Oil sucker rod intelligent manufacturing production line

An intelligent manufacturing and production line technology, applied in manufacturing tools, forging/pressing/hammering machines, forging presses, etc., can solve the problems of conveying, clamping and positioning difficulties, inability to achieve cold processing of threaded connection parts, and no automatic production line for processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

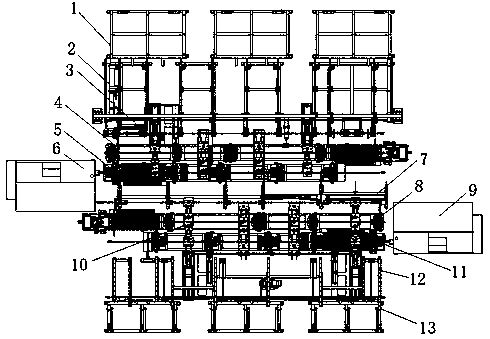

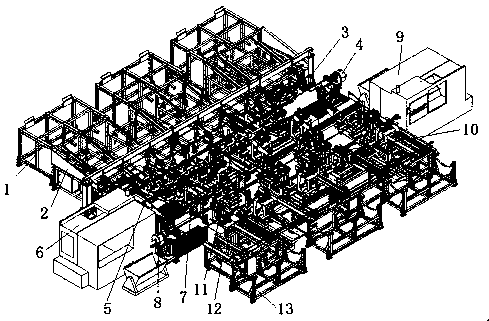

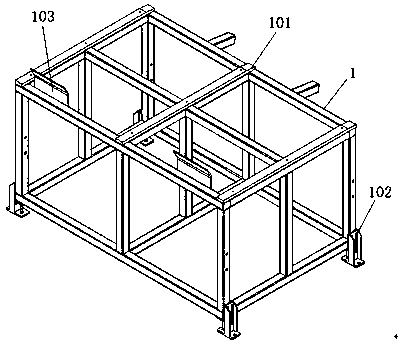

[0068] Such as figure 1 with figure 2 As shown, the intelligent manufacturing production line of the present invention, according to the running direction of the workpiece, includes a loading rack 1, a loading bin 2, a first stepping and pushing device 3, a first angular positioning device 4, and a first running device 5 arranged in sequence. , The axial running device 7, the second angular positioning device 8, the second stepping push device 10, the second running device 11, the lower bin 12 and the lower rack 13. The first machine tool 6 is provided outside the first operating device 5 , and the second machine tool 9 is provided outside the second operating device 11 . The first stepping and pushing device 3 and the second stepping and pushing device 10 are arranged oppositely in the workpiece running direction, the first angular positioning device 4 and the second angular positioning device 8 are arranged oppositely in the workpiece processing direction, the first runnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com