Camellia oil cold pressing and molecular distillation device and oil preparation method

A technology of molecular distillation and oil cooling, which is applied in the fields of fat oil/fat refining, fat oil/fat production, fat production, etc. It can solve the problems of wasting raw materials, slow work efficiency, and reducing the oil yield of raw materials, so as to improve the oil yield, Clarity of color, effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below through specific embodiments.

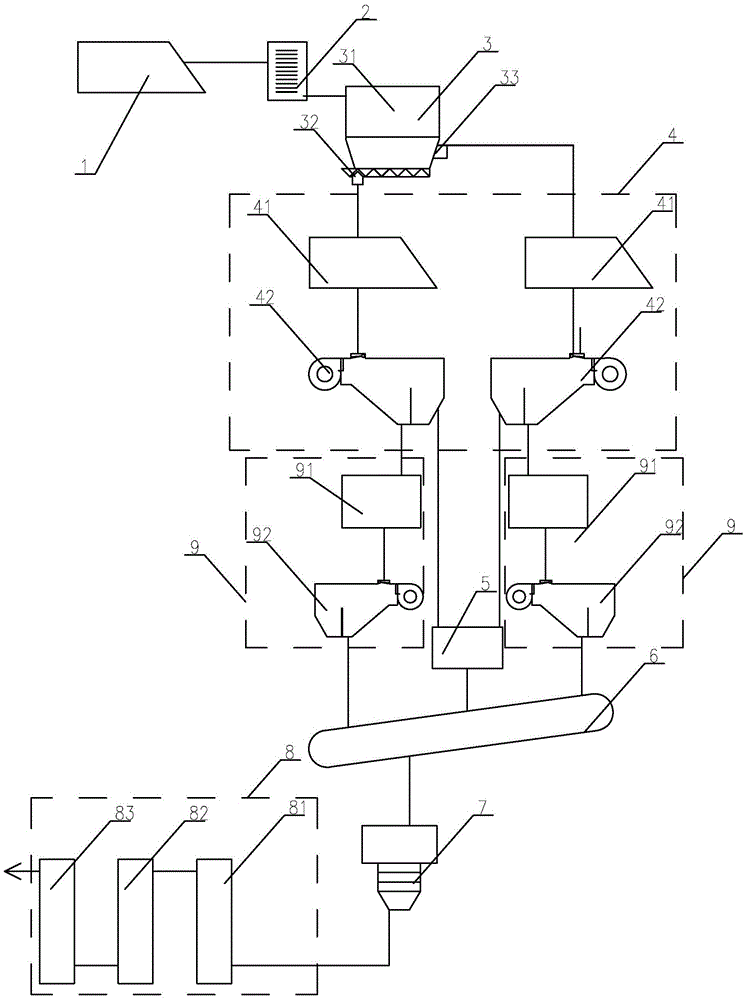

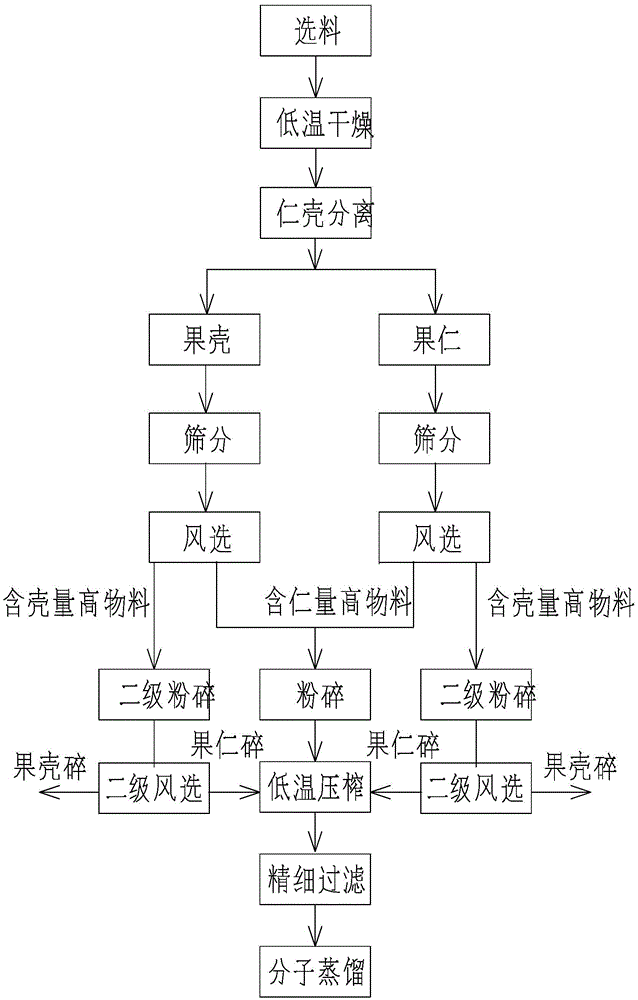

[0028] refer to figure 1 As shown, the camellia oil cold pressing and molecular distillation equipment includes tea seed screening system 1, low temperature drying system 2, shell kernel separation system 3, fine screening system 4, crushing system 5, low temperature pressing system 6, fine Filtration system 7, molecular distillation system 8, secondary crushing and fine screening system 9;

[0029] Tea seed sieving system 1 comprises the vibrating screen that is used to sieve tea seed into the same particle size;

[0030] The low temperature drying system 2 includes a fully sealed pipeline drying device with heat transfer oil as the carrier;

[0031] The shell kernel separation system 3 includes a sheller 31, which is provided with a kernel outlet 32 and a shell outlet 33;

[0032] Fine screening system 4 has two sets, is connected with kernel outlet 32 and shell outlet 33 resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com