Integrated multi-section multi-functional extension clamping tool

A multi-functional, multi-stage technology, applied in the direction of collets, manufacturing tools, workpiece clamping devices, etc., can solve the problems of lower positioning accuracy, easy to slip, and potential safety hazards, so as to reduce the time for fixture replacement, improve positioning or The effect of assembly precision and tight rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings.

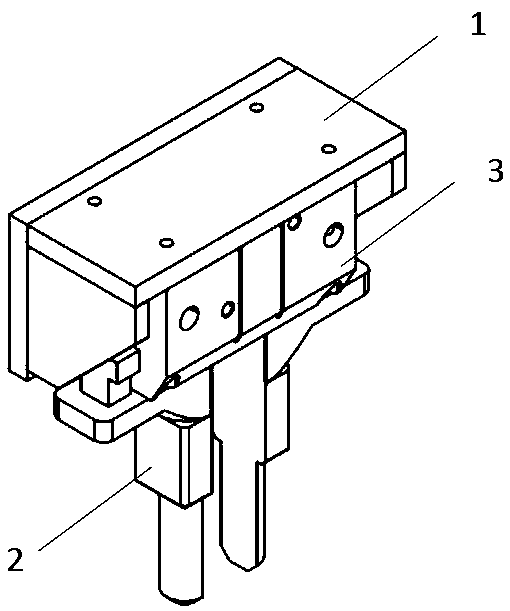

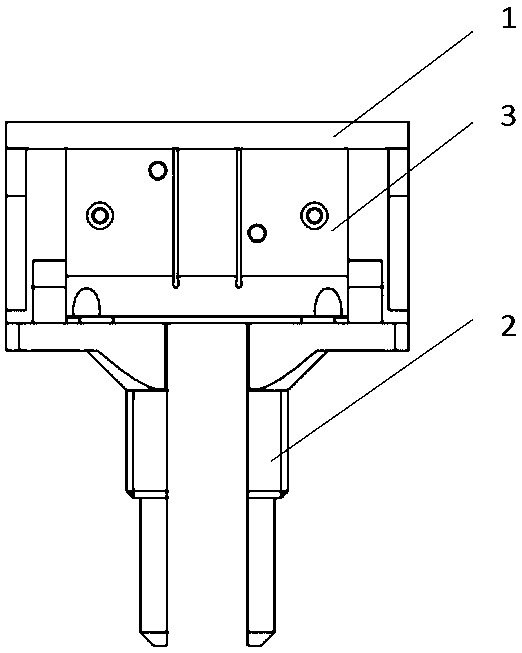

[0015] The present invention provides an integrated multi-segment multifunctional external tensioning fixture, such as figure 1 , figure 2 and image 3 As shown, it includes an installation base 1, a stepped outward expansion fixture 2 and a telescopic cylinder 3. The stepped outward expansion fixture 2 is installed at the bottom of the telescopic cylinder 3, and the telescopic cylinder 3 is installed on the bottom of the installation base 1. The step-shaped outward stretching fixture 2 is opened or closed under the push of the telescopic cylinder 3, the step-shaped outward stretching fixture 2 is a segmented structure, and the contact surface between each segment of the step-shaped clamping fixture 2 and the article into different shapes.

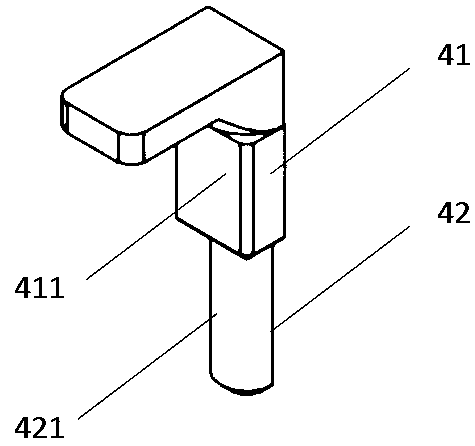

[0016] The stepped outward expansion fixture 2 is an inverted 'L'-shaped claw 4 separated from each other, and the inverted '...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com