Patents

Literature

46results about How to "Tight rhythm" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

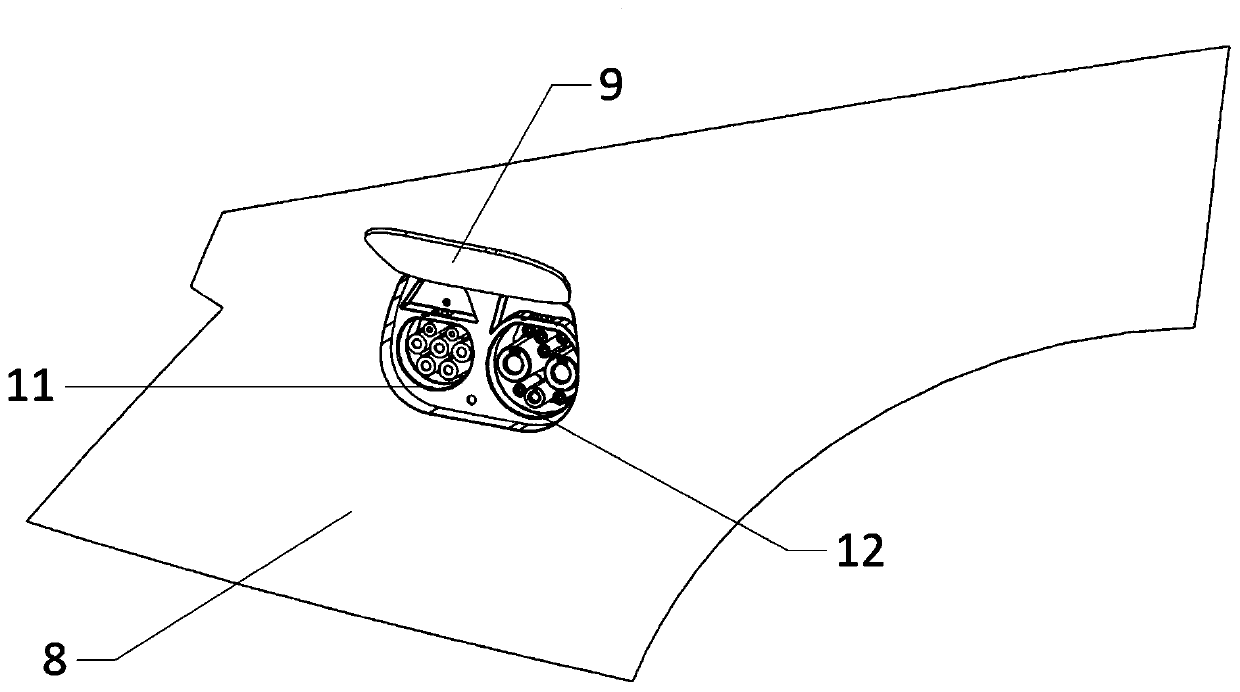

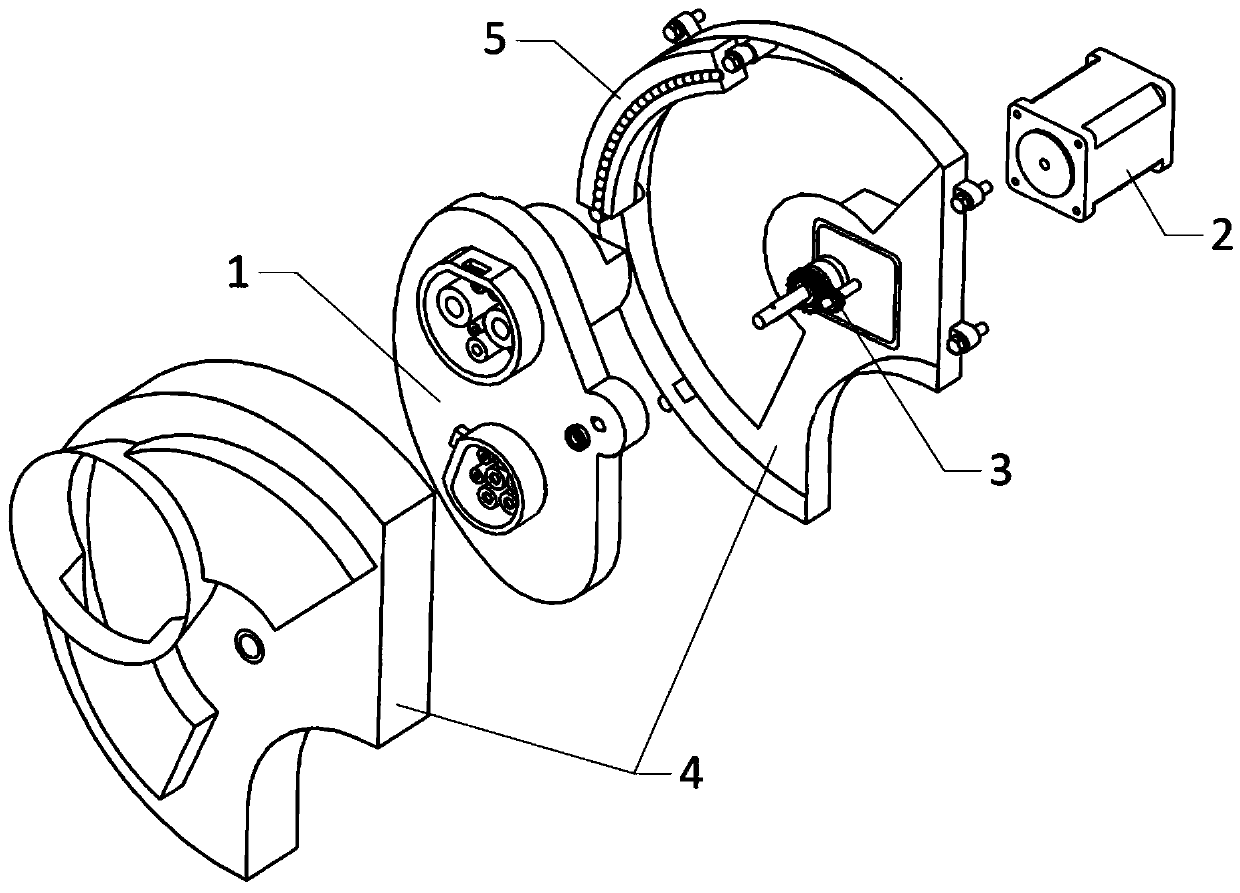

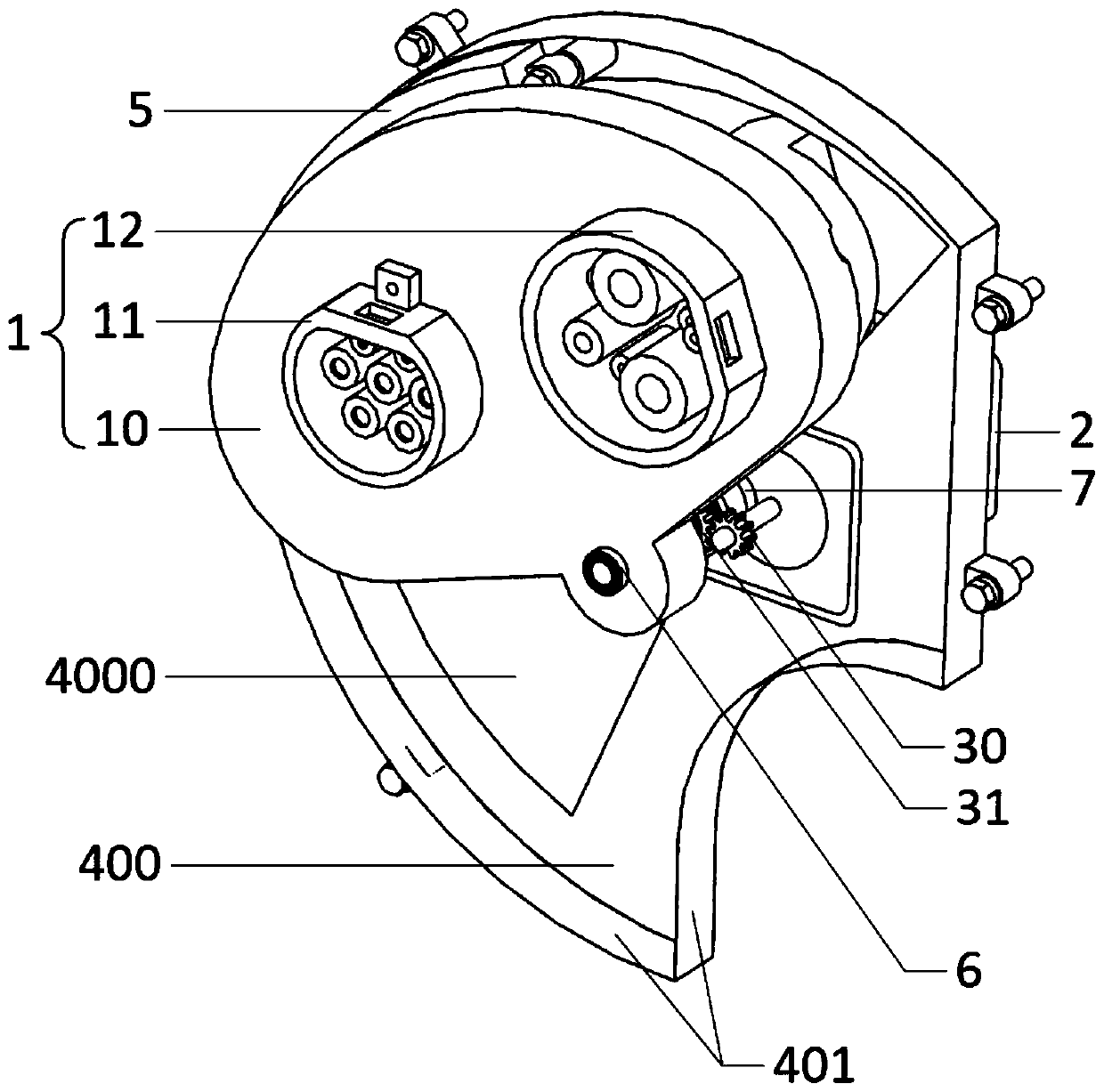

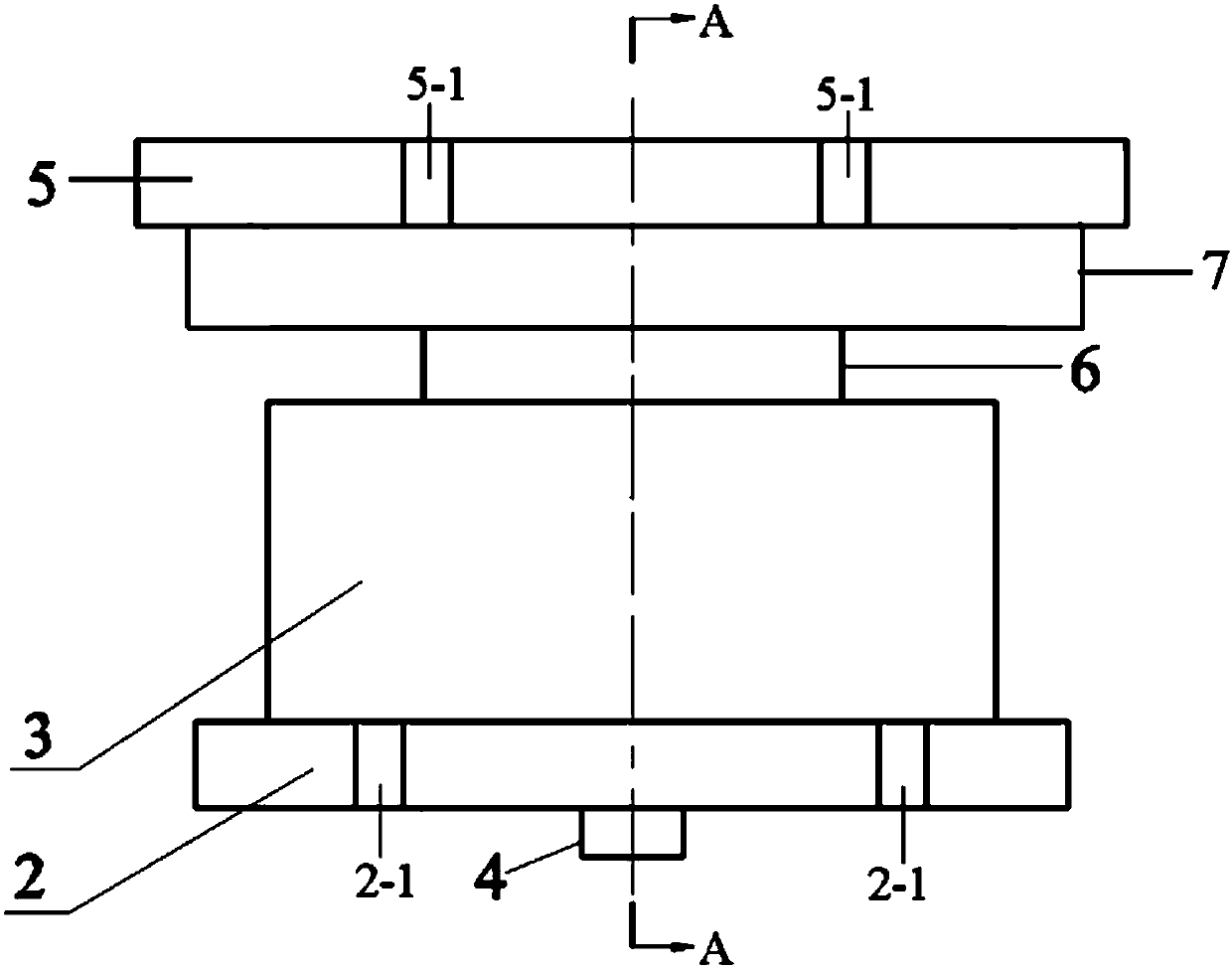

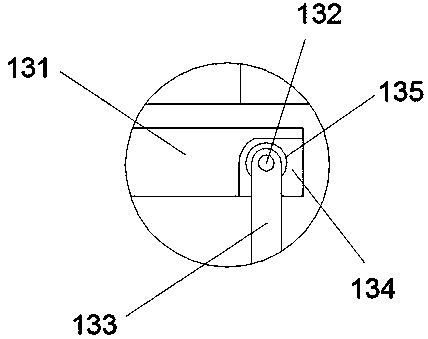

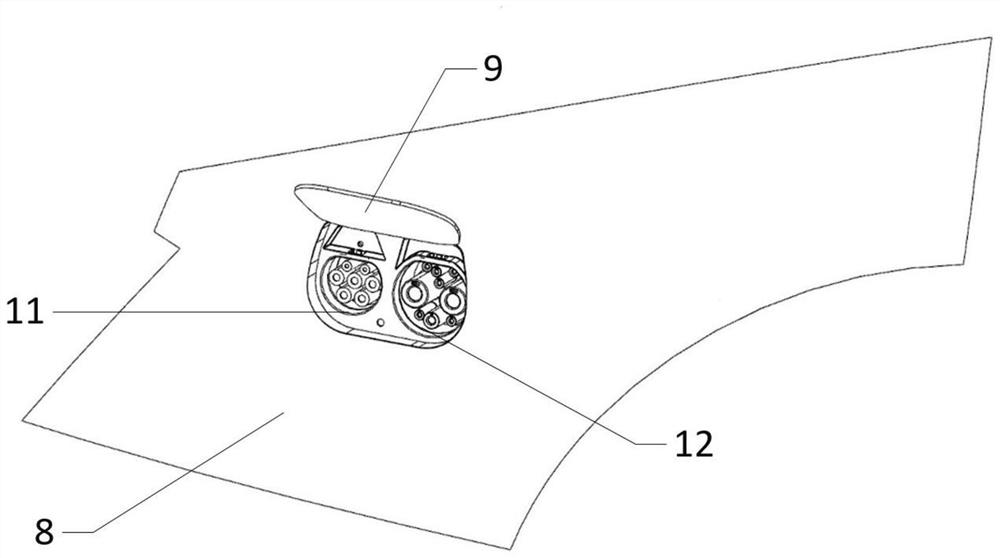

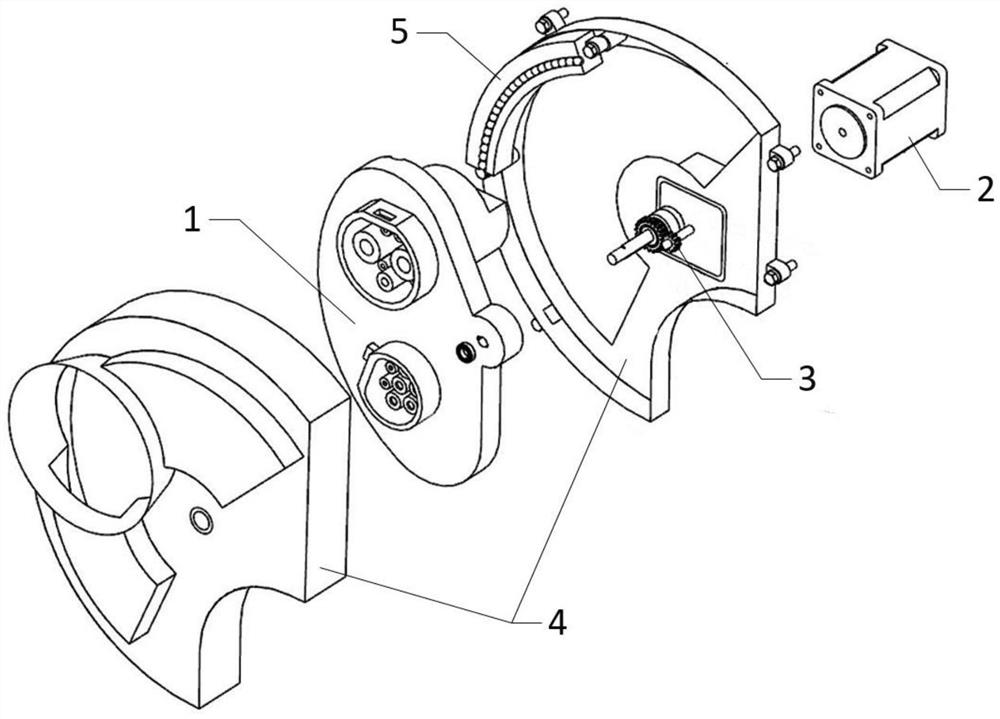

Convertible charging interface component and electric vehicle

ActiveCN109921247AReduce failureLow costCharging stationsCouplings bases/casesEngineeringElectric vehicle

The invention relates to the technical field of charging doors of electric vehicles, and aims to solve the problem that the existing charging interface of the electric vehicle occupies a large surfacearea of a vehicle body and has poor protection performance. To this end, the invention provides a convertible charging interface component and an electric vehicle. The charging structure component comprises: an insertion inlet; a rotating member at least comprising a first charging socket and a second charging socket; and a driving member connected to the rotating member for driving the rotatingmember to rotate; the rotating member is configured to selectively align the insertion inlet with the first charging socket or the second charging socket under the action of the driving member, so asto form a charging interface. The charging interface component provided by the invention occupies a small surface of the vehicle body, is convenient to operate, reduces the probability of contact withexternal rain, dust and hard objects, helps to reduce the cost of users.

