A manufacturing process of a steel pipe threaded sleeve with an iron core

A technology of process flow and threaded sleeves, applied in the direction of coating, etc., can solve the problems of low automation, high labor intensity, and low work efficiency, and achieve the effects of reducing labor intensity, increasing automation, and reducing labor force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

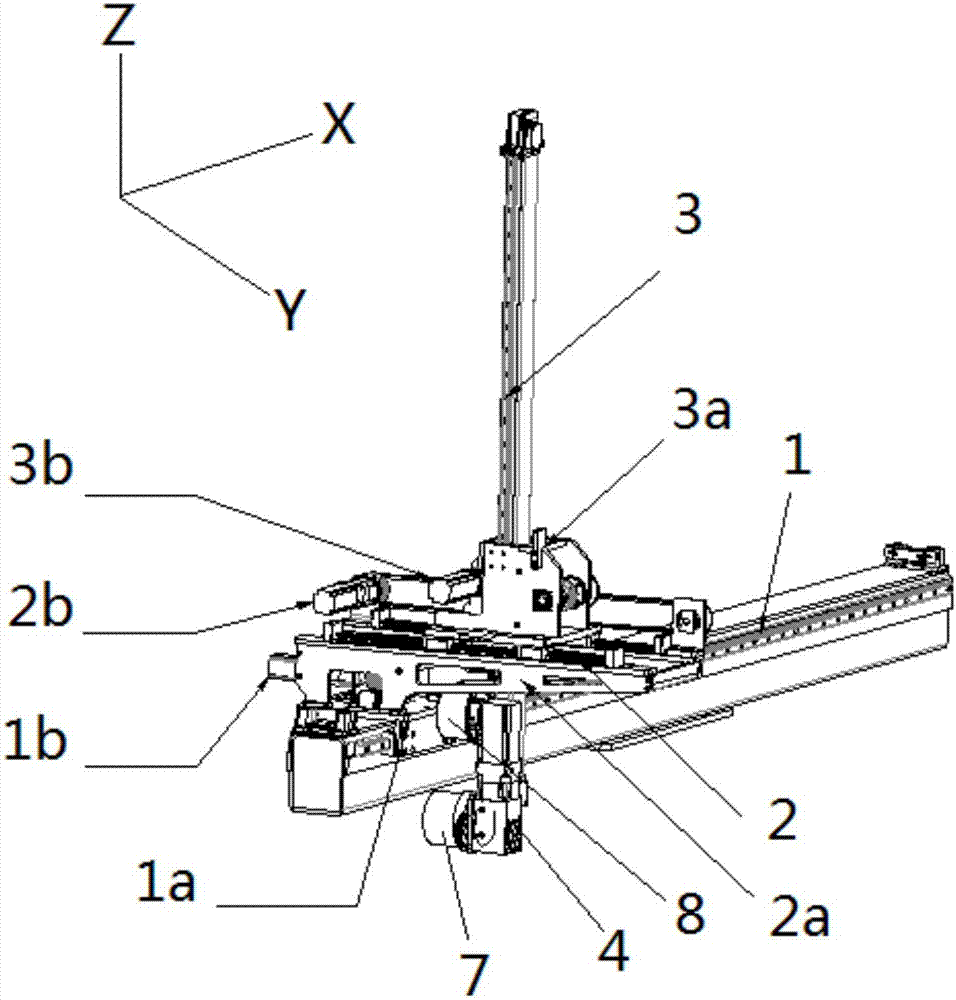

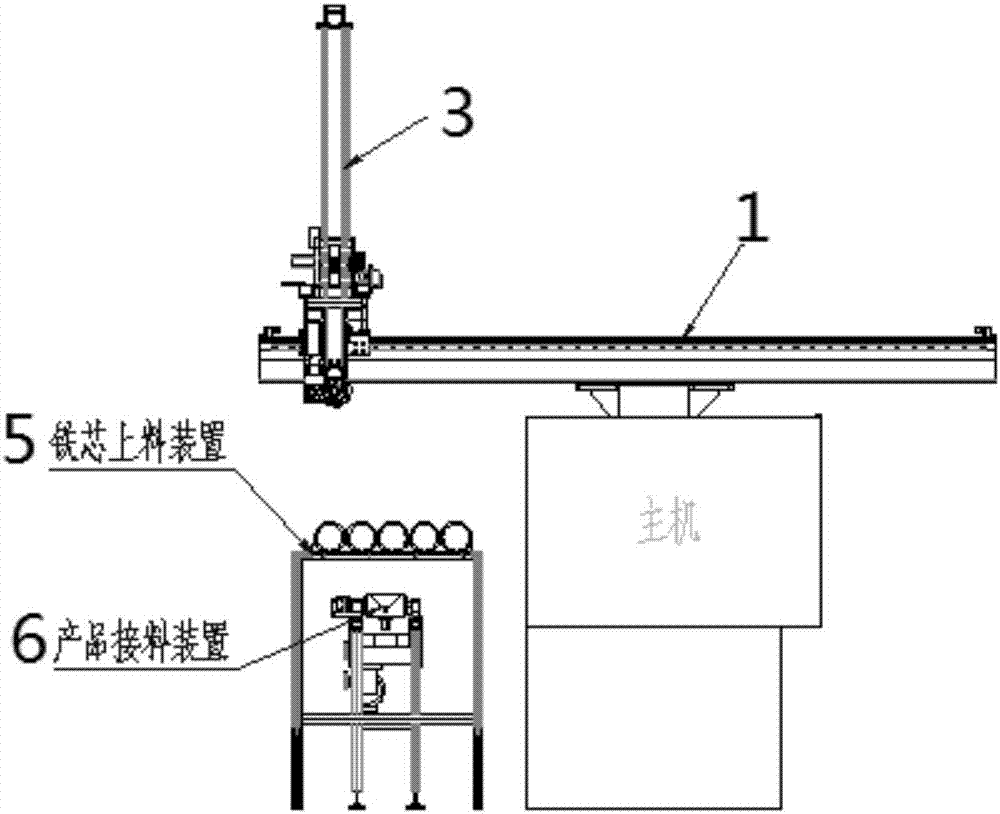

[0044] This machine is designed for injection molding machine thread protector series, the main function is to discharge and grab the thread protector. Among them, the incoming material adopts the form of vibrating plate