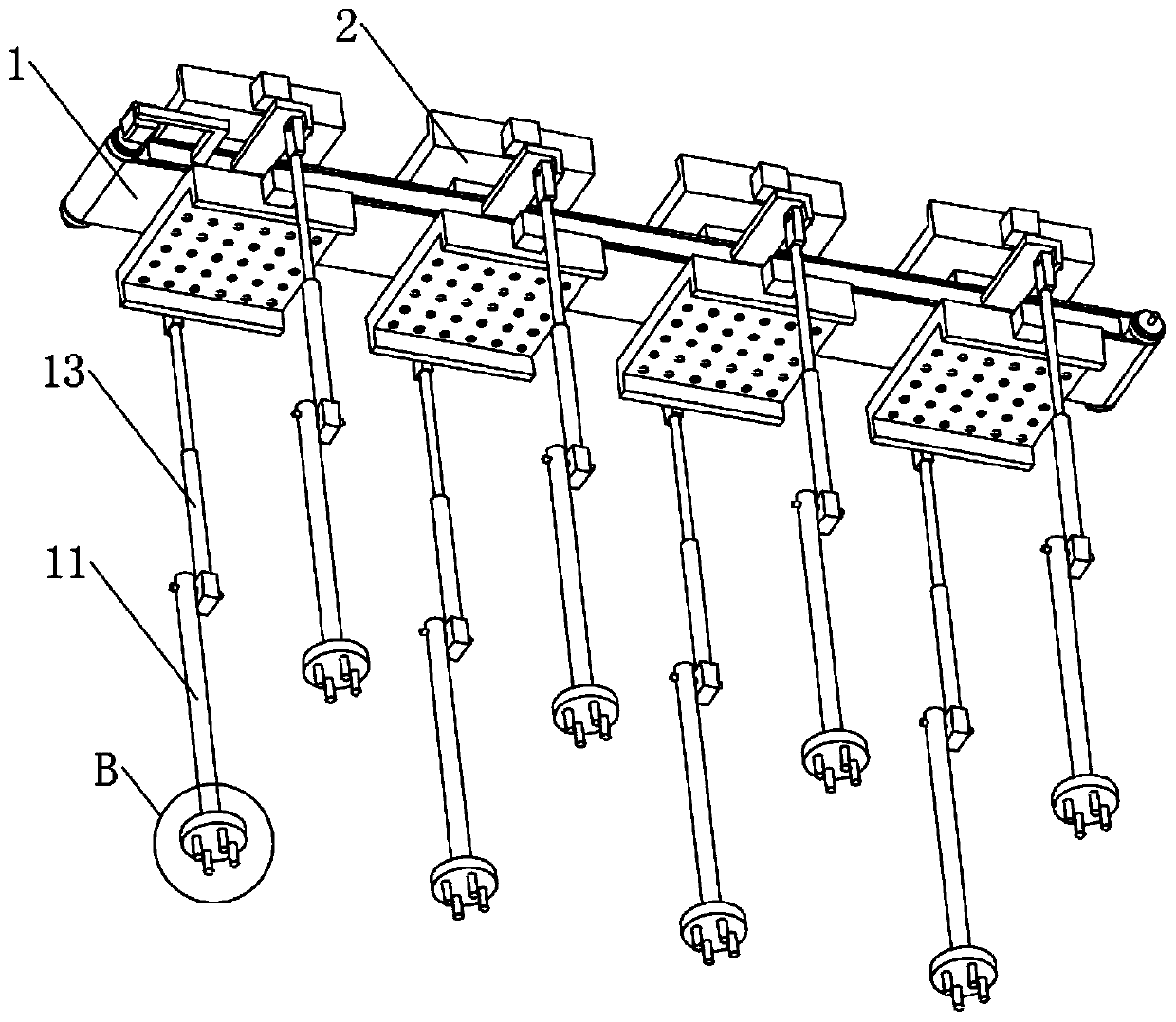

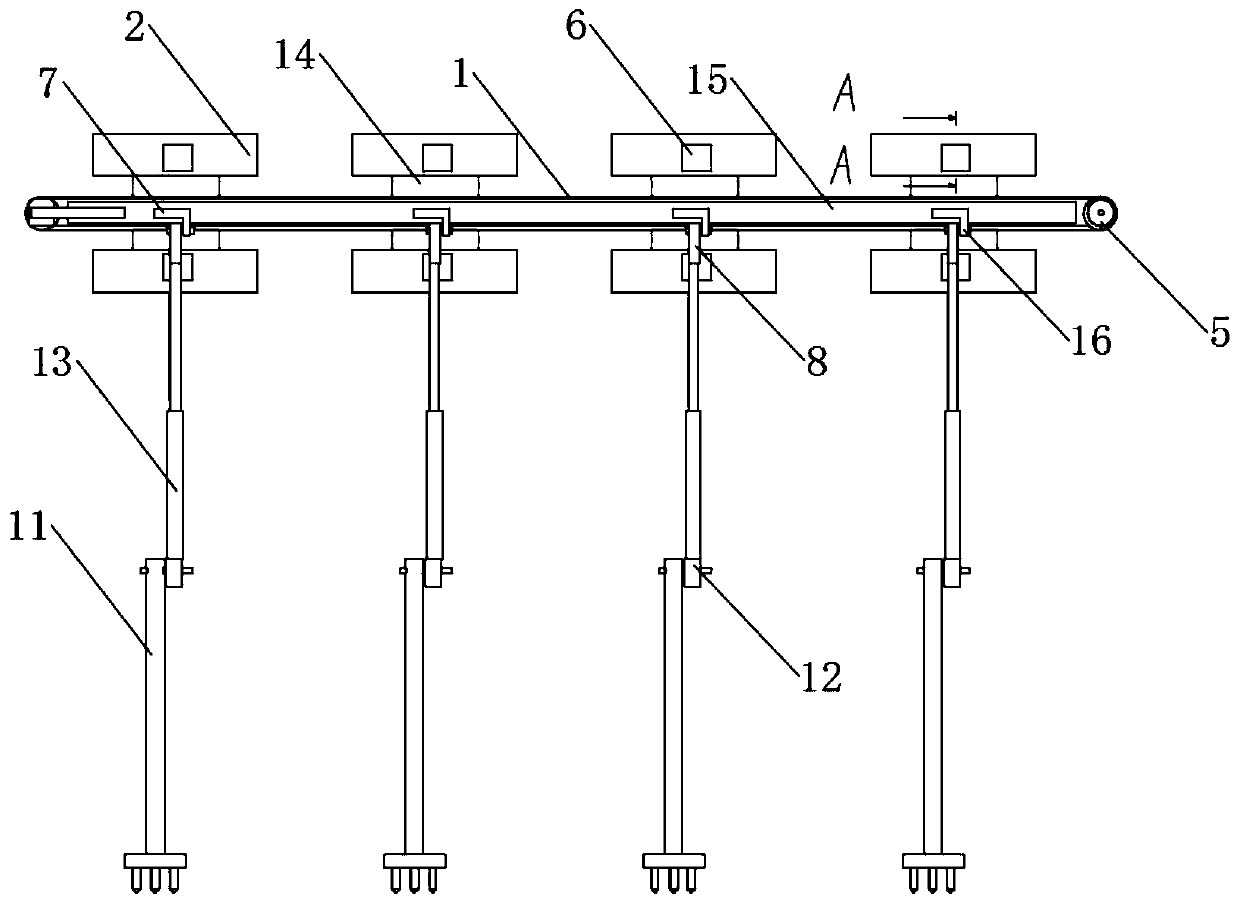

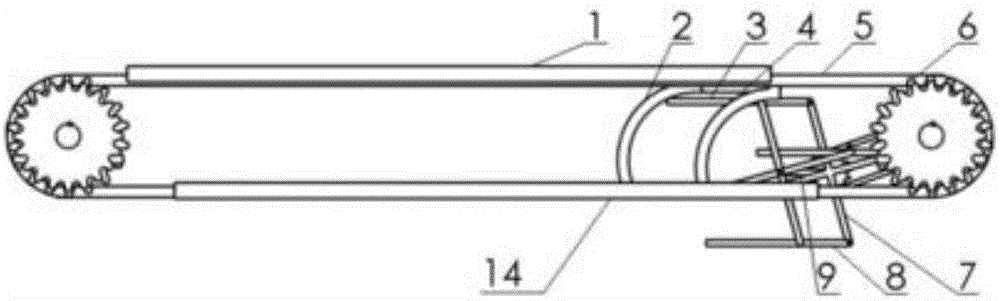

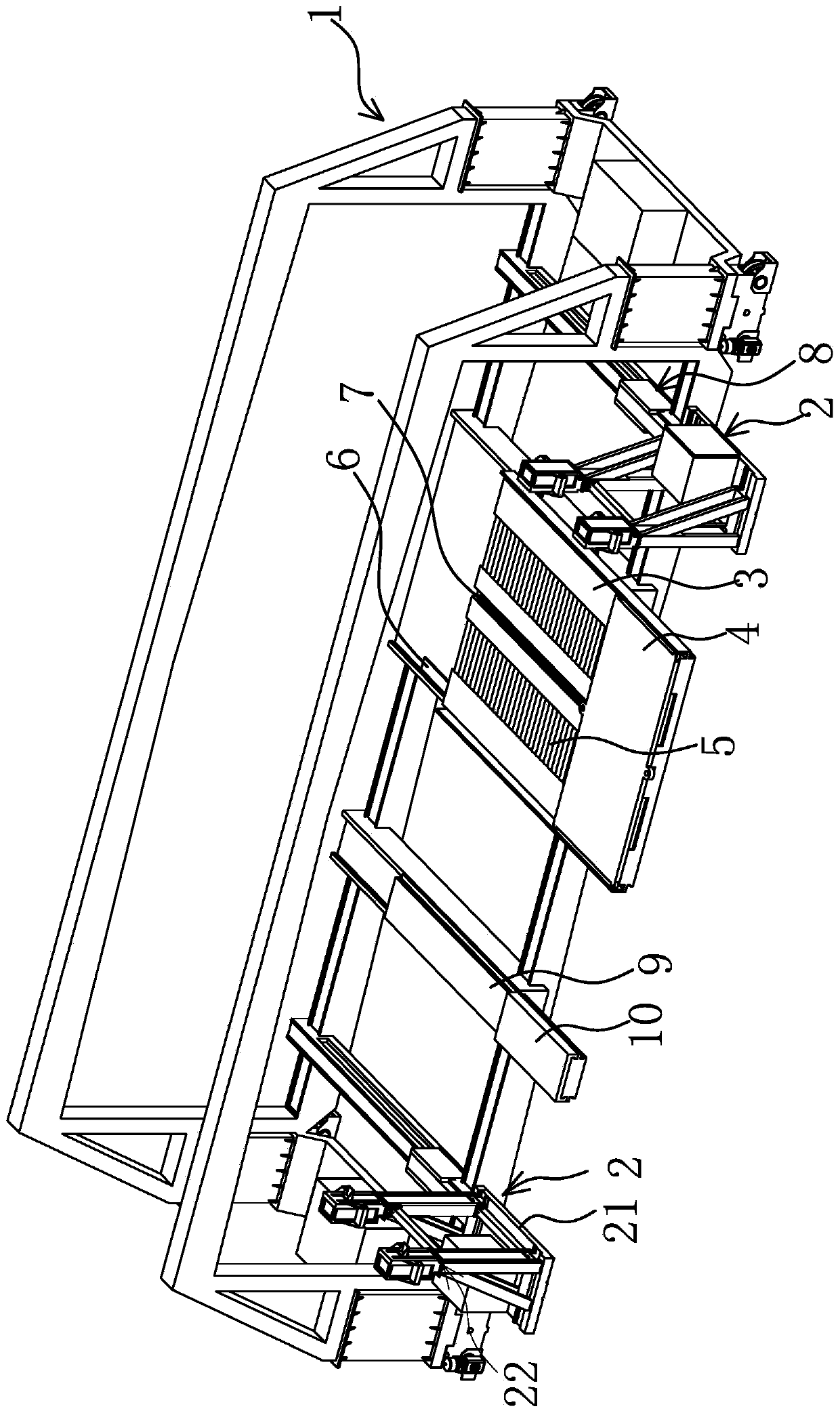

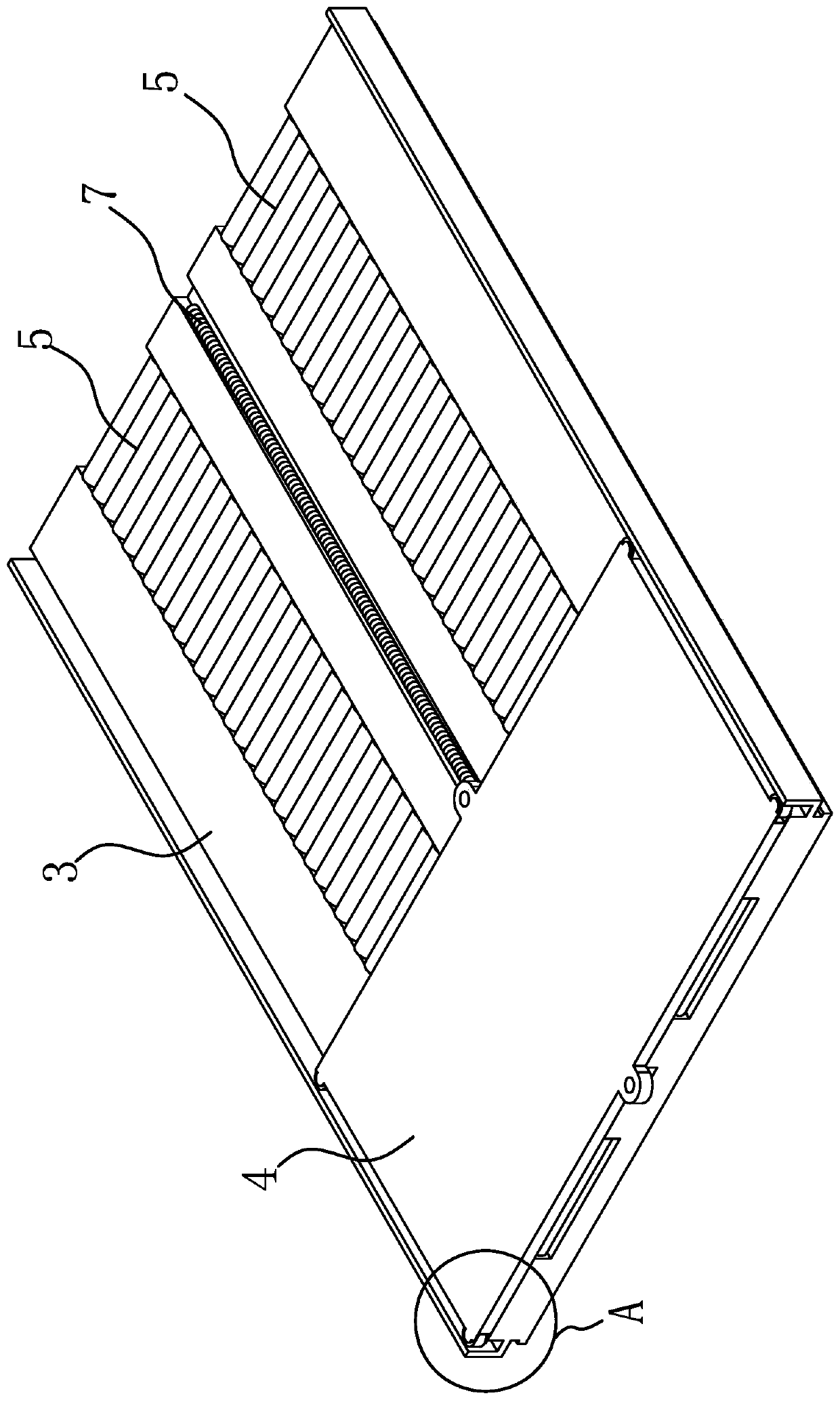

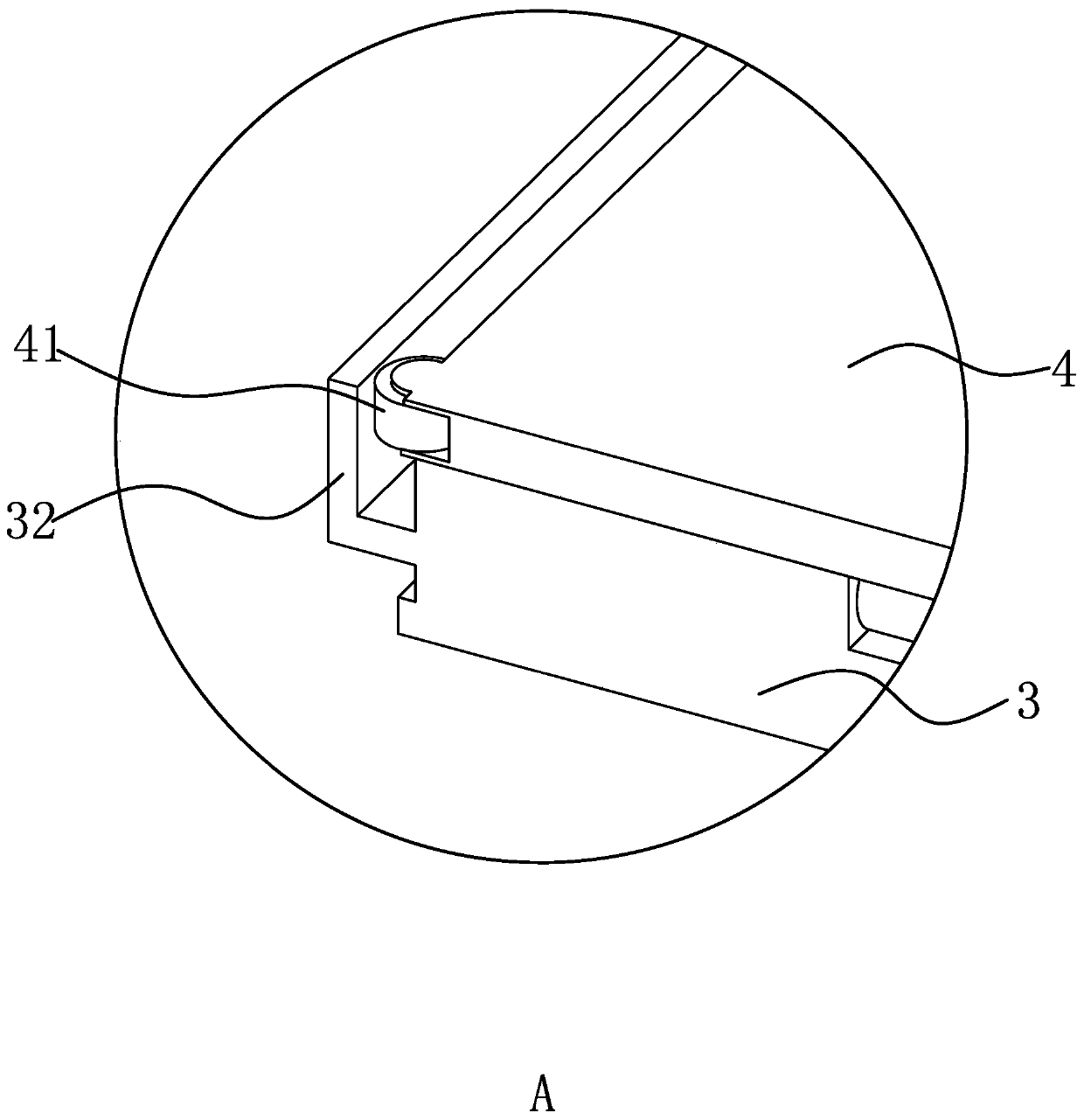

Connecting assembly for clothing manufacturing hanging system and clothing manufacturing hanging system

InactiveCN106892248AAvoid the risk of sheddingThe transfer process is stableMechanical conveyorsEngineeringMechanical engineering

The invention discloses a connecting assembly for a clothing manufacturing hanging system and the clothing manufacturing hanging system comprising the same. The connecting assembly for the clothing manufacturing hanging system comprises a guiding connector and a guide rod, wherein one end of the guide rod is rotatably connected to the tail end of the guiding connector while the other end of the guide rod extends to a work station; the first end of the guiding connector is a free end, and the first end of the guiding connector can be selectively overlapped to a circular track; bearing beads are arranged on two opposite outer side walls of the guiding connector in a protruding manner for bearing two rollers of a clothes rack clamping a cloth material, so that the two rollers roll on the bearing beads; a guiding bead which extends along the extending direction of the guiding connector is formed on the top of the guiding connector for leaning against a roller connecting shaft between two rollers of the clothes rack clamping the cloth material; when the two rollers roll on the bearing beads, the guiding bead guides the two rollers. The connecting assembly facilitates the working stability of the clothing manufacturing hanging system.