Owner:NIO ANHUI HLDG CO LTD

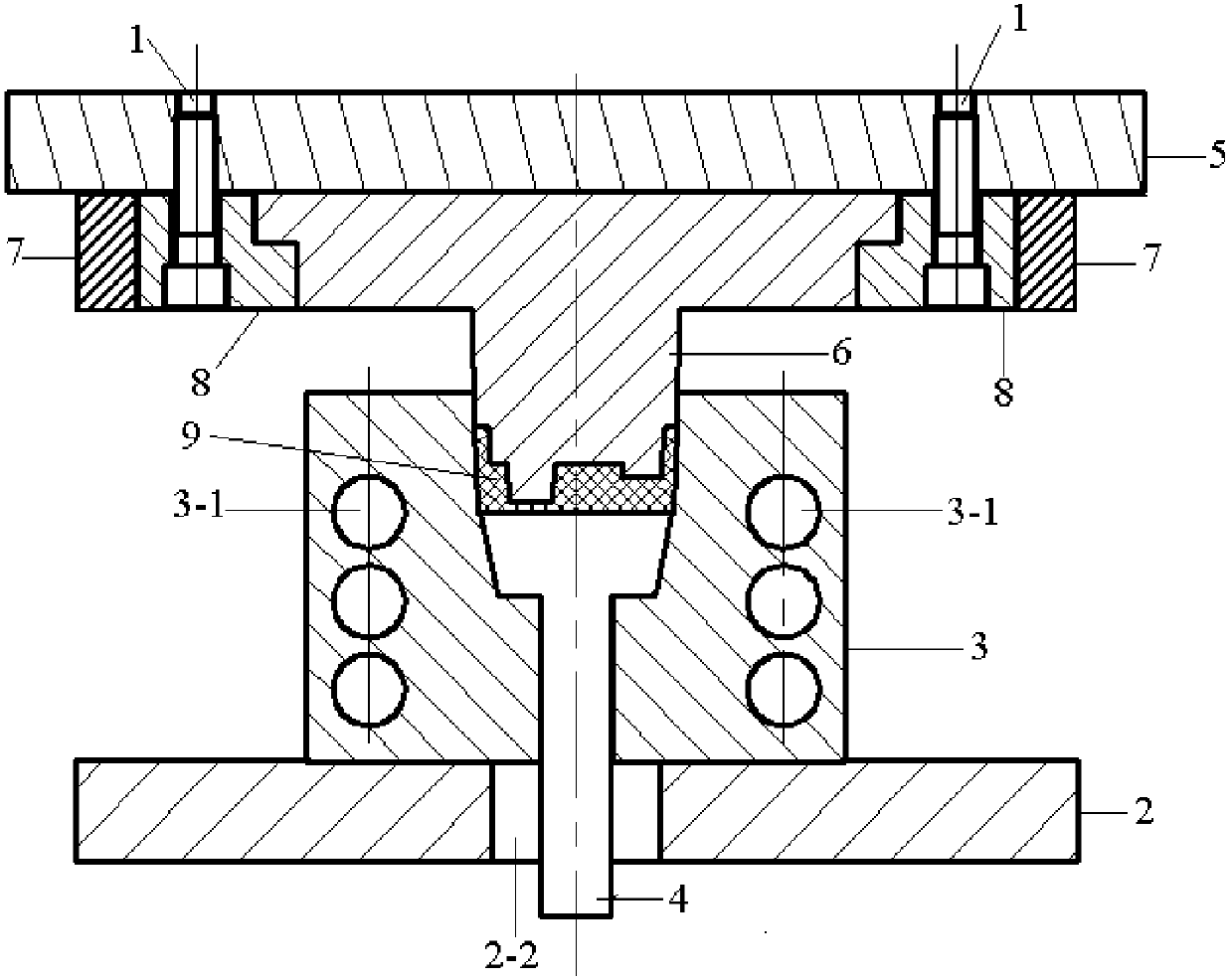

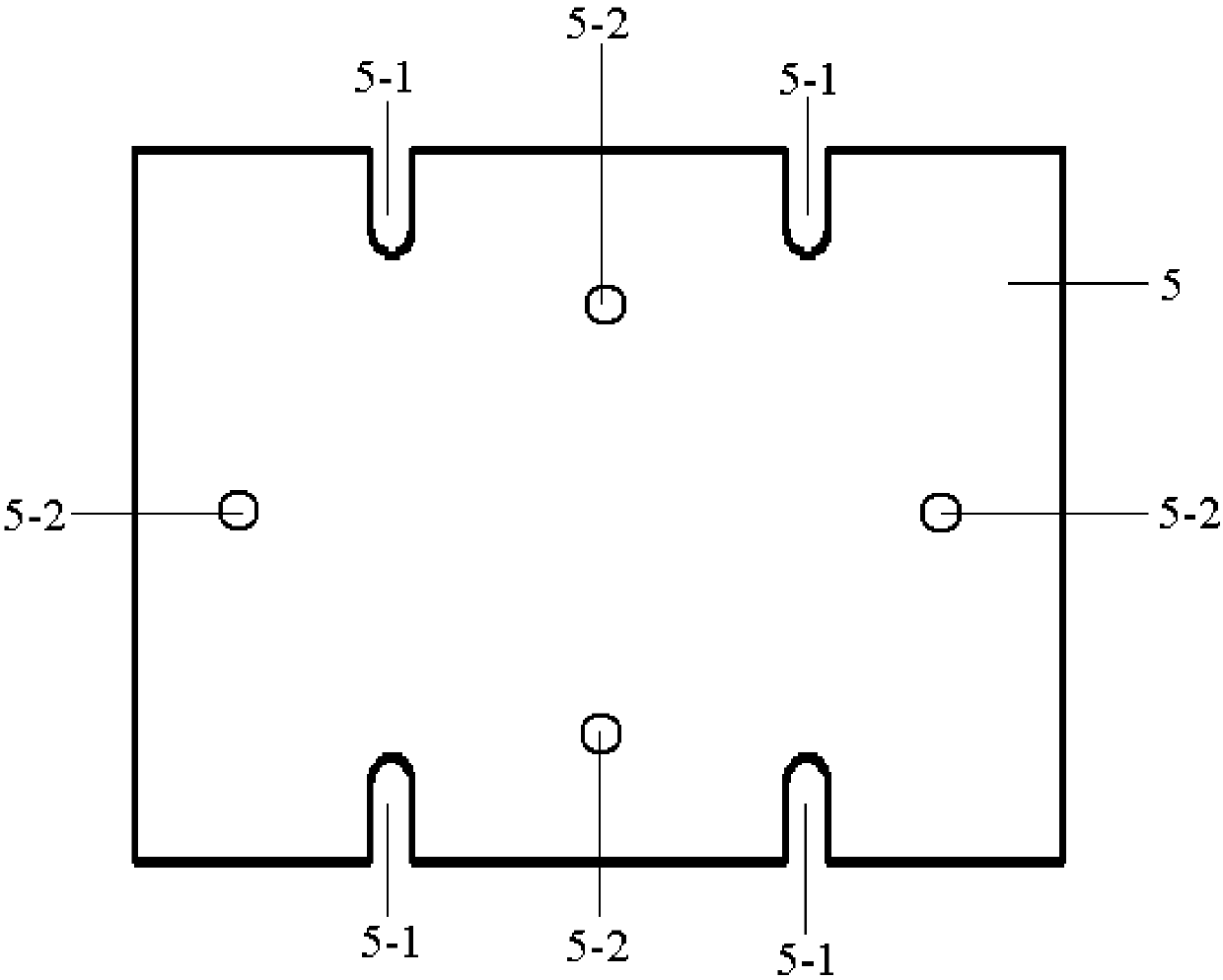

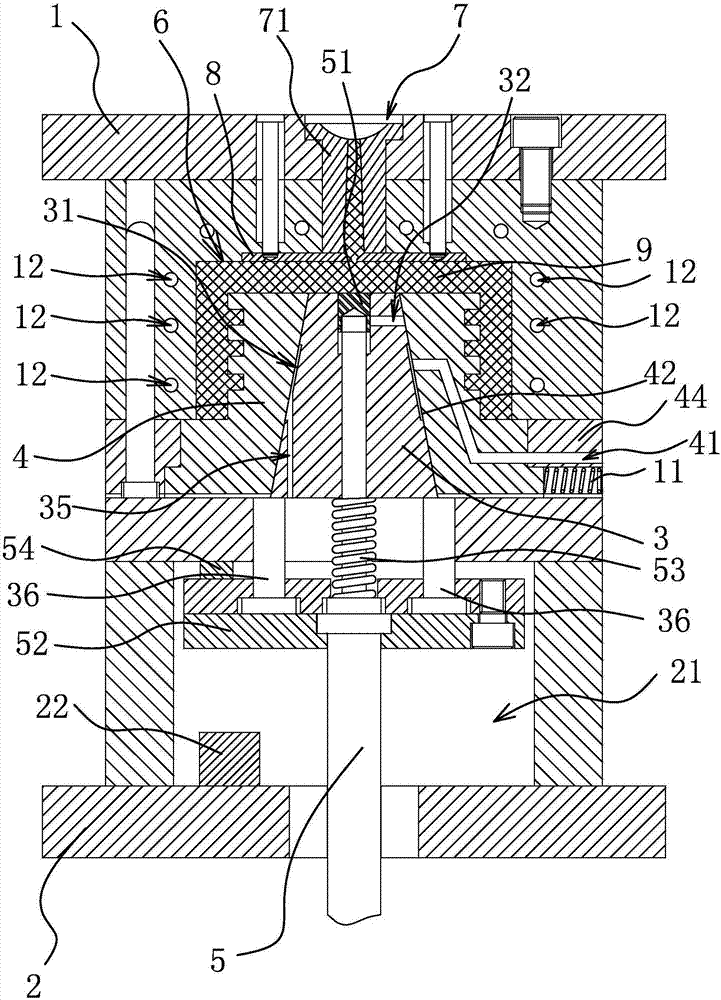

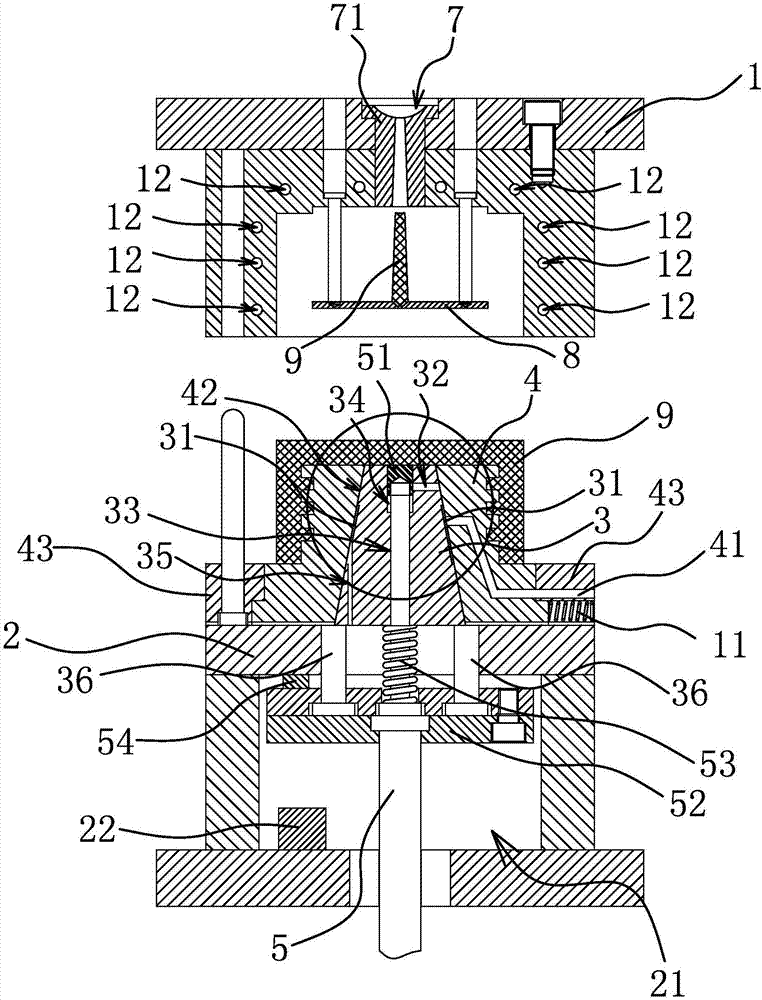

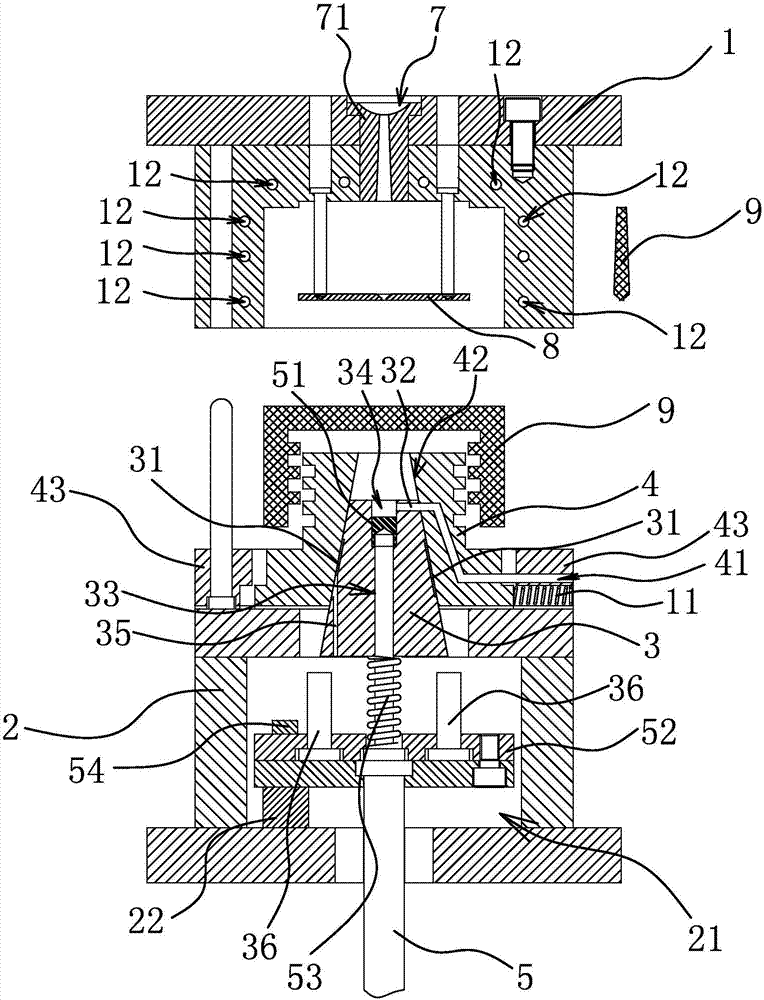

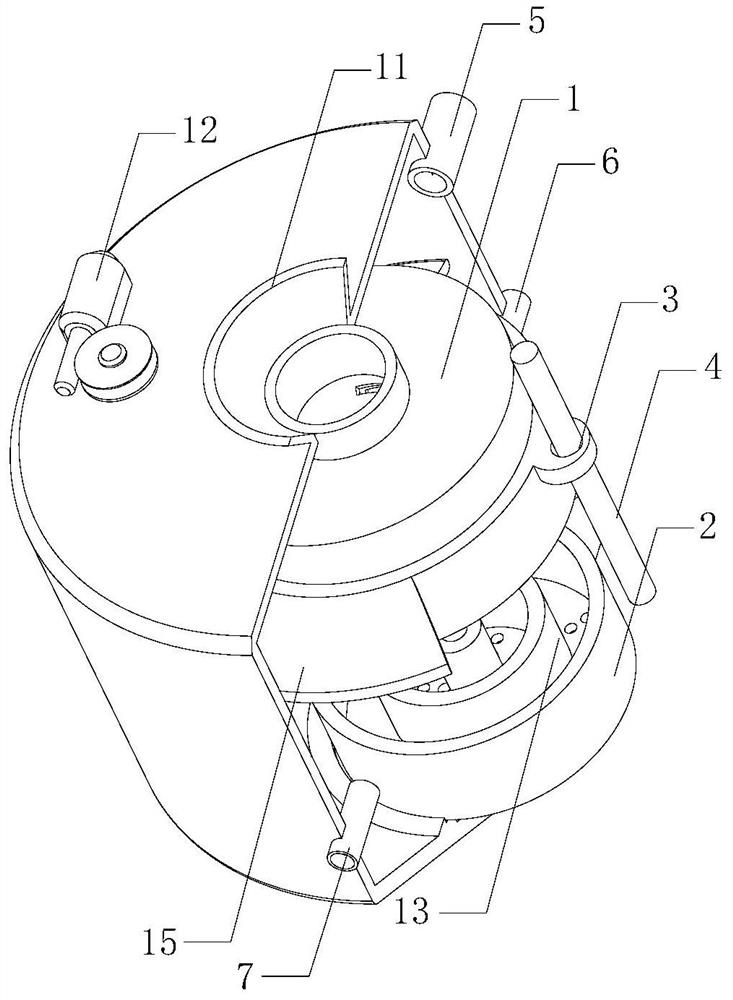

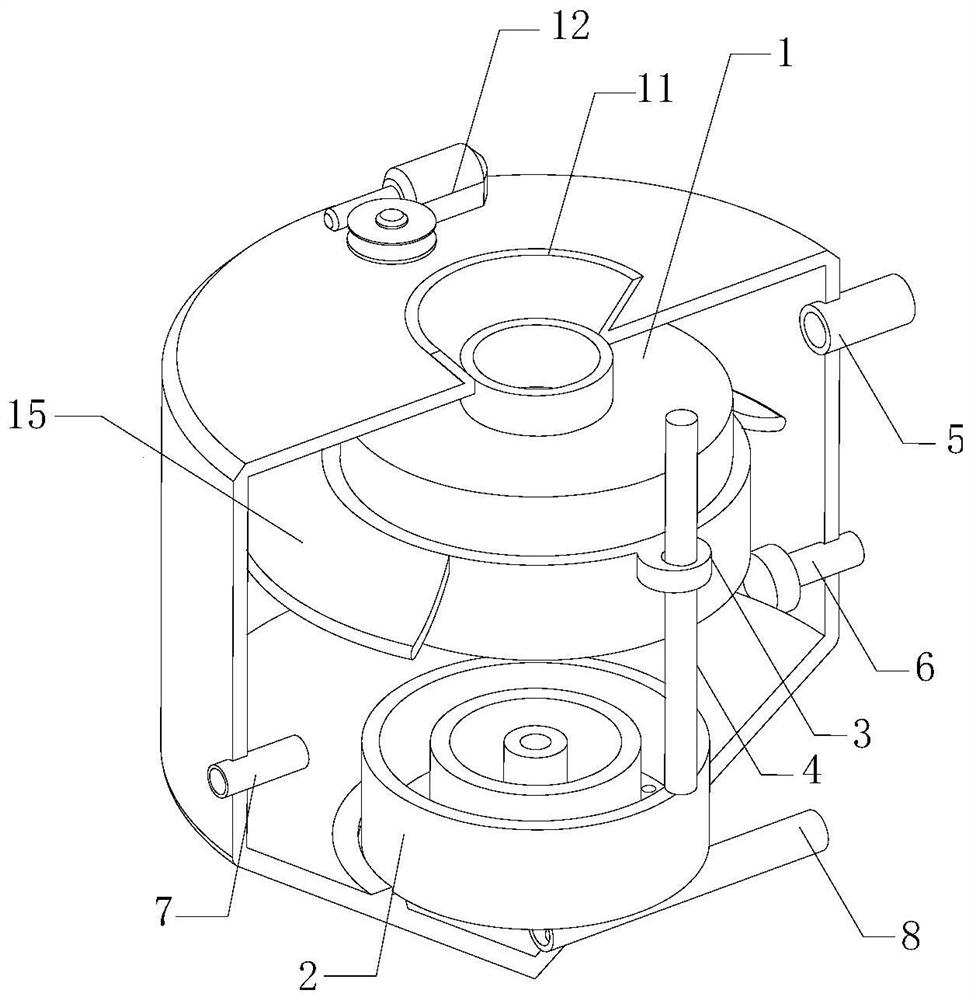

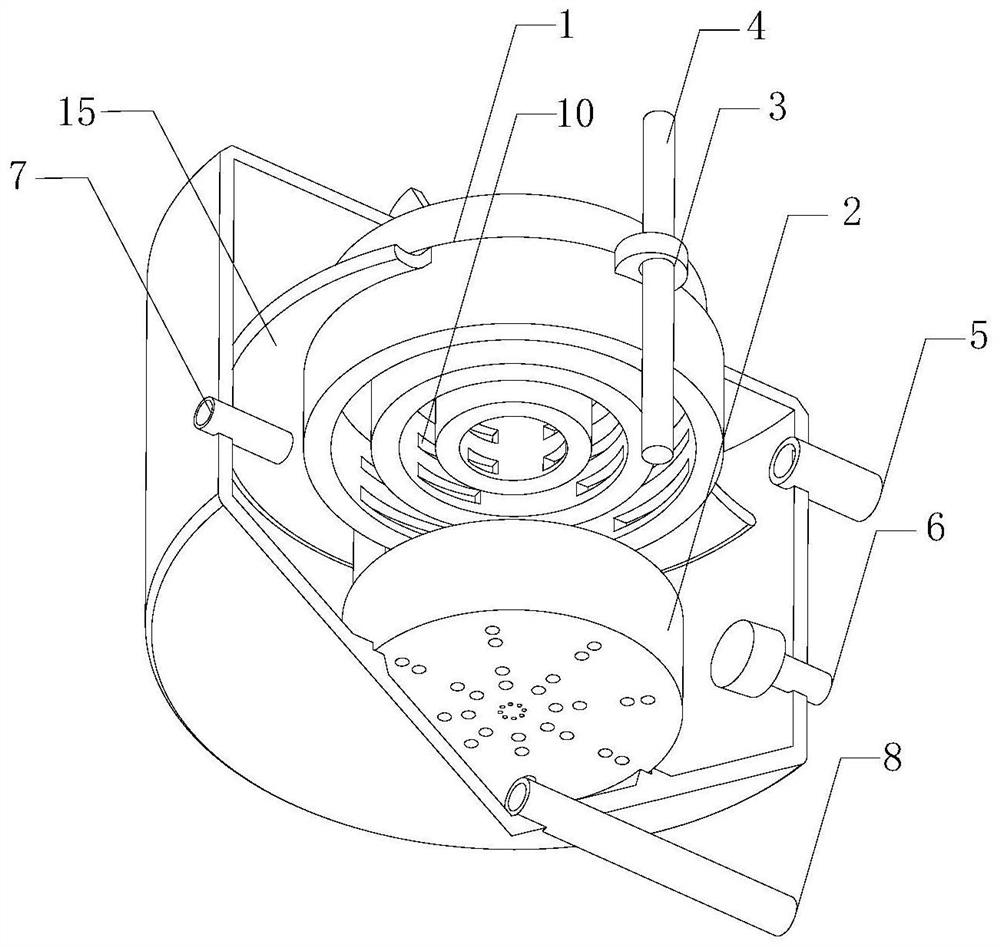

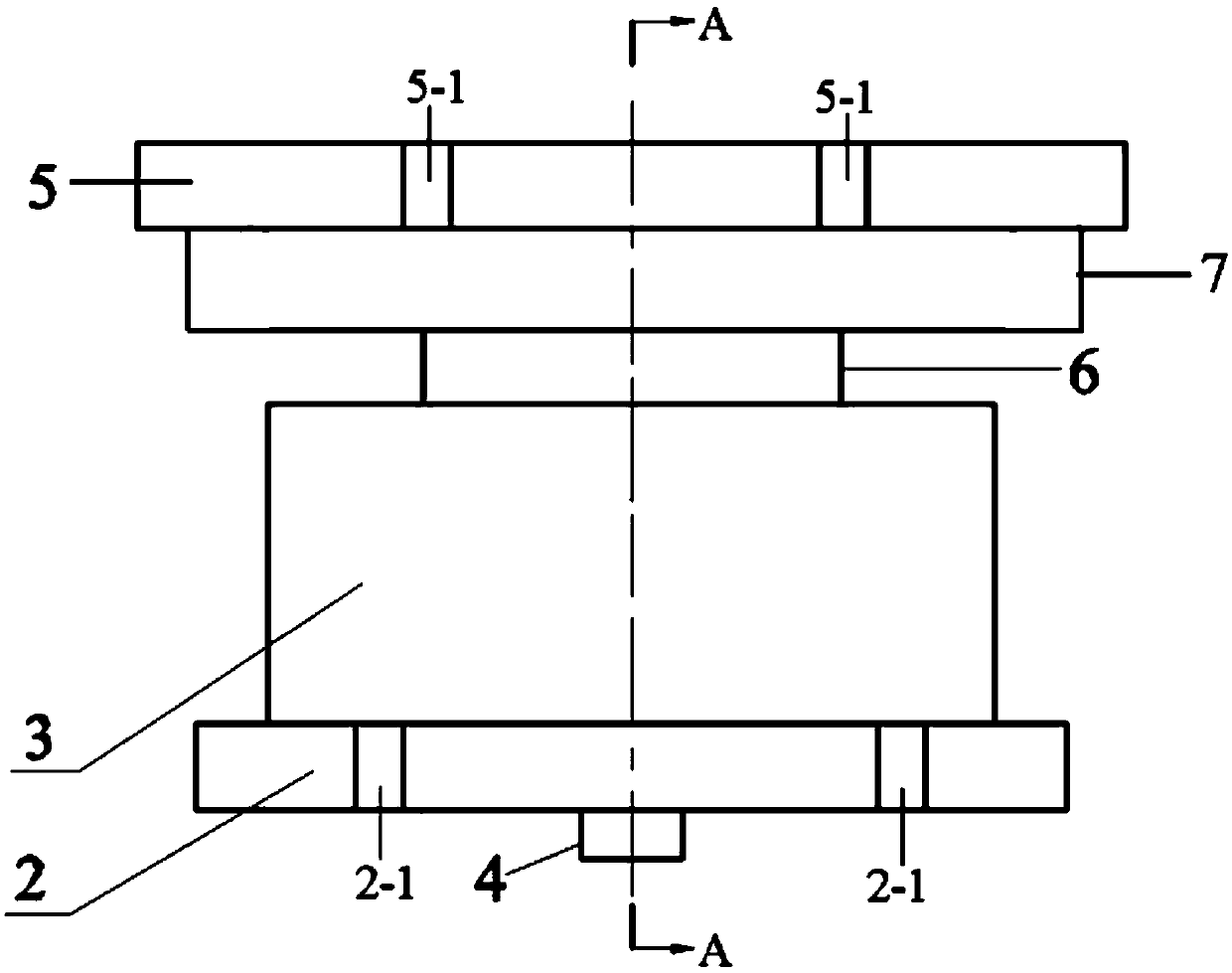

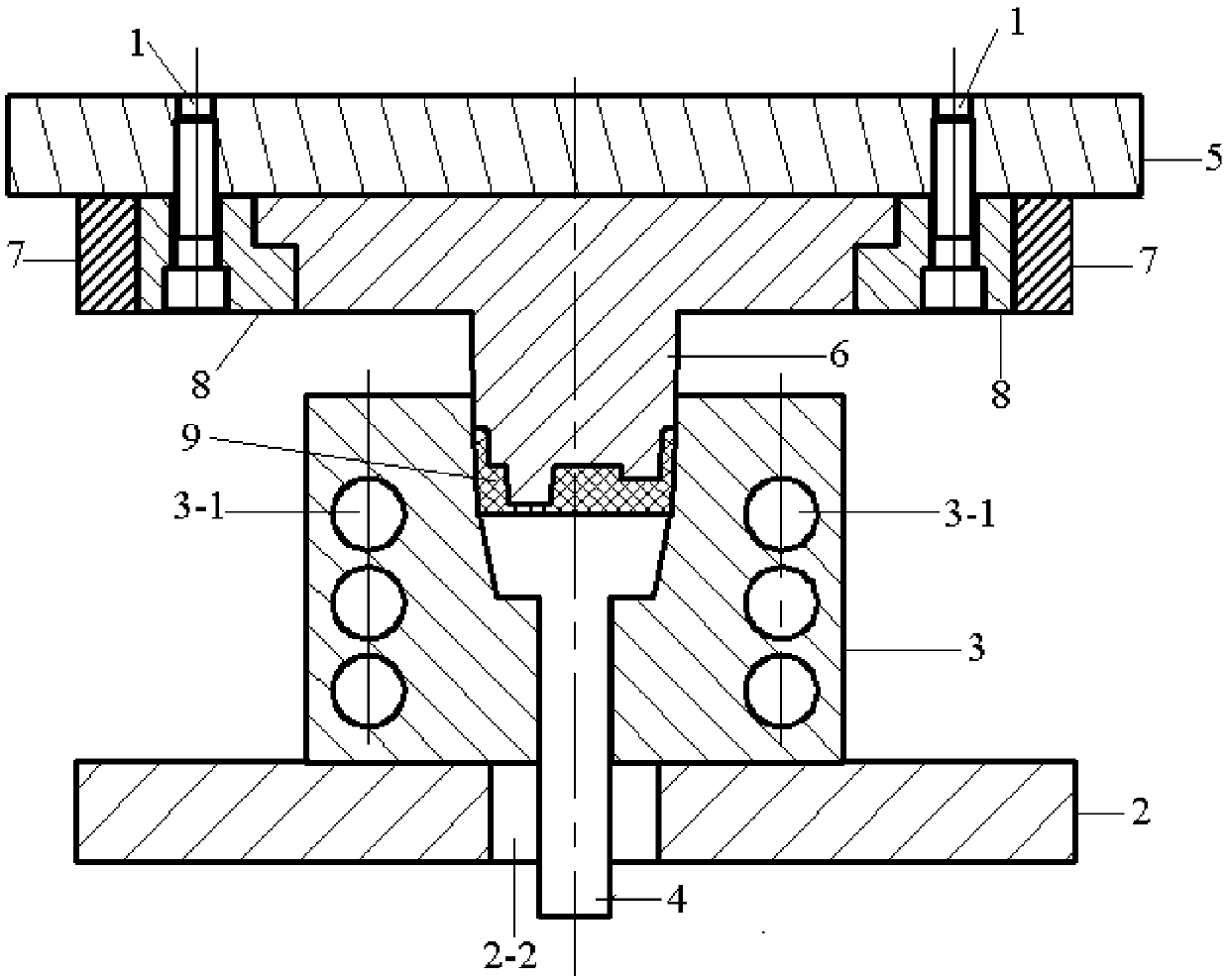

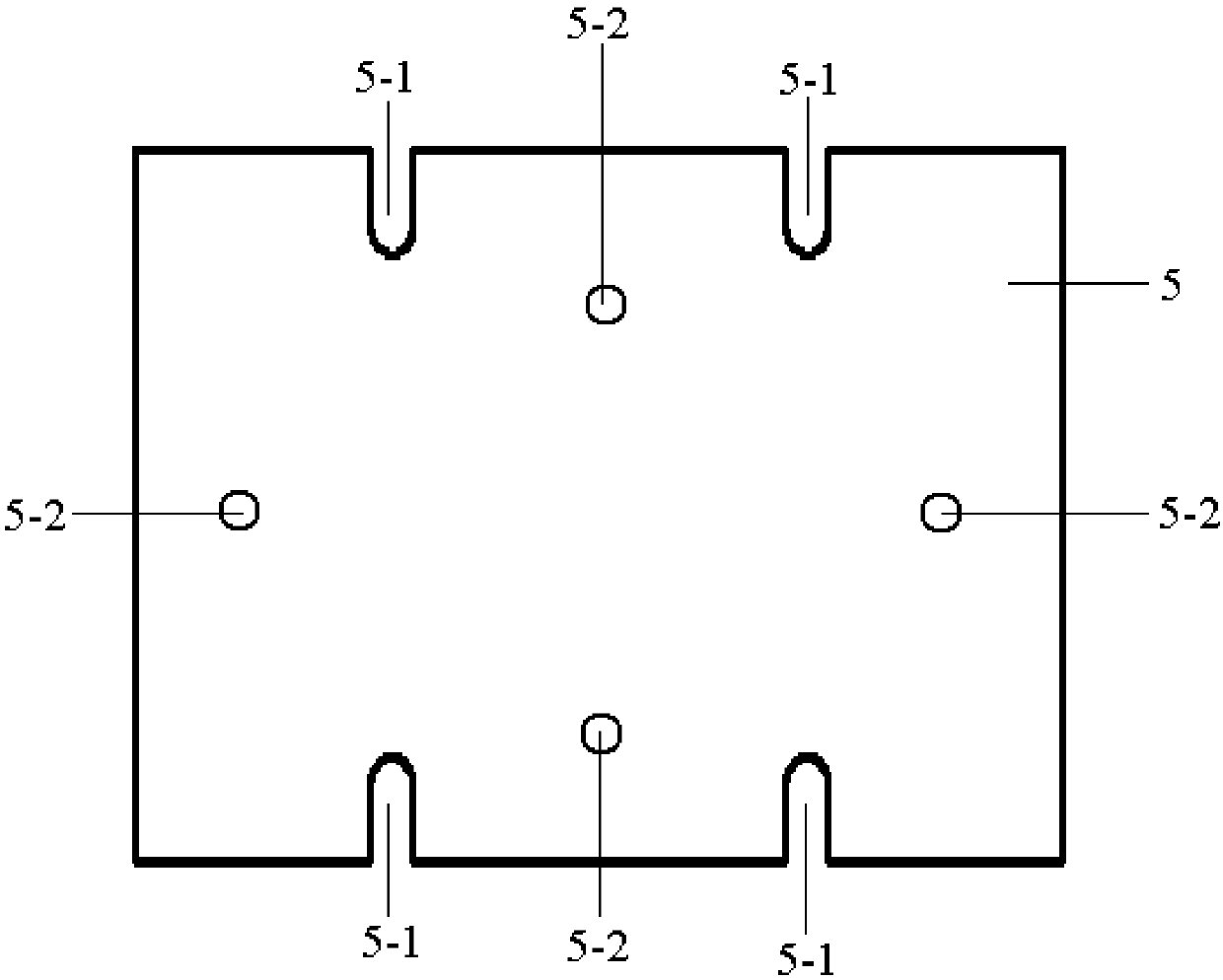

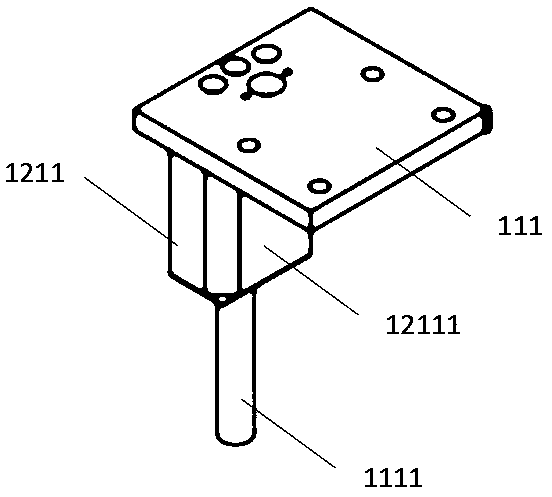

Wrought aluminum alloy complex shell semisolid thixotropic extrusion device and using method thereof

The invention discloses a wrought aluminum alloy complex shell semisolid thixotropic extrusion device and a using method of the wrought aluminum alloy complex shell semisolid thixotropic extrusion device, and relates to a wrought aluminum alloy semisolid thixotropic extrusion device and a using method of the wrought aluminum alloy semisolid thixotropic extrusion device. The technical problems thatan existing manufacturing method for wrought aluminum alloy complex shells is complex in working procedure and low in material utilization rate are solved. The device is composed of a die plate, a female die, an ejector rod, a male die, a male die fixing sleeve and an annular heater. When the male die and the female die are matched, the male die stretches into the female die by 30 mm. The using method of the device comprises the steps that quantitative cutting is carried out to obtain blanks; the device is fixedly installed to a hydraulic machine; 3, the male die and the female die are heated; 4, the product is heated to semisolid temperature; 5, the product is conveyed into a cavity of the female die; 6, die assembling is carried out; 7, online water quenching is carried out; 8, die removal is carried out, and air cooling is carried out to room temperature; and 9, natural aging is carried out after heat treatment and water quenching. The device is simple in structure, and the material utilization rate and the near net forming degree are greatly improved.

Owner:HARBIN INST OF TECH +1

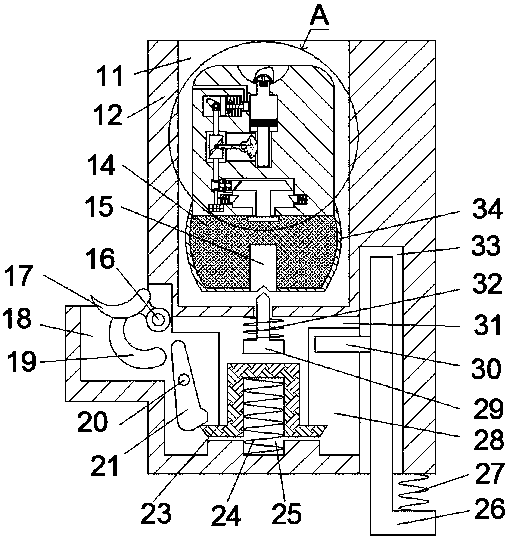

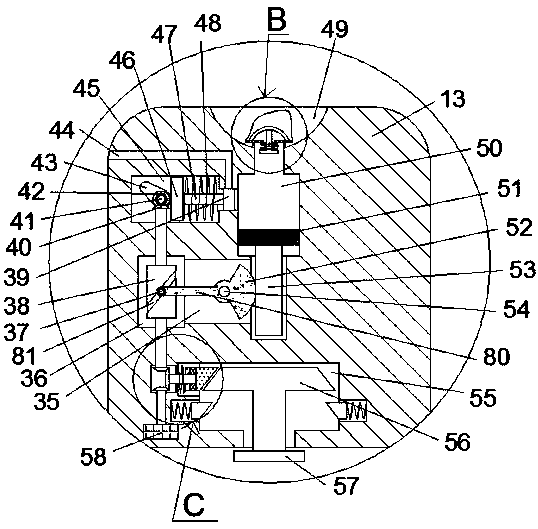

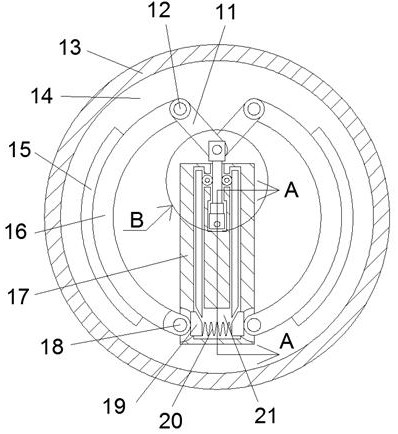

Smoke alarm

ActiveCN110363940AEasy to sendMake up for no signalSmoke/fire/colored-gas signallingDistress signalling devicesSmoke bombSmoke Emission

The invention discloses a smoke alarm, which comprises a body and a launching cavity with an upward opening, wherein the launching cavity is formed in the body, a smoke bomb combustion shell body is arranged in the launching cavity, the central position of the inner wall of the smoke bomb combustion shell body is fixedly connected with an ignition block cooperatively, the smoke bomb combustion shell body is filled with smoke ammunition, and a slidable smoke bomb device is arranged in the smoke bomb combustion shell body. According