Intelligent repulping and feeding linked system in pulp molded pulping process

A technology of pulping process and pulp molding, applied in pulp beating/refining method, pulp beating method, chemical/physical process, etc., can solve the problems of low degree of automation, affecting production efficiency, large manpower demand, etc., to achieve High degree of automation, improved pulping efficiency and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

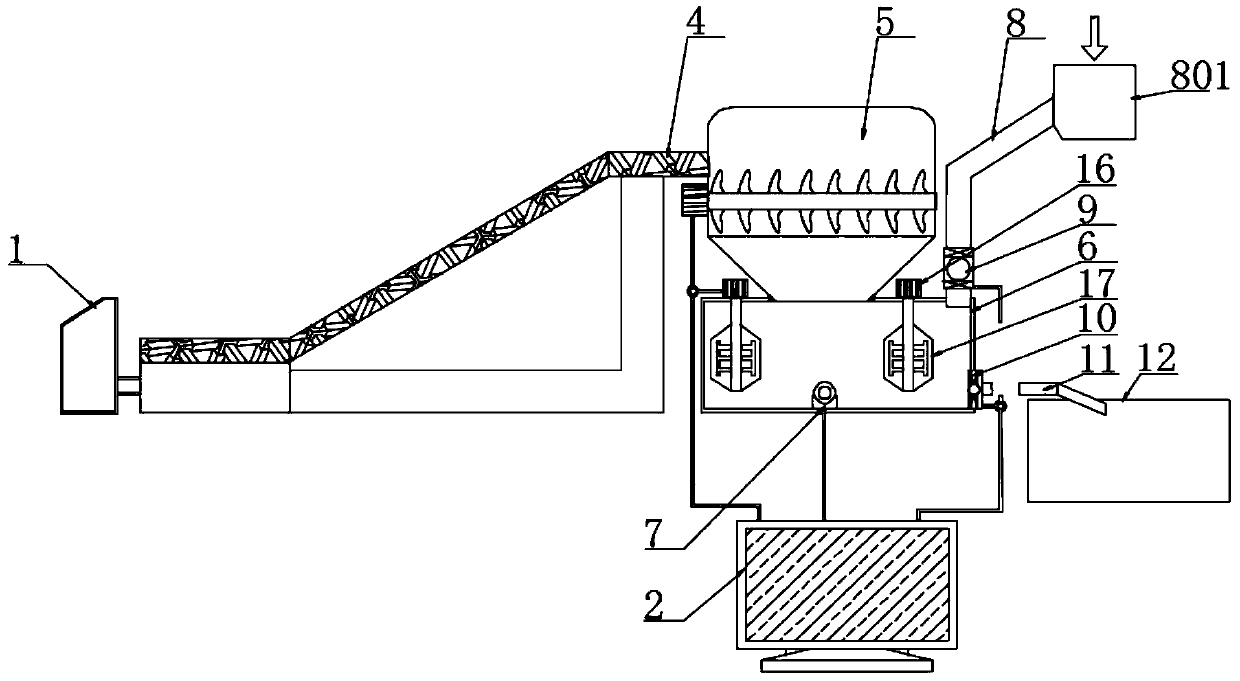

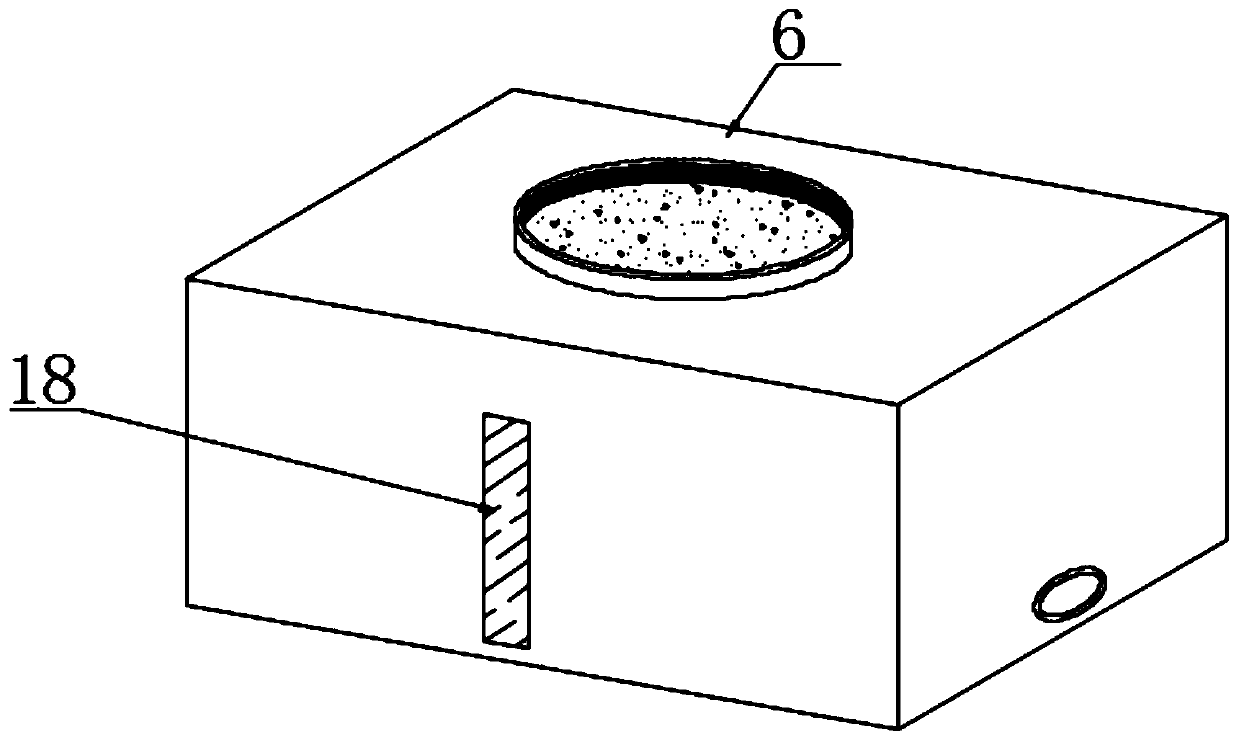

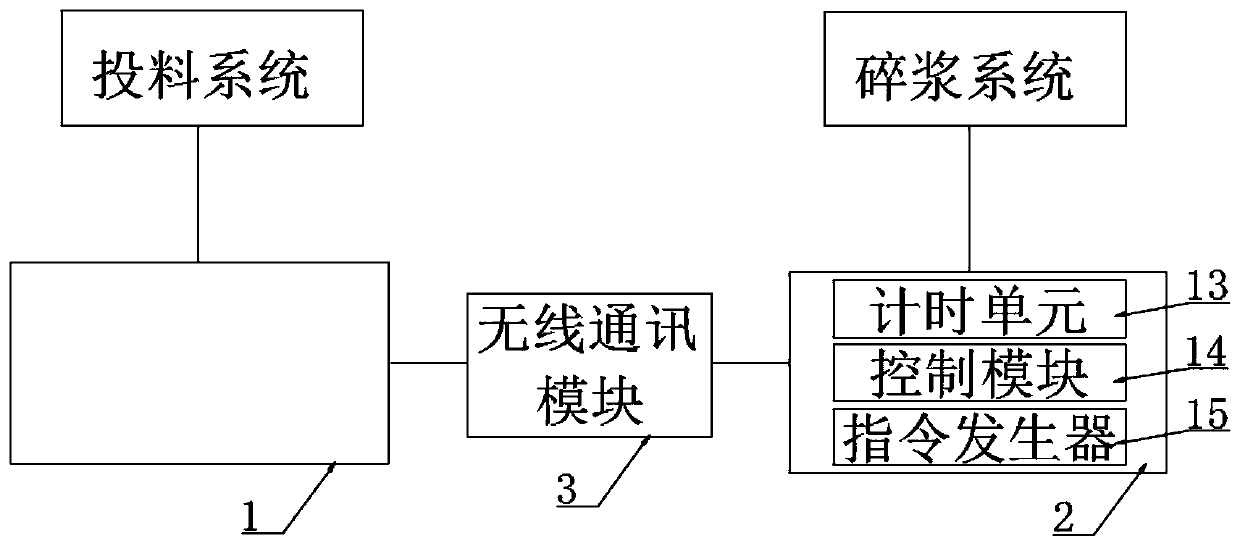

[0025] according to Figure 1-4 The pulping intelligent feeding linkage system shown in the pulping process of pulp molding includes a feeding control cabinet 1 and a pulping control computer 2, and the feeding control cabinet 1 and the pulping control computer 2 are connected by wireless communication The module 3 is remotely connected, the connection end of the feeding control cabinet 1 is provided with a feeding system, the feeding system includes a scale conveyor 4, the scale conveyor 4 is electrically connected with the feeding control cabinet 1, and the pulping control The connection end of the computer 2 is provided with a pulping system, and the pulping system includes a pulper 5, and the output end of the pulper 5 is provided with a pulping tank 6, and the inner bottom of the pulping tank 6 is fixedly connected with a pressure transformer. Conveyor 7, the top side of the crushing tank 6 is provided with a water replenishment port, the water replenishment port is provi...

Embodiment 2

[0030] according to figure 1 with 3Shown is an intelligent pulping feeding linkage system in the pulping process of pulp molding, the feeding control cabinet 1 is provided with a feeding control surface frame, and the pulping control computer 2 is provided with a pulping control surface frame , the pulping control surface frame is electrically connected with the instruction generator 15, and is used for setting and changing the pulping process parameters, and can also display the pulping process, time setting and pulping state, and the feeding control The surface frame is used to select the manual control feeding switch, and is also used to display the feeding time and feeding amount. The manual and automatic feeding can be selected through the feeding control surface frame. The production order, feeding control panel and pulping control panel display the working status, which is convenient for testing the production line.

[0031] Further, the output end of the scale convey...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com