High-precision flow metering mechanism

A flow measurement, high-precision technology, applied in the direction of relative volume flow measurement, liquid/fluid solid measurement, measuring devices, etc., can solve the problem of large axial size of linear displacement sensor, general measurement repeatability accuracy, and axial requirements of valve core. Problems such as large space size, to achieve the effect of high-precision fuel metering function, reduced volume, and compact mechanism rhythm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

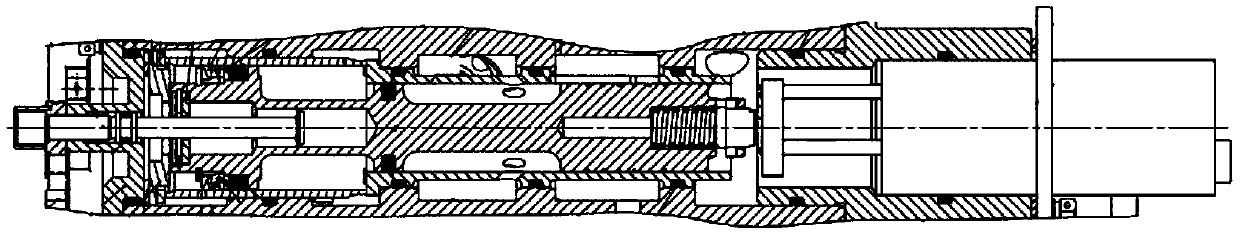

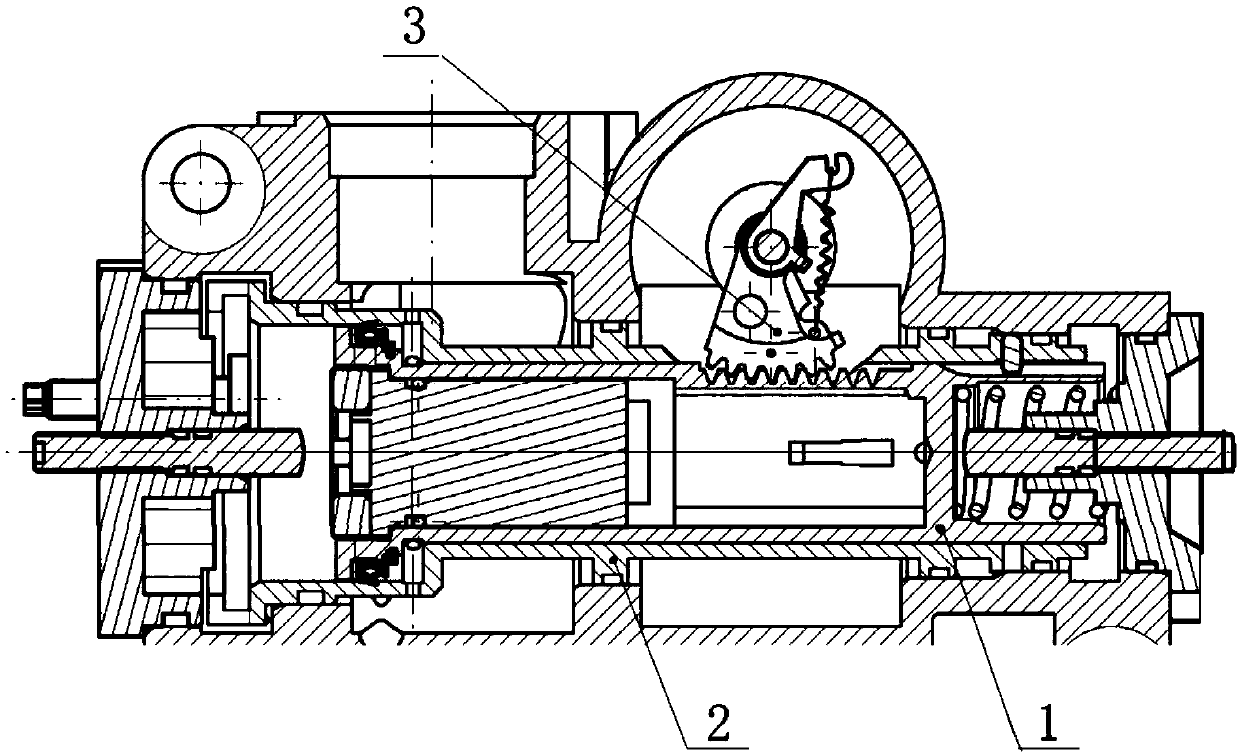

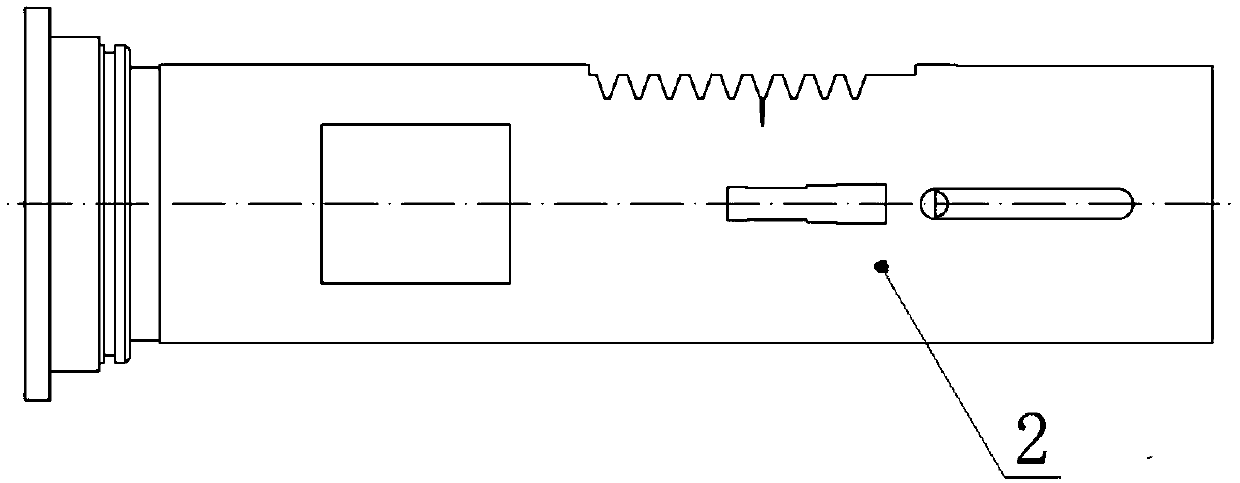

[0019] Such as Figure 2-4 , a high-precision flow metering mechanism, including a valve core, a bushing, a housing, and an angular displacement measurement assembly; the angular displacement measurement assembly includes a first sector gear, a second sector gear, a spring, an angular displacement sensor, and a rotating shaft; the valve The core, bushing and angular displacement measurement components are all set in the housing,

[0020] One of the first sector gear and the second sector gear is rotatably mounted on the shaft, and the other of the first sector gear and the second sector gear rotates integrally with the shaft; the angular displacement sensor measures the rotation angle of the shaft; A spring is arranged between the first sector gear and the second sector gear;

[0021] The bushing has an opening, and the part of the spool corresponding to the opening is formed with a rack; both the first sector gear and the second sector gear are engaged with the rack; the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com