to the smoke alarm, the energy generated after the combustion of the smoke ammunition sends the smoke bomb device into the air, a trigger movable assembly is designed at first, thus the smoke bomb can be launched simply and conveniently, the smoke bomb device isdesigned at the same time, an inflatable activating assembly, a balloon inflatable assembly, a piston driving assembly and an inspiration assembly are designed in the smoke bomb device, a balloon marked with an SOS distress signal can be automatically inflated, and the smoke alarm is simple in structure and convenient to operate.

Owner:桐乡市织盟知识产权运营有限公司

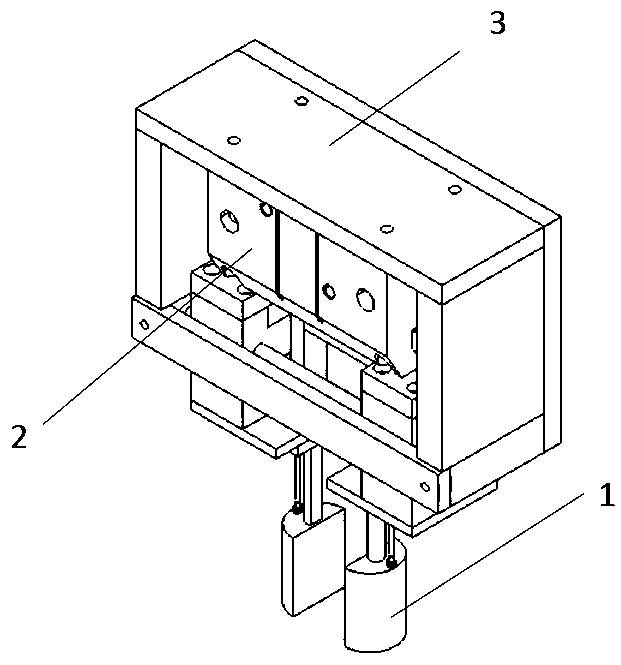

Plastic mould

The invention provides a plastic mould, and belongs to the technical field of mould equipment. The plastic mould solves the problem that the production efficiency of an existing plastic mould is low. The plastic mould comprises an upper mould block and a lower mould block, a moulding cavity is formed between the upper mould block and the lower mould block, an insert and a mould core are arranged between the upper mould block and the lower mould block, air cooling channels are formed in the circumferential direction of the insert, a through hole axially penetrating through the insert is formed in the insert, the through hole communicates with the moulding cavity, a limiting groove is formed in the hole wall of the through hole, the insert is slidably connected with a slide rod in the through hole, the end portion of the slide rod is embedded into the limiting groove and abuts against the groove wall of the limiting groove, an air guide channel is formed in the insert, and an air inlet pipe is arranged on the mould core. The plastic mould can improve the production efficiency of the mould.

Owner:ZHEJIANG SAIHAO IND CO LTD

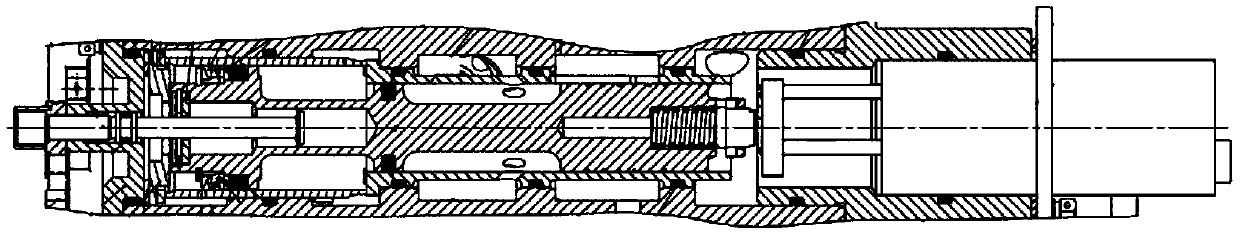

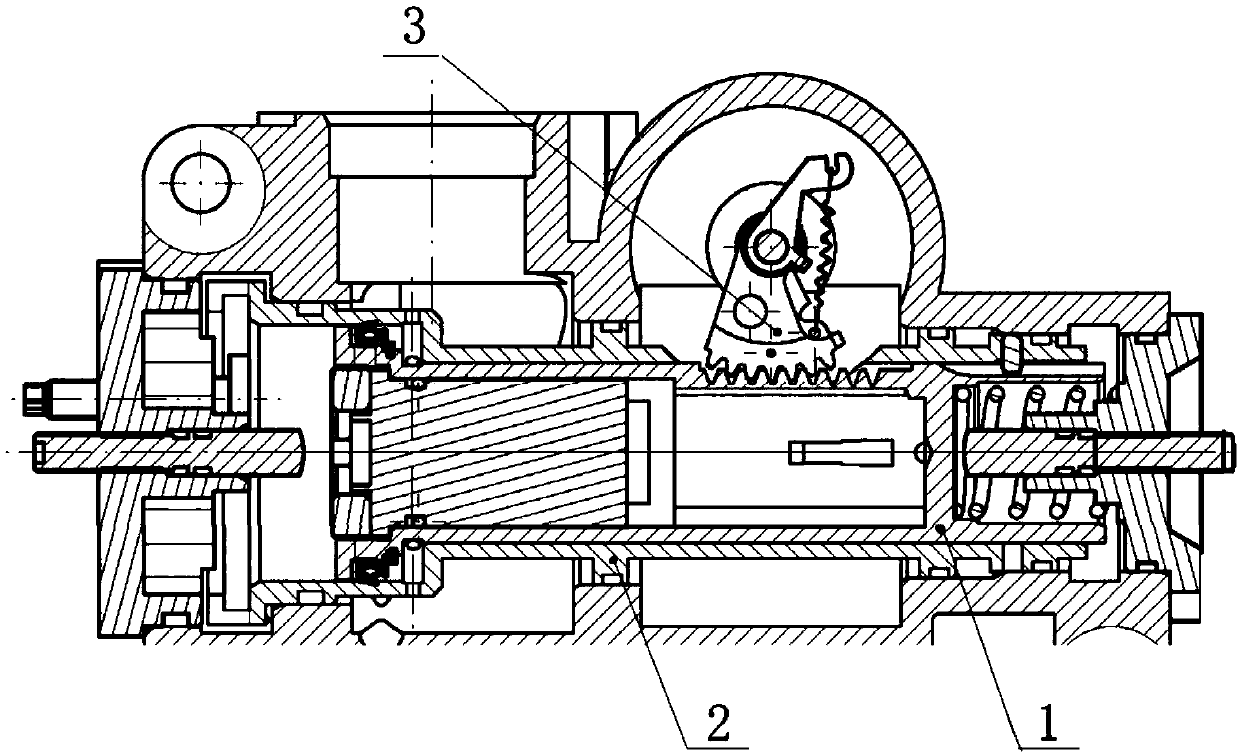

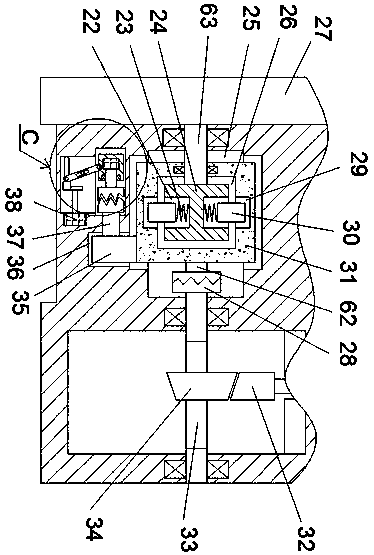

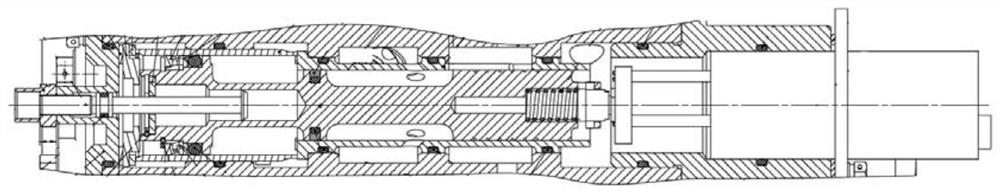

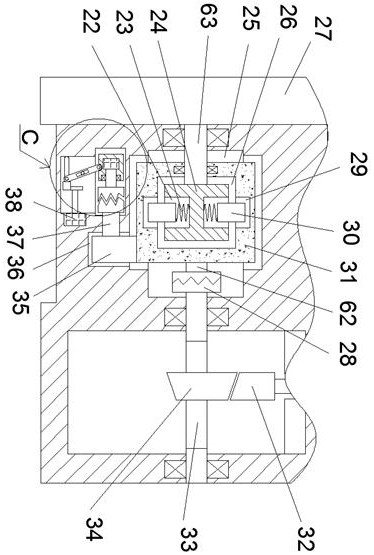

High-precision flow metering mechanism

ActiveCN109556670ARealize the metering functionTight rhythmRelative volume flow measurementsControl systemEngineering

The invention relates to a high-precision flow metering mechanism, and belongs to a fuel metering device of a fuel control system. The mechanism comprises a valve element, a bushing, a housing and anangular displacement measuring assembly. The angular displacement measuring assembly comprises a first sector gear, a second sector gear, a spring, an angular displacement sensor and a rotating shaft.According to the high-precision flow metering mechanism, the axial position size of a metering valve assembly can be maximally improved, position signals of the valve element can be transmitted withhigh precision, and meanwhile the angular displacement sensor can be used as a sensing element for receiving and transmitting the position signals of the valve element.

