Patents

Literature

57results about How to "Keep natural ingredients" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

External oculentum for treating amblyopia, astigmatism, strabismus, myopia and visual fatigue of teenagers

InactiveCN101732506ANo side effectsKeep natural ingredientsSenses disorderInorganic active ingredientsSide effectNear sightedness

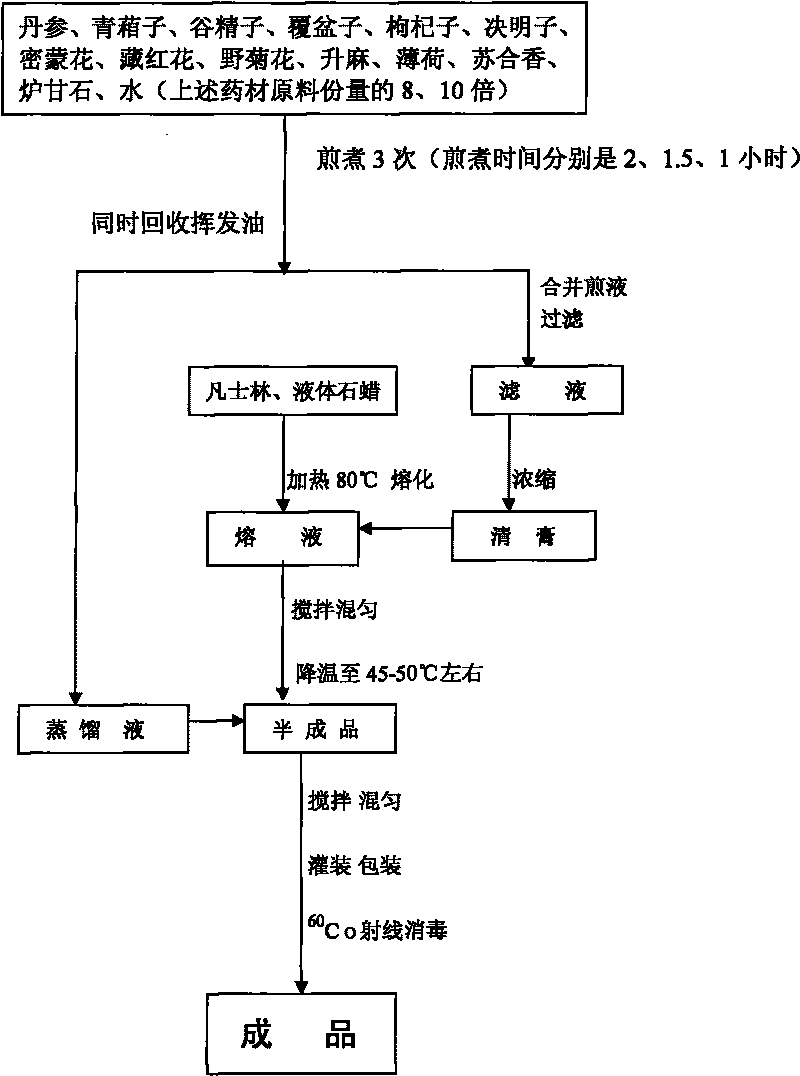

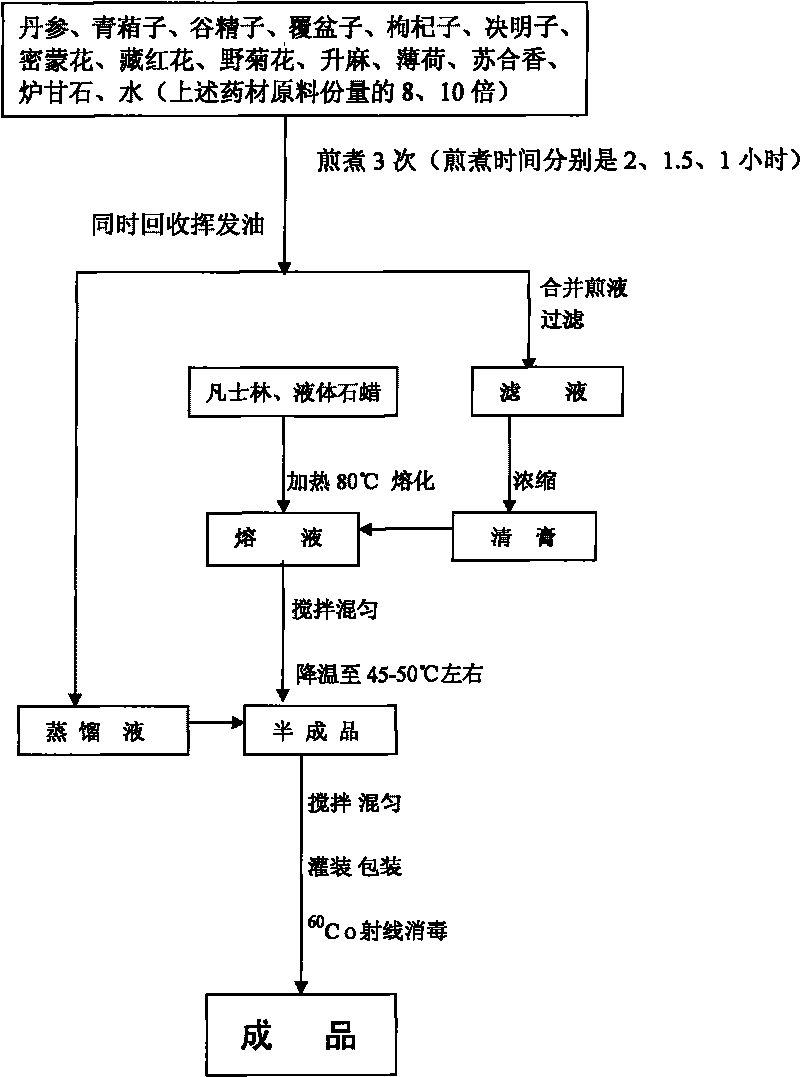

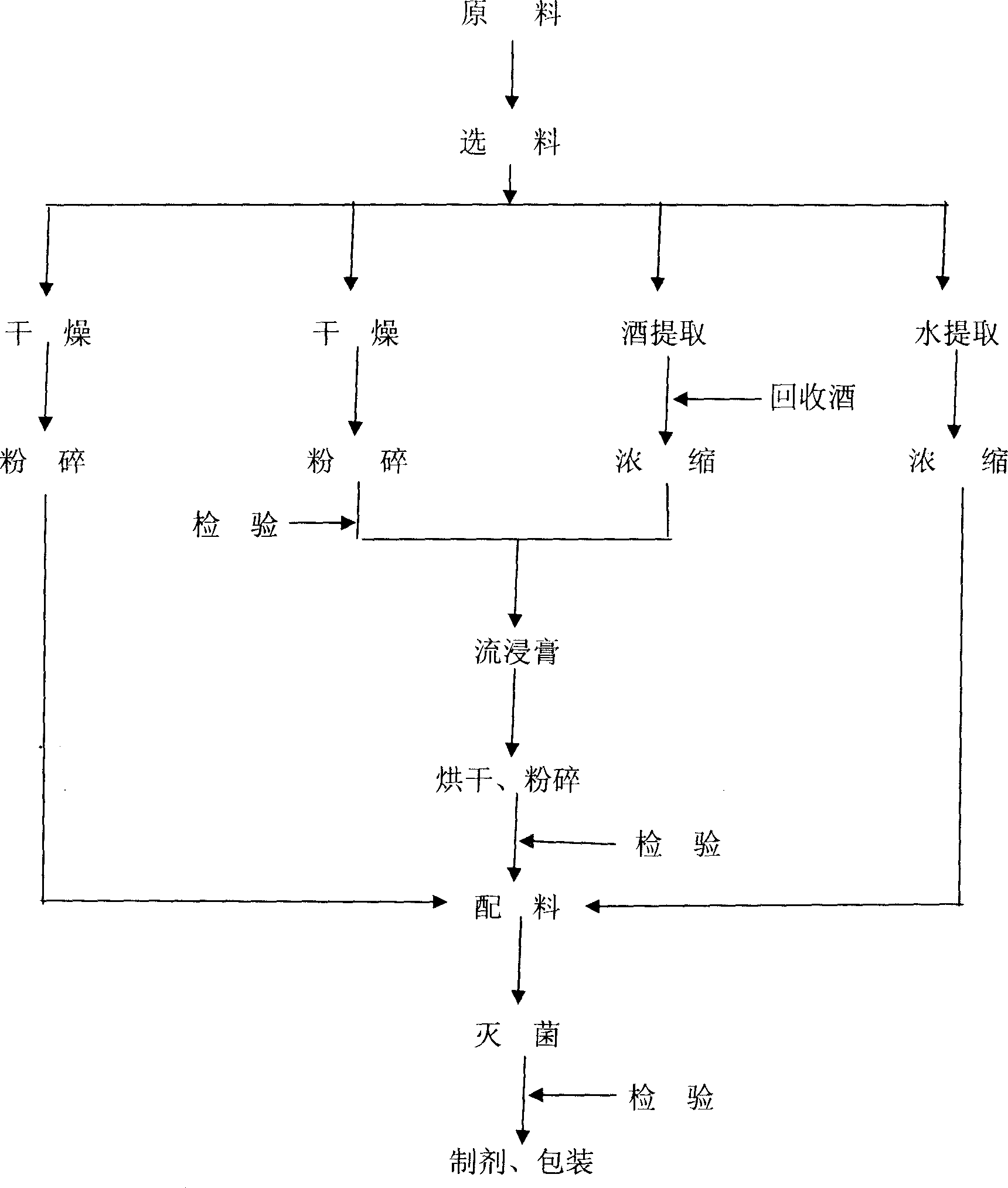

The invention relates to external oculentum for treating amblyopia, astigmatism, strabismus, myopia and visual fatigue of teenagers and a preparation method thereof. The oculentum comprises the following components: 20 to 40 parts of feather cockscomb seed, 20 to 40 parts of flower of small pipewort, 20 to 50 parts of raspberry, 30 to 60 parts of cassia seed, 25 to 50 parts of medlar, 30 to 60 parts of pale butterflybush flower, 20 to 40 parts of saffron, 20 to 40 parts of wild chrysanthemum, 30 to 50 parts of danshen root, 30 to 50 parts of largetrifoliolious bugbane rhizome, 20 to 40 parts of mint, 20 to 40 parts of storax, 30 to 50 parts of calamine, 2,000 to 3,000 parts of Vaseline, 300 to 500 parts of liquid paraffin and appropriate amount of water. The external oculentum is prepared by removing impurities from the medicinal raw materials; decocting, filtering and concentrating the medicinal raw materials; and adding the Vaseline and the liquid paraffin. The external oculentum is scientifically prepared according to compatible principle of monarch, minister, assistant and guide of Chinese medicinal theory. The external oculentum can effectively treat the amblyopia, the astigmatism, the strabismus, the myopia, the visual fatigue and ametropia of the teenagers, and has the advantages of exact curative effect and no toxic or side effects on human bodies.

Owner:赵世伟

Processing method of grain and nut nutrient composite paste food

ActiveCN103404771ASolve the problem of easy oxidationEasy to store for a long timeFood shapingFood preparationNutrientMicroencapsulations

The invention provides a processing method for grain and nut nutrient composite paste food. The mass ratio of the principle raw materials, namely oat to tartary buckwheat to corn to soybean to peanut to apricot kernel to walnut to Chinese chestnut, is (4-8) to (4-8) to (1-4) to (1-4) to (0.5-2) to (0.5-2) to (0.5-2) to (0.5-2). The preparation method comprises the following steps: smashing grains at low temperature; adding complex enzyme for enzymolysis, then puffing and smashing; performing microencapsulation by taking smashed zymolytic nuts as a core material and taking grains and cyclodextrin as embedding media; finally, drying and packaging in a sterile environment so as to prepare the paste food suitable for middle and old aged people. The paste food contains multiple types of grains and nuts, has rich nutrition, is easy to brew, has low probability of agglomerating and clustering, is fine and smooth in taste and easy to digest, and is more suitable for middle and old aged people.