feeding, the installation iron core adopts the clamping installation form, and the retrieving material adopts clamping and rotating screwing. The core control components of the machine include PLC, servo motor and Delta touch screen. Users can operate each part of the machine individually through the man-machine interface, and can intuitively adjust the relevant parameters of the product on the man-machine interface.

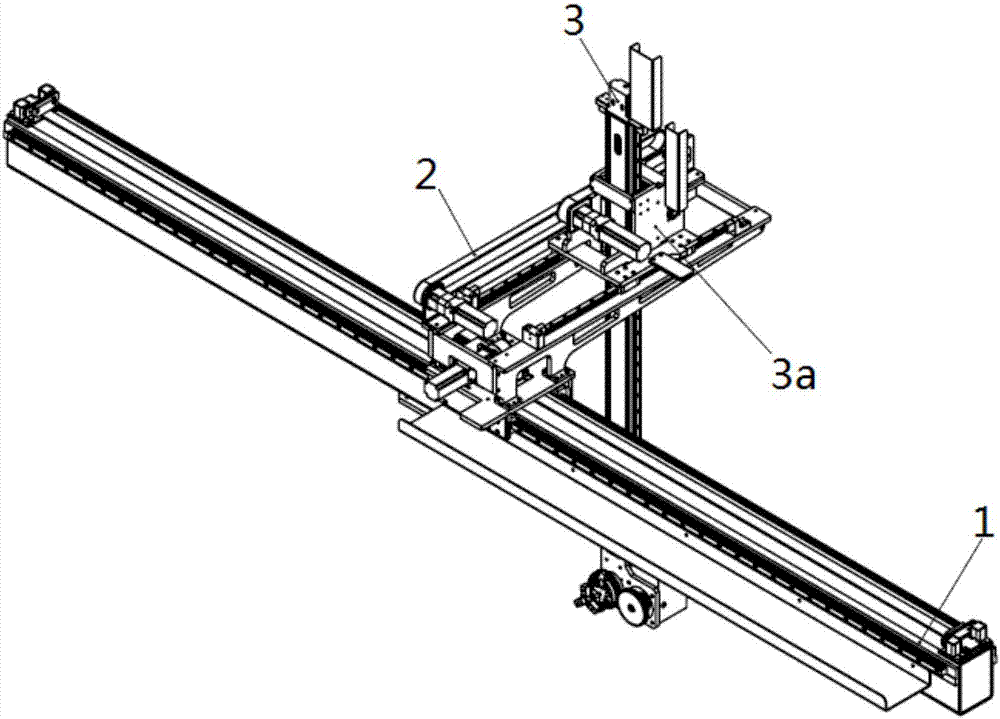

[0045] see Figure 1-Figure 4 , The whole machine is composed of X-axis, Y-axis, Z-axis, R-axis, demoulding gripper 7, iron core gripper 8, product receiving device 6, iron core feeding device 5, finished produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com