Digital quenching equipment for leaf springs

A technology of leaf springs and quenching equipment, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems that the cooling curve cannot be accurately controlled, the material structure and properties cannot be obtained, and the mold change takes a lot of time, so as to improve the finished product Improvement of quality and decarbonization control indicators and fast production pace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

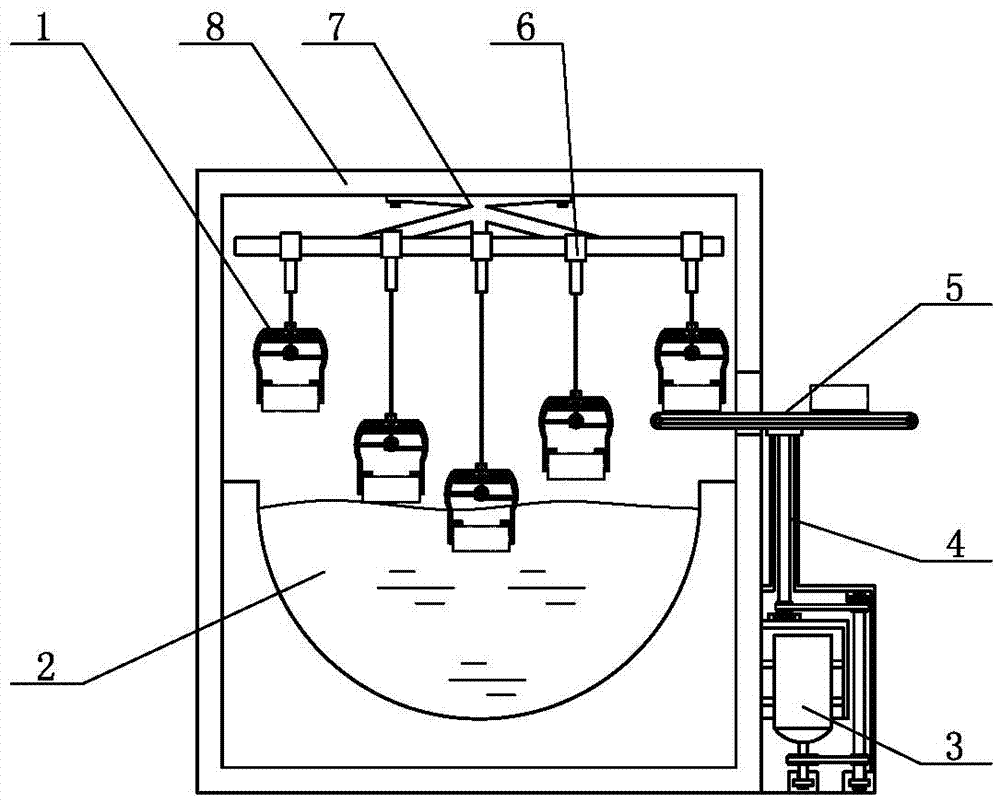

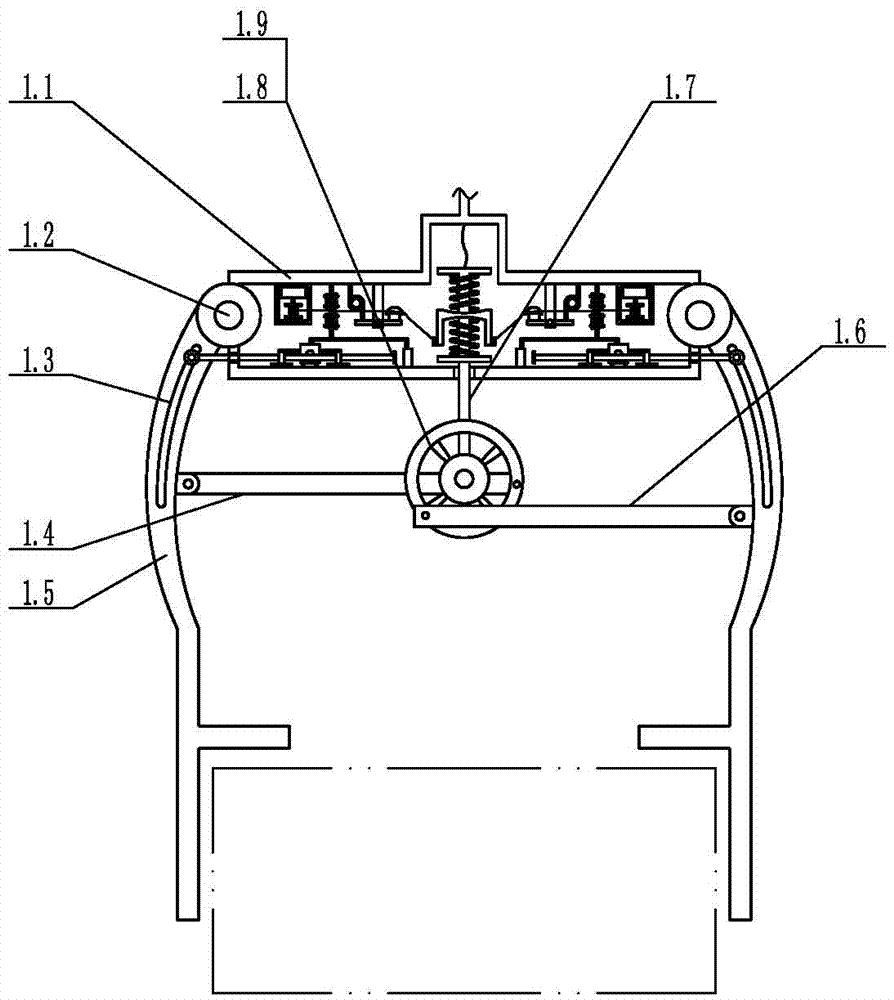

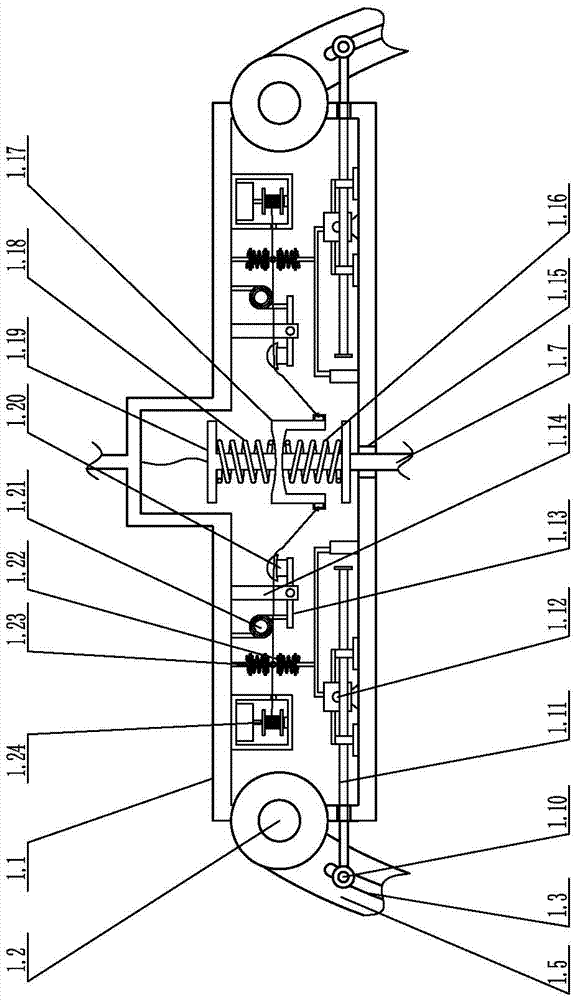

[0029] Such as figure 1As shown, the digital quenching equipment of a leaf spring according to the present invention includes a quenching box, a quenching pool, an electric runner, a hoisting device, a manipulator, a cooling chamber, a constant temperature antifreeze equipment and an exhaust gas treatment equipment; the quenching pool is arranged in a quenching The lower part of the box; the electric runner is installed on the top wall of the quenching box, and more than three manipulators are installed on the electric runner through hoisting equipment, and the electric runner can drive the hoisting equipment and manipulators to rotate above the quenching pool. The hoisting equipment can drive the manipulator to move up and down, and the manipulator can automatically loosen or clamp the leaf spring, and under the drive of the hoisting equipment, the leaf spring can be immersed in and lifted out of the quenching pool; the constant temperature antifreeze equipment is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com