Owner:ZHEJIANG YIPAI FOOD

Production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton

The invention relates to the technical field of condiment production with biological enzyme method, especially relating to a production technology for producing nutrient seasoning powder by enzymatic method with comprehensive utilization of avian skeleton. The production technology includes the following steps: (a) preparing raw materials; (b) performing cooking process; (c) performing a first step of enzymolysis reaction; (d) performing a second step of enzymolysis reaction; (e) performing Maillard reaction; (f) performing homogenizing treatment; and (g) performing powder spraying treatment: subjecting the mixture after homogenizing treatment to powder spraying treatment in a spray tower, sieving to remove the residues with a sieve mesh, and uniformly stirring to obtain the nutrient seasoning powder. The invention uses new biological enzyme to perform enzymolysis and extraction to the nutrients in the avian skeleton completely, so that the prepared condiment has rich nutrition, rich aroma, good quality, pure natural taste, and high product yield.

Owner:广东味霸味业科技有限公司

Preparation and application of nerve tissue matrix derived tissue engineering scaffold material

InactiveCN102218160AKeep natural ingredientsGood biocompatibilityCatheterProsthesisFreeze-dryingDefect repair

The invention discloses preparation and application of a nerve tissue matrix derived tissue engineering scaffold material. A nerve tissue is taken as a raw material, matrix components (including nano-scale collagen microfilaments, fibronectin microfilaments and laminin microfilaments) favorable for nerve regeneration are extracted by means of medicine expansion, mechanical pulverization, enzymolysis treatment, dialysis collection and the like, and immunogenicity components (including Schwann cells, phospholipid and axons) not favorable for nerve regeneration are removed. The prepared nerve tissue matrix derived material can be further prepared into a three-dimensional porous oriented scaffold through oriented crystallization, freeze drying and crosslinking separately or by matching other polymer materials, or is prepared into a nano-scale film by an electrospinning technology, and the film is wound to form a nerve regeneration catheter. The tissue engineering scaffold or catheter prepared by the method is favorable for adhesion, proliferation and migration of seed cells, promotes nerve generation and can be used for never defect repair.

