Leaf moistening control method, storage medium, detection device and leaf moistening system

A control method and the technology of the leaf moistening machine, which are applied in the fields of the leaf moistening control method of the leaf moistening machine, the detection device and the leaf moistening system, the storage medium, and the tobacco leaf material detection device, which can solve the problem of inaccurate calculation of incoming material flow and electronic flow without installation Problems such as weighing, inaccurate steam and water addition, etc., achieve low maintenance cost, reduce equipment failure rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

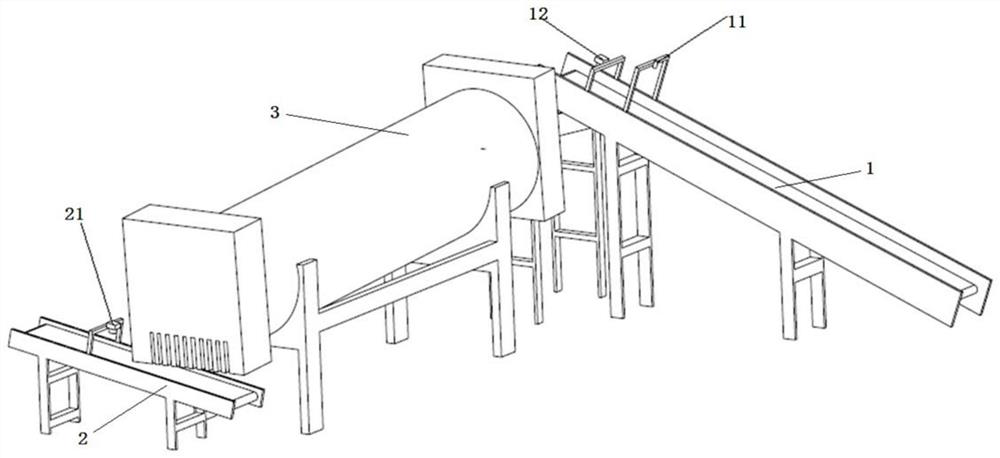

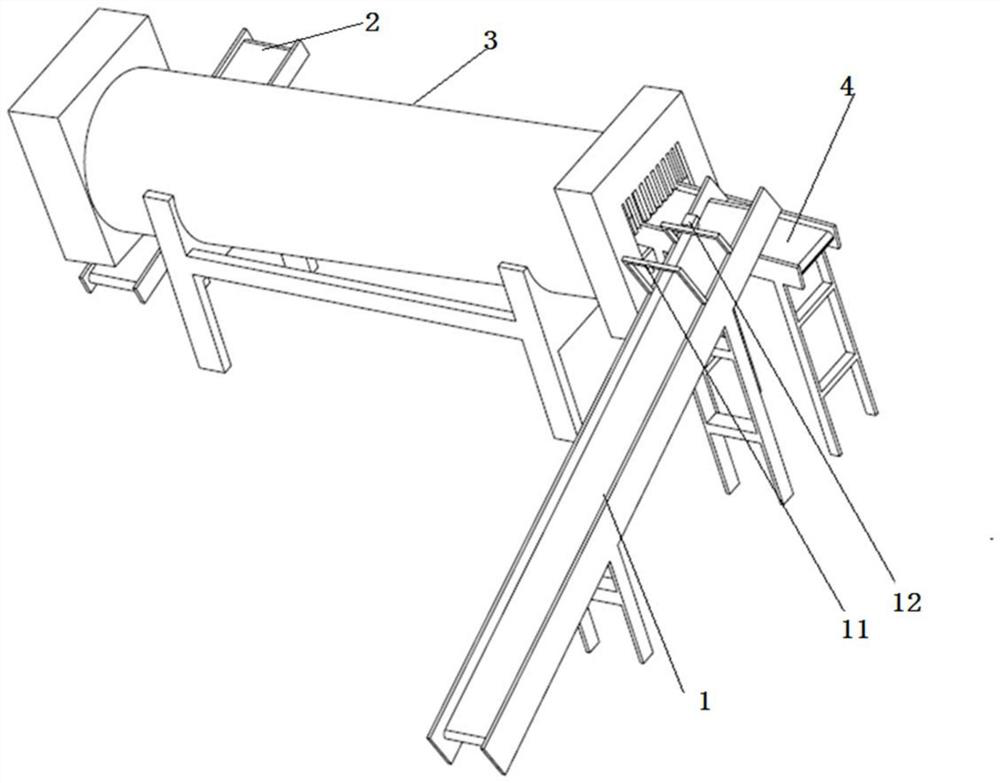

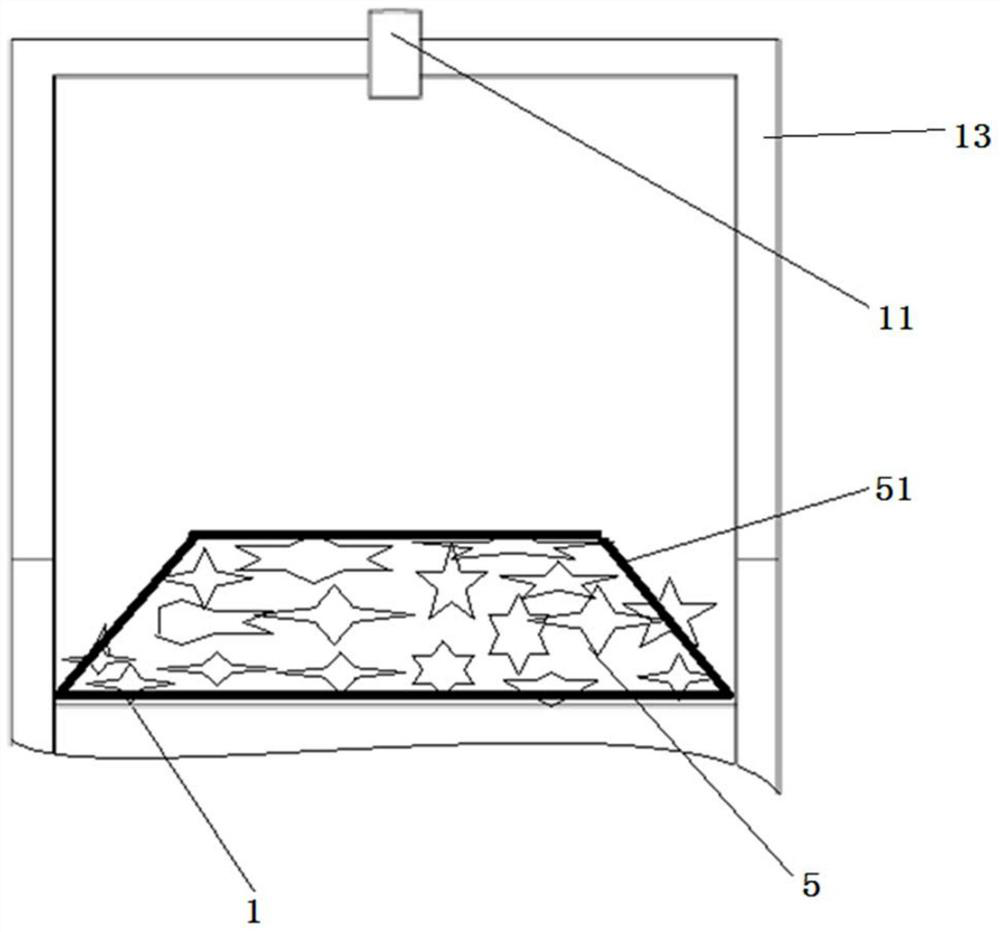

[0064] like Figure 1-3 As shown, a material and moisture detection device of a leaf moistening machine includes an ultrasonic sensor 11 arranged sequentially above the incoming material belt 1 in the direction of the incoming material, an infrared moisture meter 12 before moistening and an infrared moisture meter 12 after moistening arranged above the discharge belt 2. The moisture meter 21, the infrared moisture meter 12 before moistening, the infrared moisture meter 21 after moistening and the ultrasonic sensor 11 are connected to the PLC controller of the leaf conditioner 3.

[0065] A tobacco leaf moistening system composed of the detection device includes a leaf moistening machine 3, which is equipped with a PLC controller, an electromagnetic flow valve of a water adding pipeline and a pneumatic membrane valve of a steam adding pipeline, and also includes all The material and moisture detection device of the leaf moistening machine; the PLC controller is connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com