A silicon industrial park wastewater treatment process and device

A technology for wastewater treatment and treatment process, which is applied in water/sewage treatment, water/sewage multi-stage treatment, biological water/sewage treatment, etc. It can solve the problems of difficult biochemical, high salt, and unsatisfactory denitrification process treatment effect. , to achieve the effect of efficient removal and ensure normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of silicon industrial park wastewater treatment process of the present embodiment, such as Figure 6 As shown, the process includes park comprehensive wastewater treatment process and white carbon black wastewater treatment process.

[0037] The white carbon black wastewater treatment process includes two flow paths, the wastewater in the first flow path enters the sulfate dissimilation step for treatment, the sulfate in the waste water is converted into reduced sulfur by sulfate reducing bacteria, and after filtration, the reduced sulfur It is used in the comprehensive wastewater treatment process of the park, and the unconverted sulfate enters the second flow path; the second flow path wastewater treatment process includes the following steps: coagulation, sand rate, reverse osmosis and MVR evaporation, and the by-product sodium sulfate is produced . The return of the filtered sulfate in the first flow path is the reverse osmosis step. The by-product sodium s...

Embodiment 2

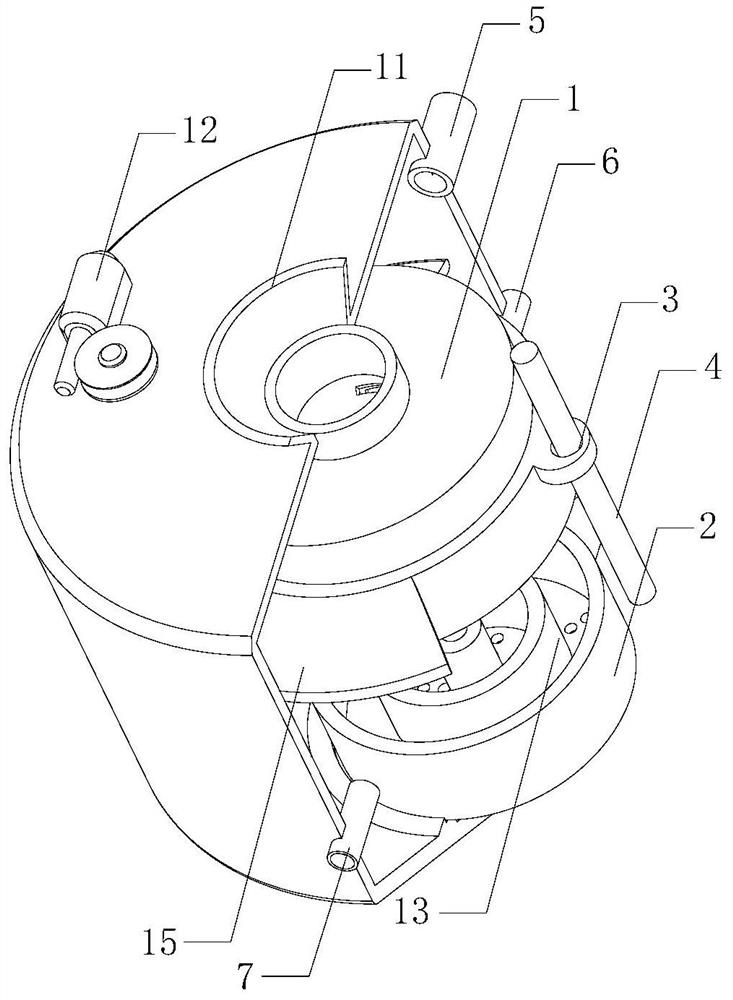

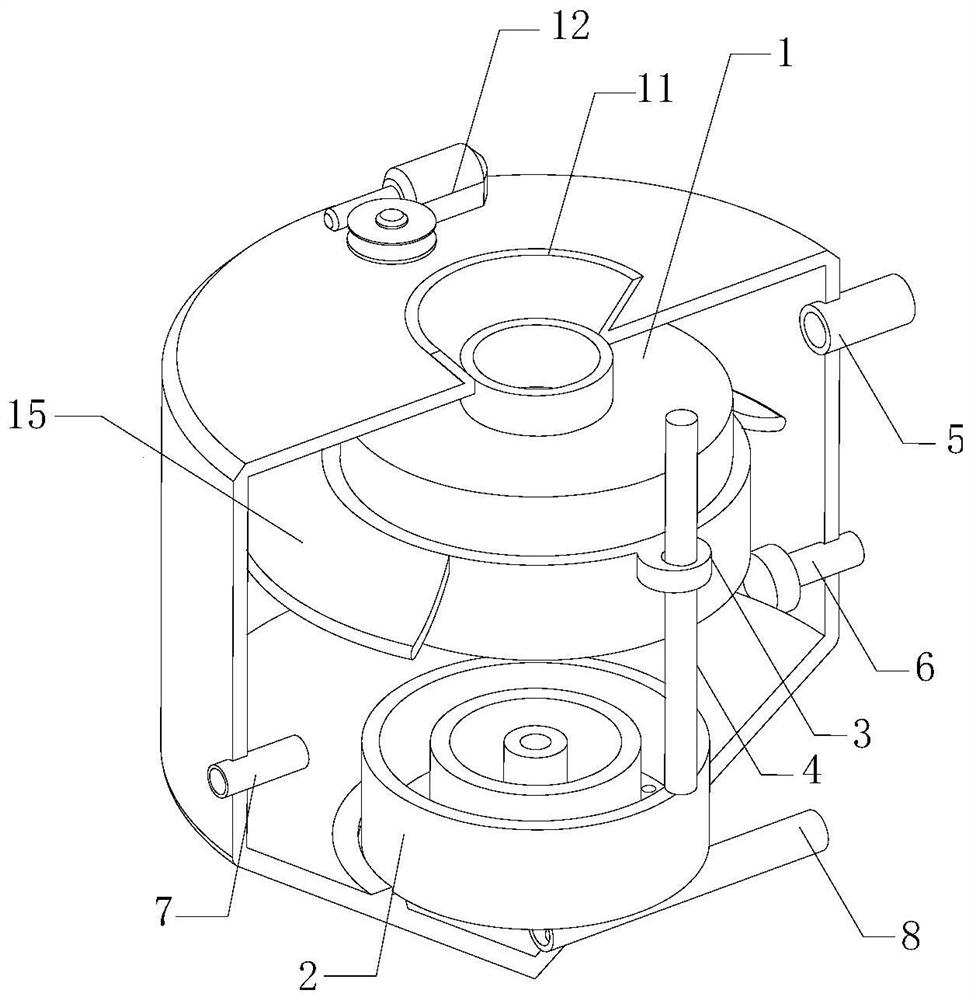

[0041] The dissimilation / denitrification device adopted in embodiment 1, such as Figure 1-5 As shown, the body of the device is cylindrical, the bottom is conical, and the conical bottom is convenient for the collection and discharge of sludge. The top of the device body is provided with an integrated wastewater inlet 11 and a motor 12 in the park.