Owner:HUIZHOU TECHZEN IOT SCI & TECH CO LTD

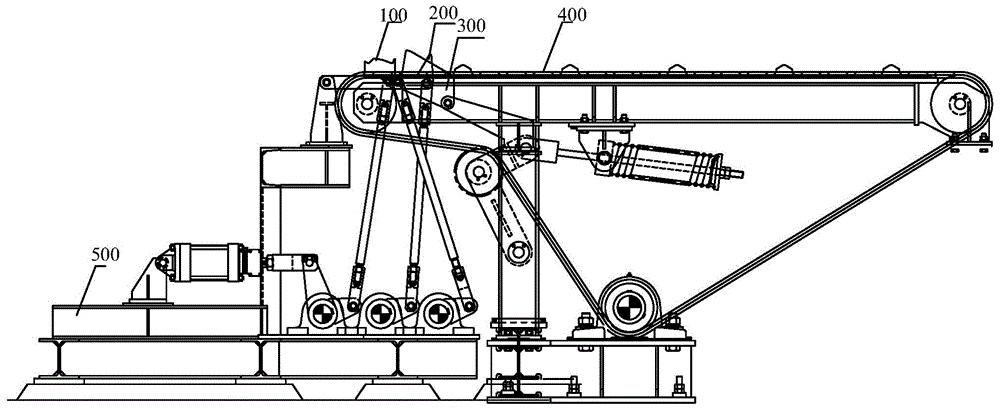

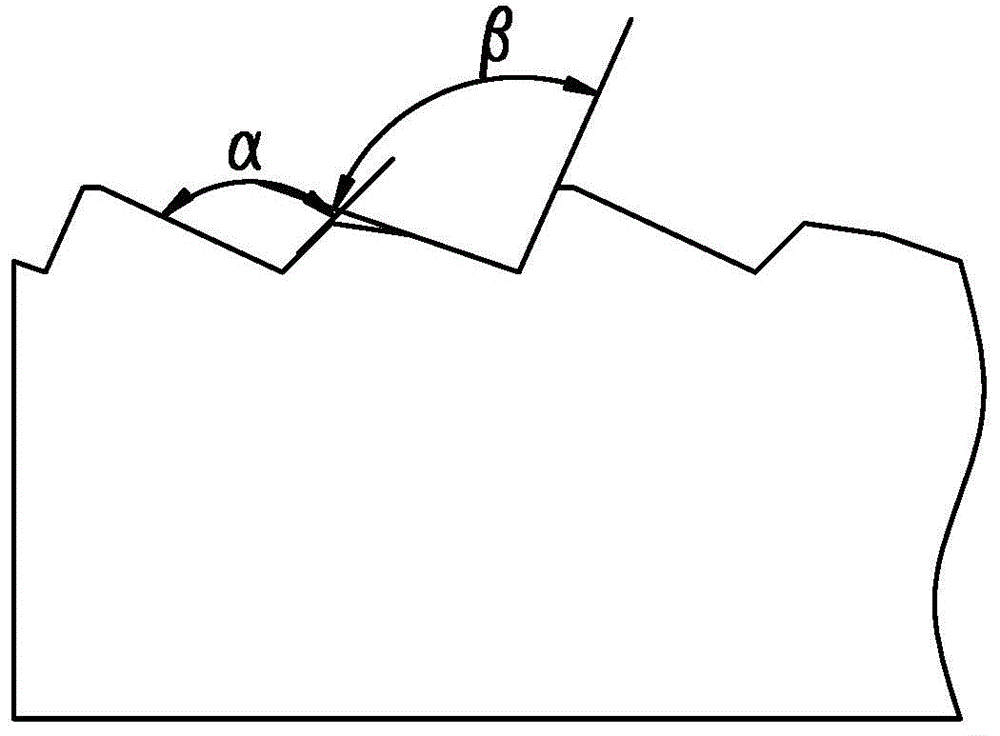

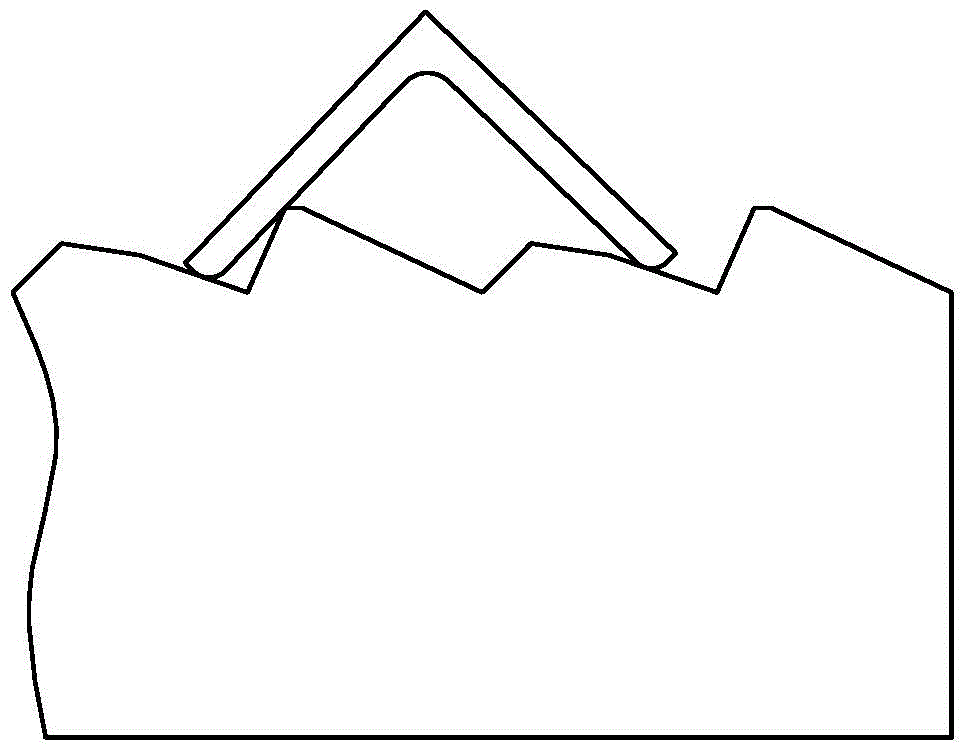

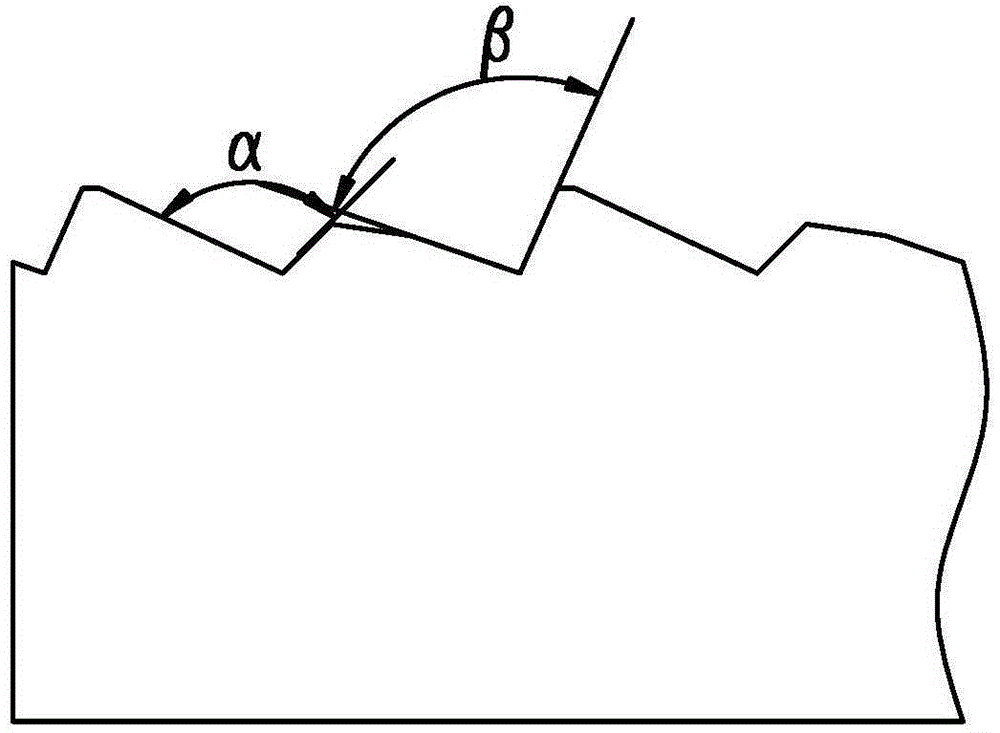

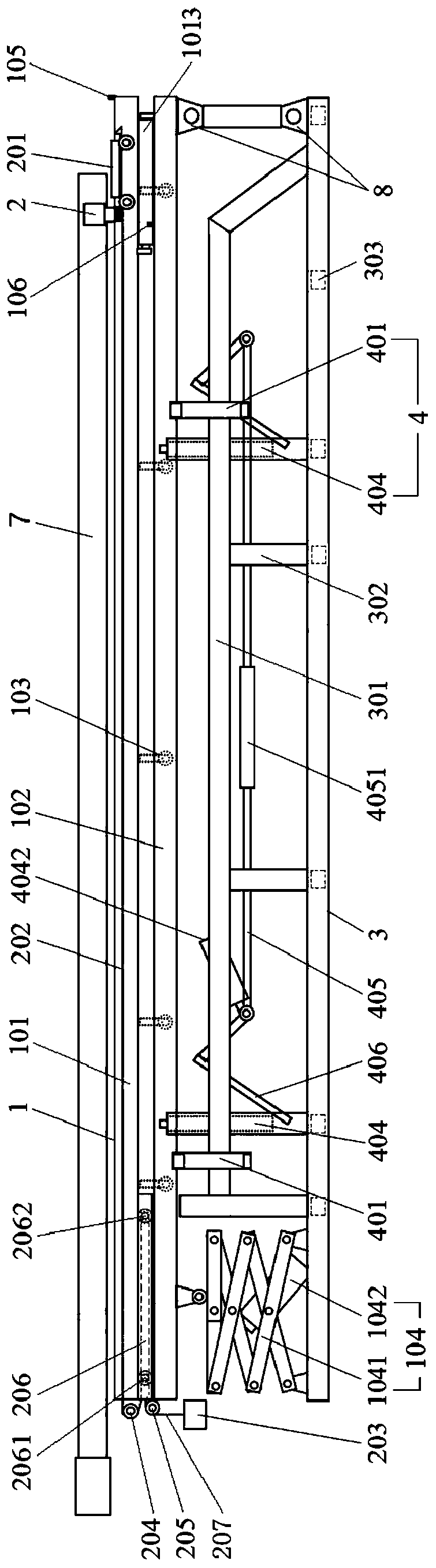

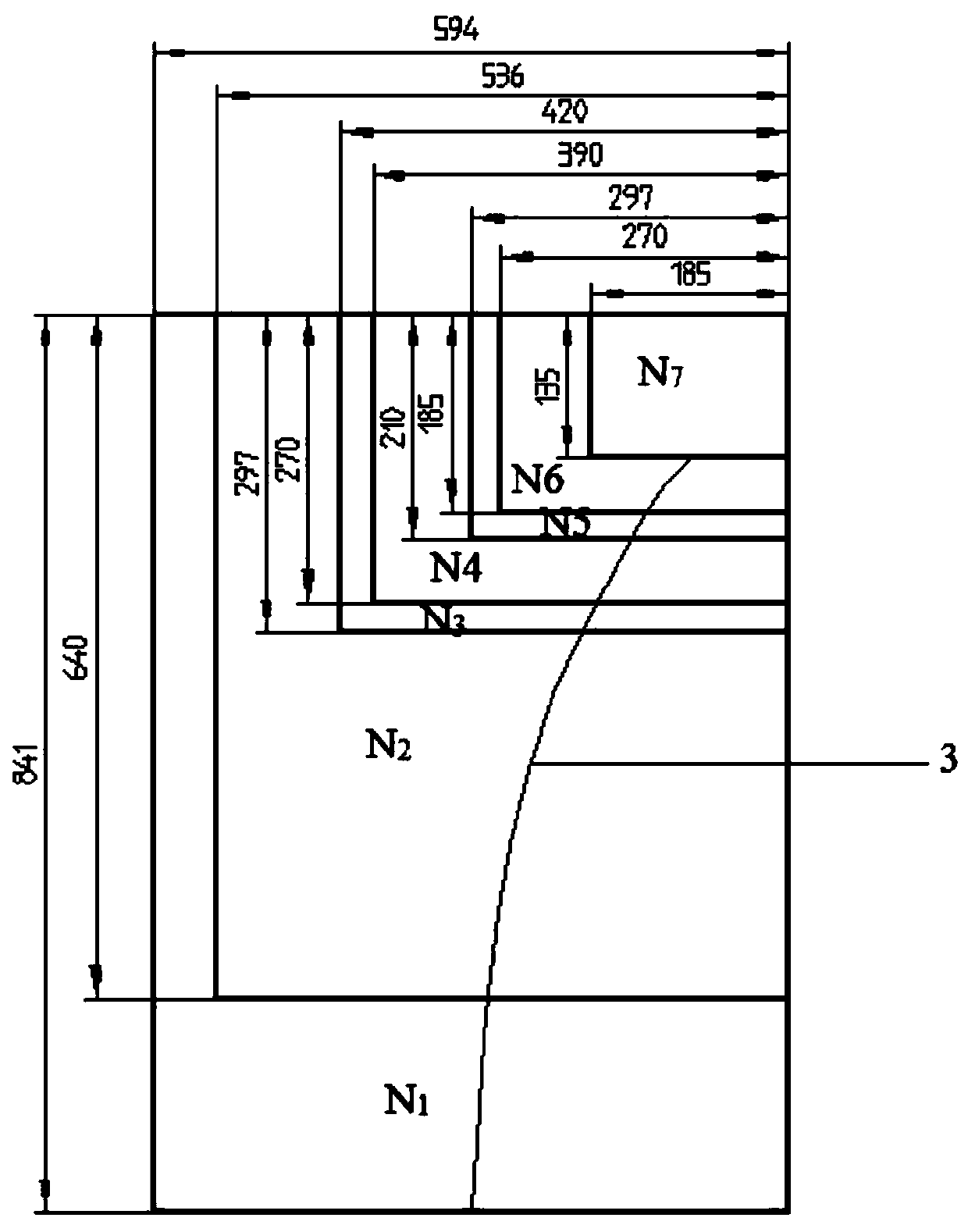

Steel unloading system suitable for bars and section steel

ActiveCN104309998AThe transfer process is stableReduce equipment costsConveyorsMetallurgyMaterials science

The invention discloses a steel unloading system suitable for bars and section steel, and mainly aims to solve the problem that steel unloading of bars and section steel cannot be implemented simultaneously in the prior art. The steel unloading system comprises a stepping steel unloading device, an auxiliary steel unloading device and a conveying device, wherein the stepping steel unloading device comprises a movable rack, a static rack and a rack driving device; the auxiliary steel unloading device comprises an auxiliary steel unloading baffle plate, a first driving device and a first transmission device; the first driving device is used for controlling the auxiliary steel unloading baffle plate to be positioned at a higher position or a lower position through the first transmission device; the conveying device comprises a conveying chain and a chain driving device. The shapes of recesses of the movable and static racks are improved, so that the section steel is conveyed more stably without being overturned. Therefore, the steel unloading system can be suitable for steel unloading of the bars and the section steel.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

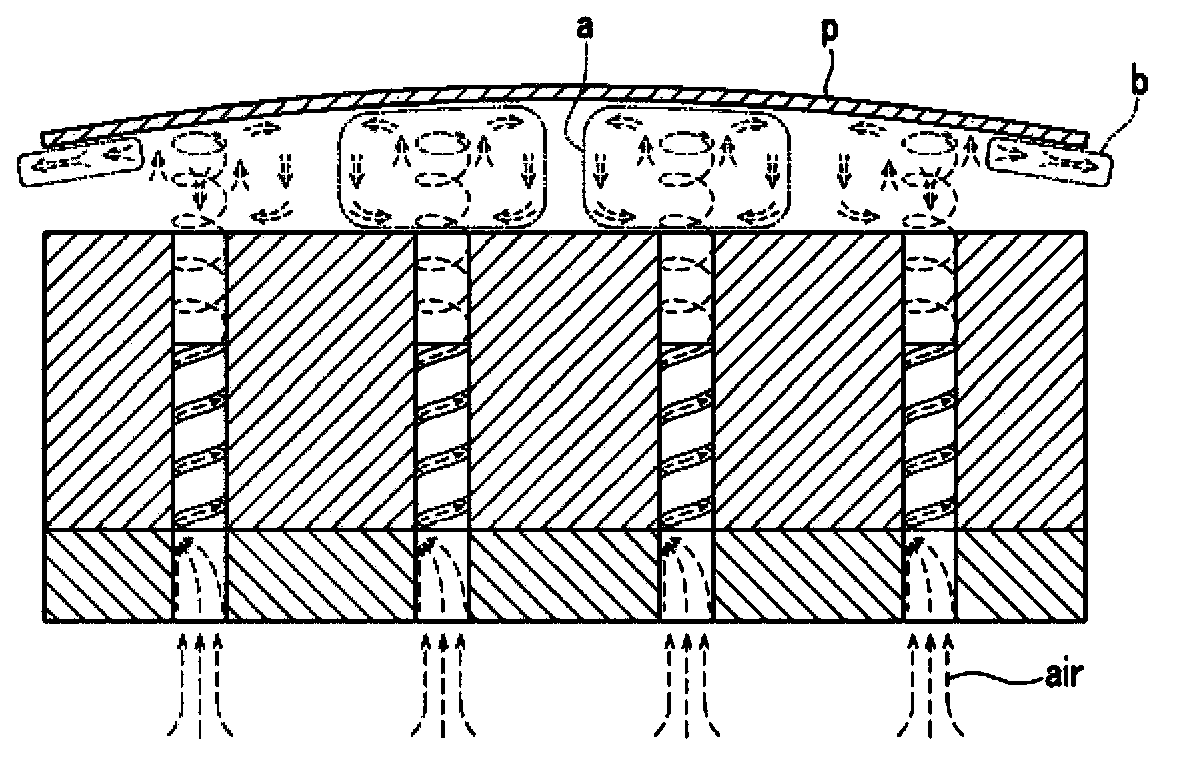

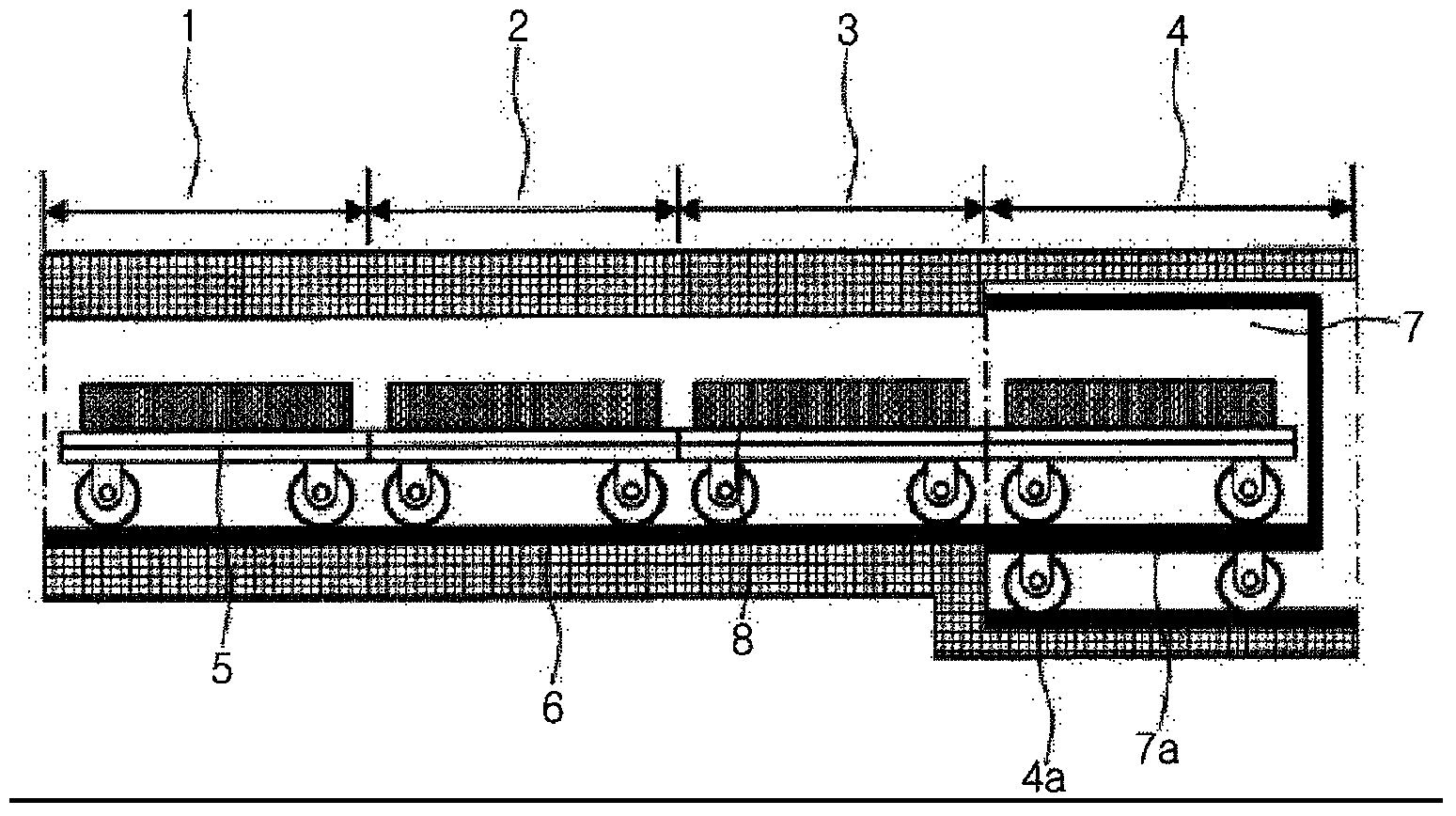

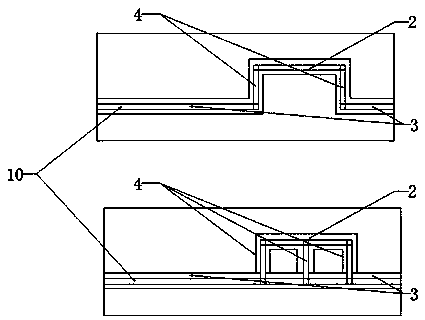

Conveying plate for large area panel

ActiveCN103373606AControl flatnessImprove delivery rateConveyorsSemiconductor/solid-state device manufacturingVacuum pressureEngineering

PURPOSE: A noncontact conveying plate for a large area panel is provided to minimize the generation of tremor due to vibration generating while transferring a target object, and to properly maintain the floated flatness of the target object. CONSTITUTION: A noncontact conveying plate for a large area panel comprises a lower plate(10), an upper plate(30), a vacuum branch plate, and an air branch plate(20). The lower plate comprises an air port(a1) and a vacuum port through which air and vacuum pressure are respectively supplied from the outside. The lower plate is connected to the vacuum port at the top to form a vacuum chamber. The upper plate comprises an air chamber, air holes, and vacuum holes. The vacuum branch plate is arranged between the lower plate and the upper plate and is connected to the vacuum chamber to form a vacuum load for delivering the vacuum pressure to the vacuum holes. The air branch plate is arranged at the top or the bottom of the vacuum chamber.