Owner:XIAN AERO ENGINE CONTROLS

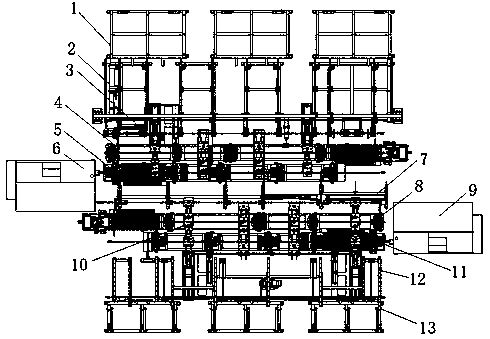

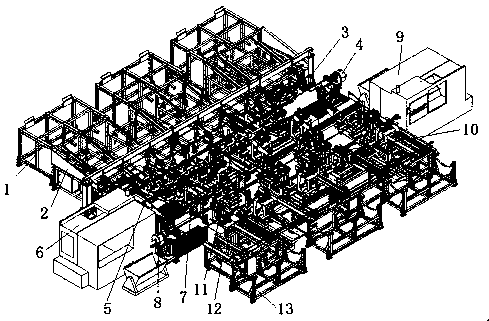

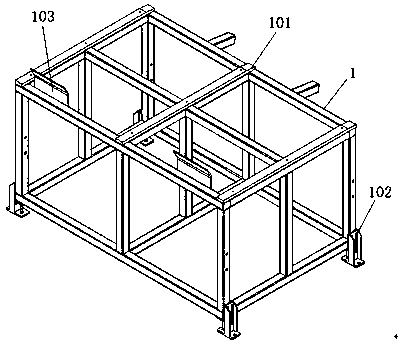

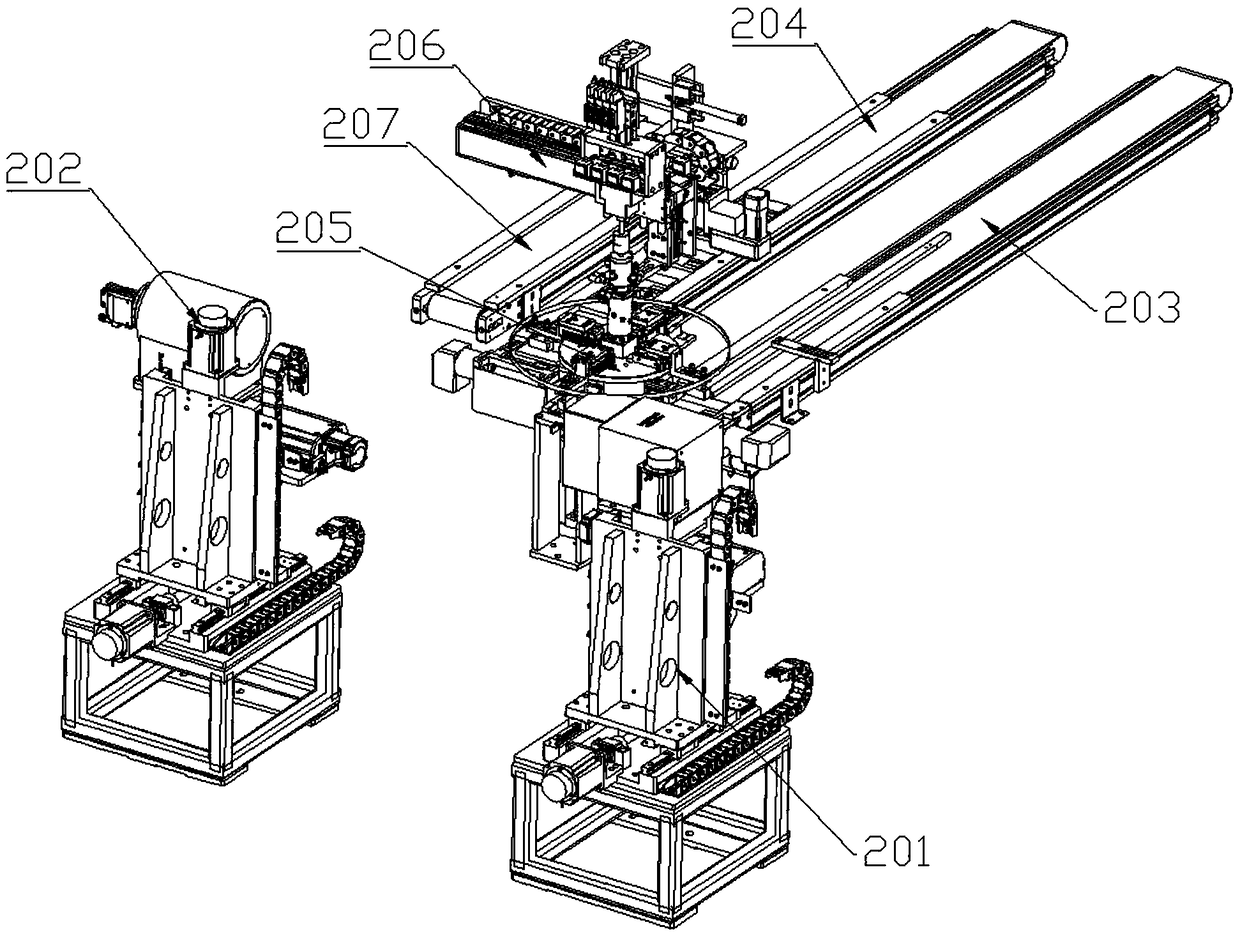

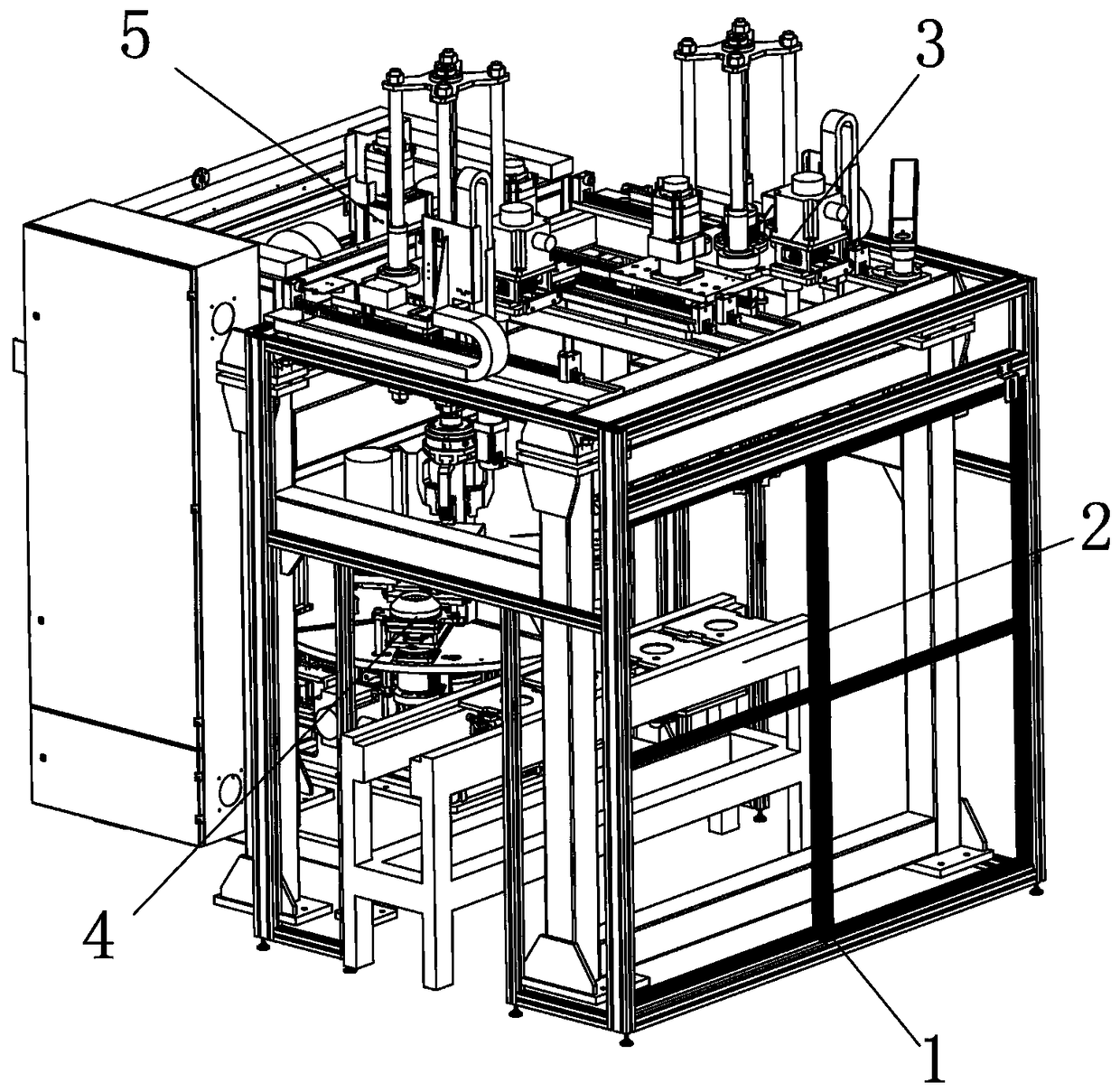

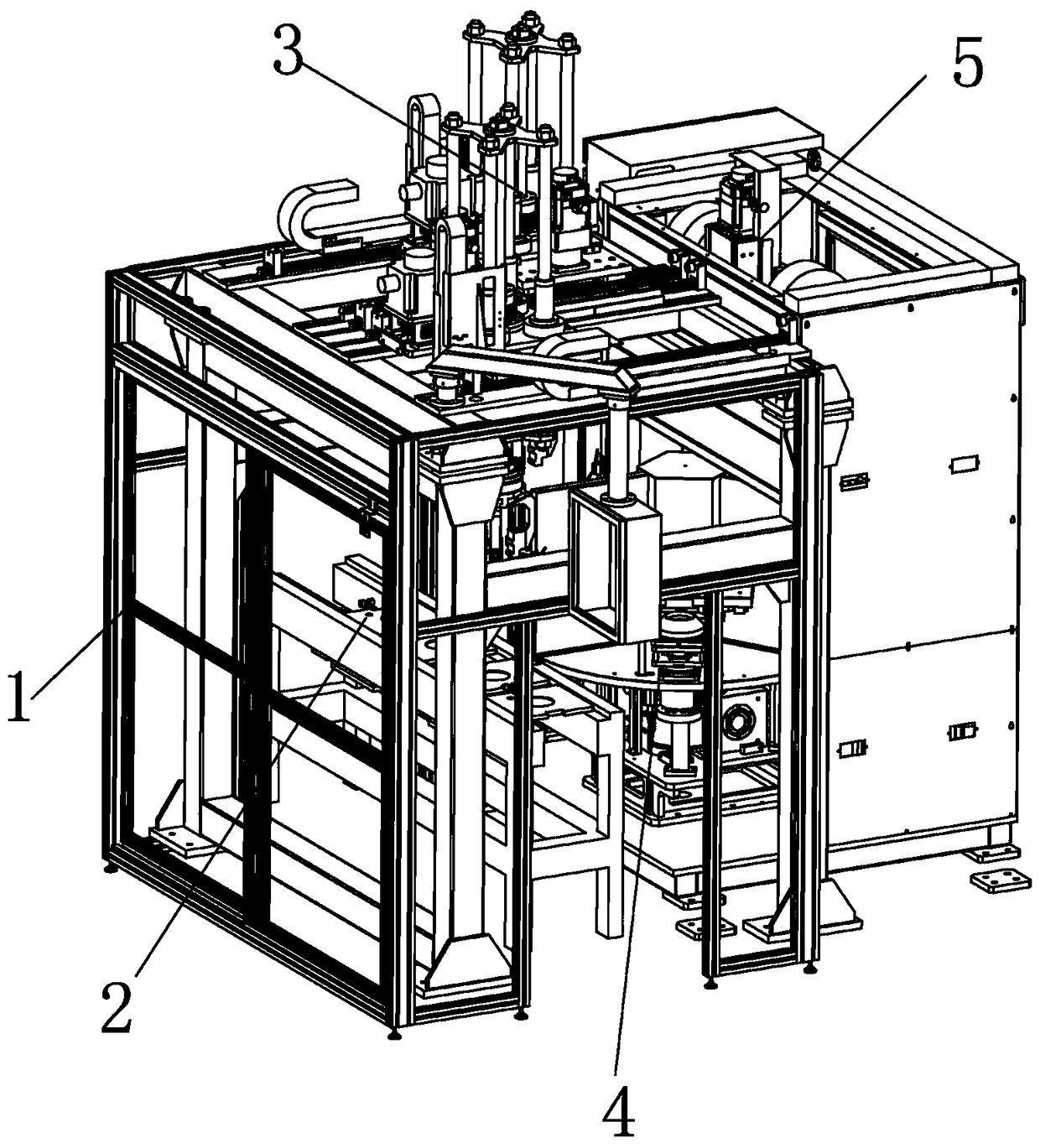

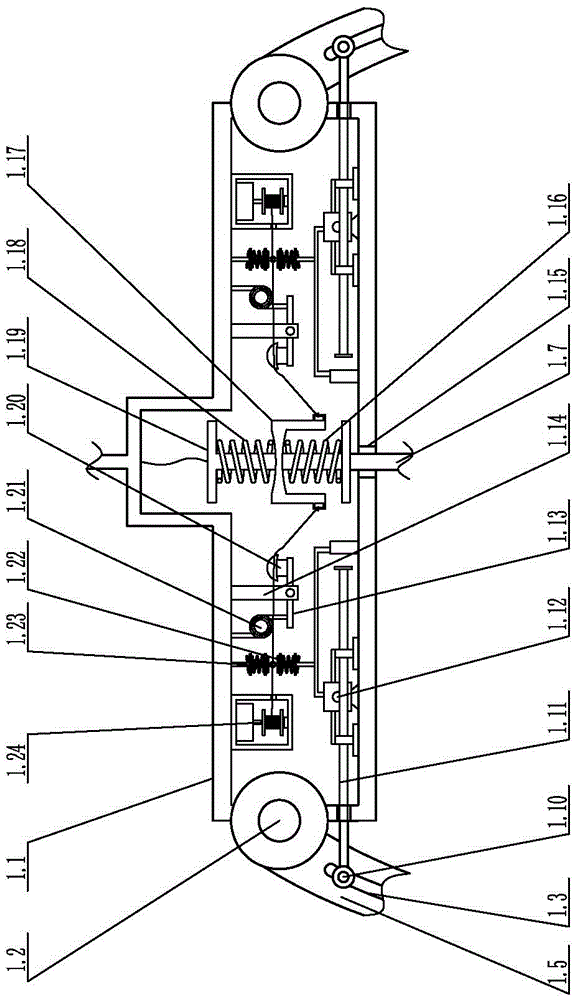

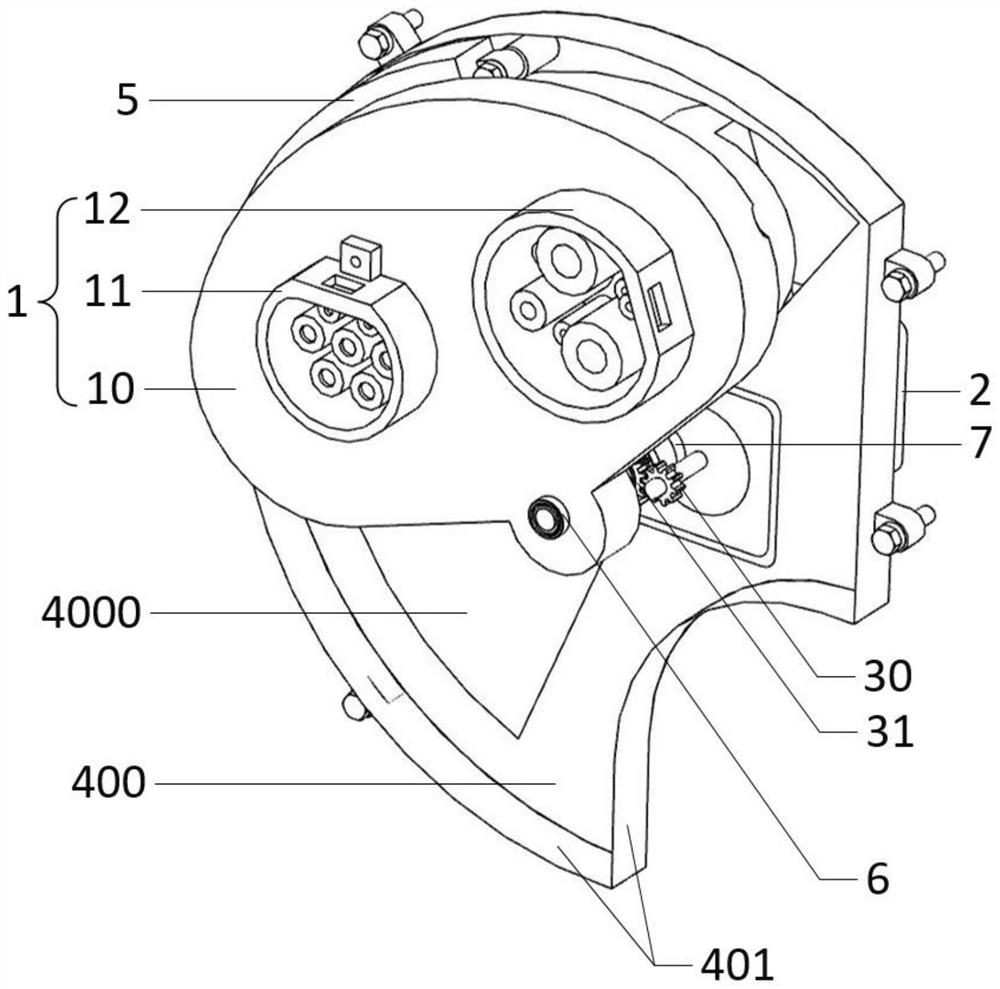

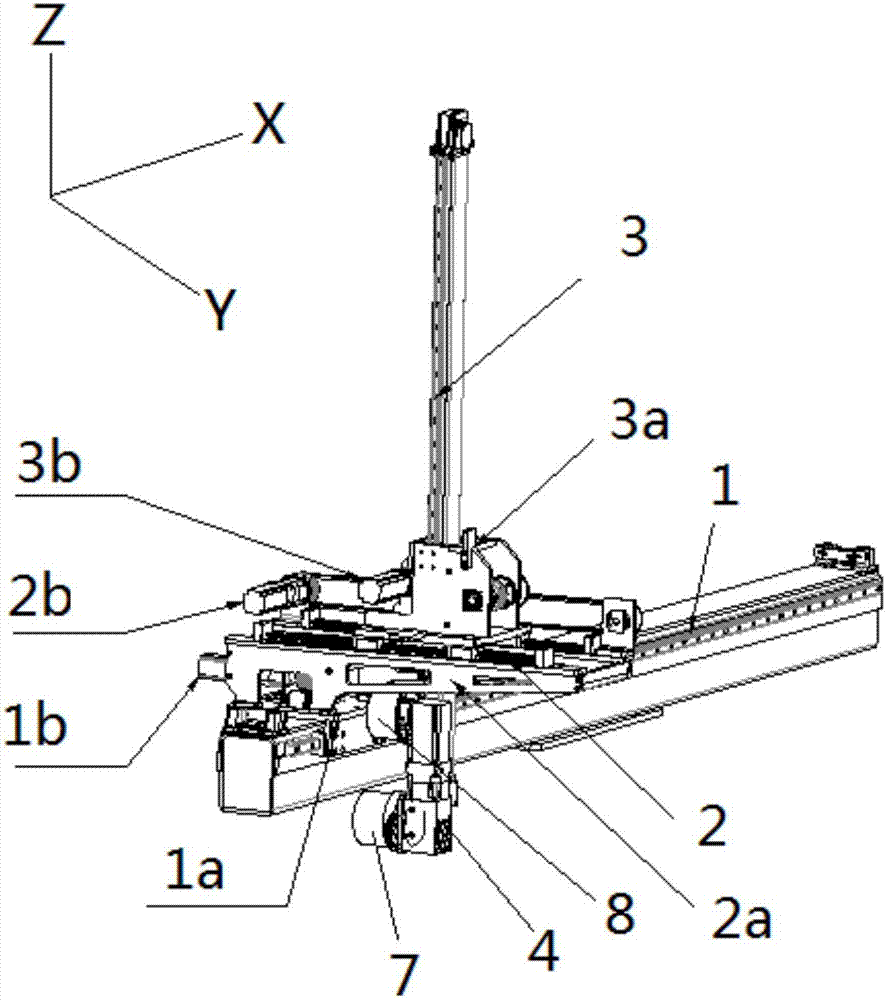

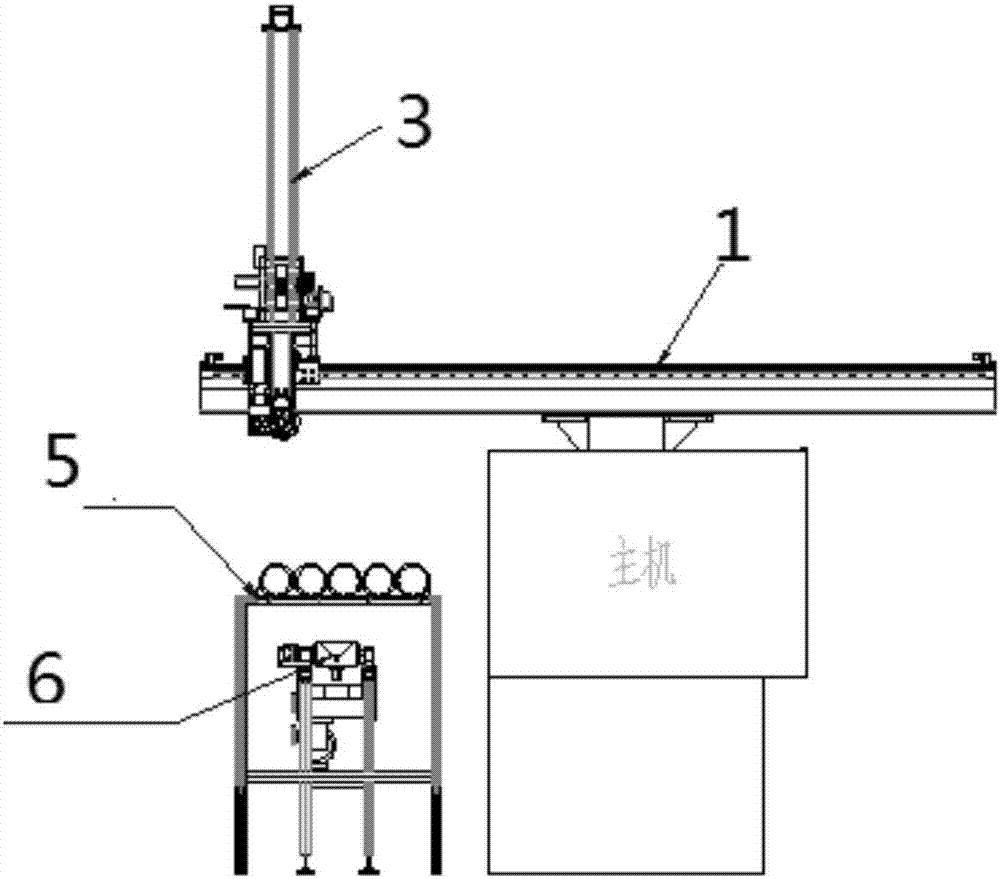

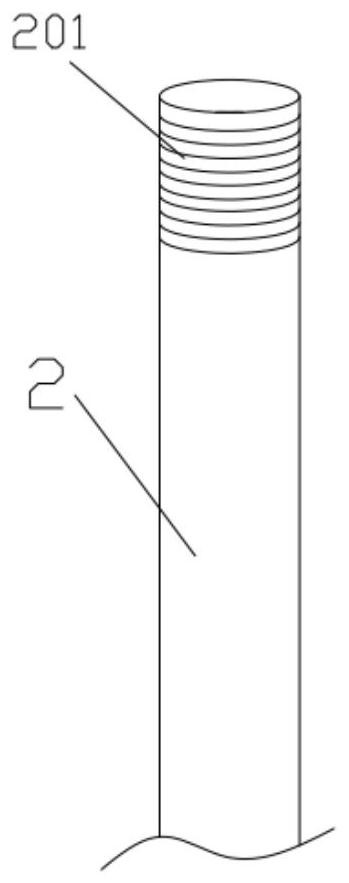

Oil sucker rod intelligent manufacturing production line

ActiveCN111390087AThe transfer process is stableRealize intelligent automatic productionForging/hammering/pressing machinesForging press detailsMachineMachining process

An oil sucker rod intelligent manufacturing production line comprises a feeding bin, a first stepping push device, a first angular positioning device, a first transferring device, an axial operation device, a second angular positioning device, a second stepping push device, a second transferring device and a discharging bin arranged in sequence in the workpiece operating direction; the outer sideof the first transferring device and the outer side of the second transferring device are both provided with machine tools; the first stepping push device pushes workpieces on the feeding bin, the first angular positioning device and the first transferring device forwards in sequence; and the second stepping push device pushes the workpieces on the axial operation device, the second angular positioning device, the second transferring device and the discharging bin forwards. According to the production line, the problems that conveying, clamping and positioning are difficult in the machining process of long and thin oil sucker rods are solved, intelligent automatic production of external threads of two ends of an oil sucker rod is achieved, the workpiece transferring stability is ensured, the paces are intense, the production efficiency is high, and the production cost is reduced.

Owner:山东弘名智能科技有限公司

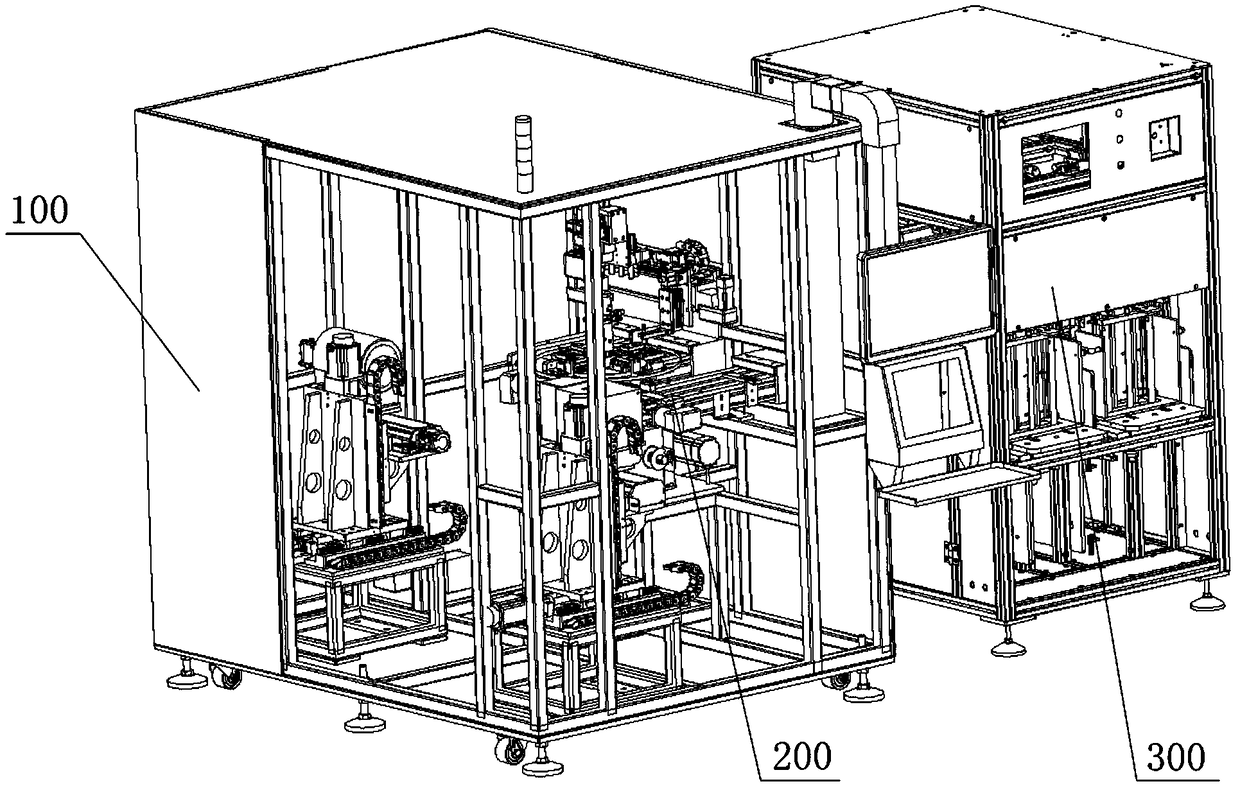

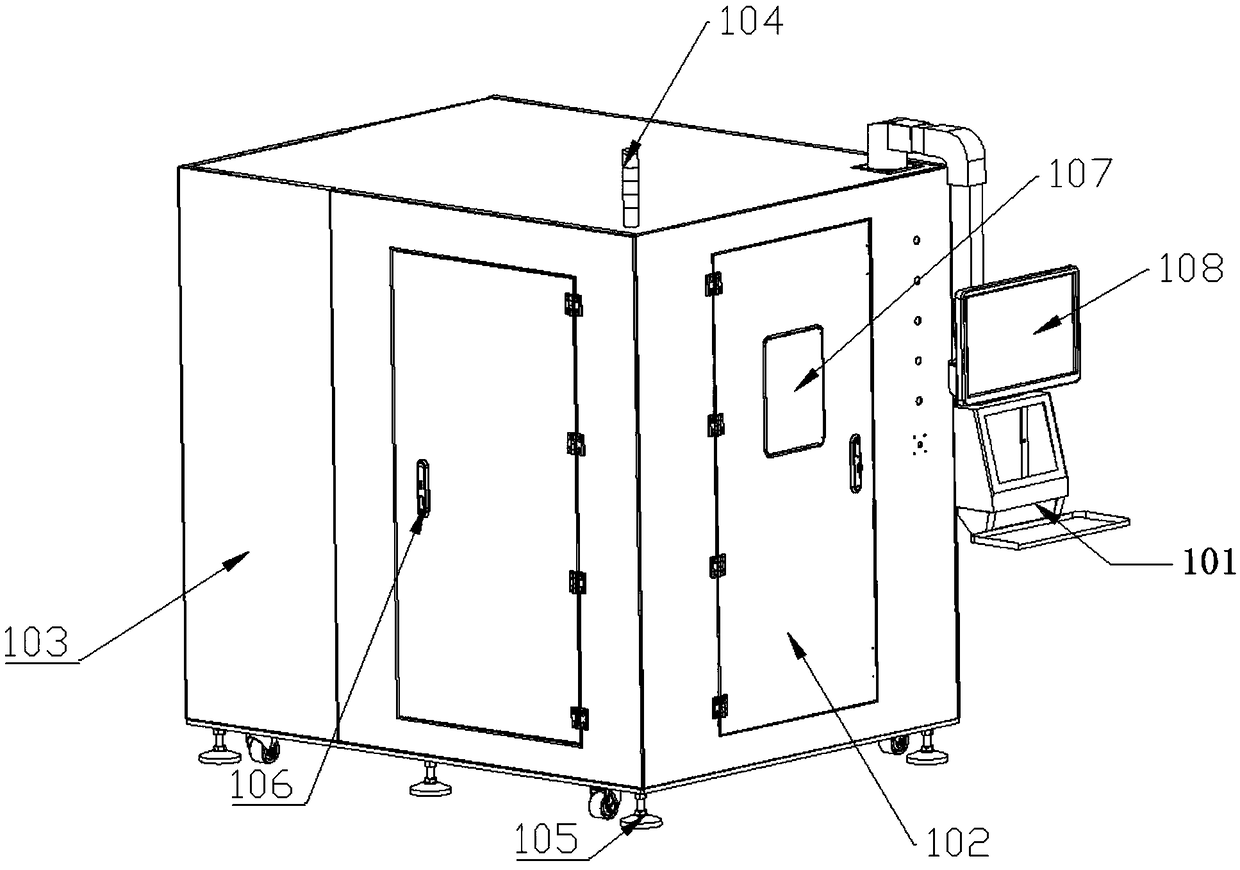

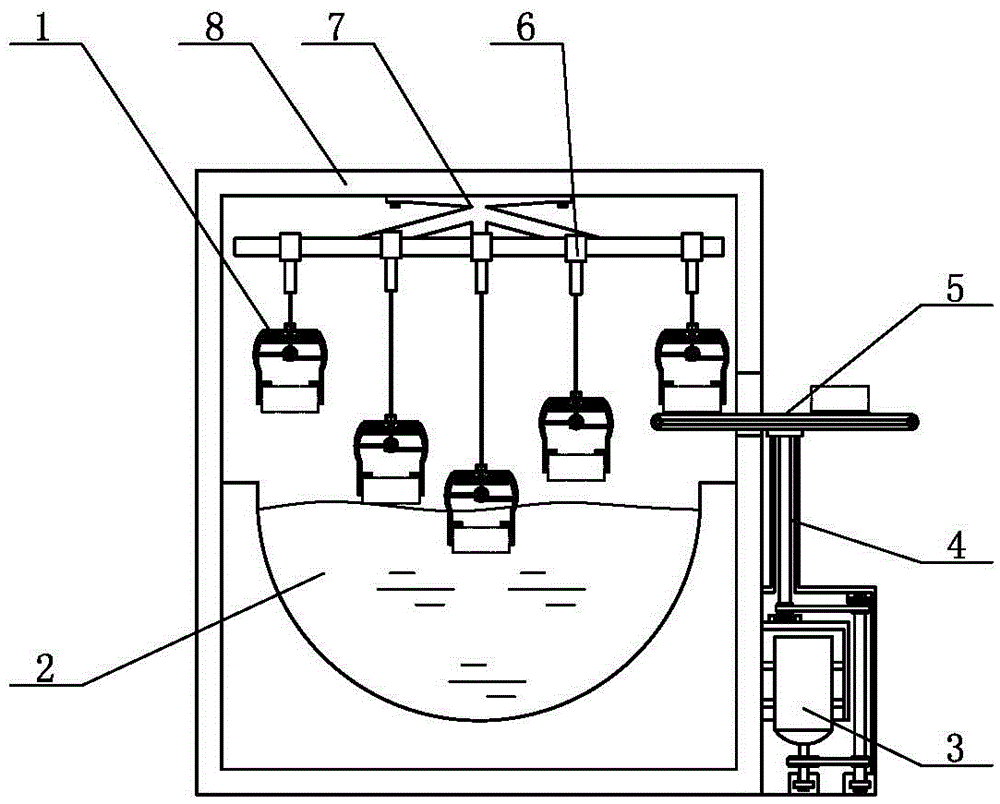

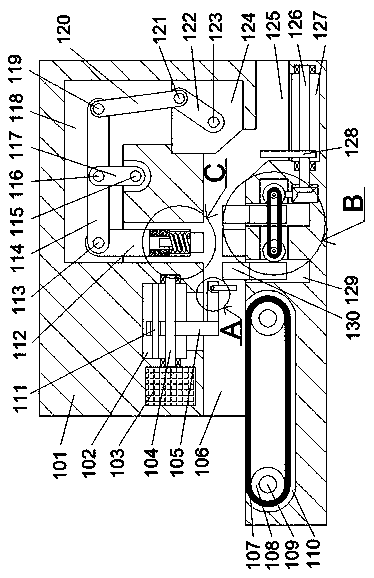

Full-automatic high-speed detection equipment for inner structure of battery shell body

PendingCN108855982AConvenient imaging detectionEfficient detectionSortingUltimate tensile strengthConveyor belt

The invention discloses full-automatic high-speed detection equipment for an inner structure of a battery shell body. The full-automatic high-speed detection equipment comprises a feeding conveyor belt, a discharging conveyor belt, a testing rotary table, a sorting mechanical arm, a defective product conveyor belt and an image detector, wherein the feeding conveyor belt is used for conveying a workpiece to be detected to the testing rotary table; the testing rotary table is used for taking materials from the feeding conveyor belt in sequence and conveying the materials to the image detector for carrying out quality detection; when the detection of the current workpiece to be detected is finished, the workpiece is conveyed to the discharging conveyor belt through he testing rotary table; the image detector is used for imaging the inner structure of the workpiece to be detected and judging whether the quality is qualified or not through a built-in procedure; the image detector is in signal connection with a signal end of the sorting mechanical arm; a triggering signal is sent to the sorting mechanical arm when a detection result of the image detector is unqualified, and the current workpiece is transferred to the defective product conveyor belt from the discharging conveyor belt. The full-automatic high-speed detection equipment for the inner structure of the battery shell body is used for conveniently and efficiently realizing quality detection of the inner structure of a battery, the detection efficiency and quality are improved, and the labor cost and the labor intensity are reduced.