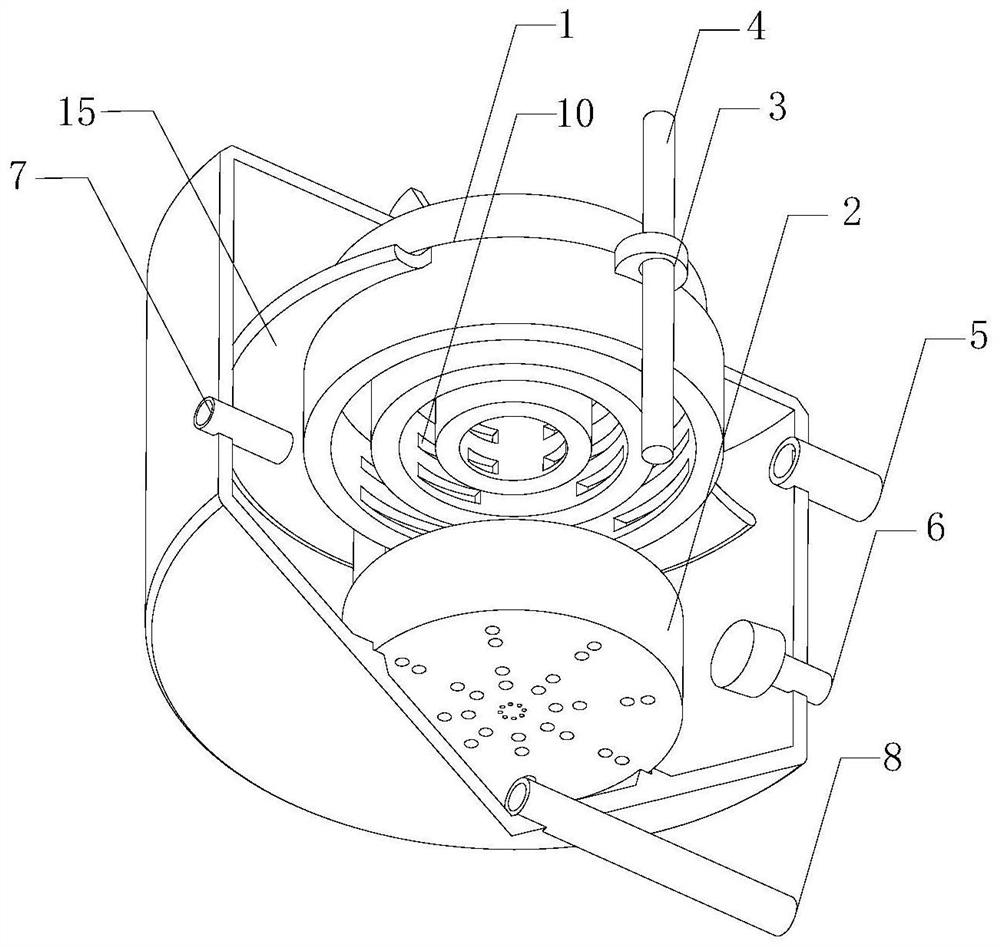

[0042] A mounting seat 19 is provided at the bottom of the tapered device body, on which the sulfur adsorption module 2 is erected for easy disassembly and assembly, so as to clean and maintain the interior of the device body. The bottom plate of the sulfur adsorption module 2 and the bottom of the tapered device body form a mud collection chamber 20, the bottom plate of the sulfur adsorption module 2 is provided with holes, and the bottom plate of the sulfur adsorption module 2 can also be a plate-shaped sand filter structure. The sulfur adsorption module 2 includes a second fitting mechanism 13, and the second fitting mechanis...

Embodiment 3

[0046] The operating steps of the device described in embodiment 2 are as follows:

[0047] It operates in the form of periodic sequence batches. At the beginning of an operation cycle, there is no waste water residue in the device body. After the reaction starts, the effluent of the anaerobic reactor enters the device body from the silica waste water inlet 7, and the waste water contains more sulfides, which are leached to the sulfur adsorption module 2 by spraying, on which the second fitting mechanism 13 The loaded filler is "iron oxide + clinoptilolite" mixed filler mainly composed of iron oxide. After passing through the sulfur adsorption module 2, the waste water enters the nanofiltration device after being filtered by the sand filter at the bottom of the device body. The unadsorbed sulfide will be separated from sulfate and sulfide through nanofiltration, which not only avoids high-concentration sulfate from entering the biochemical system, but also provides a sulfur s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com