Owner:デフンハイテク株式会社

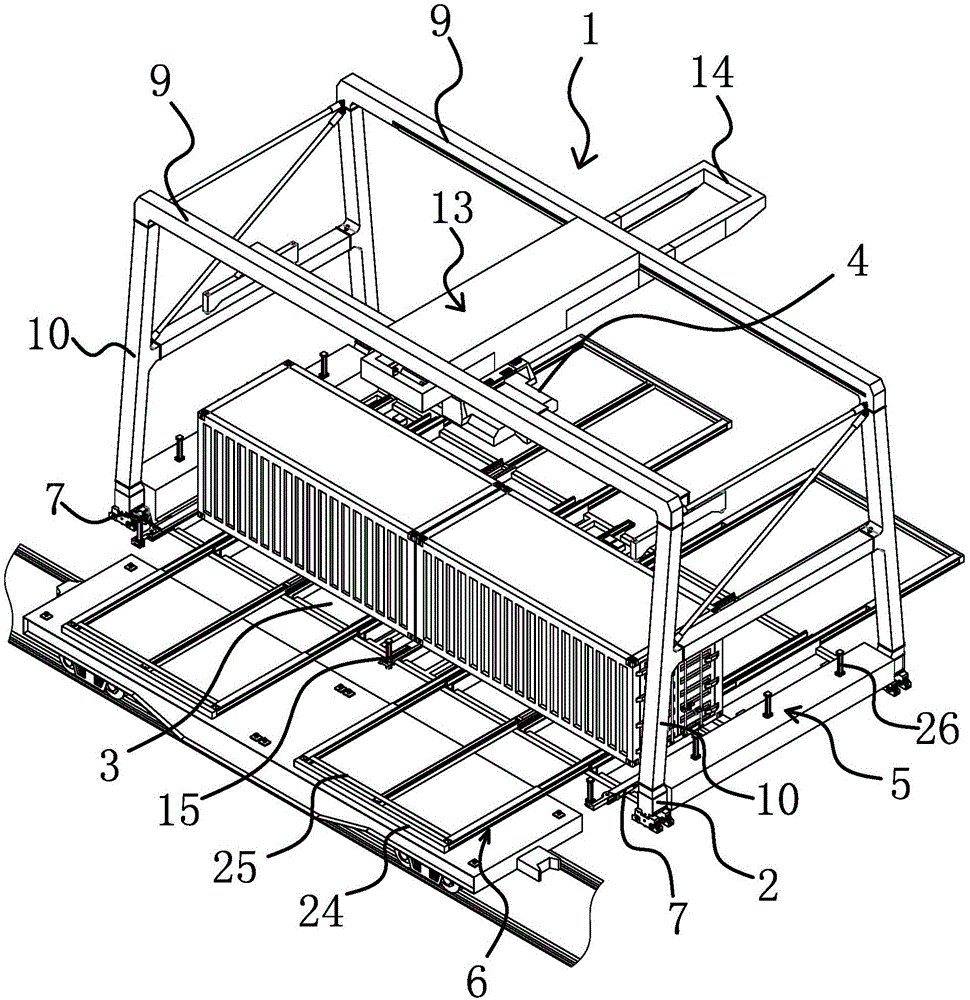

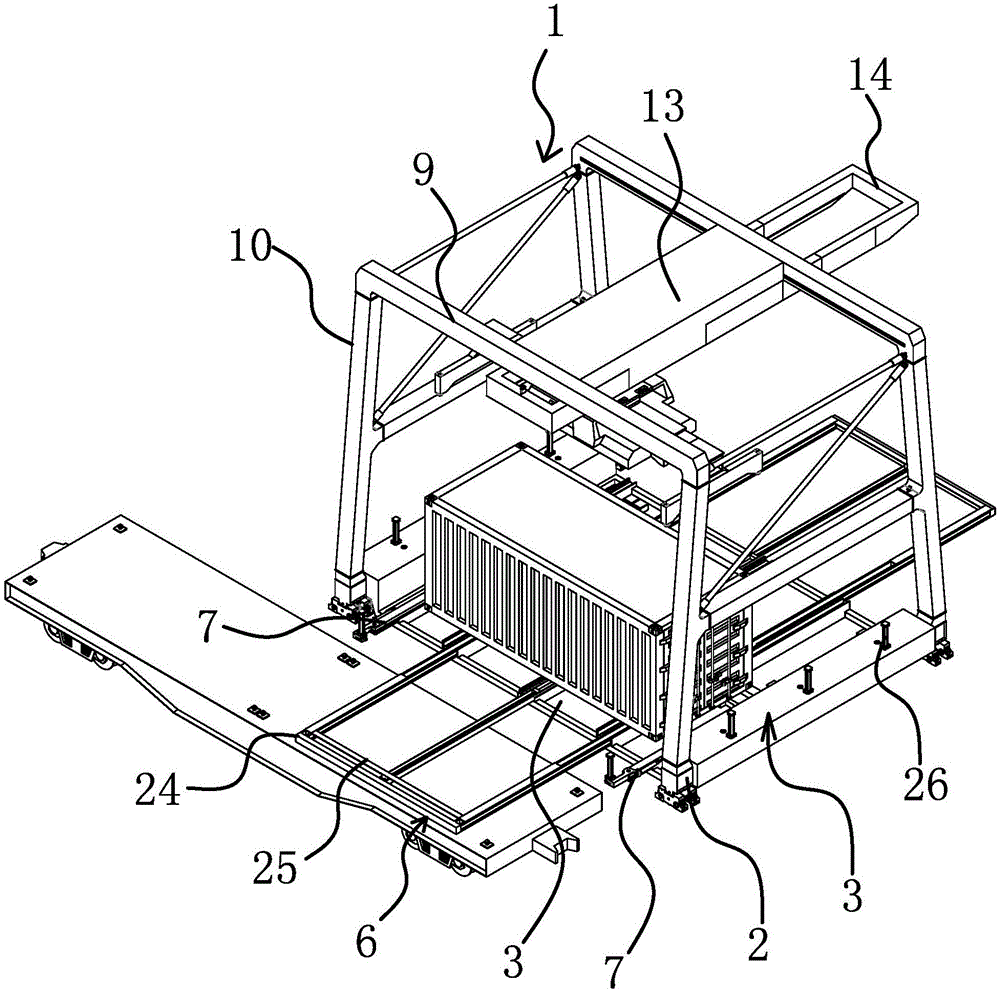

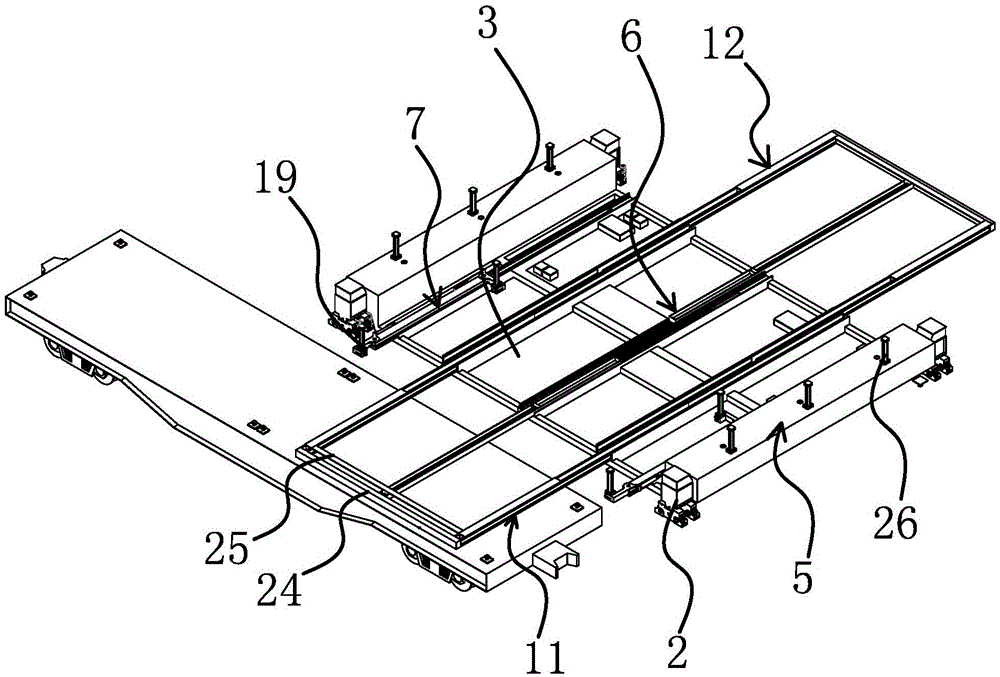

Loading and unloading system for container

ActiveCN105129676AThe transfer process is stableSafe transferLifting devicesContainer craneSafety coefficient

The invention provides a loading and unloading system for a container and belongs to the technical field of machines. The technical problems that when the container is loaded and unloaded through an existing container crane, the operation space of a suspension arm interferes with a cable, the suspension arm of the container crane can difficultly extend to the position above the container, unloading operation is troublesome, and the safety coefficient is low are solved. The loading and unloading system for the container comprises a frame. The frame comprises a walking frame and a base board arranged on the walking frame. A suspension arm is arranged on the frame and above the base board. An adjusting structure capable of adjusting the height of the base board is arranged between the base board and the walking frame. At least one movable support is arranged on the base board and connected to the base board in a sliding manner and can extend out of one side of the base board. Two strip-shaped first jacking arms are arranged on the two sides of the portion, perpendicular to the moving direction of the movable support, of the movable support and the two jacking arms are symmetrically arranged. The moving direction of the suspension arm is parallel to the moving direction of the movable support. By the adoption of the loading and unloading system for the container, the container can be conveniently and stably conveyed.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

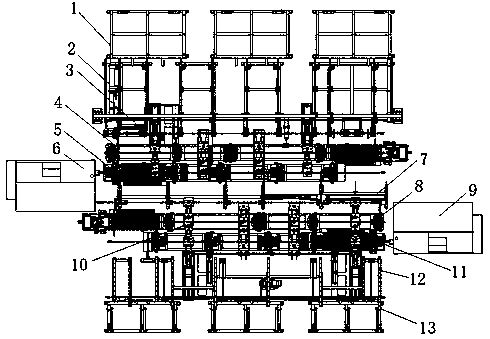

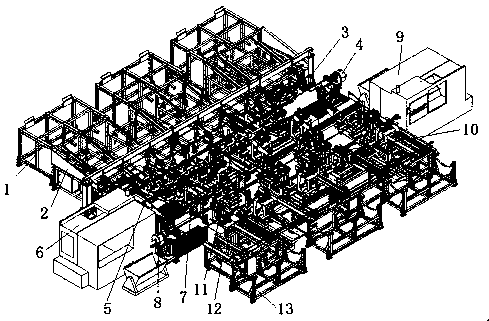

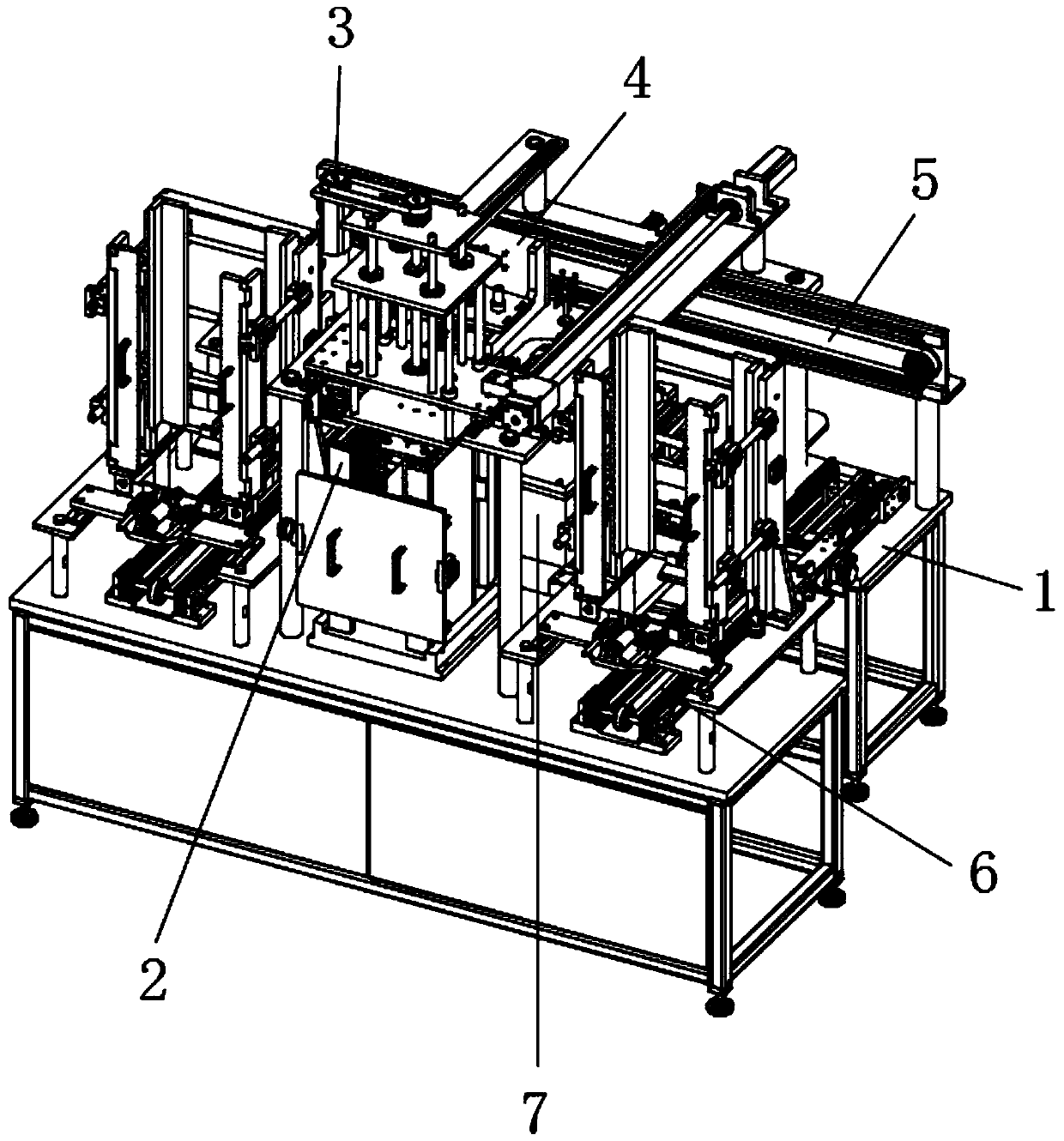

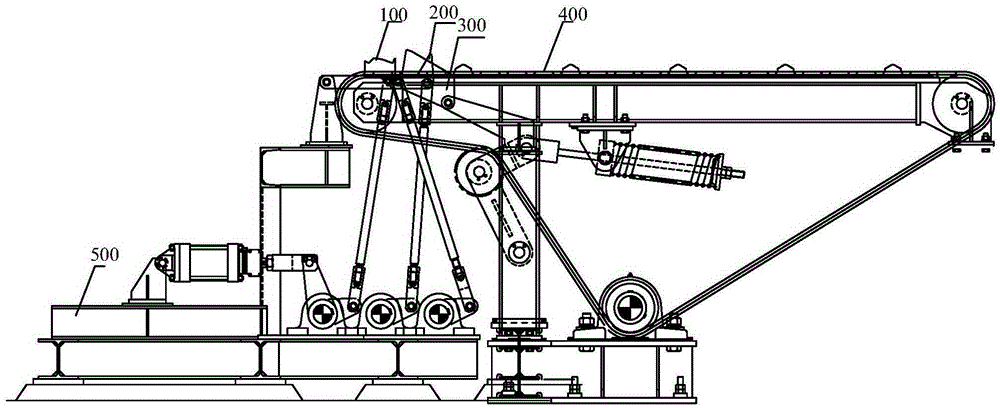

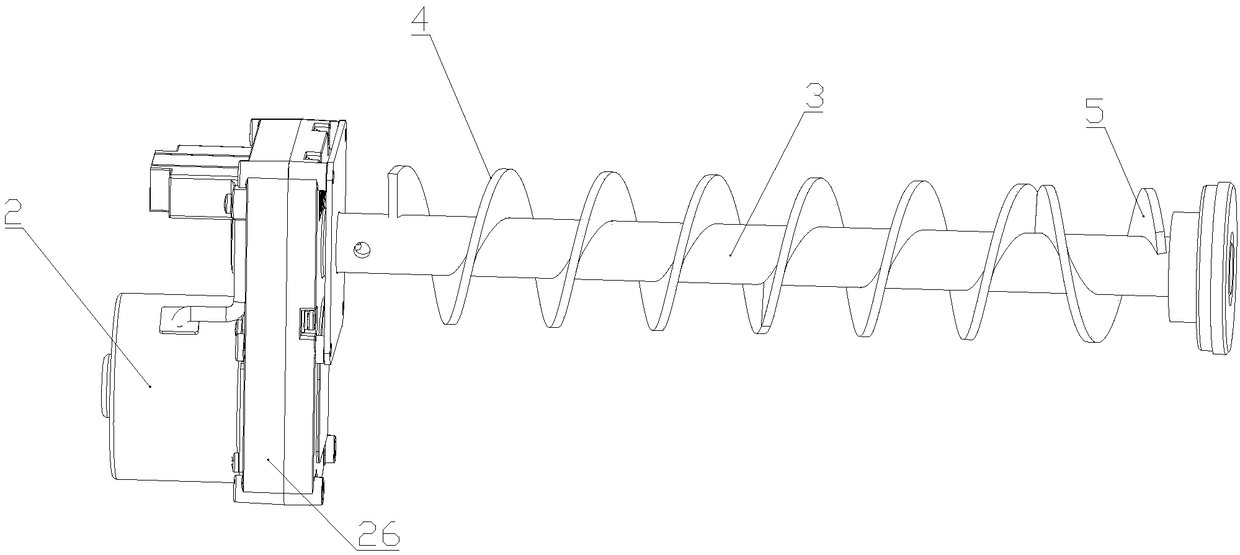

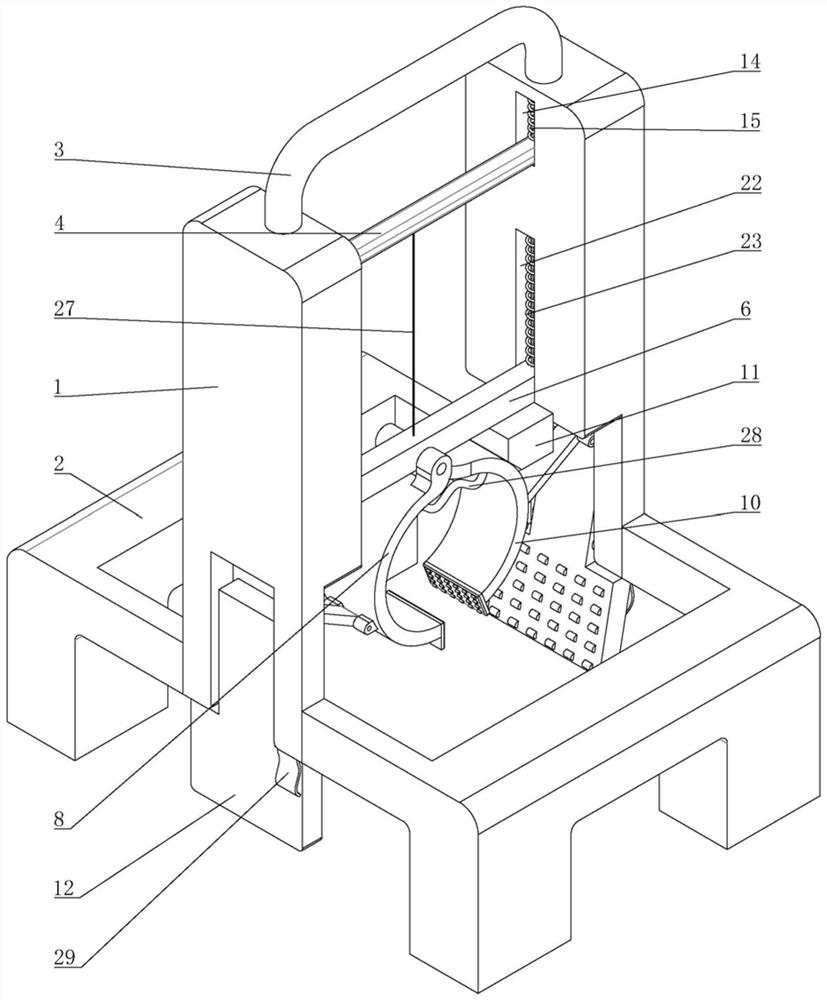

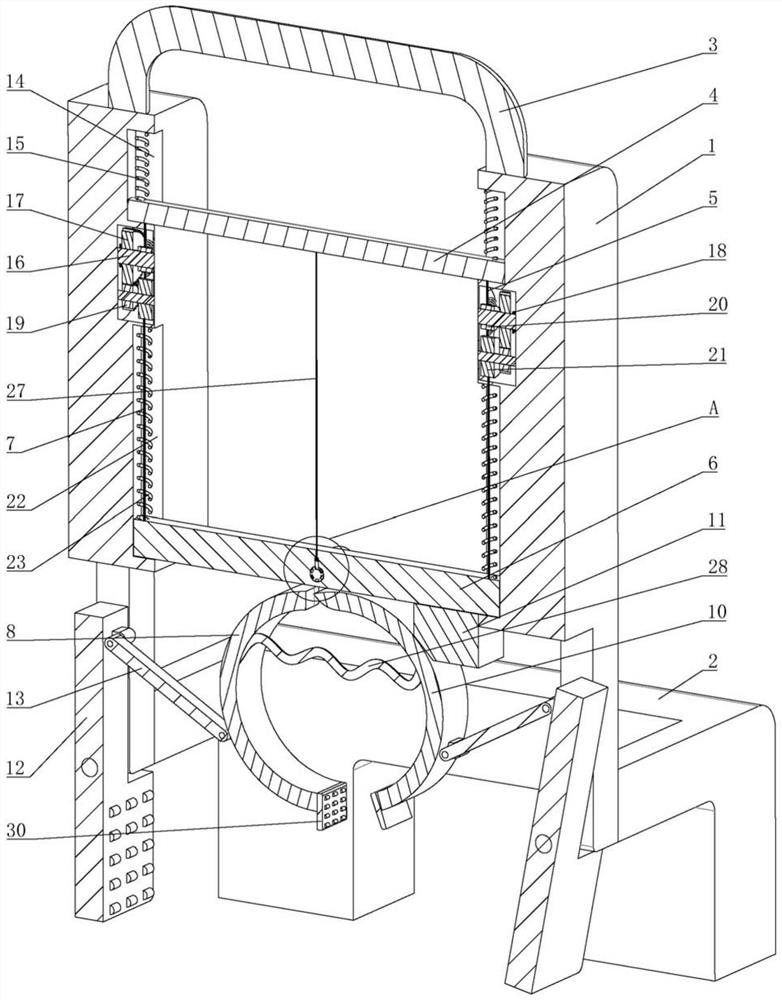

Oil sucker rod intelligent manufacturing production line

ActiveCN111390087AThe transfer process is stableRealize intelligent automatic productionForging/hammering/pressing machinesForging press detailsMachineMachining process

An oil sucker rod intelligent manufacturing production line comprises a feeding bin, a first stepping push device, a first angular positioning device, a first transferring device, an axial operation device, a second angular positioning device, a second stepping push device, a second transferring device and a discharging bin arranged in sequence in the workpiece operating direction; the outer sideof the first transferring device and the outer side of the second transferring device are both provided with machine tools; the first stepping push device pushes workpieces on the feeding bin, the first angular positioning device and the first transferring device forwards in sequence; and the second stepping push device pushes the workpieces on the axial operation device, the second angular positioning device, the second transferring device and the discharging bin forwards. According to the production line, the problems that conveying, clamping and positioning are difficult in the machining process of long and thin oil sucker rods are solved, intelligent automatic production of external threads of two ends of an oil sucker rod is achieved, the workpiece transferring stability is ensured, the paces are intense, the production efficiency is high, and the production cost is reduced.

Owner:山东弘名智能科技有限公司

Feeding device for automatic tin dipping machine and working method of feeding device

PendingCN110253105AThe transfer process is stableImprove feeding efficiencySoldering auxillary devicesDrive wheelEngineering

The invention discloses a feeding device for an automatic tin dipping machine and a working method of the feeding device. A transmission wheel is driven by a second motor to rotate so as to drive a driven wheel to rotate by a first belt; a first screw rod is driven to rotate by the driven wheel, so that a rotating plate is moved above a workpiece placed between two clamping plates, and the workpiece is absorbed by a plurality of sucking discs; and after adsorption, the first screw rod is driven by the second motor to rotate reversely so as to drive the rotating plate to move upwards, and therefore the workpiece is transferred to a tin dipping table by the plurality of sucking discs. As the workpiece is absorbed by the plurality of sucking discs, the workpiece is more stable in the transferring process and is prevented from deformation or falling damage for excessive or less force, and the feeding efficiency is greatly improved; the feeding is completed through the driving of a first motor, so that the transferring process is more stable and efficient, and the collision with other workpieces in the transferring process is avoided; and the whole process is simple to operate and does not need a large amount of labors, and the labor cost and the time cost are greatly reduced.

