Fumigation liquid and preparation method and application thereof

A smoking liquid and smoking technology, applied in the direction of food science, etc., can solve the problems that are not conducive to industrialization and automated production, destroy the naturalness of smoked liquid products, reduce the quality of smoked liquid products, etc., and achieve good smoked flavor , Accelerate purification efficiency and improve safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a method for preparing smoked liquid, specifically:

[0046] After the apple sawdust is dried, it is heated by a spiral conveying device into a stepwise heating retort furnace. The temperature of the first layer space is 100°C, and the equilibrium time is 20 minutes. The temperature of the second layer space is 250°C, and the equilibrium time is 20 minutes. The third layer space The temperature is 350°C, the equilibrium time is 20min, the temperature of the fourth layer is 450°C, the dry distillation time is 20min, and then the waste is emptied, and the continuous production is 6h; the generated flue gas is condensed through the condensation system, and the obtained condensate is left at room temperature for 13h , take the supernatant, pass through a plate-and-frame filter purification machine, first pass through a 1 μm pre-filter, and then use a 0.45 μm filter membrane to filter, sub-package, and store.

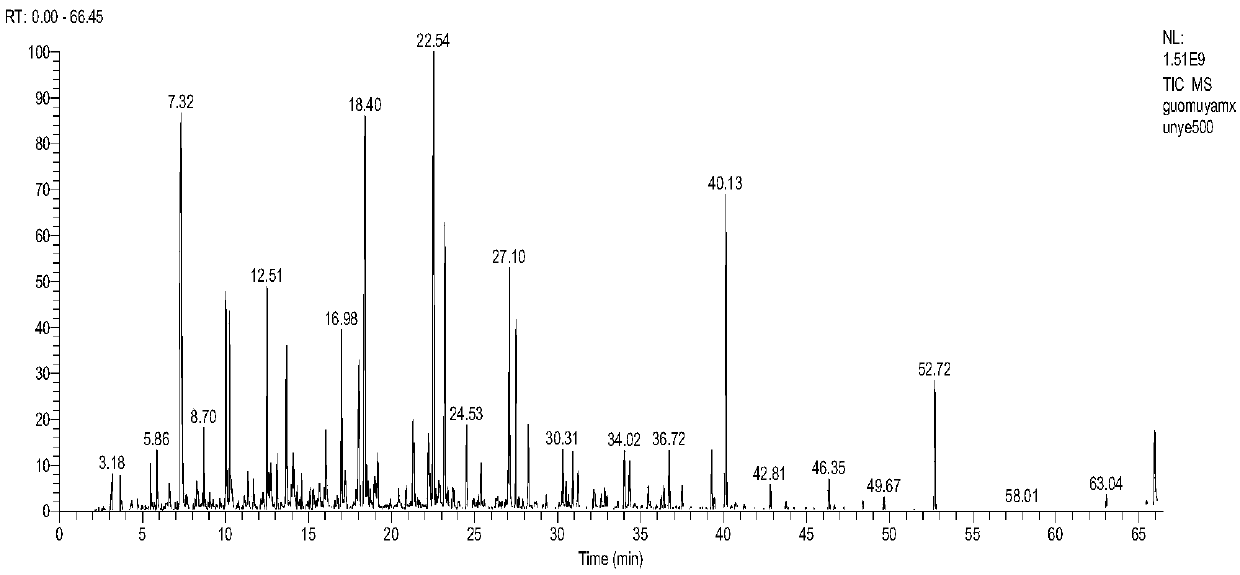

[0047] Analysis and detection of smoke ...

Embodiment 2

[0061] This embodiment provides a method for preparing smoked liquid, specifically:

[0062] After the hawthorn core is dried, put it into the staged stepped heating retort furnace for heating through the screw conveyor. The temperature of the first layer space is 100°C, and the equilibrium time is 20 minutes. The temperature is 400°C, the equilibrium time is 20 minutes, the fourth layer space temperature is 500°C, the equilibrium time is 20 minutes, the fifth layer space temperature is 600°C, the dry distillation time is 20 minutes, and then the waste is emptied, and the continuous production is 24 hours; the generated flue gas is condensed Condensate the system, let the obtained condensate stand at room temperature for 12 hours, take the supernatant, pass it through a plate and frame filter purifier, first pass through a 1 μm pre-filter, and then use a 0.45 μm filter membrane to filter, pack and store.

Embodiment 3

[0064] This embodiment provides a method for preparing smoked sausage, specifically:

[0065] Weigh 10kg of pork, mince it and mix it evenly with seasonings and spices, then enema, dry, smoke, cook, pack and sterilize to obtain smoked sausage;

[0066] Wherein, the smoking is specifically: the product obtained by spraying the smoked liquid prepared in Example 1 onto the surface of the product by spraying is a product prepared by the liquid smoking process of apple wood smoked liquid; The product obtained by smoking for 30 minutes is a product prepared by a traditional wood smoking process.

[0067] Compared with the product of the traditional wood smoking process (comparative example 1) to compare the color and luster, the time of spraying the smoked liquid is 3 times.

[0068] Table 2 Color analysis of sausages with different smoking techniques

[0069] project

[0070] It can be seen from Table 2 that the products obtained by the two processes have good similarit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com