Controlled rolling and controlled cooling method for steel with low yield ratio and low welding crack sensitivity

A technology with low welding cracks and low yield ratio, applied in metal rolling, furnace, heat treatment equipment, etc., can solve the problems of complex manufacturing process, long production cycle, high alloy cost, etc., and achieve simple manufacturing process, high production efficiency, Effect of narrow rolling temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

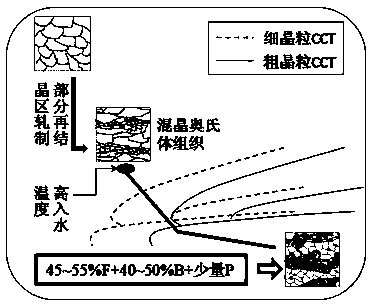

Method used

Image

Examples

Embodiment 1

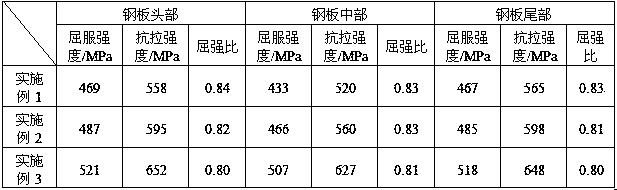

[0026] Example 1: 10mm thickness Q370qD.

[0027] The chemical composition of the steel is shown in Table 1. The thickness of the continuous casting slab is 260 mm, and the thickness of the steel plate is 10 mm. The key process parameters of controlled rolling and controlled cooling are:

[0028] (1) Controlled rolling: when the rolling temperature is 1046°C, the pass reduction rate is 25.5%; when the rolling temperature is 1038°C, the pass reduction rate is 24.8%; when the rolling temperature is 975°C, the pass reduction rate is 25.0%; When the rolling temperature is 954°C, the pass reduction rate is 20.8%; when the rolling temperature is 925°C, the pass reduction rate is 17.4%; when the rolling temperature is ≤900°C, the cumulative reduction rate is 33.5%; the final rolling temperature is 858°C.

[0029] (2) Controlled cooling: accelerated cooling to 600~620°C after final rolling, with a cooling rate of 4~5°C / s.

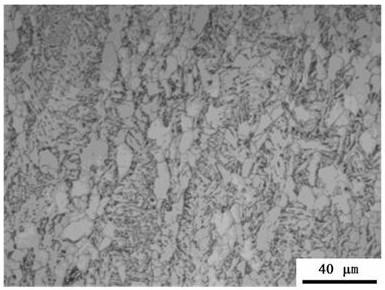

[0030] Carry out microstructure observation to embodiment ...

Embodiment 2

[0031] Example 2: 50mm thickness Q420qD.

[0032]The chemical composition of the steel is shown in Table 1; the thickness of the slab is 300 mm; the thickness of the steel plate is 50 mm. The key process parameters of controlled rolling and controlled cooling are:

[0033] (1) Controlled rolling: when the rolling temperature is 1055°C, the pass reduction rate is 23.5%; when the rolling temperature is 1051°C, the pass reduction rate is 21.7%; when the rolling temperature is 958°C, the pass reduction rate is 22.5%; When the rolling temperature is 954°C, the pass reduction rate is 21.8%; when the rolling temperature is 949°C, the pass reduction rate is 10.5%; when the rolling temperature is ≤900°C, the cumulative reduction rate is 29.1%; the final rolling temperature is 870°C.

[0034] (2) Controlled cooling: accelerated cooling to 580~600°C after final rolling, with a cooling rate of 5~6°C / s.

Embodiment 3

[0035] Example 3: 32mm thickness Q460GJC.

[0036] The chemical composition of the steel is shown in Table 1. The thickness of the continuous casting slab is 260 mm, and the thickness of the steel plate is 32 mm. The key process parameters of controlled rolling and controlled cooling are:

[0037] (1) Controlled rolling: when the rolling temperature is 1054°C, the pass reduction rate is 22.0%; when the rolling temperature is 1052°C, the pass reduction rate is 27.7%; when the rolling temperature is 973°C, the pass reduction rate is 20.1%; When the rolling temperature is 970°C, the pass reduction rate is 18.0%; when the rolling temperature is 967°C, the pass reduction rate is 18.6%; when the rolling temperature is ≤900°C, the cumulative reduction rate is 39.6%; the final rolling temperature is 863°C.

[0038] (2) Controlled cooling: accelerated cooling to 580~600°C after final rolling, with a cooling rate of 5~6°C / s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com