Owner:BENGBU ZHENGYUAN ELECTRONICS TECH

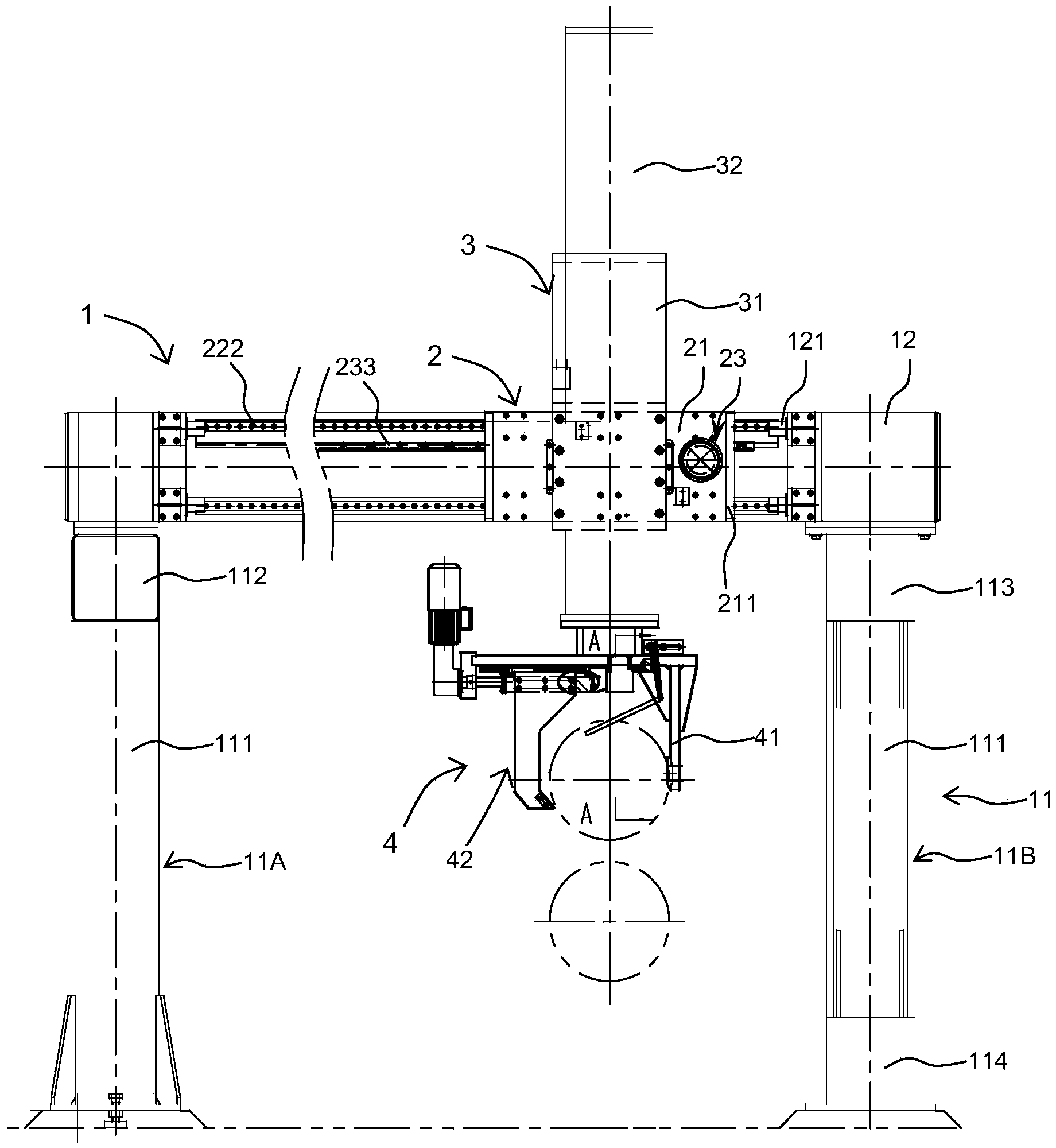

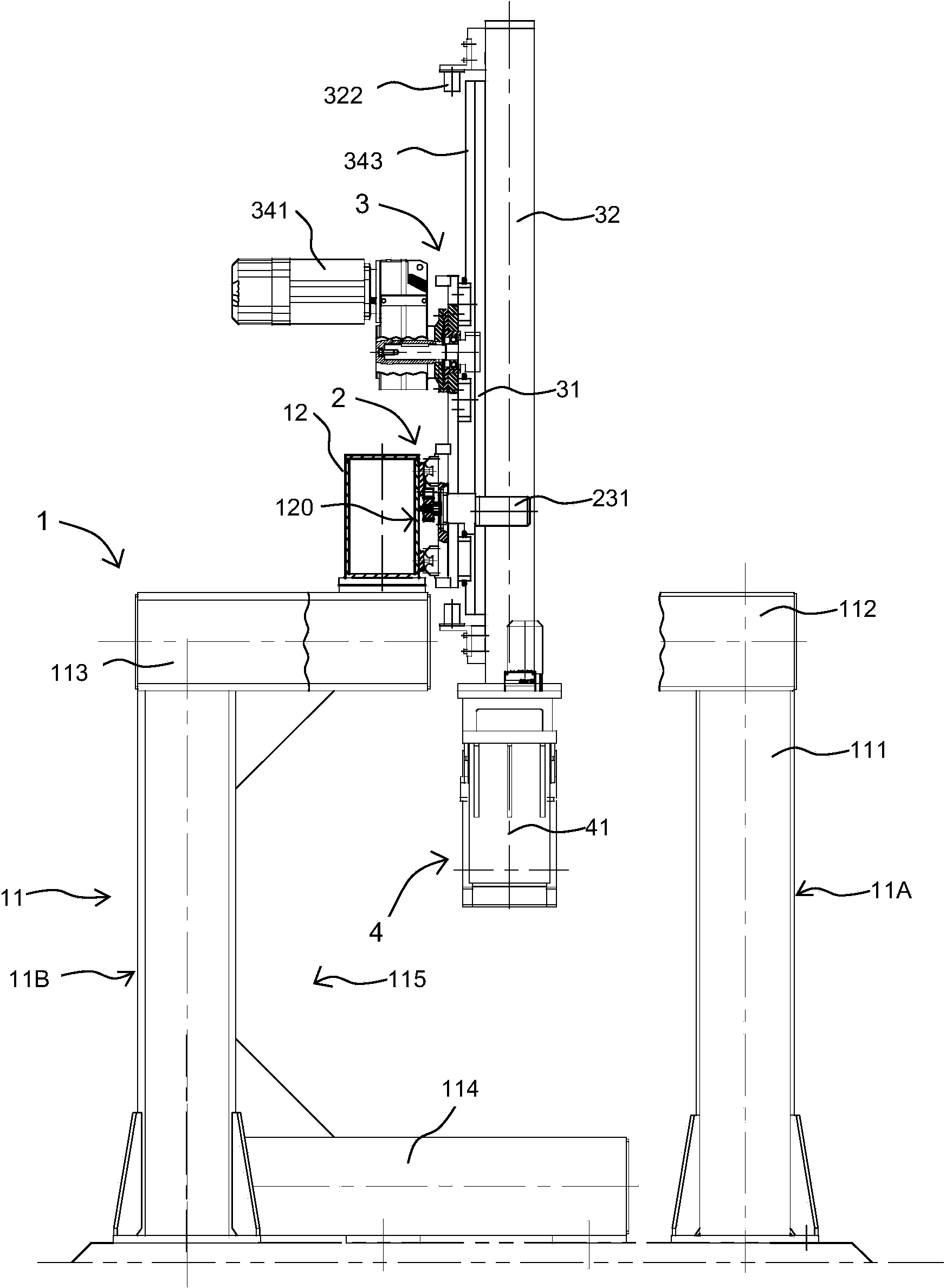

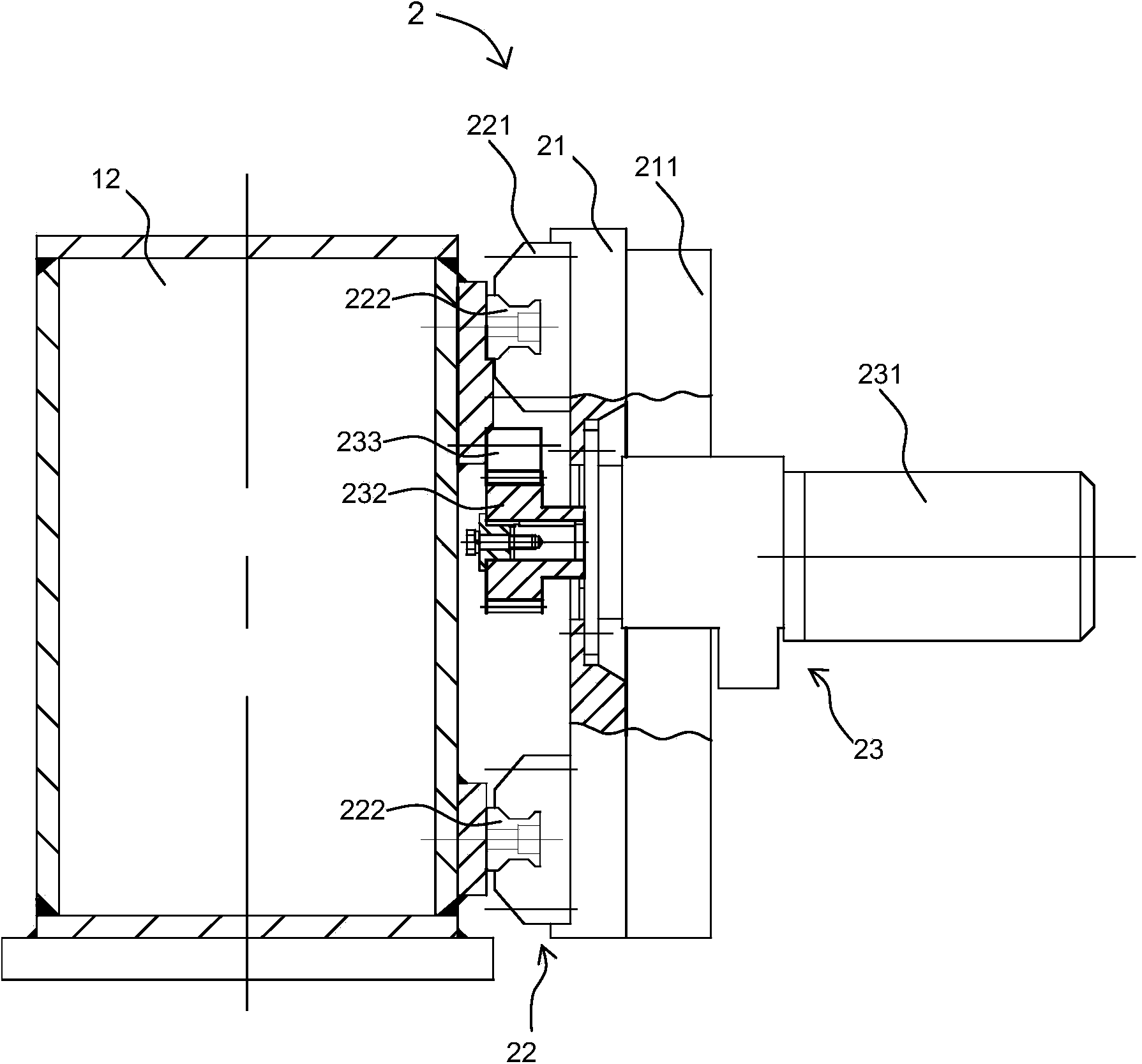

Large-size metal blank hoisting equipment

The invention provides large-size metal blank hoisting equipment which comprises a rack, a transverse moving device, a vertical moving device and a jaw device, wherein the rack comprises a support rack and a transverse beam; the support rack is used for fixing the transverse beam on a blank conveying stroke of an extruder; the transverse moving device comprises a transverse rack, a guide track pair and a power device; the transverse rack is arranged on the transverse beam through the guide track pair in a sliding manner; the power device is used for driving the transverse rack to move transversely on the transverse beam; the vertical moving device is fixed on the transverse rack; the vertical moving device comprises an elevating rack, a guide track pair and a driving device; the elevating rack is movably arranged on the transverse rack through the guide track pair; the driving device is used for driving the elevating rack to vertically move on the transverse rack; the jaw device is fixed on the elevating rack; the jaw device can be used for clamping or unclamping blanks. The clamping, elevation and horizontal moving of large-size metal blanks can be effectively realized.

Owner:TAIYUAN HEAVY IND

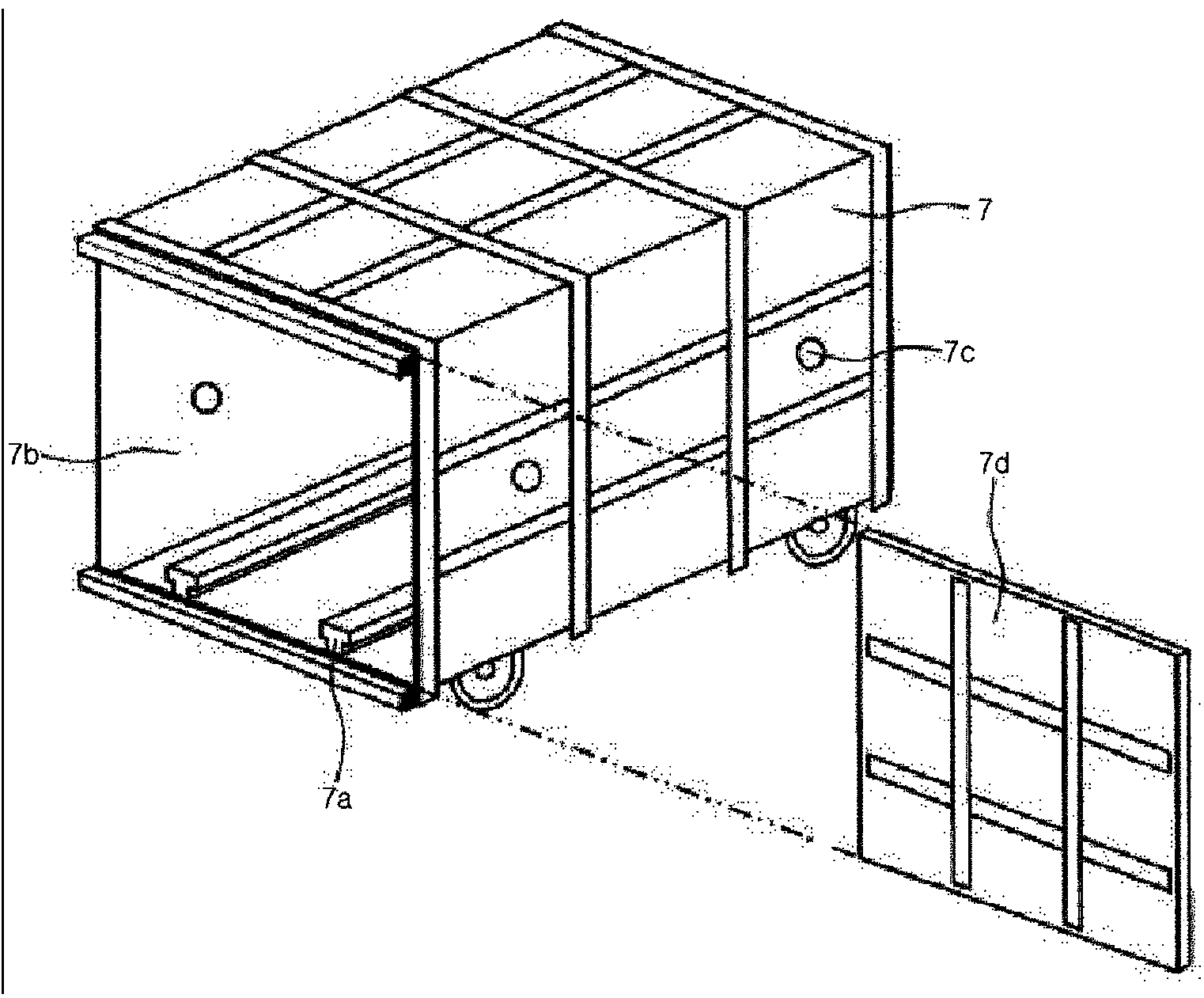

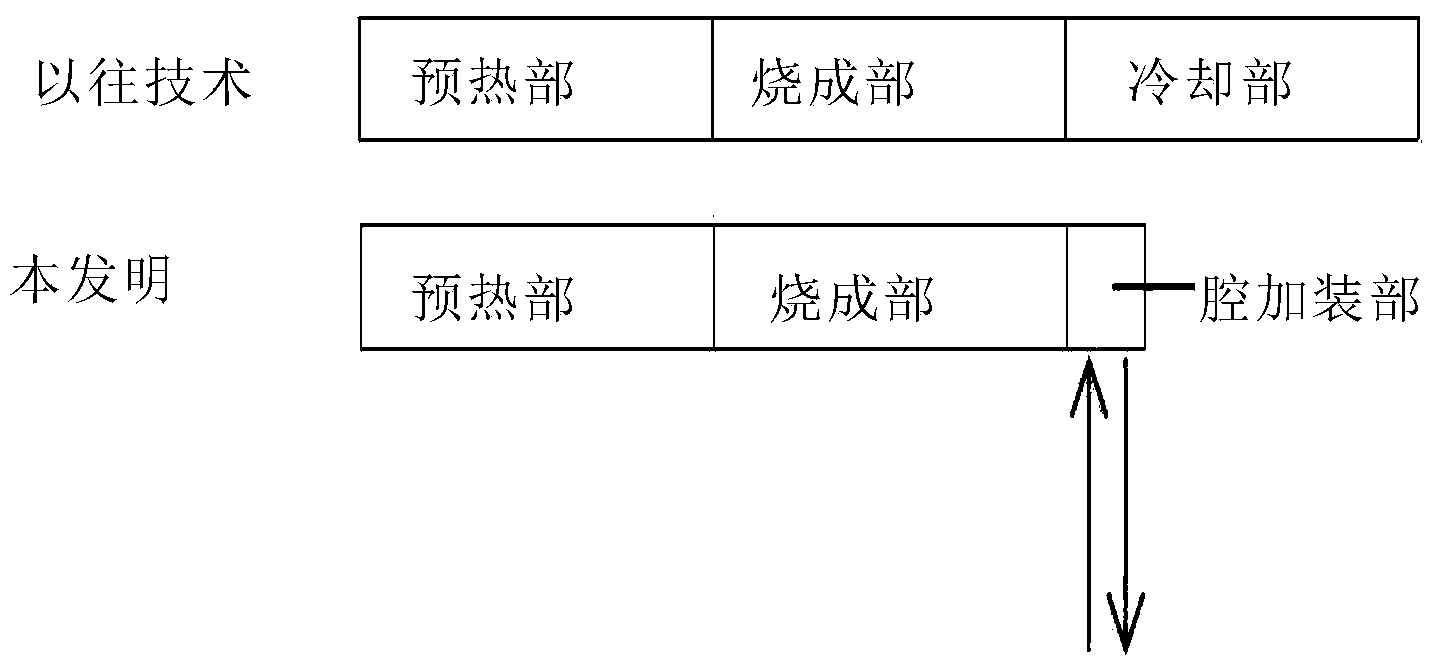

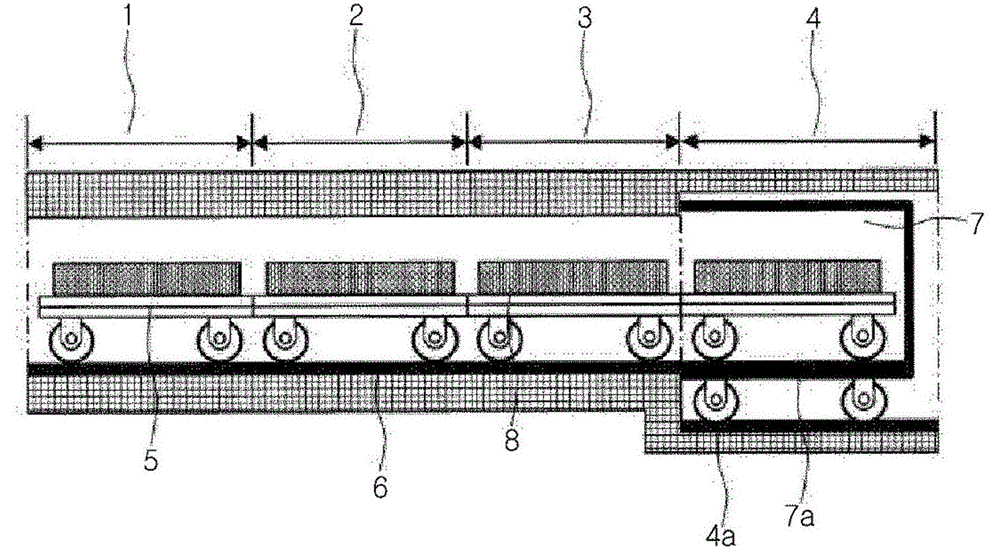

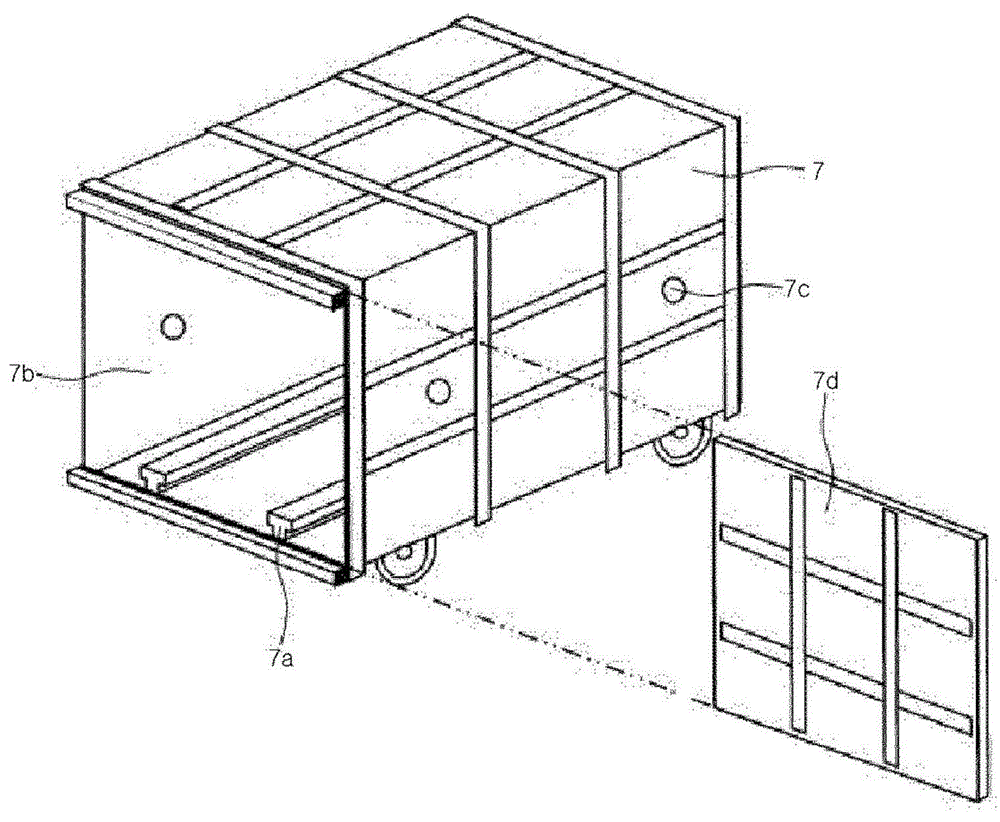

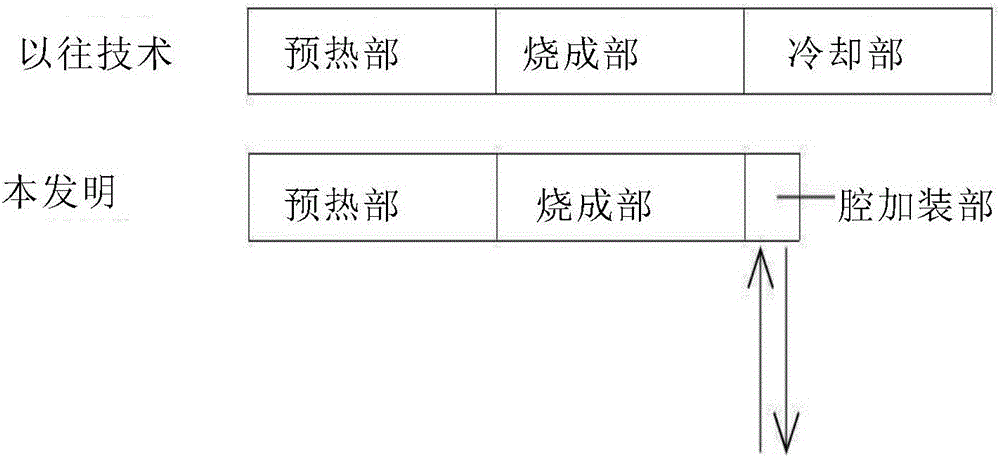

Apparatus and method for manufacturing traditional carbonized tiles

InactiveCN103884177AEvenly loadedStable storageCharge manipulationFurnace typesRegulation temperatureTunnel kiln

