Wrought aluminum alloy complex shell semisolid thixotropic extrusion device and using method thereof

A technology for deforming aluminum alloys and extrusion devices, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of low material utilization rate, complex process, and high parts manufacturing cost, and achieve high material utilization, simple operation, The effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

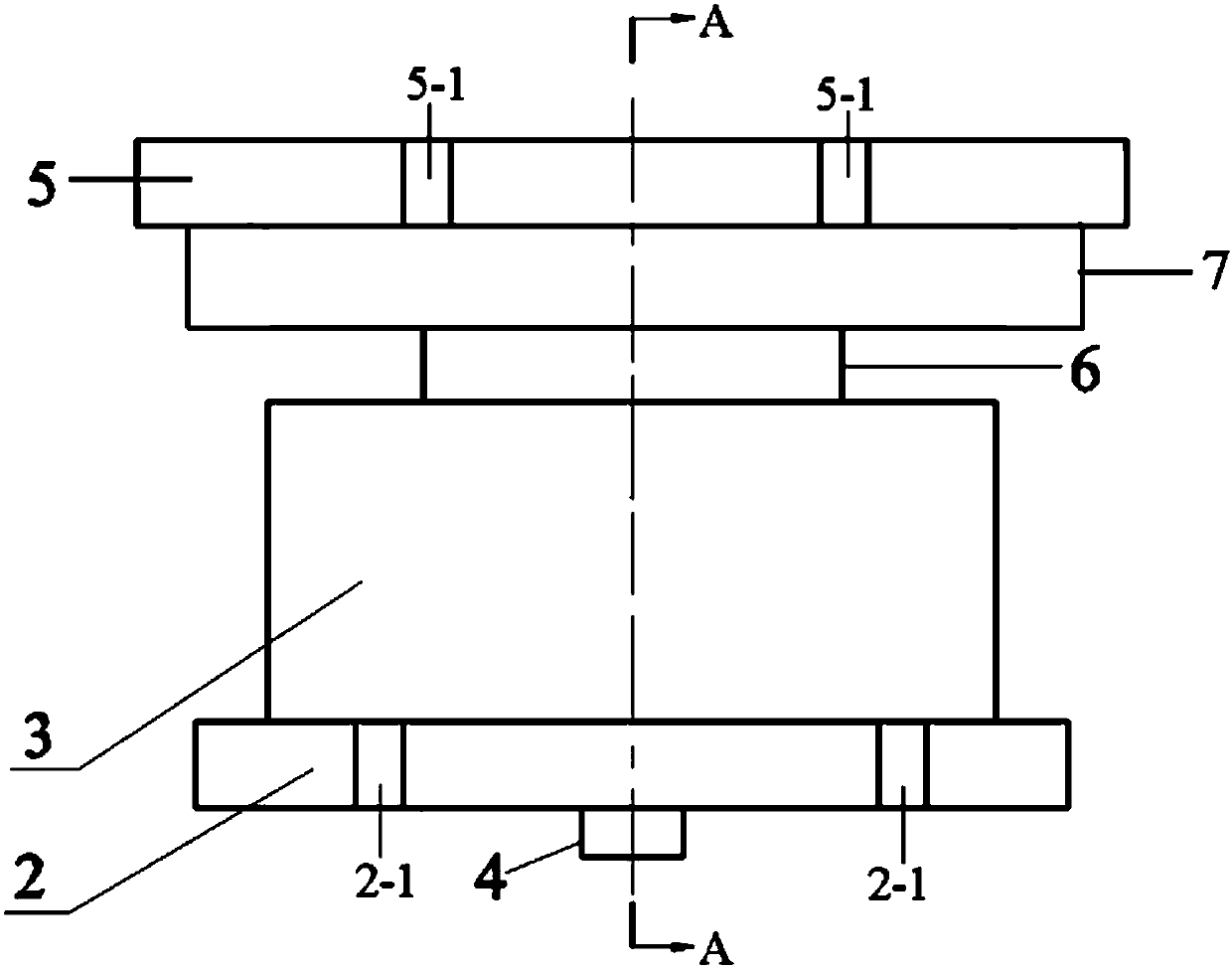

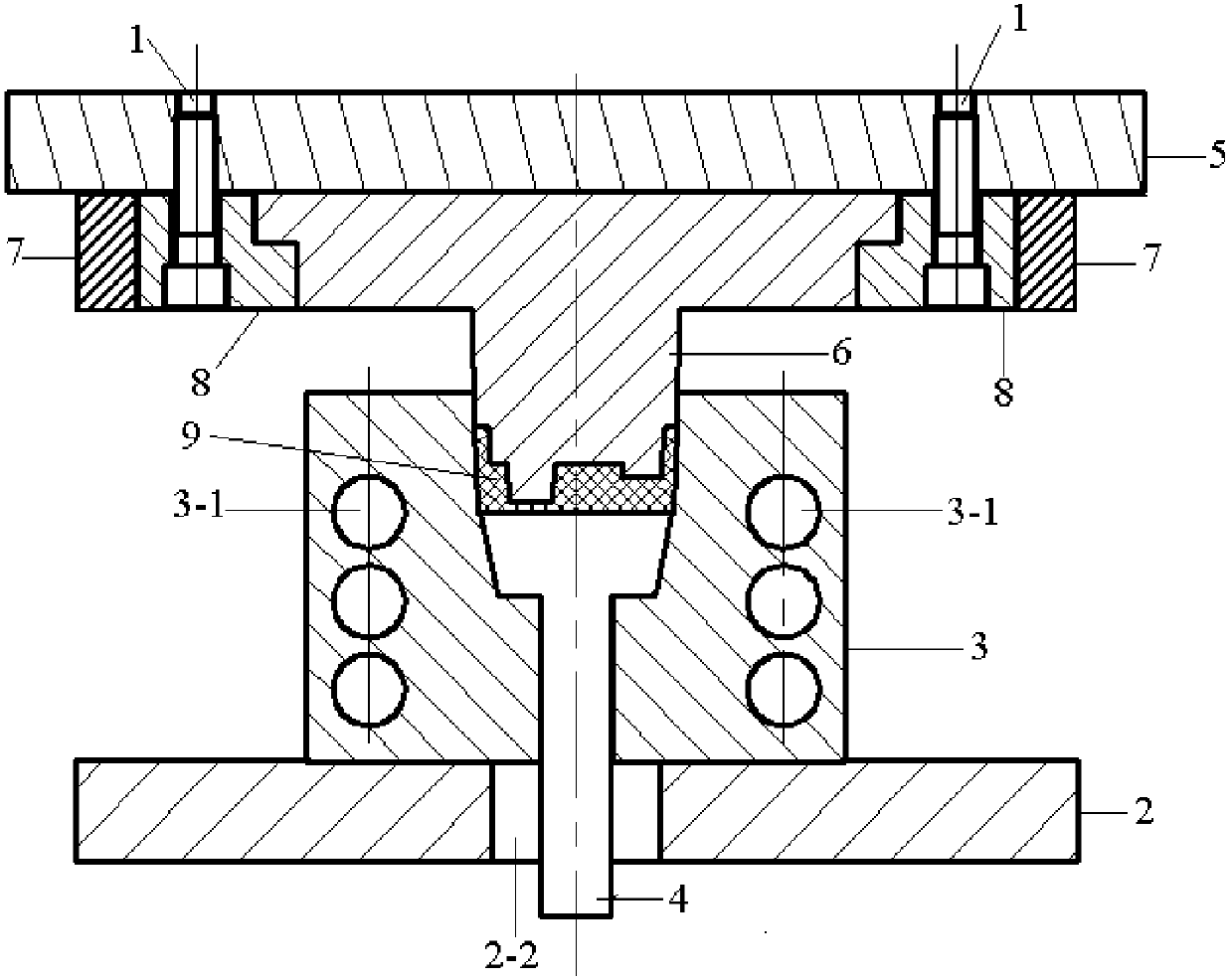

[0045] Specific implementation mode one: combine Figure 1-14 , this embodiment is a semi-solid thixotropic extrusion device for deformed aluminum alloy complex shell parts, specifically composed of bolt 1, lower template 2, die 3, ejector rod 4, upper template 5, punch 6, punch The fixed sleeve 8 and the annular heater 7 are composed;

[0046] The lower formwork 2 is a rectangular plate, a rectangular through hole 2-2 is arranged at the center of the larger surface of the rectangular plate, and two longer sides of the rectangular through hole 2-2 Five circular through-holes 2-3 are evenly arranged on the outer side along the direction parallel to the two longer sides; two U-shaped through-holes are respectively arranged on the two longer sides on the surface with a larger area in the rectangular plate. Through hole 2-1;