Owner:GUANGDONG ZHENGYE TECH

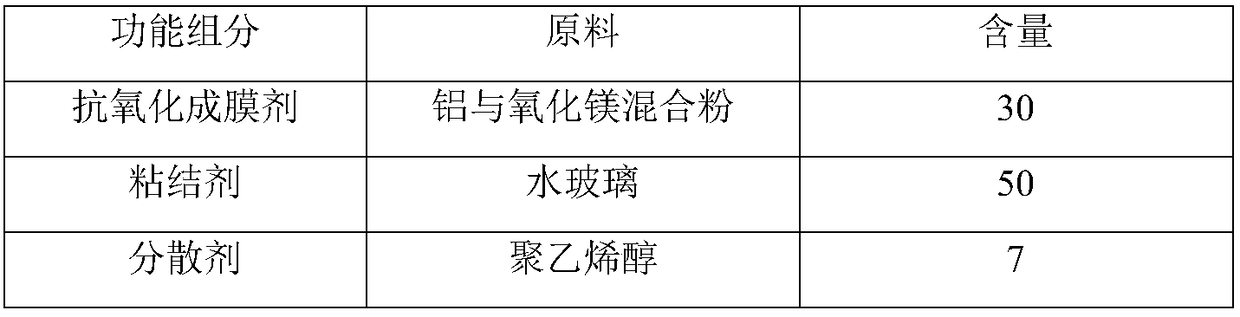

Method of prolonging service life of oxygen lance of converter

ActiveCN108642233AHigh temperature resistantImprove adhesionManufacturing convertersSlagBoron nitride

The invention relates to a method of prolonging the service life of an oxygen lance of a converter. The method comprises the following steps: carrying out treatment on bottom end surface of a spray head of the oxygen lance and treatment on side wall of an oxygen lance body, coating a high-temperature-resistant antioxidant coating to the bottom end surface of the spray head of the oxygen lance, carrying out induction heating or flame heating treatment on the end surface, spraying a first layer with a coal gas type flame high pressure spray gun, and spraying a second layer with an oxygen-acetylene flame high pressure spray gun; derusting the side wall of the gun body to a range 2-10 m far from the bottom end surface by taking the bottom end surface of the spray head of the oxygen lance as the starting point, and then smearing a coating; and spraying boron nitride powder to the coating by using the oxygen-acetylene flame high pressure spray gun. The method has the advantages that the service life of the oxygen lance is prolonged, and the labor intensity of workers is alleviated to a great extent; the deslagging treatment time as slag is attached to the oxygen lance is saved, the blowing rhythm is more compact, the effective operating efficiency of the converter is increased, and the output of steel is improved.

Owner:ANGANG STEEL CO LTD

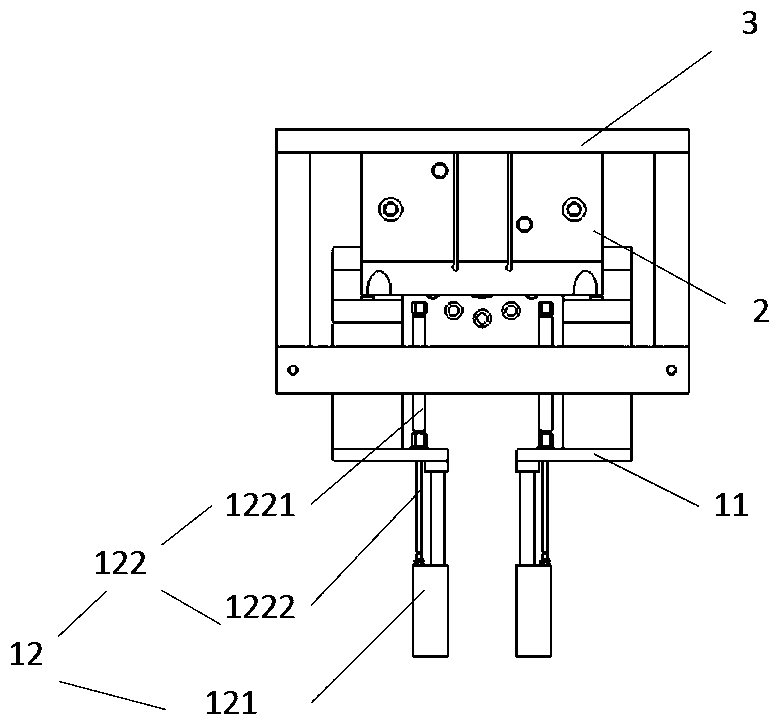

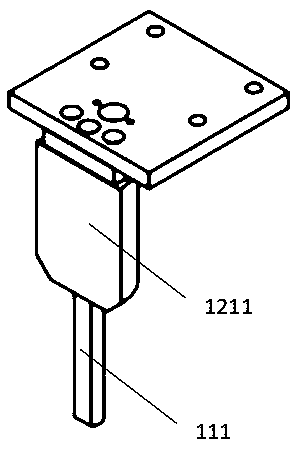

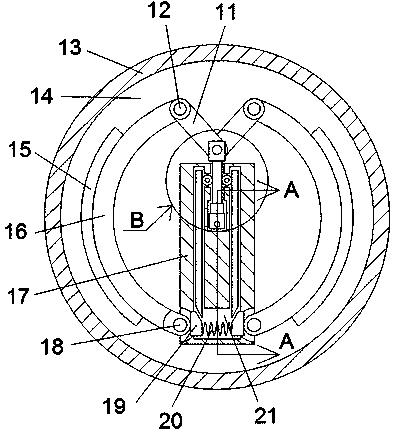

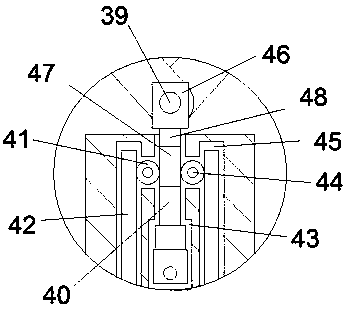

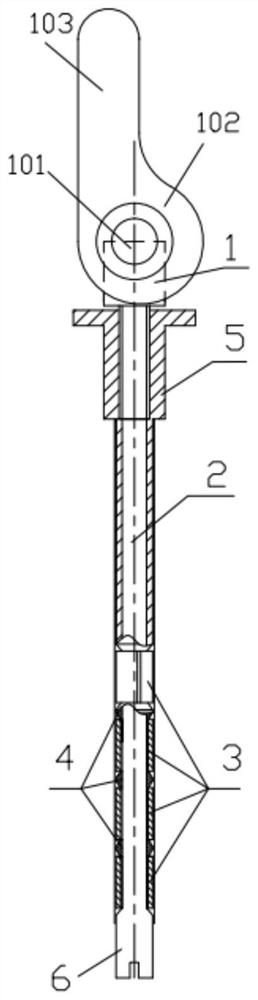

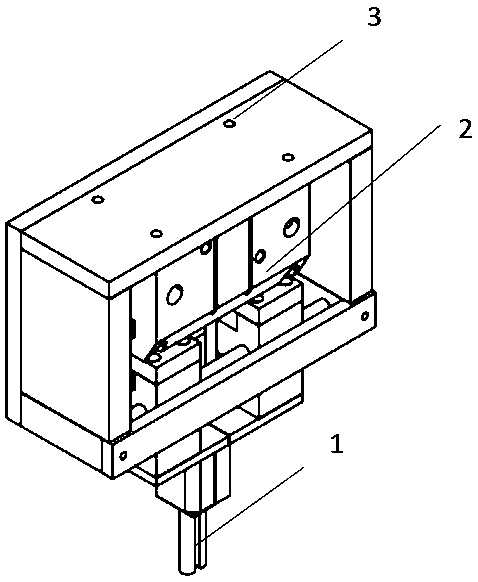

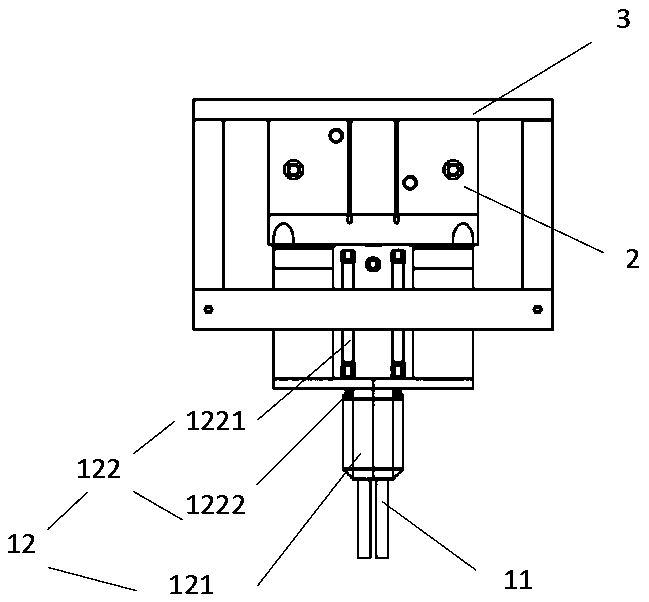

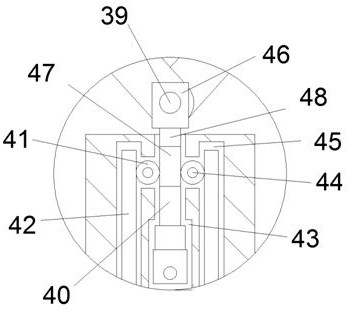

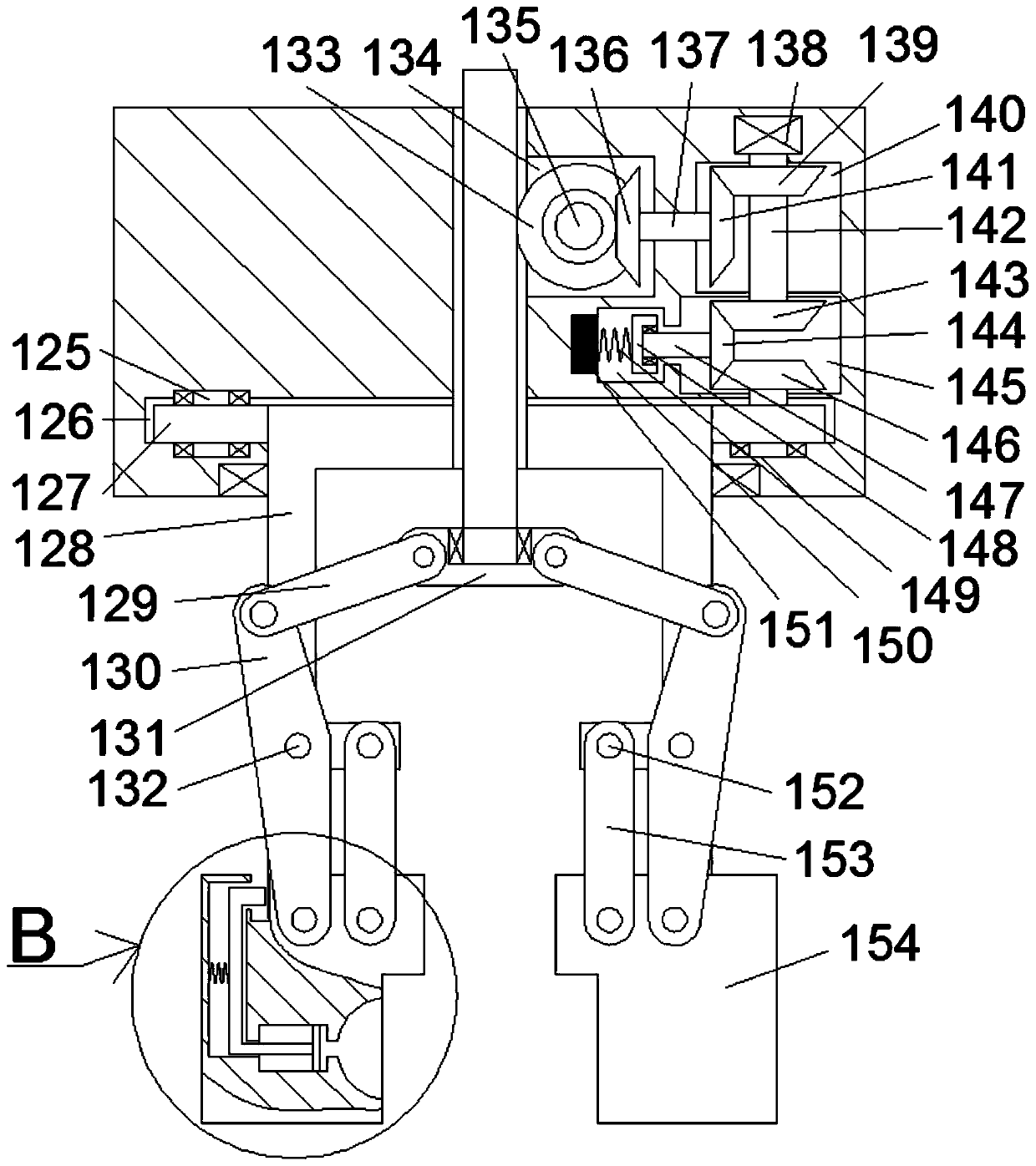

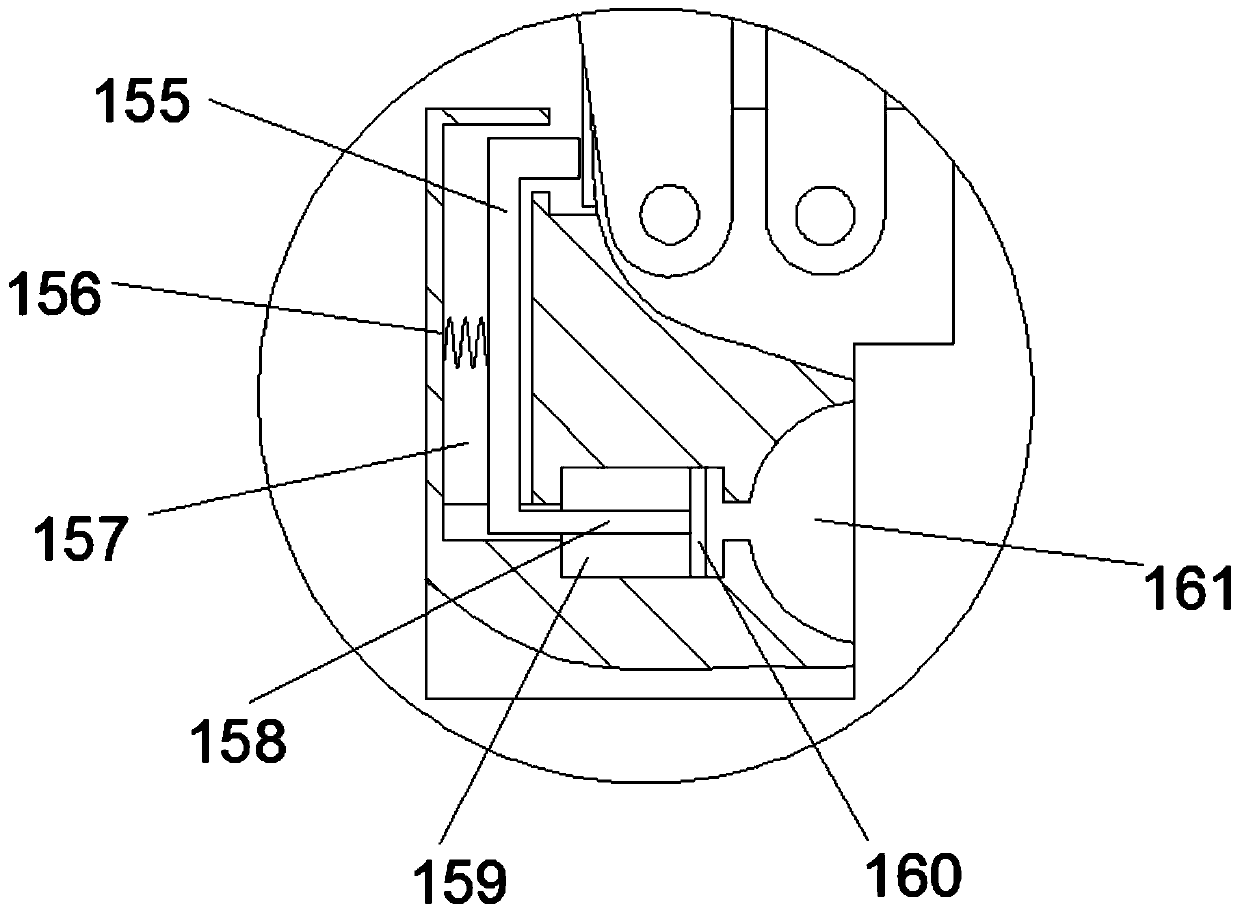

Segmented outward stretching clamp

The invention relates to a segmented outward stretching clamp which comprises a plurality of segments of outward stretching mechanisms, a telescopic cylinder and an installation base. The segmented outward stretching clamp has the advantages of compact rhythm and small size, can be embedded into articles to pick up the articles and can pick up the articles in a larger size range, and the time forreplacing clamps is reduced.

Owner:NANJING KINGYOUNG INTELLIGENT SCI & TECH

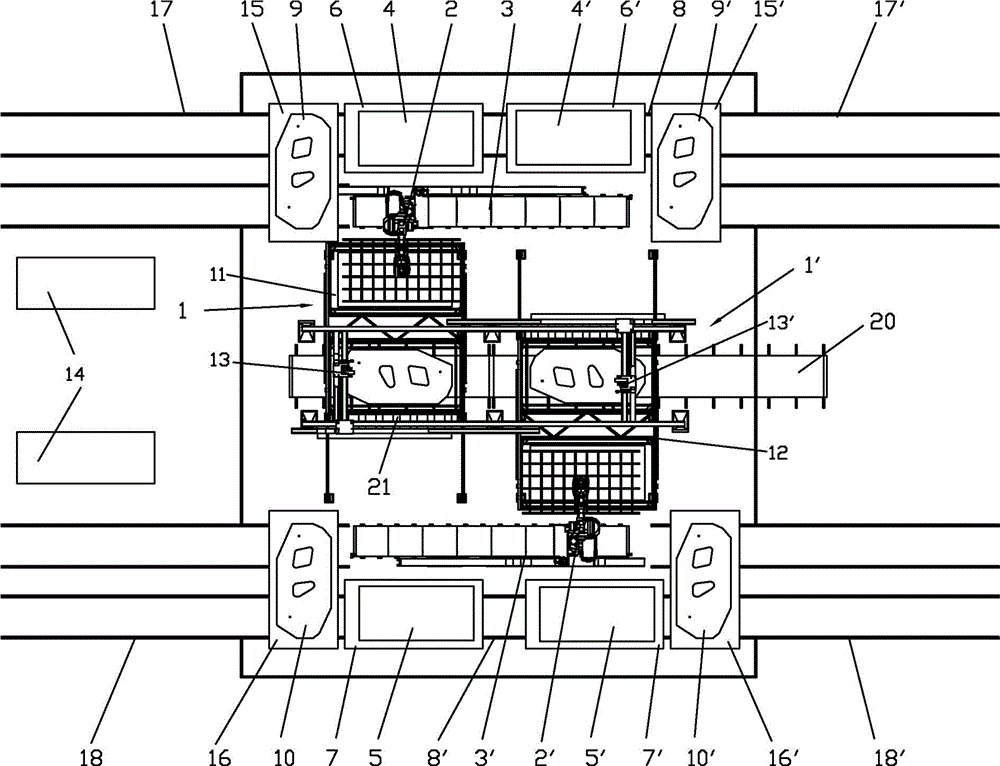

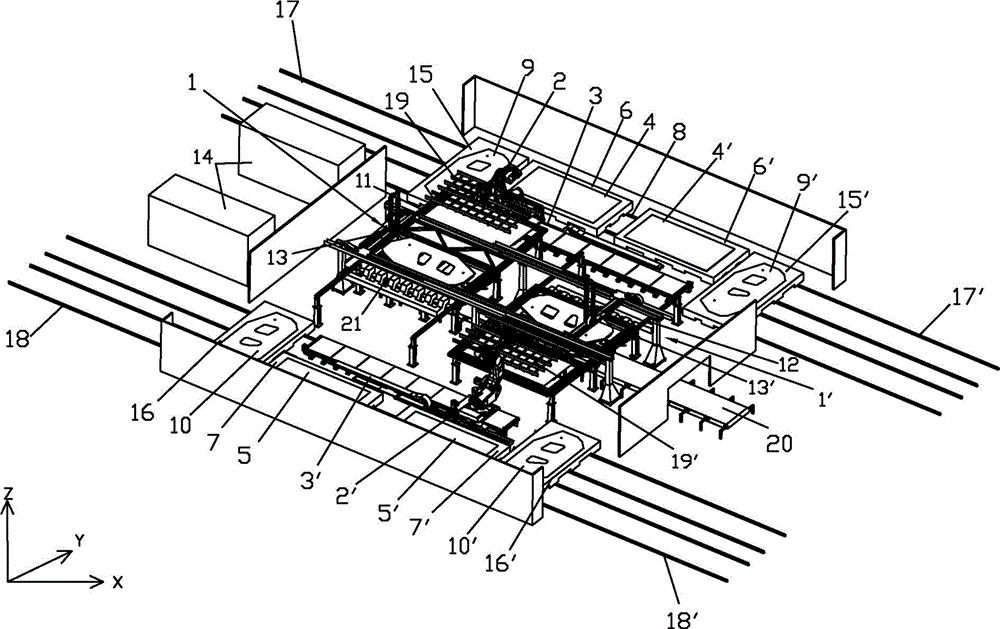

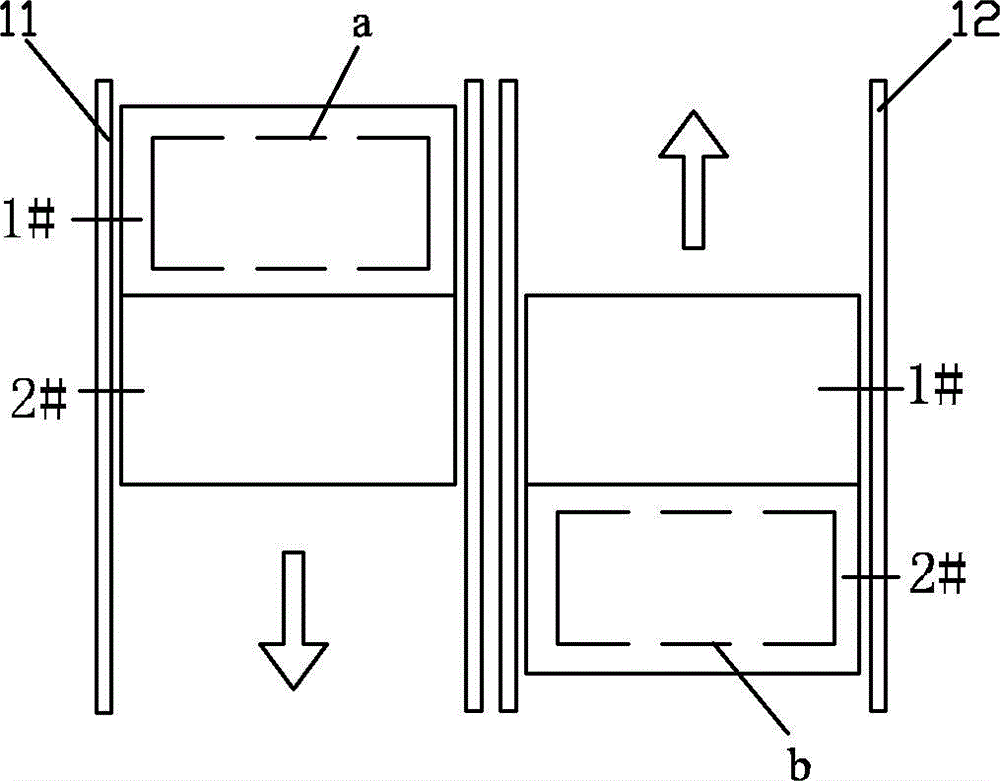

Method and system for two-station fast table cutting

ActiveCN103600173BImprove work efficiencyCompact layoutVehicle componentsMetal working apparatusLaser cuttingEngineering

Provided are a double-station quick-table cutting method and a system adopting the method. The system comprises two cutting units, two carrying-stacking robots, four material feeding positions, four sheet material discharging positions and a waste material conveying system. Each cutting unit comprises a first mobile quick table, a second mobile quick table and two laser cutting heads, and the first mobile quick table and the second mobile quick table are parallelly arranged. Each mobile quick table is provided with one cutting position and two material receiving positions 1# and 2#. The carrying-stacking robots are respectively arranged on two sides of the cutting units, and external shafts of the robots are perpendicular to the mobile quick tables. The material feeding positions are arranged on the outer sides of the outside of the carrying-stacking robots and provided with material trolleys and corresponding guide rails, wherein the guide rails are parallel to the external shafts of the robots. The waste material conveying system is arranged under the cutting positions of the cutting units. The system can simultaneously achieve steel plate feeding and discharging operation, effectively improve the operation speed and the yield and can meet the small-scale production requirement.