The invention relates to an apparatus for manufacturing traditional carbonized tiles, a carbonized chamber which is used in the apparatus for manufacturing the traditional carbonized tiles, and a manufacturing method. More particularly, the invention relates to the apparatus for manufacturing the traditional carbonized tiles, the carbonized chamber, and a tile manufacturing method utilizing the same, wherein after the tiles are sintered at a high temperature in a tunnel kiln, a trolley is closely combined with a chamber, while a closed state is kept, supplying and discharging amounts of fuel and air are adjusted so that a carbonizing step can be performed in a carbonizing chamber which can adjust the temperature, thereby manufacturing the high-quality carbonized tiles with a target color without a cooling room or a cooling kiln. Additionally, after the tiles are sintered at the high temperature in the tunnel kiln, in a chamber adding part, the carbonized chamber can be closely added at the upper part of each trolley; after easy movement by a conveying track, the carbonizing step is realized in the chamber outside the tile, thereby realizing no requirement for the cooling chamber or the cooling kiln equipment in the tunnel kiln. The apparatus has an advantage of simplifying the structure of a carbonizing processing device.

Owner:(株)东部窑业

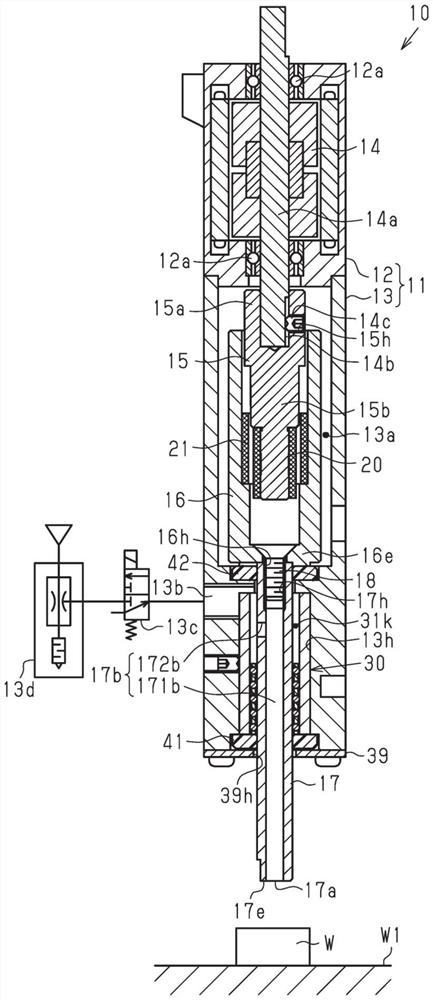

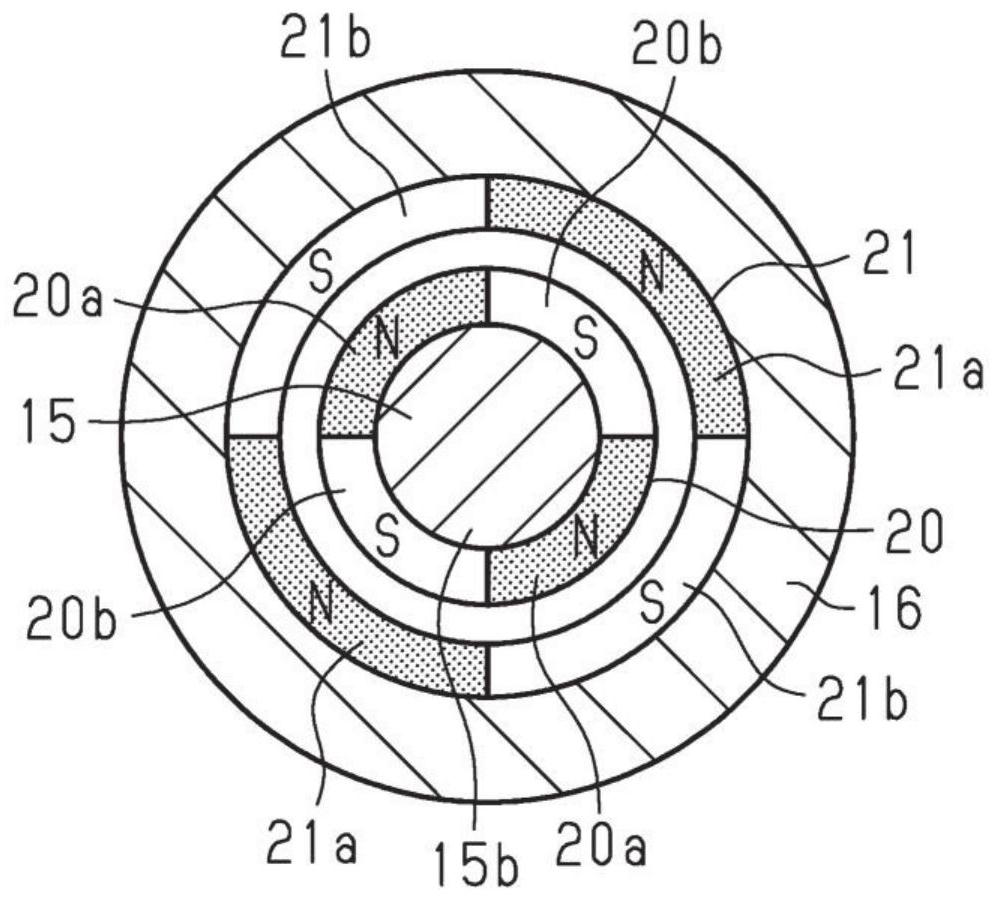

Adsorption buffer device

An adsorption buffer device includes a housing, a drive shaft, a driven shaft, magnets, and a sealing member. The opposing surfaces of the magnets are magnetized with different magnetic poles, so thatthe magnets are non-contact and deviate the overlap of the axial magnetic poles. While the attractive force in the axial direction to be restored acts on a movable shaft, the movable shaft moves. Thefront end portion of the driven shaft adjacent to the movable shaft and the base end portion of the sealing member opposed to the driven shaft can be abutted against each other. At least any one of the front end portion of the driven shaft and the base end portion of the sealing member opposed to the driven shaft is provided with a connecting passage that communicates the outer periphery and theinner periphery of the side opposed to the driven shaft of the sealing member.

Owner:CKD

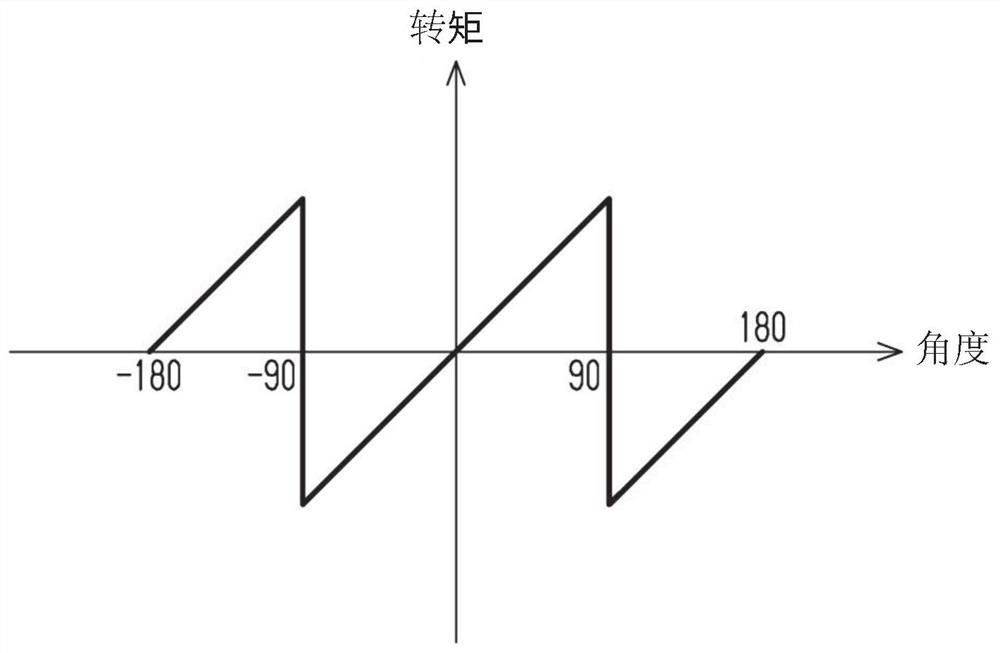

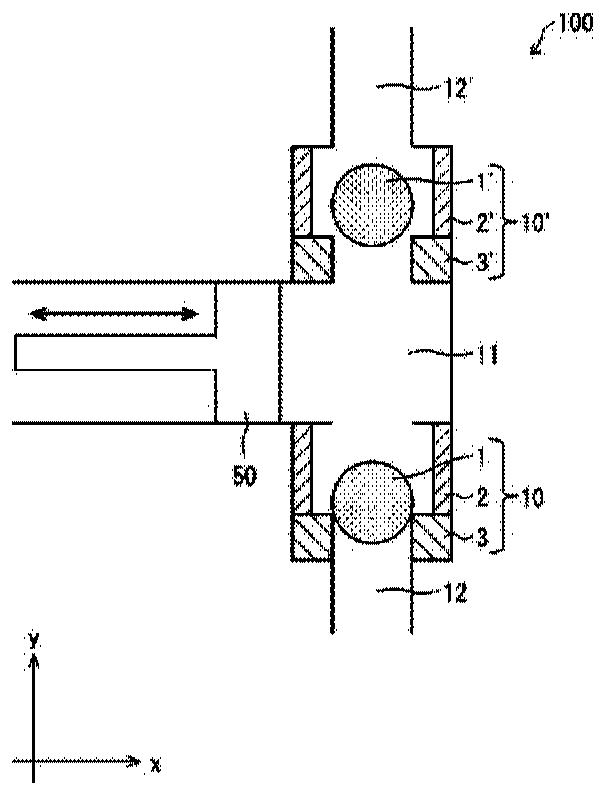

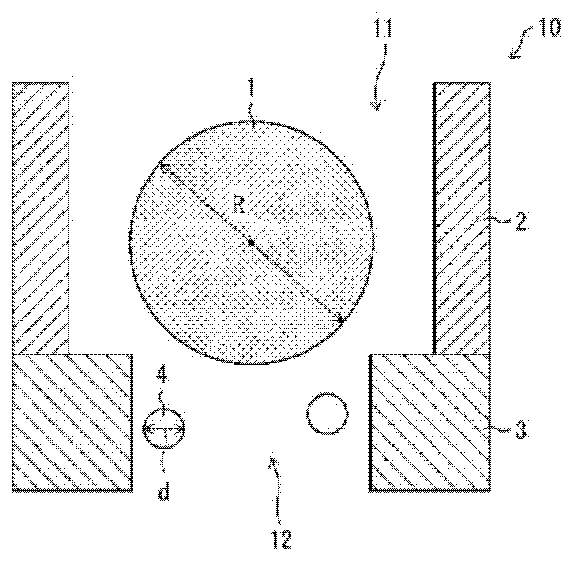

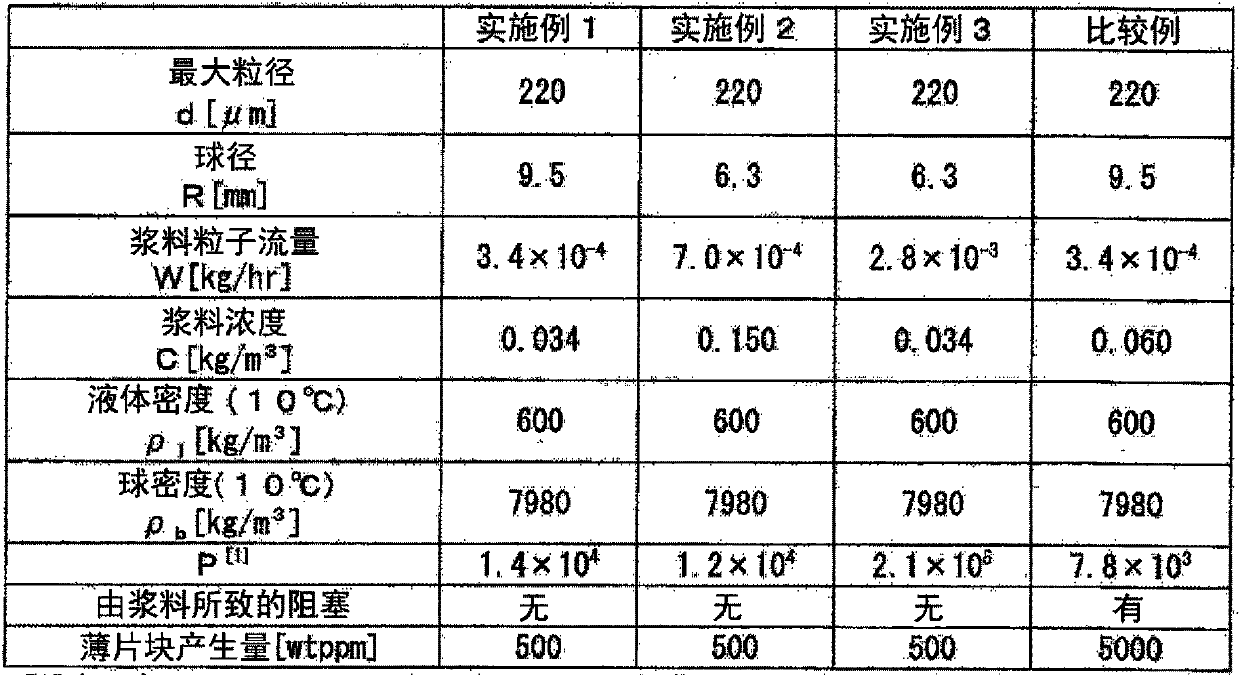

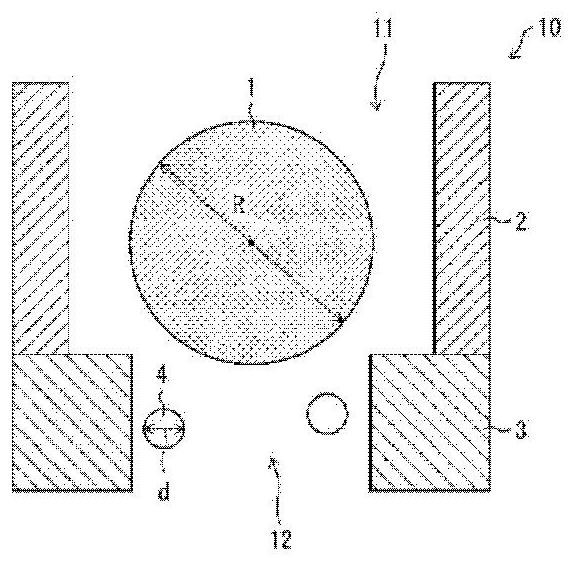

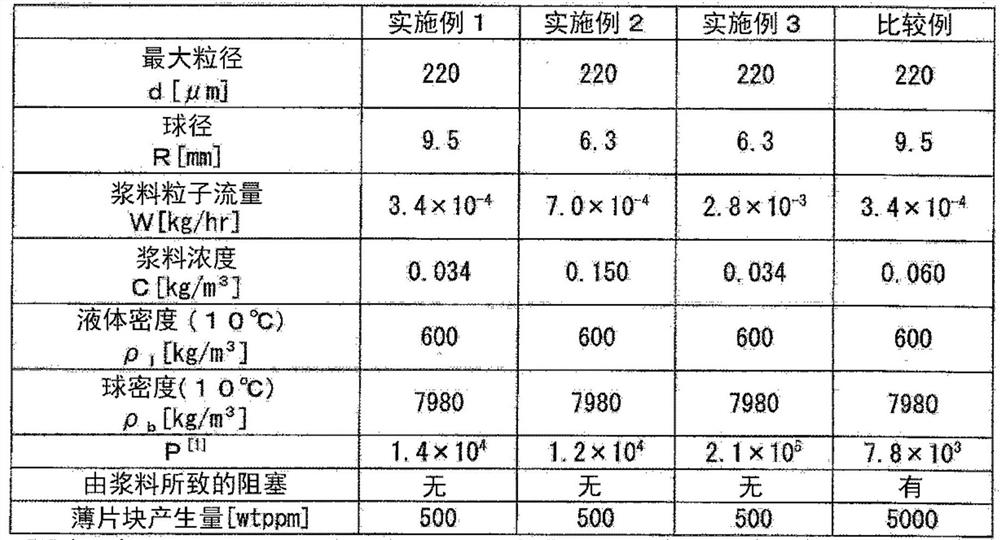

Method of transferring slurry, method of producing polyolefin and use thereof

ActiveCN110639434AAvoid blockingThe transfer process is stableChemical/physical processesParticle flowPolyolefin

The invention realizes a slurry transfer method which can operate stably for a longer period of time a plunger pump for supplying a slurry under high pressure. A method of transferring a slurry, in which a transfer pump equipped with a ball type check valve is operated under the condition satisfying the following formula (1) to transfer a slurry containing particles and a liquid, 7.8*103<P<-5.0*105 (1), wherein,P=W([rho]1 / ([rho]b-[rho]1))0.5 / (C.d(d+R)0.5), in the formula (I), W represents the particle flow rate (kg / hr) in the slurry passing through the ball type check valve, C represents the particle concentration (kg / m3) in the slurry, d represents the maximum particle diameter (m) of the particles in the slurry, R represents the ball diameter (m) of the check valve, [rho]1 represents thedensity (kg / m3) of the liquid, and [rho]b represents the density (kg / m3) of the ball of the check valve.

Owner:SUMITOMO CHEM CO LTD

Traditional carbonized brick and tile manufacturing device and manufacturing method

The invention relates to an apparatus for manufacturing traditional carbonized tiles, a carbonized chamber which is used in the apparatus for manufacturing the traditional carbonized tiles, and a manufacturing method. More particularly, the invention relates to the apparatus for manufacturing the traditional carbonized tiles, the carbonized chamber, and a tile manufacturing method utilizing the same, wherein after the tiles are sintered at a high temperature in a tunnel kiln, a trolley is closely combined with a chamber, while a closed state is kept, supplying and discharging amounts of fuel and air are adjusted so that a carbonizing step can be performed in a carbonizing chamber which can adjust the temperature, thereby manufacturing the high-quality carbonized tiles with a target color without a cooling room or a cooling kiln. Additionally, after the tiles are sintered at the high temperature in the tunnel kiln, in a chamber adding part, the carbonized chamber can be closely added at the upper part of each trolley; after easy movement by a conveying track, the carbonizing step is realized in the chamber outside the tile, thereby realizing no requirement for the cooling chamber or the cooling kiln equipment in the tunnel kiln. The apparatus has an advantage of simplifying the structure of a carbonizing processing device.