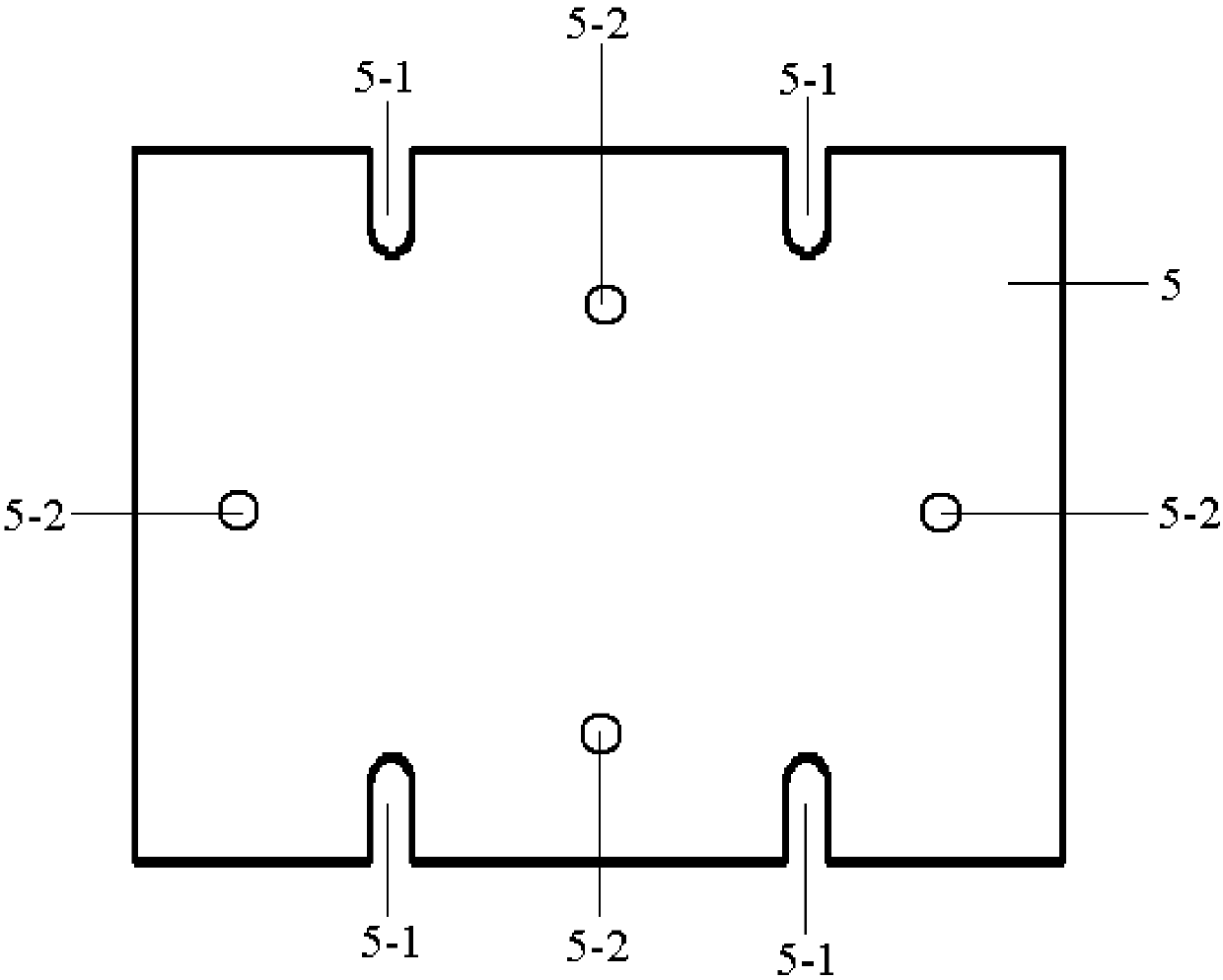

[0047] The upper template 5 is a rectangular plate, and two U-shaped through holes 5-1 are respectively arranged on the two longer sides of the larger sur...

specific Embodiment approach 2

[0056] Embodiment 2: This embodiment is a method of using the semi-solid thixotropic extrusion device for deformed aluminum alloy complex shell parts in Embodiment 1, specifically according to the following steps:

[0057] Step 1: Quantitatively divide the hot-rolled plate into blanks; the volume of the blank is 1.11 times that of the deformed aluminum alloy shell to be formed; the blank is on two opposite sides of a plane of a cuboid An object obtained by removing a triangular prism; the length and width of the blank are both 2 mm to 3 mm smaller than the length and width of the corresponding position of the deformed aluminum alloy shell part to be formed;

[0058] Step 2: Fix and install the 4 U-shaped through holes 5-1 of the upper formwork 5 with T-bolts and a 5000kN hydraulic press movable beam, and move the 4 U-shaped through holes 2-1 of the lower formwork 2 with a 5000kN hydraulic press. The beam is fixedly installed; the ejector pin 4 is put into the cavity of the die...

specific Embodiment approach 3

[0066] Embodiment 3: This embodiment is different from Embodiment 2 in that: the blank described in step 1 is 2A12 aluminum alloy. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com