Owner:BAOSHAN IRON & STEEL CO LTD +1

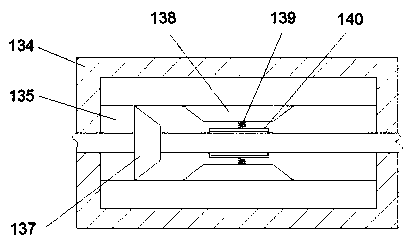

Rose essential oil extraction device

InactiveCN110184123ASimple structureEasy to operateEssential-oils/perfumesProduct gasTemperature difference

The invention discloses a rose essential oil extraction device. The rose essential oil extraction device comprises a machine and a gas compression cavity formed in the machine, wherein a gas compression assembly is arranged in the gas compression cavity, gas is compressed into high-pressure gas by the gas compression assembly, the gas releases heat when compressed, part of the gas starts to liquify, a gas inlet pipeline communicates with the left side of the gas compression cavity, and is connected with the left side of the gas compression cavity, a power transmission cavity is formed in the right side of the gas compression cavity, a power transmission assembly is arranged in the power transmission cavity, a working cavity with a closed opening is formed in the upper side of the power transmission cavity, and an assembly with a closed opening is arranged in the working cavity with the closed opening. Firstly, the gas is compressed, the gas is a high-temperature high-pressure gas-liquid mixed state when compressed, by adopting single-threaded rod compression design, the device volume is reduced, a novel power generation mode of temperature difference semiconductor power generationis adopted for a core heat exchange part, and the rose essential oil extraction device is simple in structure and convenient to operate.

Owner:杭州君笑文化传播有限公司

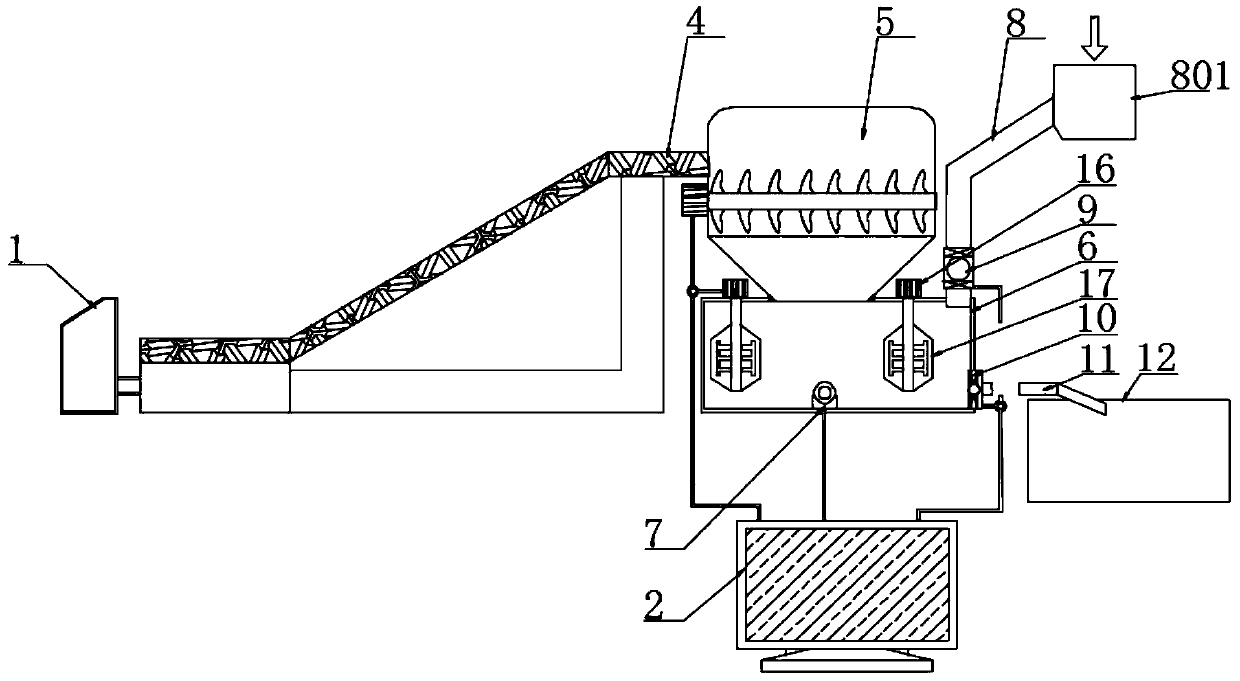

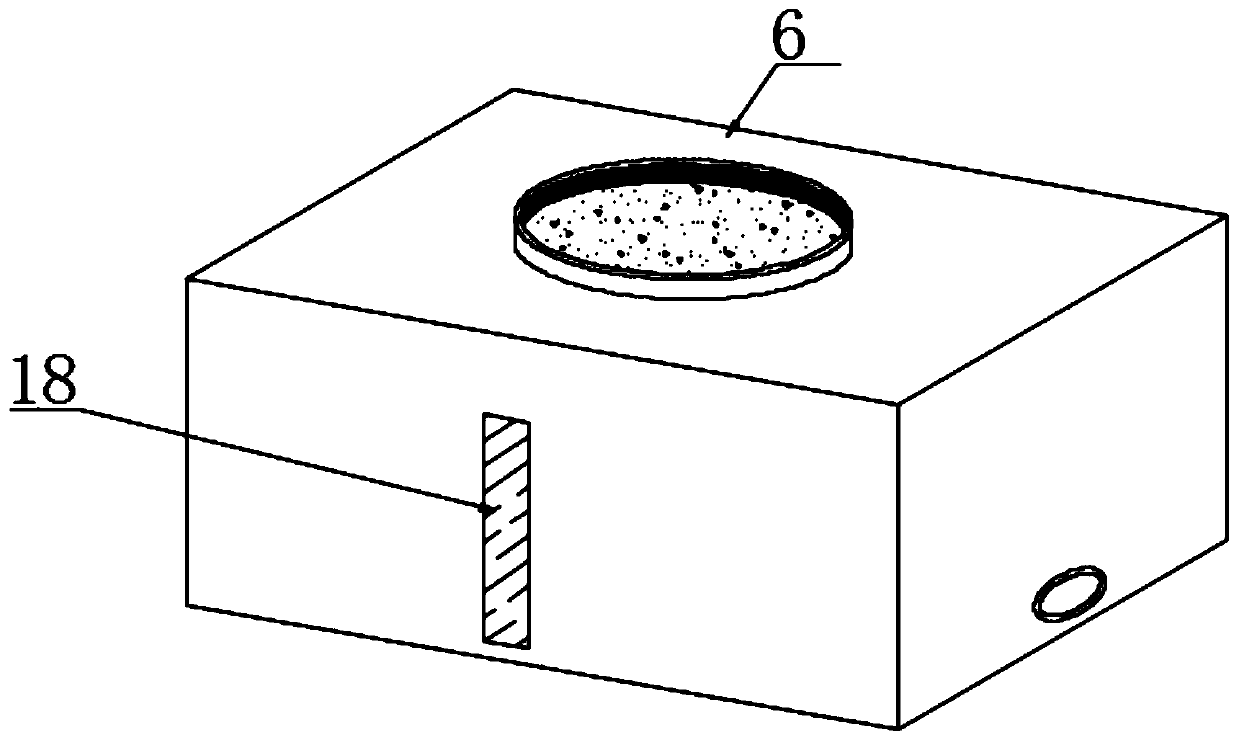

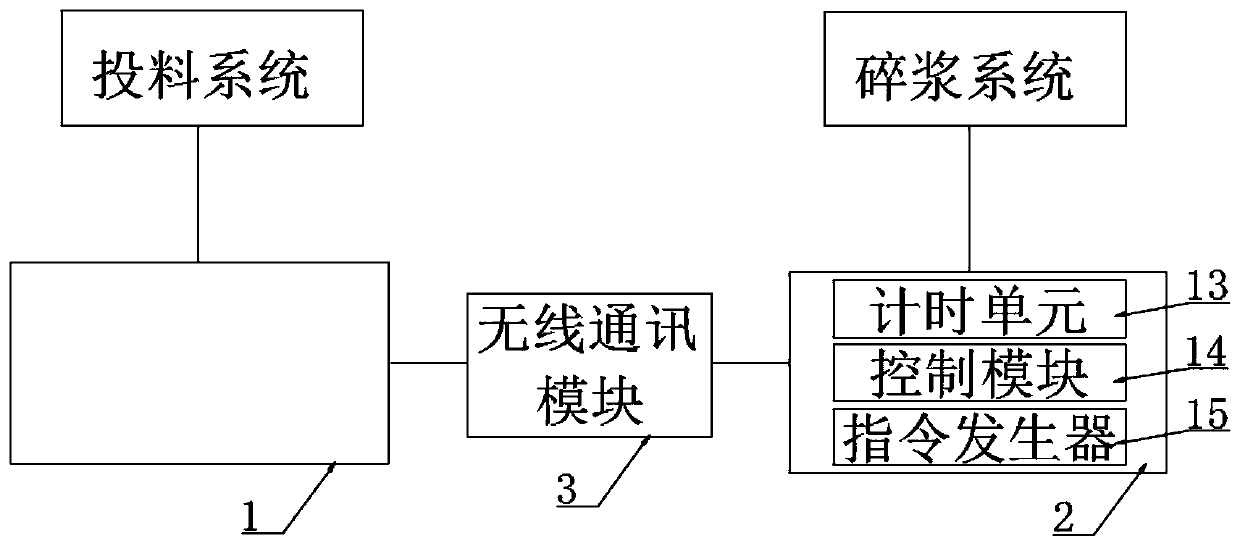

Intelligent repulping and feeding linked system in pulp molded pulping process

PendingCN109763368AClosely connectedMeet supplyRotary stirring mixersPulp beating methodsComputer modulePulp and paper industry

The invention discloses an intelligent repulping and feeding linked system in the pulp molded pulping process, and particularly relates to the technical field of molded pulping. The intelligent repulping and feeding linked system in the pulp molded pulping process comprises a feeding control cabinet and a pulping control computer, and the feeding control cabinet is in remote connection with the pulping control computer through a wireless communication module. Through the wireless communication module, the pulping control computer edits work commands through a command generator, and a control module intelligently controls an apron conveyer and a pulper to work; and pulping work automatically operates through a pressure transmitter and a timing unit, and the pressure transmitter and the timing unit send sensing information to the control module for analysis process; the control module controls the apron conveyer, the pulper, a water supplement pneumatic value, a discharging electromagnetic value and a motor to work, intelligent repulping can be achieved, manual feeding is replaced, the safety factor is high, intelligent repulping and intelligent feeding linked control are achieved, repulping and feeding process connects tightly, the production efficiency is extremely high, large-scale production can be met, and continuous slurry supply is provided.

Owner:永发(江苏)模塑包装科技有限公司

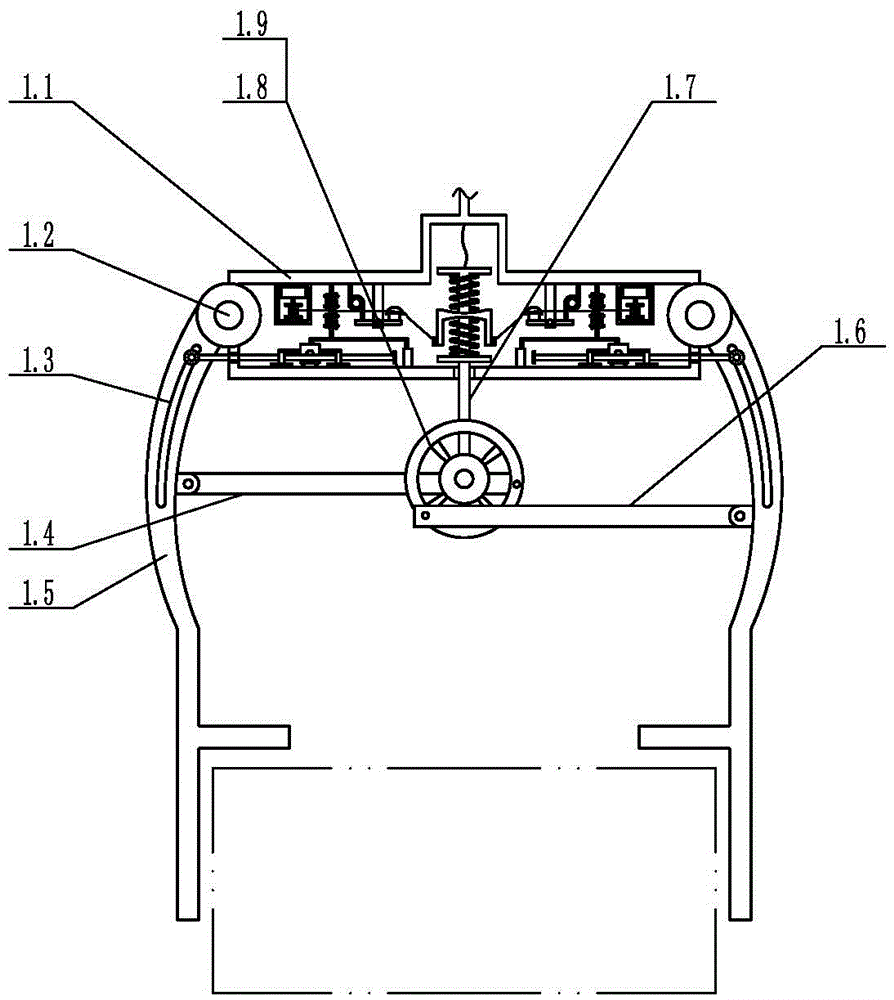

Multi-station compressor shell ring welding machine

InactiveCN108723555AAchieving Spin WeldingRealize autogenous spin weldingWelding/cutting auxillary devicesAuxillary welding devicesElectricityButt joint

The invention relates to a multi-station compressor shell ring welding machine. The multi-station compressor shell ring welding machine comprises a rack and further comprises a feeding conveying line,a taking mechanical arm, a multi-station positioning disc and a welding mechanical arm which are installed on the rack; the multi-station positioning disc comprises a rotating base and a rotating disc arranged on the rotating base, the rotating disc is provided with a plurality of rotary ventilation electric conduction bases, a positioning clamp is installed at the top end of each rotary ventilation electric conduction base, and to-be-welded workpieces are placed into the positioning clamps through the taking mechanical arm to be fixed; and a jacking rotation mechanism is arranged below the rotating disc and is in butt joint with the rotary ventilation electric conduction bases to drive the rotary ventilation electric conduction bases to rotate. The multi-station compressor shell ring welding machine has the beneficial effects that assembly line type production is achieved, the rhythm is compact, and the production efficiency is high. The unique multi-station positioning disc structure is adopted, while compressor shell rotary welding is carried out, air guide and electricity conduction are achieved, a compressor shell can achieve autologous rotary welding, and the welding effectis guaranteed.

Owner:SANHE IND AUTOMATION EQUIP CO LTD SHUNDE DISTRICT FOSHAN CITY

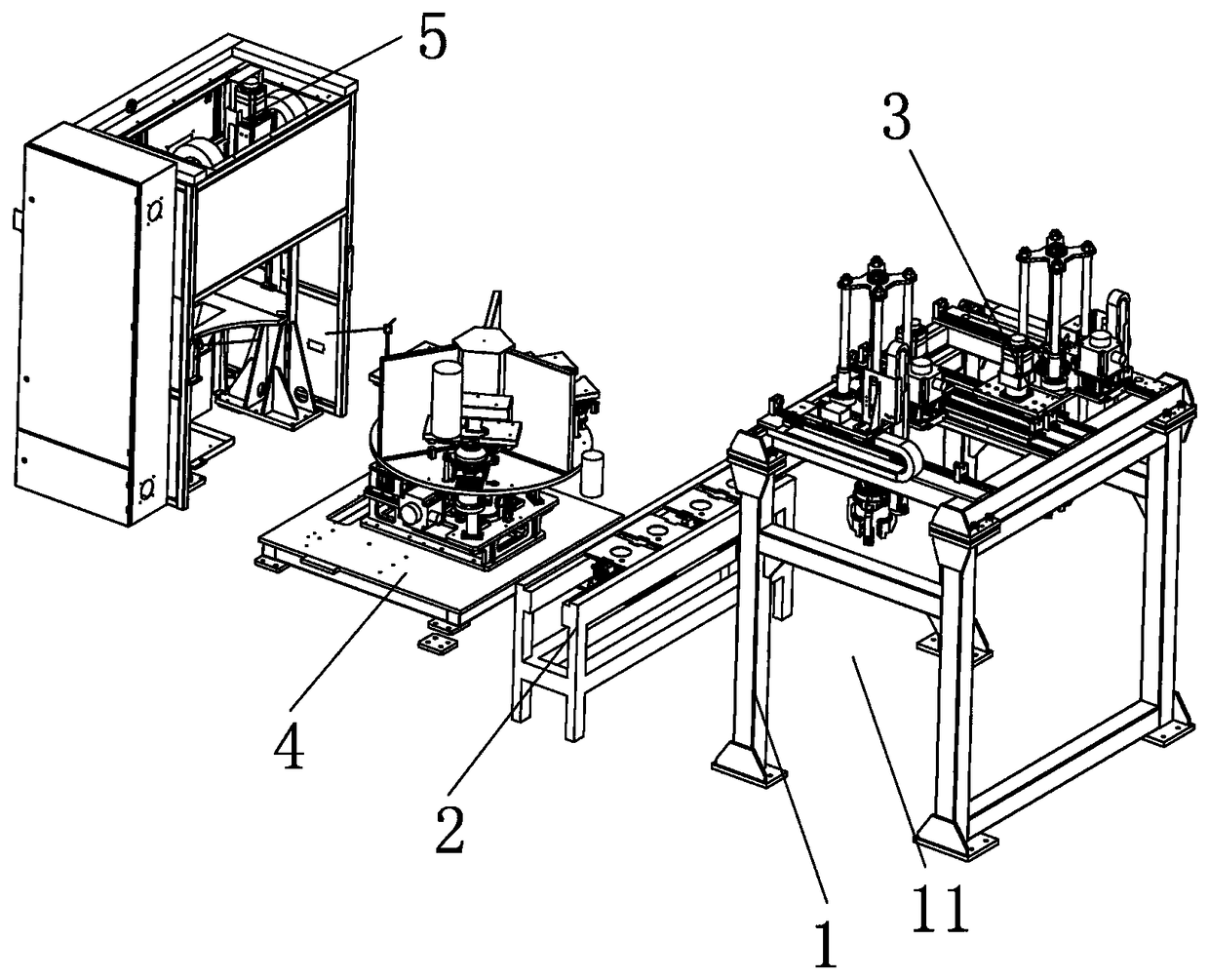

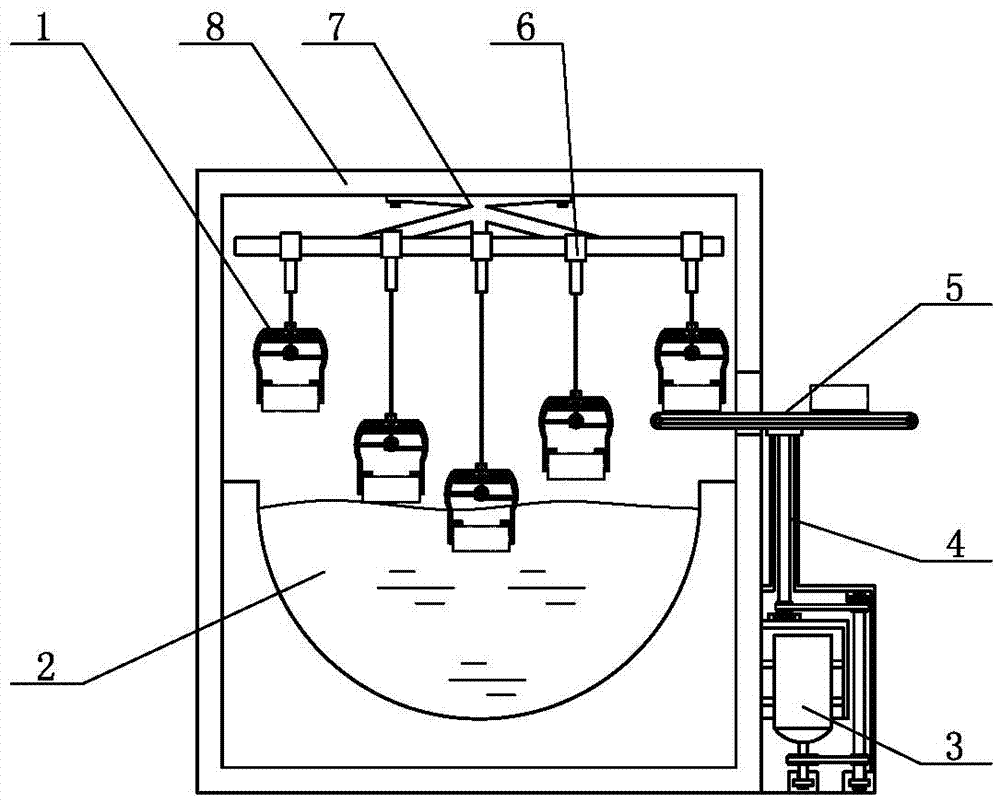

Dedicated quenching device of steel plate spring

ActiveCN106119482AIdeal organizationIdeal performanceFurnace typesHeat treatment process controlCooling curveQuenching

The invention discloses a dedicated quenching device of a steel plate spring, and belongs to the field of heat treatment quenching cooling equipment of steel plate springs. According to a whole quenching and cooling dedicated device designed by an inventor, quenching cooling temperature is controlled through a numeric terminal, the cooling curve approaching to the design technology is achieved, the ideal material structure and the ideal performance can be obtained, and the finished product quality of the steel plate spring is greatly improved. The dedicated quenching device can be suitable for small-batch multispecies steel plate spring heat treatment, the production rhythm is rapid, the device is compact in rhythm, and energy consumption losses are small.