Owner:(株)东部窑业

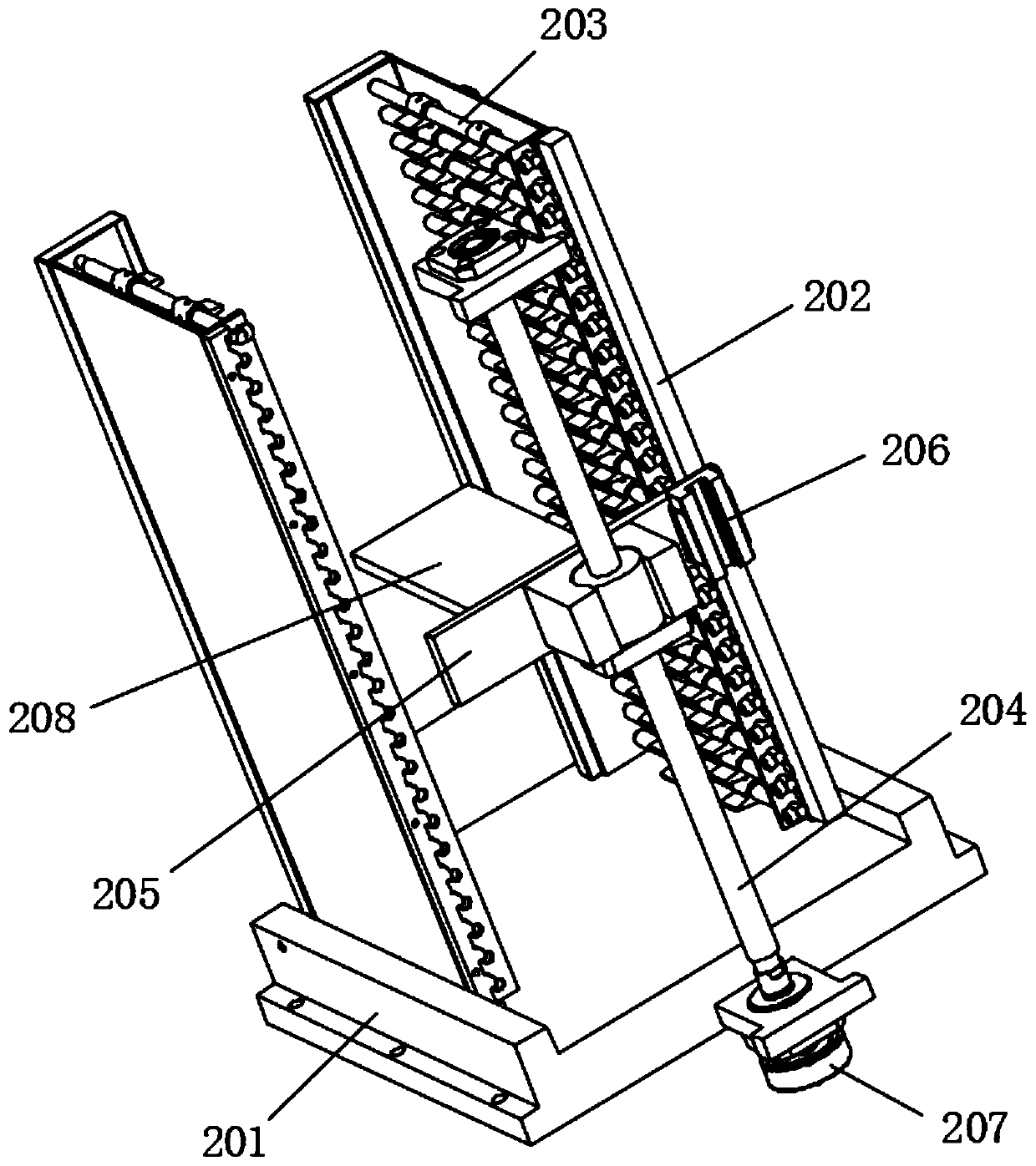

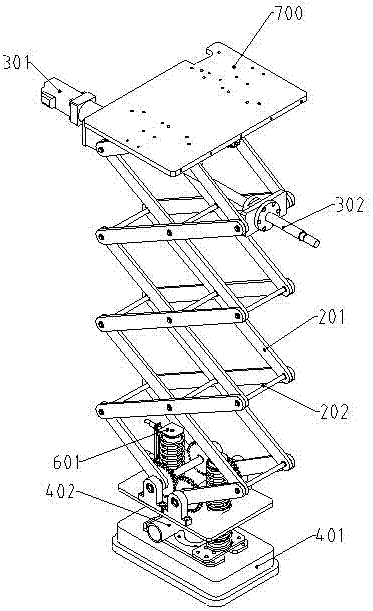

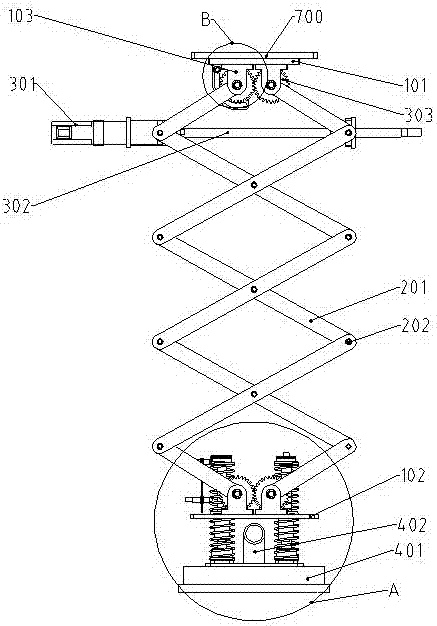

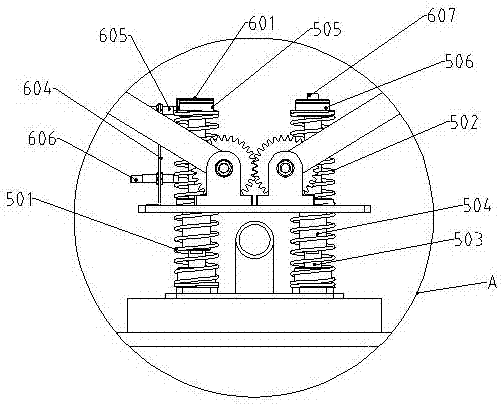

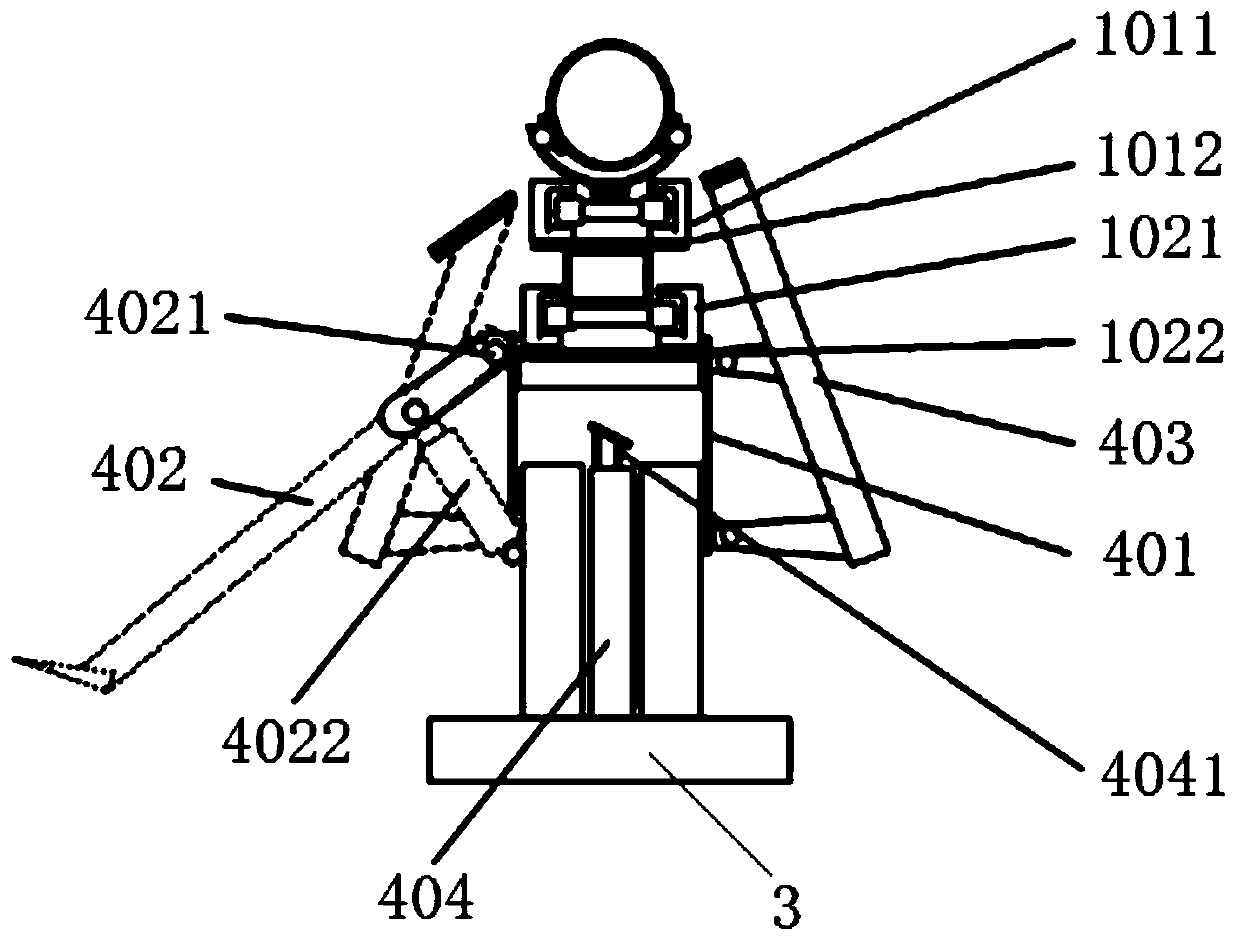

Bagged powder or particle material hoisting and taking system

PendingCN107160384AMechanism telescopic movement flexibleIncrease the itineraryProgramme-controlled manipulatorGripping headsStructural engineeringPowder

The invention discloses a bagged powder or particle material hoisting and taking system. The bagged powder or particle material hoisting and taking system comprises a lifting assembly, a hoisting installation assembly and a material taking assembly; the hoisting installation assembly comprises a top-face installation plate and a bottom-face installation plate; the top-face installation plate is connected with a mechanism top beam; the lifting assembly is installed on the mechanism top beam through the top-face installation plate; the material taking assembly is connected with the lifting assembly through the bottom-face installation plate; the lifting assembly comprises a drive device and a scissors fork device, and the drive device drives scissors forks to stretch and contract; the material taking assembly comprises a sucker, an air blower and a suction pipe, and the air blower is connected with the sucker through the suction pipe to provide negative pressure for the sucker. The drive device drives the scissors fork device to contract and stretch, movement for a large vertical displacement distance of the sucker is completed, when the sucker is used for grabbing bagged particle materials or bagged powder materials, transfer is steady, the sucking effect is firm, the grabbing strength is large, and the system is quite convenient to apply.

Owner:ZTT HUAYU INTELLIGENT TECH CO LTD

Unloading system for bars and sections

The invention discloses a steel unloading system suitable for bars and section steel, and mainly aims to solve the problem that steel unloading of bars and section steel cannot be implemented simultaneously in the prior art. The steel unloading system comprises a stepping steel unloading device, an auxiliary steel unloading device and a conveying device, wherein the stepping steel unloading device comprises a movable rack, a static rack and a rack driving device; the auxiliary steel unloading device comprises an auxiliary steel unloading baffle plate, a first driving device and a first transmission device; the first driving device is used for controlling the auxiliary steel unloading baffle plate to be positioned at a higher position or a lower position through the first transmission device; the conveying device comprises a conveying chain and a chain driving device. The shapes of recesses of the movable and static racks are improved, so that the section steel is conveyed more stably without being overturned. Therefore, the steel unloading system can be suitable for steel unloading of the bars and the section steel.

Owner:HUATIAN NANJING ENG & TECH CORP MCC

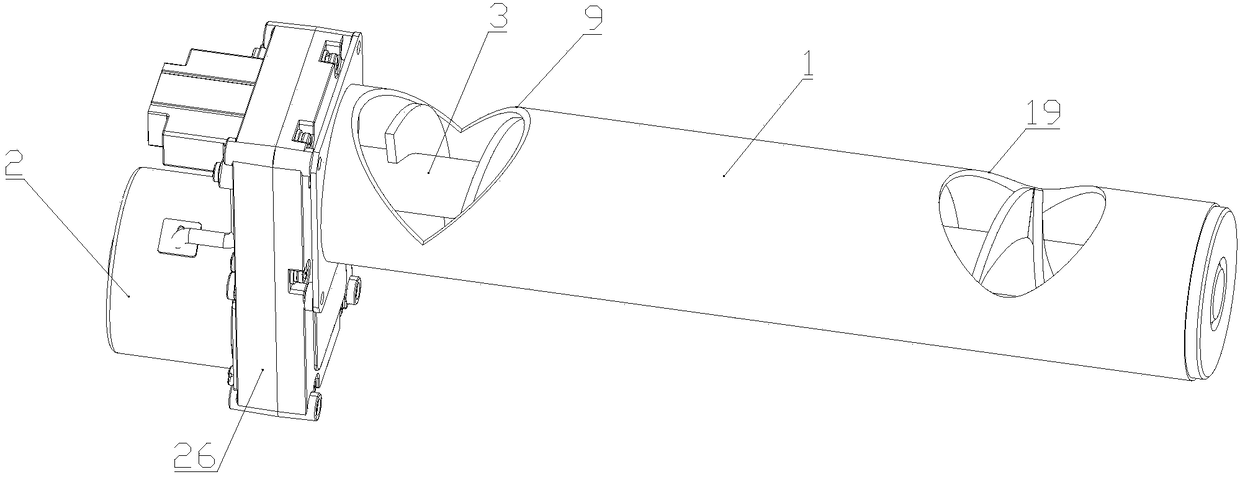

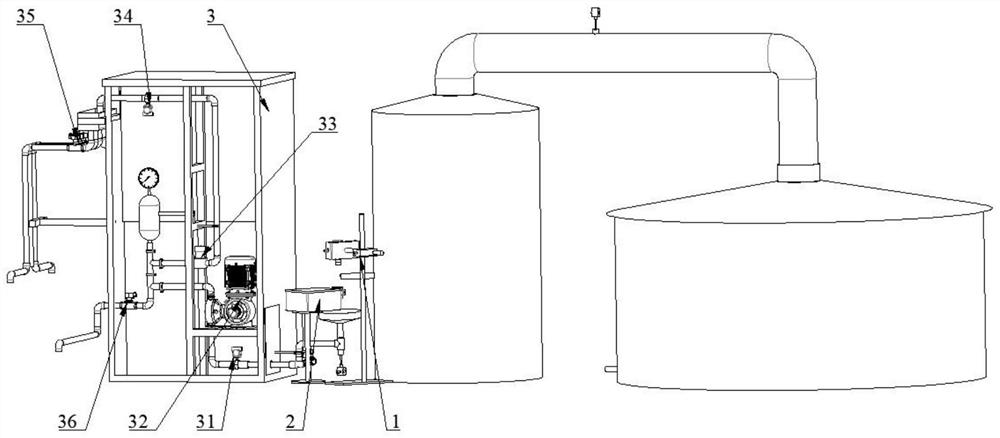

Wall furnace and loading device thereof

InactiveCN108571751ABurn fullyThe transfer process is stableDomestic stoves or rangesLighting and heating apparatusEngineeringRight-to-left

The invention relates to the technical field of heating equipment and discloses a wall furnace and a loading device thereof. The wall furnace comprises a first feeding section (1), wherein a first driving motor (2) is arranged on the left side of the first feeding section (1), a first feeding rod (3) is arranged in the first feeding section (1), the left end of the first feeding rod (3) is connected to the first driving motor (2), the first driving motor (2) drives the first feeding rod (3) to rotate, a first spiral section (4) spirally winding the first feeding rod (3) from left to right is arranged on the first feeding rod (3), a second spiral section (5) is arranged at the right end of the first feeding section (3), the second spiral section (5) winds on the first feeding rod (3) spirally from right to left, and the right end of the first spiral section (4) is connected to the left end of the second spiral section (5). The wall furnace provided by the invention can extrude a fuel, so that the fuel moves upward and is prevented from being accumulated in the first feeding section, and therefore, the utilization ratio of the fuel is increased.

Owner:浙江奥邦科技有限公司

A kind of oil pipe remote control transfer machine

ActiveCN107780855BThe transfer process is stableAvoid wear and tearDrilling rodsDrilling casingsRemote controlEngineering

The invention discloses an oil tube remote control mobile device, and belongs to the field of well service equipment. The device comprises a slideway assembly, an automatic return tackle, a main rack,a tube taking and placing mechanism, an electrically controlled hydraulic device and a hand-held remote controller. The slideway assembly comprises a slideway, a support guide rail, slideway rollingwheels and a lifting machine. The slideway and the support guide rail are provided with rectangular grooves, wheels of the automatic return tackle can move forward and backward in the rectangular groove of the slideway, the slideway moves forward and backward in the rectangular groove of the support guide rail, and the front end of the support guide rail is driven by the lifting machine to do lifting motion. The tube taking and placing mechanism comprises a support plate, a tube taking arm, a tube jacking piston and a tube placing arm. An oil tube on the slideway is ejected out through the tube jacking piston and rolls down onto a tube rack along the tube placing arm; the oil tube on the tube rack is lifted and turned onto the slideway through the tube taking arm. The hand-held remote controller is in wireless connection with the electrically controlled hydraulic device, and then movement of the slideway, the lifting machine, the tube jacking piston and the tube taking arm is driven remotely. By means of the mobile device, oil tube screw thread damage can be avoided.

Owner:PETROCHINA CO LTD

Slurry transfer method, polyolefin production method and utilization thereof

ActiveCN110639434BAvoid blockingThe transfer process is stableChemical/physical processesPolyolefinPhysical chemistry

The present invention realizes a slurry transfer method capable of stably operating a plunger pump that supplies slurry at high pressure for a long period of time. A method for transferring slurry, wherein a transfer pump equipped with a ball check valve is operated under the conditions satisfying the following formula (1) to transfer the slurry containing particles and liquid, 7.8×10 3 <P≤5.0×10 5 (1). Here, P=W(ρ 1 / (ρ b -ρ 1 )) 0.5 / (C d(d+R)R 0.5 ), in formula (1), W represents the particle flow rate (kg / hr) in the slurry passing through the ball check valve, and C represents the particle concentration (kg / m 3 ), d represents the maximum particle diameter (m) of the particles in the slurry, R represents the ball diameter (m) of the one-way valve, ρ 1 Indicates the density of the liquid (kg / m 3 ), ρ b Indicates the density of the ball of the check valve (kg / m 3 ).

Owner:SUMITOMO CHEM CO LTD

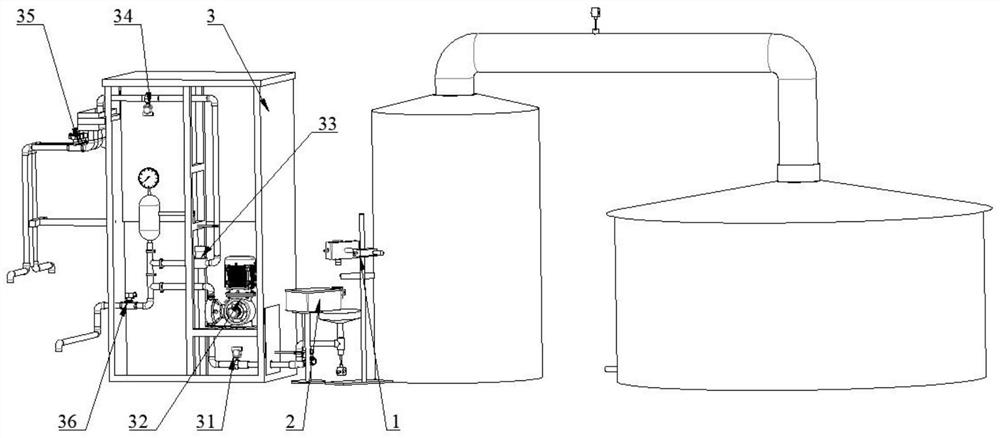

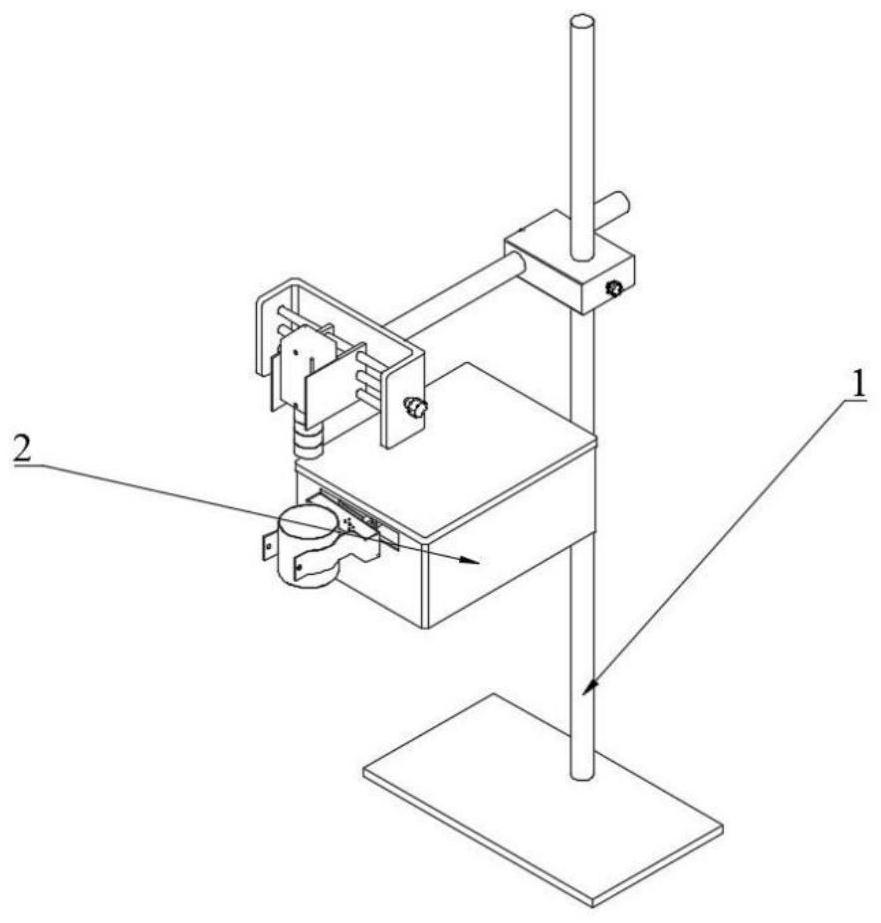

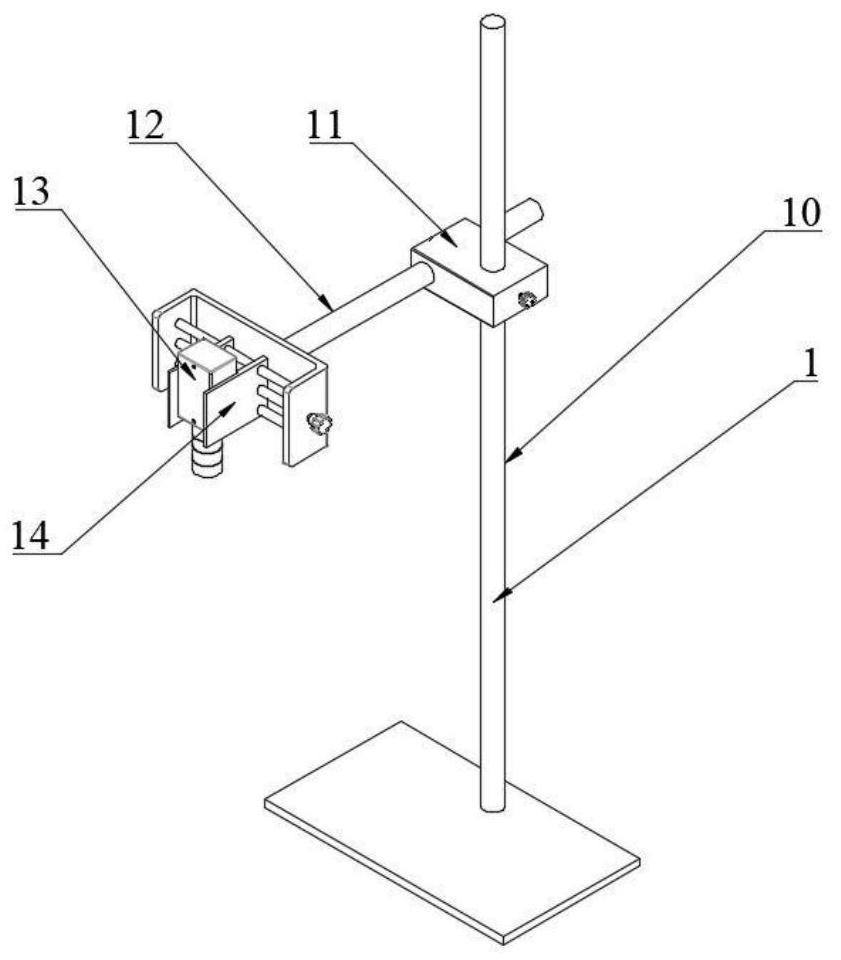

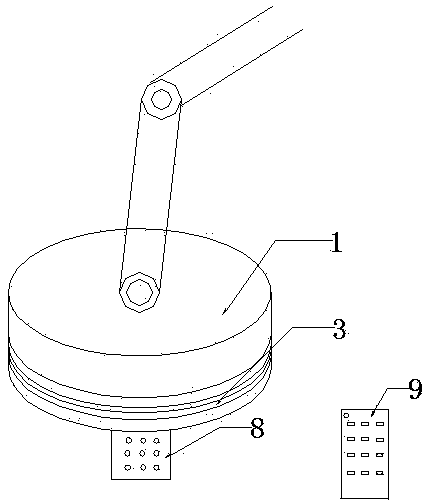

A kind of wine picking equipment and method based on liquor hop image

ActiveCN112699968BHigh degree of intelligenceNeat layoutAlcoholic beverage preparationCharacter and pattern recognitionMotor driveElectric machinery

The invention is a wine picking device based on liquor hop images, comprising a camera fixing part and a hop collecting part, the camera fixing part is used to fix the position of the camera and collect pictures; the camera fixing part includes an adjustable fixing bracket and is installed on a fixed The camera on the bracket; the function of the hop collection part is to control the wine glass to collect the original wine and move the wine glass to the middle position of the camera to facilitate the collection of hops, and at the same time, the wine glass can be returned from the collection position to the wine flow position; the hop collection part includes a stepper The motor, the cam linkage mechanism, the end support and the wine glass fixed on the end support, the fixed bracket is fixed near the wine flow mouth of the liquor production line, and the stepping motor drives the cam link mechanism to move the wine glass to the flow mouth and the camera. Move back and forth directly below. It breaks the shortcomings of traditional manual viewing of flowers and wine picking, improves the degree of automation and intelligence, reduces human errors, and improves the rate of high-quality wine.