Owner:卢世璧

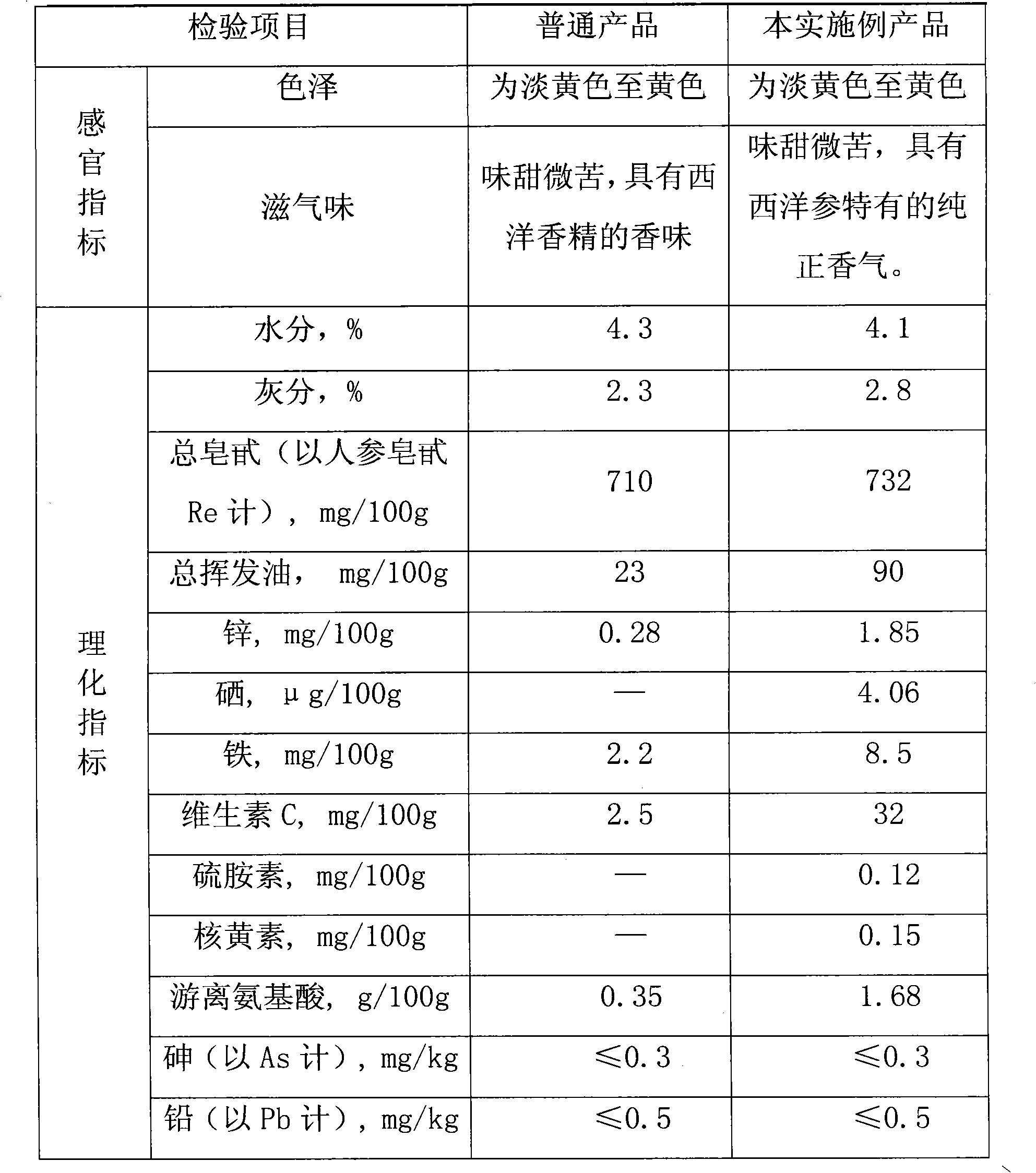

Method for preparing nano American ginseng buccal tablets

InactiveCN102077946ASave edible ethanolKeep natural ingredientsFood shapingFood preparationSolventFlavor

The invention discloses a method for preparing nano American ginseng buccal tablets, which comprises the following steps of: performing nano-scale wall-broken crushing on American ginseng into nano American ginseng powder serving as a raw material for preparing the American ginseng buccal tablets; adding a sweetener, a forming agent and an adhesive, preparing wet granules, drying, and finishing the granules; and adding a lubricating agent and a food flavor for total mixing, tabletting and packaging. An extraction process is avoided, a great amount of extraction solvent, namely edible ethanol, can be saved, the production period is greatly shortened and the production cost can be greatly reduced; more importantly, natural ingredients of the American ginseng, such as various panaxosides, panaxacid, oleanolic acid, various inorganic salts (zinc, selenium, manganese, molybdenum, strontium, copper, iron, potassium and magnesium), various amino acids, various vitamins (B1, B2 and C), volatile components and the like are completely retained, and the prepared nano American ginseng buccal tablets have better health-care effect on a human body and retain the natural flavor of the American ginseng.

Owner:福建省力菲克药业有限公司

Method for preparing quick-cooking round pearl powder

ActiveCN101574133AAdd flavor variationIncrease appetiteFood preparationFlavorCarboxymethyl cellulose

Owner:何登田

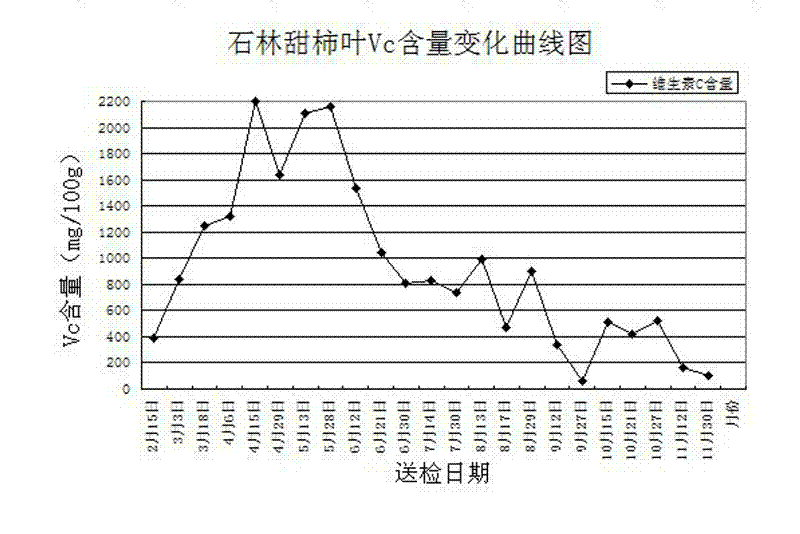

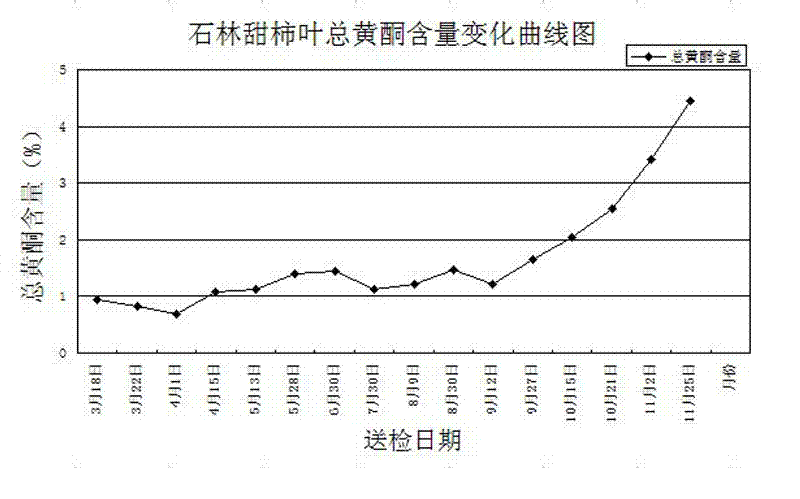

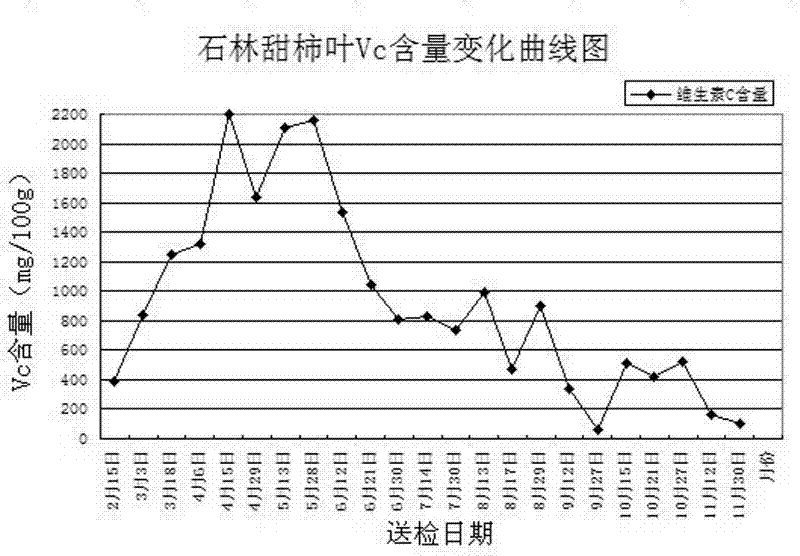

Method for preparing high-altitude sweet persimmon leaf tea

The invention relates to a method for preparing high-altitude sweet persimmon leaf tea, which comprises the following steps of: 1) picking sweet persimmon fresh leaves or sprouts from sweet persimmon trees growing at a place with the altitude of 1200-2000m, wherein the sweet persimmon fresh leaves or sprouts are picked in spring and autumn; 2) adjusting wilting; 3) killing out; 4) twisting; 5) drying and 6) bagging. The method has the beneficial effects that the best picking date of the persimmon fresh leaves is confirmed, so that the standard guidance is provided for producing the sweet persimmon leaf tea with high-content vitamin C and high-content flavone, and the sweet persimmon leaf tea with best taste can be processed by using the method; the preparation method is simple and liable in technology; and the prepared sweet persimmon leaf tea not only maintains the original natural ingredients of persimmon leaves, but also is faint scent and sweet in taste and unique in fragrance, thus being relatively beneficial to the health.