Owner:陕西雷帕得悬架系统有限公司

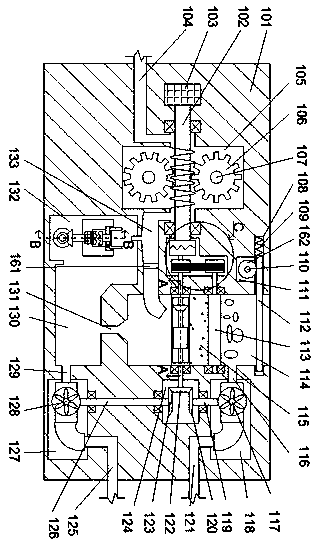

Material strength measurement device

InactiveCN109900555AAvoid injurySimple structureMaterial strength using tensile/compressive forcesMeasurement deviceEngineering

The invention relates to a material strength measurement device. The device of the present invention comprises a machine body and a concrete block transporting cavity disposed in the machine body; a measurement sliding cavity is formed at the center of the concrete block transporting cavity in a communicated manner; a squeezing rod is disposed in the measurement sliding cavity; a measuring assembly is disposed in the squeezing rod; the measurement sliding cavity is provided with a connecting rod rotation cavity in a communicated manner; a squeezing driving assembly is arranged in the connecting rod rotation cavity; the squeezing driving assembly drives the measuring assembly to squeeze a concrete block; the measuring assembly measures the compressive strength of the concrete block; and a pushing plate sliding cavity is arranged to the left side of the measurement sliding cavity. The device has the advantages of full-process mechanic transmission matching, high speed, coherent matching,improved working efficiency, simple operation and high automation degree. With the device adopted, personal safety can be ensured, and an experimental environment can be protected.

Owner:杭州致爱包装制品有限公司

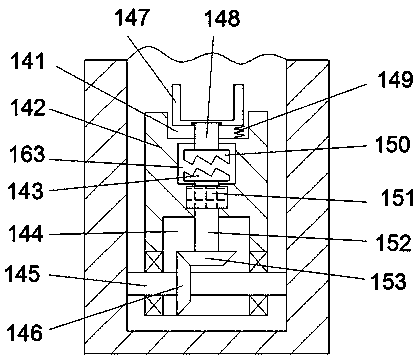

Wind driven generator braking equipment

ActiveCN109869272AHolding brake functionShorten speedWind motor controlMachines/enginesWind drivenScrew thread

The invention discloses wind driven generator braking equipment. The equipment comprises a drum brake and a drum brake cavity formed in the drum brake. A body is arranged in the drum brake cavity, andinternally provided with a braking trigger cavity. A center threaded rod extending front and back is arranged in the braking trigger cavity and connected with a push block in a screw thread fit mode.The push block is connected with a lifting block in an abutting mode. The lifting block is connected with a lifting rod in a stationary fit mode. A gear and rack engaging cavity is formed above the braking trigger cavity. The invention aims at designing a device capable of performing braking on a wind driven generator when the rotating speed of the wind driven generator reaches a certain value soas to reduce the speed of the wind driven generator device.

Owner:青岛百恒新能源技术有限公司

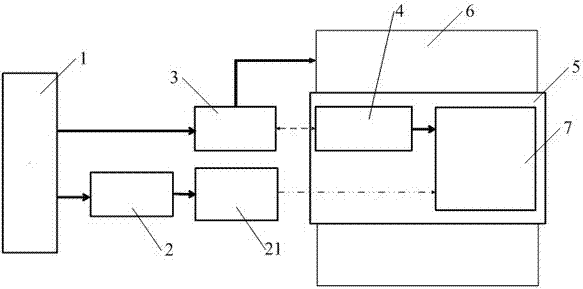

Automatic white balance adjustment equipment and method for wireless communication of liquid crystal display

InactiveCN107293241AReduce homework actionsImprove efficiencyStatic indicating devicesLiquid-crystal displayDisplay device

The invention relates to automatic white balance adjustment equipment and method for wireless communication of a liquid crystal display. The equipment comprises an industrial control computer, a color analyzer, a wireless communication control card, a wireless signal generator, a collector plate and a transport line body, wherein the industrial control computer is connected with the color analyzer and the wireless communication control card respectively, a signal communication hole of the wireless communication control card faces the transport line body, the wireless signal generator is arranged on the collector plate and connected with a display to be adjusted on the collector plate, a signal communication hole of the wireless signal generator is outward attached to the side of the collector plate, and the control end of the transport line body is connected with the wireless communication control card; and when the transport line body transports the collector plate to a debugging station, the signal communication hole of the wireless signal generator is opposite to the signal communication hole of the wireless communication control card, so that the wireless signal generator is wirelessly connected with the wireless communication control card. Compared with the prior art, the equipment and the method have the advantages of reducing the operation, improving the efficiency, improving the quality and the like.

Owner:L&T DISPLAY TECH FUJIAN

A silicon industrial park wastewater treatment process and device

ActiveCN112851018BSolve the problem of low carbon nitrogen ratioEfficient removalTreatment involving filtrationTreatment with aerobic and anaerobic processesAmmoniacal nitrogenSewage treatment

The invention belongs to the technical field of sewage treatment, and relates to a silicon industrial park wastewater treatment process and device. For silicon industrial parks in the prior art, the mixed treatment of white carbon black wastewater and comprehensive wastewater in the park has high levels of salt and difficult biochemistry, and when the two types of wastewater are treated separately, ammonia nitrogen and total nitrogen in the comprehensive wastewater of the park are high, and the carbon-nitrogen ratio is low , the treatment effect of the traditional denitrification process is not ideal, and it is necessary to add a large amount of carbon source to the technical problem. This scheme provides a silicon industrial park wastewater treatment process. By taking out a small part of the wastewater bypass branch in the white carbon black wastewater, the sulfate in the white carbon black wastewater is converted into reduced sulfur, which is a sulfur autotrophic denitrification bacteria. The group provides a sulfur source, and realizes the removal of nitrogen pollution from wastewater with a low carbon-to-nitrogen ratio under the condition of no carbon source addition. This solution also provides a dissimilation / denitrification device, which can realize sulfur conversion and sulfur autotrophic denitrification reaction in the same device, and realize efficient treatment of two different types of wastewater, with compact rhythm, no transfer process, and efficient reaction .

Owner:安徽环境科技集团股份有限公司

Convertible charging interface assembly and electric vehicle

ActiveCN109921247BReduce failureLow costCharging stationsCouplings bases/casesElectric vehicleMechanical engineering

The invention relates to the technical field of charging small doors for electric vehicles, and aims to solve the problems that the existing charging interface of electric vehicles occupies a large surface area of the body and has poor protection performance. Therefore, the invention provides a convertible charging interface assembly and an electric vehicle , the charging structure assembly includes: an insertion port; a rotating part, which at least includes a first charging socket and a second charging socket; a driving part, which is connected with the rotating part, and is used to drive the rotating part to rotate; the rotating part is configured to be able to drive Under the action of the component, the plug-in opening is selectively aligned with the first charging socket or the second charging socket, thereby forming a charging interface. The charging interface assembly provided by the invention occupies a relatively small body surface, is easy to operate, reduces the probability of contact with external rainwater, dust, and hard objects, and helps save costs for users.

Owner:NIO ANHUI HLDG CO LTD

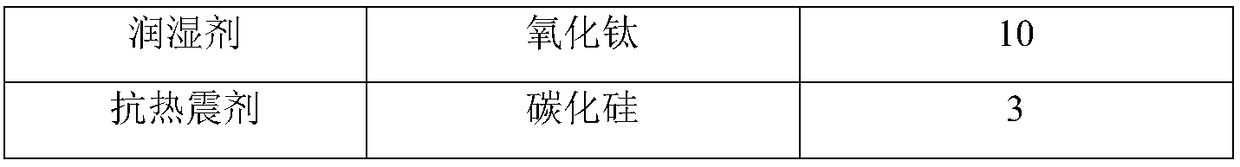

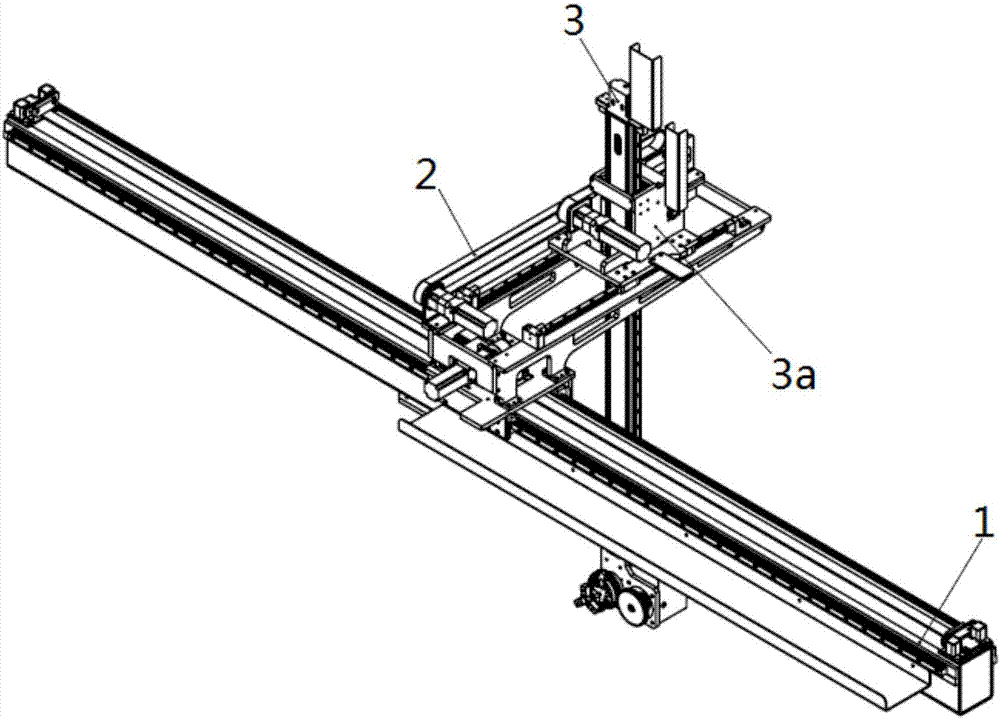

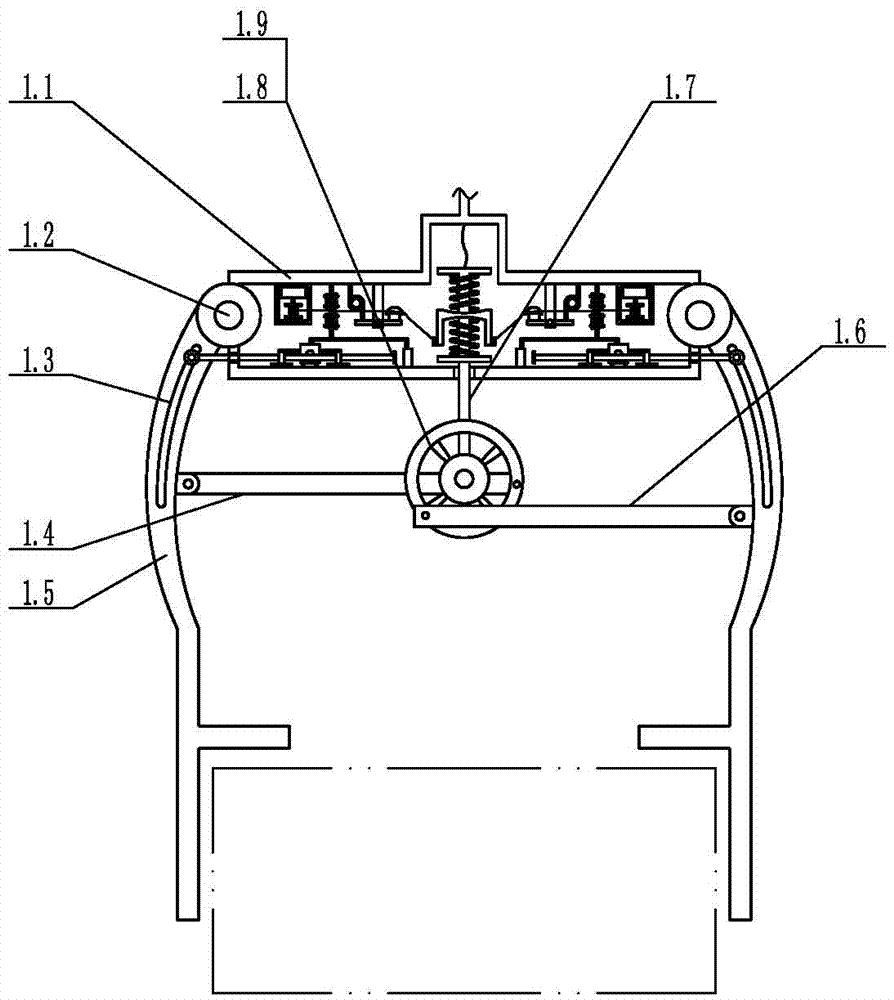

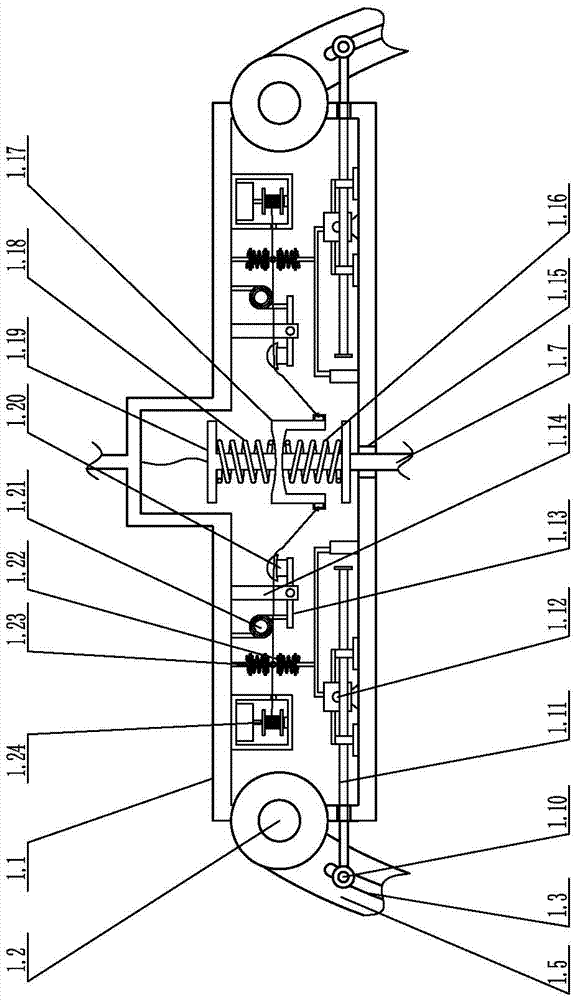

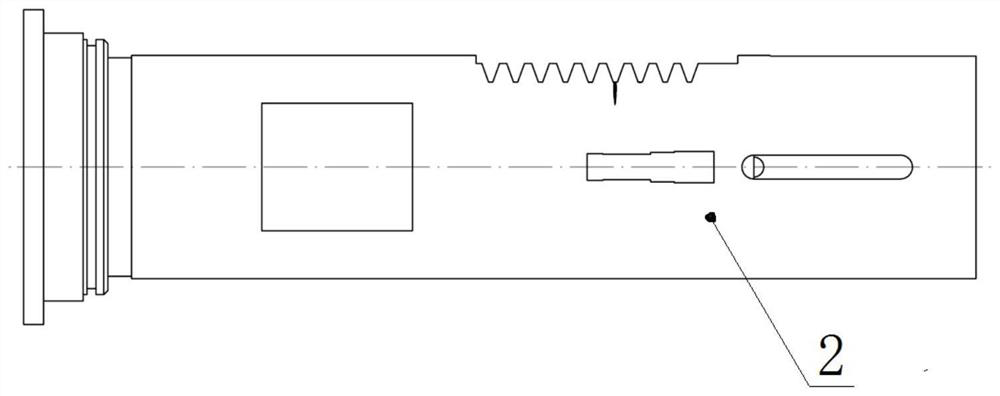

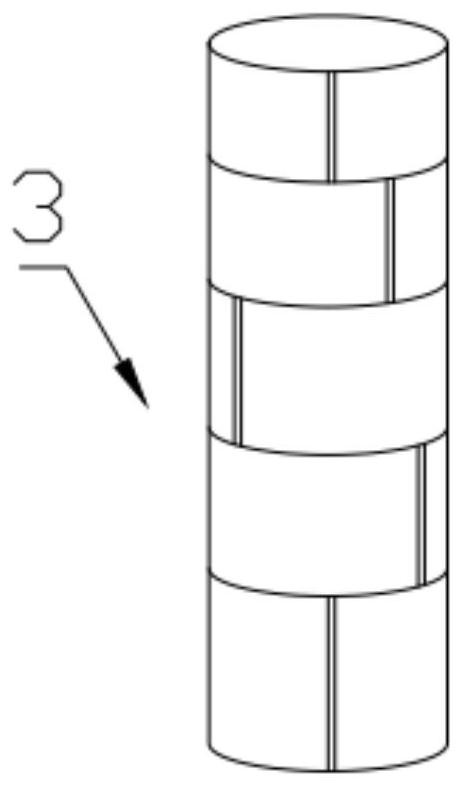

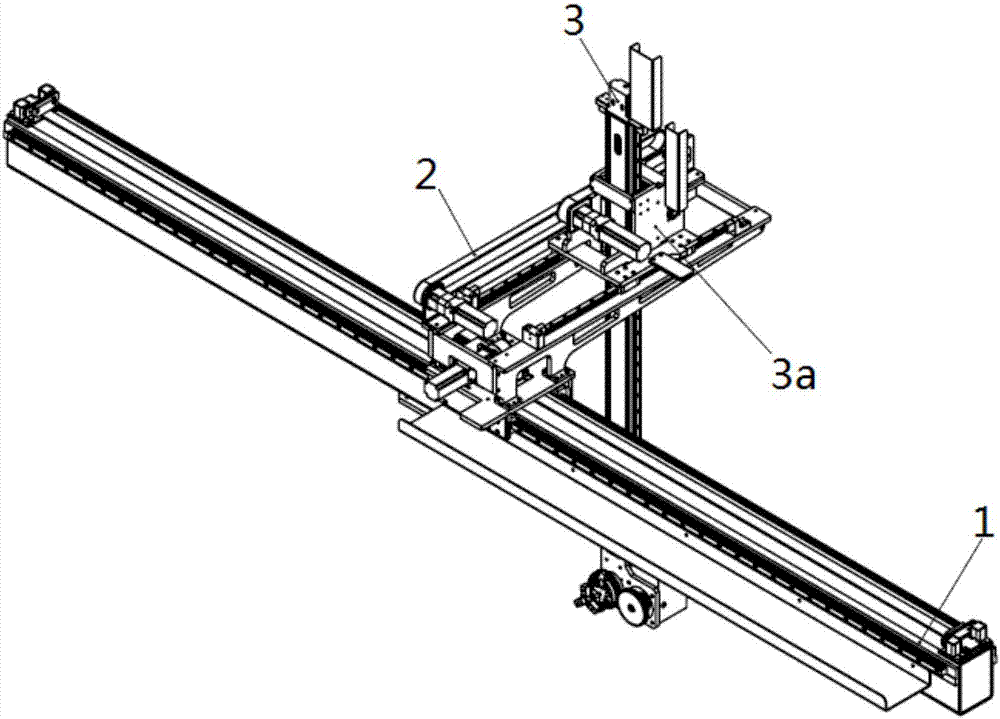

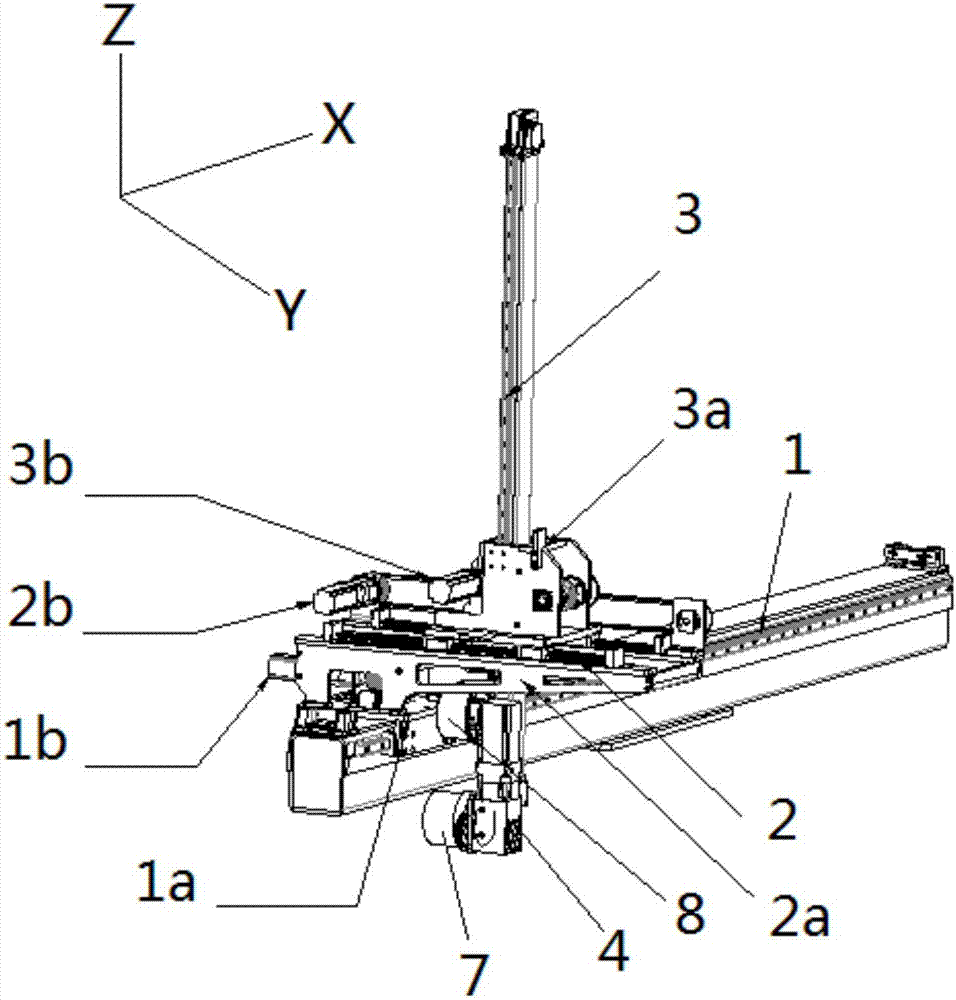

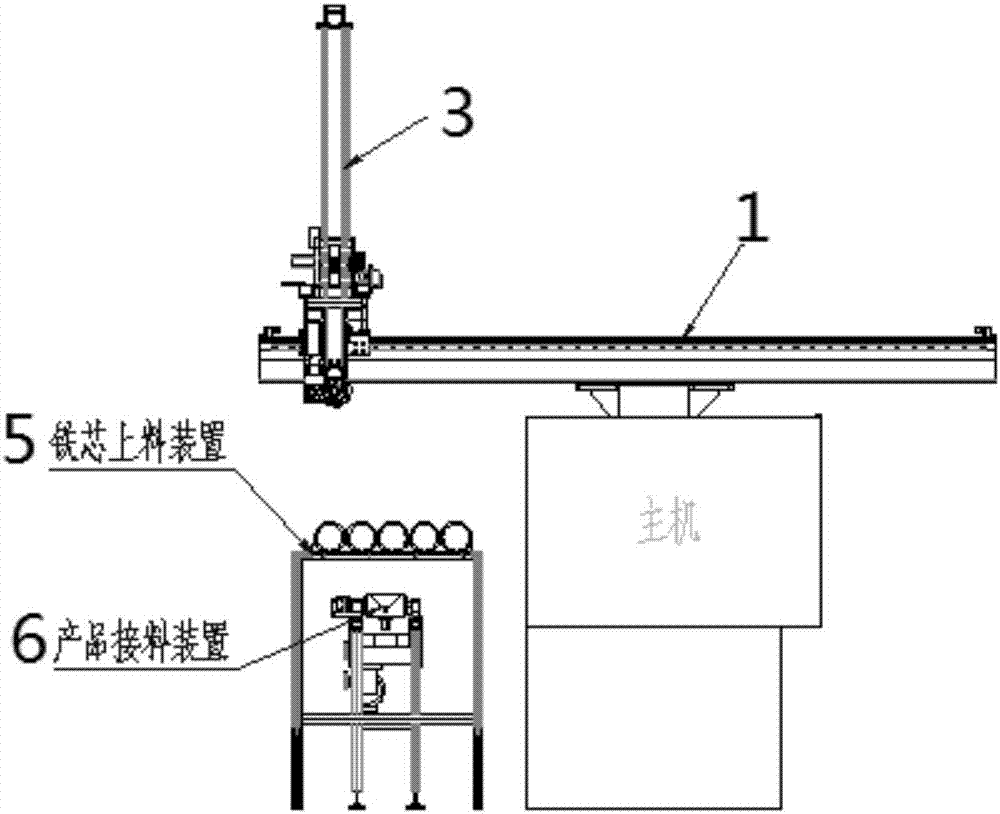

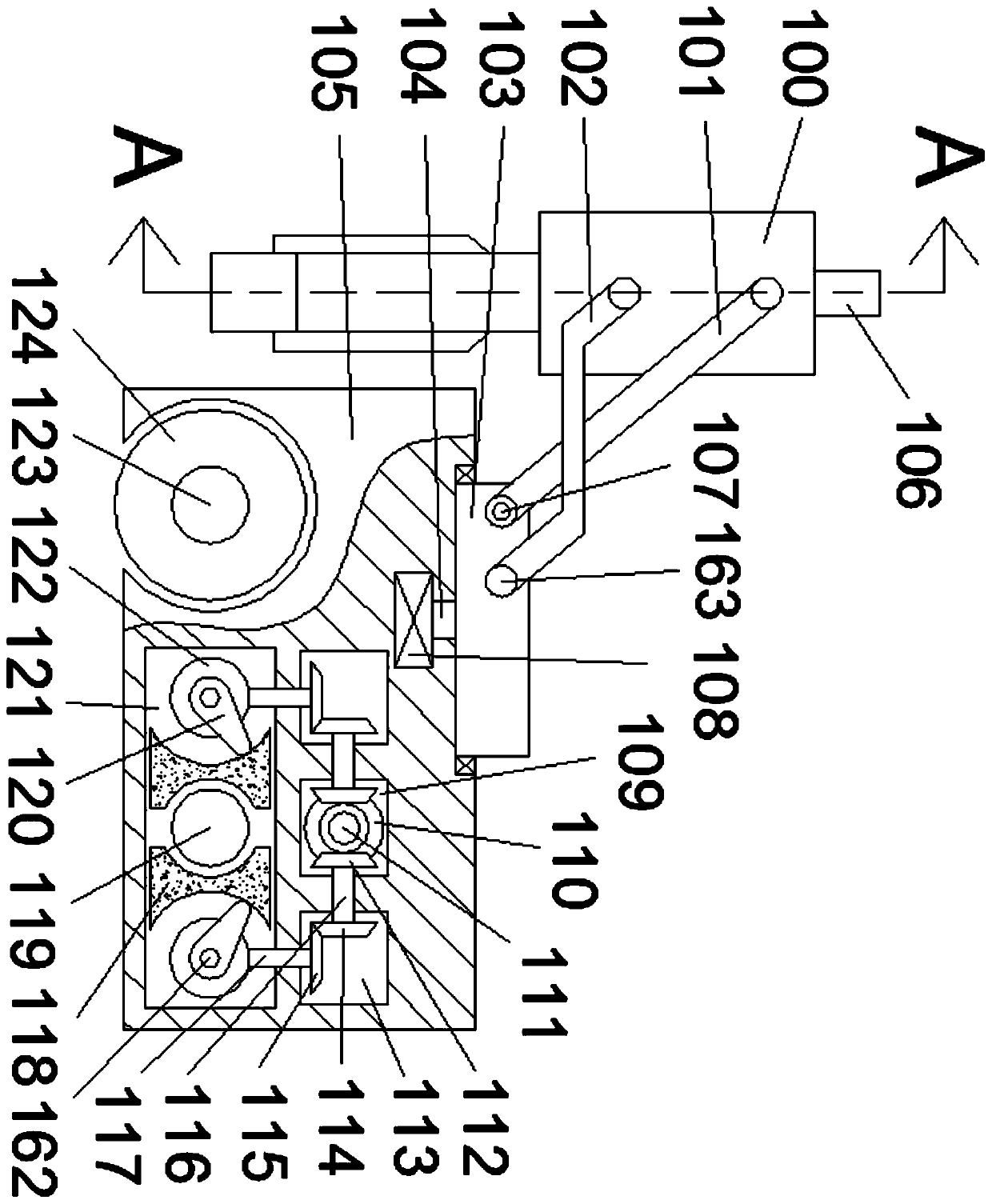

A kind of production equipment of steel pipe thread sleeve with iron core

InactiveCN105479663BImprove production efficiencyImprove demoulding efficiencyCoatingsEngineeringConveyor belt