Owner:HEBEI UNIV OF TECH

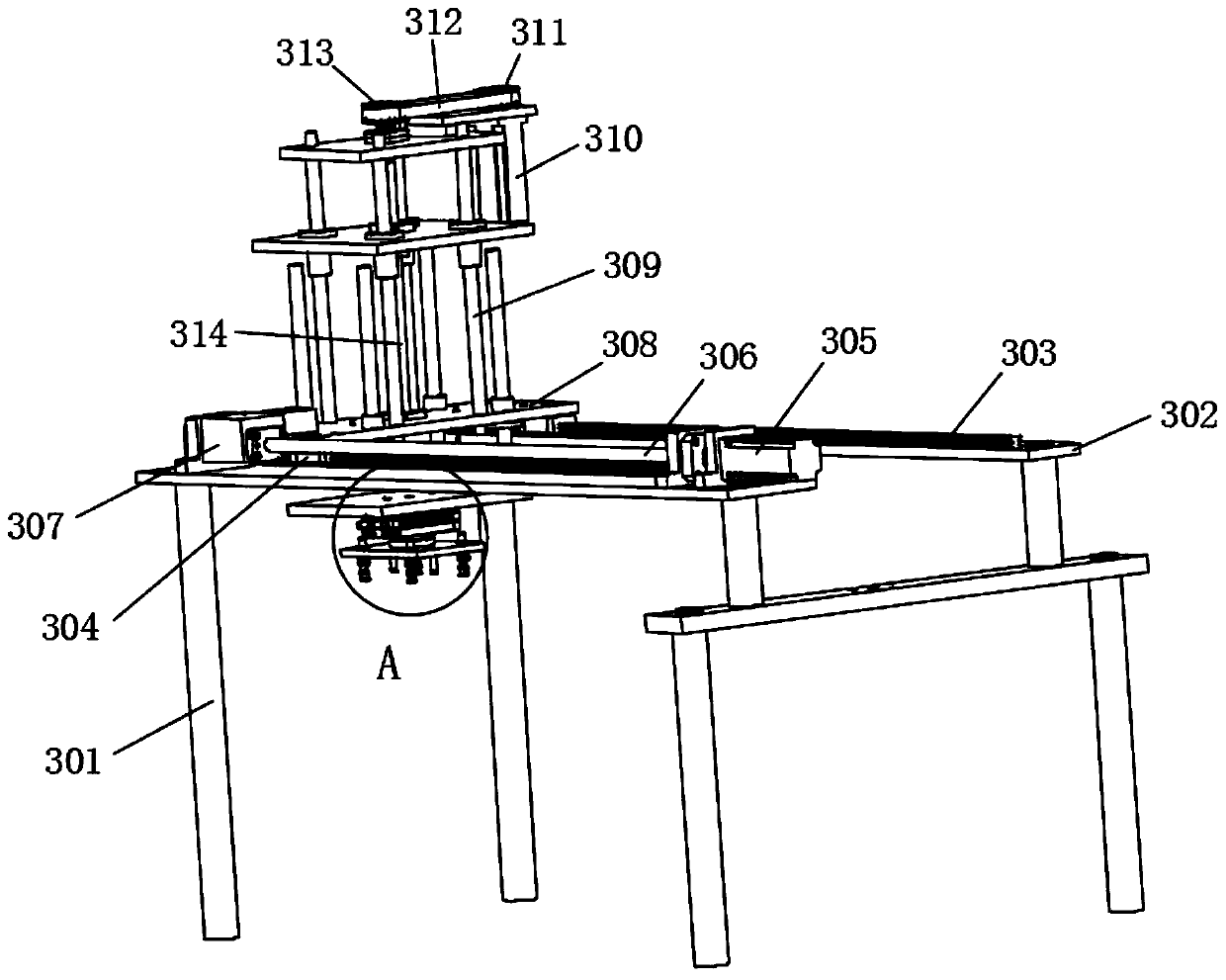

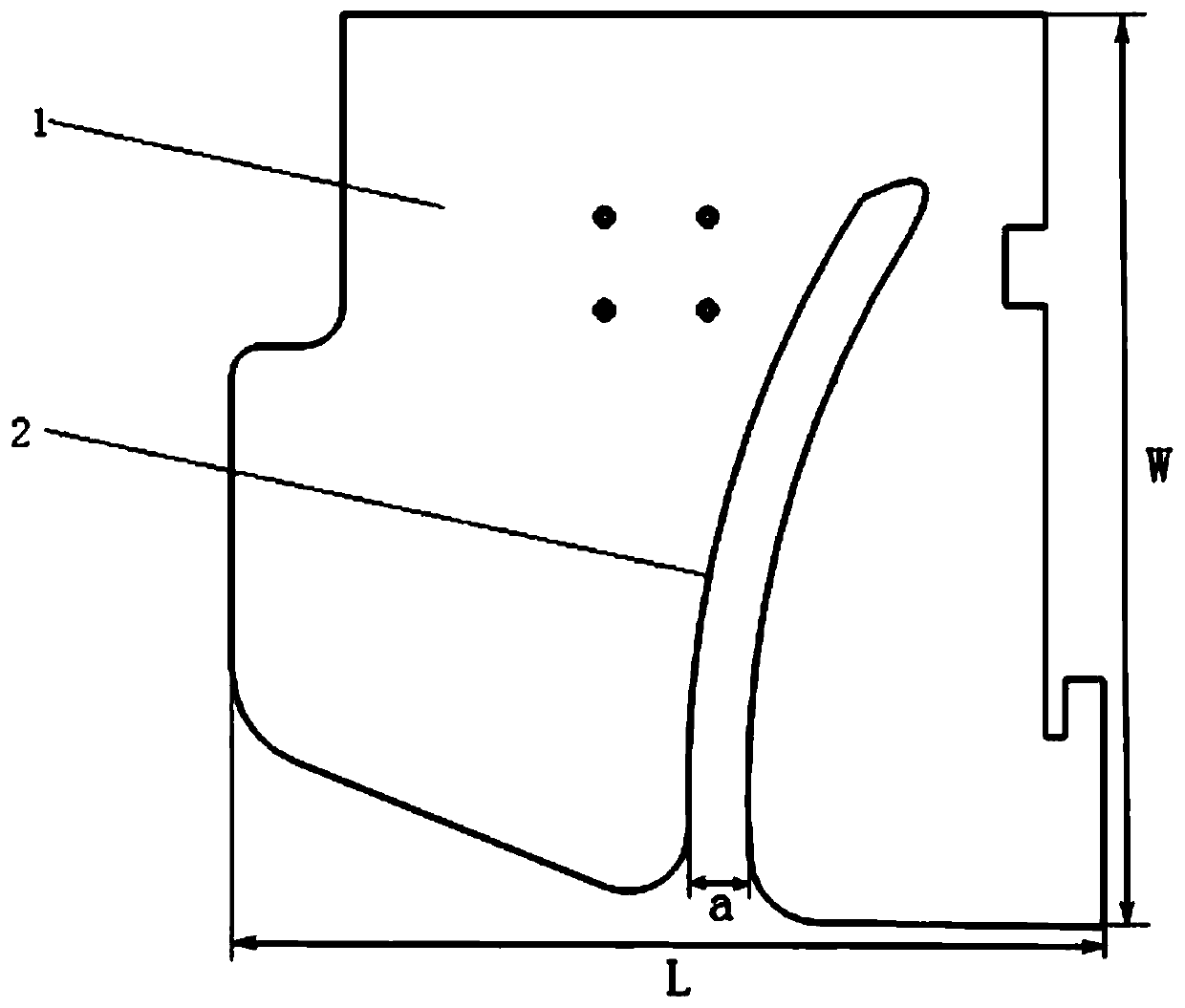

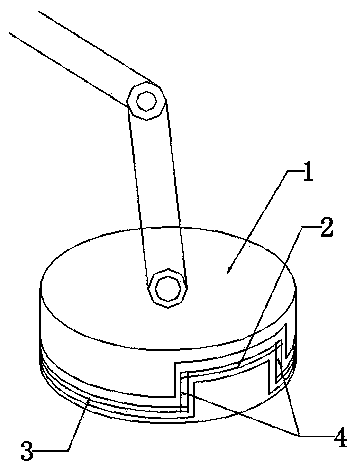

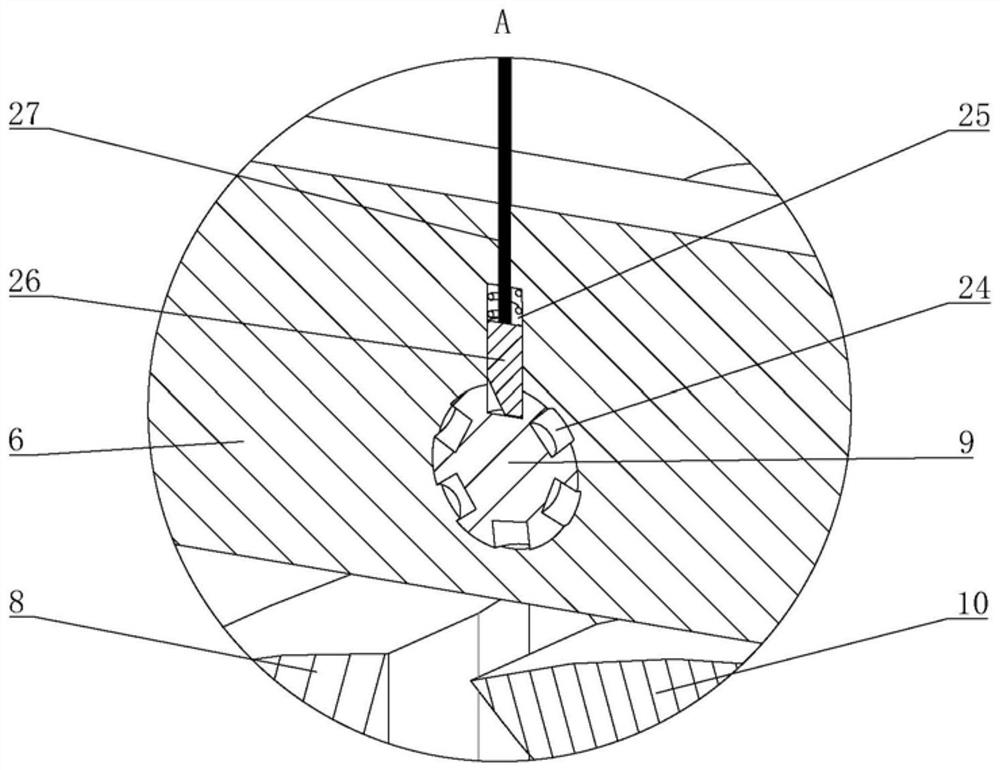

Separation blade mechanism of capsule coffee maker

The invention discloses a separation blade mechanism of a capsule coffee maker, which comprises a guide-in frame and separation blades. The separation blades are rotationally connected to two sides of the guide-in frame and used for supporting a capsule in a connected manner. The separation blade mechanism of the capsule coffee maker is used for positioning the capsule, after the coffee capsule is placed in a maker body, the separation blades support the bottom of the coffee capsule in the connected manner to prevent the coffee capsule from dropping, when coffee is brew, the separation blades rotate outwards, and the capsule is released. The separation blade mechanism is simple in structure and convenient in assembly, each separation blade is provided with a supporting portion and a clamping portion, the contact area of the coffee capsule is increased by the supporting portions, the coffee capsule is conveyed more stably, the clamping portions support the bottom of the capsule in the connected manner, accordingly, requirements on the structure of the coffee capsule are lowered, and more choices can be available to the coffee maker.

Owner:ZHEJIANG KUFEER ELECTRICAL APPLIANCE

Precast slab rail transferring device for large-scale bridge construction

InactiveCN110902269AImprove construction efficiencyShorten the construction periodConveyorsArchitectural engineeringStructural engineering

The invention relates to the technical field of bridge construction equipment, in particular to a precast slab rail transferring device for large-scale bridge construction. The precast slab rail transferring device comprises a conveyor belt, wherein a precast slab transferring plate is arranged on the surface of the conveyor belt and is fixedly connected with the conveyor belt through a rubber blanket; and side baffle plates are fixedly welded with the two sides, far away from one surface of the conveyor belt, of the precast slab transferring plate. According to the precast slab rail transferring device, the precast slab is transferred through the conveyor belt, and the conveyor belt is erected on the water surface through a support frame, so that the construction period is shortened, andthe bridge construction efficiency is improved; in addition, the conveyor belt instead of a crane or the crane and a large-scale ship is adopted to transfer the precast slab, so that the efficiency isimproved while reducing the transferring cost; and moreover, the precast slab transferring plate is arranged above the conveyor belt to stably transfer the precast slab without falling, and the practicality is high.

Owner:刘士英

Timing blanking mechanism

InactiveCN106276122AThe transfer process is stableContinuous transferConveyor partsMechanical conveyorsDrive shaftProduction effect

The invention provides a timing blanking mechanism. The timing blanking mechanism comprises a frame, a conveying mechanism, an upper double-rail mechanism, a carrying tray, a lower double-rail mechanism and at least one pair of parallel four-rod mechanisms; the conveying mechanism includes a pair of conveying chains, a driving shaft and a driven shaft; corresponding transmission gears are respectively arranged at two ends of the driving shaft and the driven shaft; the upper rail mechanism is positioned below the lower rail mechanism; the pair of parallel four-rod mechanisms are arranged in parallel, and are connected with the driving shaft therebetween through a transmission mechanism; the transmission mechanism is connected to a support frame; the support frame is arranged on the frame; and the pair of parallel four-rod mechanisms are used for feeding the carrying tray from the upper rail to the lower rail. The timing blanking mechanism is applied to the sticky material drying field, can stably receive and send materials, guarantees horizontal material movement and dropping, improves the production effect, and can be applied to load and unload the materials in the logistics field.