Owner:石林绿汀甜柿产品开发有限公司

Preparation method for instant tremella

InactiveCN102669647AKeep appearanceEasy to overflowClimate change adaptationFood preparationBiotechnologyTremella

The invention relates to a preparation method for instant tremella. The method comprises the steps as follows: steeping tremella in cleaning water, breaking up tremella cells with ultrasonic waves, uniformly spreading, placing on a reticular plate coated with Teflon or a plate with water filtering function, curing with high-temperature steam, and then drying to obtain finished instant tremella. By adoption of the method, the instant tremella retains all the natural elements of tremella and has the advantages of quickness in rehydration, good condition, stability in production, high efficiency, low cost and easiness in automatized mass production.

Owner:CHONGQING UNIV

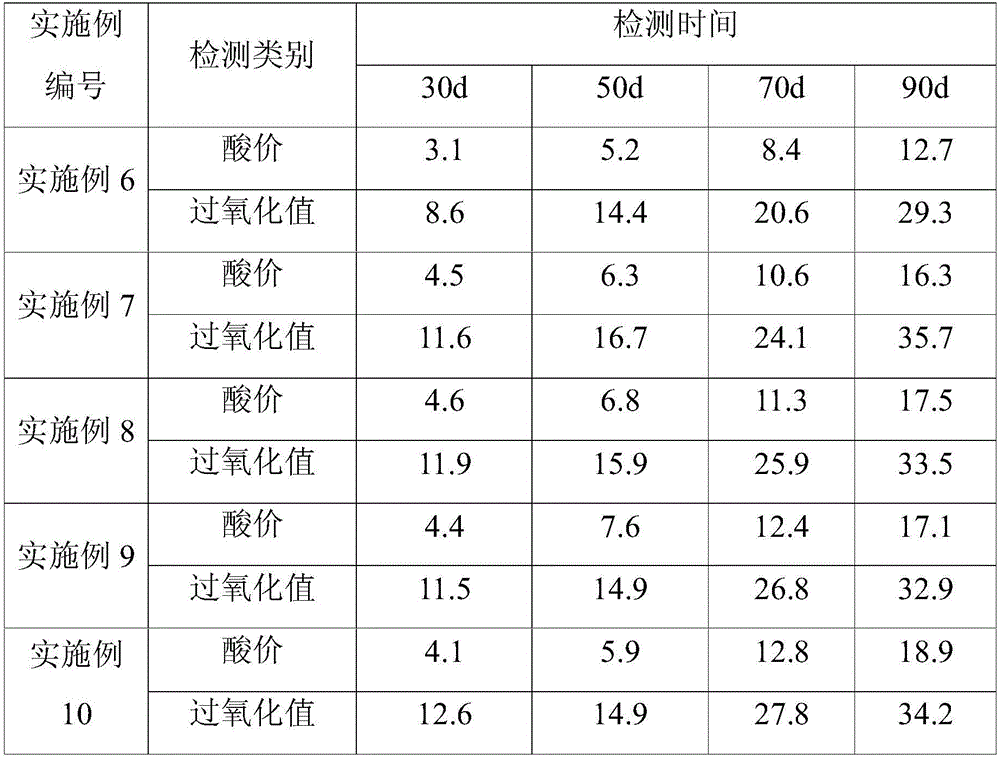

Production technology for preparing fresh zanthoxylum bungeanum oil by pressing method

ActiveCN106509167ASimple production processKeep natural ingredientsEdible oils/fatsZanthoxylum bungeanumEconomic benefits

The invention discloses a production technology for preparing fresh zanthoxylum bungeanum oil by a pressing method. The production technology comprises the following steps of adding water to zanthoxylum bungeanum raw materials, crushing a mixture of the zanthoxylum bungeanum raw materials and the water to obtain zanthoxylum bungeanum pulp in a physical pressing manner; adding salad oil to the zanthoxylum bungeanum pulp, performing uniform stirring, placing the zanthoxylum bungeanum pulp and the salad oil after being uniformly stirred into an ultrasonic wave reaction tank for soaking, and then performing separation so as to obtain water, crude oil and zanthoxylum bungeanum cake impurities; and performing prefiltration and settling on the crude oil to remove zanthoxylum bungeanum dregs, and then performing rectification and separation to remove moisture so as to obtain high-purity zanthoxylum bungeanum refined oil. According to the production technology disclosed by the invention, fresh zanthoxylum bungeanum is used as a raw material, and a normal-temperature pressing manner is used for extracting the zanthoxylum bungeanum oil, so that the production technology of the zanthoxylum bungeanum oil is optimized, and original natural ingredients and physiological activators in the fresh zanthoxylum bungeanum can be reserved to the maximum extent. The condition that high temperature treatment enables substances of amides, protein and the like in volatile oil to be denatured and lost can be avoided, and the oxidative rancidity of quality of the zanthoxylum bungeanum oil can be effectively controlled; and in the processing technology, a cold pressing method is adopted, so that the extraction time can be shortened, and the economic benefits of products can be increased.

Owner:SICHUAN AGRI UNIV +1

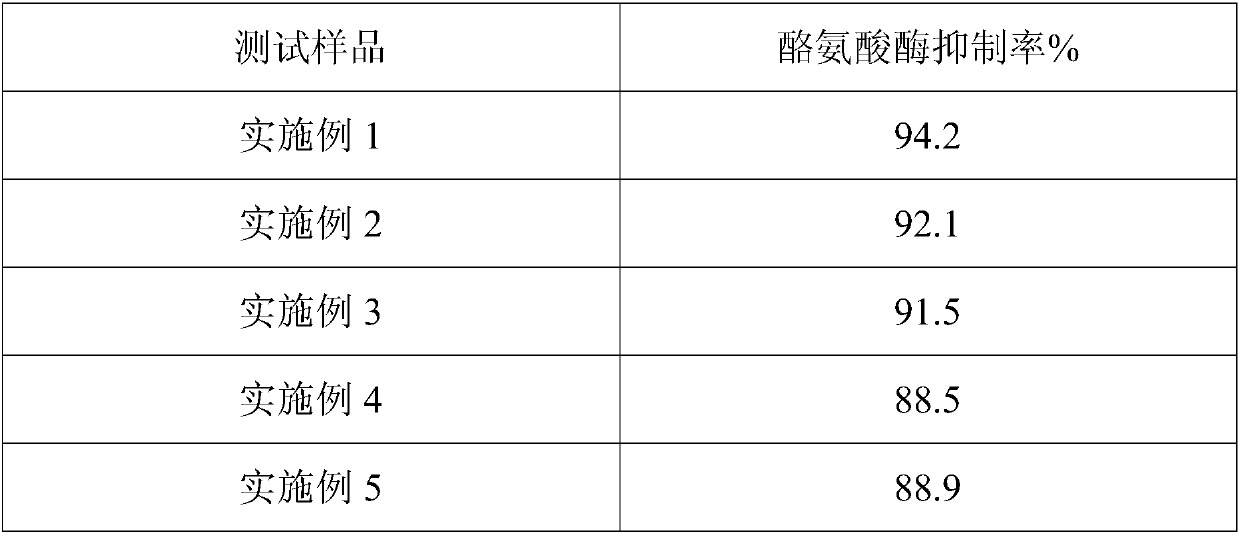

Skin-whitening anti-oxidation plant composition, plant composition fermenting liquid as well as preparation method and application thereof

ActiveCN108042433AAvoid irritationAchieve whiteningCosmetic preparationsToilet preparationsChemical synthesisWhitening Agents

The invention provides a skin-whitening anti-oxidation plant composition. The plant composition comprises the following components in percentage by mass: 15 to 50 percent of ligusticum wallichii, 10 to 40 percent of red paeony root, 10 to 35 percent of radix ampelopsis and 5 to 25 percent of mulberry leaf. The invention also provides skin-whitening anti-oxidation plant composition fermenting liquid as well as a preparation method and application thereof. The skin-whitening anti-oxidation plant composition provided by the invention performs reasonable compounding on the basis of the theory of traditional Chinese medicine and according to the compound principle of assistant and guide, so that the composite achieves the skin-whitening and anti-oxidation effects through synergistic interaction, and avoids irritation caused by the traditional chemically synthesized skin-whitening agent and antioxidant.

