Method and system for two-station fast table cutting

A technology of cutting system and cutting method, which is applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of high equipment investment in the occupied area, and achieve the effect of high operating efficiency, compact layout, and tight rhythm of the operating process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

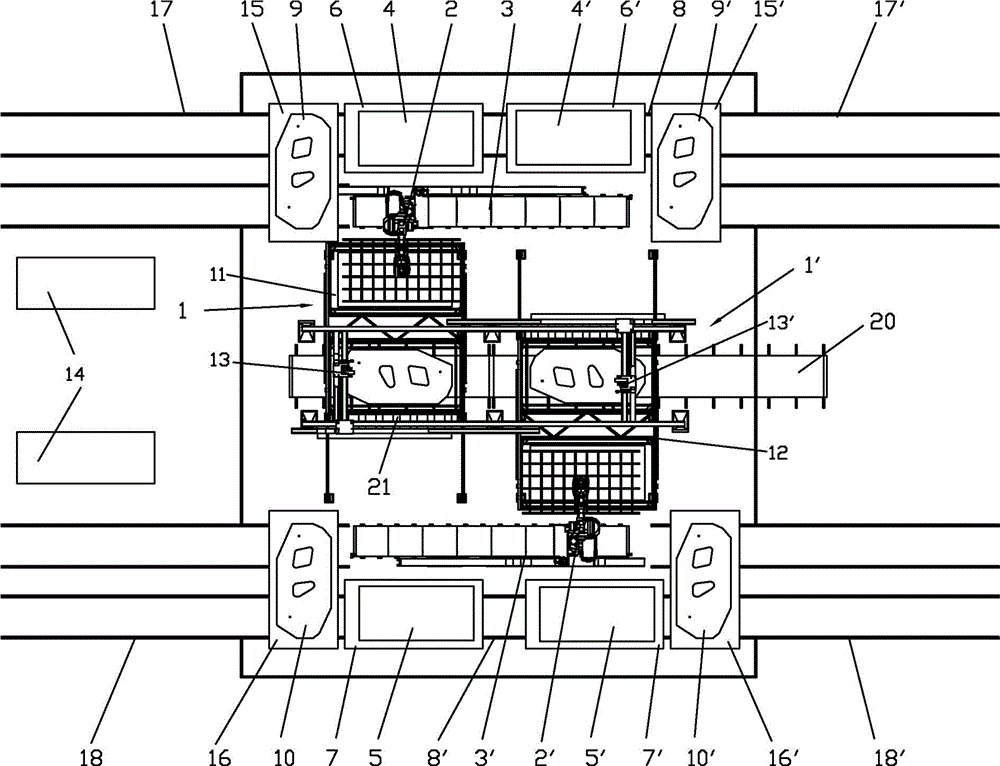

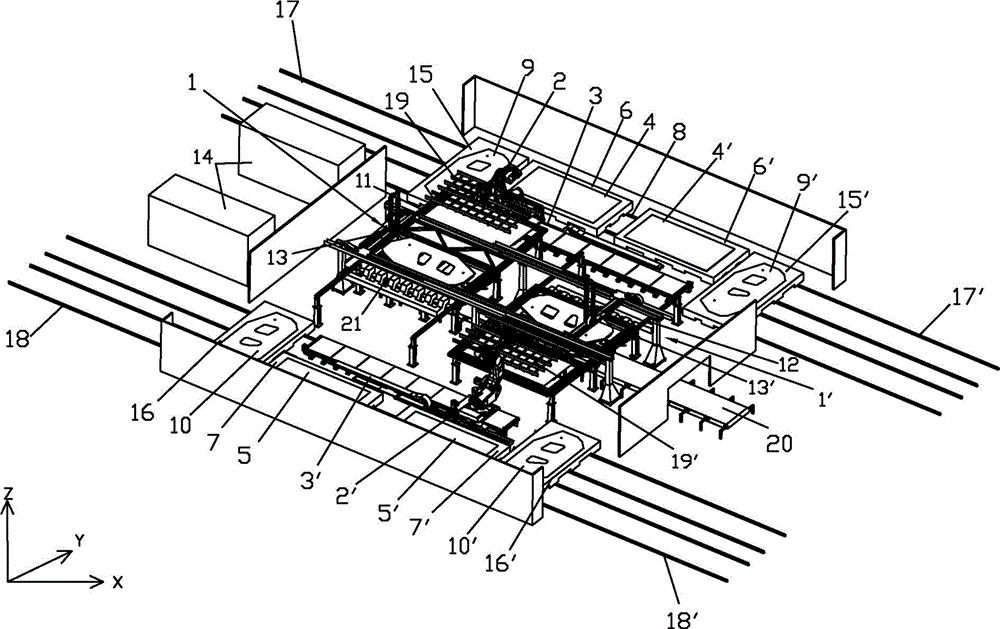

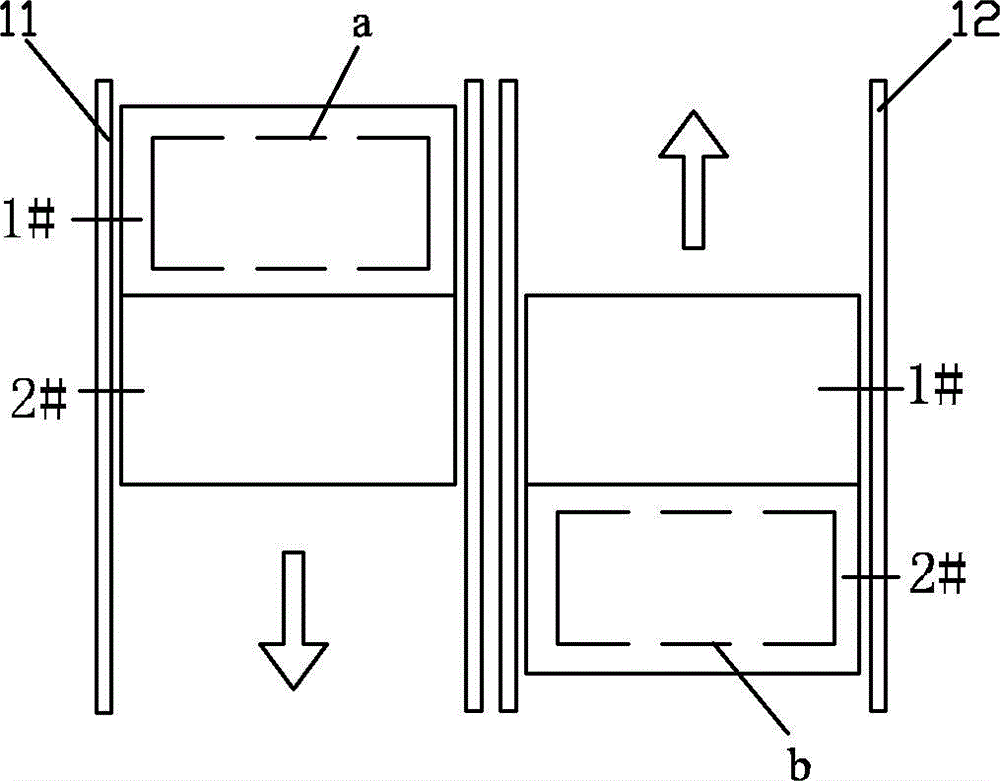

[0028] see figure 1 , figure 2 , the metal plate cutting system of the present invention, which includes two cutting units 1, 1', which include two first and second moving fast tables 11, 12 arranged in parallel, and corresponding two laser cutting heads 13, 13' And a laser generator 14; The two moving fast tables 11, 12 are two-way feeding and discharging on both sides, and a cutting position and two waiting positions are set respectively, that is, 1# and 2# waiting positions; two handling The stacking robots 2, 2' are arranged on both sides of the two cutting units 1, 1', and the robot external axes 3, 3' of the transport stacking robots 2, 2' are vertically arranged with the moving fast platforms 11, 12; The stacking robots 2, 2' are equipped with end pickers 19, 19' for picking and placing operations; the four group material loading positions 4, 4', 5, 5' are arranged side by side on the two conveyors. On the outside of the outer shaft 3, 3' of the stacking robot robot,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com