Elastic locking device for turbofan engine rotor disassembling

A technology of turbofan engine and locking device, which is applied to components of pumping devices for elastic fluids, machines/engines, liquid fuel engines, etc., can solve problems such as poor effects, and achieve simple overall structure, compact rhythm, The effect of reducing the risk of scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

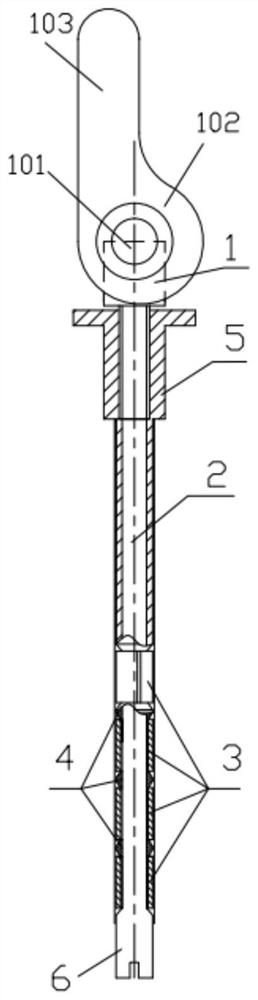

[0034] refer to Figure 1-8 , the present invention provides a technical solution:

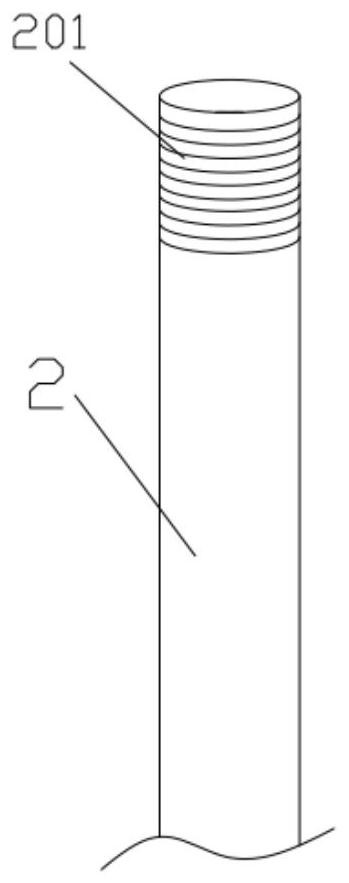

[0035] Please refer to Figure 1-4 , an elastic locking device for turbofan engine rotor disassembly, including a rotating handle 1, a support rod 2, an elastic locking assembly 3 and an extruding assembly 4, the rotating handle 1 is provided with a threaded hole 101, the The first end of the support rod 2 is provided with an external thread 201 matched with the threaded hole 101, the support rod 2 is covered with a spacer bush 5, and the first end of the spacer bush 5 is close to the rotary handle 1;

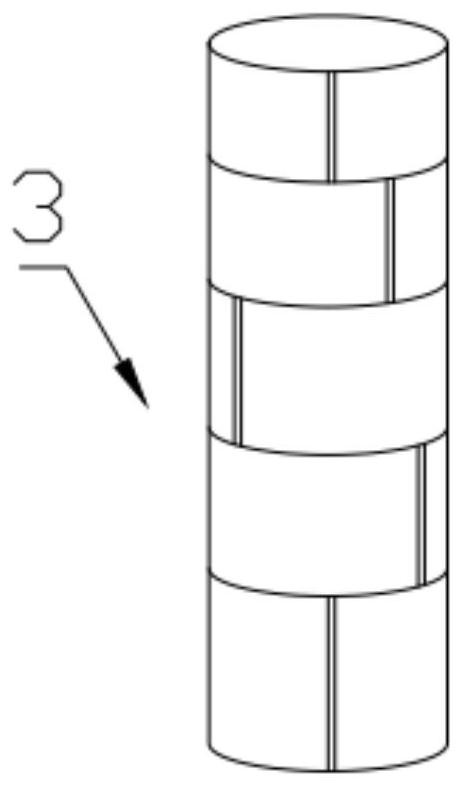

[0036] A plurality of elastic locking assemblies 3 are sheathed on the support rod 2, and the plurality of elastic locking assemblies 3 are sequentially spaced from the second end of the support rod 2 to the first end of the support rod 2. It is arranged as an elastic locking unit, the end of the elastic locking unit is close to the end of the spacer bush 5, and a plurality of extruding comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com