Owner:GUANGZHOU HUANYA COSMETIC SCI & TECH CO LTD

Production technology for producing nutrient seasoning powder by biological enzyme techniques using avian skeleton

The invention relates to the technical field of condiment production with biological enzyme method, especially relating to a production technology for producing nutrient seasoning powder by biological enzyme techniques using avian skeleton. The production technology includes (a) preparing raw materials; (b) performing cooking process; (c) performing a first step of enzymolysis reaction; (d) performing a second step of enzymolysis reaction to obtain the enzymolysis liquid; (e) performing Maillard reaction to obtain the reaction liquid; (f) performing fermentation treatment; (g) performing homogenizing treatment; and (h) performing powder spraying treatment: subjecting the mixture after homogenizing treatment to powder spraying treatment in a spray tower, sieving to remove the residues with a sieve mesh, and uniformly stirring to obtain the nutrient seasoning powder. The invention uses new biological enzyme and fermentation techniques to perform enzymolysis and extraction to the nutrients in the avian skeleton completely, so that the prepared condiment has rich nutrition, rich aroma, good quality, pure natural taste, and high product yield.

Owner:广东味霸味业科技有限公司

Preparation method for rose wine

InactiveCN106350377AKeep natural ingredientsThe wine is crystal clear and transparentAlcoholic beverage preparationLocal methodPetal

The invention discloses a preparation method for rose wine. The method comprises the following steps: (1) selecting materials, namely selecting 45-55 parts of bright rose petals without pests and standing by; (2) steaming, namely cleaning the rose petals acquired in the step (1) with clean water and then putting into a container, introducing steam and steaming for 4-6 minutes and standing by; (3) uniformly scattering 0.5-1.5 parts of wine drug into the rose petals after being sterilized in the step (2), putting the rose petals containing the wine drug into a fermentation tank, sealing and fermenting for 14-16 days; and (4) putting the rose petals fermented in the step (3) into a distilling device, and then acquiring the steamed liquid, namely, rose wine. 100% pure rose raw material is adopted in the method; a modern biotechnology is utilized to naturally ferment; on the basis of full maintenance for the traditional unique local-method brewing technology of Bouyei people, the modern production equipment is combined for distilling the rose wine; no starche or saccharic substance participates into fermentation, so that the natural valid attribute of the brewing quality is fully maintained.

Owner:贵州布医坊民族特色用品有限公司

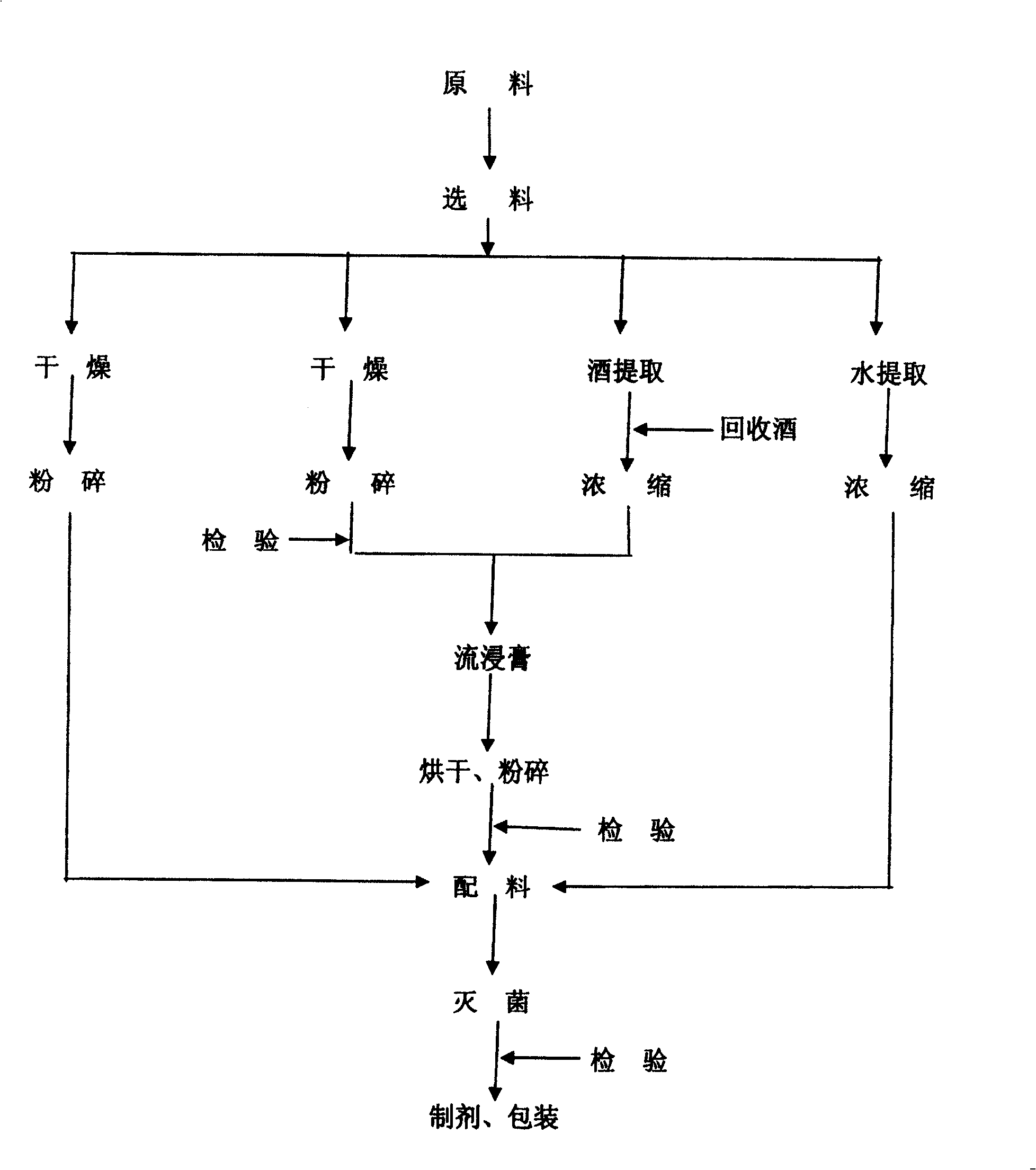

Immune function regulating antibiotic and anti-inflammatory drug with broad spectrum

InactiveCN1565581AGood curative effectShort course of treatmentAntibacterial agentsAntimycoticsMedicineMugwort

Owner:王正坤

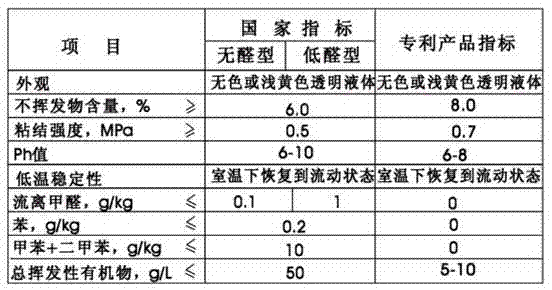

High-standard formaldehyde-free glue and preparation method thereof

InactiveCN102786897AKeep natural ingredientsAvoid pollutionUnsaturated alcohol polymer adhesivesPolyvinyl alcoholPreservative

The invention relates to a high-standard formaldehyde-free glue and a preparation method thereof. The high-standard formaldehyde-free glue is prepared from the following raw materials in percentage by weight: 3 percent of water soluble polyvinyl alcohol, 1 percent of water-retaining agent, 0.1 percent of edible antifoaming agent, 0.1 percent of edible preservative, 0.1 percent of dispersing agent, 1 percent of dispersible emulsoid powder, 0.01 percent of thickener and 94.69 percent of purified water. The preparation method comprises the following steps of mixing the raw materials in proportion, and uniformly stirring the raw materials through a stirring machine; and after uniformly stirring the raw materials, grinding the uniformly stirred mixture into the glue through a stuff grinder. The preparation method has the beneficial effects that temperature raising is not required in the whole preparation process, so that the natural components of a raw stock are kept, and meanwhile the phenomena of environment pollution and energy resource waste which are caused by temperature raising are avoided. The high-standard formaldehyde-free glue is high in bonding degree, corrosion resistant and anti-crack.