The invention relates to a manufacturing device with an iron core steel pipe thread bushing. The manufacturing device comprises a four-axis linkage track mechanism and a finished product conveying mechanism. The four-axis linkage track mechanism comprises an X-axis track, a Y-axis moving track, a Z-axis moving track and an R-axis rotation mechanism. The R-axis rotation mechanism is arranged at the bottom of the Z-axis moving track and connected with a demolding grab hand. The portion, located above the demolding grab hand, of the Z-axis moving track is fixedly provided with an iron core grab hand. The R-axis rotation mechanism comprises a drive servo motor and a transmission mechanism. The demolding grab hand comprises a screwing clamping jaw and a pneumatic clamping jaw. The R-axis rotation mechanism is used for driving the screwing clamping jaw to rotate so that a product can be demolded. After demolding, the pneumatic clamping jaw clamps the product. The finished product conveying mechanism comprises a conveyor belt. The start portion of the conveyor belt is provided with a receiving block. The receiving block is provided with a V-shaped receiving opening and driven by an overturning device to turn over by 90 degrees so that the product can stand. The receiving block is further provided with a push device used for pushing the product to the conveyor belt after the receiving block is turned over.

Owner:上海宝钢工业有限公司

Digital quenching equipment for leaf springs

ActiveCN106244778BImprove finished product qualityReduce energy lossFurnace typesHeat treatment process controlCooling curveTemperature control

The invention discloses a digital quenching device for a steel plate spring, and belongs to the field of heat treatment quenching and cooling devices for steel plate springs. The quenching and cooling temperature of the complete dedicated quenching and cooling device, designed by an applicant, is controlled by a digital terminal to obtain a cooling curve approaching to the cooling curve in the design technology, an ideal material structure is obtained, high performance is achieved, and the finished product quality of the steel plate spring is improved greatly. The digital quenching device is suitable for heat treatment of small-batch and multiple-variety steel plate springs, the production speed is high, the device structure is compact, and energy loss is low. An intelligent temperature control system is adopted to strictly control the heating quality, and the temperature uniformity of a quenching bath and the surface decarburization control index of the product are remarkably improved.

Owner:SHANDONG LEOPARD AUTOMOTIVE HLDG

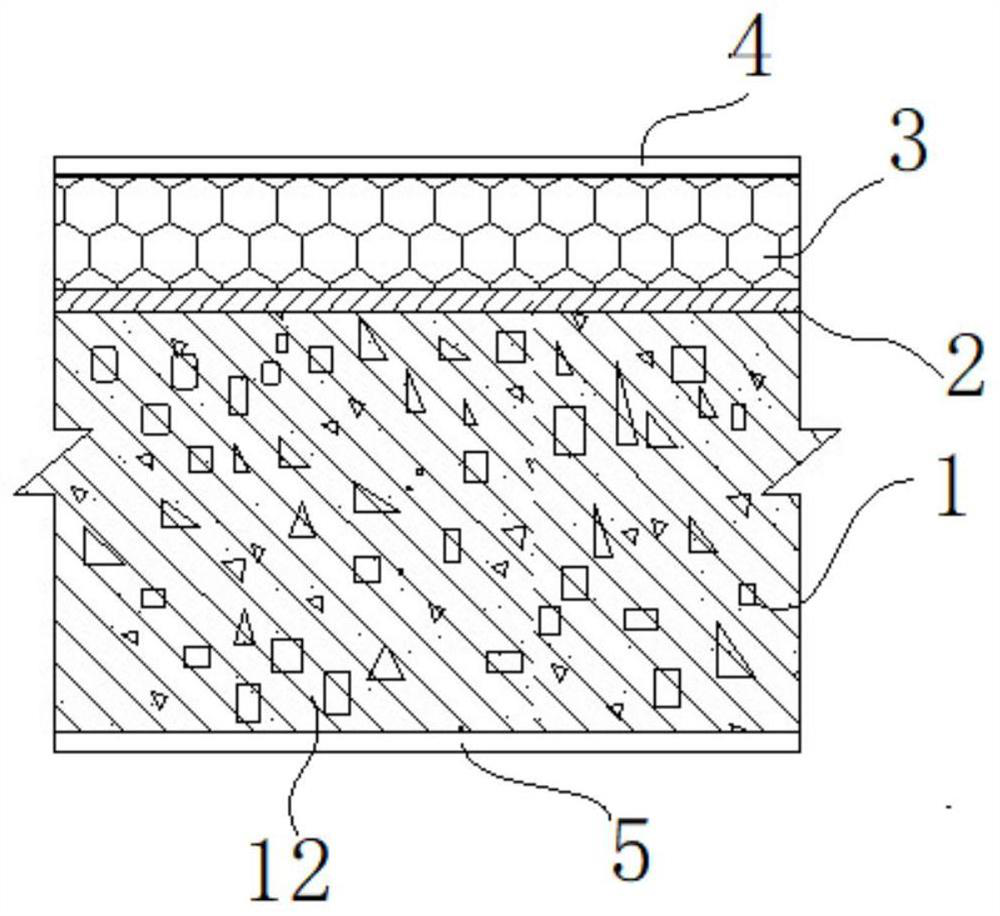

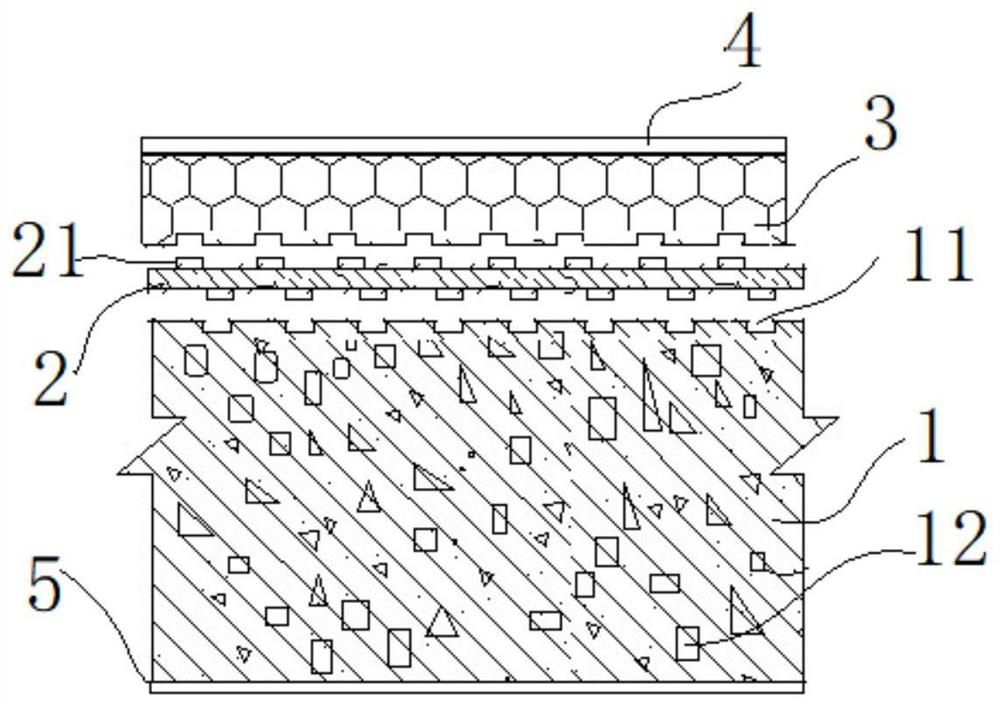

3D type soft heat preservation floor and manufacturing process thereof

InactiveCN112026284AImprove buffering effectWaterproofCovering/liningsSynthetic resin layered productsHeat conservationProcess engineering

The invention discloses a 3D type soft heat preservation floor and a manufacturing process thereof, and belongs to the technical field of plate processing. The 3D type soft heat preservation floor comprises a balance layer, a soft base plate, a cloth fiber layer, a heat preservation rock wool layer and a 3D visual effect layer which are distributed in a stacked mode from bottom to top. When the structure of the floor is distributed in a stacked mode, the cloth fiber layer can be impregnated in glue, thus horizontal friction force between the soft base plate and the heat preservation rock woollayer is improved, meanwhile, the soft base plate and the heat preservation rock wool layer are firmly bonded in the vertical direction, the stacked buffering capacity and foot feeling of the soft base plate and the heat preservation rock wool layer are relatively good, and when objects such as cups, mobile phones and tablet personal computers fall on the floor, breakage is avoided. The balance layer is mainly used for preventing water and moisture in the cement floor from corroding the interior of the soft heat preservation floor, and meanwhile the effect of protecting the internal stress balance of the floor is achieved. The problems that an existing composite wood floor is high in production cost, the phenomena of glue failure and deformation are likely to happen, impact resistance is poor, and the visual effect is single are solved.

Owner:ANHUI AIYALUN NEW MATERIAL TECH CO LTD

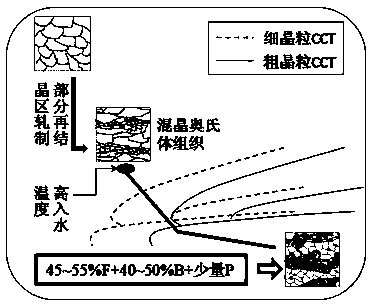

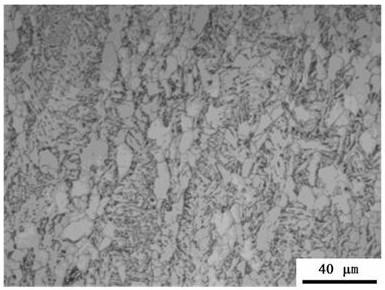

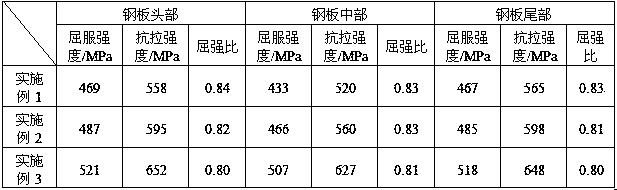

Controlled rolling and controlled cooling method for steel with low yield ratio and low welding crack sensitivity

ActiveCN108103408BHyposensitivity indexImprove solderabilityFurnace typesMetal rolling arrangementsChemical compositionMetallurgy

The invention relates to a controlled rolling and cooling method for low-yield ratio low welding crack-sensitivity steel. The steel comprises the compositions of, by weight, less than or equal to 0.10% of C, 0.30-0.50% of Si, 1.2-1.8% of Mn, less than or equal to 0.020% of P, less than or equal to 0.010% of S, 0.010-0.050% of Nb, 0.01-0.03% of Ti, less than or equal to 0.30% of Cr, 0.02-0.06% of Alt, less than or equal to 0.0005% of B, and the balance Fe and unavoidable impurity elements, wherein C*Nb is equal to 0.18-0.22ppm, and Pcm is less than or equal to 0.20%. A steel plate comprises 45-55% of ferrite, 40-50% of bainite, and a small amount of pearlite, and the yield ratio of the steel plate is less than or equal to 0.85%. The steel plate produced by the controlled rolling and coolingmethod has low cost and high production efficiency and the plate shape is easy to control.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

A semi-solid thixotropic extrusion device for deformed aluminum alloy complex shell parts and its application method

The invention discloses a wrought aluminum alloy complex shell semisolid thixotropic extrusion device and a using method of the wrought aluminum alloy complex shell semisolid thixotropic extrusion device, and relates to a wrought aluminum alloy semisolid thixotropic extrusion device and a using method of the wrought aluminum alloy semisolid thixotropic extrusion device. The technical problems thatan existing manufacturing method for wrought aluminum alloy complex shells is complex in working procedure and low in material utilization rate are solved. The device is composed of a die plate, a female die, an ejector rod, a male die, a male die fixing sleeve and an annular heater. When the male die and the female die are matched, the male die stretches into the female die by 30 mm. The using method of the device comprises the steps that quantitative cutting is carried out to obtain blanks; the device is fixedly installed to a hydraulic machine; 3, the male die and the female die are heated; 4, the product is heated to semisolid temperature; 5, the product is conveyed into a cavity of the female die; 6, die assembling is carried out; 7, online water quenching is carried out; 8, die removal is carried out, and air cooling is carried out to room temperature; and 9, natural aging is carried out after heat treatment and water quenching. The device is simple in structure, and the material utilization rate and the near net forming degree are greatly improved.

Owner:HARBIN INST OF TECH +1

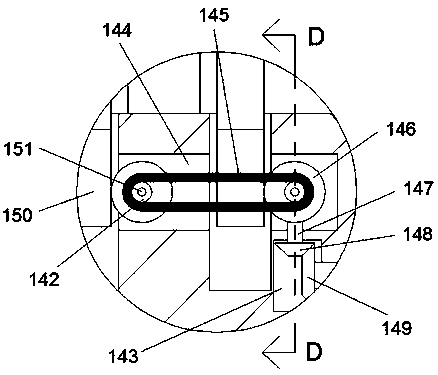

A high-precision flow metering mechanism

ActiveCN109556670BRealize the metering functionTight rhythmRelative volume flow measurementsControl systemGear wheel

The invention relates to a high-precision flow metering mechanism, and belongs to a fuel metering device of a fuel control system. The mechanism comprises a valve element, a bushing, a housing and anangular displacement measuring assembly. The angular displacement measuring assembly comprises a first sector gear, a second sector gear, a spring, an angular displacement sensor and a rotating shaft.According to the high-precision flow metering mechanism, the axial position size of a metering valve assembly can be maximally improved, position signals of the valve element can be transmitted withhigh precision, and meanwhile the angular displacement sensor can be used as a sensing element for receiving and transmitting the position signals of the valve element.

Owner:XIAN AERO ENGINE CONTROLS

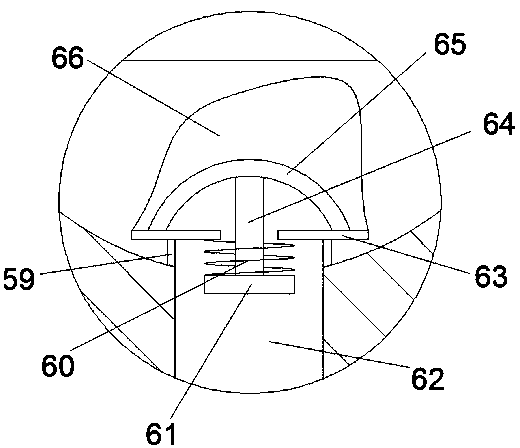

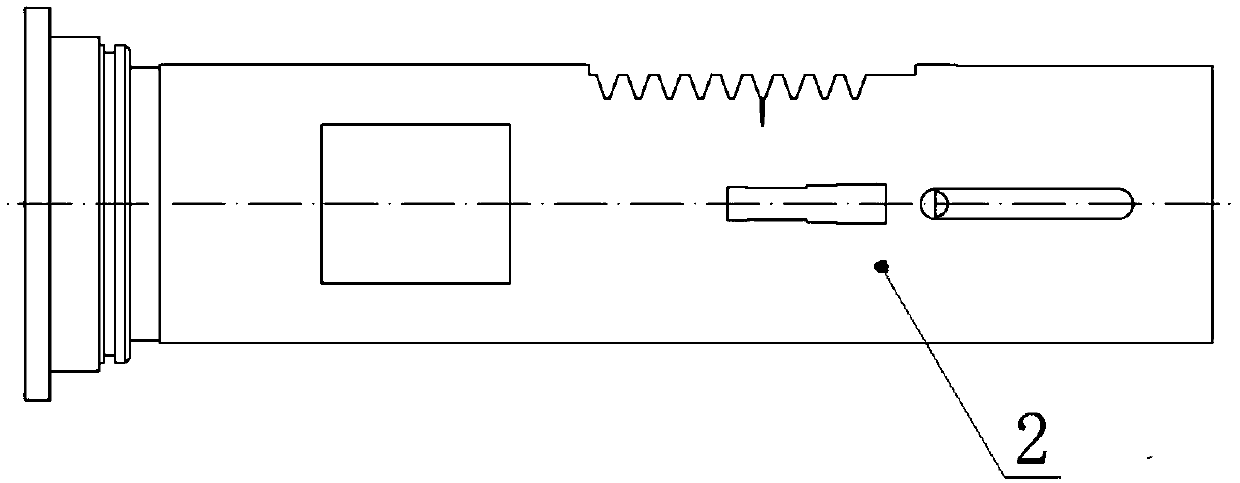

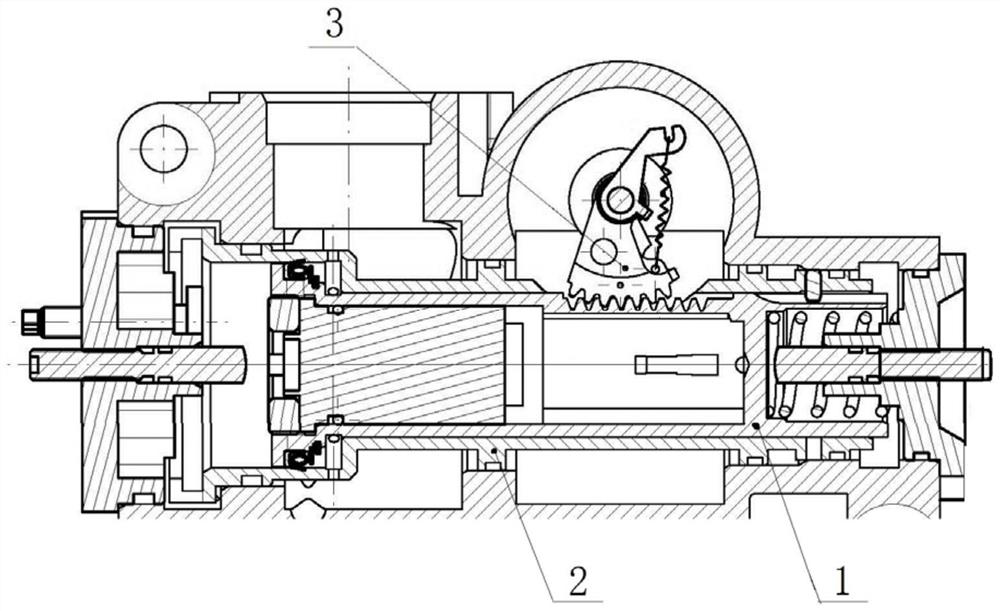

Elastic locking device for turbofan engine rotor disassembling

PendingCN112091863AThe overall structure is simpleTight rhythmPump componentsWork holdersTurbofanStructural engineering

The invention discloses an elastic locking device for turbofan engine rotor disassembling, and belongs to the field of large turbofan engine compressor assembling. The device comprises a rotary handle, a supporting rod, a plurality of elastic locking components and a plurality of extrusion components, wherein the rotary handle is provided with a threaded hole, the first end of the supporting rod is provided with an external thread matched with the threaded hole, the supporting rod is sleeved with a spacing bush, and the first end of the spacing bush is close to the rotary handle; and the supporting rod is sleeved with the elastic locking components, the elastic locking components are sequentially arranged at intervals in the direction from the second end of the supporting rod to the firstend of the supporting rod to form elastic locking units, the tail ends of the elastic locking units abut against the tail end of the spacing bush, and the extrusion components are further arranged between the elastic locking units and the supporting rod in a sleeved mode and are sequentially and tightly connected. According to the device, the disassembling and assembling efficiency of an engine rotor can be effectively improved, the risk that parts, especially blades, are scratched due to collision is reduced, and the device is easy to operate, safe and effective.

Owner:CHENGDU ENGINE GROUP

Section type multifunctional expanding fixture

Owner:NANJING KINGYOUNG INTELLIGENT SCI & TECH

A wind turbine braking device

ActiveCN109869272BHolding brake functionShorten speedWind motor controlMachines/enginesGear wheelControl theory

The invention discloses wind driven generator braking equipment. The equipment comprises a drum brake and a drum brake cavity formed in the drum brake. A body is arranged in the drum brake cavity, andinternally provided with a braking trigger cavity. A center threaded rod extending front and back is arranged in the braking trigger cavity and connected with a push block in a screw thread fit mode.The push block is connected with a lifting block in an abutting mode. The lifting block is connected with a lifting rod in a stationary fit mode. A gear and rack engaging cavity is formed above the braking trigger cavity. The invention aims at designing a device capable of performing braking on a wind driven generator when the rotating speed of the wind driven generator reaches a certain value soas to reduce the speed of the wind driven generator device.

Owner:青岛百恒新能源技术有限公司

A manufacturing process of a steel pipe threaded sleeve with an iron core

InactiveCN105583999BImprove production efficiencyImprove demoulding efficiencyCoatingsEngineeringScrew thread

Owner:上海宝钢工业有限公司

Ice unloading device

InactiveCN110790191AAffect loading and unloading workEnsure safetyLifting devicesGear wheelMechanical drive

The invention discloses an ice unloading device which comprises a device body and a front wheel rotating shaft extending in the device body in the front-back direction. The front wheel rotating shaftis rotationally matched and connected with a front wheel, and a rear wheel rotating shaft braking cavity is formed in the right side of the front wheel rotating shaft. A rear wheel axle locking assembly is arranged in the rear wheel rotating shaft braking cavity, and due to the rear wheel axle locking assembly, the whole device can also be in a braking state when being in a smashed ice environment. A synchronous gear engagement cavity is formed in the upper side of the rear wheel axle braking cavity, and a cam synchronous assembly is arranged in the synchronous gear engagement cavity. By meansof the ice unloading device, mechanical drive fit is achieved in the whole process, the rhythm is compact, matching is coherent, the work efficiency of the device is improved, design is small and exquisite, the ice unloading device is suitable for narrow-space operation, operation is easy and convenient, the automation degree is high, energy is saved, and a large amount of labor cost is further reduced.

Owner:ANHUI HUATENG AGRI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com