High-standard formaldehyde-free glue and preparation method thereof

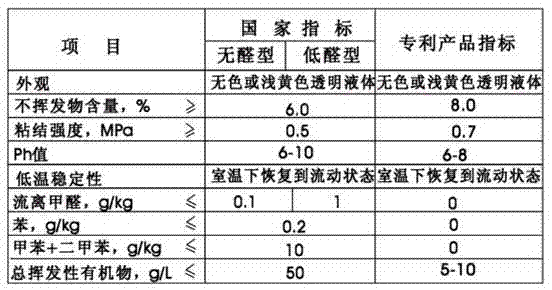

A glue, high-standard technology, applied in the direction of adhesive types, unsaturated alcohol copolymer adhesives, etc., can solve the problems of difficulty in ensuring the effective quality of raw materials, hazards, etc., and achieve the effect of low processing cost, simple process, and quality maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] A kind of high-standard formaldehyde-free glue described in Embodiment 1 of the present invention is made of the following raw materials by weight: 3 kg of water-soluble polyvinyl alcohol, 1 kg of hydroxypropyl methylcellulose, and edible defoamers of LT-825 series 0.1 kg, 0.1 kg of potassium sorbate, 0.1 kg of sodium carbonate, 1 kg of vinyl acetate, 0.01 kg of polyvinylamide and 94.69 kg of purified water.

[0012] The preparation method of described high-standard formaldehyde-free glue comprises the following steps:

[0013] Mix water-soluble polyvinyl alcohol, water-retaining agent, edible defoamer, edible preservative, dispersant, dispersible latex powder, thickener and pure water according to the above ratio, wherein the temperature of the pure water is 5°C, and pass a mixer to stir evenly; and after stirring evenly, use a refiner to finely grind the evenly stirred mixture into glue.

Embodiment 2

[0015] A high-standard formaldehyde-free glue described in Embodiment 2 of the present invention is made of the following raw materials: 6 kg of water-soluble polyvinyl alcohol, 2 kg of water-retaining agent, 0.2 kg of edible defoamer, and 0.2 kg of sodium paraben formate , sodium carbonate 0.2 kg, vinyl acetate 2 kg, thickener 0.02 kg and purified water 189.38 kg. The water-retaining agent is hydroxypropyl methylcellulose, the edible defoamer is LT-825 series edible defoamer, and the thickener is polyvinylamide.

[0016] The preparation method of described high-standard formaldehyde-free glue comprises the following steps:

[0017] Mix water-soluble polyvinyl alcohol, water-retaining agent, food defoamer, food preservative, dispersant, dispersible latex powder, thickener and pure water according to the above ratio, wherein the temperature of the pure water is 15°C, and pass a mixer to stir evenly; and after stirring evenly, use a refiner to finely grind the evenly stirred mi...

Embodiment 3

[0019] A high-standard formaldehyde-free glue described in Embodiment 3 of the present invention is made of the following raw materials: 12 kg of water-soluble polyvinyl alcohol, 4 kg of water-retaining agent, 0.4 kg of edible defoamer, 0.4 kg of potassium sorbate, Sodium carbonate 0.4 kg, vinyl acetate 4 kg, thickener 0.04 kg and purified water 378.76 kg. The water-retaining agent is hydroxypropyl methylcellulose, the edible defoamer is LT-825 series edible defoamer, and the thickener is polyvinylamide.

[0020] The preparation method of described high-standard formaldehyde-free glue comprises the following steps:

[0021] Mix water-soluble polyvinyl alcohol, water-retaining agent, edible defoamer, edible preservative, dispersant, dispersible latex powder, thickener and pure water according to the above ratio, wherein the temperature of the pure water is 30 ° C, and pass a mixer to stir evenly; and after stirring evenly, use a refiner to finely grind the evenly stirred mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com