Owner:祁高标

Preparation method of high sulphate group fucoidan polysaccharide

The invention provides a preparation method of high sulphate group fucoidan polysaccharide, and belongs to the technical field of active polysaccharides. The method solves the problems that in the process of extracting the fucoidan polysaccharide in the prior art, extraction liquid has many impurities; the polysaccharide leaching efficiency is low; the product purity is not high; the polysaccharide decomposing is caused by high temperature, strong acid or strong alkalinity environment in the preparation process; active groups such as sulphate groups are lost, and the like. According to the method, algal is used as a raw material; firstly, the algal is subjected to ultrafine crushing treatment, so that the algal cells are subjected to wall breaking; the polysaccharide leaching rate is increased; the extraction time is reduced; then, a water extraction method is used for extracting the fucoidan polysaccharide; the polysaccharide decomposing and the sulphate group activity loss can be reduced; the natural ingredients and activity of the fucoidan polysaccharide can be greatly remained; finally, the extraction liquid is subjected to protein removal by trichloroacetic acid, sodium alginate impurity removal through ethanol precipitation, and polysaccharide precipitation by ethanol, so that the high-purity and high sulphate group algal polysaccharide is obtained. The purity of the fucoidan polysaccharide prepared by the method can reach 60 to 70 percent; the organic sulfate radical content reaches 20 to 30 percent.

Owner:DALIAN SHENLAN PEPTIDE TECH R & D CO LTD

Sweet tea drink

The invention discloses a sweet tea drink. The sweet tea drink is characterized in that the sweet tea drink is prepared from 200-250 parts of honey, 8-10 parts of sweet tea, 3.5-5 parts of honeysuckle, 3-3.5 parts of chrysanthemums, 3-3.5 parts of liquorice, 2-3 parts of momordica grosvenori, 1-1.5 parts of lophatherum gracile, 1-1.5 parts of mulberry leaves and 1-2 parts of myristica fragrans. The low-temperature extraction technology is adopted for the sweet tea drink, natural components and flavor of mountain Wugong sweet tea are completely reserved, natural mineral water of mountain Wugong is used in cooperation, cost is low, and the processing technology is simple.

Owner:江西圣霖生物科技有限公司

Instant blood sauce fresh duck meat

InactiveCN104643120AKeep natural ingredientsKeep it originalFood ingredient functionsFood preparationMonosodium glutamateMicrowave oven

An instant blood sauce fresh duck meat is prepared as below: killing living ducks, collecting duck blood with a container containing 10ml of vinegar for each duck, stirring incessantly, and reserving the duck blood; depilating washing and eviscerating the ducks, removing the for the head and feet, washing, stewing in boiling water for 15 min, taking out, drying and cutting the duck meat into small pieces for standby; evenly mixing 80 parts of fresh duck meat, 3 parts of salt, 3 parts of sugar, 1 part of ginger, 0.4 part of chili, 0.1 part of pepper, 0.1 part of star anise, 0.1 part of cinnamon, 0.1 part of clove, 0.2 part of monosodium glutamate, 4 parts of soy sauce, 3 parts of liquor (45%)and 5 parts of duck blood; marinating at the temperature of 15 DEG C to 25 DEG C for 48 h; and displacing the duck meat into an opening saucepan, adding water to submerge the liquid surface, boiling under normal pressure, stirring when less water is left, evaporating the water, drying to a moisture content of 20%-25%, packaging, and conducting vacuum sealing to obtain the instant blood sauce fresh duck meat. The edible method is by eating directly, heating by a microwave oven or steaming.

Owner:曾正

Skin care cream made of natural seaweed and its prepn. method

InactiveCN1785158AExert the function of chemical compositionAvoid bleaching processCosmetic preparationsToilet preparationsMedicineUltraviolet

A skin-protecting cream features that it contains the seaweed additive, which is prepared from the high-quality red a alga with high contents of polyose sulfato and SOD and low content of pigment through digestion, filtering, and ultrasonic treating. It can moisten skin, resist against UV ray and delay the sanility of skin.

Owner:GUANGDONG OCEAN UNIVERSITY

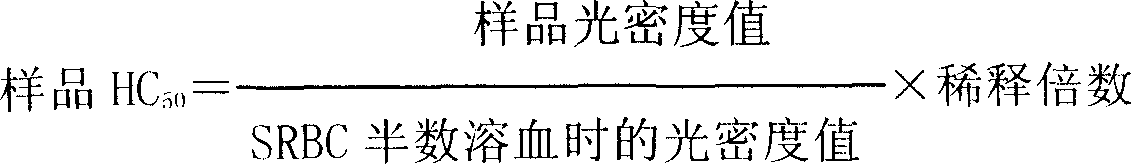

Health composition for strengthening women's immunity and its preparing method

InactiveCN1857509AEnhance female immunityPromote absorptionImmunological disordersAluminium/calcium/magnesium active ingredientsChemical compositionTraditional medicine

The present invention discloses a kind of health composition for strengthening women's immunity, and the health composition is compounded with 16 kinds of food and Chinese medicine materials, including tuckahoe, peach kernel, white chrysanthemum, glossy ganoderma, astragalus root, etc as well as montmorillonite in certain weight proportion. It may be prepared into different orally taken preparation forms. The present invention is used for strengthening women's immunity.

Owner:张雯 +2

Old-pot pickled vegetable fish soup granules

The invention discloses old-pot pickled vegetable fish soup granules. The old-pot pickled vegetable fish soup granules are prepared by the following steps: uniformly mixing 40 parts of fresh fish meat (the head, the internal organs, the scales, the bones and the like are all removed) with 3 parts of red hot-peppers cut into small pieces, 3 parts of fresh ginger without peel cut into small pieces, 3 parts of table salt and 0.9 part of edible sugar; curing the fish meat for 30 minutes and adding 25 parts of old-pot pickled vegetables and 3 folds of water; cooking the raw materials together for 120 minutes; fishing the fish meat and the vegetable residues out and performing filtration; fully draining the fish meat and drying the drained fish meat in a hot-air drying cabinet at 80 DEG C until the loss on drying is lower than 10%; crushing the dried chicken meat into fine powder for later use; going on heating the fish soup until the volume of the fish soup is concentrated to 20% of the original volume; cooling the concentrated fish soup to normal temperature and adding the fish-meat powder, 25 parts of dextrin and 0.1 part of litsea cubeba oil therein to make a soft material; compressing the soft material into granules; and then drying and sub-packing the granules, so that the solid old-pot pickled vegetable fish soup granules are prepared. The old-pot pickled vegetable fish soup granules are soaked in hot water for 2-3 minutes before drinking. The old-pot pickled vegetable fish soup granules can be taken as an accessory food for rice and noodles; and the fresh chicken soup granules can also be taken as a soup directly.

Owner:曾正

Health composition for strengthening women's immunity and its preparing method

InactiveCN100444862CStir wellImprove immunityImmunological disordersAluminium/calcium/magnesium active ingredientsAstragalus mongholicusIngested food

Owner:张雯 +2

Fumigation liquid and preparation method and application thereof

ActiveCN109549110AAdd flavorKeep natural ingredientsFood scienceLiquid productDestructive distillation

The invention relates to fumigation liquid and a preparation method and application thereof. The preparation method comprises the steps of performing sectional type step warming on fumigation raw materials to destructive distillation temperature, and performing destructive distillation, wherein the sectional type step warming at least adopts four-step warming, warming temperature in each step is 100-200 DEG C, and the destructive distillation temperature is 300-700 DEG C. The preparation method is simple in technology, the quality of products can be effectively improved, energy consumption canbe greatly reduced, and environment can be effectively protected; and the prepared fumigation liquid product can be applied to meat products in an internal addition manner and an external sprinklingmanner, gives favorable color and flavor to the meat products, besides, does not have benzo (alpha) pyrene through detection and has favorable safety.

