Plastic mould

A technology of plastic molds and inserts, applied in the field of mold equipment, can solve the problems of decreased production efficiency of molds, inability to connect, and complicated operation by staff, and achieves the effect of stable cooperation and improved production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

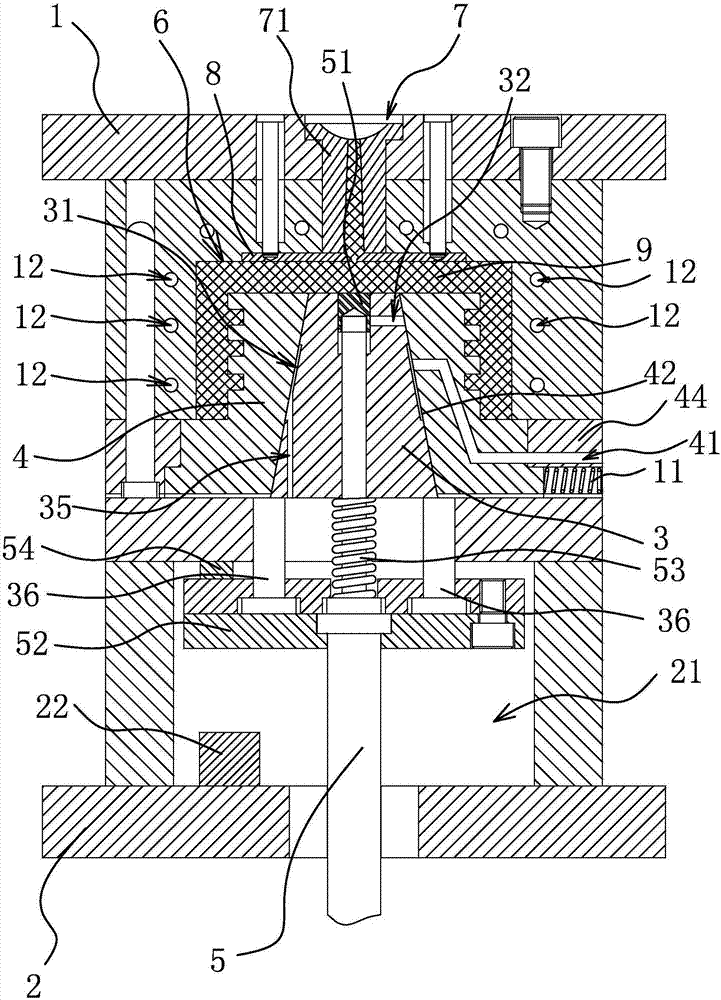

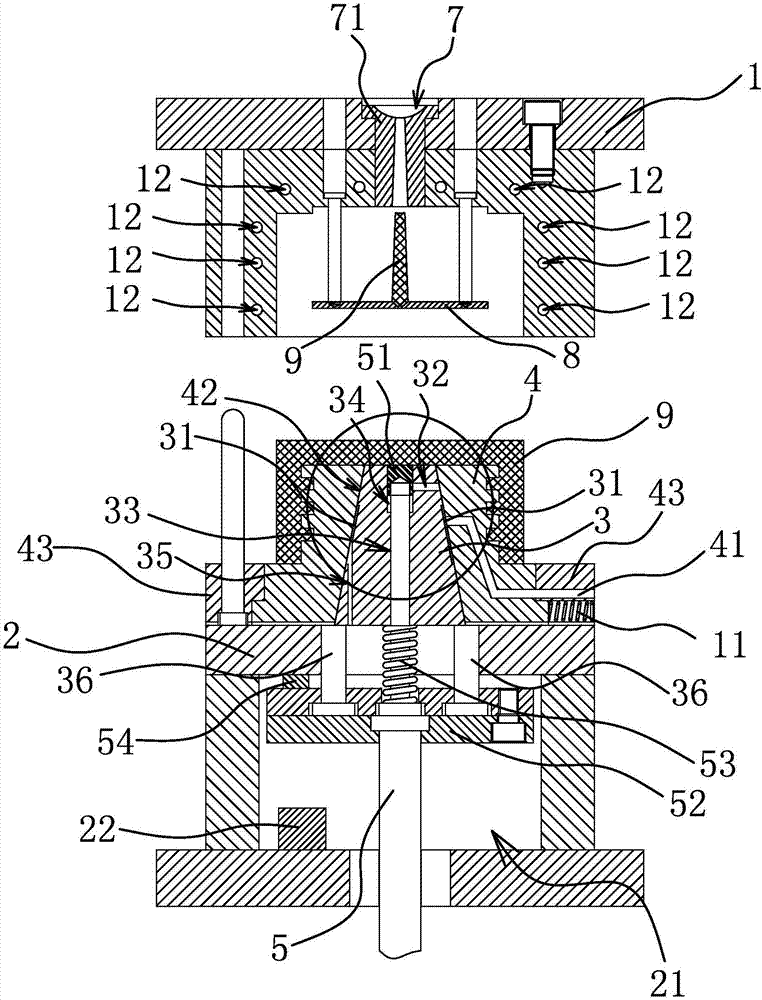

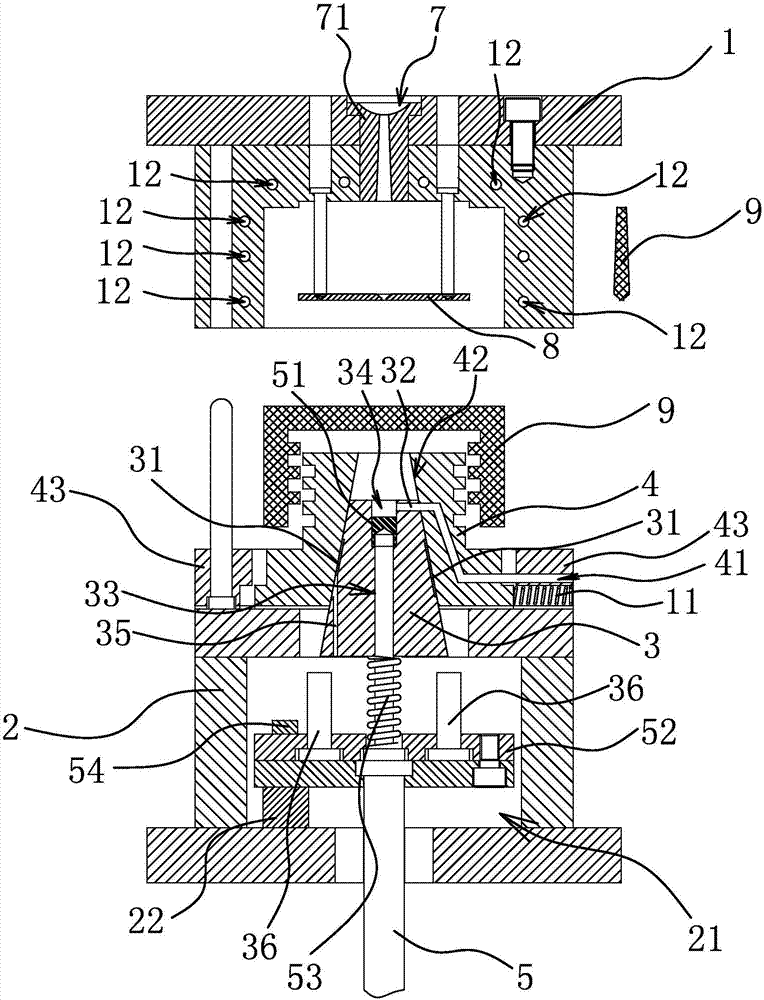

[0039] Such as figure 1 As shown, the plastic mold includes an upper module 1 and a lower module 2, an insert 3 and a core 4 are arranged between the upper module 1 and the lower module 2, and the insert 3 is provided with a gas cooling channel 31 along the circumferential direction.

[0040] Specifically, if Figure 1-4 As shown, the upper module 1 is provided with a flow channel 7 for molten plastic to flow in, the upper module 1 is also provided with a flow channel bushing 71, and the insert 3 is provided with a slide bar 5, which can move along the insert 3 slides axially and drives the insert 3 to move axially along the core 4. The insert 3 is also provided with an air guide channel 32 passing through the insert 3 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com