Segmented outward stretching clamp

A segmented, fixture technology, applied in the field of fixtures, can solve the problems of hidden safety hazards, difficult to apply, and large size of fixtures, achieving compact rhythm, reducing the time to replace fixtures, and small size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

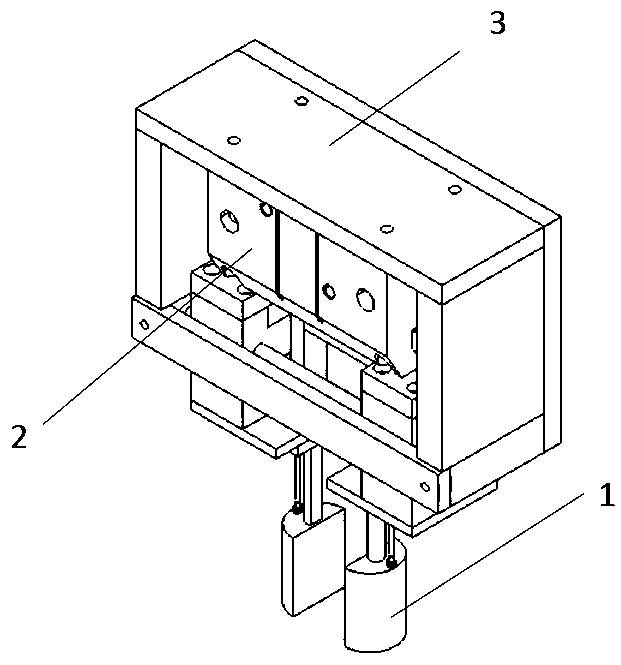

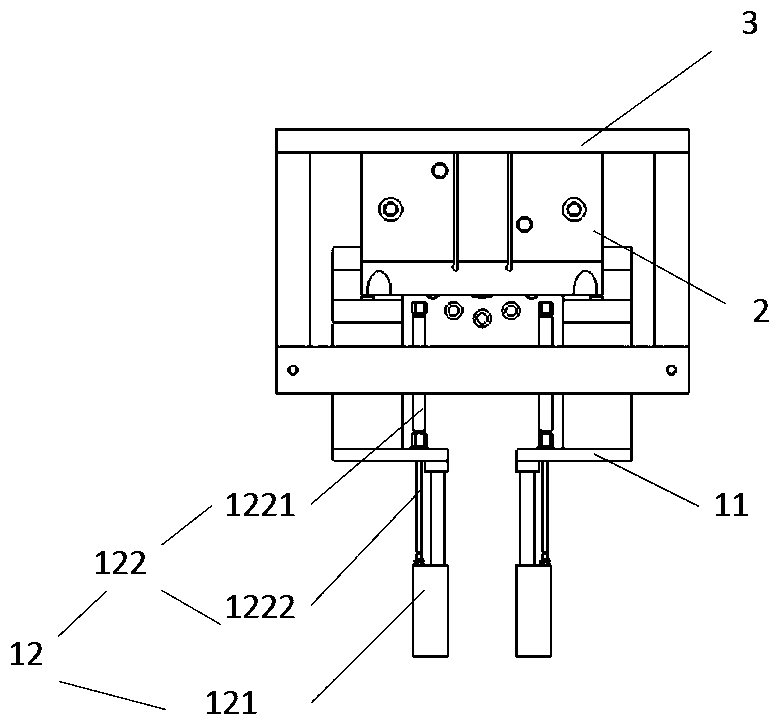

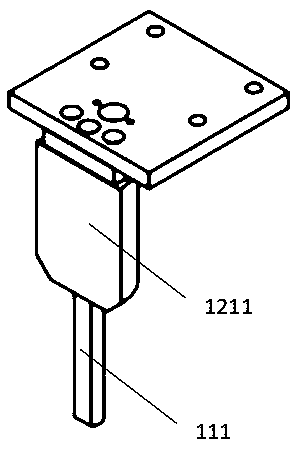

[0018] A kind of segmented external tension clamp provided by the present invention, such as figure 1 , figure 2 with image 3 As shown, it includes a multi-stage external tension mechanism 1, a telescopic cylinder 2 and an installation base 3, and the clamping cylinder 2 is installed on the bottom of the installation base 3; the multi-stage external tension mechanism 1 includes a fixed external tension mechanism 11 and a sliding external tension mechanism. Tension mechanism 12; the fixed external tension mechanism 11 is installed at the bottom of the telescopic cylinder 2; the multi-stage external tension mechanism 1 realizes separation and clamping in the horizontal direction under the push of the telescopic cylinder 2.

[0019] The sliding external tensioning mechanism 12 includes a sliding external tensioning clamp 121 and a push cylinder 122; the sliding extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com