Owner:朱震

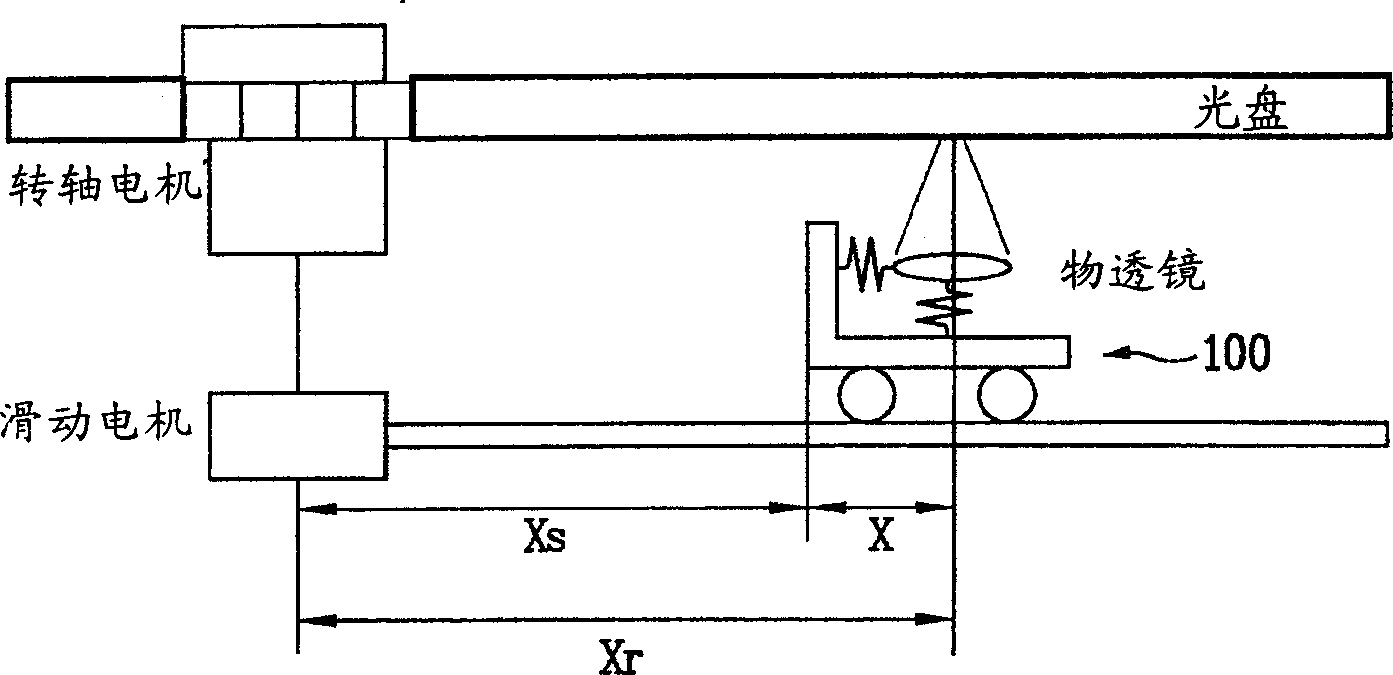

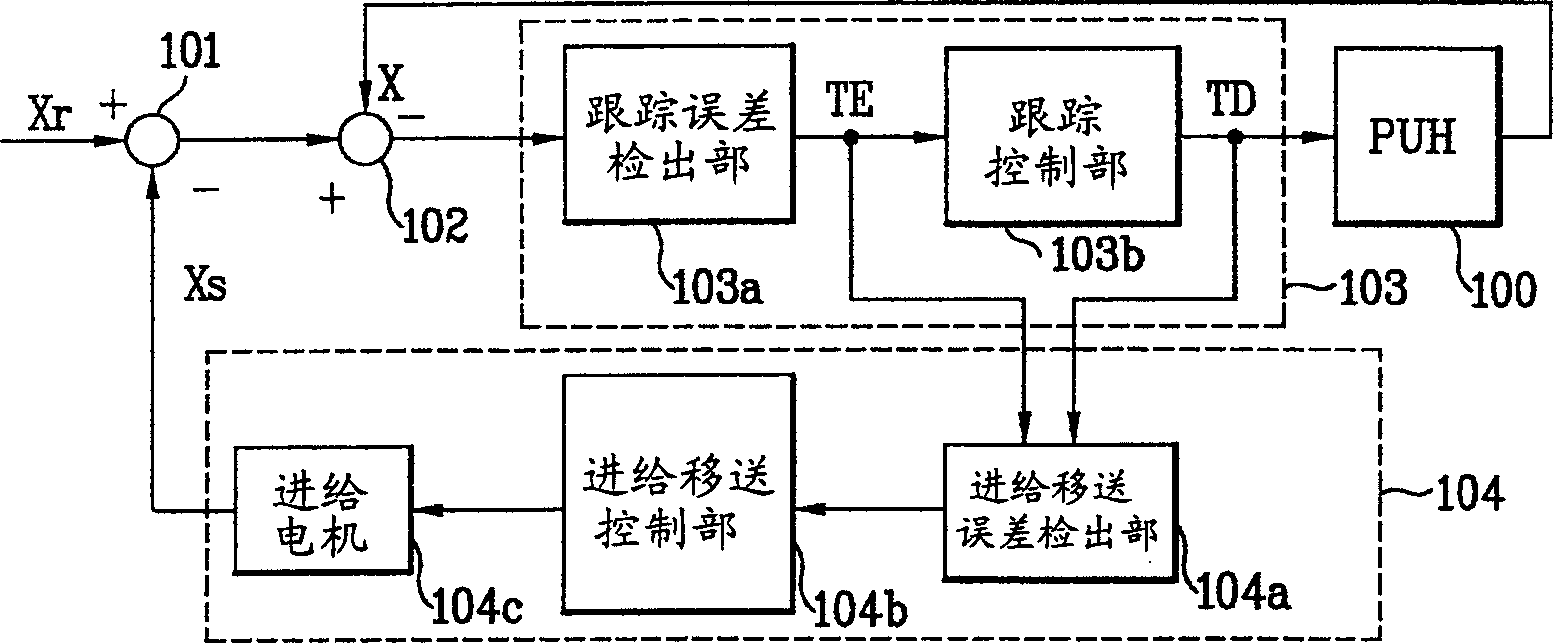

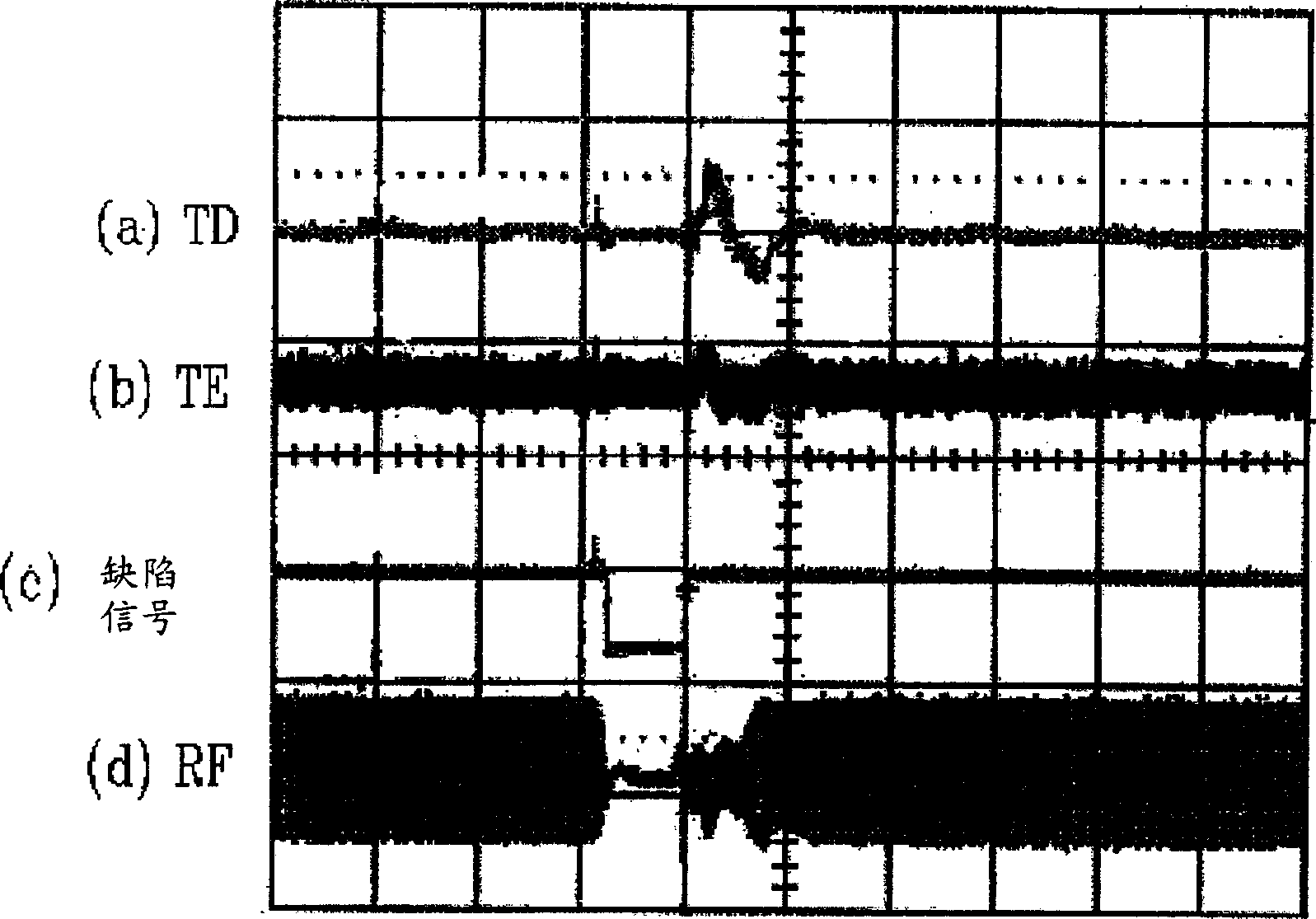

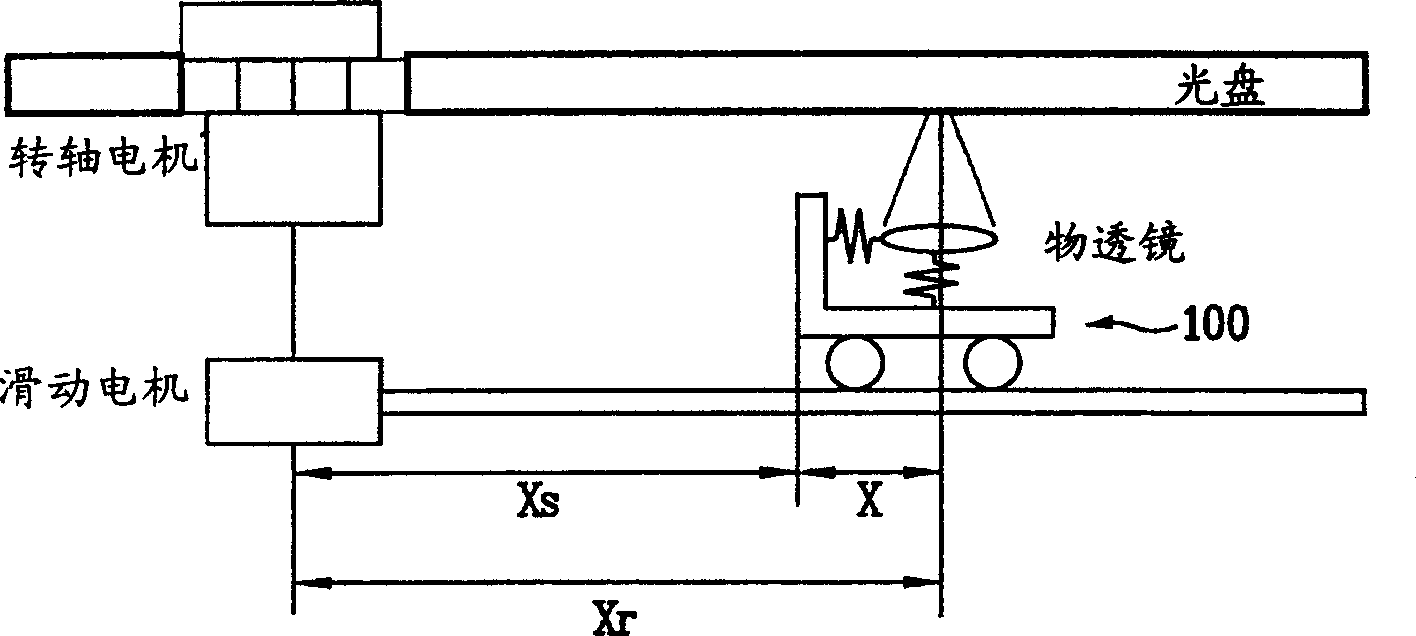

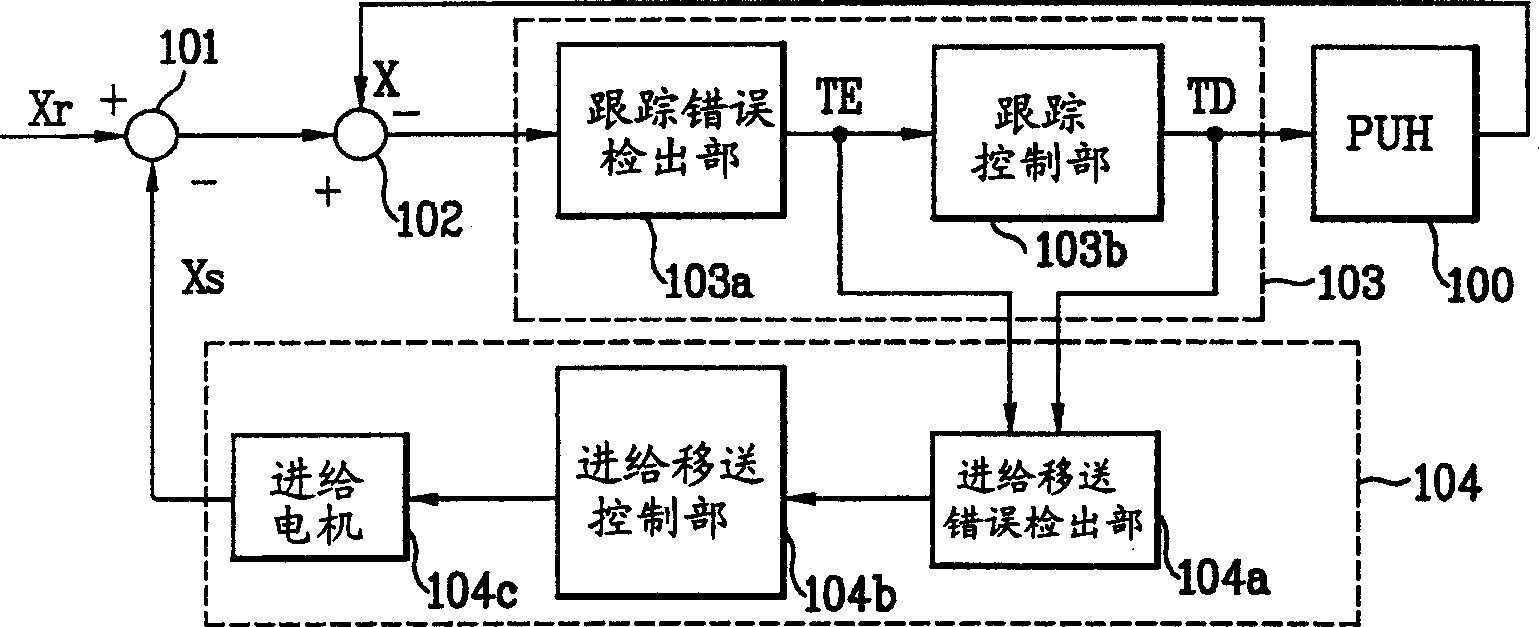

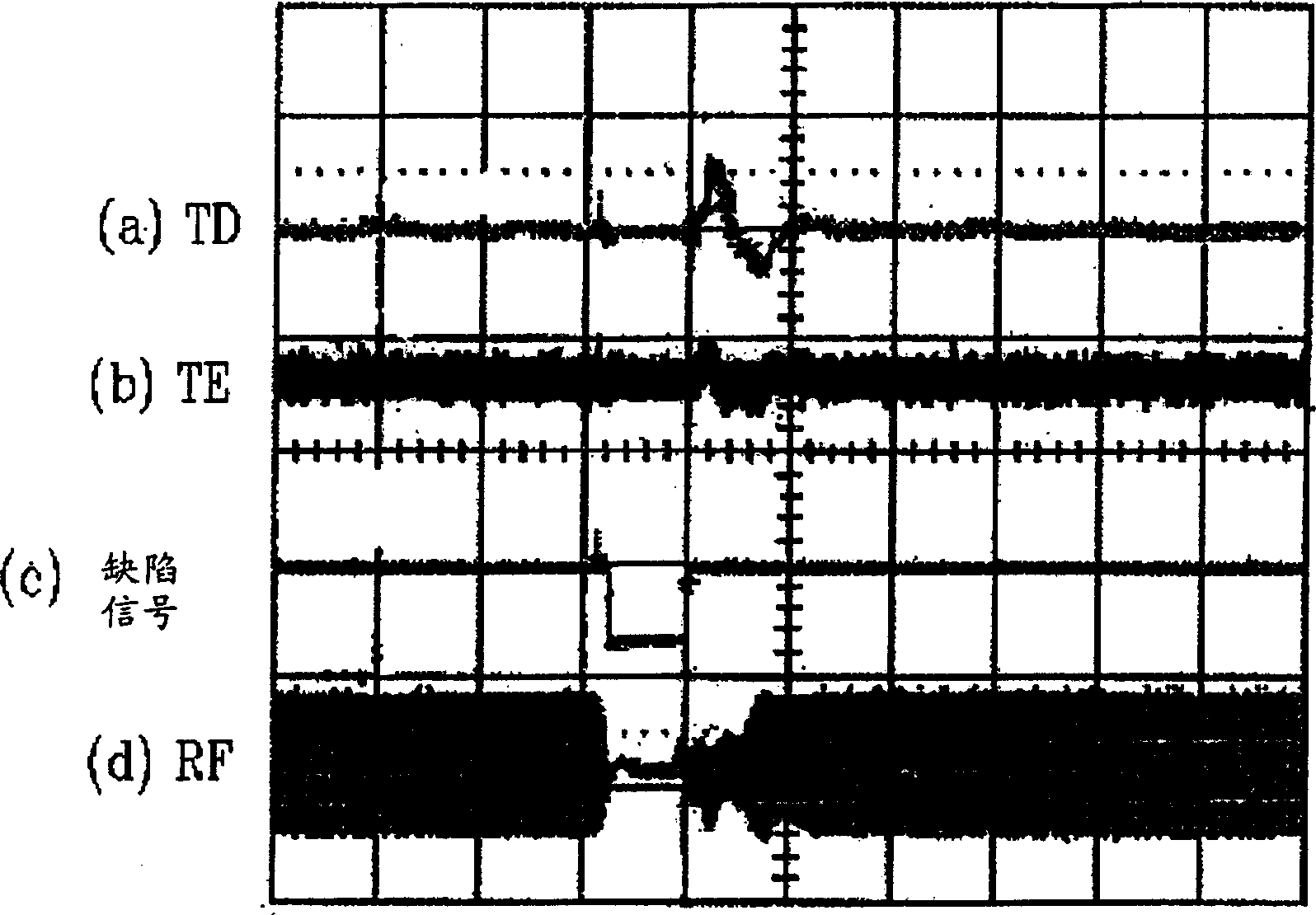

Controlling method and apparatus for feeding motor transfer of optical record player

InactiveCN1253866CResidual Error MinimizationRapid compensation of residual errorsRecord information storageRecording on magnetic disksOptical pickupElectric machine

The invention relates to a control method for the transfer of a feed motor of an optical record player, which uses the rotation information of the optical disc, that is, the number of frequency generation signals generated every time the optical disc rotates, through the feed motor, the optical pick-up According to a certain amount that has been set, that is, to move the track pitch, after that, the residual error that occurs through the existing tracking drive and feed transfer drive control, minimizes the dependence on the existing feed transfer drive, and offsets the above-mentioned rotation information. The residual error after the move. Therefore, the feed transfer error can be quickly compensated and the residual error can be minimized. Since the dependence on the existing feed and transfer driver is reduced, the joint characteristics caused by the poor control of the tracking error detection part and the tracking control part can be minimized. The invention can solve the phenomenon that the off-track cannot be tracked due to fault or interference, resulting in repeated off-track.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

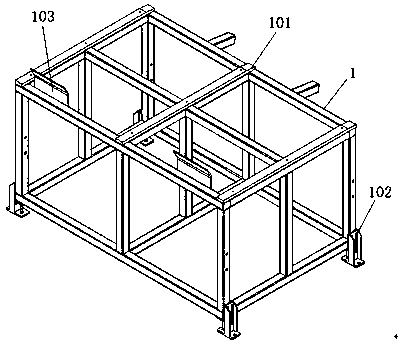

A loading and unloading device in a logistics system

ActiveCN106882606BSmooth loading and unloadingStable realization of loading and unloadingLifting devicesLoading/unloadingLogistics managementWeight-bearing ability

The invention provides a loading and unloading device in a logistics system and belongs to the technical field of machinery. The loading and unloading device solves the problem that an existing loading and unloading device is poor in bearing capacity. The loading and unloading device, of an improved structure, in the logistics system comprises a machine frame which is approximately of a cuboid frame structure. The two ends of the machine frame are each provided with a lifting mechanism, wherein each lifting mechanism can drive goods on one side of the machine frame to vertically move. The loading and unloading device in the logistics system is characterized in that the bottom of the machine frame is connected with a platelike supporting plate in a sliding manner, the supporting plate is located between the two lifting mechanisms, the supporting plate can extend out to the bottom of the goods from one side of the machine frame, the upper portion of the supporting plate is connected with a platelike transferring plate in a sliding manner, the transferring plate can move between the two ends of the supporting plate, the movement direction of the transferring plate is identical with the movement direction of the supporting plate, and a plurality of rolling wheels are arranged between the supporting plate and the transferring plate. The loading and unloading device of the improved structure has a high bearing capacity.

Owner:ZHEJIANG TOPSUN LOGISTIC CONTROL CO LTD

Liquor separation equipment based on liquor foam images

ActiveCN112699968AHigh degree of intelligenceNeat layoutAlcoholic beverage preparationCharacter and pattern recognitionProduction lineMotor drive

The invention relates to liquorseparation equipment based on liquor hop images, which comprises a camera fixing unit and a hop collecting unit, wherein the camera fixing unit is used for fixing the position of a camera and collecting pictures; the camera fixing unit comprises an adjustable fixing support and a camera installed on the fixing support. The foam collecting unit is used for controlling a wine glass to collect raw wine and moving the wine glass to the center of a camera so as to conveniently collect foam, and meanwhile, the wine glass can be returned to a wine flowing opening from a collecting position; wherein the hops collecting unit comprises a stepping motor, a cam connecting rod mechanism, a tail end support and a wine glass fixed to the tail end support, the fixing support is fixed to the position near a wine flowing opening of the white spirit production line, and the stepping motor drives the cam connecting rod mechanism to act so as to drive the wine glass to move under the wine flowing opening and the camera in a reciprocating mode. The defects of traditional manual mode of observing the hop to separate liquor are overcome, the automation degree and the intelligent degree are improved, personal errors are reduced, and the high-quality wine product rate is increased.

Owner:HEBEI UNIV OF TECH

Controlling method and apparatus for feeding motor transfer of optical record player

InactiveCN1585003AMinimize residual errorsMinimize dependenciesRecord information storageRecording on magnetic disksControl theoryElectric machine

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

A design method of sheet-fed paper positioning feeding board

ActiveCN107934603BThe transfer process is stableSolve the problem of unreasonable deviation of paper positioningArticle feedersPaperboardPulp and paper industry

Owner:XIAN UNIV OF TECH

Operation shadowless lamp capable of stably moving electric scalpels with different sizes

InactiveCN103519896AIncrease success rateSo as not to damageDiagnosticsSurgeryKey pressingEngineering

Owner:苏州市国晶电子科技有限公司

Medical experiment waste transferring device

The invention provides a medical experiment waste transferring device which effectively solves the problem that sharp instrument waste in a laboratory is inconvenient to transfer. The medical experiment waste transferring device comprises two supporting plates. The front ends and the rear ends of the two supporting plates are connected through base plates correspondingly. The upper ends of the twosupporting plates are connected through a grabbing handle. A pulling rod is connected between the two supporting plates in a sliding manner. Speed increase mechanisms are arranged on the opposite sides of the two supporting plates correspondingly. First pulling ropes at the left end and the right end of the pulling rod are connected with the speed increase mechanisms. A sliding plate is connectedbetween the two supporting plates in a sliding manner. The left end and the right end of the sliding plate are connected with the speed increase mechanism through second pulling ropes. A left clamping plate is fixed to the lower side of the sliding plate. A right clamping plate is hinged to the sliding plate through a pin shaft. A blocking block is arranged at the lower end of the supporting plate on the right side. Auxiliary clamping plates are hinged to the lower ends of the two supporting plates correspondingly. The lower sides of the back faces of the left clamping plate and the right clamping plate are connected with the upper ends of the corresponding auxiliary clamping plates in a hinged manner through the connecting rods correspondingly. The medical experiment waste transferring device is novel in concept, ingenious in structure, convenient to operate and high in practicality.

Owner:THE FIRST AFFILIATED HOSPITAL OF XINXIANG MEDICAL UNIV

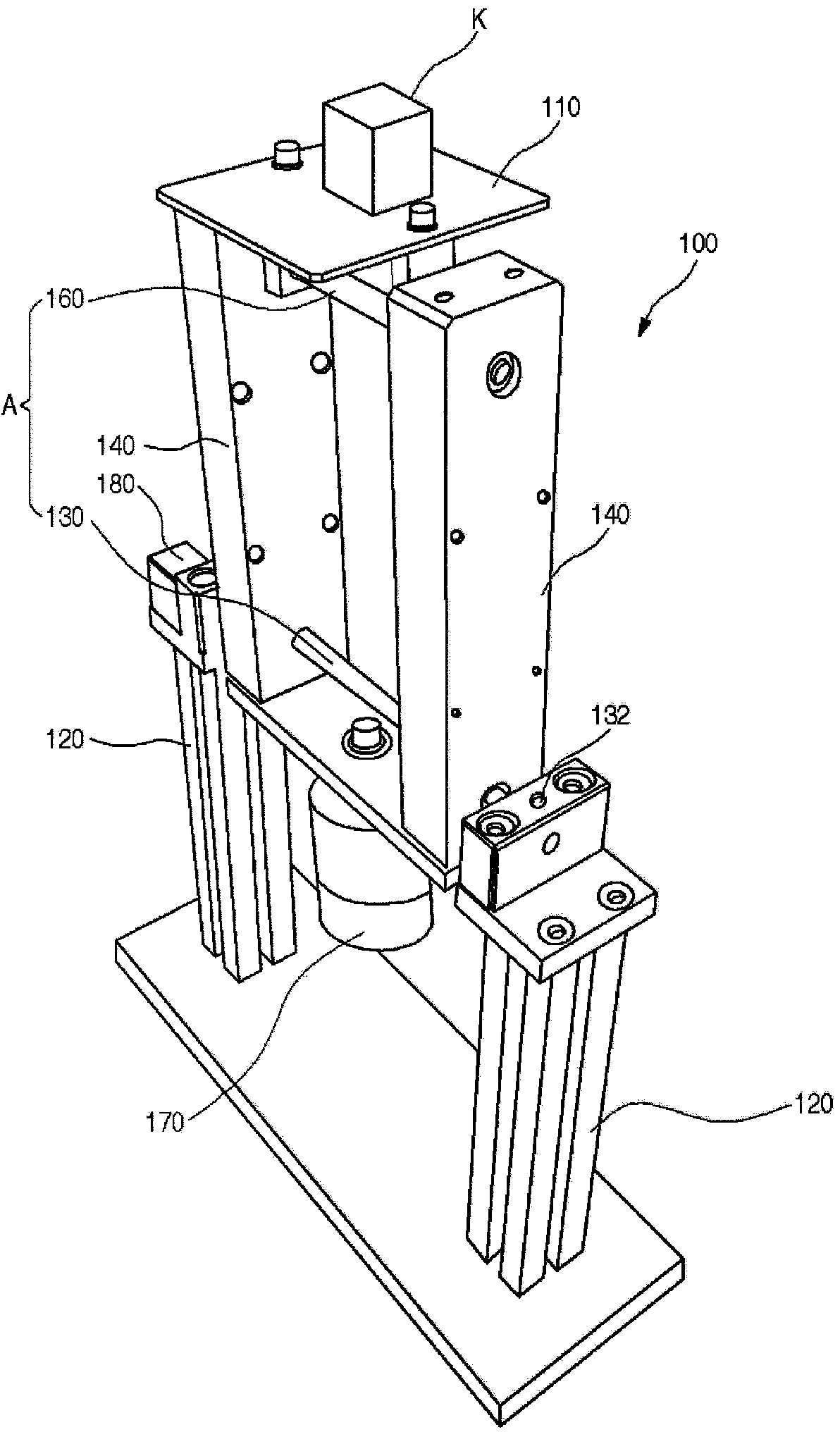

Apparatus equipped with phase maintenance means

InactiveCN103764353AThe transfer process is stableControl program simplificationProgramme-controlled manipulatorArmsForce generationEngineering

An apparatus equipped with a phase maintenance means, according to the present invention, comprises: the phase maintenance means, comprising a dummy shaft which is fixed to one side of a frame that supports a plurality of parts, a slave shaft which revolves with the dummy shaft at the center while maintaining a specific distance, a force transfer portion, which is coupled to the dummy shaft and the slave shaft, for controlling the revolution of the slave shaft, and a support portion for guiding the revolution of the slave shaft with the dummy shaft at the center when revolving, by means of a rotational force that is supplied from a force generation portion; and a phase maintenance portion which is coupled and fixed to one side of the slave shaft.

Owner:朴纯弼

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com