Owner:CHINA MEAT RES CENT

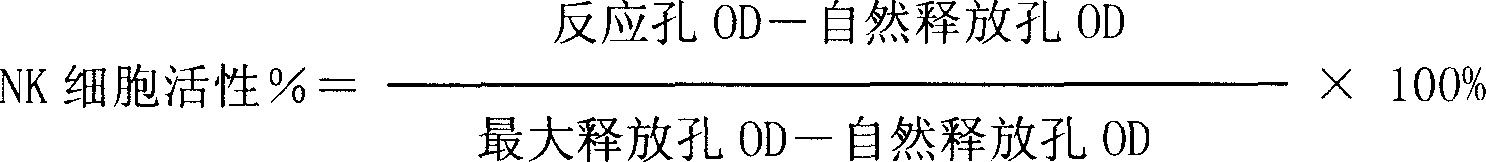

Health care composition for strengthening male's immunity and its preparing method

InactiveCN1857556AEnhance male immunityPromote absorptionPharmaceutical delivery mechanismImmunological disordersAdditive ingredientTraditional medicine

The present invention discloses a kind of health care composition for strengthening male's immunity and with Chinese herbal medicine materials as main ingredients. It is prepared with Chinese yam, Tuckahoe, glossy ganoderma, astragalus root, dogwood and other eight kinds of Chinese medicinal materials in certain weight proportion. It may be prepared into any one of orally taken preparations, and is used in strengthening male's immunity.

Owner:李旻 +2

Preparation method of zanthoxylum bungeanum maxim compound seasoning oil

The invention discloses a preparation method of zanthoxylum bungeanum maxim compound seasoning oil. The preparation method comprises the following steps: respectively drying green zanthoxylum bungeanum maxim and red zanthoxylum bungeanum maxim in the sun, removing seeds, and removing branches and leaves for later use; crushing zanthoxylum bungeanum maxim into 45-55 meshes, adding edible alcohol with the concentration of 85-95%, heating to 75-80 DEG C, performing reflux extraction for 3-5 hours, and filtering to obtain zanthoxylum bungeanum maxim volatile oil; crushing green prickleyash into 35-45 meshes, putting the crushed green prickleyash into a supercritical CO2 extraction device, performing extraction for 1.5-3h, then putting an extraction mixture into a separator, and performing separation to obtain gaseous CO2 and prickleyash numb-taste substances; mixing to prepare oil: mixing the zanthoxylum bungeanum maxim volatile oil and the zanthoxylum schinifolium maxim numb-taste substance according to a ratio of (0.5-1): (0.5-1.5). The zanthoxylum bungeanum maxim compound seasoning oil prepared by the method can meet users with different requirements, is pure and rich in fragrance,strong in numb taste and free of peculiar smell, and can retain the original natural components and physiologically active substances of zanthoxylum bungeanum maxim to the maximum extent.

Owner:ZUNYI VOCATIONAL & TECH COLLEGE +1

Brewing process of honey and pollen wine

InactiveCN102757872AKeep natural ingredientsThe production process is simple and easy to controlAlcoholic beverage preparationYeastPollen

The invention provides a brewing process of a honey and pollen wine. According to weight percentages, 1 part of honey, 1 part of pollen and 10 parts of purified water are sufficiently stirred; the mixture is cooled to a temperature of 45 DEG C; 0.1 part of distiller's yeast is added to the mixture for carrying out fermentation; fermentation is carried out for 15 days; 10 parts of 30 DEG distillate spirit is added to the mixture; and the mixture is stood for 15 days for precipitation, so that golden and transparent honey and pollen wine is formed. According to the process provided by the invention, honey and pollen are mixed for brewing. The production process is easy to control, the process flow is simple, and no chemical additive is added. Natural components of honey and pollen are preserved. The wine can be stored in normal temperature for a long time, and will not turn turbid, deteriorated, or sour. Therefore, a novel approach is provided for industrialized applications of honey and pollen.

Owner:沈世隆

Method for brewing tartary buckwheat and green plum wine

InactiveCN104593207AGood for healthSolve the problem of adding food additivesAlcoholic beverage preparationFood additivePolygonum fagopyrum

The invention discloses a method for brewing tartary buckwheat and green plum wine. The method comprises the following steps: selecting tartary buckwheat and green plums as raw materials, wherein the green plums are pure in fragrance, full in fruit, strong in taste and free from peculiar smell, breakage and worm damage; brewing tartary buckwheat wine and green plum wine by utilizing the tartary buckwheat and the green plums according to the existing technologies respectively; blending the tartary buckwheat and green plum wine by taking the intermediate wine of the tartary buckwheat wine as the main body and adding the intermediate wine of the green plum wine; decreasing the concentration of the tartary buckwheat and green plum wine; seasoning the tartary buckwheat and green plum wine by utilizing the tartary buckwheat wine and the green plum wine in former and later periods; and filtering the seasoned tartary buckwheat and green plum wine so as to obtain the final tartary buckwheat and green plum wine. According to the method disclosed by the invention, the characteristics of the tartary buckwheat wine and the green plum wine are integrated; after being taken, the tartary buckwheat and green plum wine has comprehensive good health-care effects to human bodies; the fruit wine becomes clear and transparent when the natural components in the fruit wine are effectively reserved; a food additive is replaced by natural tartaric acid; and the problem of adding the food additive while blending white wine is solved to a certain extent.

Owner:JIANGYOU CITY XIANG ZI SHEN LIQOUR LLC

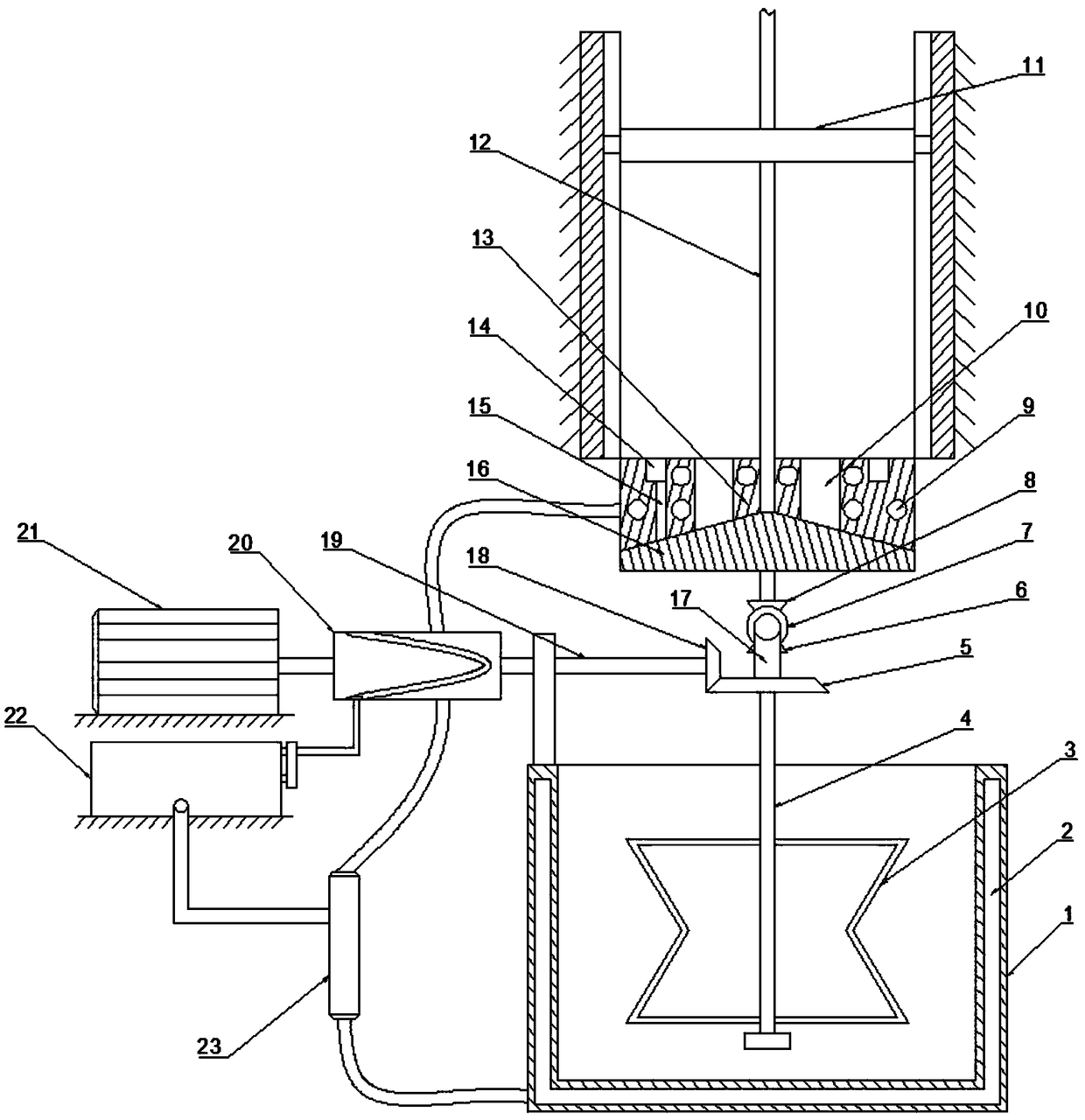

Feed for pregnant sow

The invention discloses a feed for pregnant sows in the field of the pig feed. The feed for the pregnant sows is prepared from the following raw materials in parts by mass: 2-5 parts of bamboo powder,15-18 parts of corn pulp, 16-20 parts of bran, 5-9 parts of rape seed cakes, 1-2 parts of charcoal, 0.3-0.5 part of acidifier, 18-20 parts of sweet potato leaves, and 16-18 parts of affine cudweed, wherein the bamboo powder is obtained by processing bamboos through a processing device, and raw materials are mixed and cured in the processing device. The invention further discloses the processing device for the feed. The feed for the pregnant sows prepared by the processing device is capable of effectively solving problems in the prior art that because the controlled feeding is performed on thepregnant sows, the food intake is not enough, the movement is reduced, the intestinal tract movement is weakened, and the constipation of the pregnant sows is caused.

Owner:习水德康农牧有限公司

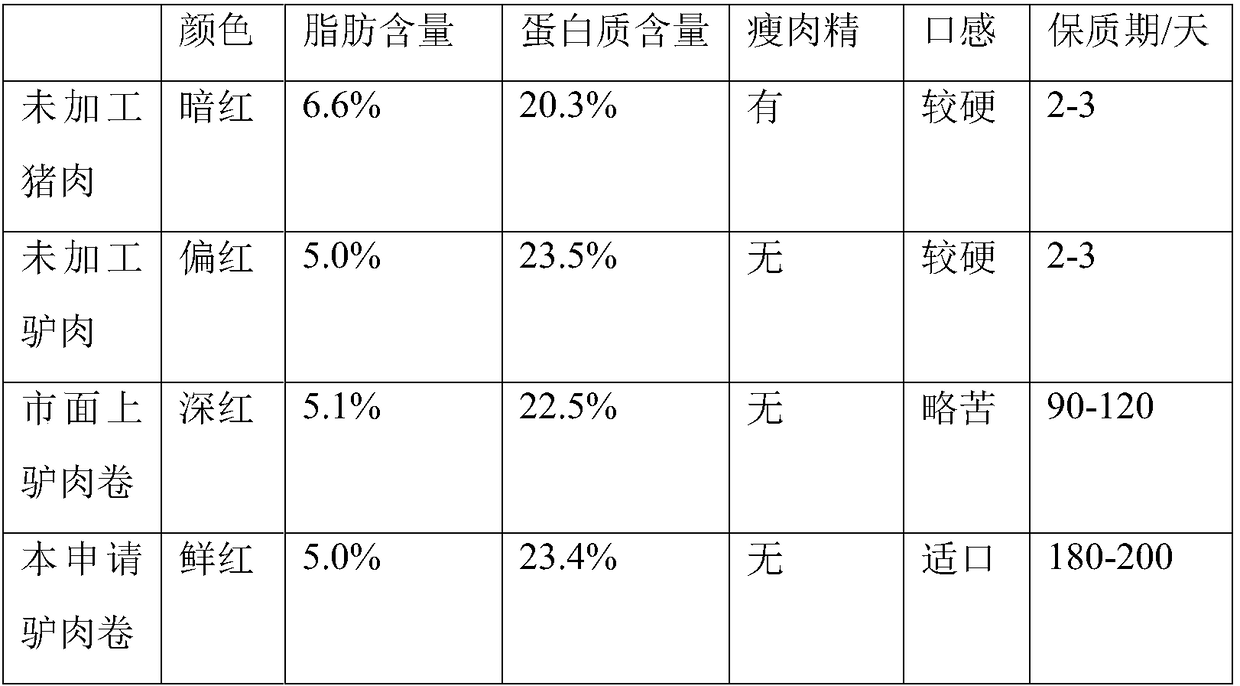

Donkey meat roll and preparation method thereof

The present invention discloses a donkey meat roll and a preparation method thereof. The donkey meat roll comprises the following raw material components in parts by weight: 100 parts of donkey meat and 15-20 parts of marinating liquid. The marinating liquid comprises 0.8-1.2 parts of glycerin, 0.4-0.8 part of compound phosphate, 0.4-1 part of sugar alcohol, 0.6-1 part of salt, 0.6-1 part of sugar, 10-15 parts of water and 0.05-0.12 part of a color protection agent. The preparation method of the donkey meat roll comprises the treatment steps of raw material donkey meat pre-preparing, marinating liquid preparing, marinating, rolling, balancing, rolling, freezing, etc. The prepared donkey meat roll is bright in color, free of unpleasant mouthfeel and unpleasant odor, and has a pH value within a normal meat product standard range. The preparation method of the donkey meat roll is simple in technology, overcomes defects of poor mouthfeel and rolling discoloration of the donkey meat roll, retains the pure natural ingredients in the donkey meat, and improves the yield and quality stability of the product.

Owner:SHAN DONG DONG E E JIAO

Glue for producing packaging paperboard and production process thereof

InactiveCN108373893AStrong initial adhesionIncrease stickinessNon-macromolecular adhesive additivesStarch adhesivesCorn flourPaperboard

The invention belongs to the technical field of glue processing and particularly discloses glue for producing a packaging paperboard and a production process thereof. The glue for producing the packaging paperboard is prepared from the following raw materials in parts by mass: 460-480 parts of corn flour, 3.8-4.3 parts of borax, 13.6-14.3 parts of sodium hydroxide, 19.5-21.5 parts of bonding agent, 2.8-3.2 parts of stabilizer and 1,400-1,600 parts of water. The production process comprises the following steps: (1) batching materials; (2) adding water into a container and then adding the sodiumhydroxide; (3) adding the corn flour; (4) adding sodium hydroxide solution; (5) adding the stabilizer; (6) adding the borax; (7) adding the bonding agent. The glue prepared by the technical scheme has certain permeability and stronger bonding property, and the packaging paperboard produced by the glue is high in bonding strength and good in effect.

Owner:重庆合信包装印刷有限公司

Preparation method of fully active component nano pearl powder

InactiveCN104161774AKeep natural ingredientsKeep aliveCosmetic preparationsMetabolism disorderActive componentCombined method

The invention discloses a preparation method of fully active component nano pearl powder. The key point and bottleneck of the pearl powder preparation are full preservation of active components in pearls, and the technical problem is not well solved and has been neglected for a long time. The preparation method comprises the following steps: choosing high quality pearls, cleaning, drying in air, and grinding, wherein pearls are grinded into pearl powder with a particle size of 2-50 [mu]m in one step through a combined method of drying in the air by cool wind, low-speed grinding and pulverizing, and winnowing; and the temperatures of all materials during the whole processing process are below 45 DEG C. The provided fully active component nano pearl powder is suitable for preparations of medicines, healthcare products, foods, and cosmetics. The preparation method is capable of preserving the characteristic natural components and bio-activity of pearl, and improving the absorption efficiency of pearl for human body, and prominently increases the medicinal value, healthcare function, and beautifying and skin moistening effect of the pearl powder.

Owner:北海市弘健科技发展有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com